Open Access

Open Access

ARTICLE

Numerical Study on the Combined Use of Corten Steel and Phase Change Materials in Container-Type Houses

1 LR2E, Research Laboratory in Industrial Eco-Innovation and Energetics, Cergy, 95000, France

2 L2MGC Laboratory of Mechanic and Materials of Civil Engineering, Cergy, 95000, France

3 Laboratory of QUARTZ (EA 7393), University of Paris-Seine, Cergy-Pontoise, 95014, France

* Corresponding Author: Feriel Mustapha. Email:

(This article belongs to the Special Issue: Materials and Energy an Updated Image for 2021)

Fluid Dynamics & Materials Processing 2023, 19(4), 953-958. https://doi.org/10.32604/fdmp.2022.022028

Received 17 February 2022; Accepted 05 July 2022; Issue published 02 November 2022

Abstract

A study is presented on the feasibility of an approach based on the combination of Phase Change Materials (PCM) with metal walls in container-type houses. This line of research finds its motivations in recent trends in the energy and building sectors about energy consumption reduction. Another important objective concerns possible improvements in the comfort provided by such houses during the summer period. The results obtained through numerical solution of the governing equations accounting for heat transfer and latent heat effects associated with the PCM show that the indoor temperature can be reduced with a varying degree of success depending on the considered conditions.Keywords

Nomenclature

| H | Enthalpy [J/kg] |

| λ | Thermal conductivity [W.mK] |

| T | Temperature [K] |

| ρ | Density [kg/m3] |

| Cp | Heat capacity [J/kg.K] |

| L | Latent Heat [kJ/kg] |

| ΔT | Amplitude |

| T0 | Initial temperature [K] |

| t | Time [s] |

| Tout | Outside temperature [K] |

| Tin | Inside temperature [K] |

| h | Convective heat transfer coefficient [W/m2.K] |

The energy transition today represents a major global challenge, mainly for the building sector, which is one of the most energy-and budget-consuming sectors for construction. Reducing energy consumption to guarantee user comfort is an important axis, which extends on several levels, starting with the pricing of construction. From this point of view, container architecture has been a worldwide success, this archetype costs about 20% less than a traditional construction [1,2], and offers other advantages, stemming from the fact that the construction is fast and modular, in one hand, the result is interesting both aesthetically and spatially. On the other hand, from an energy point of view, this type of dwelling requires special attention, as the container is made of metal envelop, with a very high thermal conductivity [3]. A forecast study of the energy balance is imperative to guarantee the thermal comfort of the occupants. Therefore, use and selection of insulating materials is a crucial step, for the winter and summer period. A study has shown that the summer discomfort present in container houses is very important [4]. For this purpose, the application of phase changing materials (PCM) has been implemented with different building materials [5]. The use of pcm with other materials, such as concrete, wood and plaster, has been beneficial to reduce summer discomfort, especially during hot periods [6]. However, the application of this material with metal is not treated in the literature.

PCMs represent a possible solution to improve the energy efficiency of a building, having the particularity of storing energy and releasing it through phase change under latent heat. Indeed, PCMs change from a solid state to a liquid state depending on their melting temperatures, which is between 20°C and 25°C. Their composition is mainly inorganic salts, paraffin and water [7].

This study mainly aims, has demonstrated the possibility of applying PCMs with a metallic wall, in this article Corten steel has been selected, as it is the majority constituent of the container. This one has become very popular for housing construction, after its first function in supply chain.

The sections are organized as follows, firstly the description of the simulated model with and without PCM, the results obtained and the discussion, and finally a conclusion.

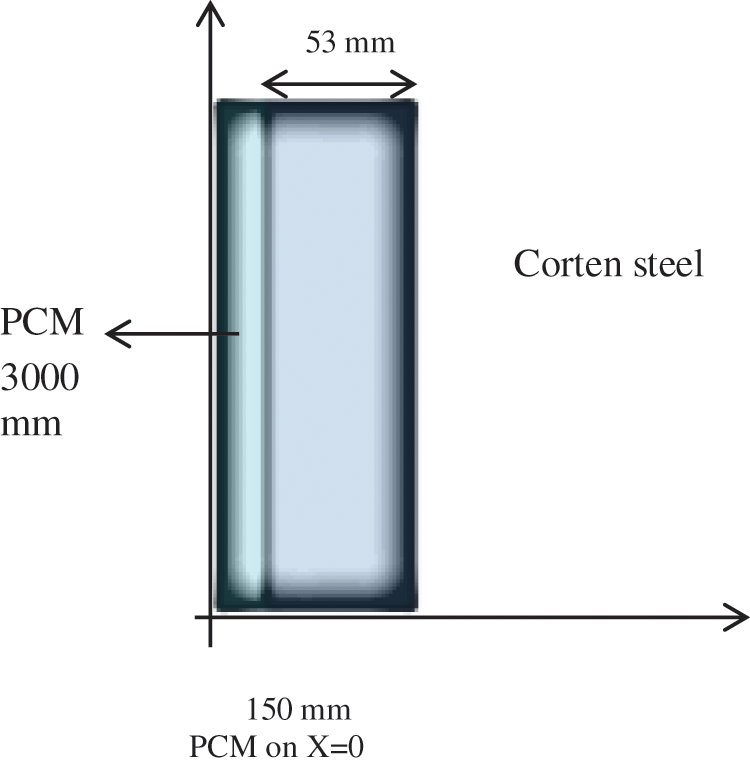

To carry out this study, the studied wall is associated with a PCM engineered by DuPont and Energain, the choice was made on the Corten material, the description and geometrical characteristics and the two-dimensional model are described in Fig. 1.

Figure 1: Two-dimensional layer of numerical studied model

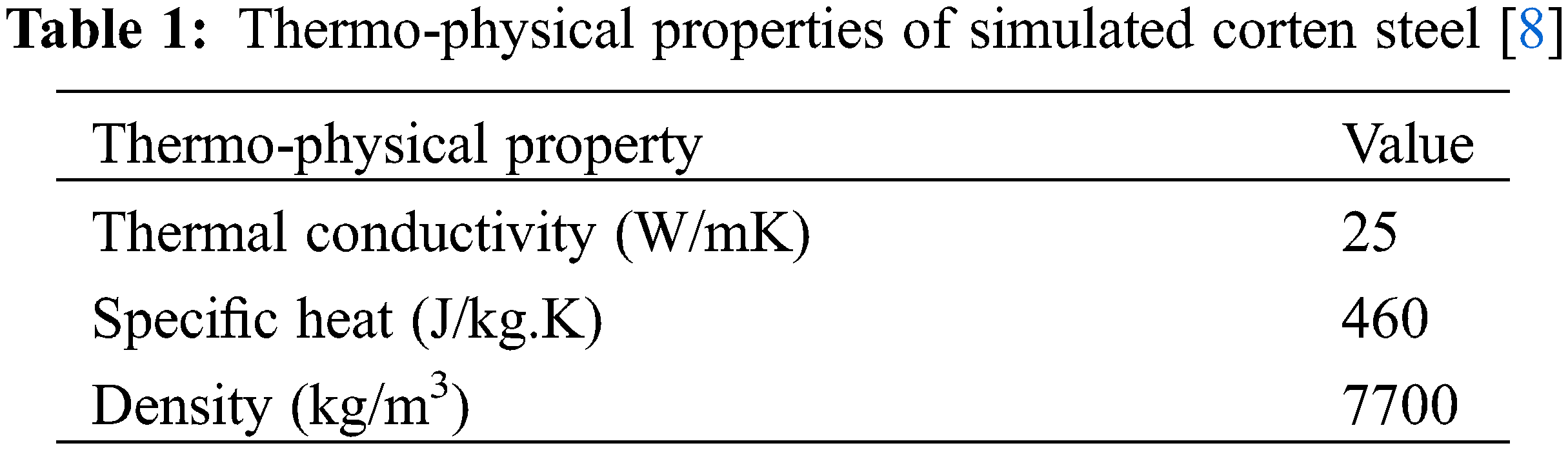

The thermo-physical characteristics of the Corten steel required for this study are showed on the following table (see Table 1) [8]:

The advantage of using Corten steel is first of all, on his very high structural strength [9], hence its use in logistics, this material is corrosion resistant, therefore low maintenance cost, it is 100% recyclable. This study aims to demonstrate the potential of coupling between PCM and Corten-steel, with the aim of application in the field of housing. The resolution method used to solve this study is the finite volume method, by using the software Ansys Fluent.

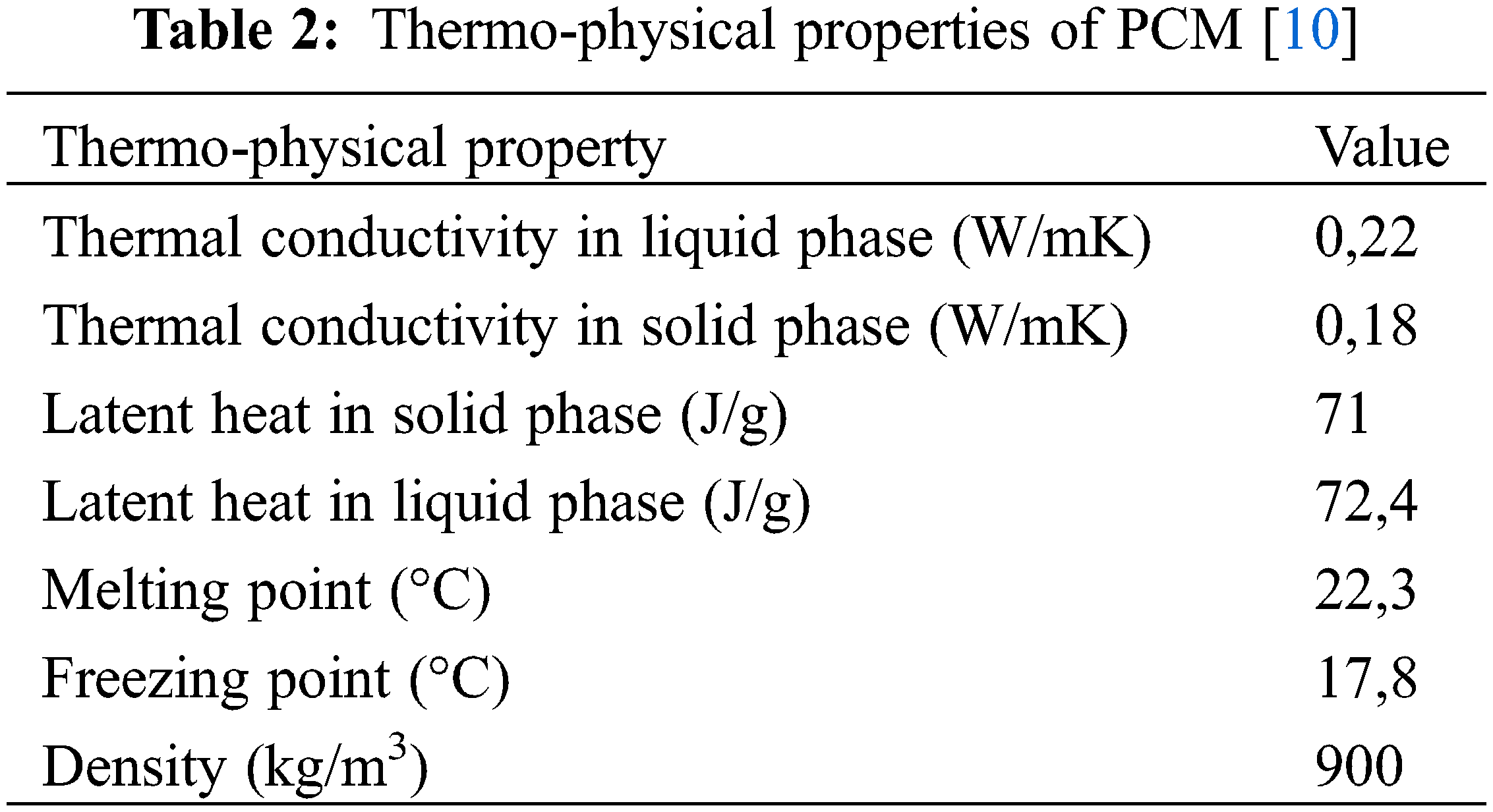

The selected PCM have the thermo-physical properties as described below:

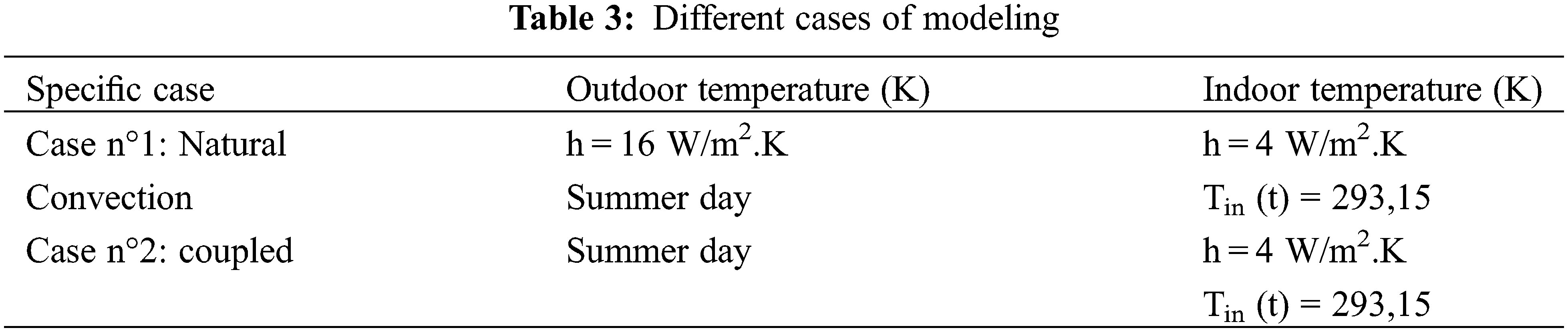

Two types of boundary conditions on the inner wall: for the first case (Case n°1) natural convection condition was imposed. The second case (case n°2) the chosen conditions are as follows and coupled with sinusoidal temperature and natural convection again.

The horizontal walls are considered in adiabatic conditions (see Table 2).

The general energy conservation equation has been simplified as follows (1):

For the phase change phenomenon, the enthalpy function H is written as below [8]:

With

In order to represent a peak of discomfort during the summer period for the occupants, a scenario was imposed through a temperature fluctuation, with a sinusoidal approximation to simulate the temperatures during a full day (24 h) (see Table 3) [8]:

With the amplitude ΔT, the initial temperature in Kelvin T0 and the time in seconds t.

It is important to mentioned that the proposed numerical model have been validated by literature [11]. This method allows us to the following results.

The results are based and were evaluated at the surface of the wall with/without the PCM. Below the results of the first case studied and described up-above.

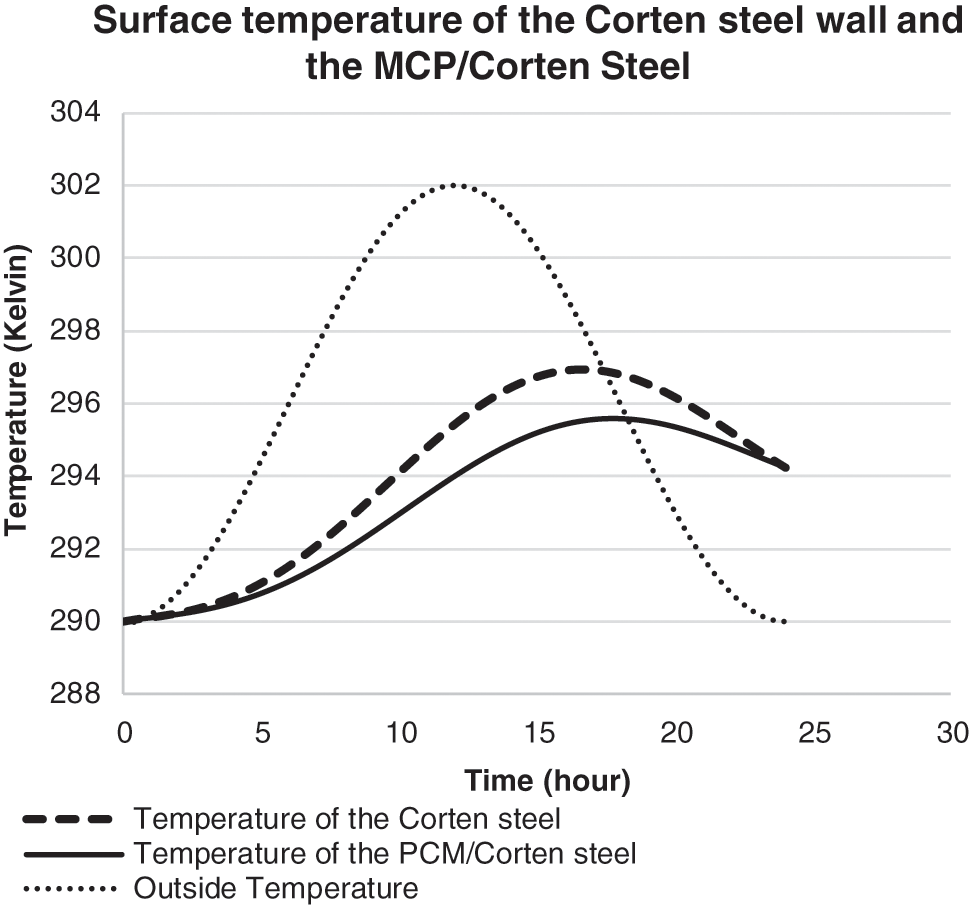

The evolution of the surface temperature of the two walls during one day (24 h) is shown on Fig. 2. An important temperature reduction is obtained in the case one (case n°1). The difference is 2 K was notified.

Figure 2: Evolution of the surface temperature of the corten steel wall and the MCP/Corten steel

Furthermore, a phase shift around 2 h was observed between the two peaks of the two walls.

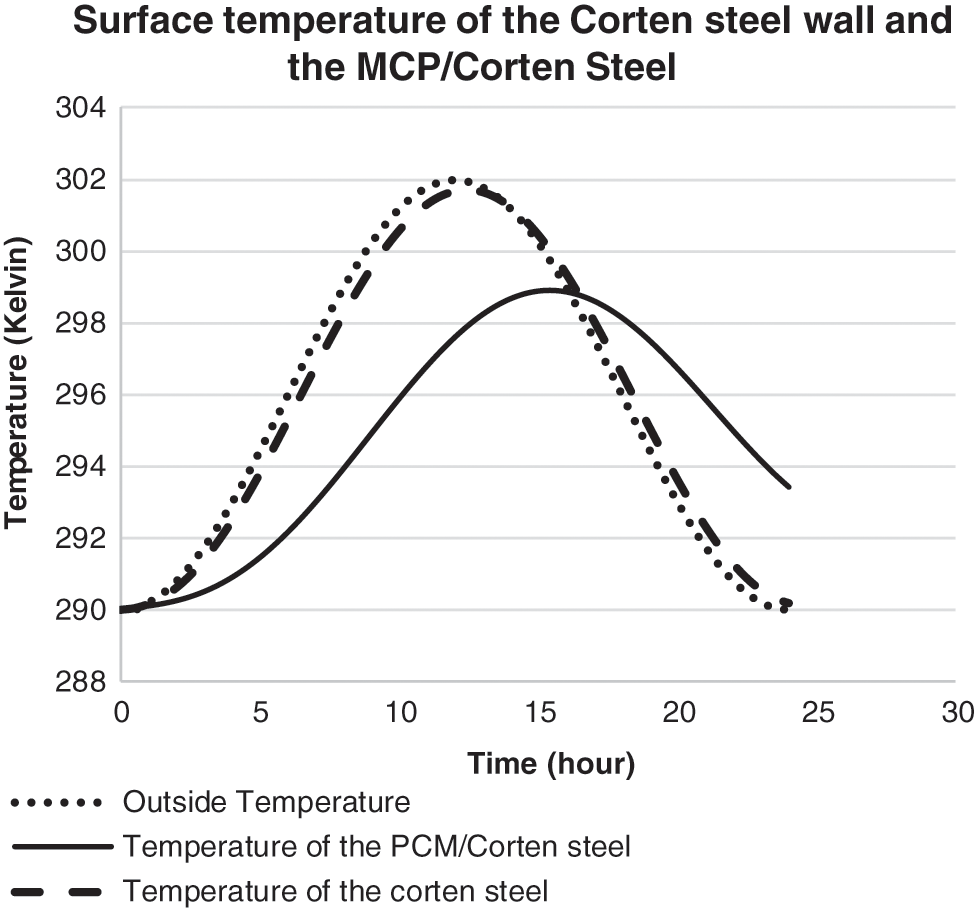

The Fig. 3 illustrates the evolution of the surface temperature of the two walls, as well as the first case, during one day. The temperature reduction is about 1,5 K was measured after a calculation time about 10 h.

Figure 3: Evolution of the surface temperature of the corten steel wall and the MCP/Corten steel

In both cases, the use of PCM reduced the temperature of the metal wall. The passive cooling through the dual combination of these two materials allowed the interior comfort of the occupants. Despite the fact that the hot period is spread over a few days, it is even longer for the occupants of this type of structure. The two cases show the advantage of adding PCM is that its thickness is low (5 mm), which allows not to lose the thickness of the wall with traditional insulation.

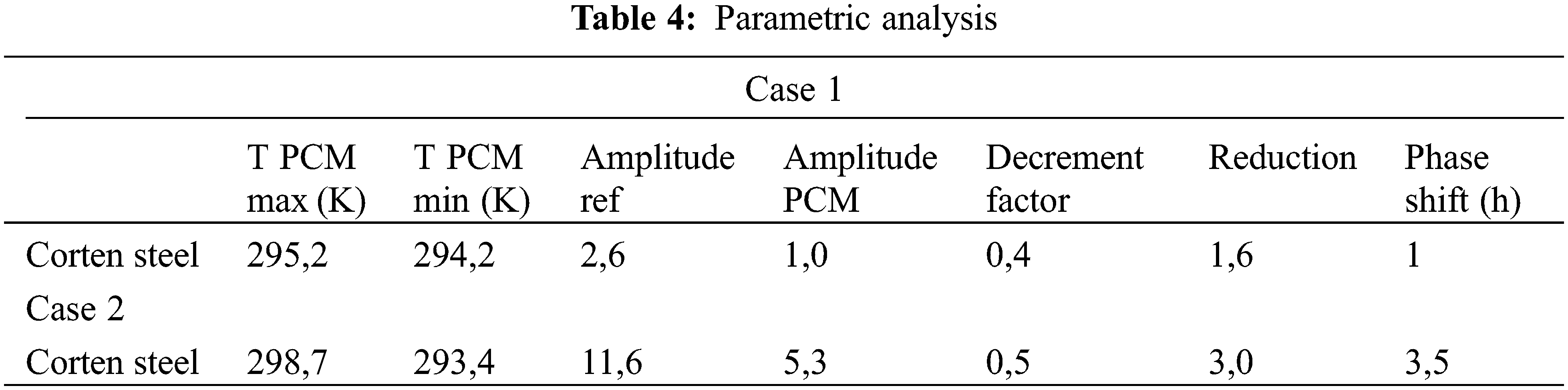

The amplitudes of the damping were assigned for the wall including the PCM panel. The damping factor was determined for both cases and is shown on the table below. As the decrement factor is an important parameter for improving the thermal comfort of a room (see Table 4). The lower this value is, the smaller the thermal amplitude, compared to the reference wall. In the opposite, the more the wall is optimized and insulated the interior temperatures.

A better damping was obtained in the first case with a factor of 0,4 against 0,5 for the second case. Due to its liquid state it allows to reduce the temperature and to provide a better comfort.

It is important to mentioned that, during the winter season, the use of phase changing materials will not adversely affect the energy balance of the structure.

The energy transition is imperative in the building sector, as it is one of the largest consumers of energy. The answer to this challenge must start with a passive strategy. Acting-on passivity, allows to adapt the built-in system in order to guarantee the comfort of the users. This study allowed us to demonstrate the effectiveness of using PCM on a metal wall, with a very expressive result, 3,8 K difference, knowing that the thermo-physical properties of Corten, present a major challenge. Indeed, the Corten steel shell has a very high thermal conductivity.

The results of this study have shown an interesting thermal performance of the metal combined with phase change materials, which encourages us to exploit this analysis with the main objective of enlarging the scale in order to be in agreement with the projection of real cases, with a complex geometry and faithful to the morphology of the container that has been designed to resist the wind. The advantage of adding PCM is that its thickness is low (5 mm), which allows not to encumber the thickness of the wall with traditional insulation.

During the winter season, this material will not adversely affect the energy balance of the structure and will reduce the building’s CO2 emissions.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Brandt, K. A. (2011). Plugging in: Reinterpreting the traditional housing archetype within a community using shipping containers. Greensboro: Master, Faculty of the Graduate School, University of North Carolina. [Google Scholar]

2. Garrido, L. (2011). Sustainable architecture: Containers, pp. 19–21. Barcelona, Monsa. [Google Scholar]

3. Smith, J. (2006). Shipping containers as building compnents. University of Brighton Department of the Built Environment: Creative Commons. [Google Scholar]

4. Mustapha, F., El Abbassi, I., Kaci, A., Kadri, E., Darcherif, A. (2020). Strategy of container assembly for a positive energy impact in Poona India. E3S Web of Conferences, 170, 1004–1009. [Google Scholar]

5. Soares, N., Costa, J., Gaspar, A. R., Santos, P. (2013). Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy and Buildings, 59, 82–103. DOI 10.1016/j.enbuild.2012.12.042. [Google Scholar] [CrossRef]

6. Ye, H., Long, L., Zhang, H., Zou, R. (2014). The performance evaluation of shape-stabilized phase change materials in building applications using energy saving index. Applied Energy, 113, 1118–1126. DOI 10.1016/j.apenergy.2013.08.067. [Google Scholar] [CrossRef]

7. Cabeza, L. F., Castell, A., Barreneche, C., de Gracia, A., Fernández, A. I. (2011). Materials used as PCM in thermal energy storage in buildings: A review. Renewable and Sustainable Energy Reviews, 15(13), 1675–1695. DOI 10.1016/j.rser.2010.11.018. [Google Scholar] [CrossRef]

8. Ferrer, G., Solé, A., Barreneche, C., Martorell, I., Cabeza, L. F. (2015). Corrosion of metal containers for use in PCM energy storage. Renewable Energy, 76, 465–469. DOI 10.1016/j.renene.2014.11.036. [Google Scholar] [CrossRef]

9. Perron, S. (1998). Resolution avec la methode des volumes finis diriges de l’equation de la chaleur pour des problemes diphasiques en une dimension et deux dimensions (Master’s Thesis). University of Quebec, Canada. [Google Scholar]

10. Kuznik, F., et Virgone, J. (2009). Experimental investigation of wallboard containing phase change material: Data for validation of numerical modeling. Energy and Buildings, 41(15), 561–570. DOI 10.1016/j.enbuild.2008.11.022. [Google Scholar] [CrossRef]

11. Zohir, Y., Hassane, N. (2017). Simulation numérique du comportement thermique d’un mur de brique intégrant des microcapsules de matériaux à changement de phase via la méthode enthalpique. 25ème Congrès Français de Thermique, SFT, Marseille. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools