| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.020351

REVIEW

A Systematic Review of Thermoelectric Peltier Devices: Applications and Limitations

1Department of Computer Science and Engineering, NMAM Institute of Technology, Udupi, 574110, India

2Department of Electrical and Electronics Engineering, NMAM Institute of Technology, Udupi, 574110, India

3Department of Engineering Management, College of Engineering, Prince Sultan University, Riyadh, 11586, Saudi Arabia

4Department of Mechanical Engineering, NMAM Institute of Technology, Udupi, Karnataka, 574110, India

*Corresponding Author: Abdul Aabid. Email: aaabid@psu.edu.sa

Received: 18 November 2021; Accepted: 18 April 2022

Abstract: Conventional refrigeration processes release ammonia and freon into the atmosphere, which results in global warming. These problems may be overcome by using thermoelectric modules because of the absence of coolants or refrigerants in these systems. However, the cooling performances of such modules are relatively small in comparison to those of conventional refrigerators. In this paper, the working principles of thermoelectric modules are discussed together with a review of different relevant aspects, namely: the thermoelectric materials, and their mechanical properties used to build thermoelectric devices, different types of thermoelectric devices available on the market, mathematical modeling of thermoelectric materials, and various applications of thermoelectric materials in different fields.

Keywords: TEG; peltier module; seebeck effect; refrigerator; CoP; TEC

The world’s demand for energy is uninterruptedly increasing each day and over utilization of non-renewable energy sources have cause various ecological issues such as dangerous atmospheric temperature deviation, corrosive downpour, ozone layer consumption, and environmental change [1]. Greenhouse gases are radiated into the air because of the abundant utilization of fridge, heating, and air-conditioning systems. Such disasters can be reduced by the consumption of conventional energy resources and the use of renewable sources or technologies. However, the world is shifting toward a renewable resource economy. Green technologies, such as wind turbines, hydrogenation, solar photovoltaic, and biomass are attaining significance in tackling energy and environmental issues [2–4]. This move towards clean power generation is an effort to decrease the carbon footprint and the amount of carbon dioxide emissions in the future. Thermoelectric devices are used as one of the technologies to achieve this goal.

The initial innovation linked to thermoelectricity occurred in 1821 by Thomas Seebeck, who established that an electric current could flow during an electric circuit fabricated from two completely different metals only if the connections of the metals were sustained at two different temperatures. The Peltier effect was discovered in 1834 by Jean Charles Athanase Peltier. He demonstrated that the utilization of current at the outskirts of two different materials results in the centralization of hotness and release of hotness at the subatomic level, which is frequently conducted with different vitality levels of materials, particularly N and P-type materials [5,6]. Thermoelectric devices are solid-state devices that transform heat into electricity. The merits of thermoelectric (TE) are that it does not have any moving parts, compact, eco-friendly, has no chemical reaction, wide operating temperature range, maintenance-free, and has a long life span [7]. Various studies have also been performed to improve the heat transfer in heat exchangers [8–15].

This review work provides a detailed study about thermoelectric Peltier devices with application and limitations. Following section elaborates the thermoelectric modules with the existing contribution in recent investigation with research gap. The section three illustrates mathematical modelling of the Peltier devices. Section four lists some of the important applications of thermoelectric modules and section five is the critical analysis of the literature with discussion and limitations. Finally, a conclusion has been provided based on the current existing work.

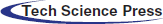

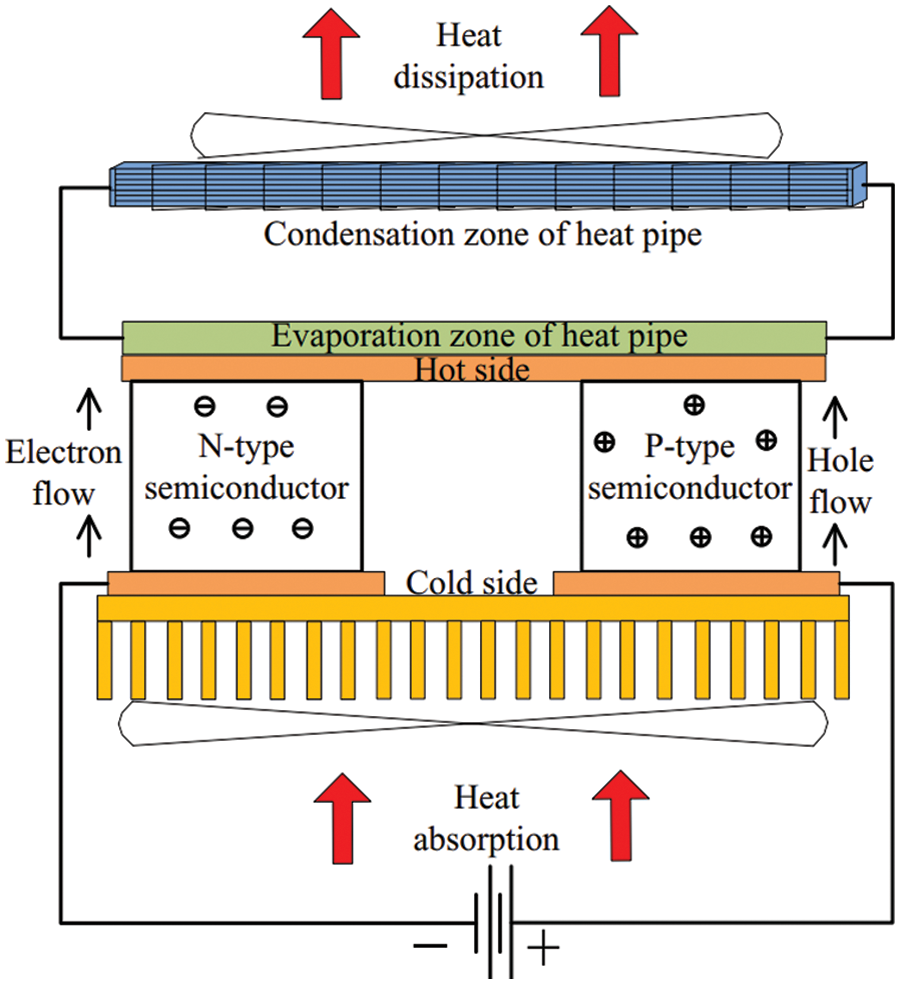

A Thermoelectric module (TEC) is a device arranged by thermoelectric couples (N and P-type semiconductor pellets) that are electrically arranged and thermally equal as shown in Fig. 1. The semiconductors were inserted between the ceramic plates. Thermoelectric semiconductor materials generally used in thermoelectric coolers are alloys of Bismuth Telluride. More thermoelectric materials are accessible according to necessary applications such as Lead Telluride (PbTe), Silicon Germanium (SiGe), and Bismuth-Antimony (Bi-Sb) alloys [16,17]. The most commonly used semiconductor material is Bismuth Telluride (Bi2Te3) which has a dissimilar electron density. A typical thermoelectric module contains an arrangement of Bi2Te3 semiconductor pellets that transmit the majority of current. Couples of P and N semiconductors are arranged so that they are coupled electrically in series, but thermally in parallel [18]. The ceramic plates exhibit mechanical integrity and also act as electrical insulators for cooled and heated surfaces. The plates also deliver great thermal conductance for heat transfer with nominal hindrance. Aluminum Oxide (Al2O3) ceramics are commonly used because of their low cost, and performance ratio. Other ceramics such as Aluminum Nitride (AlN) and Beryllium Oxide (BeO) can also be employed [19]. When an input is established at the free ends of two conductors, a temperature change is generated through the intersections of semiconductors owing to the flow of current. One aspect of the connections is identified using low temperature (heat absorbed) and another side of intersections by high temperature (heat released).

Figure 1: Thermoelectric module [20]

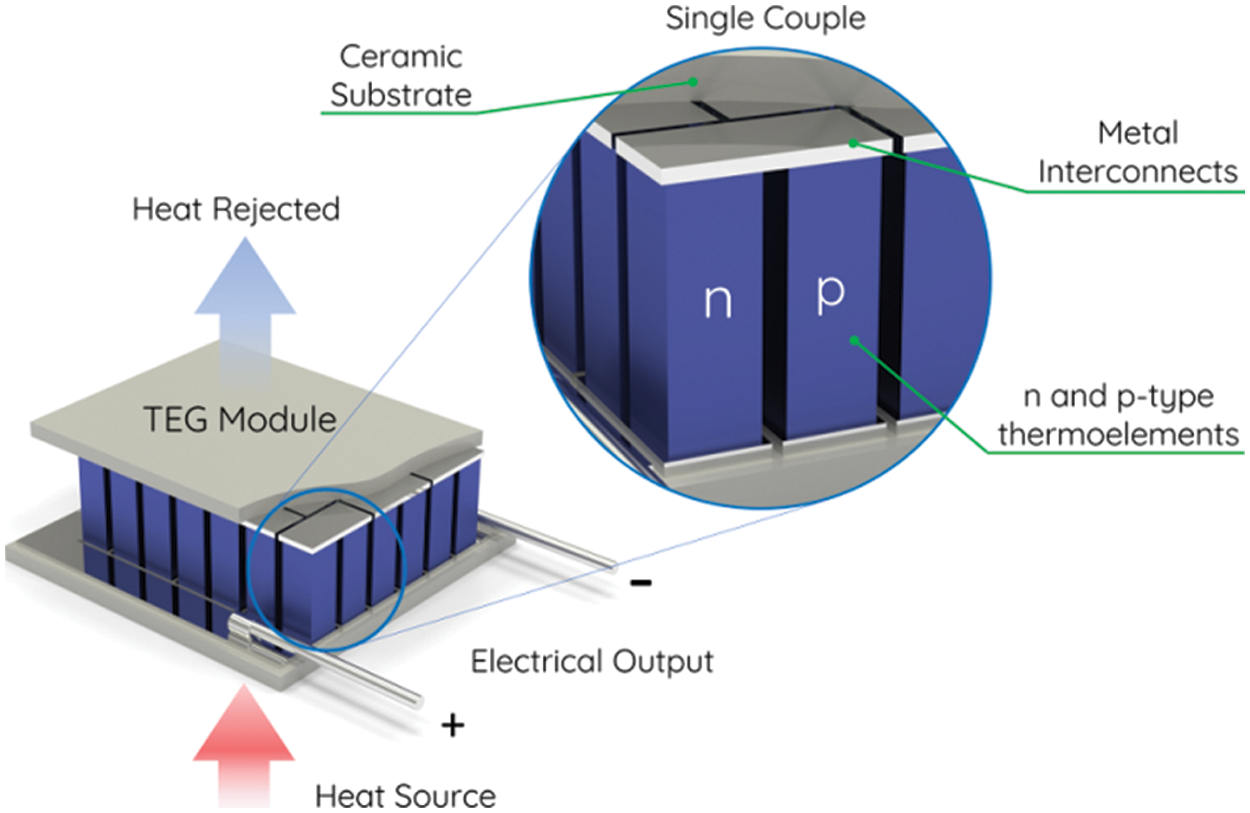

The Peltier module works on the Peltier Effect. This indicates that when voltage is applied between two completely different terminals of a conductor, which is coupled by a semiconductor material that generates an adjustment in the temperature that causes the material to draw out from the warm facet to the cold facet as shown in Fig. 2 [21]. When the current begins to flow from one side to another side of the junction, the outside layer can be warmed or chilled according to the need. When electrical energy is applied to the module, the positive and negative charge carriers absorb and release energy respectively. One side of the plate absorbs heat energy from one material surface and releases it to the other side [22]. Reversing the supply terminals results in reversed hot and cold sides.

Figure 2: Schematic of a thermoelectric cooler

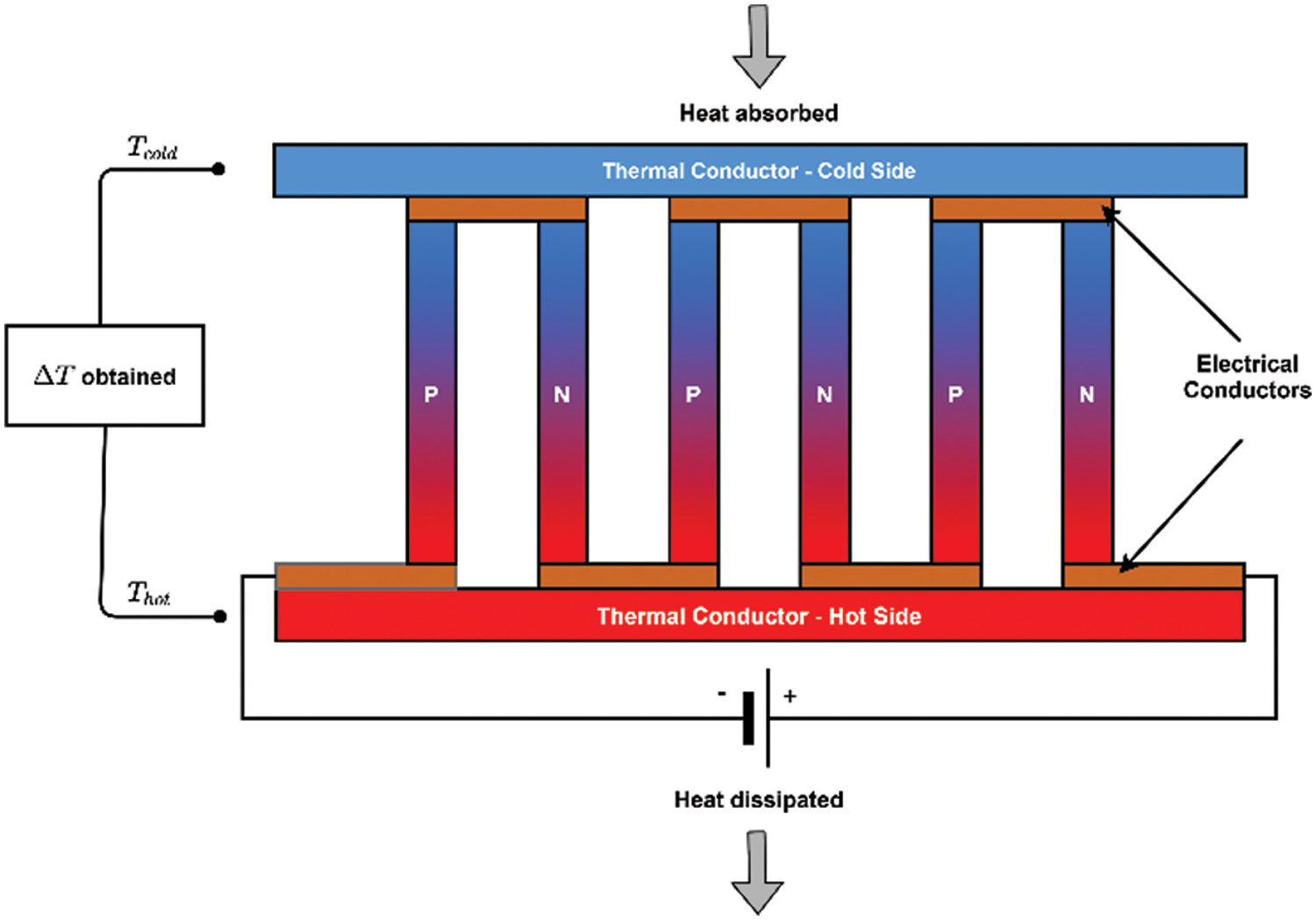

Thermoelectric materials are employed for both refrigeration and power. The structure comprises N and P-type semiconductors. The application of hotness on one facet and a cooling heat sink on another facet generates electrical power and vice versa. The efficiency is low by 10% when it is used as a power generator; however, it is advantageous because of its high electrical conductivity, high Seebeck effect, and low thermal conductivity. Usually, Bi2Te3 is used because of its high figure of merit. The mechanical properties of some thermoelectric materials are given in Table 1 [23,24] and the figure of merit (zT) characteristics for P and N-type thermoelectric materials has been studied in [25].

Depending on the industrial applications different types of thermoelectric modules are available with various dimensions and different electrical input configurations [26]. These thermoelectric modules are used in various industrial applications such as electronic equipment cooling, temperature baths, medical equipment, food industry, measurement equipment, and transport.

The process for the Peltier cooler device can be characterized accurately by modelling and the device working is evaluated through a personal computer (PC) [5]. The semiconductor material used in the module depends on numerous temperature-dependent properties that should be considered while modelling. For the selection of the thermoelectric module cooling purpose, parametric studies must be performed [27–29]. This can be performed theoretically and can be validated experimentally on a PC. An extensive investigation of numerous Peltier cooler modules over a wide range of temperatures has been carried out [22]. This study has resulted in the advancement of mathematical models that are used to consistently forecast module efficiency for different functional surroundings. Numerous parameters related to thermoelectric materials or modules should be considered to develop a mathematical model. The essential parameters for modelling thermoelectric devices include the module’s Electrical Resistance (RM), Seebeck Coefficient (SM), and Thermal Conductance (KM) [22].

3.1 Effective Seebeck Coefficient

When a temperature gradient is sustained along with the thermoelectric device, a voltage can be generated that is sensed at the input terminus. The amount of the output voltage is called the Seebeck electromotive force, which can be compared to the amount of change in temperature which is calculated using the Eqs. (1) and (2),

and

where,

SM-Module’s Seebeck coefficient in V/°K.

T–Average temperature in °K.

The electric resistance of the thermoelectric module in terms of the temperature function is calculated using Eqs. (3) and (4),

and

where,

RM-The electrical resistance of module in Ω.

T-Average temperature in °K.

r1, r2, r3and r4 are the variables whose values are given below:

Thermal conductance of the thermoelectric module in terms of temperature is calculated using Eqs. (5) and (6),

and

where,

KM–The thermal conductance of module in W/°K.

T–Average temperature in °K.

k1, k2, k2 and k3 are the variables whose values are given below:

The above parameters were calculated for 71 couples and 6 A Peltier device. For a novel or diverse thermo-molecular arrangement to be modelled, the correction factor has to be used which is given in Eqs. (7) to (9),

where,

Snew-The novel Seebeck coefficient of the new module.

Rnew-The novel electrical resistance of the new module.

Knew-The novel thermal conductance of the new module.

Nnew-The amount of couples in the new module.

Inew is the optimal current in the new module.

The figure of merit could be an amount of the performance of a thermoelectric device or material which is given in Eq. (10),

Usually, the TEC manufacturer mentions the maximum temperature gradient and specification, but the figure of merit of TEC is not disclosed; hence this can be calculated theoretically and can be validated by connecting the TEC to the PC. The MATLAB/Simulink model can be used to determine the parameters of the thermoelectric cooler and generator [28].

3.4 Coefficient of Performance

The coefficient of performance (CoP) may be defined as the ratio of the cooling capacity of the module to the power consumed by the module. The operation of a thermoelectric cooler device can be estimated theoretically by identifying the maximum temperature gradient (ΔTmax) and cold facet heat pumping rate (QC) [30–32]. This can be calculated by using Eqs. (11)–(14),

Heat rejected by the Peltier module on the hot side

Total energy supply

Hence the CoP of the TEC is given as

Generally, the value of CoP for the TEC is less than one when compared to a commercial cooling refrigerator whose CoP is greater than one. Hence it is necessary to increase the value of the CoP for TEC for effective and fast cooling purposes. Many researchers are trying to improve the CoP of TEC; hence in the future, the CoP for the TEC may increase.

4 Applications of Thermoelectric Module

A thermoelectric generator (TEG) is a solid-state device that transforms heat energy directly into electrical energy through the phenomenon of the Seebeck effect. They function as heat engines but their efficiency is low and the cost of the TEG is high [33]. Generally, this TEG can be used in power plants to convert waste heat energy into electrical energy and can also be used in automobiles as automobile TEGs to increase fuel efficiency [34]. Automobiles transform unused warmth present in the dissipated gases unswervingly into electrical energy by employing TEG. The pump delivers cooled water from the side to the cooling water circulation paths. A variety of stacks are connected with thermoelectric elements that are associated with the exhaust pipe and the cooling water pipe consecutively in a path from the upward to downstream of the exhaust gas [35]. The downstream stack has an increased temperature difference between the cooling pipe and exhaust which reduces the stack output and increases the total power output. The temperature difference between the hot and cold sides of the TEG increases as the motor speed increases, which generates the yield voltage level specified by the Seebeck impact. The TEG was employed on the top side of the duct [36]. The duct is linked with the exhaust manifold, to covert the energy from the TEG. When the TEG was connected in series, the performance increased. For maximum performance, the duct is completely insulated and a temperature difference is generated which increases as the motor RPM is increased [37,38]. Thermoelectric generators can be employed in various applications such as radioisotope TEGs which are applied in space probes. The TEG has high reliability and less maintenance; hence a long-time service TEG can be constructed. Various studies have been proposed to improve the performance of TEGs [39,40].

Automobiles have many systems such as locomotives, gearboxes, cooling systems, and exhaust systems which yield high temperatures throughout the ride, which can be recovered using the TEG [41]. In general, vehicular heating, ventilation, and air conditioning (HVAC) system consist of mechanical refrigeration and absorption systems. It includes moving parts with noisy operations and refrigerants. However, the efficiency of the thermoelectric refrigerator is less than the mechanical refrigerator, but it can maintain its efficiency and works silently with no moving parts and requires less maintenance.

Most of the automobile industries such as GM, Jaguar, Hyundai, and Renault have technologically advanced their methods towards the recuperation of exhaust heat via thermoelectric generators, which keeps the seat of automotive cold or warm [42]. The installation cost of the thermoelectric cooler is considerably lower than that of conventional mechanical refrigeration [43]. The current cooling system in automobiles consumes up to 3500–4000 W for cooling compared to 700 W of consumption by the cooling system with TEG [44].

With the progress in electronic engineering, the heat dissipation of electronic devices has increased which poses a serious problem to the processing speed and the life of electronic devices. Heat dissipation can be reduced by passive cooling using fins and cooling fans; however, at their full load it fails to manage heat dissipation; hence TEC can be employed to decrease heat dissipation [45]. Generally, water-cooled TEC is utilized to decrease the temperature which has achieved better cooling than the air-cooling TEC. The heat exchanger is placed between the heating component, when the TEC is activated, it provides cooled air; hence the water inside the heat exchanger carries heat from the thermally isolated material [46]. This reduces the heat dissipation which increases the processor speed. The Peltier system incorporated with the gravity assistant heat pipe (GAHP) is arranged just as built up, which was intended for cooling the electrical gadgets as shown in Fig. 3 [47]. The heat pipe transfers the hotness with a minor change in temperature because of the stage progress. A heat sink can be incorporated on the cooling side to increase the concentration of heat on the thermoelectric plate. The GAHP through a uniform and even vaporization exterior is fixed on the heating side of the thermoelectric unit and to the build-up zone of the GAHP to blow the hot air. When the DC is passed to the TEC, the Peltier unit absorbs the temperature from the heating surface and dissipates warmness to the warm facet of the TEC. Fig. 4 shows a variation in the two TEC systems. The deployment of GAHP improved the cooling capability by almost 73.54%, linking with the TEC with the heat sink and the electrical energy intake was decreased by 42.20% to generate an equal quantity of cooling [48]. The chilling capability of the TEC with heat sink improved and was later reduced by methods for aggregating the surrounding air temperature, which influenced the working effectiveness of the electrical framework.

Figure 3: Schematical diagram of a TEC system integrated with GAHP [47]

Figure 4: Cooling capacity of TEC systems [47]

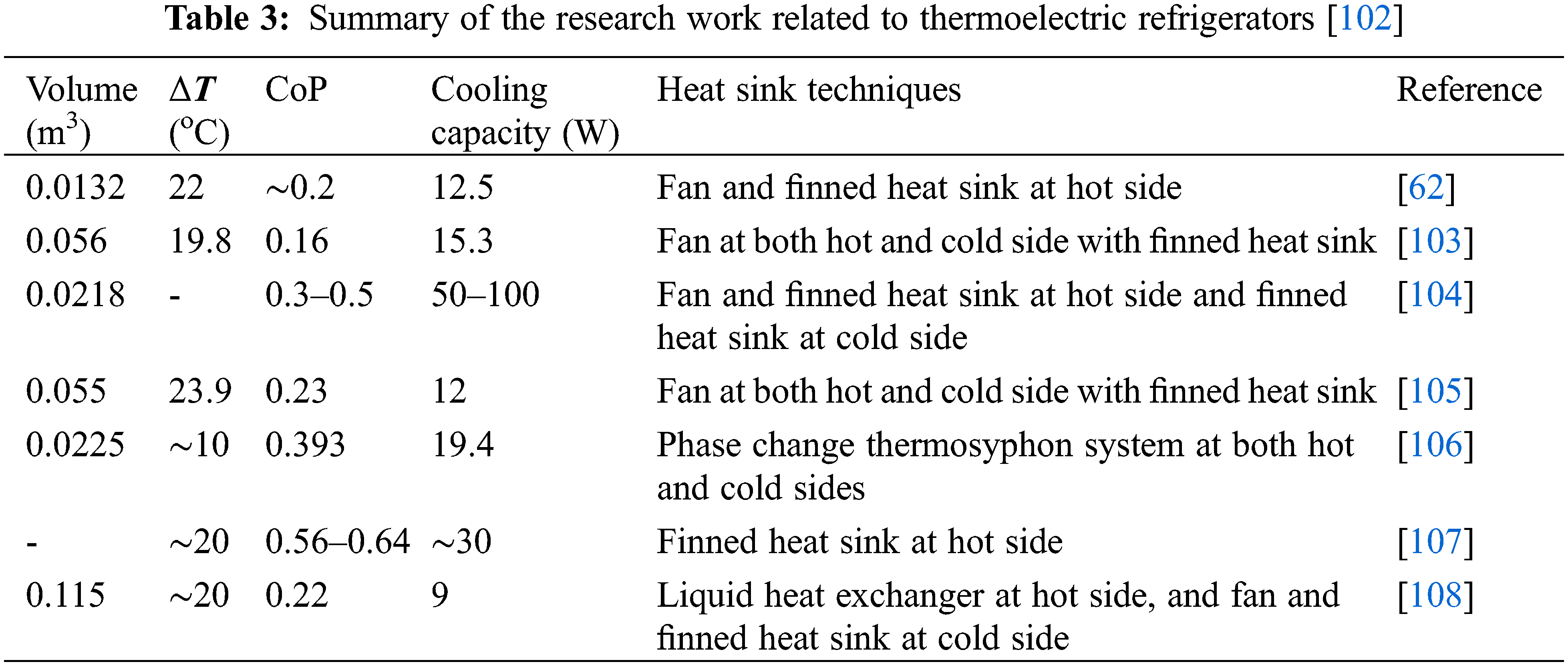

4.4 Thermoelectric Refrigerators

Refrigeration is a process in which heat is removed to maintain the required temperature [49–51]. Generally, refrigerators are used to preserve food, beverages, fruits, and vegetables. However, a commercial refrigerator uses a vapor compressor cycle where it uses refrigerant for cooling purposes [52–55]. This refrigerant leads to a greenhouse effect; hence this can be reduced by using a thermoelectric refrigerator. In TEC there is no moving part and it has no refrigerant; hence it is eco-friendly [56]. The thermoelectric refrigerator is portable [57] and can be carried anywhere and can be used to preserve food and cold drinks [58]. The thermoelectric refrigerator uses electricity to cool the space, charging the TEC can be done through batteries and the solar cells may be used to charge the batteries [3,25,59,60]. The main components of thermoelectric refrigerators consist of thermoelectric modules, aluminum water blocks, heat sinks, and cooler fans [61–64]. The schematic diagram of the thermoelectric refrigerator is shown in Fig. 5. The CoP of a thermoelectric refrigerator usually ranges between 0.3–0.7 which is less than that of a vapor-compressed refrigerator [65,66]. Experimental results show that the effectiveness of solar cell integrated thermo-electric refrigerators remains highly dependent on the concentration of solar insulation and the temperature of the thermoelectric module [67–70].

Figure 5: Schematic of thermoelectric refrigerator [25]

Thermoelectric cooling is broadly used in numerous areas of science and technology, specifically in medicine. It is very important to preserve the vaccines and other medicinal syringes at a very low temperature so that they do not lose their potency [71,72]. To reach low temperatures, liquid nitrogen is being usually preserved at low temperatures, which significantly limits its usage in hospitals [73–75]. In most circumstances such devices are massive, and proper temperature control could cause damage [76]. The use of thermoelectric cooling can resolve this problem because it has several benefits when correlated with conventional thermal effects [77]. Thermoelectric cooling can be used in practical applications [78], such areas of medicine as cryosurgery, cryotherapy, neurosurgery, urology, plastic surgery, and dermatology. In dermatology thermoelectric devices can be implemented for the smoothening of wrinkles, strengthening parts of the human body, and other medical procedures. Homeostasis is a unique function of the human body for temperature control in the body. Patients with spinal cord injury (SCI) lose the ability to adjust their body temperature [79]. Hence TEC can be employed to maintain the body temperature using artificial means of cooling which offers patients thermoregulatory ability lost due to SCI [80]. The development and improvement of thermoelectric medical devices for skin disease treatment are becoming more important.

4.6 Miscellaneous Applications

There are various additional applications of the thermoelectric module which can be improved because of its compactness in size, transferability, and non-rotational part. Numerous uses of TEC such as wearable Solar e-uniform meant for soldiers who maintain the required temperature by increasing the temperature in cold and decreasing the temperature in extremely hot weather conditions [81]. TEC is also employed in the umbrella to provide cold air to people with high deviations in temperature and abundant sunlight [82]. A Peltier device transforms heat energy into electrical energy using a collection of thermocouples. Using these thermocouples integrated with a TEC battery can be recharged by the thermoelectric generator principle which can be used to charge mobile phones or cell phones [83,84]. A thermoelectric cooler can also be employed to improve the lifetime of the battery. This module can also be employed in a thermoelectric lunch box to preserve food at the necessary temperature [85]. The moisture content present in the soil and drying of the wet soil can be completed using a thermoelectric device with infrared light [86]. TEC is also used in the measurement of the thermal characteristics of low-cost MEMS IMU sensors [87]. It is also used for cooling and humidity control over engineering surfaces [88,89]. Similarly, there are various applications of thermoelectric devices depending on the application.

Over the last 5 years, the number of works has been reported in the literature. When it has been compared the selected application of this review it has been found the thermoelectric module was used in electronic devices with the highest range up to 43% following to thermoelectric generator 30% and then medical application 17% (Fig. 6). When observed thermoelectric refrigerators and automobile cooler only 7% and 3% used were found respectively and this range compared to other types of application is small. It discloses that in the recent studies and investigation Peltier devices was highly used for electronic and medical application additionally to the thermoelectric generator.

Figure 6: Overview of thermoelectric module application used in last five years [25]

5 Critical Analysis of the Literature

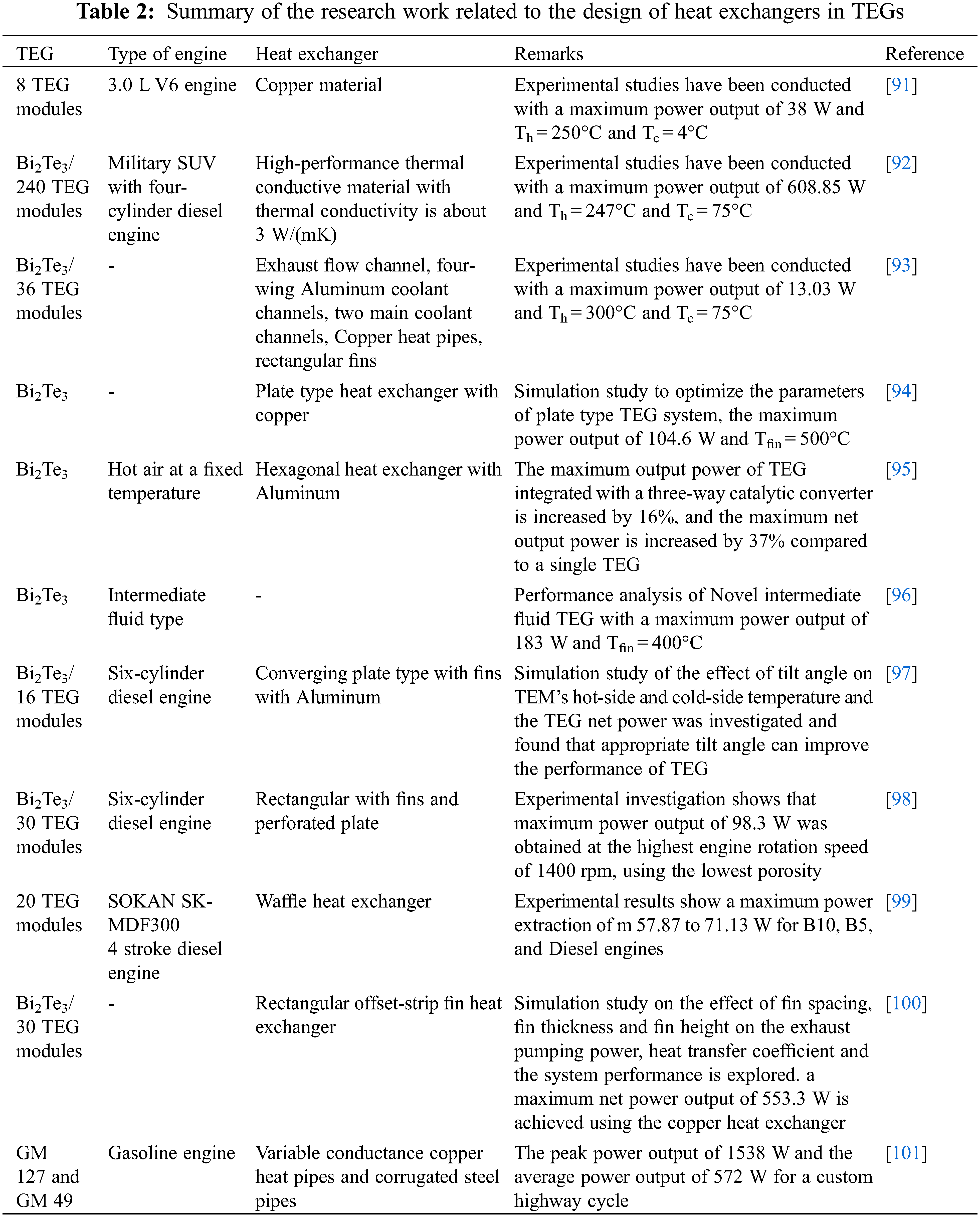

The output power and thermoelectric conversion efficiency of segmented TEG components with changed length proportions under two different thermal boundary conditions are studied in [90]. The increasing and decreasing patterns in the output power and efficiency of the thermoelectric materials with an increase in the length ratio. It is observed that the maximum efficiency and the maximum output power of the tentatively acquired segmented thermoelectric devices are very close and equivalent to the calculated value. The error obtained was less than 4%. Zhang et al. [90] studied the Seebeck potential, Ohmic potential, and internal resistance of the segmented TEG units for various length ratios. The maximum output power of a segmented TEG depends on both the Seebeck potential and the internal resistance. Table 2 shows the different designs of heat exchangers in TEGs.

A higher Seebeck potential and lower internal resistance lead to higher output power. Because there was an increasing and decreasing trend as shown in, the ideal length proportion is required to achieve good efficiency [90]. The GAHP is integrated into the Peltier device for electronic cooling application, Fig. 7 shows the performance of the Peltier plate with heat sink and with GAHP, it is observed that when the surrounding temperature was 30°C, 35°C, and 40°C the accumulation of the heat was reduced by the heat sink whereas the GAHP did not increase the performance [47].

Figure 7: Mean air temperature in the box for different conditions (a) 30°C, (b) 35°C, (c) 40°C, (d) 45°C, and (e) 50°C [47]

However, when the surrounding temperature was increased to 45°C and 50°C, the heat removal rate of the heat sink with Peltier was not effectively related to that of GAHP as shown in Figs. 7d and 6e, which remarkably reduced the heat accumulation on the heating side of the Peltier device which increased the efficiency of the system.

The thermoelectric cooler system was set inside the vehicle and the analysis was directed for various natural conditions, for example, in the morning, afternoon, and at night and it was noticed that the cooling at night was more positive than on different occasions [41]. The thermoelectric refrigerator was investigated by varying the input power. The cool side of the heat sink temperature and cooler box temperature with a variety of input powers (50.5, 72.72, and 113.64 W) for 2 h, respectively [109].

The rate of input power rate influences the temperature of the cooling device. The results show that the temperature at the cool side of the heat sink and cooler box decreases with the increase in the input power that is provided to the system, owing to the higher heat absorption on the cool side of the TEC modules. Thus, a lower temperature is acquired at the cool side of the heat sink and cooler box. The hot side of the heat sink temperature with the surrounding temperature and CoP of the cooler box with a variety of input powers [109,110]. The measure of input power likewise influences the temperature on the hot side of the heat sink. The results show that the hot side temperature of the heat sink increases with an increase in the input power, and because of the greater heat absorption on the cool side of the TEC, the more heat dissipated in the hot side of TEC so the temperature of the hot sink will rise. CoP decreases when the input power is increased to decrease the temperature rapidly. Table 3 shows the different designs of heat sinks in thermoelectric refrigerators. Additionally, some study has been found on energy observations in a turbine blade to resist the thermal effects [111,112] and few others study was in [113–115].

6 Conclusion and Recommendations

This paper is focused on a review of thermoelectric (Peltier devices). Due to the peculiarity and straightforwardness of the thermoelectric guideline, the conversion of vitality makes it progressively advantageous for various applications. It has decent future opportunities due to natural concerns and innovation advancement. The main disadvantage of the thermoelectric module is that it has got less efficiency. The CoP of the thermoelectric module is less than 1 usually in the range of 0.3–0.7 hence the CoP of TEC should be increased in the future. Thermoelectric generators assume an essential job in a few fields, for example, power plants, electrical powerhouses, heaters to deliver power from squandering heat recuperation. There are different odds of immediate and incorporated utilization of the thermoelectric component for cooling if the unit dimensions are increased or familiarize with stage change constituents. A compact cooler is suggested by analysts in their examination. In electronic gadgets cooling and execution improvement, TEC shows an exceptionally basic job because of its compacted dimensions, working system. The standard of thermoelectric vitality has adaptable applications for cars as talked about.

In the clinical field, thermoelectric has an exceptionally broad assortment of uses, for example, surgery tools, sensors, medical procedure apparatuses. The benefits of long-life expectancy, no moving parts, and calm activity of thermoelectricity are appropriate for little and medium purpose, yet it has got low proficiency. It could turn into creative significant environmentally friendly power vitality goals when the examination endeavors are progressed, and appropriate material improvement may build effectiveness later on. The fuse of thermoelectric with present frameworks would assume a significant job in the expansion of their exhibition.

Acknowledgement: This research is supported by the Structures and Materials (S&M) Research Lab of Prince Sultan University.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. He, W., Zhang, G., Zhang, X., Ji, J., Li, G. et al. (2015). Recent development and application of thermoelectric generator and cooler. Applied Energy, 143, 1–25. DOI 10.1016/j.apenergy.2014.12.075. [Google Scholar] [CrossRef]

2. Huang, B. J., Chin, C. J., Duang, C. L. (2000). Design method of thermoelectric cooler. International Journal of Refrigeration, 23(3), 208–218. DOI 10.1016/S0140-7007(99)00046-8. [Google Scholar] [CrossRef]

3. Patil, R. P., Suryawanshi, P., Pawar, A., Pawar, A. (2017). Thermoelectric refrigeration using peltier effect. International Journal of Engineering Sciences & Research Technology, 6, 614–618. DOI 10.5281/zenodo.800636. [Google Scholar] [CrossRef]

4. Radermacher, R., Yang, B., Hwang, Y. (2007). Integrating alternative and conventional cooling technologies. ASHRAE Journal, 49(10), 28–35. [Google Scholar]

5. Chakib, A. (2011). Peltier thermoelectric modules modeling and evaluation. International Journal of Engineering, 5, 114–121. [Google Scholar]

6. Cosnier, M., Fraisse, G., Luo, L. (2008). An experimental and numerical study of a thermoelectric air-cooling and air-heating system. International Journal of Refrigeration, 31(6), 1051–1062. DOI 10.1016/j.ijrefrig.2007.12.009. [Google Scholar] [CrossRef]

7. Balkrishan, Gupta, A., Chand, S., Patel, N. K., Soni, A. (2016). Review on thermoelectric cooler. International Journal for Innovative Research in Science & Technology, 2(11), 674–679. [Google Scholar]

8. Samadifar, M., Toghraie, D. (2018). Numerical simulation of heat transfer enhancement in a plate-fin heat exchanger using a new type of vortex generators. Applied Thermal Engineering, 133, 671–681. DOI 10.1016/j.applthermaleng.2018.01.062. [Google Scholar] [CrossRef]

9. Toghraie, D. (2016). Numerical thermal analysis of water’s boiling heat transfer based on a turbulent jet impingement on heated surface. Physica E: Low-Dimensional Systems and Nanostructures, 84, 454–465. DOI 10.1016/j.physe.2016.07.017. [Google Scholar] [CrossRef]

10. Hemmat Esfe, M., Esfandeh, S., Toghraie, D. (2021). Optimization of influential geometrical parameters of single slope solar still equipped with thermoelectric system to achieve maximum desalinated water. Energy Reports, 7, 5257–5268. DOI 10.1016/j.egyr.2021.08.106. [Google Scholar] [CrossRef]

11. Rahmati, A. R., Akbari, O. A., Marzban, A., Toghraie, D., Karimi, R. et al. (2018). Simultaneous investigations the effects of non-newtonian nanofluid flow in different volume fractions of solid nanoparticles with slip and no-slip boundary conditions. Thermal Science and Engineering Progress, 5, 263–277. DOI 10.1016/j.tsep.2017.12.006. [Google Scholar] [CrossRef]

12. Hemmat Esfe, M., Esfandeh, S., Toghraie, D. (2021). Numerical simulation of water production from humid air for Khuzestan province: Investigation of the Peltier effect (Thermoelectric cooling system) on water production rate. Case Studies in Thermal Engineering, 28, 101473. DOI 10.1016/j.csite.2021.101473. [Google Scholar] [CrossRef]

13. Fatholahi, M., Anvari, A., Akbari, O. A., Montazerifar, F., Ghaedamini, H. et al. (2021). Numerical investigation of mixed convection of nanofluid flow in oblique rectangular microchannels with nanofluid jet injection. The European Physical Journal Plus, 136(10), 1062. DOI 10.1140/epjp/s13360-021-02072-w. [Google Scholar] [CrossRef]

14. Parsaiemehr, M., Pourfattah, F., Akbari, O. A., Toghraie, D., Sheikhzadeh, G. (2018). Turbulent flow and heat transfer of water/Al2O3 nanofluid inside a rectangular ribbed channel. Physica E: Low-Dimensional Systems and Nanostructures, 96, 73–84. DOI 10.1016/j.physe.2017.10.012. [Google Scholar] [CrossRef]

15. Xu, H. J., Xing, Z. B., Wang, F. Q., Cheng, Z. M. (2019). Review on heat conduction, heat convection, thermal radiation and phase change heat transfer of nanofluids in porous media: Fundamentals and applications. Chemical Engineering Science, 195, 462–483. DOI 10.1016/j.ces.2018.09.045. [Google Scholar] [CrossRef]

16. Slanina, Z., Uhlik, M., Sladecek, V. (2018). Cooling device with peltier element for medical applications. IFAC-PapersOnLine, 51(6), 54–59. DOI 10.1016/j.ifacol.2018.07.129. [Google Scholar] [CrossRef]

17. Ruiz-Ortega, P. E., Olivares-Robles, M. A. (2019). Peltier supercooling in transient thermoelectrics: Spatial temperature profile and characteristic cooling length. Entropy, 21(3), 226. DOI 10.3390/e21030226. [Google Scholar] [CrossRef]

18. Patil, N., Hrushabh, M., Patil, C., Patil, O., Mahale, T. et al. (2019). Design & development of thermoelectric cooler using peltier plate. IARJSET, 6(3), 17–19. DOI 10.17148/IARJSET. [Google Scholar] [CrossRef]

19. Zelazna, A., Gołçbiowska, J. (2019). Life cycle assessment of cooling and heating system based on peltier module. IOP Conference Series: Earth and Environmental Science, 290(1), 6. DOI 10.1088/1755-1315/290/1/012067. [Google Scholar] [CrossRef]

20. Alfred, P. (2020). Applied thermoelectric solutions. https://thermoelectricsolutions.com/. [Google Scholar]

21. Guttmann, G. M., Gelbstein, Y. (2018). Mechanical properties of thermoelectric materials for practical applications. In: Bringing thermoelectricity into reality. IntechOpen, pp. 63–80. DOI 10.5772/intechopen.75476. [Google Scholar] [CrossRef]

22. Ferrotec, A. (2021). Ferrotec technology. https://ferrofluid.ferrotec.com/technology. [Google Scholar]

23. Sharma, S., Dwivedi, V. K., Pandit, S. N. (2014). A review of thermoelectric devices for cooling applications. International Journal of Green Energy, 11(9), 899–909. DOI 10.1080/15435075.2013.829778. [Google Scholar] [CrossRef]

24. Chavan, R. S., Dhawde, M. (2015). Review on performnace and analysis of thermoelectric cooling in various applications. International Journal of Advance Research in Science and Engineering, 4(9), 167–173. [Google Scholar]

25. Sagar, D. P., Devade, K. (2016). Review on thermoelectric refrigeration: Materials and technology. International Journal of Modern Trends in Engineering and Research, 4, 67–71. DOI 10.14741/ijcet/22774106/spl.4.2016.11. [Google Scholar] [CrossRef]

26. Kryotherm (2017). Hermoelectric coolers and related subsystems. Kyrotherm, 1–41. [Google Scholar]

27. Belovski, I., Staneva, L., Aleksandrov, A., Rahnev, P. (2017). Mathematical model of thermoelectric peltier module. Journal of Communication and Computer, 14(2), 60–64. DOI 10.17265/1548-7709. [Google Scholar] [CrossRef]

28. Tsai, H. L., Lin, J. M. (2010). Model building and simulation of thermoelectric module using matlab/Simulink. Journal of Electronic Materials, 39(9), 2105–2111. DOI 10.1007/s11664-009-0994-x. [Google Scholar] [CrossRef]

29. Luo, B. Z., Properties, P., Cooler, T., This, P. (2008). A simple method to estimate the physical characteristics of A thermoelectric cooler from vendor datasheets. Elecronics Cooling, 14, 4–13. [Google Scholar]

30. Bansal, P. K., Martin, A. (2000). Comparative study of vapour compression, thermoelectric and absorption refrigerators. International Journal of Energy Research, 24(2), 93–107. DOI 10.1002/(SICI)1099-114X(200002)24:2<93::AID-ER563>3.0.CO;2-6. [Google Scholar] [CrossRef]

31. Pathak, P. K., Singh, A., Boriwal, L. (2017). Performance analysis of water-cooled thermoelectric module TEC-12715. International Journal of Engineering Research & Technology, 6(4), 257–261. DOI 10.17577/IJERTV6IS040333. [Google Scholar] [CrossRef]

32. Varghese, A., Ale, A., Daniel, D., Thomas, D. (2017). Modelling of portable temperature conditioner based on peltier module. IJARIIE, 2(4), 201–207. [Google Scholar]

33. Ankit Kumar, M., Ankit Kumar, S., Ankur, P., Ambekar, R. S. (2017). Thermoelectric generator. International Research Journal of Engineering and Technology, 4(6), 854–856. [Google Scholar]

34. Dalala, Z. M., Hamdan, Z. S., Al-Taani, H., Al-Addous, M., Albatayneh, A. (2019). Battery charging application with thermoelectric generators as energy harvesters. The Academic Research Community Publication, 3(1), 248. DOI 10.21625/archive.v3i1.446. [Google Scholar] [CrossRef]

35. Ismail, B. I., Ahmed, W. H. (2009). Thermoelectric power generation using waste-heat energy as an alternative green technology. Recent Patents on Electrical Engineering, 2(1), 27–39. DOI 10.2174/1874476110902010027. [Google Scholar] [CrossRef]

36. Saikhedkar, N. K., Dewangan, A. (2015). Experimental analysis of waste heat recovery using TEG for an internal combustion engine. International Journal of Innovative Science, Engineering & Technology, 2(6), 711–720. [Google Scholar]

37. Kumar, N., Setia, V., Bajpai, P. (2019). Analysis of energy generation from exhaust of automobile using peltier thermoelectric generator. International Journal of Trend in Scientific Research and Development, 3(3), 749–751. DOI 10.31142/ijtsrd22986. [Google Scholar] [CrossRef]

38. Lagrandeur, J., Crane, D. T. (2005). Vehicle fuel economy improvement through thermoelectric waste heat recovery. DEER Conference, Chicago, IL. [Google Scholar]

39. Jaziri, N., Boughamoura, A., Müller, J., Mezghani, B., Tounsi, F. et al. (2020). A comprehensive review of thermoelectric generators: Technologies and common applications. Energy Reports, 6, 264–287. DOI 10.1016/j.egyr.2019.12.011. [Google Scholar] [CrossRef]

40. Pandey, A., Hansdah, D. (2021). Heat exchangers for automotive exhaust thermoelectric generators: A review. AIP Conference Proceedings, 2341(1), 30022. DOI 10.1063/5.0050132. [Google Scholar] [CrossRef]

41. Raut, M. S., Walke, P. V. (2012). Thermoelectric air cooling for cars. International Journal of Engineering Science and Technology, 4(5), 2381–2395. [Google Scholar]

42. Lofy, J., Bell, L. E. (2002). Thermoelectrics for environmental control in automobiles. International Conference on Thermoelectrics, pp. 471–476. Long Beach, CA, USA. DOI 10.1109/ICT.2002.1190362. [Google Scholar] [CrossRef]

43. Deshmukh, V., Dharme, A., Gaikwad, M., Moghe, C. H., Patil, C. (2017). Air conditioning system in car using thermoelectric effect. International Journal for Research in Applied Science & Engineering Technology, 5(6), 89–95. [Google Scholar]

44. Zheng, X. F., Liu, C. X., Yan, Y. Y., Wang, Q. (2014). A review of thermoelectrics research-recent developments and potentials for sustainable and renewable energy applications. Renewable and Sustainable Energy Reviews, 32, 486–503. DOI 10.1016/j.rser.2013.12.053. [Google Scholar] [CrossRef]

45. Hu, H. M., Ge, T. S., Dai, Y. J., Wang, R. Z. (2016). Experimental study on water-cooled thermoelectric cooler for CPU under severe environment. International Journal of Refrigeration, 62, 30–38. DOI 10.1016/j.ijrefrig.2015.10.015. [Google Scholar] [CrossRef]

46. Chang, Y. W., Chang, C. C., Ke, M. T., Chen, S. L. (2009). Thermoelectric air-cooling module for electronic devices. Applied Thermal Engineering, 29(13), 2731–2737. DOI 10.1016/j.applthermaleng.2009.01.004. [Google Scholar] [CrossRef]

47. Sun, X., Yang, Y., Zhang, H., Si, H., Huang, L. et al. (2017). Experimental research of a thermoelectric cooling system integrated with gravity assistant heat pipe for cooling electronic devices. Energy Procedia, 105, 4909–4914. DOI 10.1016/j.egypro.2017.03.975. [Google Scholar] [CrossRef]

48. Huang, H. S., Weng, Y. C., Chang, Y. W., Chen, S. L., Ke, M. T. (2010). Thermoelectric water-cooling device applied to electronic equipment. International Communications in Heat and Mass Transfer, 37(2), 140–146. DOI 10.1016/j.icheatmasstransfer.2009.08.012. [Google Scholar] [CrossRef]

49. Gökçek, M., Şahin, F. (2017). Experimental performance investigation of minichannel water cooled-thermoelectric refrigerator. Case Studies in Thermal Engineering, 10, 54–62. DOI 10.1016/j.csite.2017.03.004. [Google Scholar] [CrossRef]

50. Lavanya, N., Ravalika, R. E., Dharani, V. (2018). Design and fabrication of a portable refrigerator based on peltier effect. International Journal of Mechanical Engineering and Technology, 9(6), 242–247. [Google Scholar]

51. Raj, Y., Kizhakkevila, R. S., Tapa, A., Tom, D., Radhakrishnan, K. B. (2016). Construction and evaluation of performance of liquid cooled peltier effect refrigerator. Imperial Journal of Interdisciplinary Research, 2(11), 49–55. [Google Scholar]

52. Meher, R. S. (2018). Design and fabrication of thermo electric refrigerator. Journal of Innovation in Mechanical Engineering, 1(1), 9–12. DOI 10.31142/ijtsrd23356. [Google Scholar] [CrossRef]

53. Mirmanto, A., Sayoga, I. B., Sutanto, I. M. A., Nurchayati, R., Mulyanto, A. (2018). Experimental cooler box performance using two different heat removal units: A heat sink fin-fan, and a double fan heat pipe. Frontiers in Heat and Mass Transfer, 10(34), DOI 10.5098/hmt.10.34. [Google Scholar] [CrossRef]

54. Rahman, S. M. A., Sara, A., Asmaa, R., Rasha, S. (2017). Design and experimental investigation of portable solar thermoelectric refrigerator. International Journal of Thermal and Environmental Engineering, 14(1), 33–39. DOI 10.5383/ijtee.14.01.005. [Google Scholar] [CrossRef]

55. Selvam, C., Manikandan, S., Kaushik, S. C., Lamba, R., Harish, S. (2019). Transient performance of a peltier super cooler under varied electric pulse conditions with phase change material. Energy Conversion and Management, 198, DOI 10.1016/j.enconman.2019.111822. [Google Scholar] [CrossRef]

56. Zabihi, N., Gouws, R. (2015). Design a thermoelectric cooling holder supplied by photovoltaic panels. 23rd Southern African Universities Power Engineering Conference (SAUPEC), pp. 444–449. Johannesburg, South Africa. [Google Scholar]

57. Martínez, A., Astrain, D., Rodríguez, A., Pérez, G. (2013). Reduction in the electric power consumption of a thermoelectric refrigerator by experimental optimization of the temperature controller. Journal of Electronic Materials, 42(7), 1499–1503. DOI 10.1007/s11664-012-2298-9. [Google Scholar] [CrossRef]

58. Zabihi, N., Gouws, R. (2015). Verifying the cooling capacity and power consumption of thermoelectric cooling holders for vaccine storage. Proceedings of the 23rd Conference on the Domestic Use of Energy, pp. 115–119. Cape Town, South Africa. DOI 10.1109/DUE.2015.7102970. [Google Scholar] [CrossRef]

59. Elmaaref, M. M. A., Askalany, A. A., Salem, M., Harby, K. (2015). Solar thermoelectric cooling technology. Proceedings of 3rd International Conference on Energy Engineering, pp. 1–7. Aswan-Egypt. [Google Scholar]

60. Kumar, S., Gupta, A., Yadav, G., Singh, H. P. (2015). Peltier module for refrigeration and heating using embedded system. 2015 International Conference on Recent Developments in Control, Automation and Power Engineering, pp. 314–319. Noida, India. DOI 10.1109/RDCAPE.2015.7281416. [Google Scholar] [CrossRef]

61. Rahimi, A. S., Subki, A., Rashid, W. N. A., Hadi, N. A. A., Jidin, A. Z. et al. (2018). Development of portable air conditioning using peltier effect for small area uses. Journal of Telecommunication, Electronic and Computer Engineering, 10(2–6), 99–103. [Google Scholar]

62. Abdul-Wahab, S. A., Elkamel, A., Al-Damkhi, A. M., Al-Habsi, I. A., Al-Rubai'ey', H. S. et al. (2009). Design and experimental investigation of portable solar thermoelectric refrigerator. Renewable Energy, 34(1), 30–34. DOI 10.1016/j.renene.2008.04.026. [Google Scholar] [CrossRef]

63. Chein, R., Chen, Y. (2005). Performances of thermoelectric cooler integrated with microchannel heat sinks. International Journal of Refrigeration, 28(6), 828–839. DOI 10.1016/j.ijrefrig.2005.02.001. [Google Scholar] [CrossRef]

64. Sharma, A., Kumar, M., Ranjan, R., Krishnan, A. A. (2016). Conversion of dessert cooler into low cost air conditioner using peltier module. International Journal of Research in Engineering and Technology, 5(4), 347–352. DOI 10.15623/ijret. [Google Scholar] [CrossRef]

65. Arpitha, V., Rudagi, G. S., Hombaradi, M. (2018). Solar based air conditioning using peltier. International Journal of Scientific Research in Computer Science, Engineering and Information Technology, 4, 924–929. DOI 10.1109/CSSim.2009.40. [Google Scholar] [CrossRef]

66. Harivardhanreddy, B., M, H., Prashanth, M., Amood, S. M. (2018). Design and analysis of solar refrigeration using peltier plate. IJSRSET, 4, 917–920. DOI 10.32628/IJSRSET207265. [Google Scholar] [CrossRef]

67. He, W., Zhou, J., Hou, J., Chen, C., Ji, J. (2013). Theoretical and experimental investigation on a thermoelectric cooling and heating system driven by solar. Applied Energy, 107, 89–97. DOI 10.1016/j.apenergy.2013.01.055. [Google Scholar] [CrossRef]

68. Ahmad, S., Chandra Sekhar, P., Srinivasa Rao, O., Bhaskar, M., Kiran Kumar, S. (2019). Design and investigation on portable thermoelectric air chiller. International Journal of Engineering Trends and Technology, 67(2), 18–22. DOI 10.14445/22315381/IJETT-V67I2P204. [Google Scholar] [CrossRef]

69. Yadav, H., Srivastav, D., Kumar, G., Yadav, A. K., Goswam, A. (2019). Experimental investigations and analysis of thermoelectric refrigerator with multiple peltier modules. International Journal of Trend in Scientific Research and Development, 3(3), 1337–1340. DOI 10.31142/ijtsrd. [Google Scholar] [CrossRef]

70. Sundayani, Sinulingga, D. F., Prasetyawati, F. M., Palebangan, F. M., Suhendi, A. et al. (2017). PID temperature controlling of thermoelectric based cool box. 2017 International Conference on Control, Electronics, Renewable Energy, and Communications, pp. 236–240. Yogyakarta, Indonesia. DOI 10.1109/ICCEREC.2017.8226671. [Google Scholar] [CrossRef]

71. Sadighi Dizaji, H., Jafarmadar, S., Khalilarya, S., Pourhedayat, S. (2019). A comprehensive exergy analysis of a prototype peltier air-cooler; experimental investigation. Renewable Energy, 131, 308–317. DOI 10.1016/j.renene.2018.07.056. [Google Scholar] [CrossRef]

72. Mirmanto, M., Syahrul, S., Wirdan, Y. (2019). Experimental performances of a thermoelectric cooler box with thermoelectric position variations. Engineering Science and Technology, an International Journal, 22(1), 177–184. DOI 10.1016/j.jestch.2018.09.006. [Google Scholar] [CrossRef]

73. East, A. R., Smale, N. J. (2008). Combining a hybrid genetic algorithm and a heat transfer model to optimise an insulated box for use in the transport of perishables. Vaccine, 26(10), 1322–1334. DOI 10.1016/j.vaccine.2007.12.055. [Google Scholar] [CrossRef]

74. Chatterjee, S., Pandey, K. G. (2003). Thermoelectric cold-chain chests for storing/transporting vaccines in remote regions. Applied Energy, 76(4), 415–433. DOI 10.1016/S0306-2619(03)00007-2. [Google Scholar] [CrossRef]

75. Putra, N. (2009). Design, manufacturing and testing of a portable vaccine carrier box employing thermoelectric module and heat pipe. Journal of Medical Engineering and Technology, 33(3), 232–237. DOI 10.1080/03091900802454517. [Google Scholar] [CrossRef]

76. Hassaan-Younis, M., Ur-Rashid, H. (2019). Energy efficient, peltier based portable cabinet cooling system for vaccine cold chain. 4th International Conference on Power Generation Systems and Renewable Energy Technologies, Islamabad, Pakistan. DOI 10.1109/PGSRET.2018.8685969. [Google Scholar] [CrossRef]

77. Sujith, G., Raj, S. (2015). Design and fabrication of portable thermoelectric vaccine preservator. International Journal of Mechanical and Industrial Technology, 3(12), 50–62. [Google Scholar]

78. Reid, E., Barkes, J., Morrison, C., Ung, A., Patel, R. et al. (2018). Design and testing of a thermoelectrically-cooled portable vaccine cooler. Journal of Young Investigator, 35(2), 50–55. DOI 10.22186/jyi.35.2.50-55. [Google Scholar] [CrossRef]

79. Mahadeo, S. M., Huang, T. H., Artur Zych, Yu, S., Sanakov, D. et al. (2019). A smart cooling vest for people with thermoregulatory disorder. Proceedings of the 2019 Design of Medical Devices Showcase, pp. 1–4. Minneapolis, MN, USA. [Google Scholar]

80. Naz, T., Atif, M., Aslam, A., Aslam, A., Ashraf, F. (2019). Design and implementation of automatic body heat sink for the hypohidrosis patient. Biomedical Research, 30(3), 413–416. DOI 10.35841/biomedicalresearch.30-19-114. [Google Scholar] [CrossRef]

81. Srivastava, M. K. (2020). Solar based E-uniform for soldiers. International Journal for Research in Applied Science and Engineering Technology, 8(5), 728–733. DOI 10.22214/ijraset.2020.5115. [Google Scholar] [CrossRef]

82. Marati, N., Sandhya, C., Haarica, V., Gaggar, S., Reddy, T. K. (2019). Design and development of solar umbrella based on peltier effect. 2019 International Conference on Computing, Power and Communication Technologies, pp. 853–856. New Delhi, India. [Google Scholar]

83. David, A. P. J. (2017). Thermoelectric generator: Mobile device charger. 8th CEBU International Conference on “Recent Trends in Engineering and Technology” (RTET-17), pp. 7–11. Cebu, Philippines. DOI 10.17758/uruae.ae09171002. [Google Scholar] [CrossRef]

84. Sombra, A. K. R., Sampaio, F. C., Bascope, R. P. T., Torrico, B. C. (2017). Digital temperature control project using Peltier modules to improve the maintenance of battery lifetime. 2016 12th IEEE International Conference on Industry Applications, pp. 1–7. Curitiba, PR, Brazil. DOI 10.1109/INDUSCON.2016.7874565. [Google Scholar] [CrossRef]

85. Yelavkar, A. P., Yelavkar, V. S., Deshmukh, S. B. (2017). Design manufacturing and experimental analysis of thermoelectric lunch box. International Journal of Engineering Research and Technology, 10, 757–761. [Google Scholar]

86. Dipova, N. (2019). Design and development of peltier assisted infrared drying based soil moisture content device. KSCE Journal of Civil Engineering, 23(1), 29–36. DOI 10.1007/s12205-018-0011-0. [Google Scholar] [CrossRef]

87. Ruzza, G., Guerriero, L., Revellino, P., Guadagno, F. M. (2019). A low-cost chamber prototype for automatic thermal analysis of MEMS IMU sensors in tilt measurements perspective. Sensors, 19(12), 41. DOI 10.3390/s19122705. [Google Scholar] [CrossRef]

88. Gupta, R., Das, C., Roy, A., Ganguly, R., Datta, A. (2018). Arduino based temperature and humidity control for condensation on wettability engineered surfaces. 2018 Emerging Trends in Electronic Devices and Computational Techniques, pp. 1–6. Kolkata, India. DOI 10.1109/EDCT.2018.8405062. [Google Scholar] [CrossRef]

89. Harikrishnan, B., Sathil, P. T. (2017). Experimental investigation and thermal analysis of radiant floor cooling system incorporated with peltier effect. International Journal of Innovative Research in Science, Engineering and Technology, 6, 9070–9078. DOI 10.15680/IJIRSET.2017.0605105. [Google Scholar] [CrossRef]

90. Zhang, G., Fan, L., Niu, Z., Jiao, K., Diao, H. et al. (2015). A comprehensive design method for segmented thermoelectric generator. Energy Conversion and Management, 106, 510–519. DOI 10.1016/j.enconman.2015.09.068. [Google Scholar] [CrossRef]

91. Orr, B., Akbarzadeh, A., Lappas, P. (2017). An exhaust heat recovery system utilising thermoelectric generators and heat pipes. Applied Thermal Engineering, 126, 1185–1190. DOI 10.1016/j.applthermaleng.2016.11.019. [Google Scholar] [CrossRef]

92. Quan, R., Liu, G., Wang, C., Zhou, W., Huang, L. et al. (2018). Performance investigation of an exhaust thermoelectric generator for military SUV application. Coatings, 8(1), 18. DOI 10.3390/coatings8010045. [Google Scholar] [CrossRef]

93. Cao, Q., Luan, W., Wang, T. (2018). Performance enhancement of heat pipes assisted thermoelectric generator for automobile exhaust heat recovery. Applied Thermal Engineering, 130, 1472–1479. DOI 10.1016/j.applthermaleng.2017.09.134. [Google Scholar] [CrossRef]

94. He, W., Guo, R., Takasu, H., Kato, Y., Wang, S. (2019). Performance optimization of common plate-type thermoelectric generator in vehicle exhaust power generation systems. Energy, 175, 1153–1163. DOI 10.1016/j.energy.2019.03.174. [Google Scholar] [CrossRef]

95. Yang, H., Shu, G., Tian, H., Ma, X., Chen, T. et al. (2018). Optimization of thermoelectric generator (TEG) integrated with three-way catalytic converter (TWC) for harvesting engine’s exhaust waste heat. Applied Thermal Engineering, 144, 628–638. DOI 10.1016/j.applthermaleng.2018.07.091. [Google Scholar] [CrossRef]

96. Zhao, Y., Wang, S., Ge, M., Liang, Z., Liang, Y. et al. (2019). Performance investigation of an intermediate fluid thermoelectric generator for automobile exhaust waste heat recovery. Applied Energy, 239, 425–433. DOI 10.1016/j.apenergy.2019.01.233. [Google Scholar] [CrossRef]

97. Luo, D., Wang, R., Yu, W., Sun, Z., Meng, X. (2019). Modelling and simulation study of a converging thermoelectric generator for engine waste heat recovery. Applied Thermal Engineering, 153, 837–847. DOI 10.1016/j.applthermaleng.2019.03.060. [Google Scholar] [CrossRef]

98. Choi, Y., Negash, A., Kim, T. Y. (2019). Waste heat recovery of diesel engine using porous medium-assisted thermoelectric generator equipped with customized thermoelectric modules. Energy Conversion and Management, 197, 111902. DOI 10.1016/j.enconman.2019.111902. [Google Scholar] [CrossRef]

99. Ramírez, R., Gutiérrez, A. S., Cabello Eras, J. J., Valencia, K., Hernández, B. et al. (2019). Evaluation of the energy recovery potential of thermoelectric generators in diesel engines. Journal of Cleaner Production, 241, 118412. DOI 10.1016/j.jclepro.2019.118412. [Google Scholar] [CrossRef]

100. Najjar, Y. S. H., Sallam, A. (2019). Optimum design, heat transfer and performance analysis for thermoelectric energy recovery from the engine exhaust system. Journal of Electronic Materials, 48(9), 5532–5541. DOI 10.1007/s11664-019-07416-y. [Google Scholar] [CrossRef]

101. Pacheco, N., Brito, F. P., Vieira, R., Martins, J., Barbosa, H. et al. (2020). Compact automotive thermoelectric generator with embedded heat pipes for thermal control. Energy, 197, 117154. DOI 10.1016/j.energy.2020.117154. [Google Scholar] [CrossRef]

102. Zhao, D., Tan, G. (2014). A review of thermoelectric cooling: Materials, modeling and applications. Applied Thermal Engineering, 66(1), 15–24. DOI 10.1016/j.applthermaleng.2014.01.074. [Google Scholar] [CrossRef]

103. Hermes, C. J. L., Barbosa, J. R. (2012). Thermodynamic comparison of peltier, stirling, and vapor compression portable coolers. Applied Energy, 91(1), 51–58. DOI 10.1016/j.apenergy.2011.08.043. [Google Scholar] [CrossRef]

104. Jugsujinda, S., Vora-ud, A., Seetawan, T. (2011). Analyzing of thermoelectric refrigerator performance. Procedia Engineering, 8, 154–159. DOI 10.1016/j.proeng.2011.03.028. [Google Scholar] [CrossRef]

105. Astrain, D., Vián, J. G., Albizua, J. (2005). Computational model for refrigerators based on peltier effect application. Applied Thermal Engineering, 25(17), 3149–3162. DOI 10.1016/j.applthermaleng.2005.04.003. [Google Scholar] [CrossRef]

106. Vián, J. G., Astrain, D. (2009). Development of a thermoelectric refrigerator with two-phase thermosyphons and capillary lift. Applied Thermal Engineering, 29(10), 1935–1940. DOI 10.1016/j.applthermaleng.2008.09.018. [Google Scholar] [CrossRef]

107. Dai, Y. J., Wang, R. Z., Ni, L. (2003). Experimental investigation and analysis on a thermoelectric refrigerator driven by solar cells. Solar Energy Materials and Solar Cells, 77(4), 377–391. DOI 10.1016/S0927-0248(02)00357-4. [Google Scholar] [CrossRef]

108. Min, G., Rowe, D. M. (2006). Experimental evaluation of prototype thermoelectric domestic-refrigerators. Applied Energy, 83(2), 133–152. DOI 10.1016/j.apenergy.2005.01.002. [Google Scholar] [CrossRef]

109. Mainil, A. K., Aziz, A., Akmal, M. (2018). Portable thermoelectric cooler box performance with variation of input power and cooling load. Aceh International Journal of Science and Technology, 7(2), 85–92. DOI 10.13170/aijst.7.2.8722. DOI 10.13170/aijst.7.2.8722. [Google Scholar] [CrossRef]

110. Morelli, D. T. (2017). Thermoelectric materials. In: Springer handbooks, pp. 1. Springer, Singapore. DOI 10.1007/978-3-319-48933-9_57. [Google Scholar] [CrossRef]

111. Aabid, A., Jyothi, Zayan, J. M., Khan, S. A. (2019). Experimental and numerical investigation on gas turbine blade with the application of thermal barrier coatings. In: Advances in materials research. South Korea: Techno Press. DOI 10.12989/amr.2019.8.4.275. [Google Scholar] [CrossRef]

112. Aabid, A., Khan, S. A. (2018). Optimization of heat transfer on thermal barrier coated gas turbine blade related. IOP Conference Series: Materials Science and Engineering, 370(5), 1–9. DOI 10.1088/1757-899X/370/1/012022. [Google Scholar] [CrossRef]

113. Delvi, H. A., Faheem, M., Aabid, A., Math, M. C., Khan, S. A. (2020). Investigation of characteristics of spark ignition engine fuelled with ethanol-gasoline blends using iso-octane additive. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 66, 151–163. [Google Scholar]

114. Kumar, K., Singh, A., Shaik, S., Saleel, C. A., Aabid, A. (2022). Comparative analysis on dehumidification performance of KCOOH–LiCl hybrid liquid desiccant air-conditioning system: An energy-saving approach. Sustainability, 14(6), 22. DOI 10.3390/su14063441. [Google Scholar] [CrossRef]

115. Aabid, A., Murtuza, M. A., Shushrutha, A. (2015). Experimental study of mechanical properties of tellurium nanowires reinforced epoxy composites. American Journal of Materials Science, 5, 194–197. DOI 10.5923/c.materials.201502.37. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |