| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.022165

ARTICLE

Characterization of the Omni-Processor Sewage Sludge Ash for Reuse as Construction Material

1LE3PI of E S P-UCAD, Dakar, Senegal

2LGCGM of INSA of Rennes, Rennes, France

*Corresponding Author: Prince Momar Gueye. Email: princemomar.gueye@insa-rennes.fr

Received: 23 February 2022; Accepted: 28 April 2022

Abstract: Omni Processors (OP) are machines which use sludge as a fuel to generate electricity and clean water, but create ash at the same time. In the present study, fly ash and bottom ash are investigated as materials for potential reuse in the construction field. First, the granular size, density and Blaine finesse are determined. Then, the chemical composition and microstructure are obtained by means of X-ray fluorescence and Scanning Electron Microscopy-Energy Dispersive Spectroscopy (SEM-EDS), respectively. Finally, ashes reactivity is determined by two chemical methods (modified Chapelle test, bound water content R3) and a mechanical method (pozzolanic activity index). The characterization results indicate two material types: fly ash similar to cement and bottom ash similar to fine sand. That’s why the mortars mechanical strength with fly ash 0%-30% is better than that with bottom ash at the same rate. Fly ash slightly decreases the mechanical strength of mortars while bottom ash induces a much more significant decrease.

Keywords: Characterization; Omni-processor; fly Ash; bottom ash

Nomenclature

| CVOP | Cyclone ash of Omni-processor |

| CFOP | Bottom ash of Omni-processor |

| OP | Omni-processor |

| | Apparent density, kg/m3 |

| | Absolute density, kg/m3 |

| Ssp | specific area, cm²/g |

| M | weight, kg |

| k | Blaine constant |

| ŋ | dynamic air viscosity |

| e | porosity |

| t | time s |

| v | volume en l |

Today a new method of waste management is being tested in Senegal by Bills and Melinda Gates Foundation. This method valorizes dry sludge thanks to Omni-Processor. OP is a machine which uses sludge as a fuel to generate electricity and clean water, but it creates ash at the same time. This ash must be managed to completely eradicate the waste in the environment. Previous studies have shown that sludge ash is mainly composed of silica, iron, calcium, alumina, magnesium oxide and phosphorus pentoxide [1–3]. This chemical composition confers it the potentiality to be valorized in the agriculture [4], in the chemistry [5], and in the construction [6]. While the presence of heavy metals traces slows down its valorization. Nevertheless, the use of ash in construction is encouraged because the cementitious matrix stabilizes heavy metals [7] and it reduces the consumption of cement, the solicitation of natural career as well as environmental pollution [8]. Minerals addition in the cementitious material is often known with coal ash or metakaolin [9,10]. In recent years, with the strong urbanization which increases the amount of sludge worldwide on the one hand and the gradual disappearance of coal power plants on the other hand, leads to many research works are invested in sludge ash valorization in cementitious materials [11–14]. Sewage sludge ash has been used as an alternative material to small diameter aggregates like sand and wire mesh in concrete [15–18]. In cement production sludge ash has been used as a raw material for clinker production or as a direct cement component [19–21]. In opposition to coal ash sludge ash has a wide variety depending on its origin, treatment and incineration system [22]. That is why sludge ashes characteristics are specific to each particular ash. A large review of sludge ash characterization has been done by Lynn et al. [23]. It was found that sludge ash specific gravity is generally in the range of 1800 kg/m3 to 2300 kg/m3 [24], and its average bulk density is 805 kg/m3 [25,26]. Grain size is identical to silt grain spindle and fine sand [27,28]. Blaine fineness is in the range of 500 m²/kg to 3900 m²/kg [29–31]. This large specific area is due to the irregular shape of the particles and the porosity of the microstructure [32–34]. Sludge ash loss on ignition is between 3.5% and 13% [35,36], and its mineralogical composition consisting mainly of quartz and hematite [20,37] as well as other low percentage oxides such as iron oxides, iron phosphate, calcium phosphate, aluminum phosphate. The P2O5 content influences C3S and C2S formation which are the main clinker components by reducing the rate of C3S/C2S and delays the cement setting [38–41]. Ash compatibility with cement matrix is due to its pozzolanic activity according to Donatello et al. [42]. Thus, it has been demonstrated that 10% substitution of cement by sludge ash does not change the characteristic strength of the cement [43]. The mechanical strengths obtained with 30% substitution of cement by sludge ash exceed control strength in the short time [44]. Other studies suggest that sludge ash reactivity depends to the particles thinness. This is the case of Monzó et al. [45] who reports a strength increase of mortars which are incorporated of small diameters ash (20 µm, 40 µm and 80 µm). Pan et al. [46] showed that the grinding time of sludge ash increases the mechanical strength of mortars with ash. On the other hand, Cyr et al. [47] observed a mechanical performance decrease of mortars containing ash, due to the presence of an oxide in crystalline form that hinders the pozzolanic activity of sludge ash. On the other hand, Cyr et al. [47] observed a decrease in the mechanical performance of mortars containing ash, due to the presence of an oxide in crystalline form which slows down the pozzolanic activity of the sludge ash. This study highlighted the characteristics of OP ash and their possibility of reuse in cementitious materials.

The materials used in this study are the ashes from the Omni-processor, the ashes are showed out in two types: an ash which coming from cyclone (Fig. 1a) and another ash from bottom (Fig. 1b).

Figure 1: a: Fly ash of Omni-processor. b: Bottom ash of Omni-processor

The sand used is a standardized silica sand (EN 196-1). A Portland cement CEM 1 52.5 R, is used.

2.2.1 Physicochemical Characterization

Density and porosity were measured in conformity with the French standards NF ISO 11272 and NF ISO 11508. First the bulk density was determined by measuring a mass of sample contained in 500 ml test tubes, flowing Eq. (1). The experiment was repeated 3 times.

Then the absolute density is defined as the ratio of the mass of the sample to the absolute volume of sample. For this measurement, a dry sample was weighed (m2) and introduced into a pycnometer half full of water and the pycnometer was filled with demineralized water and weighed (m1). Finally, the pycnometer was emptied, filled only with demineralized water and weighed (m2). The real density (ρ) is given as the ratio of the mass of the dry sample (m) to the volume of liquid displaced by that mass, according to Eq. (2).

Thus, the porosity of the material will be deduced from the apparent and absolute densities by Eq. (3).

The specific area of Blaine was determined using the Blaine permeabilimeter NF196-6. It means to determine the time of air passage through a compacted layer of the material and with the Eq. (4) we can calculate the specific area.

Ash grain size was measured with a Cilas particle size analyser 1064 laser granulometer. It allows to measure fine particles generally lower than 500 µm. A suspension of the sample in a solution is necessary to realise the test. A portable XRF device Niton XLT900s was used to analyze the chemical composition of the sludge ashes in terms of major and minor elements.

2.2.2 Reactivity and Microstructure

Chapel Test

It makes it possible to determine the pozzolanic activity of a material. 1 g of ash was mixed with 2 g of CaO in the presence of H2O for 16 H at a temperature of 90°C.

Bound Water R3

R3 pastes were cured at 40°C in sealed plastic containers for 7 days. They were then placed again in the oven at 105°C for 24 h and cooled in a desiccator after 2 h. The cooled hydrated sample is finally heated to 350°C for 2 h.

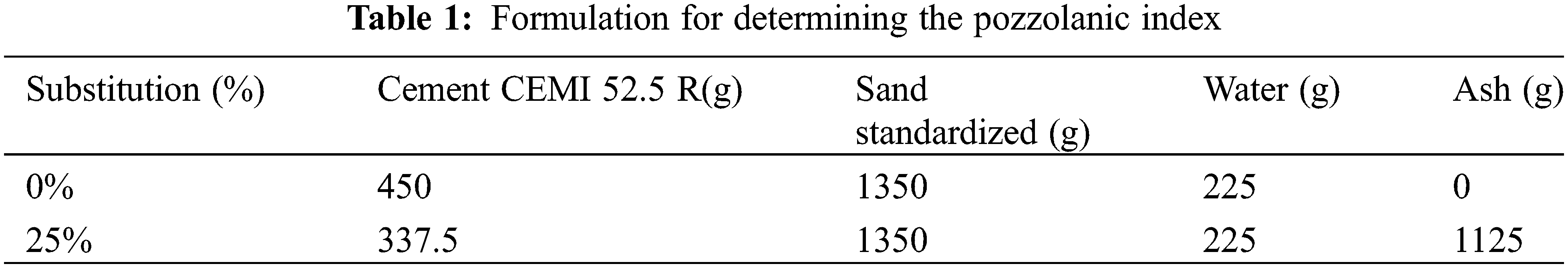

Pozzolanic Activity Index

Pozzolanic activity index was determined according to ASTM C618. It is the substitution of 25% of cement by ash. The Table 1 gives the formulation used to determine the pozzolanic activity.

Microstructure

Ashes were viewed under a scanning electron microscope to determine particle morphology and microstructure.

2.2.3 Mechanical Characterization

Composition of the standard mortar according to the standard (EN 196-1) was adopted. The water/binder ratio (w/b) is equal to 0.5 and the sand/cement ratio is equal to 3. In all, seven different mortars were produced, a control mortar containing no ash and mortars containing 10%, 20% and 30% ash as a substitute for Portland cement. Prismatic specimens 40 mm × 40 mm × 160 mm were made and then stored in a humid room at 20°C and 97% relative humidity. Flexural and compressive strength of each formulation was measured at 7, 28, 90 and 365 days of curing, using a Controlab press with a loading rate of 0.05 KN/s for flexure and 2.4 KN/s for compression.

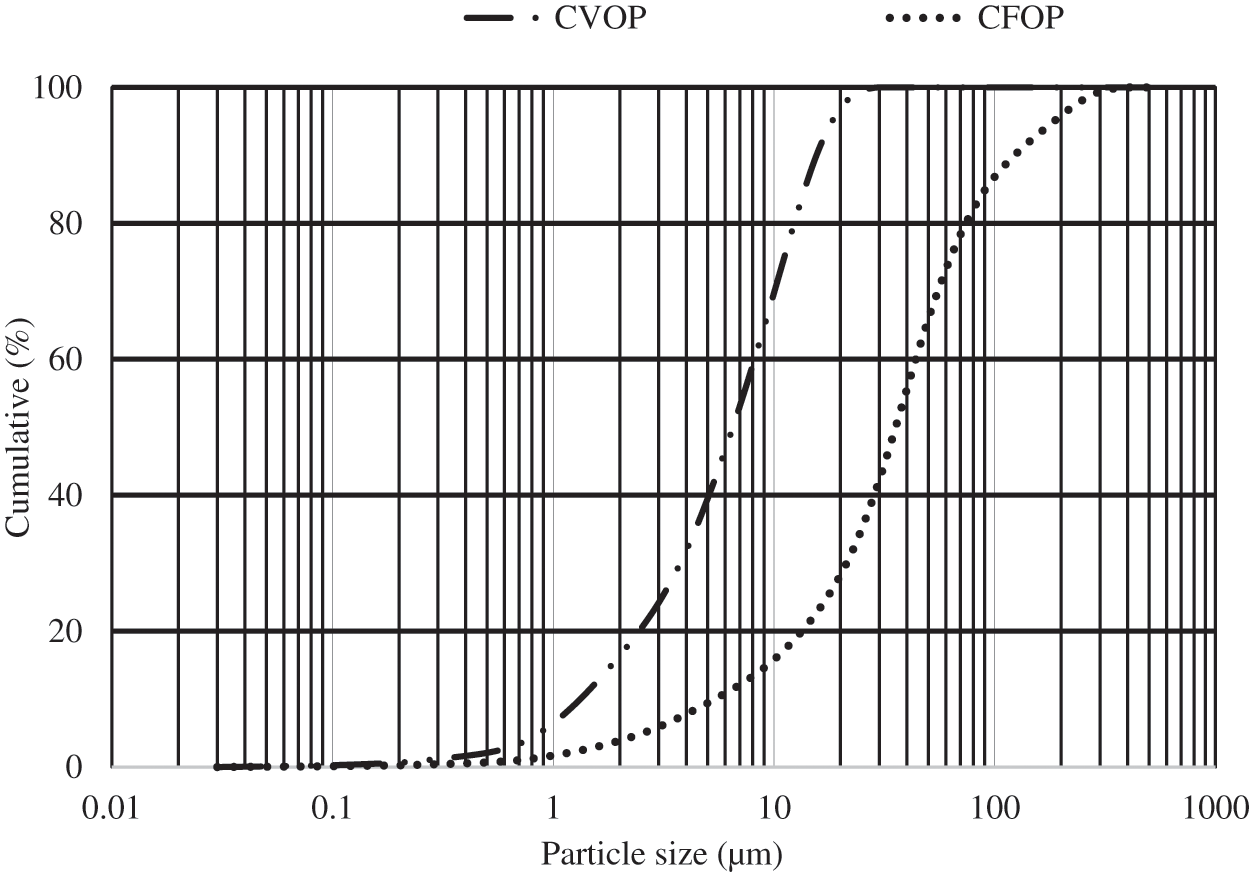

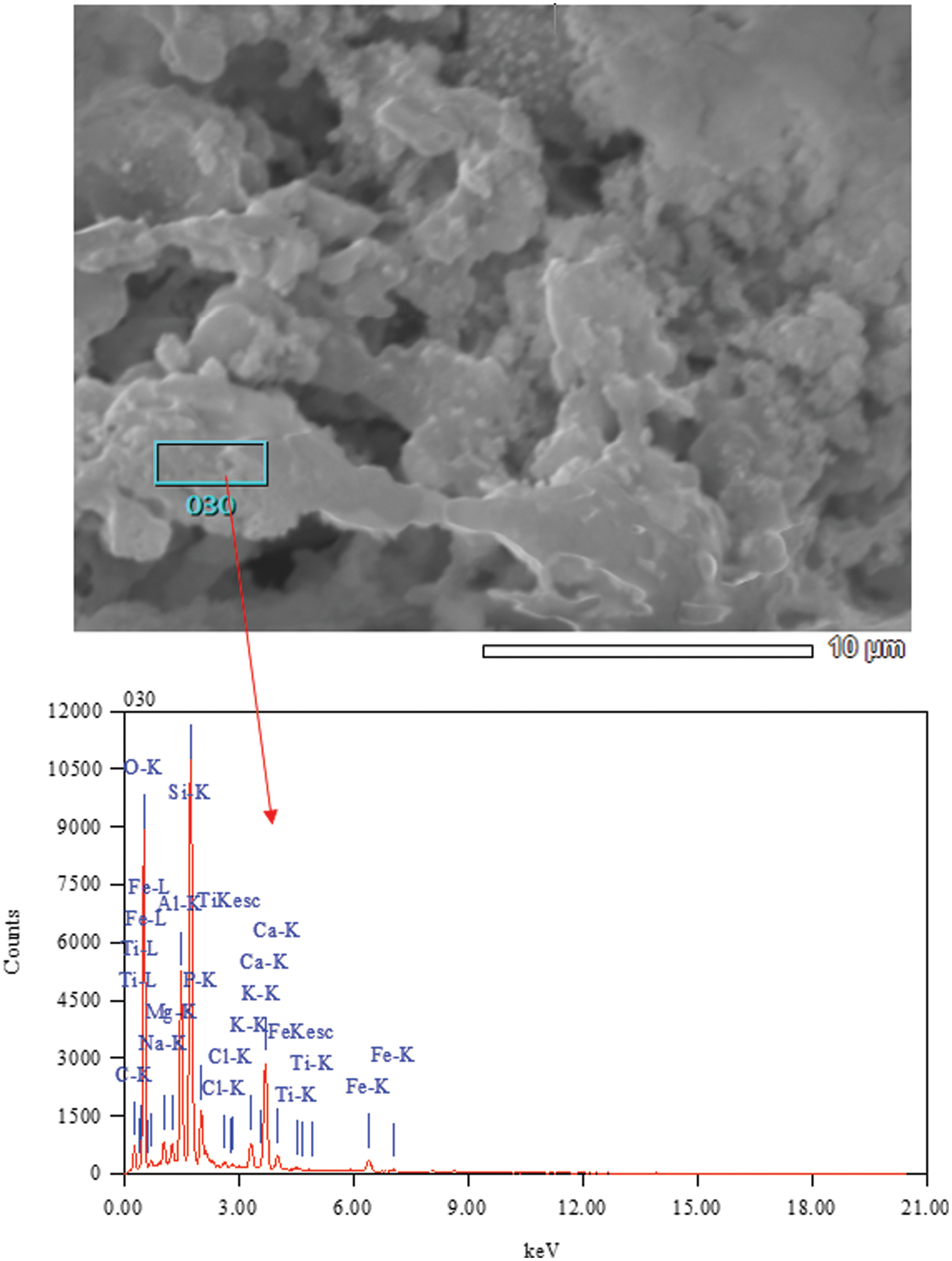

The granular distributions of the two typical of ash are shown in Fig. 2. OP fly ash ranges from 0 to 30 µm with an average diameter of 7 µm and OP bottom ash ranges from 0 to 400 µm with an average diameter of 36 µm.The particle size analysis reveals two materials types, CVOP can be assimilated to cement which has an average diameter of 10 µm while CFOP is similar to silt and fine sand as indicated by the literature. The shape of the particle size curves shows that the bottom ash is more spread out (tighter) than the fly ash (uniform) which can affect the bulk density. Thus, in Table 2, the bulk density of bottom ash is higher than that of fly ash. On the other hand, the absolute density of both ashes is almost identical because it is the same material. The difference in bulk densities makes the fly ash more porous than the bottom ash. The Blaine fineness is three times higher for the fly ash. Indeed, the fineness of a material participates in the reactivity.

Figure 2: Distribution of ashes particles size

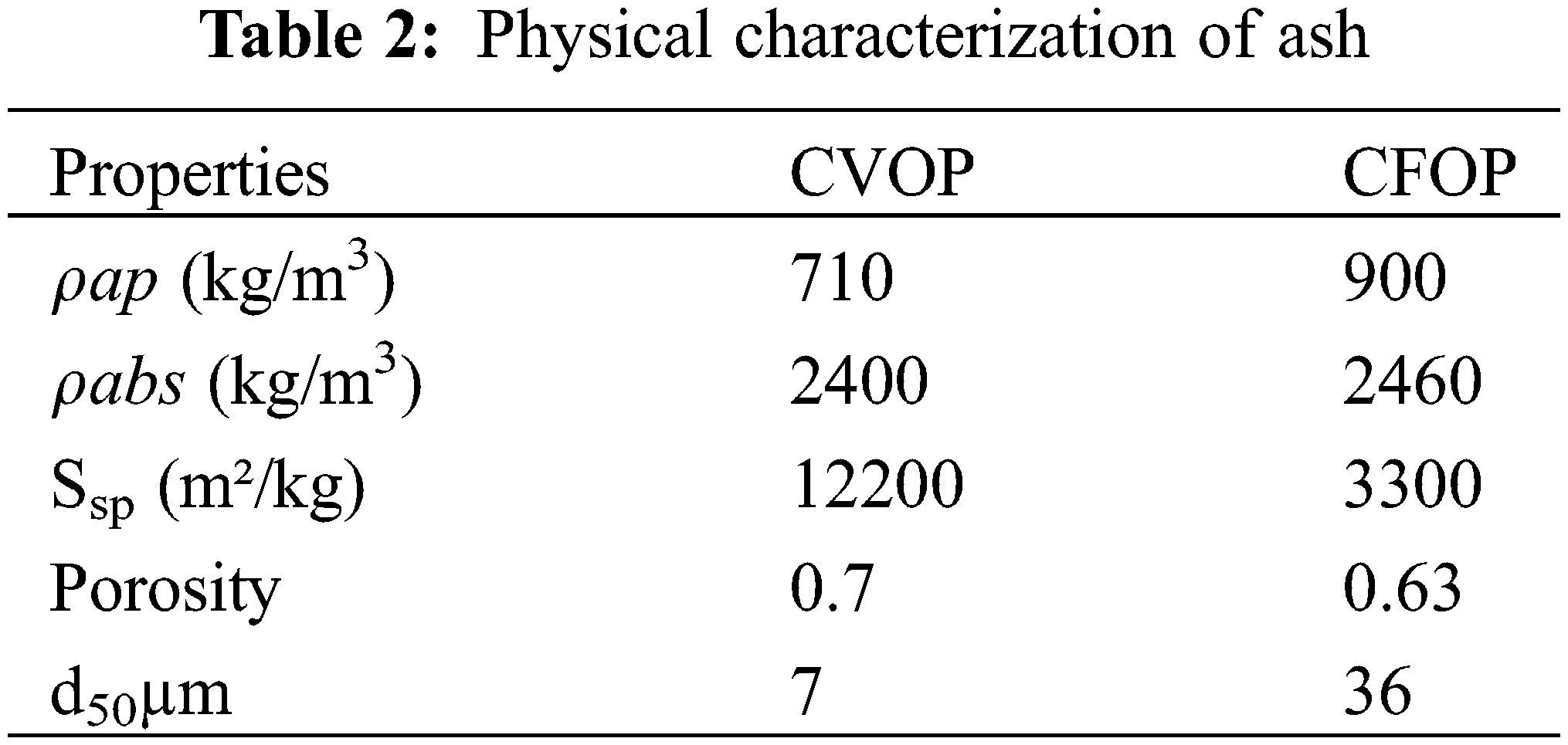

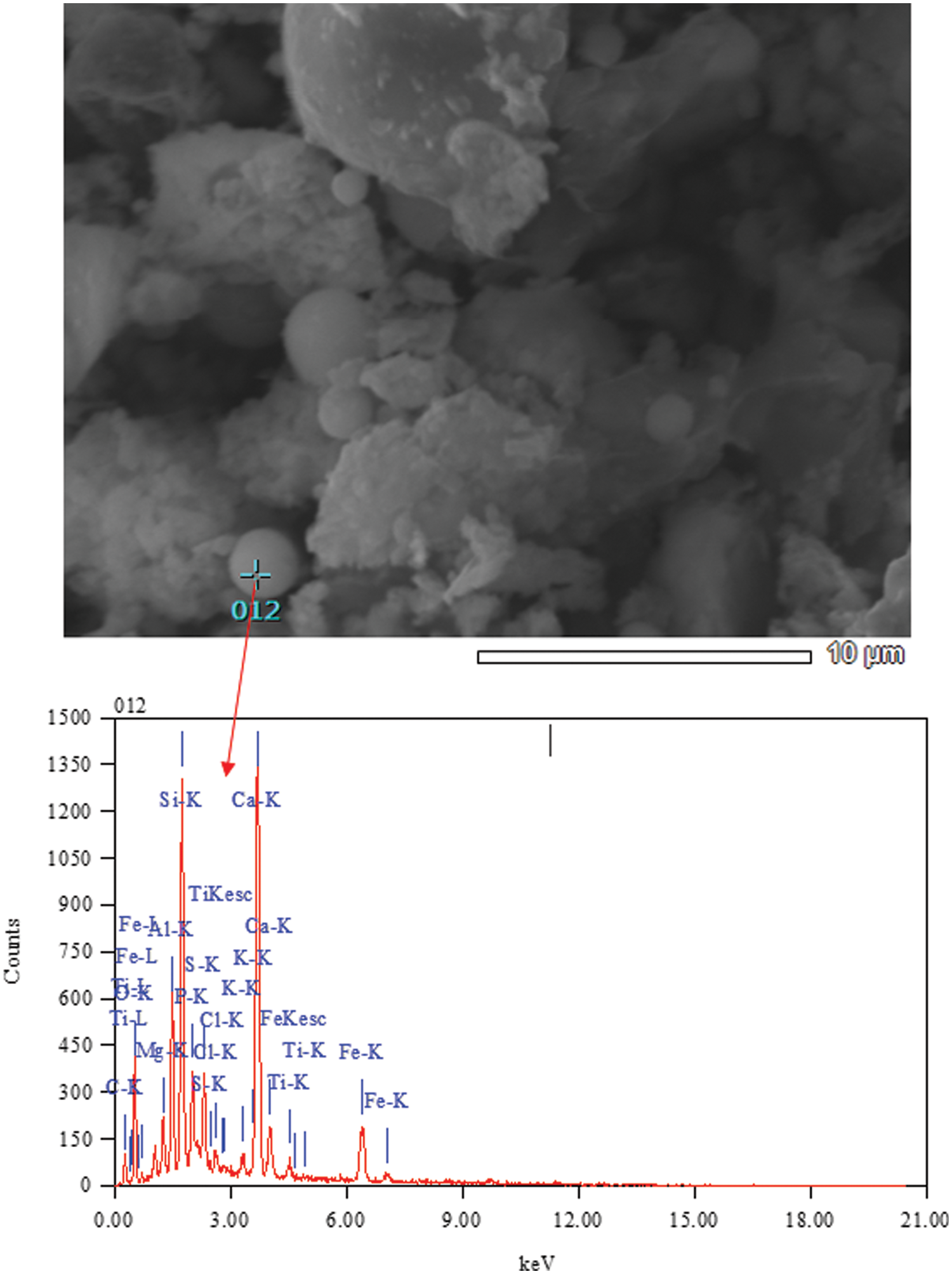

3.2 SEM and Chemical Composition of Ash

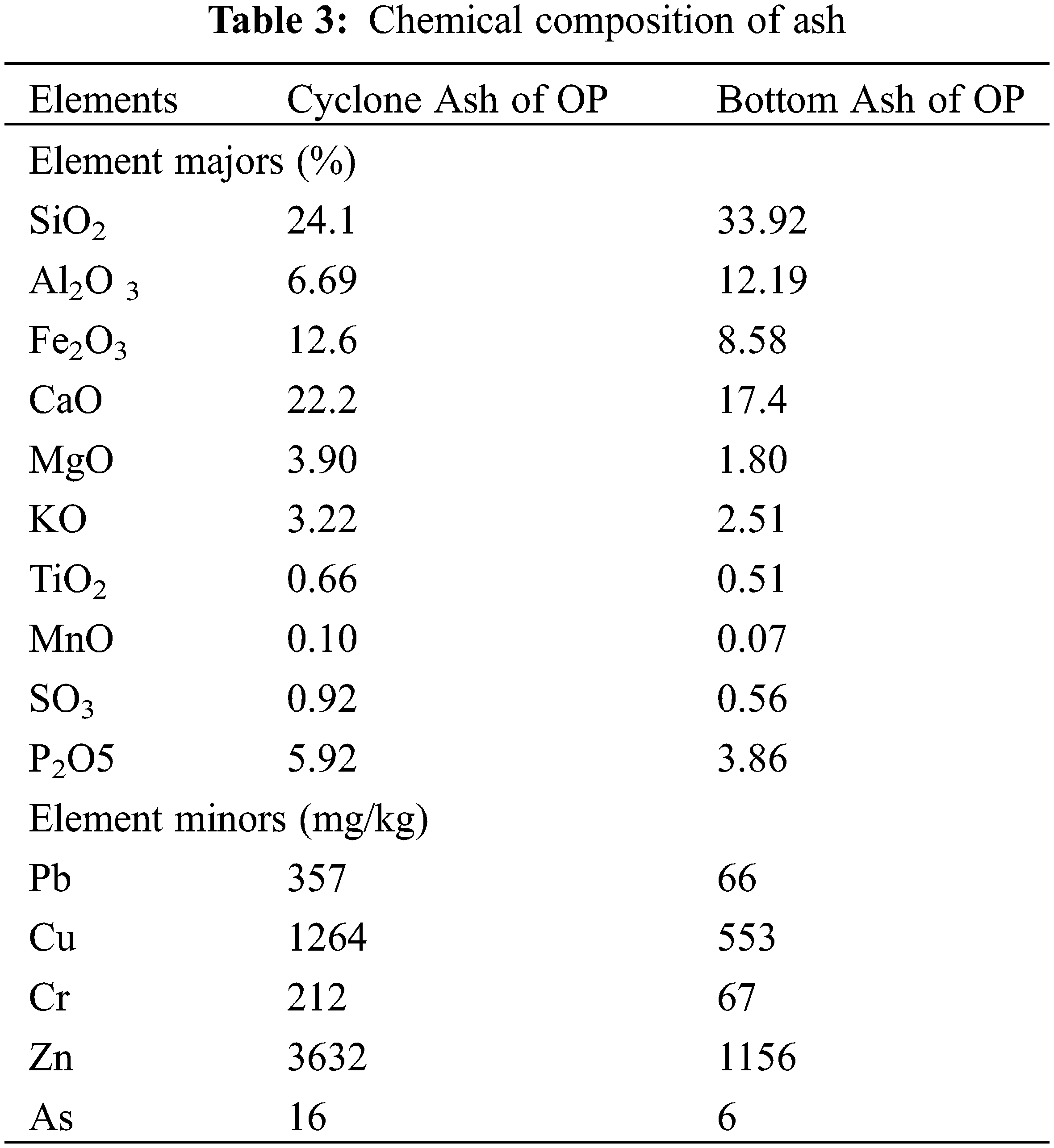

Scanning electron microscope images of ashes show that the fly ash is composed of both spherical and irregular particles (Fig. 3) while the bottom ash is composed primarily of irregular particles (Fig. 4). In Table 3, we can see that the sum of the pozzolanic agents SiO2, Al2O3 and Fe2O3 is 43.39 for the cyclone ash and 54.69 for the bottom ash. These values are less than 70% of the material. This means that the material is not pozzolanic according to ASTM C618. The content of P2O5 and Zn content can also delay the setting of sewage sludge ash incorporated materials. The presence of sulphate can be a concern if dissolution is slow as it can cause delayed ettringite formation.

Figure 3: Picture of fly ash obtained by SEM

Figure 4: Picture bottom ash obtained by SEM

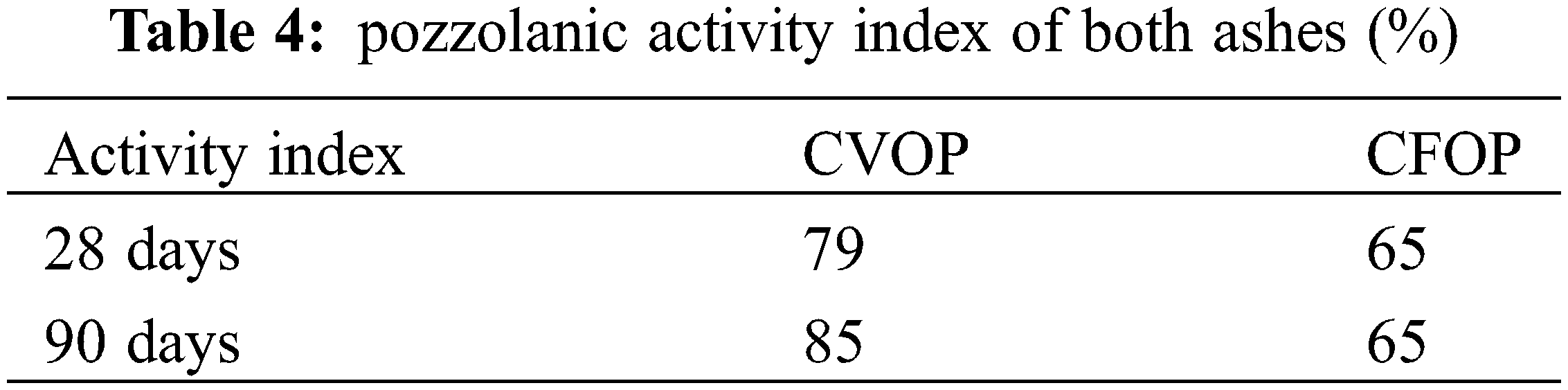

To appreciate the pozzolanic activity of the ashes two chemical and a mechanical method were adopted. The lime amount fixed by the material gives information on reactivity. For this purpose, Chapelle test modified NF (P18-513) was used to determine the lime consumption of OP ashes. The results obtained by this test are in identical with those obtained previously, as a weak pozzolanic reaction is observed, with 280 mg Ca(OH)2 fixed by 1 g of fly ash and 165 mg Ca(OH)2 fixed by 1 g of bottom ash. The small quantities fixed show that the material is not pozzolanic according to Chapelle. Given that modified Chapelle test is not consistent with the mechanical results of mortars and concrete, the R3 bound water content was realized. The results of bound water shown by this R3 test are also similar to usual ash bound water. The amount of bound water in the bottom ash is slightly higher than the fly ash, with 6% compared to 4%. These results show that bottom ash contains more alumina and silica than fly ash. It is similar of chemical results. This is in perfect harmony with the previous results. To support the chemical results which shown a low pozzolanic reaction potential, we assessed pozzolanicity by the mechanical method. In Table 4 we can see pozzolanic activity of the ashes at 28 days and 90 days. The activity index of fly ash from OP increases over time, whereas activity index of the bottom ash no longer changes after 28 days. The results show that the omni-processor ashes are not a pozzolanic material according to the EN 450-1.

3.4 Mechanical Properties of Mortars with OP Ashes

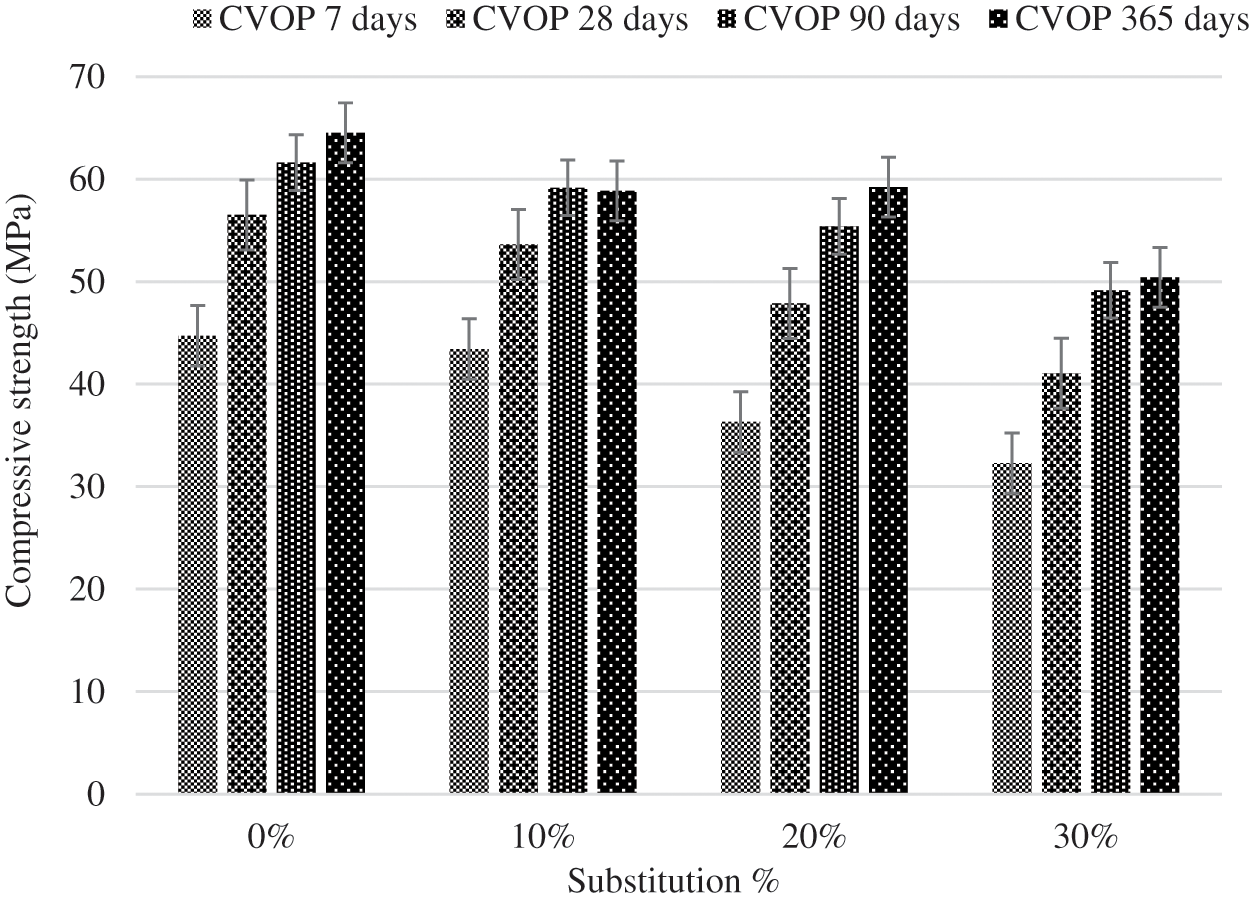

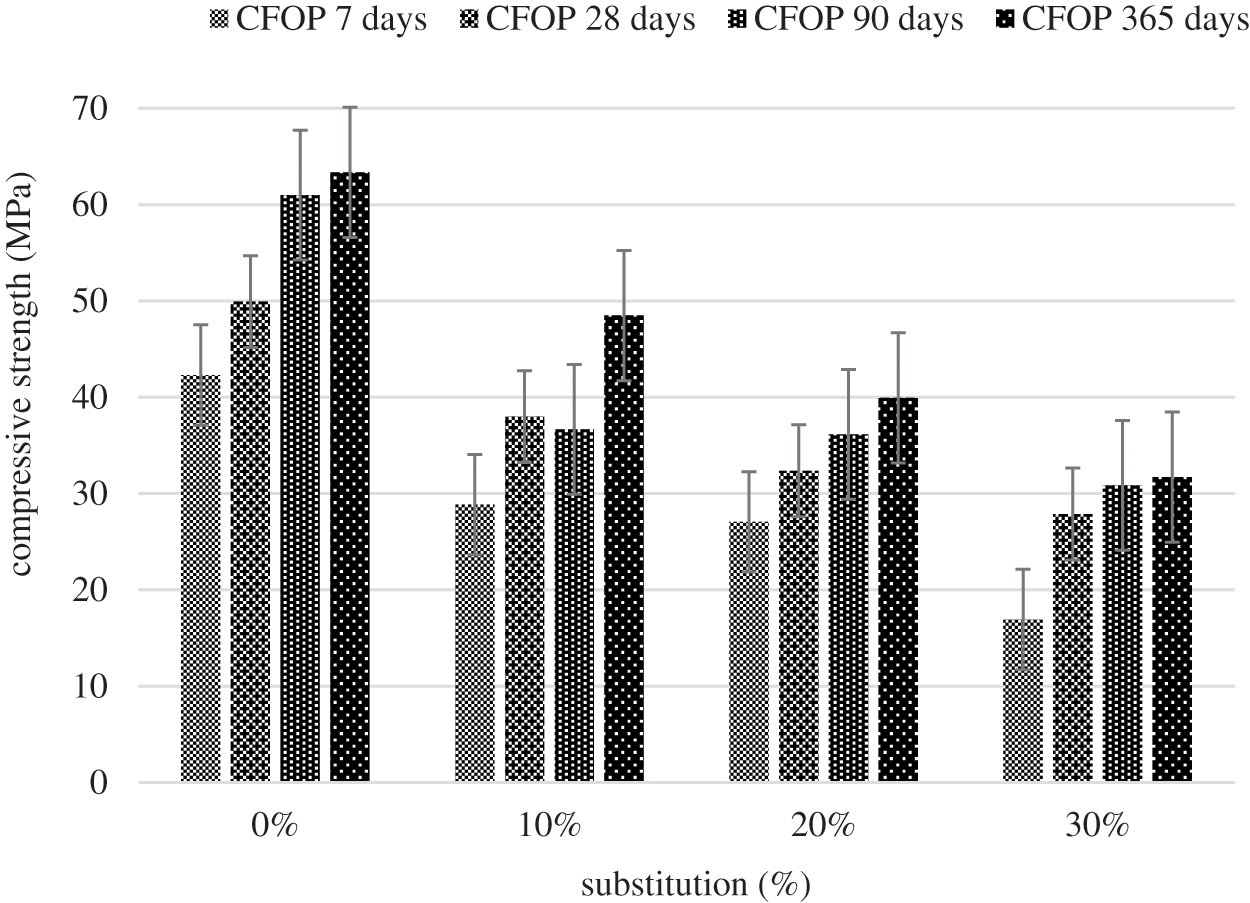

As the mechanical characterization of the binder is obtained with standardized mortar, we made 40 mm × 40 mm × 160 mm mortar specimens with different substitution rates. The results of control mortar and mortar with ash replace pertially cement are given in Figs. 5 and 6. We can see that compressive strength increase with age at the control mortar as well as mortars with ash partially replace cement. The compressive strength decreases when substitution rate increase. This regression is more remarkable in mortars which cement is substituted by bottom ash. This results can be explained by physical characteristics of bottom ash and pozzolanic activity of fly ash. By extending the curing time sufficiently long, the difference between the strength of mortars with fly ash and the control sample is insignificant. The phenomenon can be related to the slight pozzolanic activity of Omni-processor fly ash.

Figure 5: Compressive strength of mortars with fly ash

Figure 6: Compressive strength of mortar with bottom ash

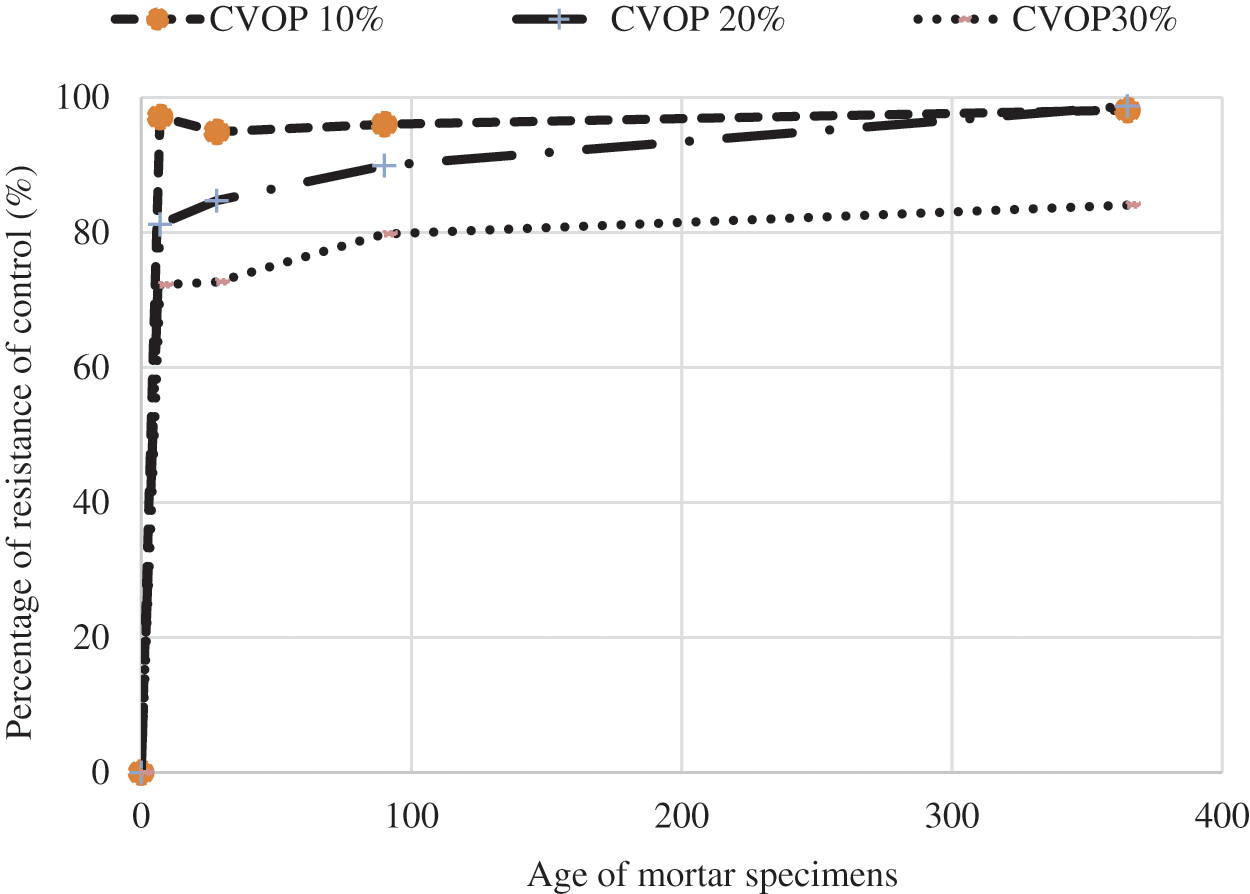

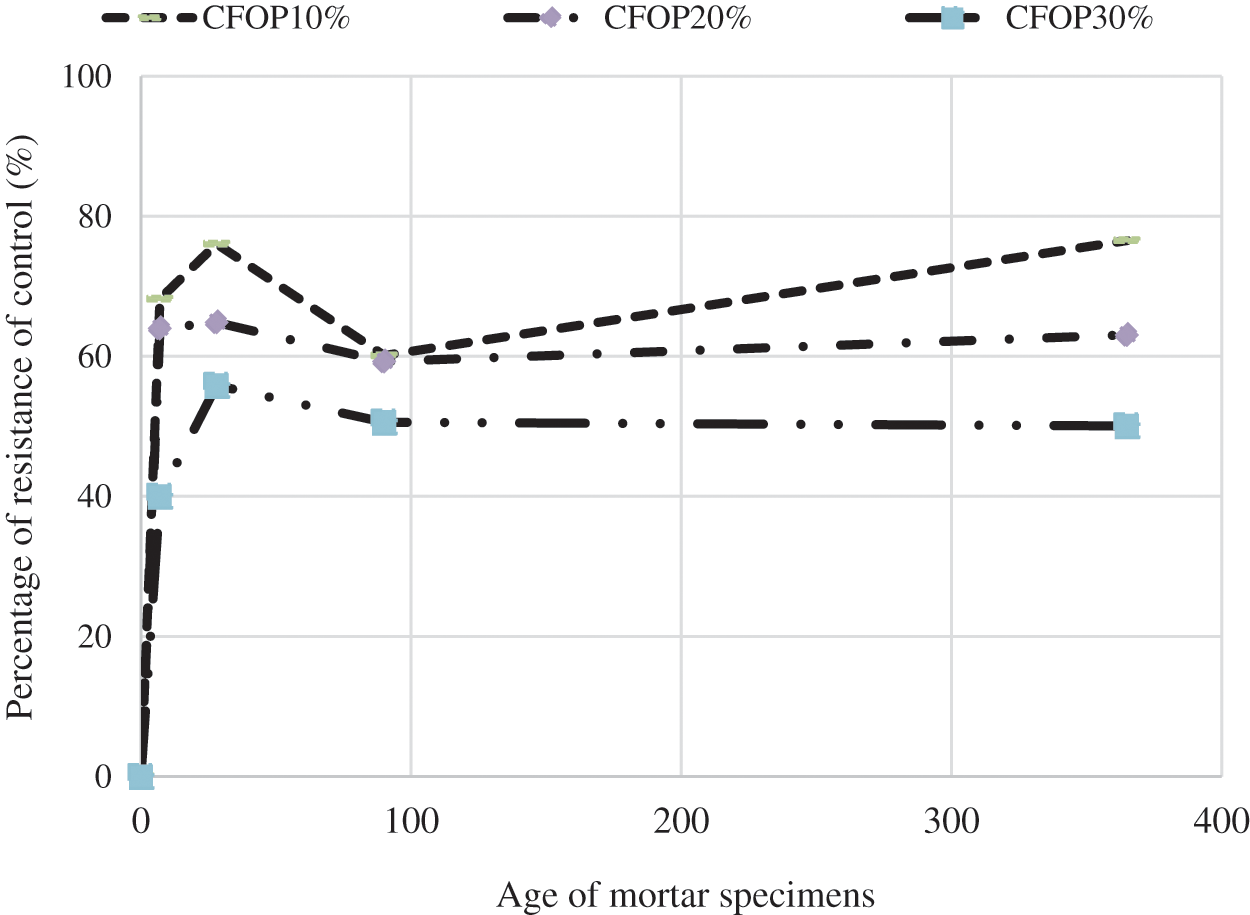

3.4.2 Relative Resistances of Mortars

In order to better evaluate the effect of the substitution rate on the strength of the standardized mortar, the compressive strength ratio of the mortar with ash on the strength of the control mortar at a given age is calculated. The evolution of this ratio is plotted in Figs. 7 and 8. These results show that the substitution of 10% cement by fly ash slightly reduces the compressive strength. This decrease lowered over time. At 365 days, the 10% fly ash mortar has a resistance identical to that of the control mortar. At 20% this decrease is more important at a young age but becomes null at 365 days. At 30%, the decrease in resistance is more significant but remains moderate compared to the substitution rate. Indeed, at 30% substitution with fly ash, a 20% loss of resistance compared to the control at 90 days is calculated against a 16% loss at 365 days. The evolution of the relative strength of mortars with bottom ash indicates a significant drop in strength generated by this addition (Fig. 8). In fact, as soon as 10% of cement is replaced by bottom ash, a drop in strength of more than 20% is observed at a young age and in the long term. Substitutions of 20 and 30% result in mechanical performance losses of 40% and 50% compared to the control.

Figure 7: Evolution over time of the ratio compressive strength of mortar with cyclone ash/compressive strength of control mortar

Figure 8: Evolution over time of the ratio compressive strength of mortar with bottom ash/compressive strength of control mortar

The results of characterizations show a difference between fly ash and bottom ash. They have the same chemical element, fly ash is finer than bottom ash and has a slight pozzolanic activity. Pozzolanic activity of fly ash is better than that for bottom ash. Mechanical results show that the use of bottom ashes of Omni-processor in a standard mortar as partial substitution of Portland cement decreases compressive strength. If the curing time is sufficiently long, the difference between the strength of mortars with fly ash and the control sample is insignificant. In perspective, it would be interesting to complete the characterization with DRX and ATG tests of ashes as well as some chemical elements which are harmful in cementitious materials.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Merino, I., Arévalo, L. F., Romero, F. (2005). Characterization and possible uses of ashes from wastewater treatment plants. Waste Management, 25(10), 1046–1054. DOI 10.1016/j.wasman.2004.12.023. [Google Scholar] [CrossRef]

2. Monzό, J., Payá, J., Borrachero, M. V., Girbés, I. (2003). Reuse of sewage sludge ashes (SSA) in cement mixtures: The effect of SSA on the workability of cement mortars. Waste Management, 23(4), 373–381. DOI 10.1016/S0956-053X(03)00034-5. [Google Scholar] [CrossRef]

3. Corella, J., Toledo, J. M. (2000). Incineration of doped sludges in fluidized bed. Fate and partitioning of six targeted heavy metals. І. Pilot plant used and results. Journal of Hazardous Materials, 80(1–3), 81–105. [Google Scholar]

4. Mattenberger, H., Fraissler, G., Jöller, M., Brunner, T., Obernberger, I. et al. (2010). Sewage sludge ash to phosphorus fertiliser (IIInfluences of ash and granulate type on heavy metal removal. Waste Management, 30(8–9), 1622–1633. DOI 10.1016/j.wasman.2010.03.037. [Google Scholar] [CrossRef]

5. Franz, M. (2008). Phosphate fertilizer from sewage sludge ash (SSA). Waste Management, 28(10), 1809–1818. DOI 10.1016/j.wasman.2007.08.011. [Google Scholar] [CrossRef]

6. Cyr, M., Coutand, M., Clastres, P. (2007). Technological and environmental behavior of sewage sludge ash (SSA) in cement-based material. Cement and Concrete Research, 37(8), 1278–1289. DOI 10.1016/j.cemconres.2007.04.003. [Google Scholar] [CrossRef]

7. Chen, M. (2012). Faisabilité technique et environnementale de l’utilisation dans des matériaux de construction cimentaires de cendres d’incinération de boues de station d’épuration. 2012, INSA Lyon France. [Google Scholar]

8. Yadav, S., Agnihotri, S., Gupta, S., Tripathi, R. K. (2014). Incorporation of STP sludge and fly ash in brick manufacturing: An attempt to save the environment. International Journal of Advancements in Research & Technology, 5(3), 138–144. DOI 10.15327/ijoart.2014.05.001. [Google Scholar] [CrossRef]

9. Kurama, H., Kaya, M. (2008). Usage of coal combustion bottom ash in concrete mixture. Construction and Build Materials, 22(9), 1922–1928. DOI 10.1016/j.conbuildmat.2007.07.008. [Google Scholar] [CrossRef]

10. Singh, N., Arya, M. M. S. (2019). Utilization of coal bottom ash in recycled concrete aggregates based self-compacting concrete blended with metakaolin. Resources Conservation & Recycling, 144, 240–251. [Google Scholar]

11. Deja, J., Antosiak, B. (2012). Degree of progress of the fly ash reaction in alkali-activated fly-ash binders. Cement Lime & Concrete, 79(17), 67–76. [Google Scholar]

12. Rutkowska, G., Wichowski, P., Fronczyk, J., Franus, M., Chalecki, M. (2018). Use of fly ashes from municipal sewage sludge combustion in production of ash concretes. Construction and Building Materials, 188, 874–883. DOI 10.1016/j.conbuildmat.2018.08.167. [Google Scholar] [CrossRef]

13. Chen, M., Blanc, D., Gautier, M., Mehu, J., Gourdon, R. (2013). Environmental and technical assessments of the potential utilization of sewage sludge ashes (SSAS) as secondary raw materials in construction. Waste Manage, 5(33), 1268–1275. DOI 10.1016/j.wasman.2013.01.004. [Google Scholar] [CrossRef]

14. Chen, Z., Poon, C. S. (2017). Comparative studies on the effects of sewage sludge ash and fly ash on cement hydration and properties of cement mortars. Construction and Building Materials, 154(9), 154791–154803. DOI 10.1016/j.conbuildmat.2017.08.003. [Google Scholar] [CrossRef]

15. Kosior-Kazberuk, M. (2011). Application of SSA as partial replacement of aggregate in concrete. Polish Journal Environmental Studies, 20(2), 365–370. [Google Scholar]

16. de Lima, J. F., Ingunza, D., Del Pilar, M. (2015). Effects of sewage sludge ash addition in Portland cement concretes. International Conference on Civil, Materials and Environmental Sciences,London, UK. [Google Scholar]

17. Jamshidi, M., Jamshidi, A., Mehrdadi, N., Pacheco-Torga, F. (2012). Mechanical performance and capillary water absorption of sewage sludge ash concrete (SSAC). International Journal of Sustainable Engineering, 5(3), 228–234. DOI 10.1080/19397038.2011.642020. [Google Scholar] [CrossRef]

18. Baeza-Brotons, F., Garces, P., Paya, J., Sava, J. M. (2014). Portland cement systems with addition of sewage sludge ash: Application in concretes for the manufacture of blocks. The Journal of Cleaner Production, 82(2014), 112–124. DOI 10.1016/j.jclepro.2014.06.072. [Google Scholar] [CrossRef]

19. Kikuchi, R. (2001). Recycling of municipal solid waste for cement production: Pilot-scale test for transforming incineration ash of solid waste into cement clinker. Resources Conservation Recycling, 31(2), 137–147. DOI 10.1016/S0921-3449(00)00077-X. [Google Scholar] [CrossRef]

20. Lam, C. H. K., Barford, J. P., Mckay, G. (2010). Utilization of Incineration waste ash residues in Portland cement clinker. Chemical Engineering Transactions, 21, 757–762. [Google Scholar]

21. Lin, K. L., Lin, C. Y. (2006). Feasibility of using ash from sludge incineration as raw materials for eco-cement. Journal of the Chinese Institute of Engineers, 16(1), 39–46. [Google Scholar]

22. Cieślik, B. M., Namieśnik, J., Konieczka, P. (2015). Review of sewage sludge management: Standards, regulations and analytical methods. Journal of Cleaner Production, 90, 1–15. DOI 10.1016/j.jclepro.2014.11.031. [Google Scholar] [CrossRef]

23. Lynn, C. J., Dhir, R. K., Ghataora, G. S., West, R. P. (2015). Sewage sludge ash characteristics and potential for use in concrete. Construction and Building Materials, 98, 767–779. DOI 10.1016/j.conbuildmat.2015.08.122. [Google Scholar] [CrossRef]

24. Merino, I., Arévalo, L. F., Romero, F. (2017). Preparation and characterization of ceramic products by thermal treatment of sewage sludge ashes mixed with different additives. Waste Management, 27(12), 1829–1844. DOI 10.1016/j.wasman.2006.10.008. [Google Scholar] [CrossRef]

25. Tay, J. H., Show, K. Y. (1992). Utilization of municipal wastewater sludge as building and construction materials. Resources, Conservation and Recycling, 6(3), 191–204. DOI 10.1016/0921-3449(92)90030-6. [Google Scholar] [CrossRef]

26. Tay, J. H. (1987). Sludge ash as filler for Portland cement concrete. Journal of Environmental Engineering, 113(2), 345–351. DOI 10.1061/(ASCE)0733-9372(1987)113:2(345). [Google Scholar] [CrossRef]

27. Donatello, S., Freeman-Pask, A., Cheeseman, C. R. (2010). Effect of milling and acid washing on the pozzolanic activity of incinerator sewage sludge ash. Cement Concrete Composite, 32(1), 54–61. DOI 10.1016/j.cemconcomp.2009.09.002. [Google Scholar] [CrossRef]

28. Donatello, S., Tong, D., Cheeseman, C. R. (2010). Production of technical grade phosphoric acid from incinerator sewage sludge ash (ISSA). Waste Management, 30(8/9), 1634–1642. DOI 10.1016/j.wasman.2010.04.009. [Google Scholar] [CrossRef]

29. Coutand, M., Cyr, M., Clastres, P. (2006). Use of sewage sludge ash as mineral admixture in mortars. Construction Materials, 159(4), 153–162. [Google Scholar]

30. Perez-Carrion, M., Baeza-Brotons, F., Paya, J., Saval, J. M., Zornoza, E. et al. (2013). Potential use of sewage sludge ash (SSA) as a cement replacement in precast concrete blocks. Materiales de Construcción, 64(313), e002. DOI 10.3989/mc.2014.06312. [Google Scholar] [CrossRef]

31. Lin, D. F., Lin, K. L., Luo, H. L., Cai, M. Q. (2008). Improvements of nano-SiO2 on sludge/fly ash mortar. Waste Management, 28(6), 1081–1087. [Google Scholar]

32. Morais, L. C., Dweck, J., Goncalves, E. M., Buchler, P. M. (2005). An experimental study of sewage sludge incineration. Environmental Technology, 27(9), 1047–1051. [Google Scholar]

33. Wang, L., Skjevrak, G., Hustad, J. E., Grønli, M. G. (2012). Sintering characteristics of sewage sludge ashes at elevated temperatures. Fuel Processing Technology, 96, 88–97. [Google Scholar]

34. Gil-Lalaguna, N., Sanchez, J. L., Murillo, M. B., Gea, G. (2015). Use of sewage sludge combustion ash and gasification ash for high-temperature desulphurization of different gas streams. Fuel, 141, 99–108. DOI 10.1016/j.fuel.2014.10.036. [Google Scholar] [CrossRef]

35. Merino, I., Arévalo, L. F., Romero, F. (2005). Characterization and possible uses of ashes form wastewater treatment plants. Waste Management, 25(10), 1046–1054. DOI 10.1016/j.wasman.2004.12.023. [Google Scholar] [CrossRef]

36. Monzo, J., Paya, J., Borrachero, M. V., Bellver, A., Peris-Mora, E. (1997). Study of cement-based mortars containing Spanish ground sewage sludge ash. Studies in Environmental Science, 71(1), 349–354. DOI 10.1016/S0166-1116(97)80217-8. [Google Scholar] [CrossRef]

37. Tantawy, M. A., El-Roudi, A. M., Abdalla, E. M., Abdelzaher, M. A. (2013). Fire resistance of sewage sludge ash blended cement pastes. Journal of Engineering, 2013(3), 1–7. DOI 10.1155/2013/361582. [Google Scholar] [CrossRef]

38. Lin, K. L., Lin, C. Y. (2004). Hydration properties of eco-cement pastes from waste sludge ash clinkers. Journal of the Air & Waste Management Association, 54(12), 1534–1542. DOI 10.1080/10473289.2004.10471011. [Google Scholar] [CrossRef]

39. Lin, K. L., Lin, C. Y. (2005). Hydration characteristics of waste sludge ash utilized as raw cement material. Cement Concrete Resources, 35(10), 1999–2007. DOI 10.1016/j.cemconres.2005.06.008. [Google Scholar] [CrossRef]

40. Lin, K. L., Chiang, K. Y., Lin, C. Y. (2005). Hydration characteristics of waste sludge ash that is reused in eco-cement clinker. Cement and Concrete Research, 35(6), 1074–1081. DOI 10.1016/j.cemconres.2004.11.014. [Google Scholar] [CrossRef]

41. Lin, K. L., Lin, D. F., Luo, H. L. (2009). Influence of phosphate of the waste sludge on the hydration characteristics of eco-cement. Journal of Hazardous Materials, 168(2–3), 1105–1110. DOI 10.1016/j.jhazmat.2009.02.149. [Google Scholar] [CrossRef]

42. Donatello, S., Tyrer, S., Cheeseman, C. R. (2010). Comparison of test methods to assess pozzolanic activity. Cement Concrete Composite, 32(2), 121–127. DOI 10.1016/j.cemconcomp.2009.10.008. [Google Scholar] [CrossRef]

43. Garcés, P., Pérez-Carrión, M., García-Alcocel, E., Payá, J., Monzó, J. et al. (2008). Mechanical and physical properties of cement blended with sewage sludge ash. Waste Management, 28(12), 2495–2502. [Google Scholar]

44. Fontes, C. M. A., Barbosa, M. C., Toledo Filho, R. D., Gonçalves, J. P. (2004). Potentiality of sewage sludge ash as mineral additive in cement mortar and high-performance concrete. International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona. [Google Scholar]

45. Monzó, J., Payá, J., Borrachero, M. V., Córcoles, A. (1996). Use of sewage sludge ash (SSA)-cement admixtures in mortars. Cement Concrete Resources, 26(9), 1389–1398. DOI 10.1016/0008-8846(96)00119-6. [Google Scholar] [CrossRef]

46. Pan, S. H., Tseng, D. H., Lee, C. C., Lee, C. (2003). Influence of the fineness of sewage sludge ash on the mortar properties. Cement Concrete Resources, 33(11), 1749–1754. DOI 10.1016/S0008-8846(03)00165-0. [Google Scholar] [CrossRef]

47. Cyr, M., Gilles, K., Simone, J., Pierre, C. (2003). Les cendres d’incinération de boues de stations de traitement des eaux polluées sont-elles utilisables dans les matrices cimentaires? Comparaison avec les cendres volantes de charbon. Environnement, Ingénierie & Développement, Episciences, 2003, N°29 - 1er Trimestre 2003, pp. 22–29. ff10.4267/dechets-sciences-techniques.2227. Revue francophone d’écologie industrielle, 29. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |