Open Access

Open Access

ARTICLE

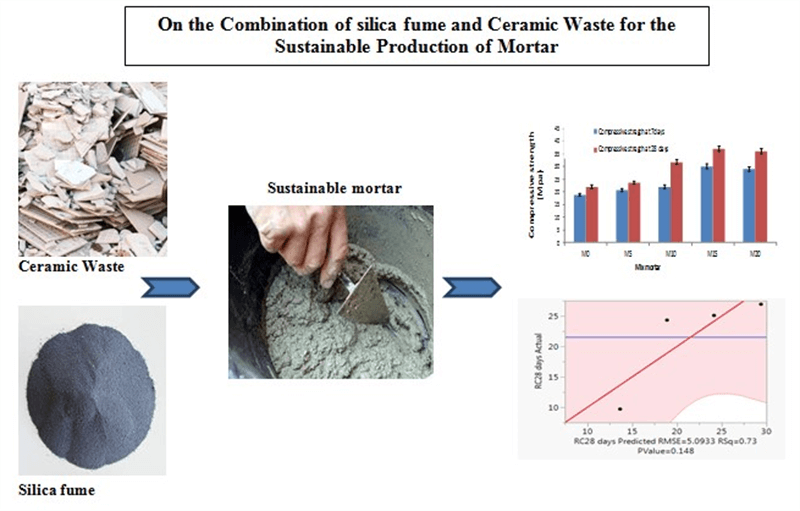

On the Combination of Silica Fume and Ceramic Waste for the Sustainable Production of Mortar

1 Civil Engineering Department, Faculty of Technology, M’sila University, M’sila, 28000, Algeria

2 Institute of Technical Urban Management, M’sila University, M’sila, 28000, Algeria

* Corresponding Author: Zine El Abidine Rahmouni. Email:

(This article belongs to the Special Issue: Materials and Energy an Updated Image for 2021)

Fluid Dynamics & Materials Processing 2023, 19(5), 1083-1090. https://doi.org/10.32604/fdmp.2022.021970

Received 23 February 2022; Accepted 24 June 2022; Issue published 30 November 2022

Abstract

The combined use of silica fume (SF) and ceramic waste (CW) for the production of mortar is studied. Sand is replaced by 5%, 10%, 15% and 20% of CW while a fixed 5% percentage (% wt of cement) of SF is used. The results show that the best results are obtained by using silica fume and ceramic waste sand with 15% weight of sand and 5% wt of cement. With the addition of sand ceramic waste (SCW), the mortar compressive strength and density increase, while the porosity displays an opposite trend. The experimental analysis is complemented with theoretical considerations on the matrix strength and related improvements in mechanical behavior. It is shown that the agreement between the experimental values and the estimated values is good.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools