Open Access

Open Access

ARTICLE

Weak Expansive Soil Physical Properties Modification by Means of a Cement-Jute Fiber

1

School of Architectural and Civil Engineering, Zhongyuan University of Technology, Zhengzhou, 450007, China

2

Yellow River Institute of Hydraulic Research, Zhengzhou, 450003, China

3

School of Civil Engineering, Tianjin Chengjian University, Tianjin, 300384, China

* Corresponding Authors: Xuelei Cheng. Email: ;

Fluid Dynamics & Materials Processing 2023, 19(8), 2119-2130. https://doi.org/10.32604/fdmp.2023.025444

Received 12 July 2022; Accepted 24 November 2022; Issue published 04 April 2023

Abstract

Sixteen groups of comprehensive tests have been conducted to investigate the modifications in the physical properties of a weak expansive soil due to the addition of a cement jute fiber. The tests have been conducted to analyze the liquid plastic limit, the particle distribution and the free expansion rate. The results show that: (1) With an increase in the cement-jute fiber content, the free expansion rate of the modified expansive soil gradually decreases, however, such a rate rebounds when the fiber content exceeds 0.5% and the cement content exceeds 6%. (2) With an increase in the cement percentage, the particle unevenness coefficient (Cu) and curvature coeffi- cient (Cc) of the modified expansive soil tend to grow gradually. The Cc coefficient reaches 1.0 when the cement content is 6%. The unevenness coefficient of 16 soil samples is greater than 5.0, however, the Cu coefficient decreases when the cement content reaches 6%. (3) The plastic limit of soil increases as the cement content is made higher, while the liquid limit and plastic index decrease gradually. When the content of the modified material is 2% + 0.1%~2% + 0.7% (Cement content + jute fiber content), the change of particle size distribution is most obvious. (4) When the contents of cement and jute fiber are is 6% and 0.5%, respectively, the modification induced in the physical properties of soil samples corresponds to the best case.Keywords

Expansive soil is a cohesive soil composed mainly of mineral components such as illite, kaolinite and montmorillonite or montmorillonite illite. Its liquid limit is generally greater than 40% and has a special expansive structure system with the characteristics of expansion in water and shrinkage in water loss [1,2]. Common urban road maladies in areas where expansive soils are distributed include: (1) longitudinal cracks, mud pumping, slurry splashing, bulges and depressions in road surfaces; (2) weathering, inversion, collapse and landslides in slopes [3]. These undesirable phenomena have serious adverse effects on the stability and operational safety of the road, as shown in Figs. 1 and 2.

Figure 1: Cutting slope slip

Figure 2: Subgrade cracks

Cement is a commonly used modifying material for improving expansive soil in practical engineering applications. The internal structure and chemical composition of expansive soil changes with the addition of cement, and its physical and mechanical properties also change accordingly. Goodarzi et al. [4] studied the improvement effect of silica fume cement mixture with 10% cement; Horpibulsk et al. [5] studied the influence of different salt contents on the mechanical properties of cement soil; Reddy et al. [6] concluded that the performance of chemical additives outperformed other types among cement-based, non-cement based, and chemical additives used to stabilize expansive soil; Phanikumar et al. [7] found that the bearing capacity and compressive strength of the pavement were significantly improved by using cement to modify the expansive soil; Akbulut et al. [8] studied the reinforcement mechanism of cement on expansive soil and observed that cement would increase the ion exchange capacity of expansive soil; Wajeeha et al. [9] proposed to optimize the use of waste recycled wool banana fiber composites by adding an appropriate amount of the repair of expansive clay. Similar to reinforced soil, the fiber modification mechanism of expansive soil is to further restrict the deformation of soil is to use stress redistribution between soil particles and fibers to further limit soil deformation, resulting in improved physical and mechanical properties of the modified expansive soil. As the reinforced soil is filled by horizontal bars, only its lateral deformation can be controlled [10]; In contrast, the state of fibers in fiber-modified soil is randomly distributed [11]. Therefore, fiber-modified soil can effectively limit not only the lateral deformation of the soil, but also the vertical deformation of the soil [12,13]. Mohamed [14] found that the shear strength of soil increased with increasing fiber content, but began to decrease when fiber content reached 1%; Zhu et al. [15] explored the influence of polypropylene fiber on the swelling and shrinkage properties of expansive soil; Tiwari et al. [16] looked at the influence of polypropylene fiber on the strength and durability of expansive soil subgrade, and carried out cross-validation by using numerical simulation; Yuan et al. [17] investigated and analyzed the mechanical properties and microstructural changes of glass fiber-modified expansive soil. Lime and ionic soil solidifying agents (ISS) are widely adopted to modify expansive soil, which is a chemical modification method with a significant improvement effect. Stocker [18] thought that 0.5% Ca (OH)2 can produce a layer of reactants that can eliminate the swelling of expansive soil; Aldaood et al. [19] found that the hardening rate of lime would increase by about six times when the temperature increased from 20°C to 50°C, and with the change of the microstructure of expansive soil, its moisture content would change accordingly to improve the expansion and contraction performance of the soil. Katz et al. [20] concluded that ISS could eliminate cations in the crystal layer of montmorillonite and change the structure of the crystalline layer; Liu et al. [21] obtained the optimal ratio of 1:350 for ISS solution in improving expansive soils; Han et al. [22] found that ISS can significantly inhibit the vertical shrinkage of expansive soil during the dehumidification process. Fly ash, rice husk ash, and industrial alkali residue are also commonly used solidification agents for improving expansive soil. Keskin et al. [23] compared the swelling and strength parameters of weak and swellable soils with calcium carbide residue remaining from acetylene industrial production with lime and fly ash; Mypati et al. [24] studied the durability and leachate behavior of alkali-activated fly ash as a binder to stabilize expansive soil in deep mixing application; Fly ash as a key to stabilise expansive soils was found in a study by Darikandeh et al. [25] presented the results of laboratory-scale swell-shrink tests on an expansive soil stabilized by calcium carbide residue-fly ash columns; Mahedi et al. [26] found that the addition of slag significantly improves the mechanical properties of cement expansive soil.

To sum up, research into the modification of cement and expansive soil is relatively mature, and its modification effect is relatively significant. However, the modification of expansive soils using cement alone can lead to a reduction in the strength of the modified soil due to the cracking of the cement, while the dissolution and loss of cement hydration products due to natural erosion conditions, such as rainfall, can lead to a significant decline in the modification of expansive soil. As a result, the durability, physical, and mechanical properties of the soil are greatly reduced. At present, basalt and glass fiber are widely used in fiber-modified expansive soil, which are ductile and can easily be pulled out when the soil is cracked, so it cannot achieve the effect of improving the ductility of expansive soil.

For the modification of expansive soil, jute fiber has good hygroscopic properties. A moderate amount of jute fiber was evenly mixed into the expansive soil to allow it to absorb a certain amount of water that had seeped into the soil and reduce the formation of water molecule films in the expansive soil particles, so that the swelling and shrinkage of the expansive soil could be improved [27–29]. After jute fiber ceased to function in the soil, its biodegradation rate would slow down and would not cause soil pollution, which is in line with the concept of sustainable development. Therefore, it is of great engineering significance to study the modification of expansive soil by cement-jute fiber composite material. Based on this, a comprehensive study of expansive soil modified with different contents of cement-jute fiber composites was carried out in this study. The influence of the content of cement jute fiber composite modified material on the free expansion rate, particle gradation and plasticity index, physical, and mechanical parameters of expansive soil was investigated, and the mechanism of the effect was clarified through x-ray diffraction (XRD) and scanning electron microscopy (SEM) analysis. The purpose of the study is to determine the optimal amount of cement jute fiber to be added to the expansive soil to achieve optimal effects on its basic physical properties, so that a basic study of the engineering applications of cement jute fiber composite modified expansive soil can be carried out.

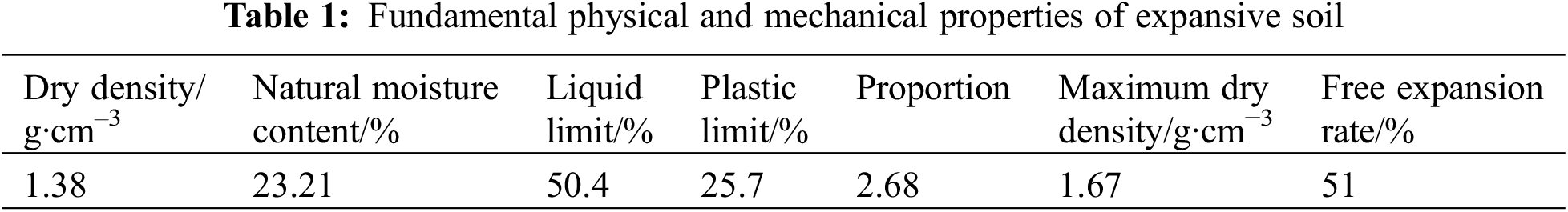

The basic physical and mechanical properties of the test soil sample are listed in Table 1. The soil sample conforms to the typical characteristics of weak expansive soil.

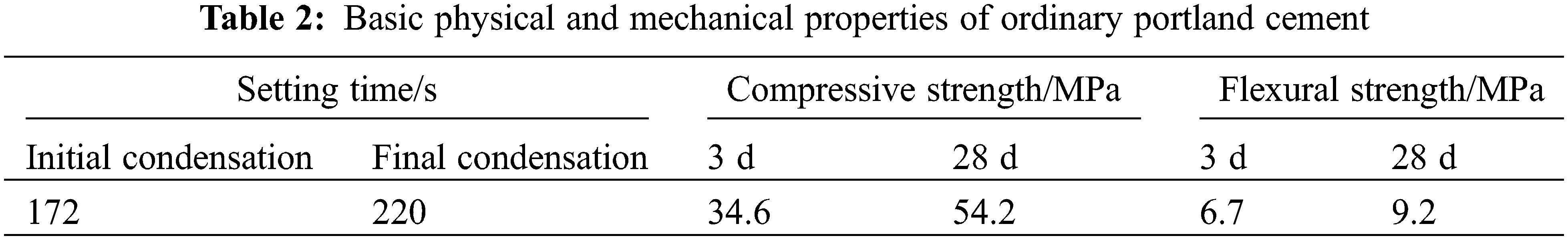

The test used P.O 42.5 cement with a density of 3.08 g·cm−3. It had a 0.08 mm sieve residue of 1.6%, a specific surface area of 375 m2·kg−1, a mortar fluidity of 187 mm, and a water consumption of 27.30% for standard consistency. The various physical and mechanical properties are listed in Table 2.

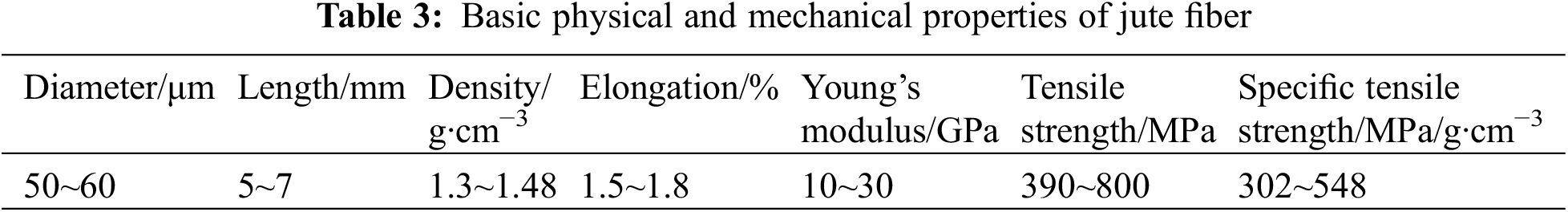

The experimental chopped jute fiber is characterized by fast water dispersion, low ductility, good hygroscopicity and biodegradability. The main physical and mechanical properties are presented in Table 3.

To determine the optimal mixing amount of cement jute fiber on the physical properties of expansive soil, sixteen groups of comprehensive tests were carried out through particle analysis, free expansion rate test and liquid plastic limit test. During the test, the soil samples were dried for 24 h, then manually crushed, and the samples were uniformly prepared according to the mass ratio (the ratio of the mass of dry soil to that of other modified materials). Cement contents of 2%, 4%, 6% and 8% and jute fiber contents of 0.1%, 0.3%, 0.5% and 0.7% were homogeneously mixed into the expansive soil.

3.1 Effect of Cement-Jute Fiber Content on Free Expansion Rate

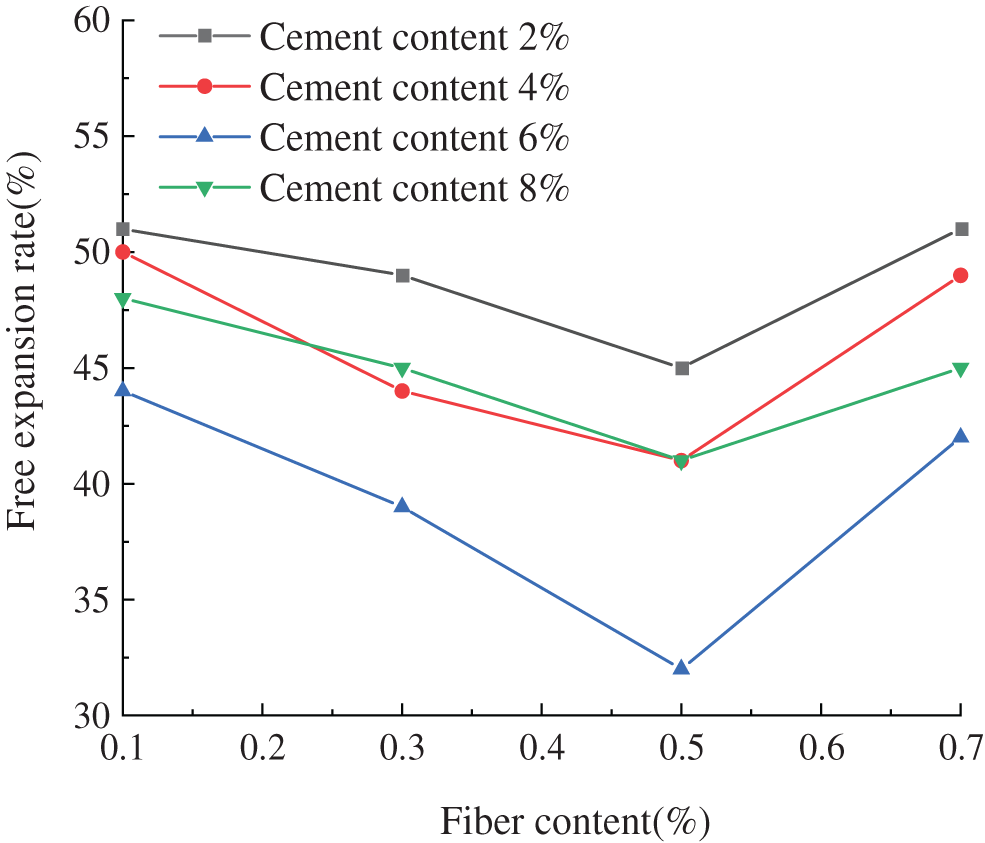

The free expansion rate is the ratio of the volume increased by expansion in water to the original volume of a manually prepared dried and milled soil sample, expressed in percentage, which shows the expansion characteristics of soil particles without the influence of structural force. The free expansion rate of plain expansive soil is 52%. In Fig. 3, the free expansion rate of soil samples decreases gradually with increasing jute fibre content as the cement content increases from 2% to 6% after the addition of different proportions of the composite modified materials. However, a turning point occurs when the jute fiber load is 0.5%. This phenomenon is due to the fact that jute fiber content thereafter exceeds its optimal content, resulting in the amount of jute fiber directional distributions in the modified soil beginning to increase. As a result, the amount of jute fibres distributed in a random direction decreases further. Therefore, jute fiber agglomeration is more likely to occur in expansive soil. This phenomenon will weaken the connection effect of fibers in the three-dimensional spatial network structure system. The friction between expansive soil particles, the inlaying between soil particles and jute fibers, and the decrease of their biting force at the same time will further increase the free expansion rate of the modified soil. After the cement content exceeds 6%, the free expansion rate of the soil turns to an increasing trend, with the reaction rate of the ions gradually decreasing as the cement content becomes too high, and the excess modified material reacts with water, increasing the free expansion rate of the soil sample, as shown in Fig. 4.

Figure 3: Relationship between cement-jute fiber and free expansion ratio

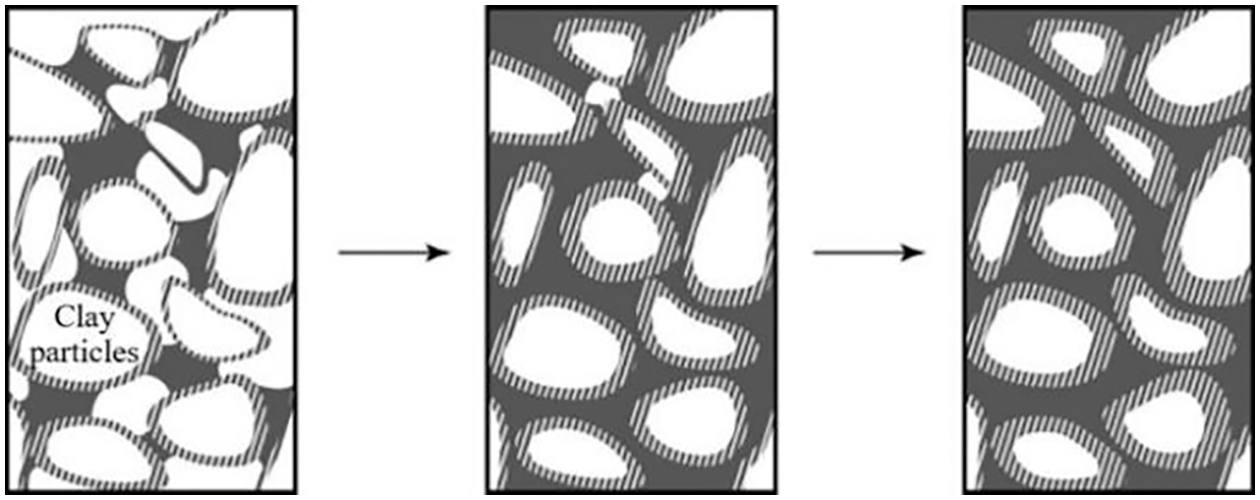

Figure 4: Formation and thickening of hydration film (adapted with permission from reference [28] Copyright © 2022)

3.2 Effect of Cement-Jute Fiber Content on Particle Size Distribution of Expansive Soil

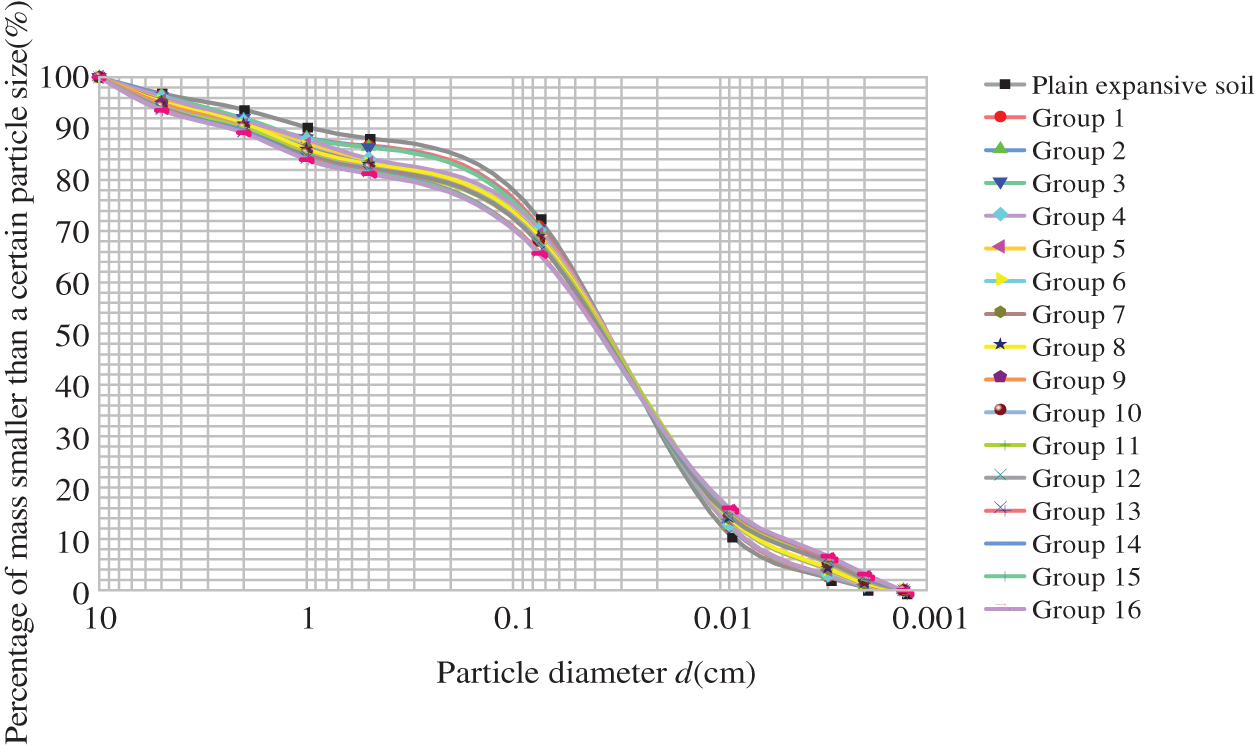

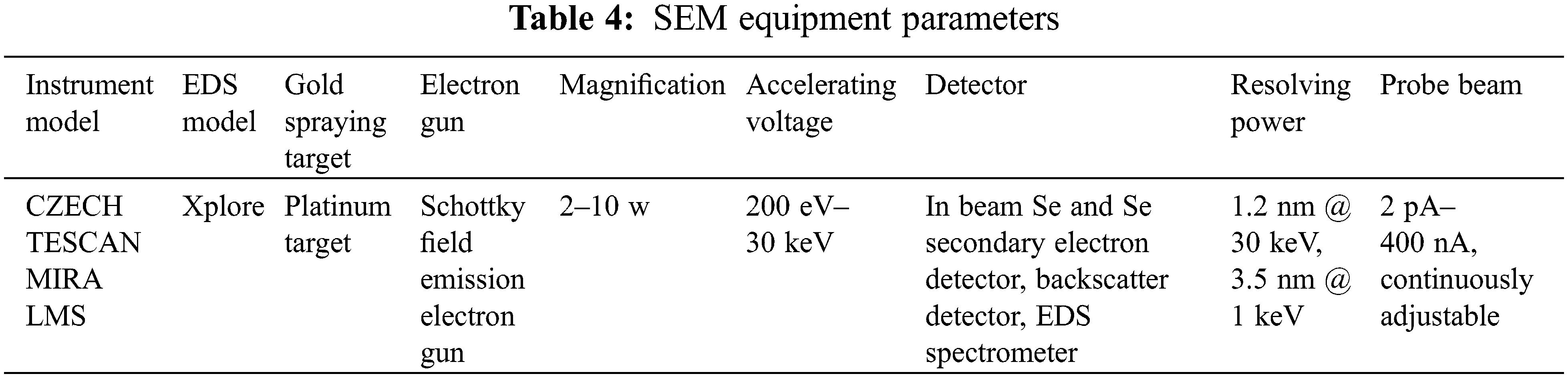

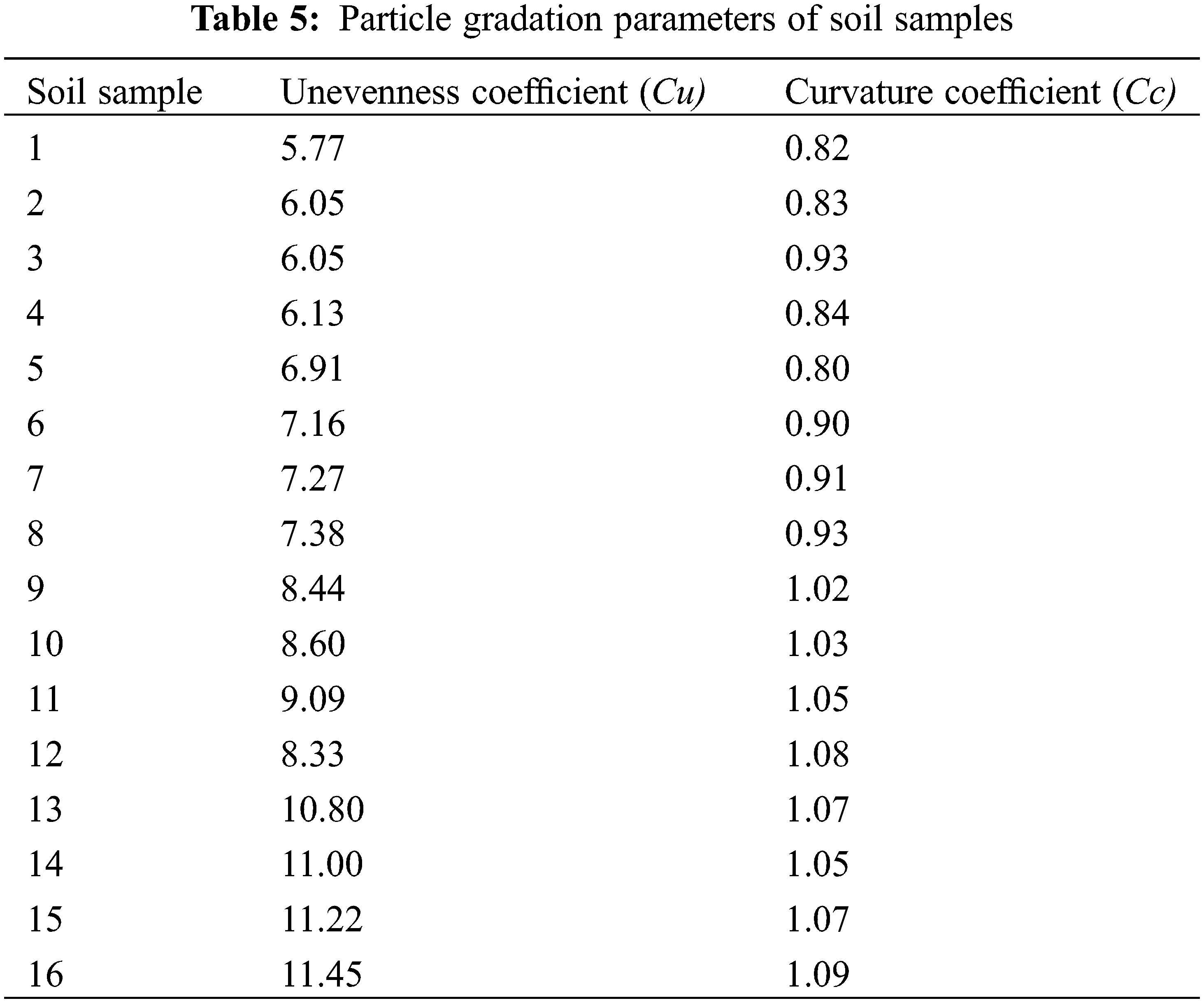

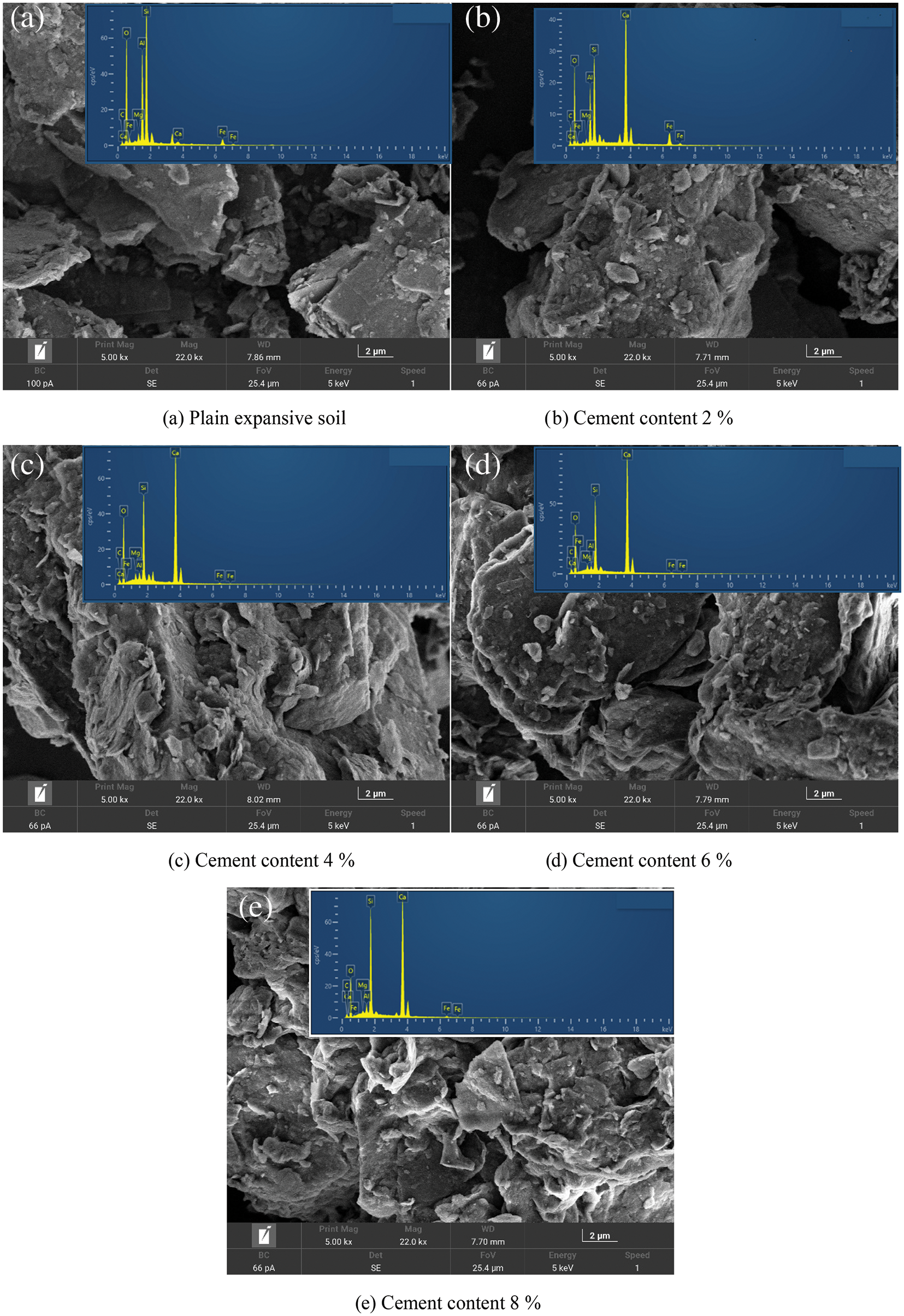

Sixteen groups of soil samples greater than 0.075 mm and smaller than 0.075 mm were tested and analyzed by screening method and a laser particle size analyzer. The results of the analyses are shown in Fig. 5. The particle grading curve of the soil samples mixed with different amounts of modified materials is similar to that of plain expansive soil. Among them, the jute fiber content had no significant effect on the particle gradation of expansive soil. The addition of cement changed the mass proportion of each particle size in the modified soil to a certain extent, increasing the content of particles smaller than 2 mm in the soil. After adding cement to the expansive soil, the mass percentage of clay particles in the plain expansive soil begins to gradually decrease, while the mass percentage of silt particles continues to increase. This can be ascribed to the fact that the ion exchange of cement particles on the surface of the expansive soil, which generates cementing substances that coagulates the expansive soil particles into larger-sized particles. Soil samples with cement contents of 2%, 4%, 6% and 8% were analyzed by SEM and the equipment model and parameters, as listed in Table 4. The particle grading parameters of the soil sample are listed in Table 5. With the increase of the amount of cement added, the curvature coefficient Cc and the unevenness coefficient Cu of the composite modified expansive soil sample are gradually increasing. The soil sample Cc reaches 1 when the amount of cement added reaches 6%, and the unevenness coefficient of sixteen groups of soil samples is greater than 5. The particle grading of the modified soil is satisfactory.

Figure 5: Particle analysis graph

The results of the SEM analysis are shown in Fig. 6. It is evident that the pores of the plain soil is composed of a large number of cracks and other coarse pores, which is caused by the dry shrinkage characteristics of expansive soil, and the adhesion between particles is weak. After adding cement, the surface of the particles becomes rugged and steep, and the calcium silicate hydrogel (C–S–H gel) produced by the cement hydration reaction agglomerates with soil particles, which is consistent with the phenomenon of the increased Ca2+ in the XRD test results. The soil particles gradually bond to form bulky flocs, reinforcing the soil and making it denser, and these results are consistent with the above analysis. The particle grading curve largely overlaps when the cement content is 6% and 8%, which indicates that the sensitivity of the modified expansive soil decreases after the cement content reaches 6%. So the optimal content of cement for improving the particle size grading of expansive soil is 6%.

Figure 6: SEM analysis diagram

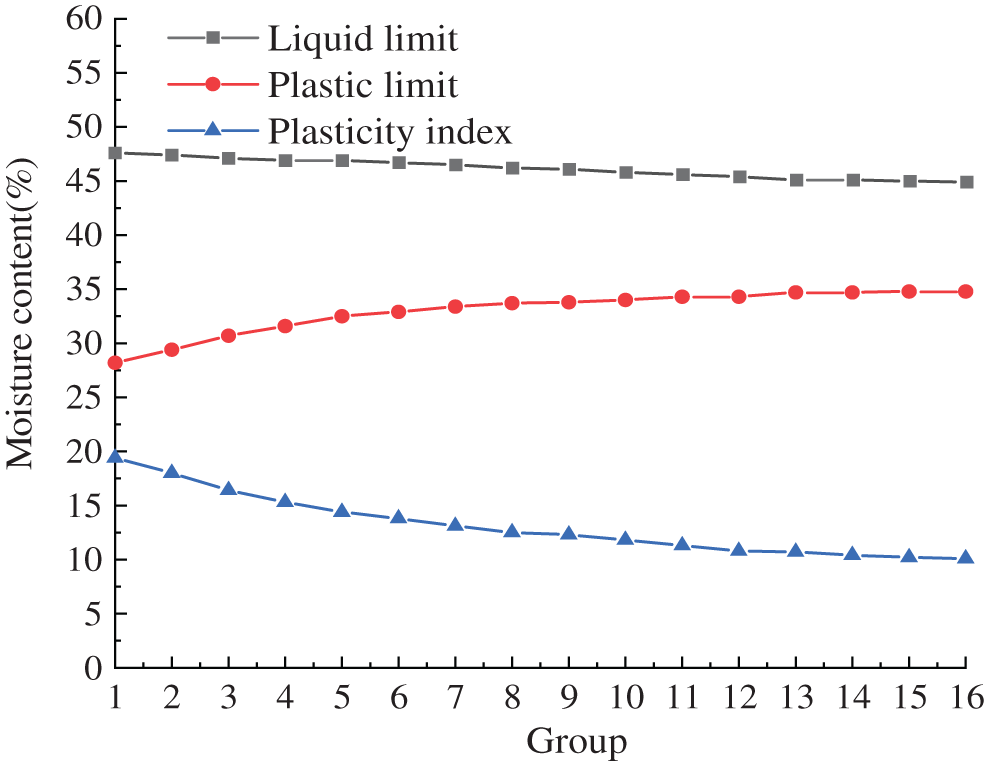

3.3 Influence of Cement-Jute Fiber Content on Plasticity Index of Expansive Soil

The measurement of the liquid plastic limit of the soil is particularly important when it comes to understanding the properties of soils. The plastic limit and liquid limit of each cement jute fiber-modified expansive soil sample group at different dosages were measured by the liquid plastic limit joint tester, and the test results are shown in Fig. 7. As the content of cement and jute fiber increases, the liquid limit of the modified soil sample gradually decreases, and the effect of modification tends to be level off after the cement content reaches 8%; the plastic limit of modified soil samples exhibits an upward trend, and its range is slightly larger than the decrease of liquid limit; The plasticity index tends to decrease and gradually levels off. The expansive soil is more sensitive to cement jute fiber in groups 1 to 4 (the content of composite modified material is 2% + 0.1%~2% + 0.7%). This phenomenon is attributed to the large amount of cements produced when the modified soil samples are exposed to water. Compounds containing a large amount of Ca2+ are hydrated to produce hydrates such as Ca(OH)2, as shown in Fig. 6, so that the original loose soil pieces are bonded into orderly soil particles with a larger particle size, and the jute fibers with a certain moisture absorption capacity absorb some of the water, which is why the moisture content of the soil samples decreases, resulting in a smaller liquid limit. However, there are many anions around the expansive soil particles themselves, and under the action of an electric field, anions combine with cations in water to form a double electron layer, which is neatly arranged on the surface of soil particles and forms a binding hydration film. At this point, the expansive soil mixed with cement reacts with water to produce soluble Ca2+, which can exchange with low valence ions in the soil, as shown in Fig. 8, so that the thickness of the hydration film is reduced accordingly, and its plastic limit changes as a result. As the soil particles are cemented together and the cement particles without hydration are filled between the soil particles, the porosity of the soil decreases, the compactness increases, and the plasticity index further decreased. However, the amount of ions in expansive soil is limited, and the excessive addition of modified materials prevents them from fully participating in the chemical reaction, resulting in a gradual flattening trend of the liquid plastic limit curve.

Figure 7: Relationship between cement content and liquid-plastic limit

Figure 8: Ion exchange (adapted with permission from reference [29] Copyright © 2022)

In conclusion, the effect of cement jute fiber on the liquid plastic limit of weak expansive soil is obvious. Among them, when the cement content is 8% and jute fiber content is 0.7%, the liquid limit decreases to about 44.9%, the plastic limit increases to about 34.8%, and the plastic index decreases to about 10.1, which indicates that the addition of cement jute fiber has a significant inhibitory effect on the swelling and shrinkage of weak expansive soil.

In this study, the influence of the content of cement jute fiber composite modified material on the free expansion rate, particle gradation and plasticity index, physical, and mechanical parameters of expansive soil is investigated, and the influence mechanism is clarified by comparing the morphology and phase analysis of plain expansive soil to that of modified expansive soil. The following conclusions can be drawn:

1. The expansive soil modified with cement jute fiber can effectively reduce the free expansion rate of the soil. With the increase of composite-modified materials, the free expansion rate of soil decreases; however, when the cement content exceeds 6% and the fiber content exceeds 0.5%, the free expansion rate rises.

2. The modified expansive soil particles Cc and Cu increase slowly with the increase of cement content; When the cement content is 6%, the Cc of the modified expansive soil sample reaches 1, and the Cu of 16 groups of soil samples is greater than 5, but the sensitivity decreases after the cement content reaches 6%.

3. The addition of cement to expansive soil can effectively reduce its plasticity index. The plastic limit of modified soil samples increases gradually with the increase of cement content, while its liquid limit and plastic index decreases; and the expansive soil is more sensitive to cement jute fiber when the content of the composite modified material is 2% + 0.1%~2% + 0.7%.

4. The basic physical properties of expansive soils are significantly improved after being modified with cement jute fiber. The best content of the composite modified material is 6% of cement and 0.5% of jute fiber.

Funding Statement: This research was supported by the National Natural Science Foundation of China (Grant No. 41877251, Li, https://www.nsfc.gov.cn/), the Key Scientific Research Projects of Colleges and Universities in Henan Province (Grant No. 22A560021, Yang, http://jyt.henan.gov.cn/, Grant No. 23A560014, Cheng, http://jyt.henan.gov.cn/), the Key Scientific and Technological Support Projects of Tianjin Key R&D Plan (Grant No. 19YFZCSF00820, Li, https://kxjs.tj.gov.cn/), and the Special Fund for Basic Scientific Research and Young Backbone Teachers of Zhongyuan University of Technology (K2020QN015, 2020XQG14, Cheng, https://www.zut.edu.cn/).

Availability of Data and Materials: The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Hasan, H., Dang, L., Khabbaz, H., Fatahi, B., Terzaghi, S. (2016). Remediation of expansive soils using agricultural waste bagasse ash. Procedia Engineering, 143(5), 1368–1375. https://doi.org/10.1016/j.proeng.2016.06.161 [Google Scholar] [CrossRef]

2. Tang, L., Cong, S., Ling, X., Xing, W., Nie, Z. (2018). A unified formulation of stress-strain relations considering micro-damage for expansive soils exposed to freeze-thaw cycles. Cold Regions Science and Technology, 153(2), 164–171. https://doi.org/10.1016/j.coldregions.2018.05.006 [Google Scholar] [CrossRef]

3. Li, K., Nowamooz, H., Chazallon, C., Migault, B. (2018). Limit deformation analysis of unsaturated expansive soils during wetting and dryin cycles. Soil Mechanics and Foundation Engineering, 55, 1–7. [Google Scholar]

4. Goodarzi, A., Akbarihr, H. R., Salm, M. (2016). Enhanced stailizaion of highly expansive clays by mixing cement and silica fume. Applied Clay Science, 132–133, 675–684. https://doi.org/10.1016/j.clay.2016.08.023 [Google Scholar] [CrossRef]

5. Horpibulsuk, S., Phojan, W., Suddeepong, A., Chinkultijniwat, A., Liu, M. (2012). Strength development in blended cement admixed saline clay. Applied Clay Science, 55(7), 44–52. https://doi.org/10.1016/j.clay.2011.10.003 [Google Scholar] [CrossRef]

6. Reddy, N., Thaslidar, J., Rao, B. (2015). Evaluatig the influence of additives on swelling characteristics of expansive soils. lnternational Journal of Geosynthetics and Ground Engineering, 1(1), 7. https://doi.org/10.1007/s40891-015-0010-x [Google Scholar] [CrossRef]

7. Phanikumar, B., Ramanjaneya, R. (2020). Compaction and strength characteristics of an expansive clay stabilised with lime sludge and cement. Soils and Foundations, 60(1), 129–138. https://doi.org/10.1016/j.sandf.2020.01.007 [Google Scholar] [CrossRef]

8. Akbulut, S., Arasan, S. (2010). The variations of cation exchange capacty, pH, and zeta potential in expansive soils treated by additives. International Journal of Civil and Structural Engineering, 1(2), 139–154. [Google Scholar]

9. Wajeeha, Q., Hassan, K., Zia, R., Zubair, M. (2022). Sustainable application of wool-banana bio-composite waste material in geotechnical engineering for enhancement of elastoplastic strain and resilience of subgrade expansive clays. Sustainability, 14(20), 13215. https://doi.org/10.3390/su142013215 [Google Scholar] [CrossRef]

10. Liu, S., Bai, F., Wang, Y., Li, Z. (2013). Treatment for expansive soil channel slope with soilbags. Journal of Aerospace Engineering, 26(4), 657–666. https://doi.org/10.1061/(ASCE)AS.1943-5525.0000198 [Google Scholar] [CrossRef]

11. Zhuang, X., Yu, X. (2015). Experimental study on strength of expansive soil treated by lime-basalt fiber. China Civil Engineering Journal, 48(S1), 166–170. [Google Scholar]

12. Chen, C., Liu, H., Li, Y. (2007). Study on grassroots-reinforced soil by laboratory triaxial test. Rock and Soil Mechanics, (10), 2041–2045. [Google Scholar]

13. Lei, S., Ding, W. (2005). Test of reinforcing fiber to inhibit expansibility of expansive soil. Chinese Journal of Geotechnical Engineering, (4), 482–485. [Google Scholar]

14. Mohamed, A. (2013). Improvement of swelling clay properties using hay fibers. Construction and Building Materials, 38(2), 242–247. https://doi.org/10.1016/j.conbuildmat.2012.08.031 [Google Scholar] [CrossRef]

15. Zhu, H., Zhang, Y., Ren, J. (2021). Study on the expansion and shrinkage characteristics of expansive soil modified by coal gangue and fiber powder. Non-Metallic Mines, 44(5), 27–30. [Google Scholar]

16. Tiwari, N., Satyam, N. (2021). Coupling effect of pond ash and polypropylene fiber on strength and durability of expansive soil subgrades: An integrated experimental and machine learning approach. Journal of Rock Mechanics and Geotechnical Engineering, 13(5), 1101–1112. https://doi.org/10.1016/j.jrmge.2021.03.010 [Google Scholar] [CrossRef]

17. Yuan, C., Zhou, Z., Zhang, J., Wang, S., Xu, K. (2021). Experimental study on strengthening mechanism of cement-modified expansive soil by epoxy resin and glass fiber. Engineering Journal of Wuhan University, 54(8), 709–716+724. [Google Scholar]

18. Stocker, P. (1969). Diffusion and diffuse cementation in lime and cement stabilized clayey soil. Clinical Cancer Research, 10(17), 5889–5894. [Google Scholar]

19. Aldaood, A., Bouaskere, M., Al-Mukhtar, M. (2014). Geotechnical properties of lime-treated gypseous soils. Applied Clay Science, 88–89(3), 39–48. https://doi.org/10.1016/j.clay.2013.12.015 [Google Scholar] [CrossRef]

20. Katz, L., Rauch, A., Liljestrand, H., Harmon, J., Shaw, K. et al. (2001). Mechanisms of soil stabilization with liquid ionic stabilizer. Transportation Research Record, 1757(1), 50–57. https://doi.org/10.3141/1757-06 [Google Scholar] [CrossRef]

21. Liu, B., Xiang, W., Zhang, W., Cui, D. (2009). Experimental study of ionic soil stabilizer-improves expansive soil. Rock and Soil Mechanics, 30(8), 2286–2290. [Google Scholar]

22. Han, L., Tan, L., Jiang, X. (2015). Experimental study on swell-shrink characteristics and strength properties of lonic soil stabilizer improved expansive soil. Yellow River, 37(6), 126–130. [Google Scholar]

23. Keskin, I., Kahraman, S. (2022). Stabilization of swelling soil by lime, fly ash, and calcium carbide residue. Arabian Journal of Geosciences, 15(10), 1009–1021. https://doi.org/10.1007/s12517-022-10291-3 [Google Scholar] [CrossRef]

24. Mypati, V., Saride, S., Challapalli, S. (2022). Durability of fly ash geopolymer binder in deep mixed expansive soils. Proceedings of the Institution of Civil Engineers-Ground Improvement, pp. 1–34. Kandi, India. [Google Scholar]

25. Darikandeh, F., Phanikumar, B. (2022). Swell-shrink behaviour of an expansive soil stabilised by CCR-fly ash (FA) columns and CCR-FA blends. Geomechanics and Geoengineering, 17(4), 1247–1259. https://doi.org/10.1080/17486025.2021.1928766 [Google Scholar] [CrossRef]

26. Mahedi, M., Cetin, B., White, D. (2018). Perfomance evaluation of cement and slag stabilized expansive soils. Transportation Research Record, 2672(52), 164–173. https://doi.org/10.1177/0361198118757439 [Google Scholar] [CrossRef]

27. Wang, Y., Guo, P., Shan, S., Yuan, H., Yuan, B. (2016). Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotechnical and Geological Engineering, 34(4), 1079–1088. https://doi.org/10.1007/s10706-016-0028-4 [Google Scholar] [CrossRef]

28. Wang, C., Zha, H., Wang, J. (2020). Review on expansion and shrinkage mechanism and new treatment methods of expansive soil. Subgrade Engineering, (2), 6–11. [Google Scholar]

29. Zhao, H., Gong, B., Zhao, C., Liu, J. (2015). A review and prospect on the mechanism of expansive soil stabilized by lime. Journal of Yangtze River Scientific Research Institute, 32(4), 65–70. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools