Open Access

Open Access

ARTICLE

A Comprehensive Method for the Optimization of Cement Slurry and to Avoid Air Channeling in High Temperature and High-Pressure Conditions

1 Zhanjiang Branch of CNOOC (China) Co., Ltd., Zhanjiang, 524000, China

2 College of Petroleum Engineering, Yangtze University, Wuhan, 430100, China

* Corresponding Author: Huanqiang Yang. Email:

(This article belongs to the Special Issue: Meshless, Mesh-Based and Mesh-Reduction Methods Based Analysis of Fluid Flow in Porous Media)

Fluid Dynamics & Materials Processing 2023, 19(5), 1237-1248. https://doi.org/10.32604/fdmp.2022.023147

Received 12 April 2022; Accepted 30 June 2022; Issue published 30 November 2022

Abstract

Air channeling in the annulus between the casing and the cement sheath and/or between the cement sheath and formation is the main factor affecting the safe operation of natural gas wells at high temperatures and pressures. Prevention of this problem requires, in general, excellent anti-channeling performances of the cement sheath. Three methods to predict such anti-channeling performances are proposed here, which use the weightless pressure of cement slurry, the permeability of cement stone and the volume expansion rate of cement sheath as input parameters. Guided by this approach, the anti-channeling performances of the cement slurry are evaluated by means of indoor experiments, and the cement slurry is optimized accordingly. The results show that the dangerous transition time of the cement slurry with optimized dosage of admixture is only 76 min, the permeability of cement stone is 0.005 md, the volume shrinkage at final setting is only 0.72%, and the anti-channeling performances are therefore maximized. The effective utilization of the optimized cement slurry in some representative wells (LD10–1-A1 and LD10–1-A2 in LD10–1 gas field) is also discussed.Keywords

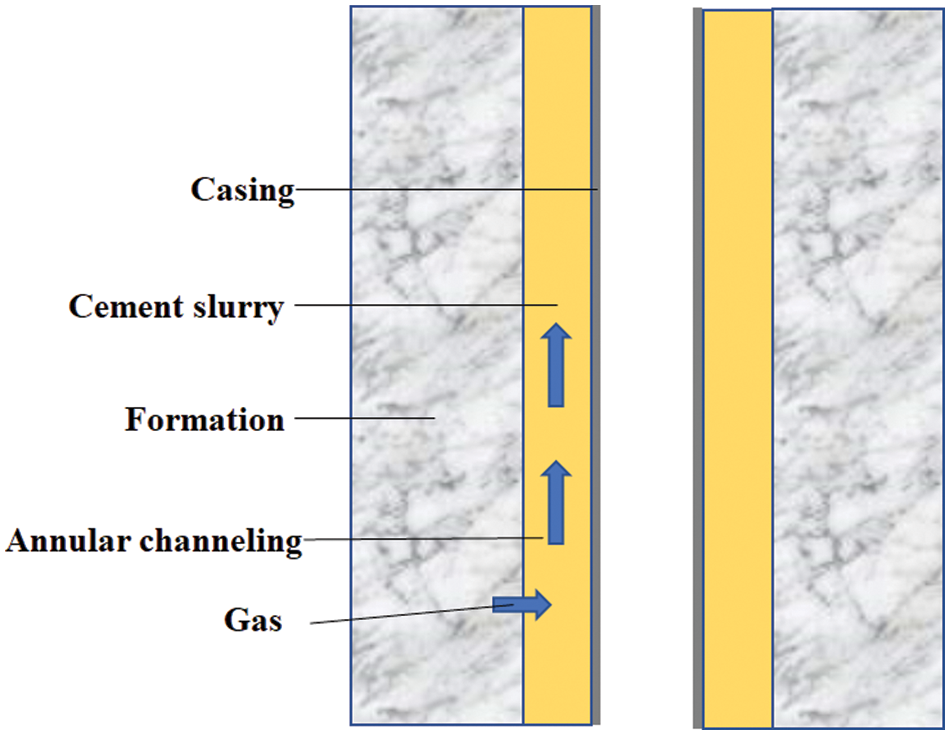

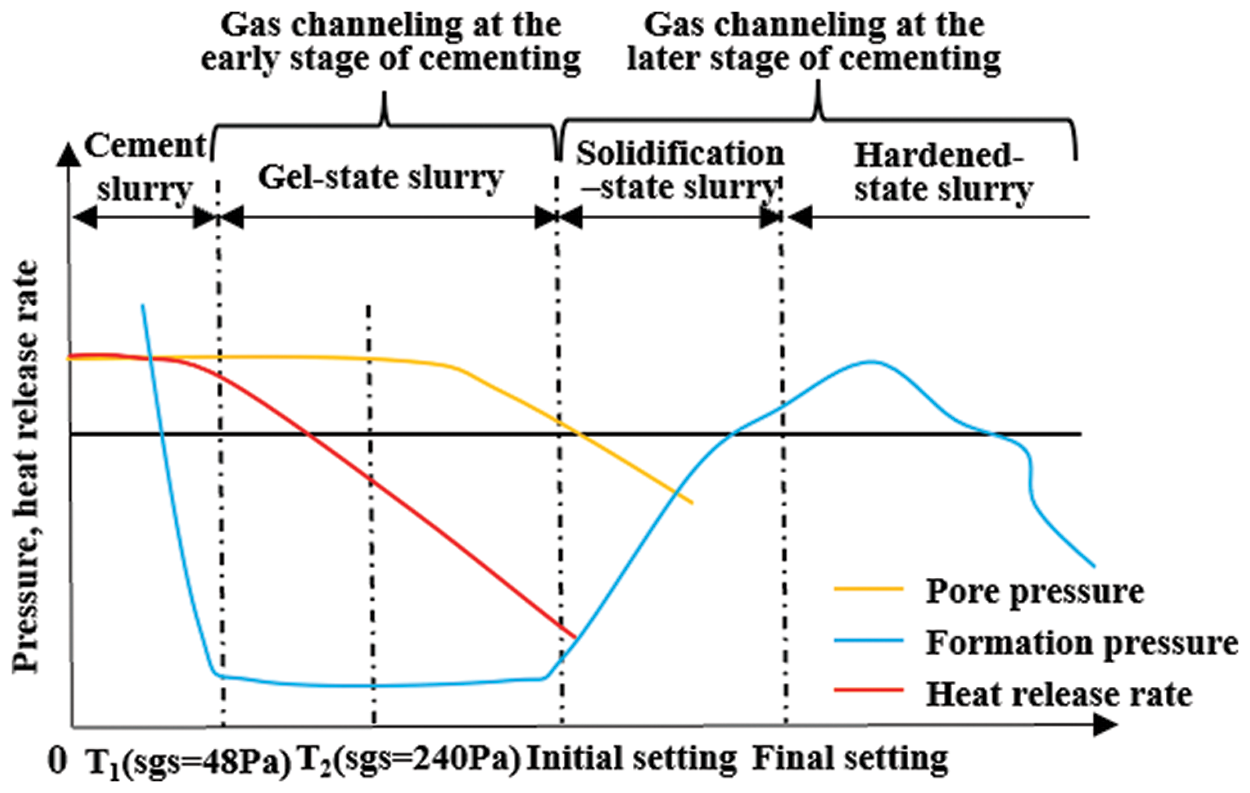

Annulus air channeling is defined as the phenomenon that gas intrudes into the annulus from formation pores and migrates to the wellhead due to the imbalance between annulus liquid column pressure and formation pressure after cementing [1], as shown in Fig. 1. The mechanism of annular air channeling is shown in Fig. 2. The harm caused by gas channeling is extremely serious, ranging from wellhead with pressure to blowout accident, which seriously affects the cementing quality and construction safety of oil and gas wells [2–5]. Therefore, in order to achieve the purpose of cementing operation, a reasonable and accurate evaluation method of anti-channeling performance of cement slurry points out the direction for the effective prevention of annular air channeling.

Figure 1: Diagram of the annular gas channeling

Figure 2: The mechanism of annular gas channeling

Annular air channeling was first proposed in the early 1960s [4]. Many scholars have researched the evaluation method of anti-channeling performance of cement slurry. Carter et al. [5] indicated that the poor cleaning efficiency of mud cake, cement slurry filtration, and poor cementation between cement slurry and casing and formation were the main reasons for channeling, and proposed the importance of controlling water loss for channeling prevention. Based on this, Christian et al. [6] presented the calculation method of filtration, pointing out that it is conducive to avoid gas channeling when the API filtration is less than 50 ml/30 min, and thus the permeability of cement stone will be reduced. Garcia et al. [7] accounted that the decrease of effective slurry column pressure in the well, caused by the weightless of bridge plugging result from the filtration of cement slurry, was the main reason for annular air channeling. Liu et al. [8] systematically analyzed and researched the weightless and channeling mechanism of cement slurry by the utilization of the self-developed device. Sabins et al. [9–11] proposed a gas channeling analysis method and a channeling potential factor for gas channeling potential evaluation, and pointed out that the inducement of the weightless of cement slurry is the development of static gel strength, the cement slurry can effectively prevent the occurrence of gas channeling when the static gel strength is 240 Pa. Sutton et al. [12] proposed a method of cement slurry response performance coefficient on the basis of comprehensively considering the relationship between the static gel strength of cement slurry, fluid loss characteristics, actual wellbore conditions and the anti-channeling performance of cement slurry. It is an improvement to the performance coefficient method of cement slurry and improves the scientificity of the evaluation method. The cement slurry performance coefficient method only reflects the anti-gas channeling performance of the cement slurry, and does not consider factors such as back depth, well diameter, and cement slurry density. While the cement slurry response performance coefficient method merely considers the static gel strength and water loss rate, without considering the effect of annular pressure balance on the anti-gas channeling ability. Therefore, Harris et al. [13] introduced the pressure stability coefficient and proposed the modified cement slurry performance coefficient method to evaluate the anti-gas channeling ability of cement slurry. Liu et al. [14] put forward the resistance coefficient method, making use of the thickening transition time of cement slurry instead of static gel strength to reflect the resistance growth rate of cement slurry, and to evaluate the anti-channeling performance of cement slurry. Zhang et al. [15] developed a pressure balance method by integrating gas invasion resistance, weight loss law of cement slurry and static gel strength, and pointed out that gas channeling will occur when the sum of effective liquid column pressure and gas invasion resistance is less than gas reservoir pressure. Zou et al. [16] and Zhu et al. [17] designed high-density anti-gas channeling cement slurry in view of the difficulties of cementing high-pressure gas wells in northeast Sichuan, and evaluated the anti-channeling performance of cement slurry by the application of permeability, static gel strength and API water loss. Liu et al. [18] proposed that the transition time of static gel strength, the permeability of cement slurry within the dangerous time of gas invasion and the volume shrinkage before initial setting should be taken as the key performance indicators for evaluating the channeling prevention of cement slurry. Zhou et al. [19] established the accurate calculation model of pressure loss of cement slurry column, proposed the subsection design method and pressure stability judgment method, and established a new evaluation method of anti-gas channeling ability based on the pressure stability judgment principle. In the same year, Chu et al. [20] combined with a large number of laboratory experiments and took advantage of the fuzzy mathematics method to establish a new method for evaluating the anti-channeling ability of cement slurry based on three parameters of static gel strength transition time, volume shrinkage rate and water loss. Li et al. [21] considered the characteristics of annular air channeling, established a comprehensive judgment model for the anti-gas channeling ability of cement slurry on the basis of the fuzzy mathematics theory and analytic hierarchy process principle, and formed a new evaluation method of the anti-gas channeling ability of cement slurry based on fuzzy mathematics theory. Zhang et al. [22] took the cement slurry performance coefficient method, resistance coefficient method, gas channeling potential factor method, cement slurry performance response coefficient method and volume shrinkage ratio method as the index layer, established the influence weight model of the evaluation method of cement slurry anti-gas channeling by applying analytic hierarchy process, and a comprehensive evaluation method for the anti-channeling performance of the cement slurry system was constructed by using the approximation ideal solution method.

These evaluation methods focus on considering one or several key factors, such as cement slurry water loss, static gel strength transition time, thickening transition time, etc. the consideration factor is single and the scope of application is narrow. Especially for high temperature and high pressure oil and gas reservoirs, the types of annular air channeling include gas channeling caused by weightless of cement slurry, gas channeling caused by excessive permeability of cement stone, and gas channeling caused by micro annulus. Therefore, it is crucially vital to evaluate the anti-channeling performance of cement slurry comprehensively, accurately and reasonably.

This paper is organized as follows. Section 2 describes experimental device and experimental method, including the experimental principles and experimental procedures of the cement slurry weightless evaluation device, the cement stone permeability measuring device and the cement stone shrinkage expansion analyzer. Section 3 describes comprehensive evaluation of anti-channeling performance of high temperature and high pressure cement slurry, including pressure loss evaluation of cement slurry, permeability evaluation of cement stone and volume expansion evaluation of cement stone. Section 4 describes the field application followed by conclusion in Section 5.

2 Experimental Device and Method

The experimental equipment includes TG-3060A constant speed mixer, high temperature and high pressure curing kettle, weightless pressure evaluation device of cement slurry, cement stone permeability measurement device, high temperature and high pressure cement stone shrinkage and expansion analyzer.

The experimental formula is as follows: “JH” Grade G cement, 0.22% polyether defoamer PC-X62L, 0.22% silanes defoamer PC-X66L, 1.45% sulfonated aldehyde ketone dispersant PC-F41L, 1.81% AMPS water loss agent G80L, 1.81% resin B83, 1.24% polycarboxylic acid low temperature early strength agent PC-H21L, 0.36% AMPS high temperature retarder PC-H40L, 29% iron ore powder D20 with 200 mesh, 1.5% expansion agent PC-B20 of calcium oxide, 13% silicon powder PC-C81 with 250 mesh and 32.26% water.

Prepare and maintain cement slurry according to GB 10238–2005 Oil Well Cement, and then test the weightless pressure of cement slurry, cement stone permeability and volume stability to comprehensively evaluate the anti-channeling ability of cement slurry from multiple angles [23]. and form a comprehensive evaluation method suitable for the anti-channeling performance of high temperature and high pressure cement slurry, which provides a basis and reference for optimizing the formula of cement slurry and improving the anti-channeling performance of cement slurry.

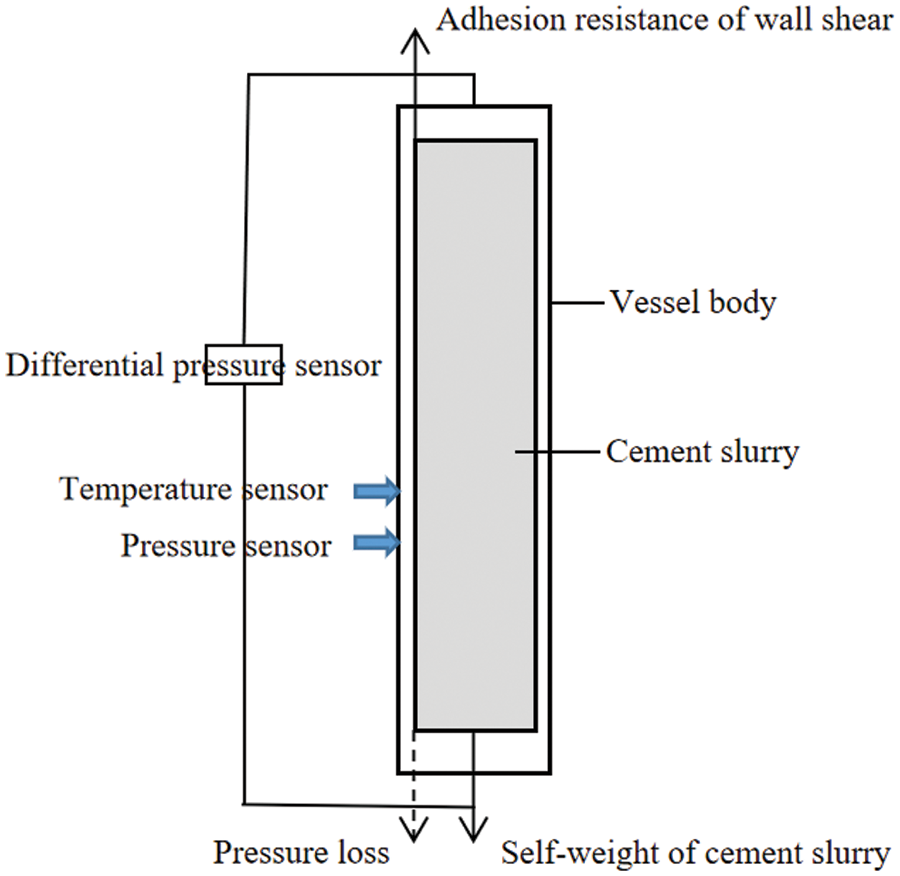

2.3.1 Evaluation of Weightless Pressure of Cement Slurry

The structure of the self-made weightless pressure evaluation device of cement slurry is shown in Fig. 3. The device mainly includes test kettle body assembly (test head), device shell and panel, pipeline system, controller, and computer system. The maximum simulated pressure is 7.1 MPa, the maximum simulated temperature is up to 232°C, the temperature control accuracy is less than ±1°C, the formation pressure measurement accuracy is less than 1%, and the weightless differential pressure measurement accuracy is less than 1%. The data is true and reliable, which can realize a large number of continuous measurements, and most operations can be completed under high temperature and high pressure. The repeatability of the data is relatively good.

Figure 3: Weightless pressure evaluation device of cement slurry

During the experiment, first edit the preheating and heating program, pour the prepared cement slurry into the high temperature and high pressure curing kettle for curing to 90°C, and then pour it into the preheated weightless test kettle. Re-edit the heating and pressurization program, start the experiment, monitor the experimental pressure, experimental temperature and weightless differential pressure in real time, end the experiment after the initial setting of cement slurry, and save the real-time data and curve transmitted to the computer system.

2.3.2 Permeability Evaluation of Cement Stone

The permeability measurement device of cement stone adopts the gas measurement method. The device is mainly composed of core holder, pressure sensor, temperature sensor, internal and external electric couple, heating device, gas flowmeter, and computer system. The inlet end is connected to the high-pressure nitrogen cylinder and the outlet end is connected to the gas flowmeter, which can simulate downhole temperature, pressure and other working conditions. Monitor the temperature and pressure of cement slurry in the kettle in real time, and transmit the data to the computer system by data transmission line for data analysis and processing, so as to simulate the change curve of the permeability of cement stone with time.

During the experiment, edit the heating and pressurization program, put the dried cement stone sample into the core holder, connect the nitrogen cylinder to apply pressure to the cement slurry in the kettle, and the internal and external galvanic couples monitor the temperature of cement slurry in real time. Under a certain confining pressure and driving pressure, record the volume flow after the gas flow rate is stable, and then calculate the permeability of cement stone.

The calculation method of permeability is shown in formula (1) [24]:

The calculation method of permeability is shown in formula (1):

where Kg is the gas permeability, μm2; P1 is the inlet pressure of gas measurement permeability, 0.1 MPa; P2 is the outlet pressure of gas measurement permeability, 0.1 MPa; P0 is the standard atmospheric pressure, 0.1 MPa; μ is the gas viscosity, mPa⋅s; Q0 is the gas volume flow under atmospheric pressure, cm3/s; L is the length of the sample, cm; A is the cross-sectional area of the sample, cm2.

2.3.3 Evaluation of Cementation Strength and Volume Shrinkage of Cement Stone Wall

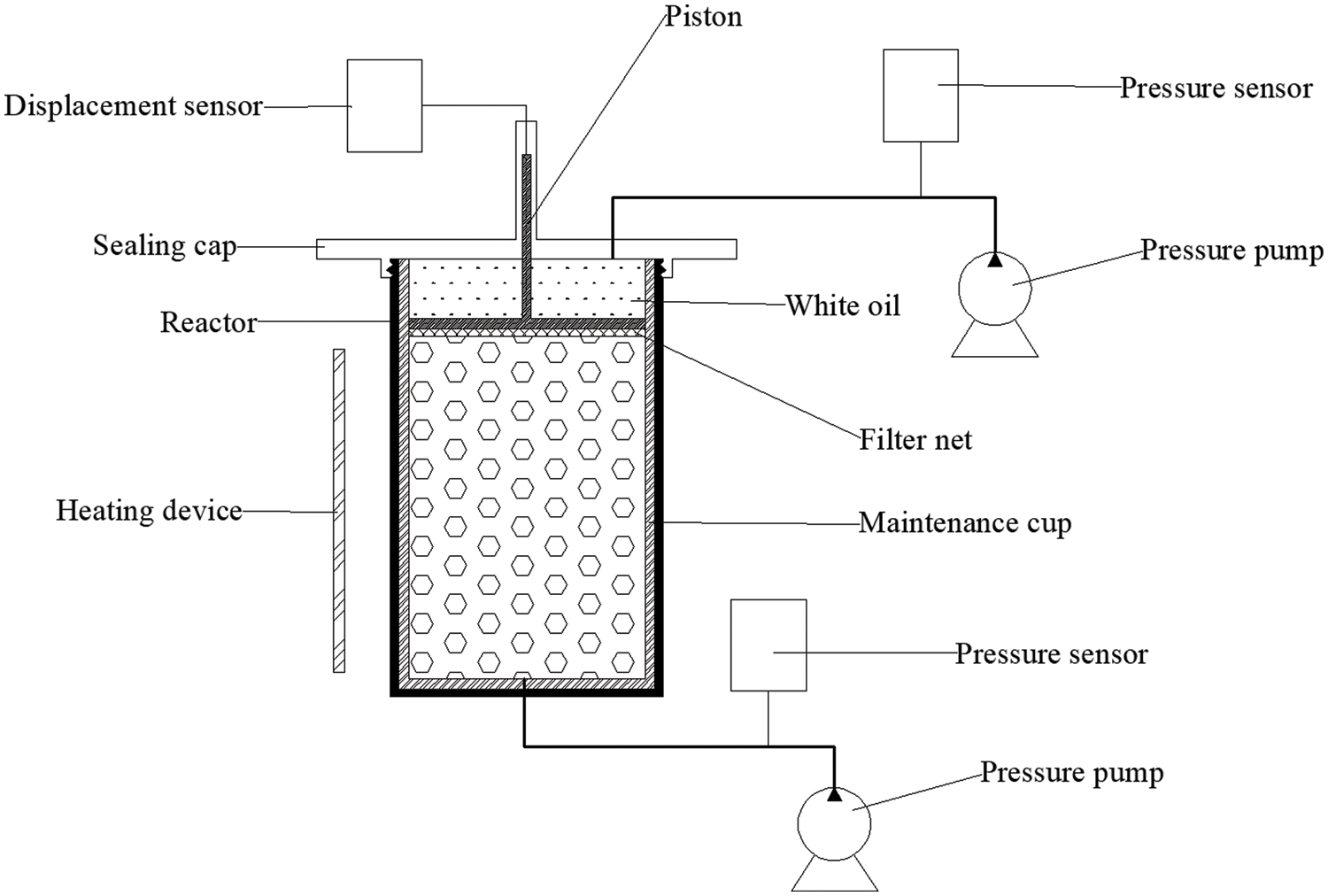

The structure of the self-made shrinkage and expansion analyzer of cement stone is shown in Fig. 4. The instrument is mainly composed of kettle, piston, filter screen, temperature sensor, pressure sensor, displacement sensor, pressure pump, and computer control system. It can accurately measure the expansion of plastic body and hardened body at the same time, and can continuously measure the volume shrinkage rate during the solidification process of cement slurry. And the maximum working temperature reaches 150°C, the maximum working pressure reaches 70 MPa, the maximum flow pressure is 7 MPa, the measurement accuracy is 0.001 mm, the permeability measurement range is 0.00001∼10 mD, and the working time range is 10 min∼150 d. The volume change of cement stone under different curing time will be measured according to the requirements of ISO 10426 Determination of Shrinkage and Expansion of Oil Well Cement under Normal Pressure.

Figure 4: High temperature and high pressure cement shrinkage and expansion analyzer

During the experiment, after setting the heating and pressurization program according to the experimental scheme, turn on the temperature and pressure control system, pour the configured cement slurry into the kettle, and cover the sealing cover. After starting the program, the computer control system will receive the volume and volume accumulation of cement slurry flowing out/into the kettle measured by the displacement sensor. By processing the experimental data, the development curve of expansion rate with time is drawn.

The calculation method of volume shrinkage is shown in formula (2):

where Et is the shrinkage rate of cement slurry at a certain time, %; Vt is the volume flowing out of the kettle at a certain time, mL; V0 is the volume of kettle, mL; The volume of cement slurry expands and the expansion rate is negative, the volume of cement slurry shrinks and the expansion rate is positive.

3 Comprehensive Evaluation of Channeling Prevention Performance of High Temperature and High Pressure Cement Slurry

3.1 Weightless Pressure of Cement Slurry

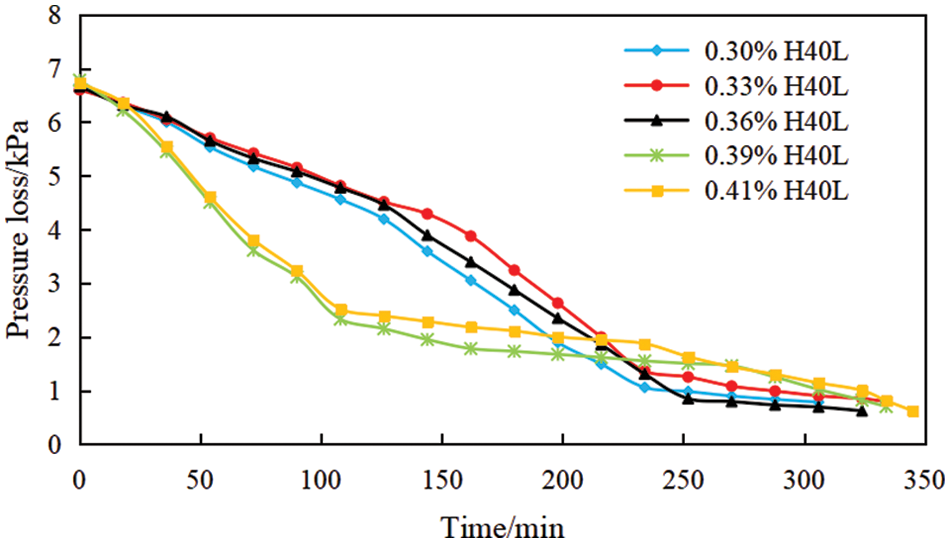

The cement slurry will lose weight during the setting process, resulting in the reduction of annulus hydrostatic column pressure, but the cement slurry gel strength is not enough to resist formation gas channeling. It is therefore necessary to evaluate the weightless pressure of cement slurry to ensure the anti-channeling ability of cement slurry in the process of setting. During the setting process of cement slurry under high temperature and high pressure, the dosage of retarder has a great influence on the weightless pressure [25]. It is considered to optimize the weightless curve from the perspective of changing the dosage of retarder H40L. Under the temperature and pressure conditions of 150°C and 6 Mpa, the weightless pressure of high temperature and high pressure cement slurry system with different dosage of retarder H40L was tested by using the weightless pressure evaluation device of cement slurry, which experimental results are shown in Fig. 5. The weightless curve presents a “three-stage” development when the dosage of retarder H40L is 0.39% and 0.41%. And the dangerous transition time of the cement slurry formed by the former is 108∼234 min (total 126 min), while the latter is 110∼252 min (total 142 min). At this stage, the hydration of cement slurry enters the induction period, the gel strength develops rapidly, the liquid column pressure drops steadily, and the gel weightless occurs. However, the weightless curve shows a “two-stage” development when the dosage of retarder H40L is 0.30%, 0.33% and 0.36%. There is no sedimentation weightless stage, and the liquid column pressure basically decreases linearly, showing gel weightless. Among them, the dangerous transition time of 0.30% H40L cement slurry is 126∼234 min (108 min in total), the dangerous transition time of 0.36% H40L cement slurry is 128∼252 min (124 min in total), while the dangerous transition time of 0.33% H40H cement slurry is the shortest (142∼234 min), and the anti-channeling performance is the best.

Figure 5: Weightless curve of cement slurry with different dosage of retarder H40L

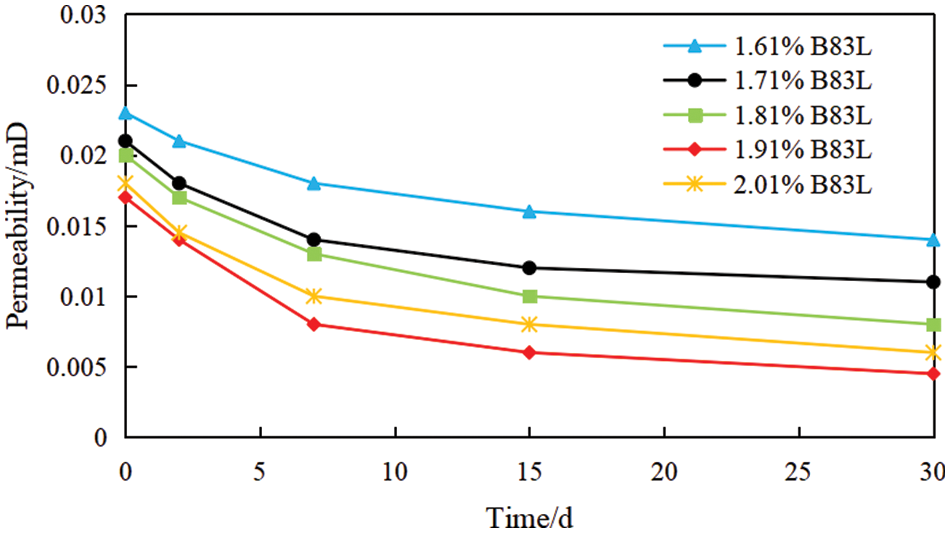

Cement slurry is used to seal oil and gas reservoirs. After the cement slurry is solidified, the cement stone should not only have good mechanical properties, but also have good sealing quality. When the permeability of the cement stone is greater, the resistance of gas channeling penetrating into the cement stone is smaller, and the risk of gas passing through the cement stone into the wellbore is higher, the gas channeling is more likely to occur, and the sealing quality is also worse [26]. The strength of cement stone will decline in the high temperature (>110°C) environment, causing the increase of the permeability of cement stone, resulting in the loss of sealing ability of cement sheath. Under the condition of high temperature and high pressure, the curing of resin B83L and the hydration of cement are carried out at the same time. The cured resin polymer improves the density of cement stone, thereby reducing the permeability of cement stone [27]. It is therefore considered to optimize the permeability of cement stone from the perspective of changing the dosage of B83L. Under the temperature of 150°C, the permeability of high temperature and high pressure cement stone with different dosages of latex B83L after curing for 0, 3, 7, 15 and 30 days was tested by using the permeability measuring device of cement stone, which experimental results are shown in Fig. 6. The permeability of the three cement slurry systems decreases continuously with the extension of curing time. After curing for 30 days, the permeability of cement stone formed by 1.61% B83L is 0.014 mD, 1.71% B83L is 0.011 mD, 1.81% B83L is 0.008 mD, 1.91% B83L is 0.0045 mD, and 2.01% B83L is 0.006 mD. Among them, the permeability of cement stone added with 1.91% B83L is the lowest, which meets the requirements of cement paste permeability in SY/T 5480–2016 Code for Cementing Design.

Figure 6: Permeability curve of cement stone with different resin B83L dosage

3.3 Volume Expansion of Cement Stone

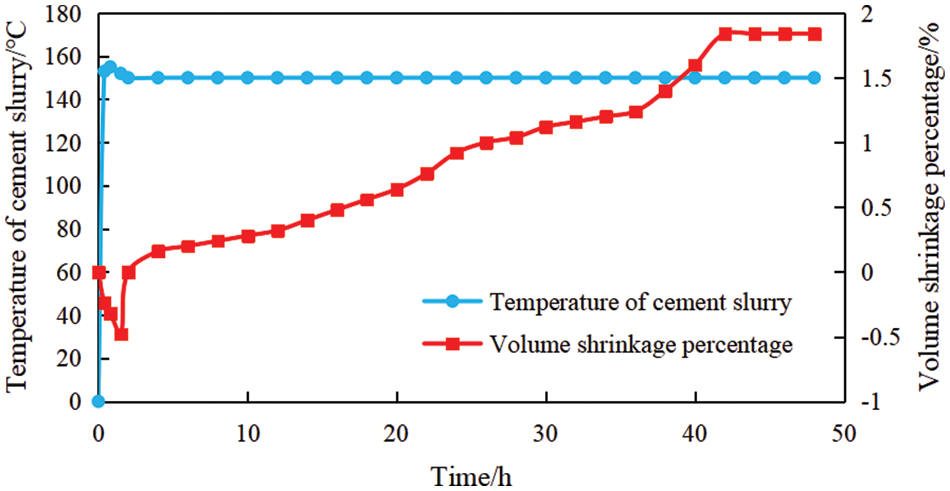

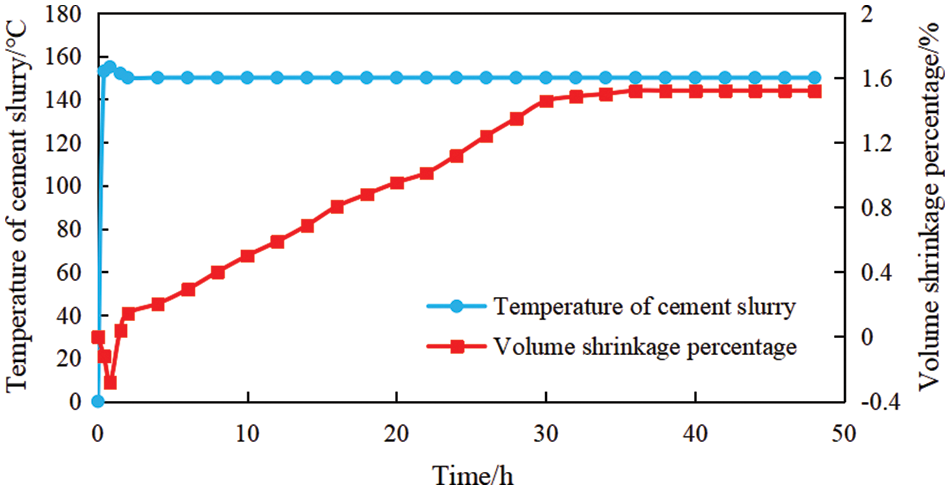

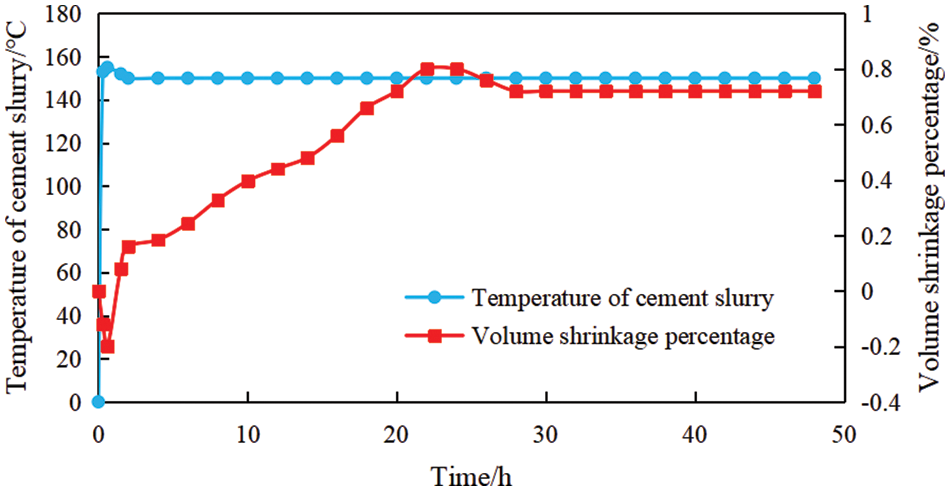

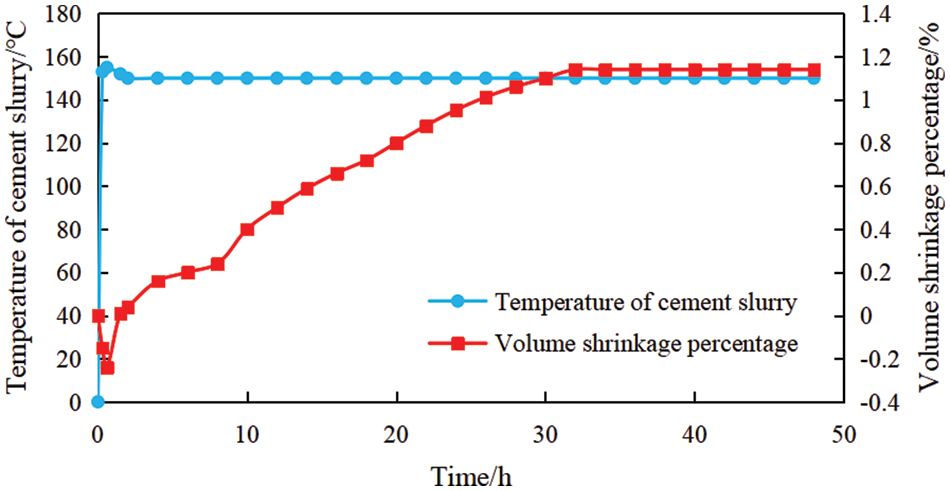

The volume of cement will change in the hydration process, and it is mainly manifested as various shrinkages in general. The volume shrinkage of cement slurry before initial setting is generally only 0.2%∼0.5%, while it will reach more than 90% when the strength of cement slurry reaches the final setting value of ATSM (0.14 MPa) [10]. Excessive volume shrinkage may lead to micro-gap and cause interfacial channeling. Therefore, the volume shrinkage is small at the final setting time, which can avoid the occurrence of interfacial channeling and reduce the risk of gas channeling. In the high temperature environment, the cement slurry system with expansion agent can generate a certain volume expansion after initial setting and partially compensate the hydration volume shrinkage of cement slurry. It is considered to optimize the permeability of cement stone from the perspective of changing the dosage of expansion agent PC-B20. Under the condition of 150°C, the volume shrinkage rate of cement stone formed by the cement slurry system with the addition of 1.5%, 1.6%, 1.7% and 1.8% B20 was tested by cement stone shrinkage and expansion analyzer, which experimental results are shown in Figs. 7–10.

Figure 7: Volume shrinkage test of 1.5% B20 cement stone

Figure 8: Volume shrinkage test of 1.6% B20 cement stone

Figure 9: Volume shrinkage test of 1.7% B20 cement stone

Figure 10: Volume shrinkage test of 1.8% B20 cement stone

The cement slurry system exhibits the law of first expansion and then shrinkage. In the early stage, the cement is rapidly hydrated at high temperature, releasing a large amount of hydration heat, which makes the slurry temperature increase to produce a larger expansion. Then the cement hydration enters the induction period, the hydration rate slows down, the released hydration heat decreases, the temperature decreases, and the cement slurry volume decreases [28]. The volume of the cement slurry system with the addition of 1.5% B20 increases slightly before 1.5 h, 1.6% B20 increases slightly before 0.8 h, 1.8% B20 increases slightly before 0.75 h, and 1.7% B20 increases slightly before 0.6 h. At the final setting, the volume shrinkage rate of the cement slurry system with the addition of 1.5% B20 reaches 1.84%, 1.6% B20 reaches 1.52%, 1.8% B20 reaches 1.14%, and 1.7% B20 is only 0.72%, which is far lower than that of other B20 cement slurry systems. Therefore, the cement slurry system with 1.7% B20 dosage has the lowest volume shrinkage and the best channeling prevention performance during final setting.

To sum up, by comparing the weightless pressure of cement slurry system with different H40L dosages, the permeability of cement stone with different resin B83L dosages, and the volume shrinkage of cement stone with different B20 dosages, the admixture dosage of cement slurry system with the shortest dangerous transition time, the lowest permeability, the lowest volume shrinkage and the best anti-channeling performance can be optimized: 0.33% H40L, 1.91% B83L and 1.7% B20.

In the development process of ultra-high temperature and high pressure gas wells in LD10–1 gas field in the west of the South China Sea. The formation pressure system of the target formation is complex, abnormally high pressure and weak formation alternately exist, and the risk of well kick and lost circulation is high. And the bottom hole temperature is high, the temperature difference is large, and the CO2 concentration is high. Therefore, the cement slurry needs to have the properties of corrosion resistance, high temperature resistance and gas channeling prevention. Taking gas Wells LD10–1-A1 and LD10–1-A2 as the research objects. The LD10–1-A1 adopts the well structure of five openings, of which the fifth opening is drilled to the depth of 4424.86 m with the Φ212.7 mm drilling bit, the Φ177.8 mm tail pipe is run, and the sealing section is 3889.64–4424.86 m. The formation pressure coefficient of the Φ212.7 mm well section is greater than 2.26, the formation fracture pressure is less than 2.32, and the safety density window is barely 0.06 g/cm3. And the LD10–1-A2 adopts the well structure of four openings, of which the fourth opening is drilled to the depth of 4066.55 m with the Φ212.7 mm drilling bit, the Φ177.8 mm tail pipe is run to 4062.74 m, and the sealing section is 3467.63–4066.55. The formation pressure coefficient of Φ212.7 mm well section is higher than 2.27, the formation fracture pressure is less than 2.35, and the safety density window is merely 0.08 g/cm3.

The cement slurry system after optimizing the dosage of admixture is applied to Wells LD10–1-A1 and LD10–1-A2. And prepare for the wellhole woke before cementing construction, strictly implement the well-opening regulations, adjust the performance of drilling fluid, scientifically design the pre-fluid system. After construction, hold pressure and setting for 24 h, and then open pressure and setting for 24 h. The acoustic amplitude logging shows that the qualified rate of cementing quality of Well LD10–1-A1 is 91%, and that of Well LD10–1-A2 is 88%. There is no gas channeling occurred in the early stage of setting process, and no annulus with pressure in the later production operation. The successful application of the cement slurry optimized in two wells proves that the comprehensive evaluation method has high accuracy and can well evaluate the anti-gas channeling ability of cement slurry. The successful application of the cement slurry optimized by the comprehensive evaluation method of the anti-channeling performance of high temperature and high pressure cement slurry in two wells proves that this method has sufficient accuracy and can perfectly evaluate the anti-gas channeling ability of the cement slurry.

(1) According to the evaluation requirements of anti-channeling performance of high temperature and high pressure cement slurry, a comprehensive evaluation method for anti-channeling performance of high temperature and high pressure cement slurry based on weightless pressure, permeability and volume shrinkage is proposed.

(2) Using the self-designed weightless pressure evaluation device, cement stone permeability measurement device and high temperature and high pressure cement stone shrinkage and expansion analyzer, based on the proposed evaluation method, the weightless pressure of cement slurry, cement stone permeability and volume shrinkage were optimized respectively, and the dosage of admixture of cement slurry system with the best anti-channeling performance is selected.

(3) The cement slurry system after optimizing the dosage of admixture has been successfully applied to Wells LD10–1-A1 and LD10–1-A2 in LD10–1 gas field, which significantly improves the cementing quality. It is proved that the comprehensive evaluation method of channeling prevention performance can provide more overall and guidance for the design of gas channeling prevention performance of high temperature and high pressure cementing cement slurry in the future.

Acknowledgement: Thanks to the Zhanjiang Branch of CNOOC (China) Co., Ltd. for providing the cement slurry system, for guiding the completion of the experiment and applying it on the gas wells.

Funding Statement: The work is funded by the CNOOC Scientific Research Project “Study of cementing key properties and its matching technology of LD-10 gas field” (Grant No. CCL2019ZJFN1227).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Lv, K., Huang, H., Zhong, X., Tong, Y., Ling, X. et al. (2021). A prediction model of pressure loss of cement slurry in deep-water HTHP directional wells. Energies, 14(23), 8180. DOI 10.3390/en14238180. [Google Scholar] [CrossRef]

2. Cheung, P. R., Beirute, R. M. (1985). Gas flow in cements. Journal of Petroleum Technology, 37(6), 1041–1048. DOI 10.2118/11207-PA. [Google Scholar] [CrossRef]

3. Sykes, R. L., Logan, J. L. (1987). New technology in gas migration control. SPE Annual Technical Conference and Exhibition, Dallas, Texas. [Google Scholar]

4. Wilkins, R. P., Free, D. (1989). A new approach to the prediction of gas flow after cementing. SPE/IADC Drilling Conference, New Orleans, Louisiana. [Google Scholar]

5. Carter, G., Slagle, K. (1972). A study of completion practices to minimize gas communication. Journal of Petroleum Technology, 24(9), 1170–1174. DOI 10.2118/3164-PA. [Google Scholar] [CrossRef]

6. Christian, W. W., Chatterji, J., Ostroot, G. W. (1976). Gas leakage in primary cementing-a field study and laboratory investigation. Journal of Petroleum Technology, 28(11), 1361–1369. DOI 10.2118/5517-PA. [Google Scholar] [CrossRef]

7. Garcia, J. A., Clark, C. R. (1976). An investigation of annular gas flow following cementing operations. SPE Symposium on Formation Damage Control, Houston, Texas. [Google Scholar]

8. Liu, C. J., Zhang, M. S. (1998). Gas channeling in the setting process of cement slurry. Journal of Southwest Petroleum Institute, 20(4), 47–52. [Google Scholar]

9. Sabins, F. L., Sutton, D. L. (1986). The relationship of thickening time, gel strength, and compressive strength of oilwell cements. SPE Production Engineering, 1(2), 143–152. [Google Scholar]

10. Sabins, F. L., Tinsley, J. M., Sutton, D. L. (1982). Transition time of cement slurries between the fluid and set states. Society of Petroleum Engineers Journal, 22(6), 875–882. DOI 10.2118/9285-PA. [Google Scholar] [CrossRef]

11. Sutton, D. L., Paul, R., Sabins, F. (1984). New evaluation for annular gas-flow potential. Oil Gas Journal, 82(51), 109–112. [Google Scholar]

12. Sutton, D. L., Ravi, K. M. (1989). New method for determining downhole properties that affect gas migration and annular sealing. SPE Annual Technical Conference and Exhibition, San Antonio, Texas. [Google Scholar]

13. Harris, K. L., Ravi, K. M., King, D. S., Wilkinson, J. G., Faul, R. R. (1990). Verification of slurry response number evaluation method for gas migration control. SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana. [Google Scholar]

14. Liu, C. J., Zhang, Y. L., Xie, Y. Q. (1999). Study on the method of predicting annular air channeling by using the change of cement slurry consistency resistance. Natural Gas Industry, 19(5), 46–50. [Google Scholar]

15. Zhang, X., Feng, M., He, Q. (2002). New realization of the relationship between losing weight of slurry and gel strength. Drilling & Production Technology, 25(6), 77–80. [Google Scholar]

16. Zou, J. L., Gao, Y. H., Zhu, H. J., Liu, A. P., Tang, S. B. (2010). Study on high density anti gas channeling cement slurry system in northeast sichuan. Petroleum Drilling Technology, 38(1), 46–49. [Google Scholar]

17. Zhu, H. J., Lv, G. M., Liu, A. P., Xie, C. B., An, S. H. (2012). Research on a new method to evaluate the hydrostatic pressure of cement slurries. IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Tianjin, China. [Google Scholar]

18. Liu, Y., Ai, Z. Q., Li, Z. Y., Guo, X. Y. (2012). Discussion on influencing factors of cementing circulation temperature. Journal of Southwest Petroleum Institute (Science & Technology Edition), 34(1), 154–158. [Google Scholar]

19. Zhou, S. M., Li, G. S., Chu, Y. T. (2013). Sectional design for anti-gas channeling cementing. Petroleum Drilling Techniques, 41(5), 52–55. [Google Scholar]

20. Chu, Y. T., Zhang, L. H., Liu, Y., Liu, J. (2013). Comprehensive evaluation method of anti-gas channeling ability of cement slurry. Fault-Block Oil & Gas Field, 20(5), 678–680. [Google Scholar]

21. Li, J., Gao, B., Gong, N., Xie, Z. C., Chen, Y. et al. (2017). A new fuzzy mathematics-based method for anti-channeling performance evaluation and its application. Drilling Fluid & Completion Fluid, 34(5), 69–74. [Google Scholar]

22. Zhang, Q. L., Han, Y. T., Zhang, M., Li, J., Liu, P. (2021). Research and application of comprehensive evaluation method for anti-channeling performance of cement slurry. Petroleum Machinery, 49(8), 16–22. [Google Scholar]

23. Liu, H., Huang, Y., Zheng, J., Tian, Y., Xu, M. et al. (2022). Assessment of the performances of carboxylic acid monomers as fluid loss additives for oil-well cement. Fluid Dynamics & Materials Processing, 18(4), 999–1013. DOI 10.32604/fdmp.2022.020059. [Google Scholar] [CrossRef]

24. Yan, S. M., Wang, J., Qing, D. Y., Pei, G. B. (2010). Research on corrosion of oil well cement stone by H2S. Oilfield Chemistry, 27(4), 366–370. [Google Scholar]

25. Zou, P., Huang, Z., Tong, Y., Tan, L., Li, R. et al. (2022). Experimental evaluation of the mechanical properties of cement sheath under high-temperature conditions. Fluid Dynamics & Materials Processing, 18(3), 689–699. DOI 10.32604/fdmp.2022.019470. [Google Scholar] [CrossRef]

26. Yang, G. G., Tao, Q., Gao, Y., Wang, X. J. (2016). Research and application of composite cement slurry system in high temperature and high pressure gas wells. Science Technology and Engineering, 16(20), 151–155. [Google Scholar]

27. Guo, Y. Y., Xu, M. B., Song, J. J., Hu, S., Zhang, M. et al. (2021). Performance evaluation of resin system for improving the sealing capacity of cement slurry. Oilfield Chemistry, 37(4), 598–603. [Google Scholar]

28. Chen, L., Chen, H. N., Zhang, L. H., Liu, G. H., Tao, Q. et al. (2019). Cementing technology for preventing annulus pressure in horizontal wells of JY shale gas field. Petroleum Drilling and Production Technology, 41(2), 152–159. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools