| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.022434

ARTICLE

Elaboration of a Road Material Based on Clayey Soil and Crushed Sand

1Group of Research in Energy and Environment from Materials (GREENMAT), Liège, Belgium

2Laboratory of Energetics and Applied Mechanics (LEMA), Cotonou, Benin

3Laboratory of Tests and Studies in Civil Engineering (L2EGC), Abomey, Benin

*Corresponding Author: H. G. R. Sekloka. Email: sekloka80@yahoo.fr

Received: 09 March 2022; Accepted: 06 May 2022

Abstract: To contribute to the enhancement of unconventional local materials used for road construction, this study characterizes a crushed sand 0/5, a clayey soil and the litho-stabilized material without and with hydraulic binder and determines their use in accordance with some reference specifications (CEBTP 1984). It is shown that the different components are not usable alone in pavement base. Indeed, the plasticity index obtained for the clayey soil is 21%, a value higher than the imposed standards. In addition, the grading of the 0/5 crushed sand does not fit into the range proposed by CEBTP. A combination of these two (02) components is therefore considered to obtain a suitable material usable for the sub-base. This new material does not enter any class of the CEBTP lateritic soils. In order to be used in base layer, a treatment with hydraulic binder is carried out with the intention to improve its mechanical performances. The optimal dosage of hydraulic binder to achieve the desired mechanical performance is obtained by studying the evolution of the mechanical characteristics of the mixture. After this treatment, the Bearing Ratio index of the mix increases from 37 to 223 for the optimal dosage and the dry compaction density decreases from 2.11 to 2.06 g/cm3 while the optimal water content increases from 9% to 10.1%.

Keywords: Clayey sand; crushed sand; hydraulic binder; road base

Nomenclature

| CEBTP | Centre Expérimental de Recherches et d’Études du Bâtiment et des Travaux Publics |

| HB | Hydraulic binder |

| HRB | Hydraulic road binder |

| AG | Particle size analysis |

| PI | Plasticity index |

| OPM | Optimum modified proctor |

| CBR | Bearing index |

| WOPM | Optimal water content |

| Ds | Maximum dry density |

| Gfmax | Maximum swelling |

The use of appropriate local materials contributes to the reduction of costs and environmental impact of construction [1]. In this perspective, this work consisted of using crushing waste to elaborate a material usable in road construction. This local material is available in large quantities in the southern region of Benin (study area) where road infrastructure is being built on a large scale. It is therefore necessary to look for alternatives to exploit the crushed sand for road construction.

Indeed, the clayey sand, highly available in the study area is most often used in pottery and in the making of hydraform bricks. This soil covers seven (07) plateaus in Southern Benin, i.e., about 40% of the study area [2,3] and the established reserves of this material are estimated at 10,410,949 m3 [4]. The realization of road structures in fine soils is often made difficult by their high humidity and/or their high clay content. The fine soils, in their natural state, are often discarded and substituted by materials with better clayey materials with hydraulic binder or to slim them down with another material that is complementary to it [5].

Indeed, the technique commonly used for use in pavement layers of plastic clay soils is stabilization with hydraulic binder such as lime [5,6] cement, or hydraulic road binder (HRB) [7] or combinations of these binders. This valorization is done more and more by the treatment of soils with hydraulic road binder (LHR), since the experience showed that it makes it possible to modify the mechanical behavior and the handiness of the soils to make them suitable for earthworks even if, in the case of very plastic fine soils, the situation is a little more delicate [7]. The services that can be expected from the incorporation of a hydraulic binder (H.B.) are varied. Firstly, it neutralizes the plastic fines of a water-sensitive soil. The fines are agglomerated into much larger particles, impermeable on the surface. As their specific surface is reduced, they are less sensitive to swelling by imbibition. The plasticity index of a treated soil is significantly lowered [7–9].

In road engineering, the use of wastes and by-products of various origins is concerned, on the one hand, for environmental issues, on the other hand, to overcome the deficit recorded in the field of road aggregates of good qualities which are becoming increasingly scarce but also because of the high price of the hydrocarbon binder that is bitumen [10]. Thus, crushed materials, crushed materials and concrete rubble are often used [11]. These previous studies have shown, for use as road materials, the possibility of slimming down the clayey materials by adding complementary materials, other than the hydraulic binders usually used. After investigation with the institutions in charge of geological and mining resources in the study area, we were able to retain as granular corrective materials (to be added to the clayey sand); lagoon sands because of the presence of watercourses and crushed sands available in quantity in the crushing quarries. As these materials are incompressible, their implementation in road construction cannot be considered without prior laboratory studies.

This study will contribute to the valorization of local materials. It proposes to valorize the crushed sand 0/5, by combining it with the nearest clayey sand, to use it in road layers.

The crushed sand used was taken from Dan in the commune of Djidja (coordinates: 7°22′6.25″N, 2°7′29.62″E) in Benin and the clayey sand is from Sodohomey in the commune of Bohicon (coordinates: 7°9′44.6″N, 2°4′51.6″E). A complete identification of the different materials was first carried out. The granulometric analysis was carried out in accordance with the NF EN ISO 17892-4 standard. The plasticity index, the compaction characteristics and the bearing capacity of each material were respectively determined in accordance with standards NF EN ISO 17892-12, NF P 94-093 and NF P 94-078. The sand equivalent test on the crushed sand was carried out in accordance with standard NF EN 933-8. Mineralogical studies were also carried out. The apparatus used is the Mobile Test Stand Niton XRF Analyser. Its principle is the X-ray fluorescence spectrometry which is a global elemental analysis technique allowing to identify and determine most of the chemical elements which compose a sample.

A formulation study was then carried out based on the granulometry of the crushed sand and the clayey sand in order to determine the various proportions to be mixed. A formula was retained after identification of the lithostabilized material.

To assess the mechanical performance, the tests of resistance to simple compression and diametrical compression were carried out using the provisions of standards NF P 98-114-3, NF EN 13286-53, NF EN 13286-42 and NF EN 13286-41 on the mixture without hydraulic binder, on the one hand, and with addition of hydraulic binder, on the other hand.

The experimental protocol adopted consisted of:

– To vary the cement dosage (0%, 1%, 2%, 3%, 4%, 5%) to appreciate the evolution of the compaction characteristics (optimal water content and maximum dry density).

– To measure the mechanical characteristics of different ages (7, 14, 28, 60 and 90 days) to appreciate the temporal evolution after the addition of a hydraulic binder or not.

The tests were carried out three times to assess the standard deviation between the values to validate each result obtained.

3.1 Characteristics of the Crushed Sand 0/5

The crushed sand 0/5 comes from the extraction in quarries of hard rocks or from the crushing, after screening, of the fraction of alluvial gravel with big elements [12].

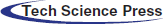

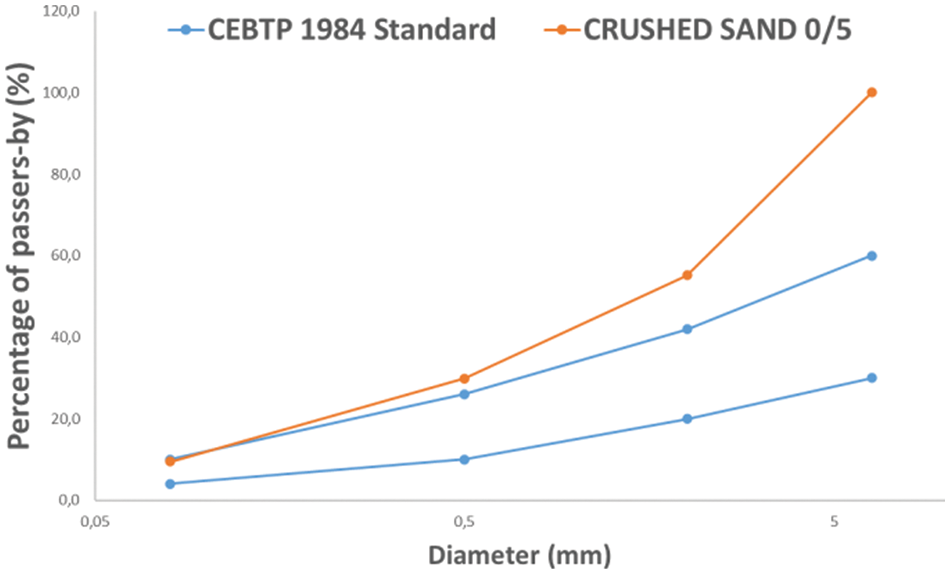

Table 1 reports the geotechnical characteristics of the crushed sand used.

By plotting the grading curve of the crushed sand 0/5 on the same graph Fig. 1 as the proposed spindle, the crushed sand curve does not pass inside the spindle. It can thus be understood that the crushed sand cannot be used as a road base. On the other hand, the sand equivalent test reveals that the crushed sand is clean enough to be considered even for hydraulic concrete.

Figure 1: Grain size curve of crushed sand 0/5 with the spindle of the CEBTP 1984 standard

3.2 Characteristics of Clayey Sand

The clayey sand comes either from sedimentary deposits of the type of the sands of the African Terminal Continental, or from the arenas resulting from the in-situ alteration of granitoid having locally undergone a reworking of colluvial type [12].

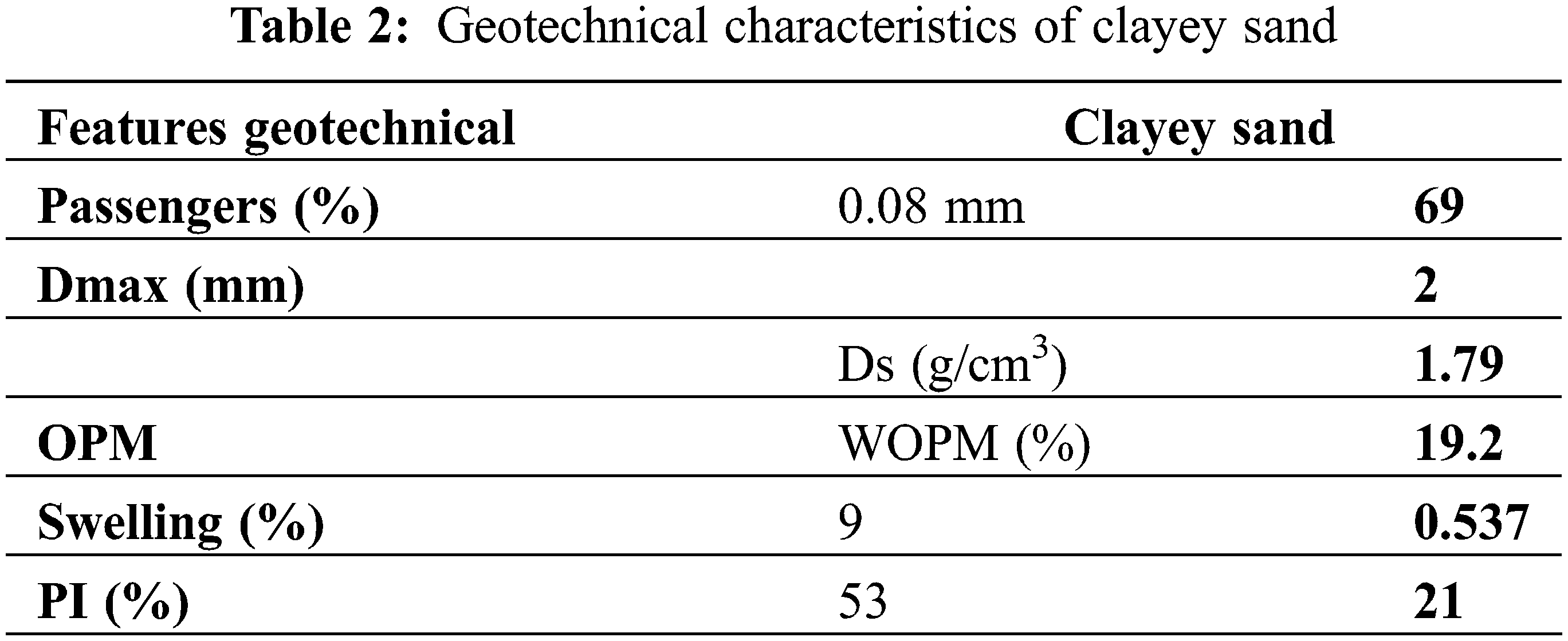

According to the 1984 pavement design guide for tropical countries, clayey sand must have the following geotechnical characteristics to be used as a sub-base only:

– Grain size: 0/10

– Passage at 0.080 mm: 10 to 30

– IP: 5 to 20

– f × IP: 100 to 500

– Ds: 1.9 to 2.10

– WOPM: 7% to 13%

– Gf max: 2.5%

The results obtained on the clayey sand used are reported in the Table 2 below:

Only the maximum swelling and the grain size are respected. This sand could not be used alone as road material. It could be used because of its high plasticity rate as a corrector for 0/5 crushed sand for a pavement layer formulation.

A formulation was thus carried out by varying the rate of clayey sand to be mixed with the crushed sand to obtain a composite meeting the specifications in force.

The method of formulation consisted of approximating as well as possible by using the method of least squares the curve of the mixture to a reference curve obtained by a simple analytical formula [13–15]:

d is the nominal opening size of the square mesh sieves (mm), D, the maximum diameter of the considered granulometry, p, the percentage passing (%) of the particles according to the sieve of nominal dimension d and n, a variable parameter.

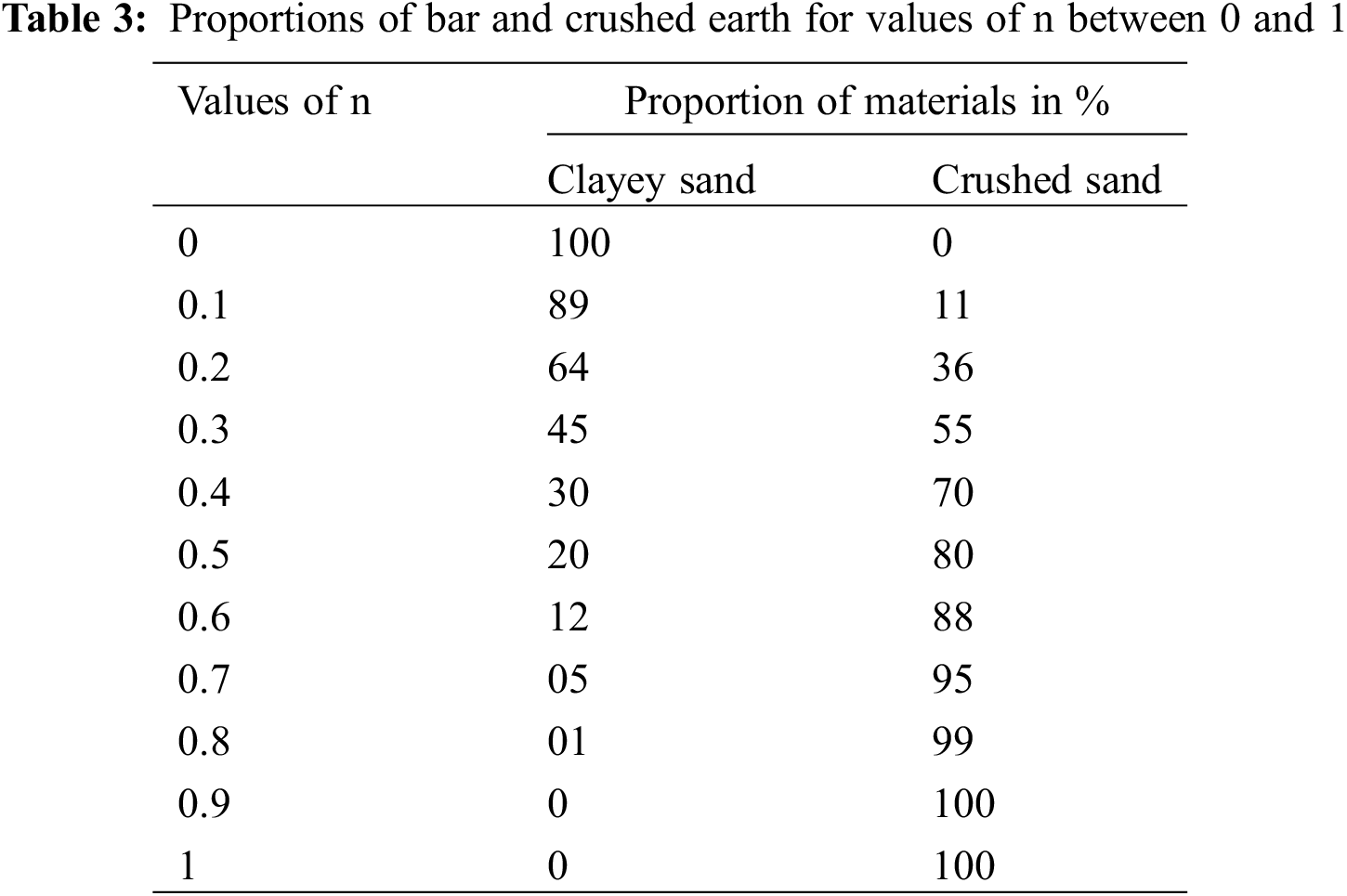

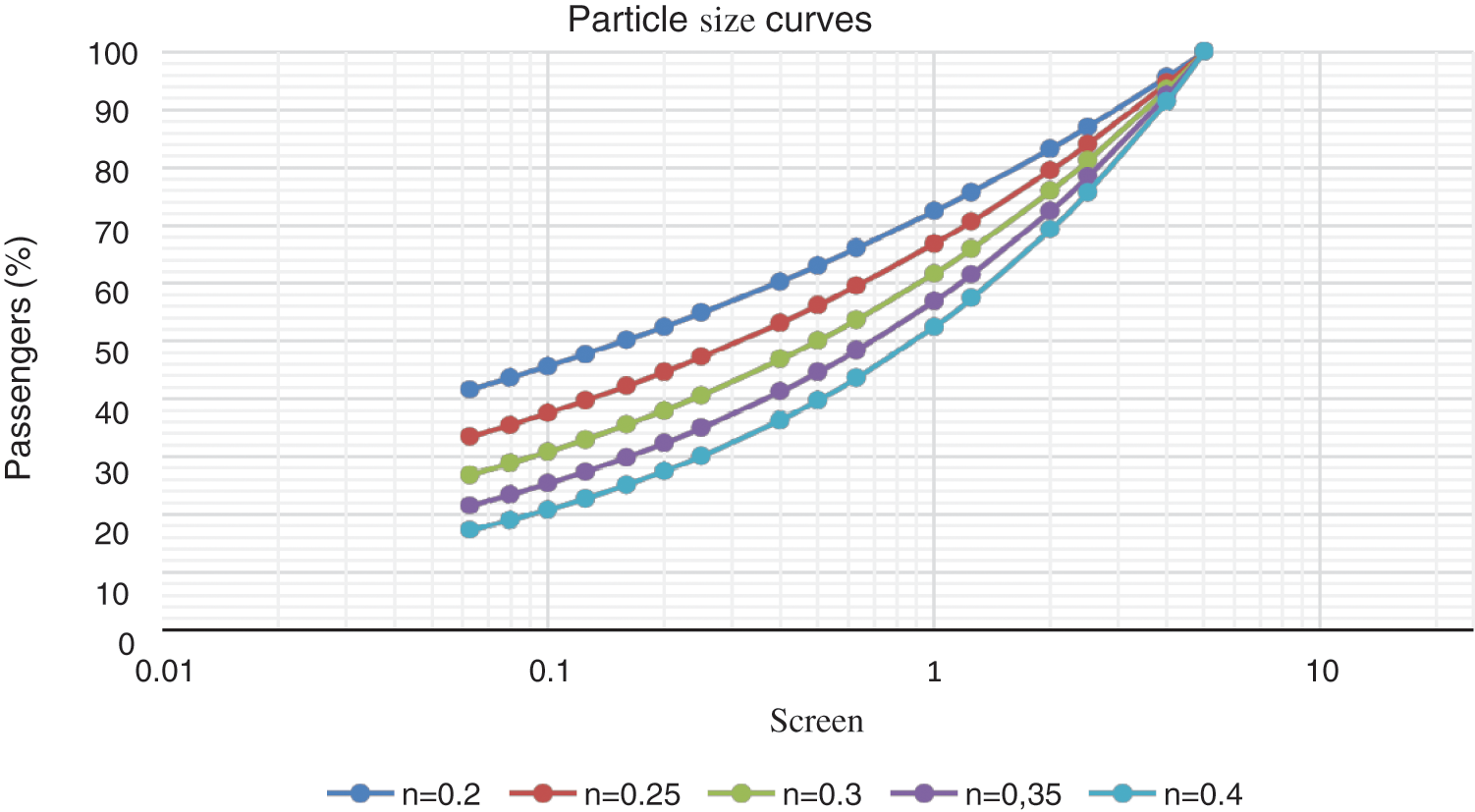

We then varied for values of n taken between 0 and 1 the proportions of the various materials to retain those which allow to have a minimum difference between the two curves. This variation was possible thanks to the Solver program of the Microsoft Excel software. The proportions found are recorded in the Table 3 below:

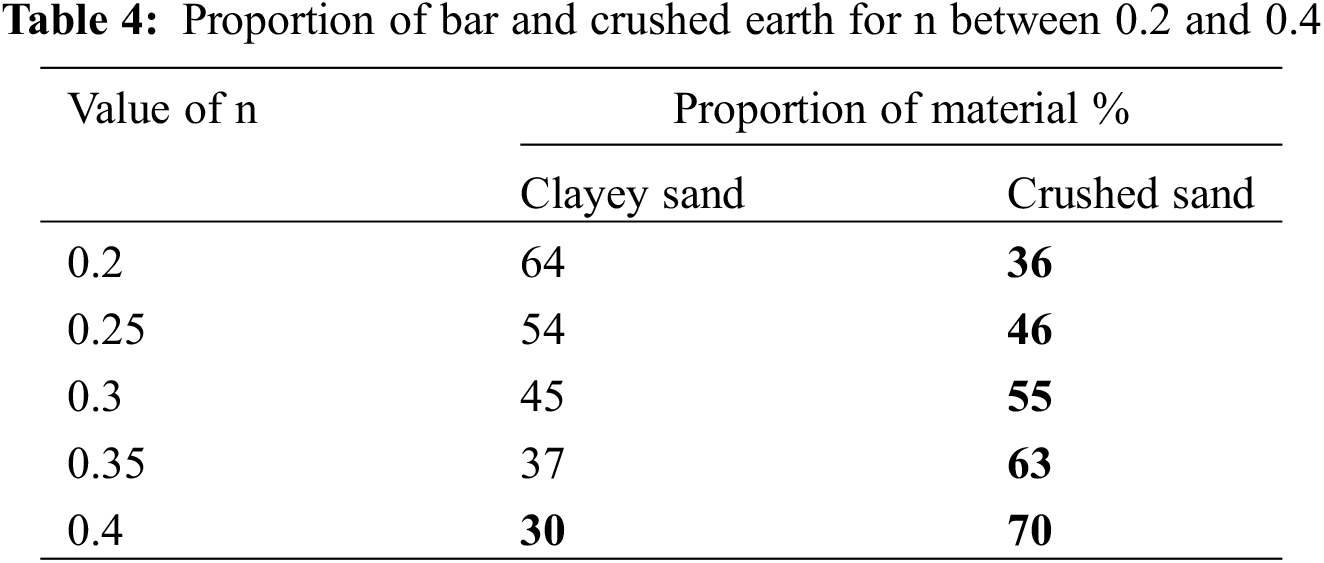

To avoid having mixtures that are too clayey, we rejected the proportions obtained for n = 0 and 0.1 because of a strong dominance of bar soil. On the other hand, for values of n ranging from 0.5 to 1 we note the dominance of crushed sand; the mixture obtained will be incompressible and difficult to implement in the pavement layer. Thus, we have varied n between 0.2 and 0.4 to obtain reasonable and feasible proportions. The results obtained are summarized in the Table 4 below:

The reference curves corresponding to each value of n are shown on the Fig. 2 below:

Figure 2: Reference curves for the bar soil and crushed stone mixture

After complete identification of the different mixes, we have retained a formula which respects the specifications of a material usable in pavement base and which contains a little more than 50% of crushed sand (material to be recovered).

The formula used is as follows: 55% crushed sand 0/5 + 45% clayey sand.

3.4 Characteristics of the Lithostabilized Material

By adding clayey sand to the crushed sand, we obtained a material with better performances. It will be seen to what extent this material can be used as road material.

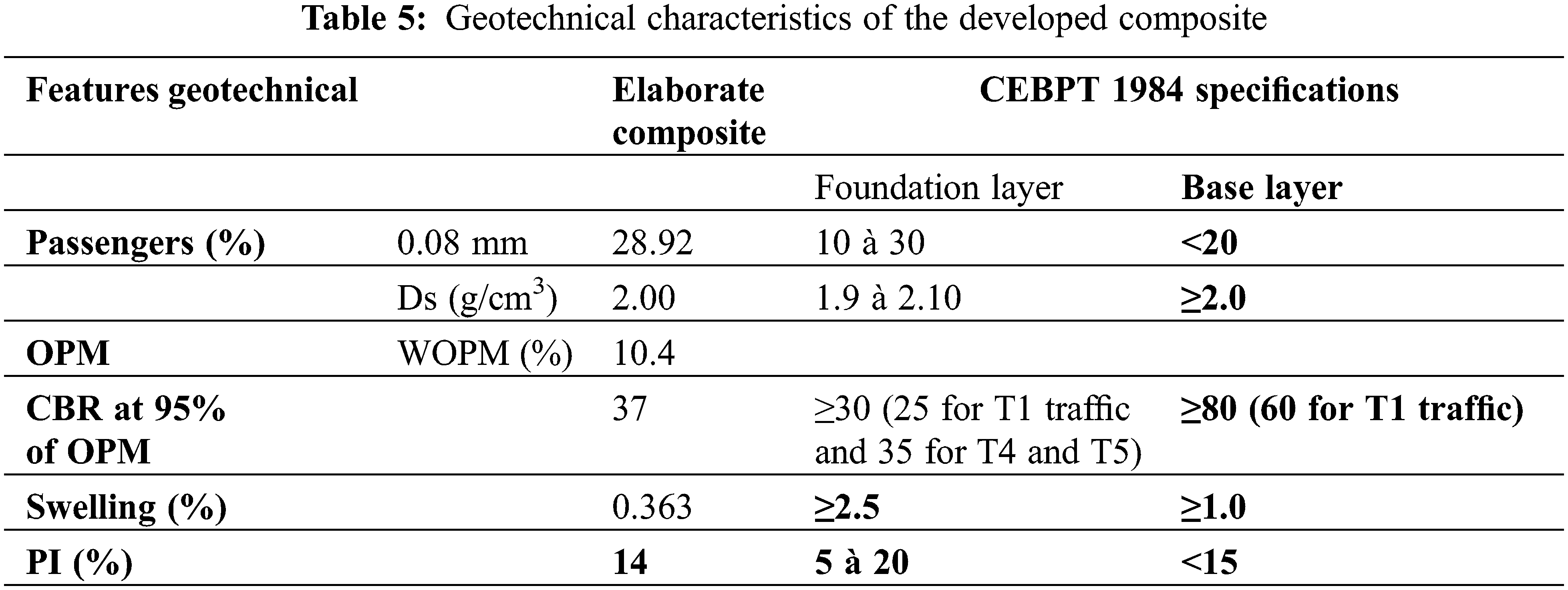

The results of the complete identification of the developed composite are summarized in the following Table 5:

– Use as a sub-base layer

The sub-base layer has fewer demanding specifications than the base layer.

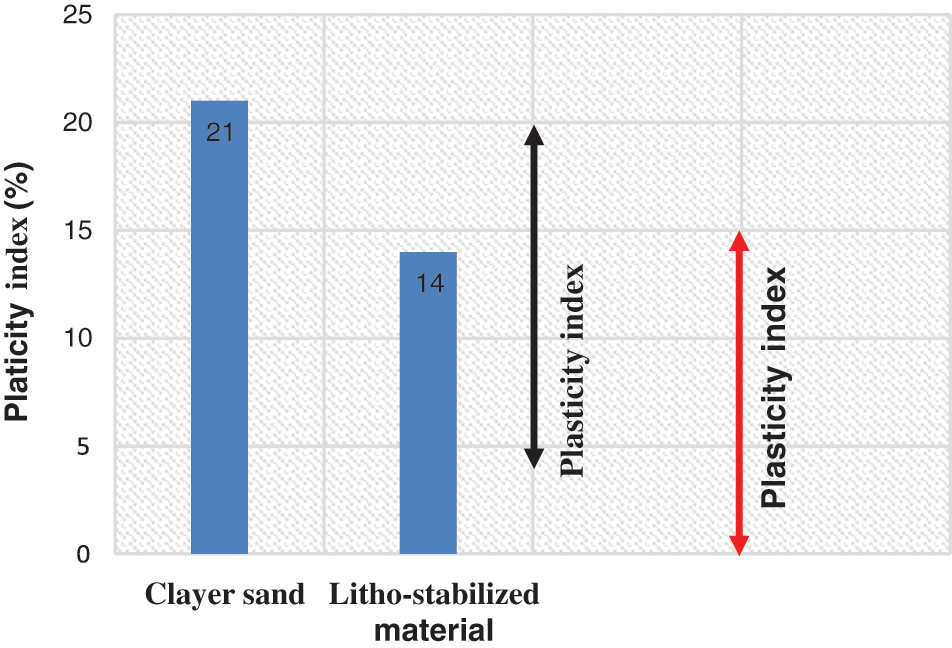

The fines content is well within the range of 10%–30%; the plasticity index has also been substantially reduced, 21 to 14 as shown in Fig. 3.

Figure 3: Evolution of the plasticity index after lithostabilization with respect to the specifications

Clayey sand does not fit within the range of plasticity index values for pavement subbase layers. On the other hand, after lithostabilization, the requirements regarding the plasticity index are respected.

In addition, the addition of the clayey sand allowed the compaction characteristics of the acceptable subbase to be obtained. Thus, we went from a dry density of 1.79 to 2.00.

The optimum water content has also been substantially reduced from 19.2% to 10.4%, so the resulting material will be less sensitive to water.

It is also noted that the bearing capacity of 37 is suitable for use as a sub-base.

The material produced can be used as a sub-base according to the requirements of CEBTP 1984.

– Use as a base layer

It can be easily seen that the parameters are also in conformity for use in base course except for the fine rate and the CBR bearing index.

To be able to use this material as a base course, it is therefore necessary to improve its mechanical performance by improving it with hydraulic binder.

Therefore, the composite material developed can be used as a sub-base layer but not as a base layer because the CBR value is too low.

3.4.1 Mineralogical Study of the Composite

Measurements of physical and mechanical parameters are counted among the most fundamental geotechnical analyses of construction geo-materials. On the other hand, the mineralogical and chemical nature of the materials remains unknown in the construction sector [16].

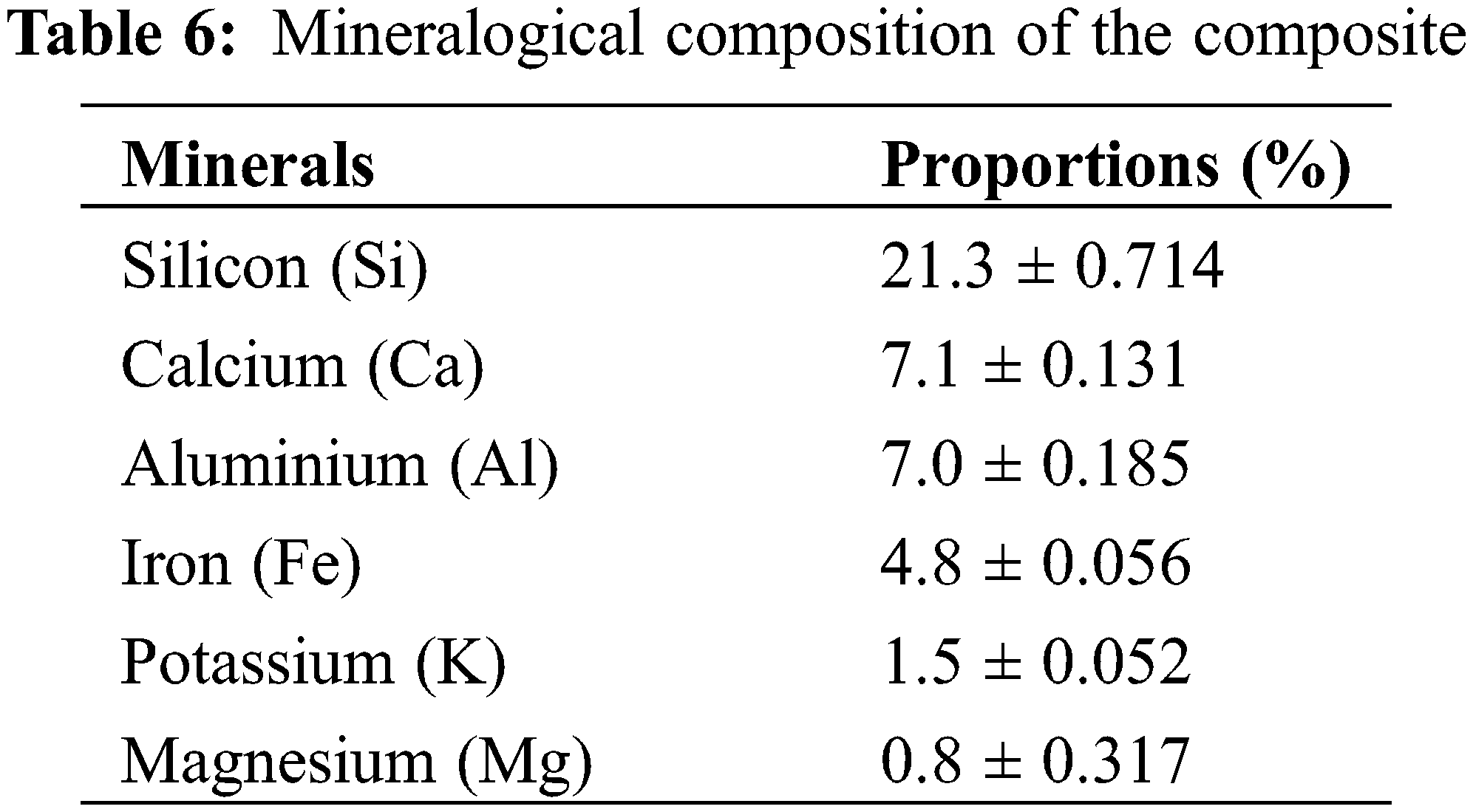

The Table 6 presents the results of the mineralogical analysis of the material.

From the analysis of this data, it appears that silicon, calcium, and aluminum are the major minerals in the composite. Slight traces of iron and potassium are also observed, due to the presence of crushed sand. In general, the silica/alumina ratio is an indicator of the content of a clay mineral sample [16]. This ratio is 3.04 for the elaborated material and reflects a minimal presence of clay in the sample. This presence of clay is explained by the addition of clayey sand at 45% in the mixture.

However, the main objective of this mineralogical study is to verify the presence of swelling clays in the sample. It is a question of highlighting or not the presence of the montmorillonite which is a mineral composed of silicate of aluminum and magnesium hydrated, of formula (Na, Ca)0, 3(Al, Mg)2Si4O10(OH)2, n H2O and belonging to the group of smectites, of the family of the phyllosilicates.

The absence of sodium Na, oxygen O and hydrogen H would allow to deduce an absence of montmorillonite in the sample.

This study allows us to conclude in the absence of swelling clays in the elaborated material, the composite is then less sensitive to the variations of the hydric conditions.

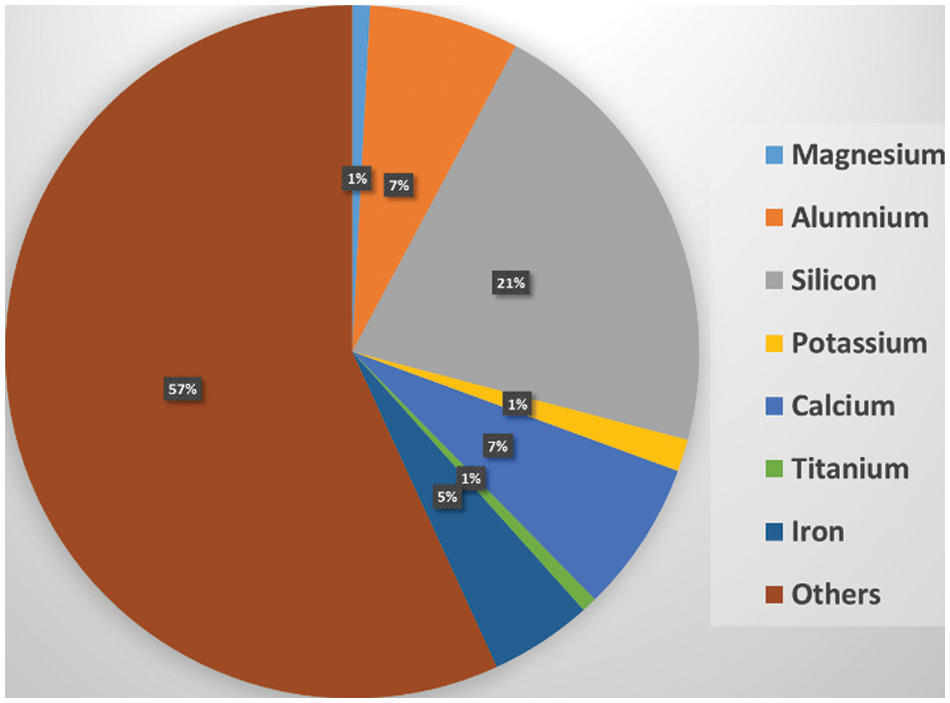

Fig. 4 below illustrates the distribution of minerals in the processed material.

Figure 4: Diagram showing the proportions of minerals in the processed material

3.4.2 Treatment with Hydraulic Binder

Soil treatment appeared in the early 1950s in several tropical countries as a cost-effective technique for creating roadbeds in areas lacking aggregate (and financial means) [17]. The services that can be expected from the incorporation of a hydraulic binder are varied. First, it neutralizes the plastic fines of a water-sensitive soil. The fines are agglomerated into much larger particles, impermeable on the surface. As their specific surface is reduced, they are less sensitive to swelling by soaking and therefore to the action of frost. The plasticity index of a treated soil is significantly lowered [18].

By varying the dosage of hydraulic binder, we measured again the parameters for characterizing a soil. Thus, at each cement dosage, the CBR index, the simple compressive strength and the indirect tensile strength were determined to judge the use of the composite as a base course.

The BH used is CEM II/B-LL 42.5R cement.

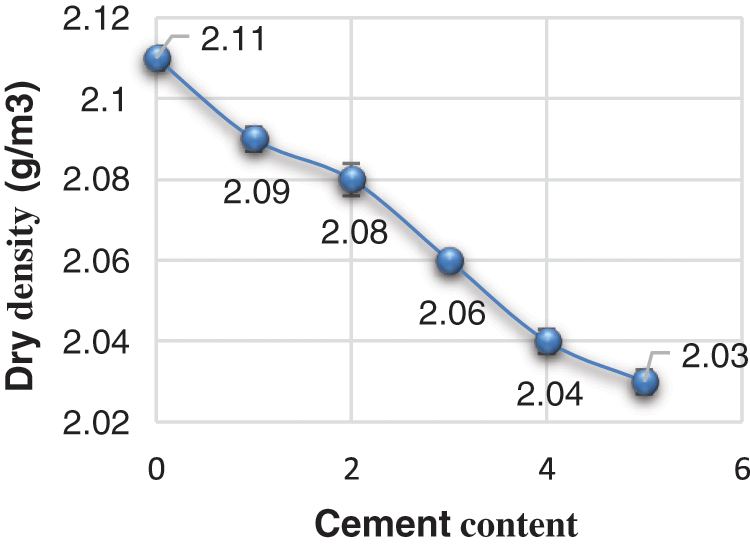

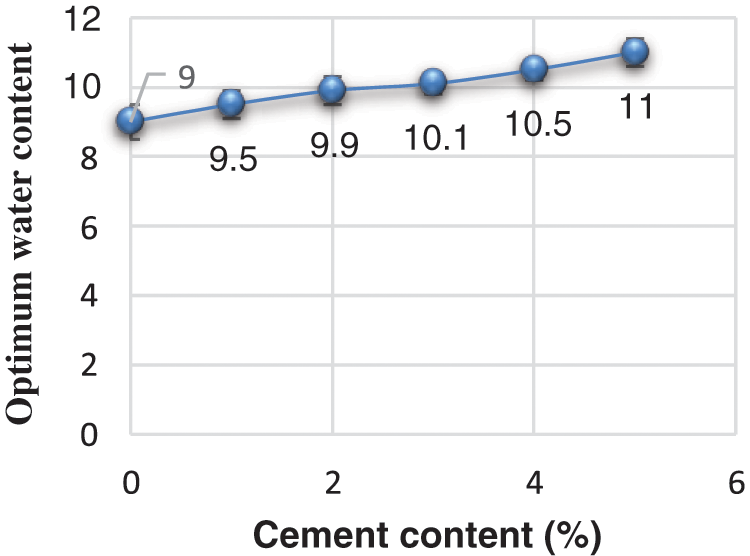

Behavior of Compaction Characteristics as a Function of Cement Dosage

By varying the cement dosage, the Proctor test was carried out to assess the evolution of the maximum dry density and the optimal water content.

The results obtained are summarized in the following Figs. 5 and 6

Figure 5: Evolution of the dry density according to the cement dosage

Figure 6: Evolution of the water content according to the cement dosage

An increase in the optimum moisture content and a decrease in the maximum proctor density of the developed material can be seen. The increase in water content is explained by the presence of cement in the mix. Indeed, fines are water sensitive particles, the more they are present in a material, the more water the material will absorb for a lower dry density. As cement is only made of fine particles, its incorporation into the material increases the proportion of fines in the latter. This results in an increase in the optimum water content and a slight decrease in the dry density.

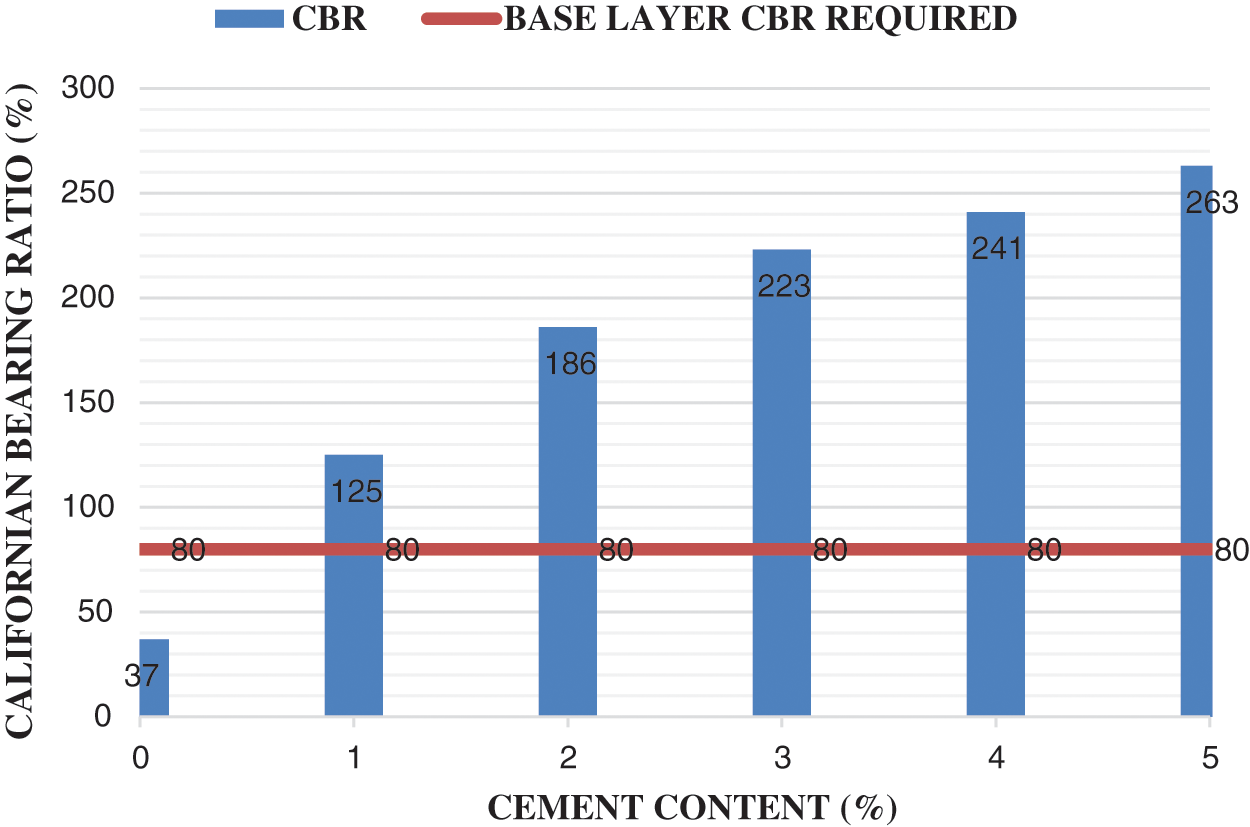

Behavior of the CBR Bearing Index as a Function of the Cement Dosage

As the aim of the hydraulic binder treatment is to improve the mechanical performance of the lithostabilized material, it is necessary to evaluate the evolution of the CBR index according to the cement dosage. The optimal dosage can then be chosen. The results obtained are illustrated in Fig. 7.

Figure 7: Evolution of CBR as a function of cement dosage

The CBR index evolves proportionally to the cement dosage. This is due to the action of cement on the soil. Indeed, cement stabilizes the material, binds the grains together and thus allows to obtain a more resistant skeleton; hence the evolution of the CBR index.

According to the CEBTP 1984 specifications, the CBR index of the material must be higher than 80 (or 60 if the traffic is low). With a cement dosage of 1%, these requirements are met. However, simple compression and diametrical compression tests will have to be carried out to choose the final optimal dosage.

To promote the valorization of the crushed sand 0/5, while taking into account the economic aspect, the works were directed towards the techniques of formulation of materials based on bars soil by addition of granular correctors. This formulation thus enabled us to carry out several mixtures, based on bars soil and crushed 0/5 of Dan.

The different phases carried out then allow, through the analysis of the mechanical requirements to be satisfied, to judge the possibility of valorizing developed materials in road construction. Thus, we can conclude that: (i) bar sand (clayey sand) cannot be used alone as a road base, (ii) crushed sand 0/5 cannot be used alone as a pavement base course, (iii) its lithostabilization with crushed sand 0/5 can be used as a foundation layer, (iv) the addition of the hydraulic binder improves the lithostabilized composite and can be used as a base layer and (v) the realization of roads based on clayey sand composite seems possible even if developments are still necessary.

Acknowledgement: We thank the staff of the GREENMAT Laboratory of the University of Liege, the LEMA Laboratory of the University of Abomey Calavi and finally the Geotechnical Laboratory of Research on Construction Materials of the Ecole Supérieure des Travaux Publics (ESITC) in Caen, France.

Funding Statement: We extend our sincere thanks to the Academy of Research and Higher Education (ARES) of Belgium, which financed this research in the framework of the exceptional scholarship for a doctorate in co-supervision between the University of Abomey Calavi and the University of Liège.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Ahouet, L., Elenga, R. G., Bouyila, S., Ngoulou, M., Kengue, E. (2019). Amélioration des propriétés géotechniques du graveleux latéritique par ajout de la grave alluvionnaire concassée 0/31, 5. Revue RAMReS – Sciences Appliquées et de l’Ingénieur, 3(1), 1–6. [Google Scholar]

2. Azontonde, A. (1993). Degradation and restoration of bar land (ferrallitic soils with low desaturation and sandy clay) in Benin. Cahiers ORSTOM. Série Pédologie, 28, 10. DOI 10.1068/p5900. [Google Scholar] [CrossRef]

3. Benbaqqal, H., Masrour, A., Mahjoubi, R., Benyassine, E. M., Erragragui, M. et al. (2017). Contribution of the geotechnical, mineralogical and geochemical study for the valorization of sand quarries in the meknes region (Maroc). European Scientific Journal, 13(24), 101. DOI 10.19044/esj.2017.v13n24p101. [Google Scholar] [CrossRef]

4. Cerema (2008). Treatment of soils with lime and/or hydrolic binders. Technical Guide: Ed Cerema (ex-Setra). https://www.cerema.fr/fr/centre-ressources/boutique/technical-guide-treatment-soils-lime-andor-hydrolic-binders. [Google Scholar]

5. Centre de Recherches Routières (2004). Guide pratique : Stabilisation des sols pour couches de sous-fondation. https://pdfcoffee.com/download/guide-pratique-stabilisation-de-sol-1-pdf-free.html. [Google Scholar]

6. Ebrahim Abu El-Maaty Behiry, A. (2013). Utilization of cement treated recycled concrete aggregates as base or subbase layer in Egypt. Ain Shams Engineering Journal, 4(4), 661–673. DOI 10.1016/j.asej.2013.02.005. [Google Scholar] [CrossRef]

7. Fédération de l’industrie extractive (2009). Traitement de sols et recyclage de terres à la chaux. https://docplayer.fr/20787223-Traitement-de-sols-et-recyclage-de-terres-a-la-chaux.html. [Google Scholar]

8. Fennis, S. A. A. M. (2011). Design of ecological concrete by particle packing optimization. Tese (Doutorado em Engenharia CivilDelft University of Technology, Holanda, 2011, 256. http://repository.tudelft.nl/view/ir/uuid:5a1e445b-36a7-4f27-a89a-d48372d2a45c/. [Google Scholar]

9. Ferber, V. (2005). Sensibilité des sols fins compactés à l’humidification. Apport d’un modèle de microstructure (PhD Thèse). École Centrale de Nantes et Université de Nantes, France. [Google Scholar]

10. Gbaguidi, V. S., Kiki, Y. T., Zankpe, M., Vedogbeton, N. (2018). Identification of the strata of lateritic soils and alterites in Benin. International Journal of Advanced Research, 6(9), 282–293. DOI 10.21474/IJAR01/7673. [Google Scholar] [CrossRef]

11. CEBTP Guide (1984). CEBTP guide–Pavement Design for Tropical Countries.pdf. [Google Scholar]

12. Hadidane, H., Oucief, H., Merzoud, M., Djebbari, Z., Hadidane, H. et al. (2015). Contribution to the improvement of road behaviour by the use of slag. [Google Scholar]

13. Kiki, S. Y. T. (2016). Mineralogical, thermal and m croscopic characterization of fine soils in road engineering (PhD Thesis). University of Bordeaux, France. [Google Scholar]

14. Laibi, A. B., Gomina, M., Sorgho, B., Sagbo, E., Blanchart, P. et al. (2017). Physicochemical and geotechnical characterization of two clay sites in Benin for their valorization in eco-construction. International Journal of Biological and Chemical Sciences, 11(1), 499. DOI 10.4314/ijbcs.v11i1.40. [Google Scholar] [CrossRef]

15. Mohamadreza, M. (2015). The optimization of concrete mixtures for use in highway applications (Master Thesis). University of Wisconcin-Milwaukee, USA. [Google Scholar]

16. National Lime Association (2004). Lime-treated soil construction manual: Lime stabilization & lime modification. [Google Scholar]

17. Zdiri, M., Neji, J., Ben Ouezdou, M., Elouni, M.R. (2005). Formulation et simulation des bétons compactés au rouleau: Applications aux matériaux de gisement locaux. CMEDIMAT Conference, Oran, Algeria. [Google Scholar]

18. Slansky, M. (1962). Contribution to the geological study of the coastal sedimentary basin of Dahomey and Togo. In: Technip (Ed.Bureau of geological and mining research, vol. 11. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |