Open Access

Open Access

ARTICLE

Exergo-Environmental Study of a Recent Organic Solar Hybrid Heat Pump

Université de Tunis El Manar, Ecole Nationale D’Ingénieurs de Tunis, Unité de Recherche Energétique et Environnement, Tunis, 1002, Tunisie

* Corresponding Author: Nahla Bouaziz. Email:

(This article belongs to the Special Issue: Materials and Energy an Updated Image for 2021)

Fluid Dynamics & Materials Processing 2023, 19(4), 991-1001. https://doi.org/10.32604/fdmp.2022.022239

Received 28 February 2022; Accepted 25 May 2022; Issue published 02 November 2022

Abstract

A hybrid heat pump (compression/absorption) with an integrated thermal photovoltaic unit is studied. The considered working fluids are organic mixtures: R245fa/DMAC and R236fa/DMAC, chosen for their low Global Warming Potential. The main objective is the optimization of energy efficiency in order to minimize the environmental impact through the implementation of a sustainable strategy. It is shown that Exergy Analysis itself is a valuable tool in energy integration. Within the imposed framework of minimizing total annual costs, entropy analysis can be instrumental in determining the optimal plant concept, optimizing energy conversion and use, and improving profitability. The present results are discussed under the optimistic hope that they may help to define new energy and environmental policies.Keywords

Nomenclature

| x | Mass fraction |

| | Mass flow (kg.s−1) |

| | Power (W) |

| T | Temperature (K, °C) |

| | Heat exchanged flow (W) |

| Ex | Specific exergy of a flow (kJ.kg−1) |

| ExD | Destruction of exergy |

| ηex | Exergy efficiency |

| P | Pressure (bar, Pa) |

| Impn | Impact of process n |

| FIn | Conservative impact factor |

| QR | Reference quantity |

| ETotal | Value of the producible |

| Pc | Maximum power of the photovoltaic installation (expressed in kWp) |

| Ir | Average annual irradiation in terms of installation |

| Main | Performance ratio or coefficient of performance of the photovoltaic system |

| δ | Annual degradation of modules |

| n | Service life of the modules (expressed in years) |

| ImpUF | Impact of the PV system per functional unit |

| ImpSystemPV | Impact of PV system |

Sustainable development brings environmental and economic aspects, while the quality of being livable integrates the concepts of environment and society and, finally, being equitable respects the economy and society.

The difficulty of sustainable development is to find harmony between these three poles, all aspects are of equal importance. Some describe the environment as a constraint due to the limited resources of our planet, which requires the adoption of efficient energy installations. In fact, this problem must be taken into account by the air conditioning sector, whose demand is constantly increasing.

The hybrid refrigeration machine has been modeled to be an effective solution to save energy, which is recommended in countries where the climate is relatively hot.

Thus, the expansion of new technologies of production is necessary. One solution seems to be viable is the tri-generation, offering a high efficiency due to the recovery of thermal energy; a technology that has recently been developed.

The operating principle of heat pumps is mainly based on the mechanical compression of steam, so the use of absorption machines could be an excellent way to improve the performance of this type of cycle [1].

Truly, these machines are more efficient especially when compared to conventional compression machines since they use natural refrigerant mixtures eliminating any undesirable effect on the ozone layer, they are also less energy consuming because compression machines are thermal [2,3].

The operation of absorption refrigeration machines is based on a fluid composed of a refrigerant and an absorbent. Often this is lithium water bromide (LiBr) or ammonia-water. It is the main association of the machine which is the most important, with four primordial elements: absorber, generator, evaporator and condenser. Absorption fluids are accessible and allow stable operation, however their coefficient of performance is low compared to compression heat pumps [4].

An environmental operation designed for absorption heat pumps at four temperature levels has been developed by Feidt et al. [5]. In reality, the machine is modified by integrating an environmental operation. Based on the two principles of thermodynamics, a new confguration of an absorption refrigeration system is proposed in view of improving the efficiency and to insure the ecological operation.

In this work, an evolutionary multi-objective approach (MOEA) based on the NSGA-II method was developed.

The study presented by Hadizadeh et al. [6] highlights another model of absorption refrigeration that has been used to produce electricity. This work consists in using an absorption cooling system instead of a mechanical compression refrigeration system. The results show that the use of this type of system in a combined cycle plant has an advantage over conventional cooling.

On the other hand, the hybrid refrigeration machine makes it possible to have a proportionally high efficiency. There is particular interest in hybrid heat pumps and absorption machines.

Essentially, the evaluation of the efficiency of this type of machine is based on the first law of thermodynamics by means of the COP. On the other hand, this energy method is not sure since it does not give any information on areas of energy failures in the system. The notion of reversibility and irreversibility was introduced in thermodynamics via the notion of “entropy” [7].

Therefore, unlike the energy approach, the exergy method, which takes into account the two principles of thermodynamics, makes it possible to evaluate the energy losses reported in each component of the machine. Based on thermodynamic analysis, recourse to the second principle is relevant [8–10]. Furthermore, the exergy approach endorses a better perception of thermodynamic processes by dealing with the consequences of the second law of thermodynamics. There are various researches devoted to the exergy method [11,12] applied to single, double and multi-stage absorption refrigeration machines operating with LiBr/H2O or NH3/H2O [13]. In this recent research, the evaluation of the energy losses of the various absorption machines was carried out based on the following assumptions: the temperatures of the condenser and the absorber are respectively 37.81°C, 7.11°C and 87°C. 81°C for the double effect cycle. Through this study, the evaluation of the irreversibility of the different absorption machines, the energy and exergy efficiency were also evaluated.

In another strategy, Diana et al. [13] studied the adaptation of thermoelectric cooling systems (TEC) to photovoltaic (PV) generators to establish PV-TEC systems.

They founded that the TEC addition increases the efficiency, the lifetime and the power capacity.

Actually, a very recent research published by Li et al. [14] suggested an example of a photovoltaic/thermochemical hybrid device. it has been proved that the coefficient of solar-electric performance can reach 41%.

We also note that the PV/T combination makes it possible to provide a prospective result in the face of certain challenges of the techniques of common use of solar energy such as simultaneous electric and thermal energy use, which is treated in this work.

Fu et al. [15] presented an investigation based on the analysis of three solar use techniques for buildings: photovoltaic, solar thermal and hybrid photovoltaic/thermal systems. It has been proven that for residential constructions with limited installation space, a photovoltaic/thermal hybrid device is likely to have the greatest possibility of limiting energy consumption. A similar analysis which is interested in an economic study of the installation of photovoltaic/thermal hybrid solar system was presented by Brahim et al. [16]. The efficiency and economic feasibility of the PVT system have been highlighted for several application areas.

Based on the reference, an exergy analysis of hybrid refrigeration systems has not yet been completed. Hence the choice of this investigation.

However, improving the exergy efficiency of processes is revered as a way to reduce environmental impacts through reducing degradation of natural resources. The goal of this investigation is to carry out a comprehensive approach of the life cycle of a cooling system from renewable energy sources, presenting its consequences on the environment.

The system subject of this study is a hybrid refrigeration machine for which a compressor has been added in spite of the absorber to improve the cooling process.

In addition, new mixtures were used. These refrigerants, with their new formulation, are free of any harmful or environmentally hazardous components and that have been chosen for their low GWP.

This machine works with an organic mixture.

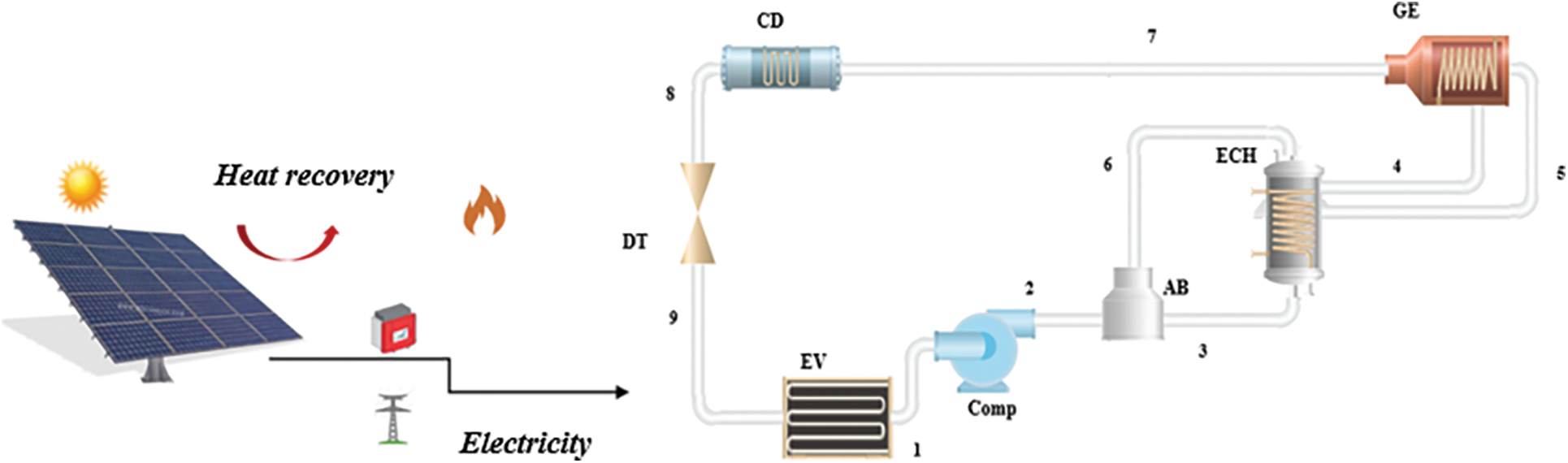

In this context, a study based on a hybrid PV-TH model was developed (Fig. 1). Our goal is to optimize the efficiency of the heat pump while taking into consideration the environmental impact.

Figure 1: One stage hybrid cycle with a photovoltaic unit

The refrigerating machine, the heart of this study, is an association between the conventional absorption machine and the compression machine. A compressor is integrated in the system before the absorber absorption part to revise the absorption process.

The heat pump acts on three pressure levels; the vapor of the operating mixture leaving the evaporator is at the least low pressure (PEV). It undergoes an isentropic compression at a pressure (P2) and finally, introduced into the absorber. The rich solution from the absorber is heated via a heat exchanger.

The condenser and the generator operate at the upper pressure (PCD) which is the condensing pressure.

The main interest of this study lies in the integration of a photovoltaic installation to meet the energy needs of the compressor.

Moreover, the heat released by the photovoltaic cells will be restored to heat the coolant in order to optimize the performance of the generator. This solution makes it possible to obtain a better production of electricity for the same surface and considerably increases the efficiency of this type of installation which is reduced following an increase in temperature.

From the perspective of producing energy more economically, the ability to limit wastage rates is a major issue. The proposed new model uses the principle of cogeneration, already applied in some thermal power plants, and which consists in producing both electricity and heat from the same primary source.

The basic function of the photovoltaic installations analyzed in the context of this work is the production of electricity.

The functional unit of the LCA [17–19] should be determined in correspondence with the function of the observed system and serves as a basis of comparison for the analysis of the results of different photovoltaic power generation systems.

To calculate these impact factors, two steps are necessary:

The first step is to calculate the impact factors per process such as:

The impacts of each of the processes are calculated and then added to obtain the impacts corresponding to each PV subsystem (PV infrastructure, additional infrastructure, site, maintenance). The impacts of the PV system are finally obtained by summing the impacts of each PV subsystem.

At the end of the first step, the impacts of the PV system on its life cycle are defined to calculate the environmental impacts by the power of the PV system:

The PV impact factor (kWp) corresponds to the environmental impacts of the photovoltaic installation per nominal power.

To assess the producible, we opt for a simplified method allowing component manufacturers to have a reference calculation to estimate production and thus serve as a basis for comparison for different products.

The worsening of the modules decreases the performance of the photovoltaic plant during the lifetime. A linear degradation of 0.7% per year must be considered, which corresponds to a total degradation of 20% at the end of the life of the modules.

A 30-year module life should be considered.

The value of the coefficient of performance of a PV plant, which is a correction coefficient for the overall performance of the photovoltaic installation, depends on:

• DC/AC conversion system

• actual operating temperature of the modules

• type of module integration

The following equation is used to estimate the environmental indicators of the PV system based on the functional unit:

Impacts by functional unit must be calculated for each impact category chosen.

Also, the sum of the exergy destruction gives the irreversibility of the life cycle of the system and therefore the impact indicator of the depletion of natural resources.

Exergy analysis is a focused approach and it does not take into account the exergy developed throughout the production chain.

It is in this sense that the Analysis of cumulative exergy consumption (CExC).

Indeed, this method is used to assess the exergy of all-natural resources consumed in a process.

It takes stock of the quality of the resources and it is expressed as follows:

with

This approach has been applied for different industrial processes [20].

CExC analysis is based on the same principle of LCA where all the elements involved in the process are taken into account.

In fact, the notion of exergy has been exploited in the context of life cycle analysis as an alternative to methods of measuring the depletion of natural resources [21].

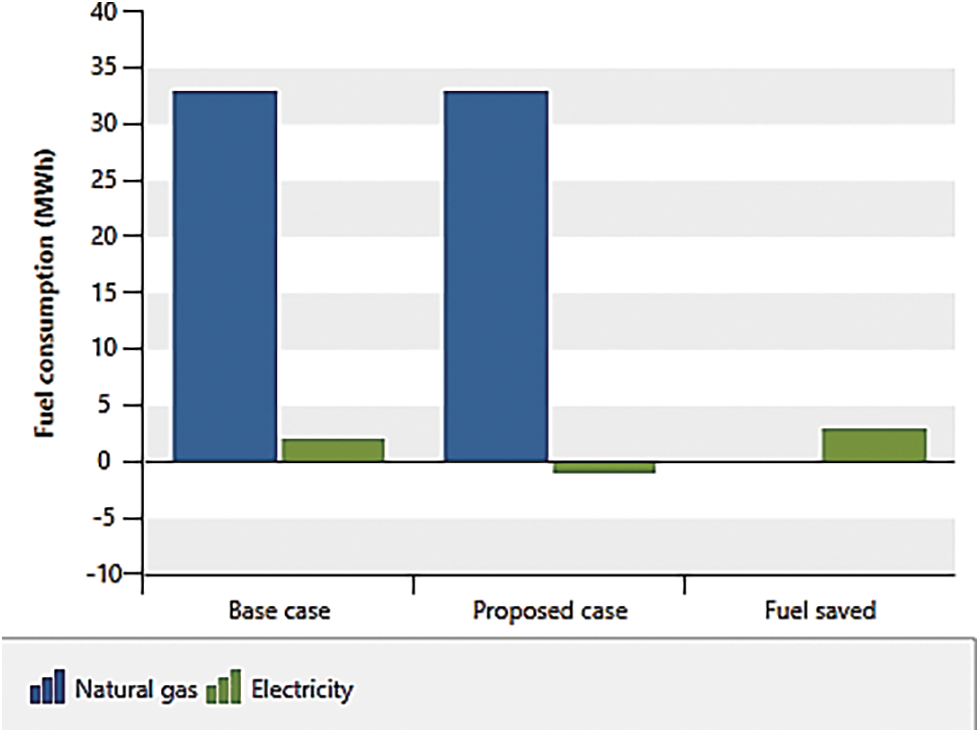

Fig. 2 shows that the proposed system allows a reduction in the order of 2.8 MWh of electricity consumption compared to the conventional configuration, which is equivalent to a gain of 269$.

Figure 2: Energy saving

PV-TH panels can provide electricity for compressor use and even an over production can be injected in the grid.

Our hybrid refrigerating machine was modeled according to the following assumptions: a generator temperature which effectively changes according to daily solar radiation and a condensation temperature which rises to 40°C.

We started with a simulation of a summer day.

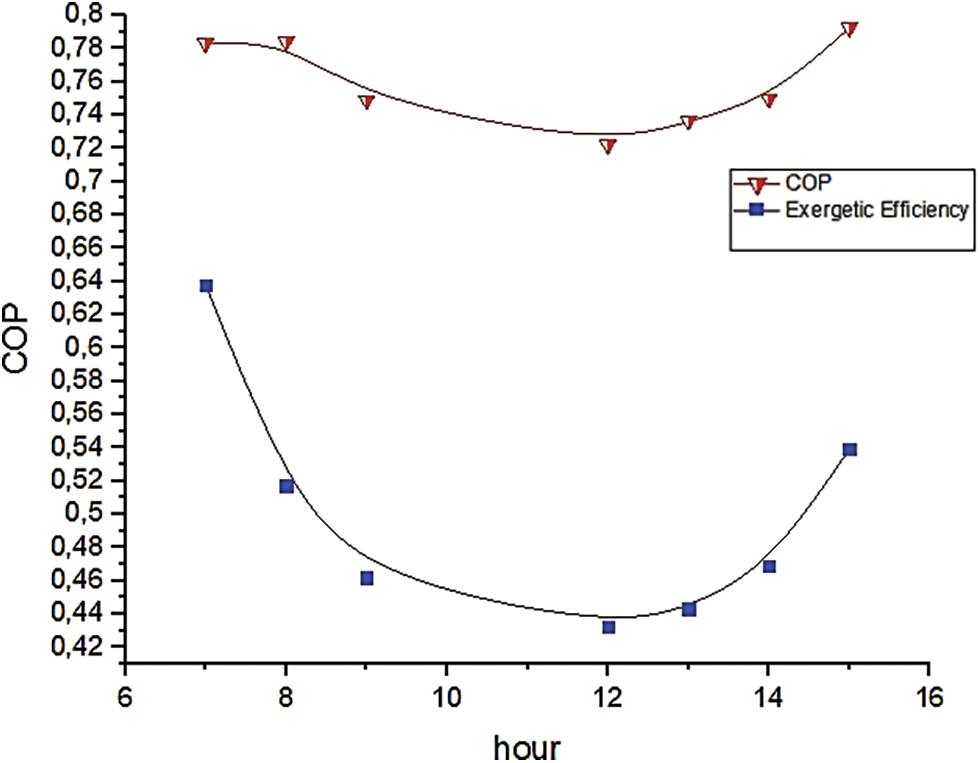

Fig. 3 illustrates the variation of the Coefficient of performance for a condensation temperature of 40°C.

Figure 3: COP and exergetic efficiency vs. time

The simulation was carried out for several times of the day.

We note that the optimal operating points are indicated at 3 p.m., it can reach an efficiency of 0.79 relative to a condensation temperature of 40°C and 88.68°C as the temperature of the generator.

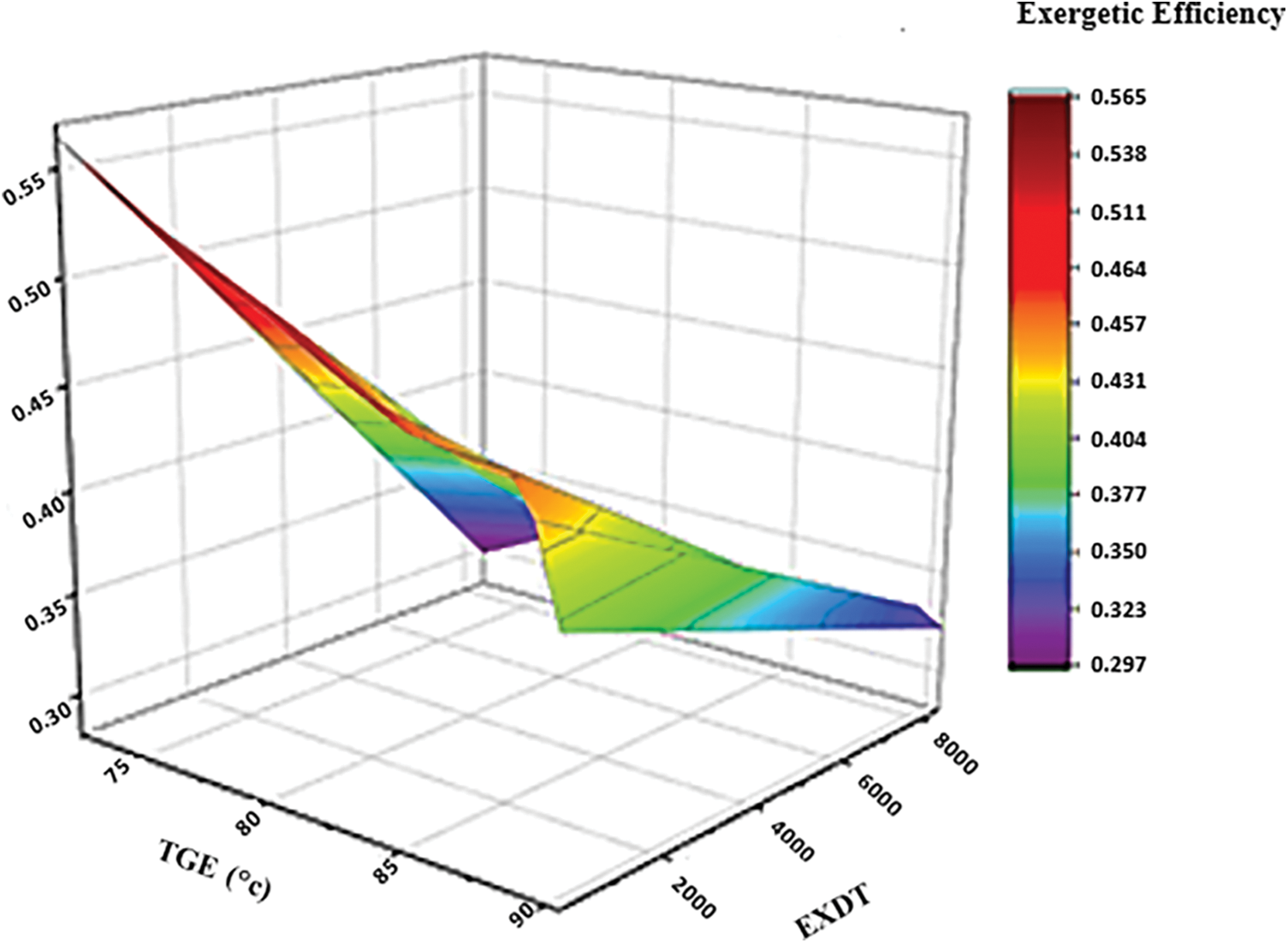

The evolution of exergy efficiency as a function of generator temperature is shown in the Fig. 4.

Figure 4: Evolution of the exergy efficiency according to the temperature of the generator

We also present the exergy loss of the system for the new configuration.

The first result observed is that the irreversibility of the system is relatively low.

In fact, the irreversibility is reduced when the temperature of the generator increases. Its optimum value is obtained between 70°C and 80°C as the temperature of the generator. It should be noted that fewer exergy losses are obtained at the start of the day for relatively low irradiation.

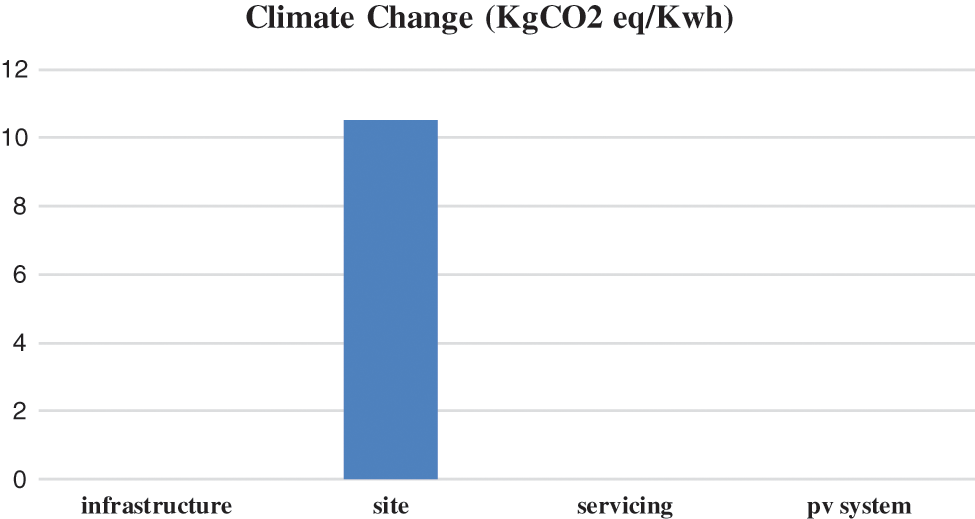

In Fig. 5, we can see the contribution of each stage of the life cycle on the indicator of global warming for solar configuration. The stage mainly responsible for the impact is the construction phase with a contribution of 88%.

Figure 5: Climate change (KgCO2eq/Kwh)

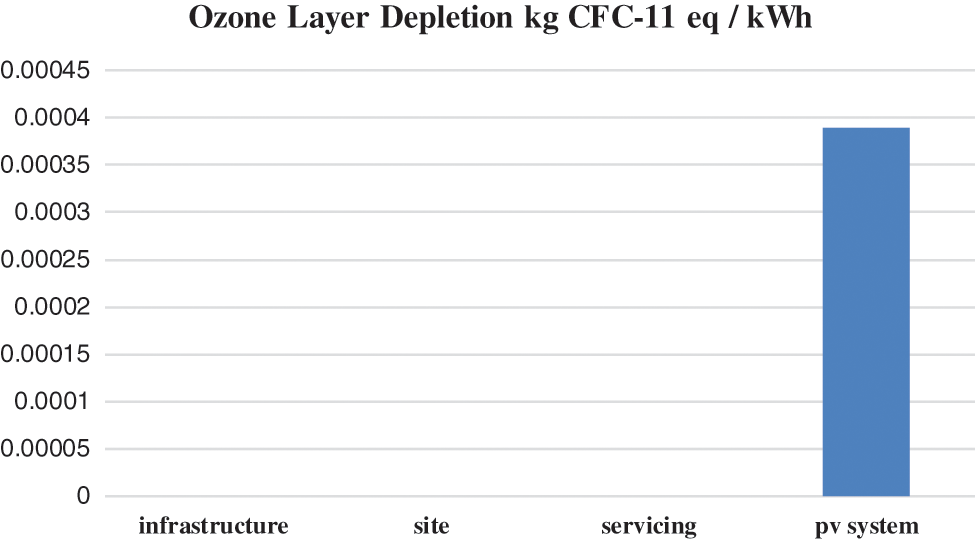

In the following Fig. 6, we can see the contribution of each stage of the life cycle on the indicator of Ozone Layer Depletion. Mainly, the element responsible for the impact is the PV system with a contribution of 90%.

Figure 6: Ozone layer depletion kg CFC-11 eq/kWh

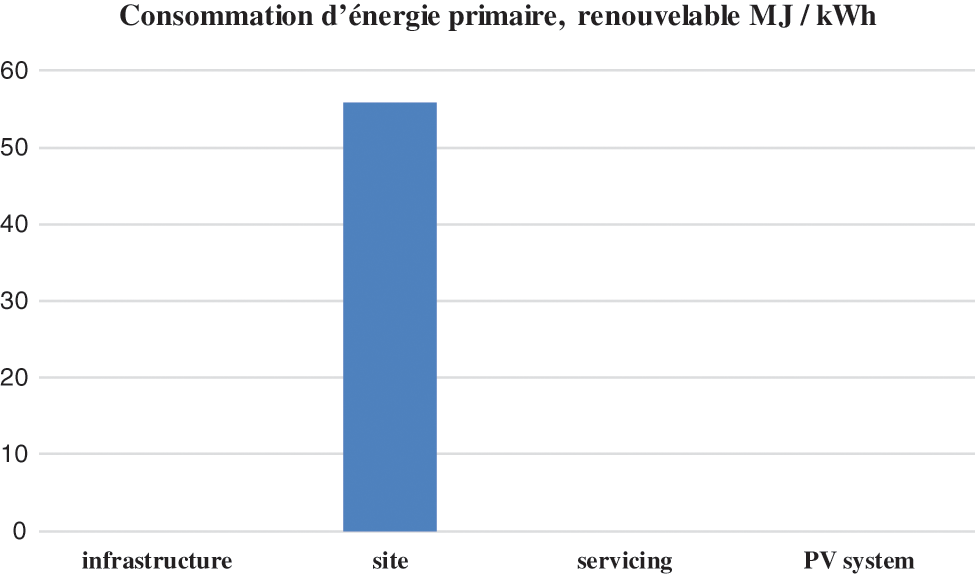

For renewable primary energy consumption (Fig. 7), the contribution at each level of the life cycle is also assessed. Essentially, the element responsible for the impact is the site.

Figure 7: Primary energy consumption

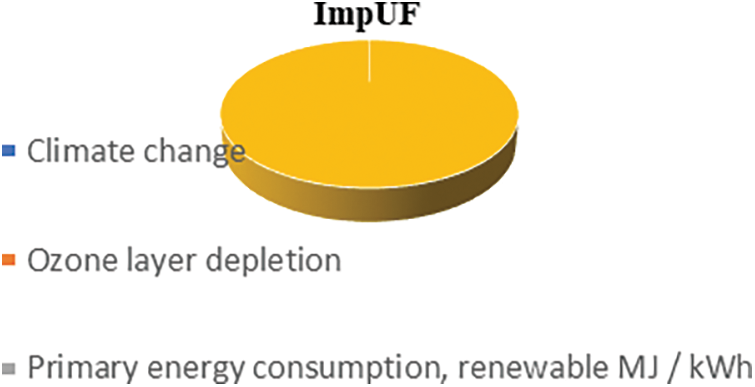

The following Fig. 8 shows the contribution of each indicator to the system life cycle.

Figure 8: Imp UF

Obviously, that of non-renewable primary energy consumption has the most important contribution.

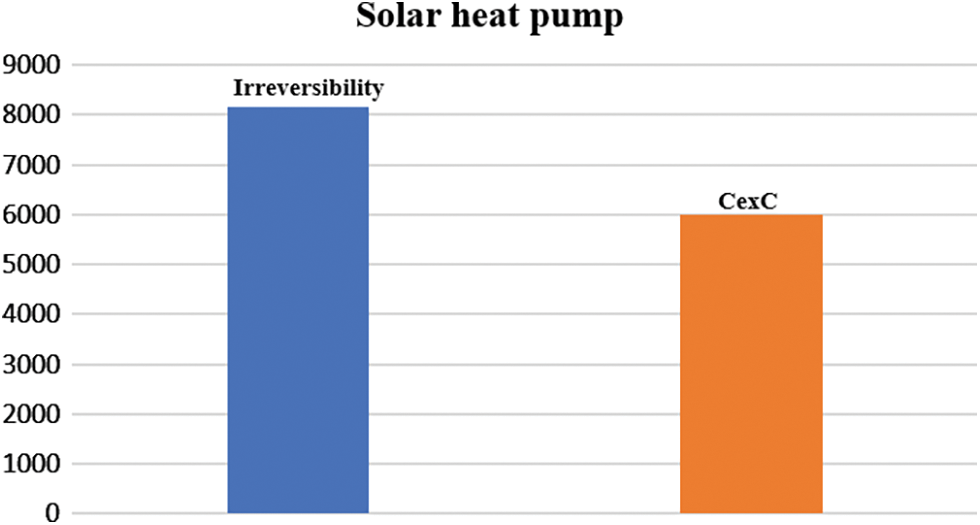

The indicators that result from the exergy methodology are irreversibility and CexC. They have been evaluated in the installation and shown in the following Fig. 9.

Figure 9: Exergy impact of the solar heat pump

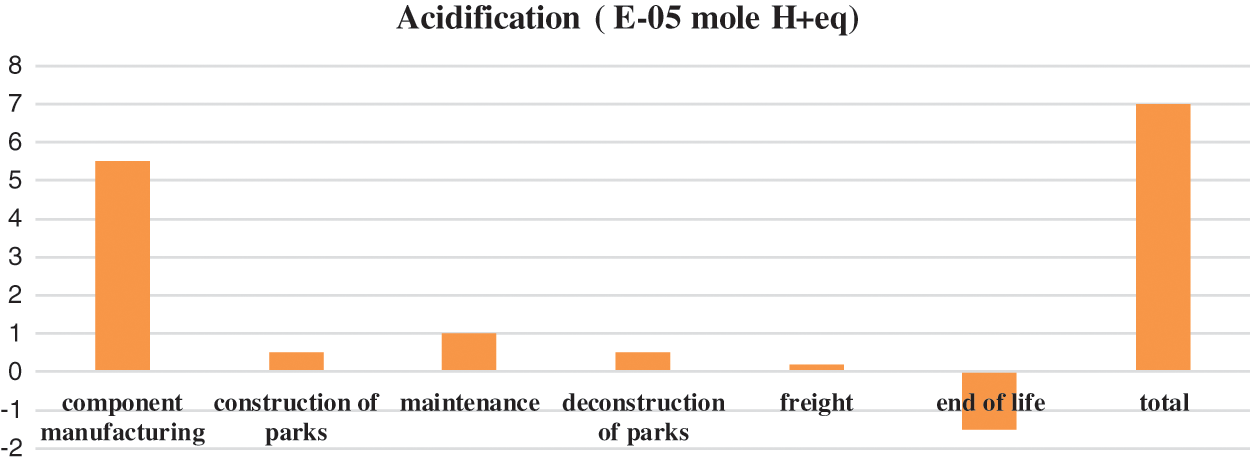

In the following Fig. 10, we can see the contribution of each stage of the life cycle on the acidification indicator. Primarily, the stage responsible for the impact is the manufacturing phase with a 60% contribution including an avoided impact of 22% through end of life.

Figure 10: Environmental impacts of 1 kWh on the acidification indicator

At a time of awareness of the finitude of resources and the growing need for energy, the concept of sustainable development must take a central place in the evolution of society. To achieve this goal, it is now recognized that a profound change in consumption is needed; whether it is energy consumption or finished products. We believe that this paradigm shift is only possible if all actors move forward in concert on the various issues we are facing. Everyone at their own level must therefore be able to make the decisions that are binding on everyone. This is the logic that motivated the study of this thesis, we are studying the possibility of a sustainable cold production solution.

Reducing energy needs and CO2 emissions is of major interest in the general context of rising exergy prices and ecological demands.

Traditional approaches to energy optimization often focus on improving the efficiency of individual equipment, or that of energy infrastructure. This is where the energy integration of processes comes into play, with the objective of optimizing processes from a global perspective.

Exergy Analysis itself is a valuable tool in energy integration. Within the imposed framework of minimizing total annual costs, entropy analysis helps determine the optimal plant concept, optimize energy conversion and use, and improve profitability.

It is an original contribution concerning the impact on the environment of all anthropogenic activities and showing that exegetical efficiency constitutes a fundamental criterion for the preservation of the environment.

The results can be seen as tools to help define new energy and environmental policies.

The consideration of exergy efficiency as an additional comparison criterion to environmental criteria, through the Exergy Life Cycle Analysis, will endow Life Cycle Analysis with more relevant tools for accounting for the consumption of abiotic resources. Thus, the increase in the exergy efficiency of the processes was considered as a solution to reduce the environmental impacts through the reduction of the degradation of natural resources. As a result, ELCA was retained in this study as a means of evaluating cold production scenarios. It has provided us with relevant tools for comparison between the different stages of the models proposed by identifying areas of potential for environmental improvement.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Bouaziz, N., Lounissi, D. (2015). Energy and exergy investigation of a novel double effect hybrid absorption refrigeration system for solar cooling. International Journal of Hydrogen Energy, 40, 13849–13856. DOI 10.1016/j.ijhydene.2015.05.066. [Google Scholar] [CrossRef]

2. Herold, K., Radermacher, R. (1996). Absorption chillers and heat pumps. Boca Raton, Florida: CRC Press. [Google Scholar]

3. Ziegler, F. (2002). State of the art in sorption heat pumping and cooling technologies. International Journal of Refrigeration, 25(4), 450–459. DOI 10.1016/S0140-7007(01)00036-6. [Google Scholar] [CrossRef]

4. Lee, S. F., Sherif, S. A. (2001). Second law analysis of various double effect lithium bromide/water absorption chillers. ASHRAE Transactions, 10, 664–673. [Google Scholar]

5. Brunin, O., Feidt, M., Hivet, B. (1997). Comparison of the working domains of some compression heat pumps and a compression-absorption heat pump. International Journal of Refrigeration, 20, 308–318. DOI 10.1016/S0140-7007(97)00025-X. [Google Scholar] [CrossRef]

6. Hadizadeh, A., Javaherdeh, K., Naghashzadegan, M., Nazari, H. (2011). Use of LP steam of HRSG for absorption cooling system and its role in improvement of power plant efficiency. Proceedings of the 3rd Conference on Thermal Power Plants, pp. 1–6. Amirkabir University of Technology, Tehran, Iran. [Google Scholar]

7. Dincer, I., Cengel, Y. A. (2001). Entropy and exergy concepts and their roles in thermal engineering. Entropy, 3(3), 116–149. DOI 10.3390/e3030116. [Google Scholar] [CrossRef]

8. Bejan, A. (1994). Entropy generation through heat and fluid flow (2nd edition) New York: Wiley. [Google Scholar]

9. Bejan, A. (1995). Convection heat transfer. New York: Wiley. [Google Scholar]

10. Bejan, A. (1996). Entropy generation minimization. Boca Raton, FL: CRC Press. [Google Scholar]

11. Lee, S. F., Sherif, S. A. (1999). Second law analysis of multi effect lithium bromide/water absorption chillers. ASHRAE Transactions, 105, 1256–1266. [Google Scholar]

12. Ravikumar, T. S., Suganthi, L., Samuel, A. A. (1998). Exergy analysis of solar assisted double effect absorption refrigeration system. Renew Energy, 14, 55–59. DOI 10.1016/S0960-1481(98)00047-0. [Google Scholar] [CrossRef]

13. Diana, E., Spertino, F. (2017). Applications of hybrid photovoltaic modules with thermoelectric cooling. Energy Procedia, 111, 904–913. DOI 10.1016/j.egypro.2017.03.253. [Google Scholar] [CrossRef]

14. Li, W., Ling, Y., Liu, X., Hao, Y. (2017). Performance analysis of a photovoltaic-thermochemical hybrid system prototype. Applied Energy, 204, 939–94. DOI 10.1016/j.apenergy.2017.05.077. [Google Scholar] [CrossRef]

15. Fu, H. D., Zhao, X. X., Ma, L., Zhang, T., Wu, Q. X. et al. (2017). A comparative study on three types of solar utilization technologies for buildings: Photovoltaic, solar thermal and hybrid photovoltaic/thermal systems. Energy Conversion and Management, 40, 1–13. DOI 10.1016/j.enconman.2017.02.059. [Google Scholar] [CrossRef]

16. Brahim, T., Jemni, A. (2017). Economical assessment and applications of photovoltaic/thermal hybrid solar technology. Solar, 153, 540–561. DOI 10.1016/j.solener.2017.05.081. [Google Scholar] [CrossRef]

17. Anand, D. K., Kumar, B. (1987). Absorption machine irreversibility using new entropy calculations. Solar Energy, 39(3), 243–256. DOI 10.1016/S0038-092X(87)80033-6. [Google Scholar] [CrossRef]

18. Dincer, I. (2002). The role of exergy in energy policy making. Energy Policy, 30(2), 137–149. DOI 10.1016/S0301-4215(01)00079-9. [Google Scholar] [CrossRef]

19. Lombardi, L. (2003). LCA comparison of technical solutions for CO2 emission reduction in power generation. Energy Conversion and Management, 44, 93–108. DOI 10.1016/S0196-8904(02)00049-3. [Google Scholar] [CrossRef]

20. Morris, D. R. (1991). Exergy analysis and cumulative energy consumption of complex chemical processes, the industrial chlor-alkali processes. Chemical Engineering Science, 46, 459–465. DOI 10.1016/0009-2509(91)80007-L. [Google Scholar] [CrossRef]

21. Cornelissen, R. L., Hirs, G. G. (2002). The value of the energetic life cycle assessment besides the LCA. Energy Conversion and Management, 43, 1417–1424. DOI 10.1016/S0196-8904(02)00025-0. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools