| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.022531

ARTICLE

Thermomechanical Characterization of a Bio-Sourced Material Based on Clay and Alfa Fibers

1EMDD_CERNE2D, Mohammed V University in Rabat, Higher School of Technology Salé, Salé, 11060, Morocco

2National School of Architecture Agadir, New Complex Ibn Zohr, Agadir, 80000, Morocco

*Corresponding Author: Sara Ibn-Elhaj. Email: sara_ibnelhaj@um5.ac.ma

Received: 14 March 2022; Accepted: 09 May 2022

Abstract: Bio-based materials are of great interest owing to their abundance and the immense potential they display as an ideal alternative to widely used industrial construction materials (that directly and indirectly harm the environment). In this scope, an in-depth experimental study is presented here on clay-based materials aimed to enhance their properties through the addition of other bio-based components such as fibers, in the present case alfa fiber. The thermal conductivity and mechanical properties (compressive and flexural tensile strengths) of the composite clay-alfa material are analyzed with the percentage of alfa fiber in the matrix ranging from 0% to 4%. It is concluded that a percentage of alfa fibers between 1% and 2% is the most effective to get the required optimization of thermal and mechanical behavior of this bio-based material.

Keywords: Hot plate method in a steady-state regime; clay; composite; mechanical; alfa fiber

Nomenclature

| λ | Thermal conductivity (W/m.K) |

| Φ | Heat flux (W) |

| Ktherm | Thermal dimensionless normalized parameter |

| Kcom | Normalized dimensionless parameter of compressive strength |

| Kflex | Normalized dimensionless parameter of flexural strength |

| Rmeasured | Thermal resistance (m².K/W) |

| Rcom,measured | Compressive strength (MPa) |

| Rflex,measured | Flexural strength (MPa) |

The construction industries are one of the largest energy-consuming sectors and it contributes significantly to environmental stress [1]. The building sector will continue to expand as the global population grows, by 2100 it will hit the staggering number of 11 billion [2]. In this context, the exploitation of bio-based construction materials is critical for reducing the environmental footprint of the construction industries.

One of the studied bio-based materials in recent years is clay. The growing interest in studying clay as a building material is due to its good physical properties, availability, and low environmental impact. However, the earth (clay) alone suffers from cracking, shrinkage, and low durability [3]. Several studies have focused on improving, stabilizing, and reinforcing the properties of soil blocks or bricks in order for it to be utilized as a durable construction material. Many types of additives were used with clay and studied experimentally. For example, a work by Mounir et al. [4] treated the thermal characterization of clay-wool composite using different percentages. Chaib et al. [5] worked on the improvement of the thermal characteristics of blocks using clay, dune sand, and date palm fibers by changing the percentages.

An extensive review of different types of natural fibers (such as leaf fibers, seed or fruit fibers, and wood fibers) with bio-composites and their different properties is conducted by Ramesh et al. [6], amongst many studies that demonstrate the importance of reinforcing bio-composite materials with bio-fibers.

In this perspective, our work consists of studying the thermal and mechanical properties of Alfa fiber which is a natural fiber. This type of fiber is used with clay to form a biomaterial based on clay and alfa plant.

For the thermo-mechanical characterization, the thermal conductivity is determined using the asymmetrical hot plate method on the composite clay-based material with alfa fiber percentages ranging from 0% to 4%. In addition to it, the compressive and flexural tensile strengths are obtained using a mechanical press. Then three dimensionless parameters are introduced in order to assess the best composition for a composite with good thermal and mechanical properties.

2 Description of the Experimental Approach

2.1 Description of the Materials Used

The materials used in this study are earth (clay) and Alfa fibers.

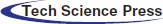

The soil used comes from Zahjouka in the region of Ksar El Kebir in the north of Morocco. The chemical analysis of this type of clay used is given in the table below (Table 1).

The Alfa’s scientific name is Stipa tenacissima L. The alfa fiber used in this study for its availability and low cost. Alfa fiber bundles are characterized by an average diameter of 113 μm (90–120 μm) and a density of 0.89 g/m3. The fibers are washed beforehand with water and air-dried for 72 h, then cut into 4 cm lengths.

The water used is the drinking water of the city of Salé. The amount of water needed to obtain a paste with normal consistency is:

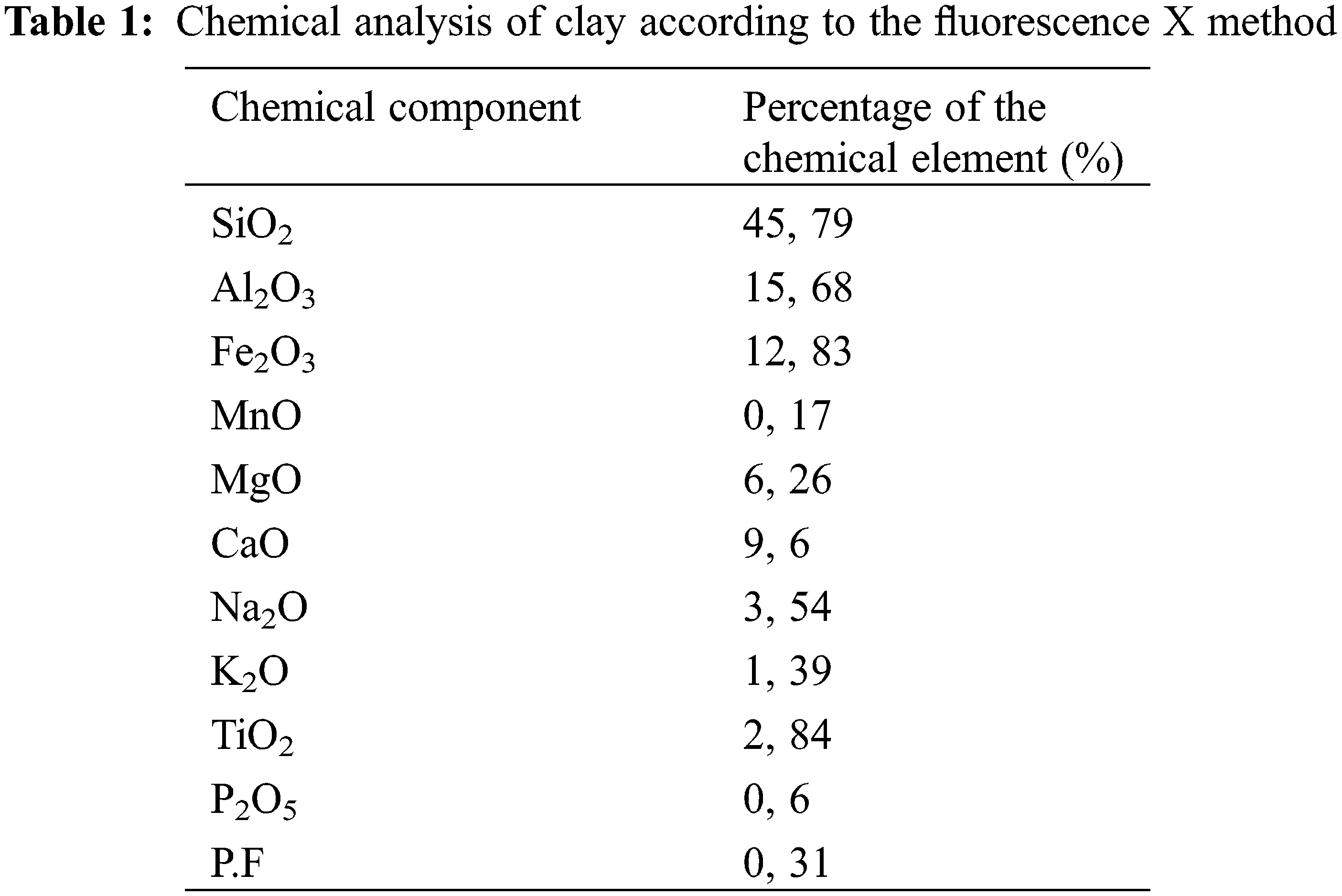

The unfired clay is mixed with water and several mass concentrations of the Alfa fiber (0.5%; 1%; 2%; 3%; 4%). After drying the soil in an oven for 24 h at 60°C, we measure the mass of the soil each time until it becomes constant. Then, it is mixed with water until the mixture becomes more manageable. Finally, the fibers are gradually added.

The mixture of clay and alfa fibers is transferred into molds that have the following shapes:

• Parallelepipeds: Dimensions of 10 cm × 10 cm × 2 cm to carry out the thermal tests (Fig. 1).

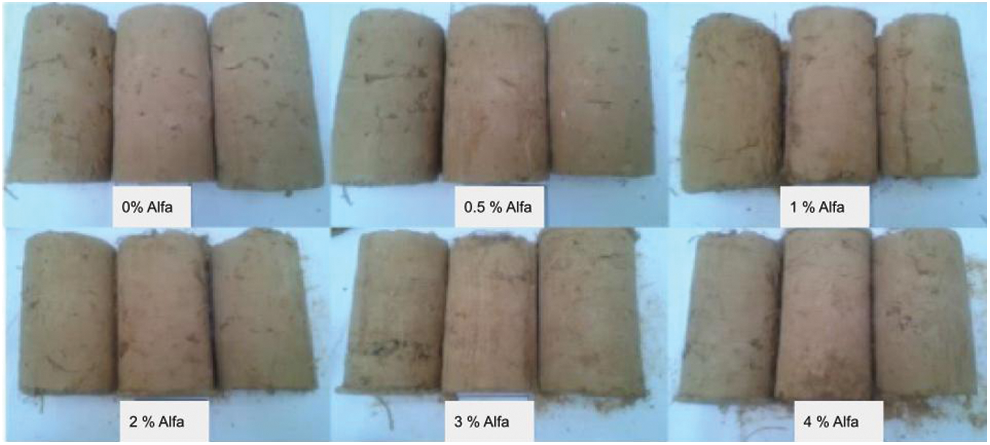

• Cylindrical: Of dimensions 11 cm × 22 cm to carry out the compression tests (Fig. 2).

• Prismatic: Of dimensions 4 cm × 4 cm × 16 cm to carry out the tests of flexion (Fig. 3).

Figure 1: Example of the parallelepiped samples

Figure 2: Example of cylindrical samples

Figure 3: Example of prismatic samples

The samples are then dried in a 60°C oven until they reach a constant mass.

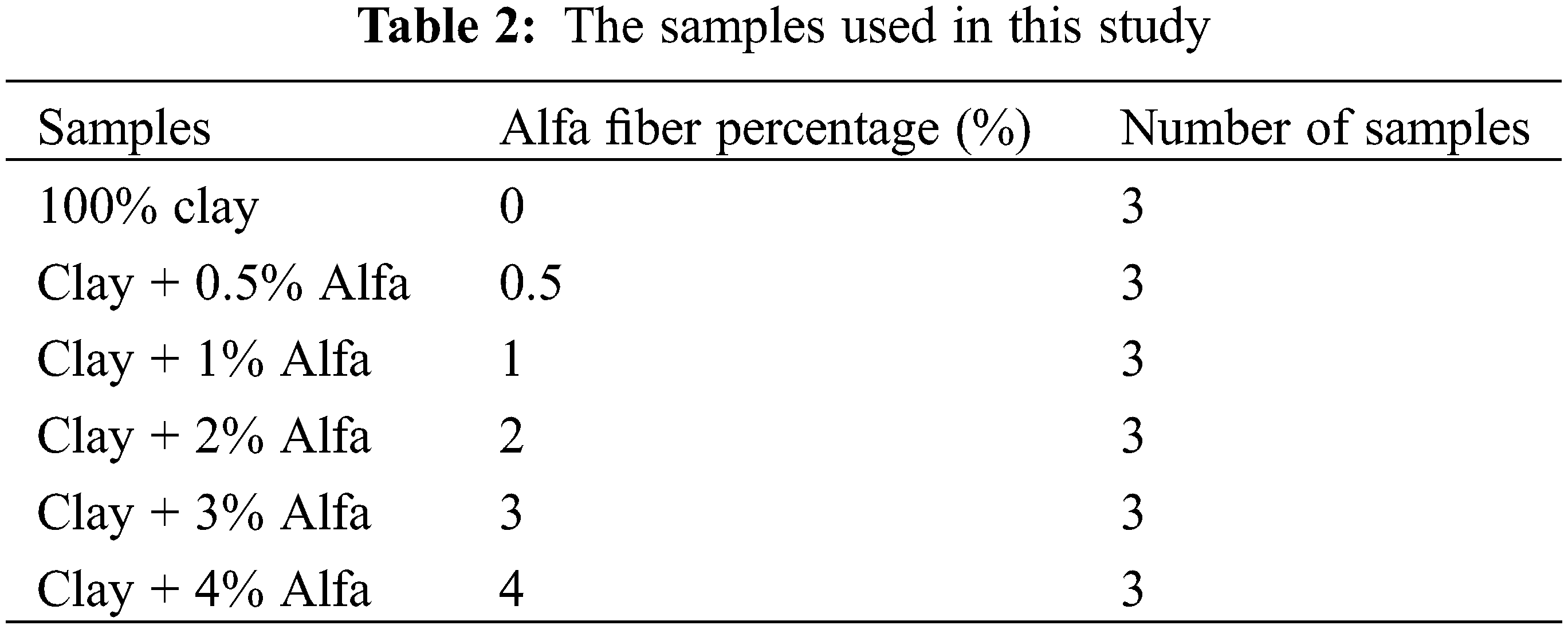

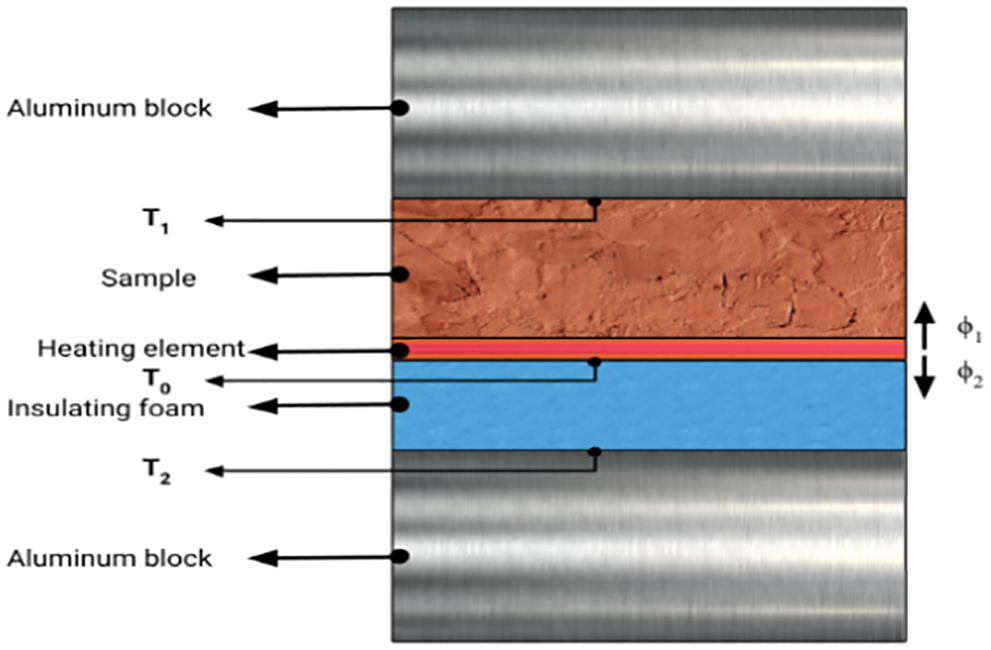

Table 2 lists the many samples developed for this research. Three samples are prepared and tested for each percentage of the alfa fibers in order to get accurate results.

The apparent densities of the samples may be calculated using the dry mass and dimensions of the samples (Table 3):

We observe that increasing the percentage of Alfa fibers decreases the density of the samples, allowing us to gain in terms of lightness.

The density of the sample containing 0% Alfa fibers is 2213.19 kg/m3, while the density of the sample containing 4% Alfa fibers is 1583.25 kg/m3. We have a gain in lightness of 28.46% between these two samples.

3.1 Measurement of the Thermal Conductivity of the Composite Clay/Alfa

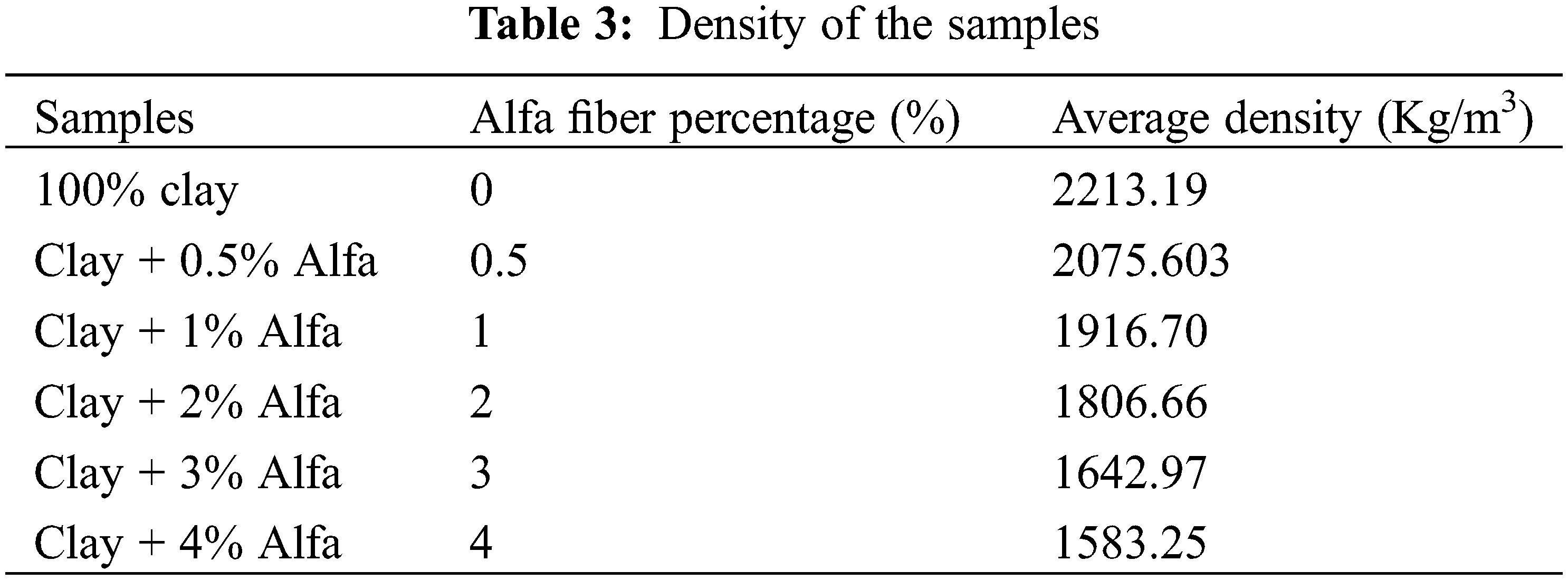

The thermal conductivity is determined using the asymmetric hot plate method in a steady-state regime [7–9].

We place the sample of dimensions 100 × 100 × 20 mm3 on a heating element. Below this heating element, an insulating foam of dimensions 10 × 100 × 100 mm3 and thermal conductivity λ2 = 0.04 W/m.K is placed. The system (heating element, sample, and insulating foam) is then placed between two 50 × 100 × 100 mm3 aluminum blocks to allow the system to reach thermal equilibrium as quickly as possible.

In order to measure the thermal conductivity of the sample, we need to measure using a thermocouple the temperature T0 at the center of the heated face of the sample, the temperature T1 at the center of the unheated face of the sample, and the temperature T2 at the center of the unheated face of the insulating foam. The following figure illustrates the method used (Fig. 4).

Figure 4: The asymmetric hot plate method in steady-state regime

We can write the following relations:

ϕ1 represents the heat flux passing through the sample, ϕ2 is the heat flux passing through the insulating foam, and ϕ is the total heat flux emitted by the heating element. λ1 and e1 are respectively the thermal conductivity and thickness of the sample to be characterized. λ2 and e2 are respectively the thermal conductivity and thickness of the insulating foam (λ2 = 0.04 W/m.K; e2 = 10 mm).

The heating element is an electrical resistance R dissipating a flux by Joule effect when the current (I) flows through under the effect of an electrical voltage (U), hence:

When combining the above equations, we find:

3.2 Measurement of the Compressive Strength of the Clay/Alfa Composite

We use a hydraulic press in order to determine the compressive strength. The cylindrical samples (110 mm × 220 mm) are centered between two mechanical plates (norm NF P 18 406).

3.3 Measurement of the Flexural Tensile Strength of the Clay/Alfa Composite

The tensile strength by bending is determined using the prismatic samples of 40 mm × 40 mm × 160 mm (norm NF P 18 407).

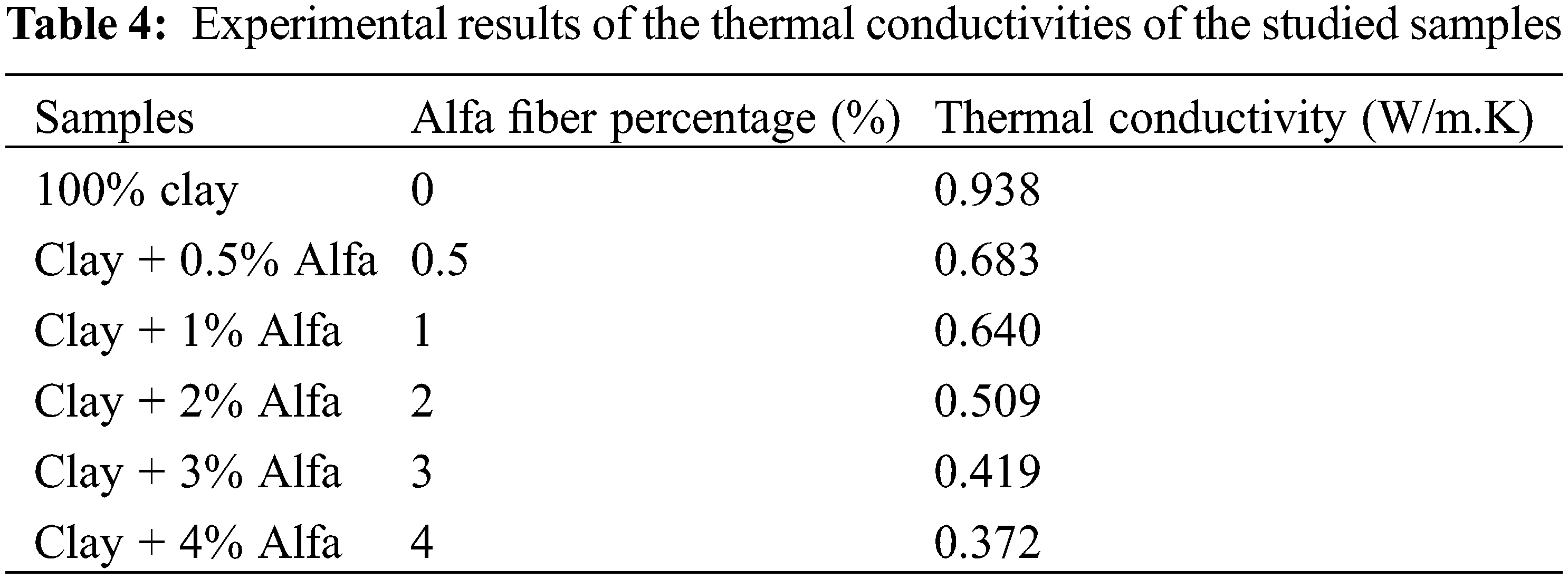

The following table shows the values of thermal conductivity determined using the asymmetric hot plate method in a steady state regime (Table 4).

The thermal conductivity of the composite decreases as the Alfa fiber content in the composite increases, as seen in the table. The thermal conductivity decreases from 0.938 W/m.K for the earth alone to 0.372 W/m.K for a percentage of 4% of Alfa fibers. There is a gain in terms of insulation.

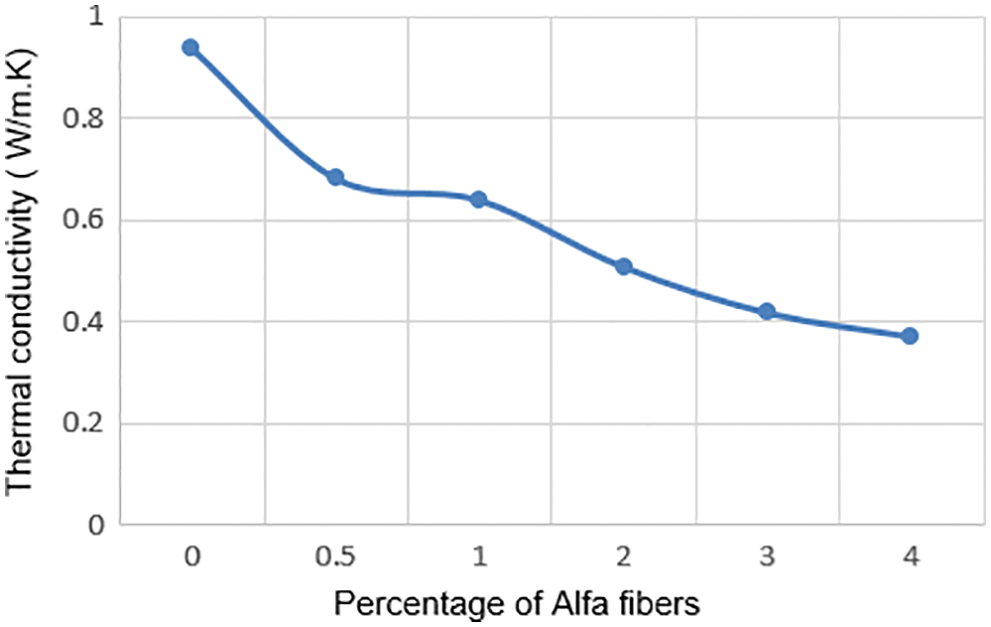

The results of thermal conductivity is interpreted in Fig. 5:

Figure 5: Thermal conductivity of different percentages of Alfa fiber

As demonstrated in Fig. 5, the thermal conductivity decreases with the increase of the percentage of Alfa fibers in the matrix. As shown in Table 3 above, the density decreases with the Alfa fiber percentage as well. This result is due the porosity caused by the Alfa fibers. Alfa fibers are highly porous due to the presence of numerous short and fine hairs within the leaves [10]. The increase of fibers in the clay matrix results in more pores. This explains the decrease of thermal conductivity and the density with the increase of Alfa fiber percentage, thus the improvement of lightness and insulation of the bio-composite.

The composite studied (clay-Alfa) is generally used for its thermal advantages. But it is required that the composite exhibits a minimum of mechanical properties as well because the material is subjected to the forces of its own weight and the loads it supports when it’s going to be used in the envelope of a building.

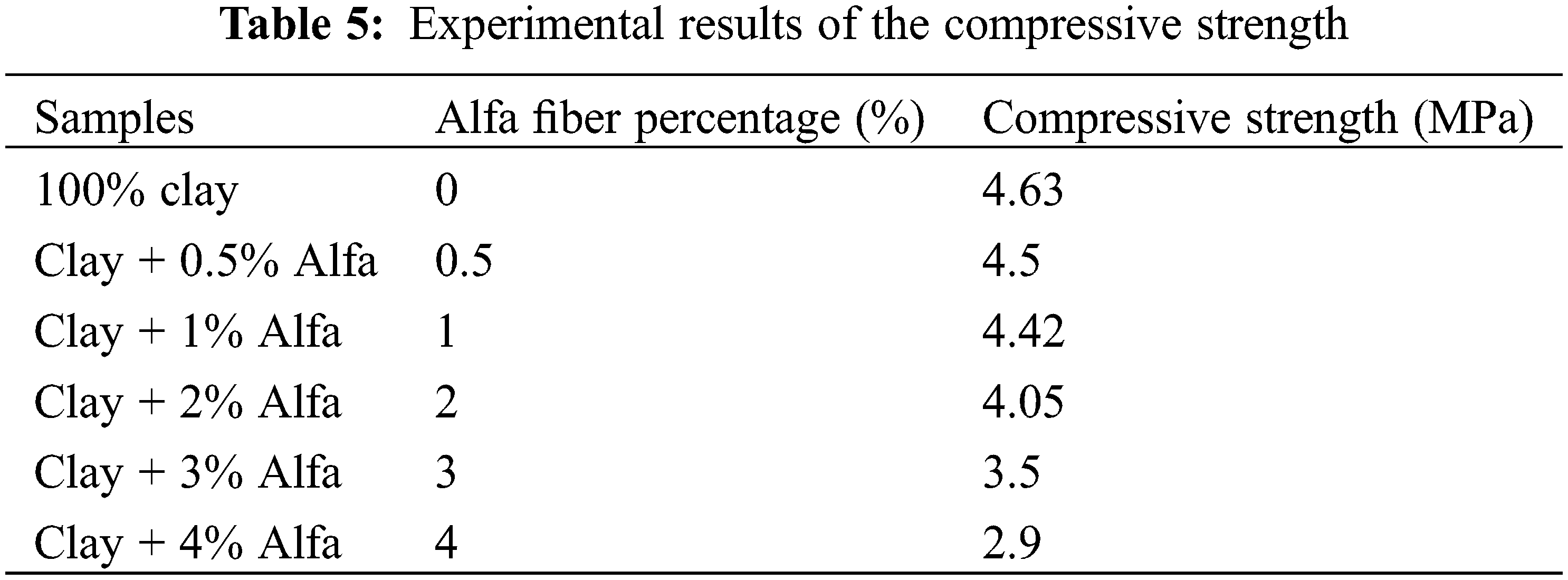

We will evaluate the compressive strength of the composite in addition to its flexural tensile strength. Table 5 presents the experimental results of the compressive strength:

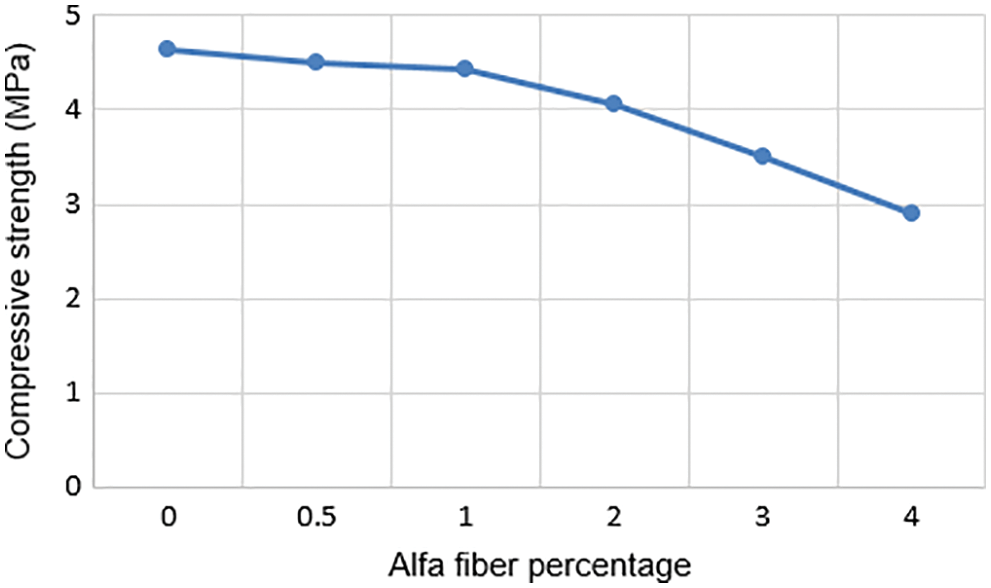

Fig. 6 illustrates the results found for the compressive strength:

Figure 6: Compressive strength of different percentages of Alfa fiber

We notice from Fig. 6 that the compressive strength is stable for samples with fiber percentages less than 1%. However, beyond the 1%, we note that there is a significant decrease in the compressive strength. Because of the heterogeneous dispersion of the fibers that could form clusters in the matrix when the percentage exceeds 1%. We can see that the incorporation of alfa fibers does not improve the mechanical compressive strength.

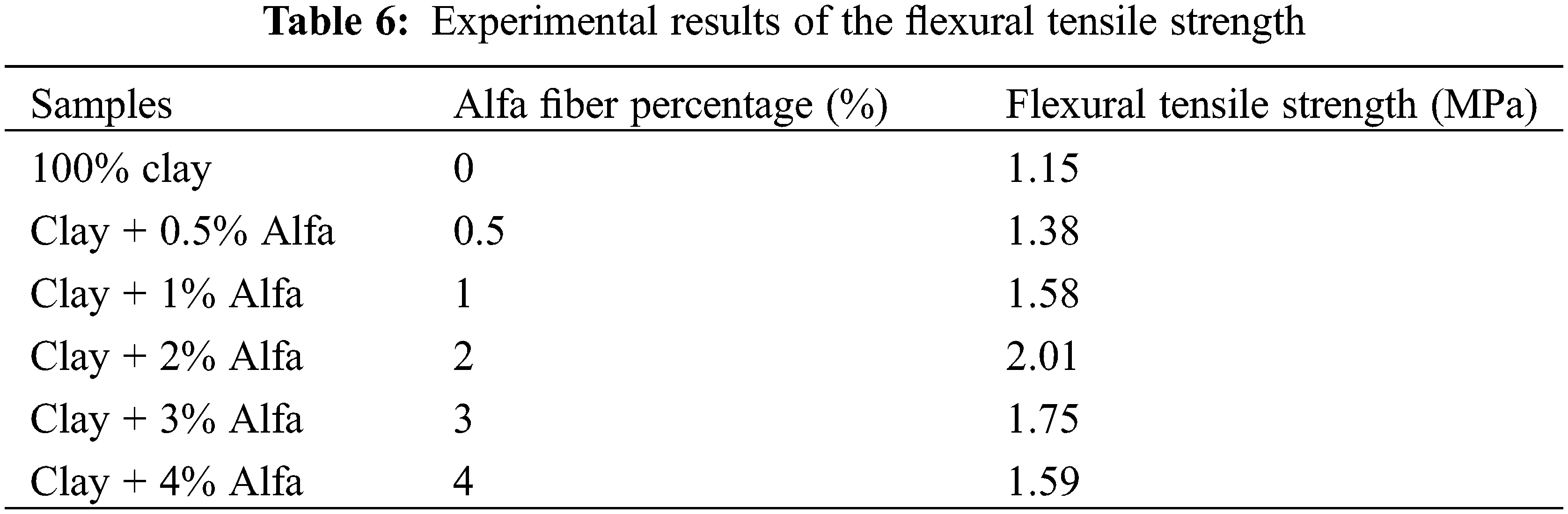

For the second mechanical property, we have the flexural tensile strength. The results are displayed in Table 6.

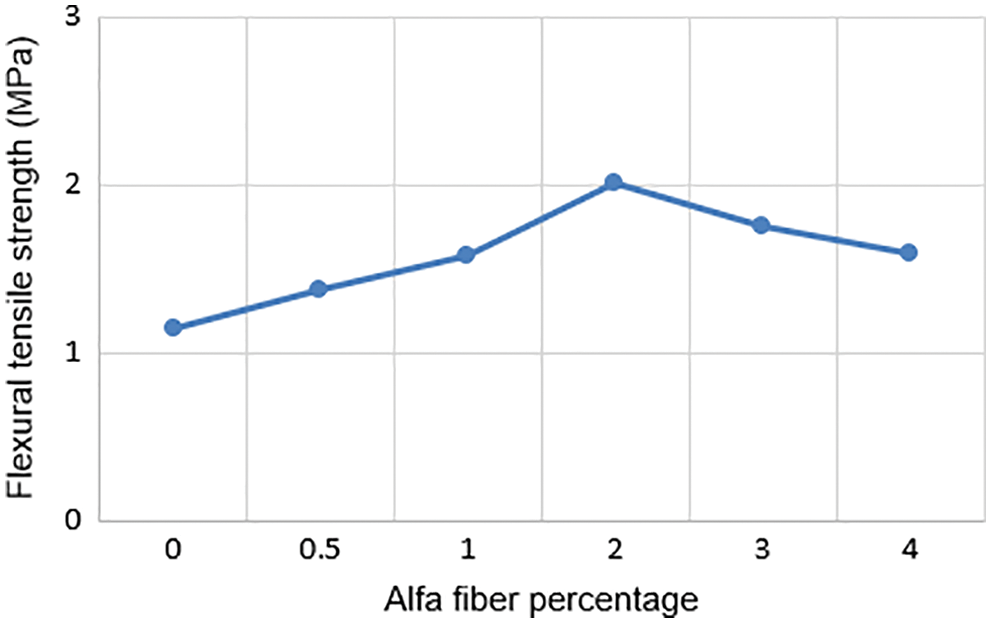

The results shown in Table 6 are represented in Fig. 7:

Figure 7: Flexural tensile strength of different percentages of Alfa fiber

We can see from Fig. 7, that all the composite samples (clay-alfa) have higher flexural tensile strength than clay alone (0% alfa); this indicates that the presence of alfa has a positive effect on the tensile strength of clay samples.

The flexural strength of clay alone is 1.15 MPa, while the composite clay with 4% Alfa has a flexural strength of 1.59 MPa, which means a 38% increase in flexural strength between the two samples.

Galán-Marín et al. [11] worked on the incorporation of animal wool (sheep’s wool) to raw earth bricks. They found that the incorporation of this wool increases the flexural strength by 30% for a percentage of 25% of wool.

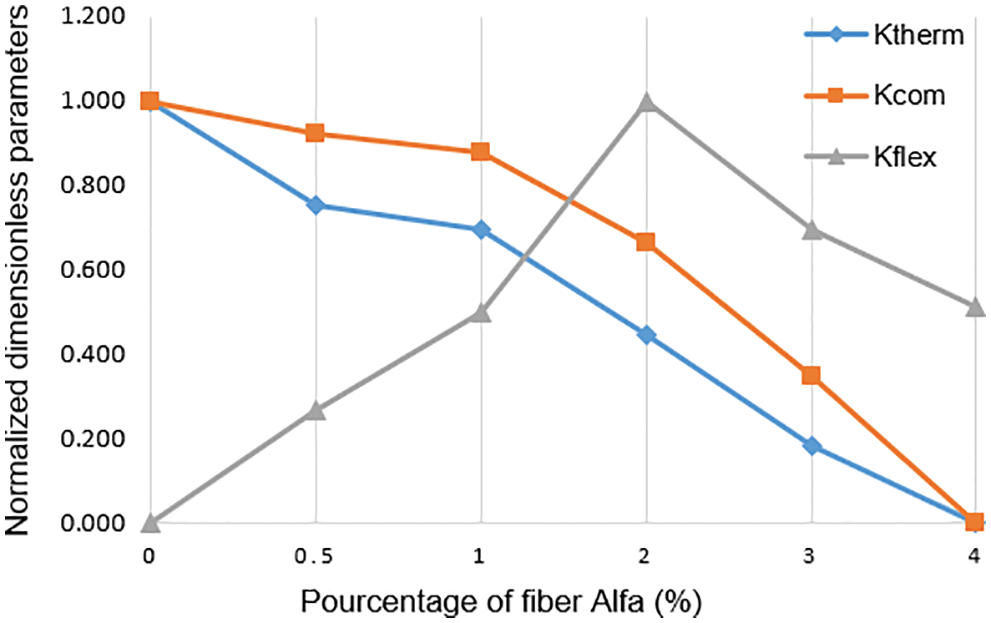

Fiber content, thermal conductivity and, mechanical resistance are crucial parameters for choosing the right insulating material. The goal is to find an optimal point on which we will have a better ratio: mechanical resistance/thermal resistance.

For this purpose, we introduced three normalized dimensionless parameters:

Ktherm, Kcom and Kflex are respectively normalized dimensionless parameters of thermal resistance, compressive strength and flexural strength.

Rmeasured is the thermal resistance in m².K/W. Rcom,measured and Rflex,measured are respectively the compressive strength and the flexural strength in MPa.

Fig. 8 shows the evolution of the three dimensional parameters as a function of the Alfa fiber content:

Figure 8: The normalized dimensionless parameters Ktherm, Kcom and Kflex as function of Alfa fiber content

Fig. 8 shows that the intersection of the Ktherm curve of thermal resistance and the Kcom curve of compressive strength and Kflex flexural strength is located between 1% and 2% of Alfa fibers.

Beyond the 2% of Alfa fibers, the homogeneity assumption is no longer valid. This explains the decrease in resistance.

It can be concluded that for the samples tested, between 1% and 2% of the alfa fiber is the recommended percentage for optimal use of the alfa fiber consolidated with the raw earth material.

Several studies have been conducted on the use of fibers as natural insulators that contribute to the improvement of thermal and mechanical parameters of a composite material. Nitcheu et al. [12] investigated the thermal and mechanical reinforcement of mud bricks with different proportions of thatch fibers from Cameroon. The results obtained show that the thermal conductivity decreases as the volume of fibers in the mixture increases. Kossi et al. [13] used soil blocks stabilized with straw or cement in different percentages. The results reveal that the thermal conductivity decreases with the addition of a percentage of straw fiber while the thermal conductivity increases.

In the current paper, an experimental study is carried out on the thermal and mechanical properties of a bio-based composite material made of clay and alfa fibers. The experimental results show that the increase of alfa fibers in the matrix of clay results to a decrease in thermal conductivity thus a gain in lightness and in insulation.

For the mechanical properties, it is shown in this study that the more alfa fiber percentage added, the less the compressive strength the composite material has. However, for the flexural tensile strength, it increases and reaches a peak in 2% of fiber content.

In order to provide an adequate ecological material for construction purposes, it is essential to find an optimal point between the thermal and mechanical characteristics. Using normalized dimensionless parameters taking into consideration the thermal and mechanical aspects, a percentage of alfa fibers between 1% and 2% is recommended for optimal use of this bio-based material in construction.

Alfa fibers do have properties that can justify their use in construction. The developed material (clay-alfa) can be considered as the optimum balance between three requirements: a low cost, a satisfactory mechanical resistance, and good thermal properties. Furthermore, the content of this paper can be used as the main basis to conduct even more in-depth studies on bio-based materials of clay and alfa fibers for the building and construction sectors.

Funding Statement: This research was funded by Centre National Center of Research and Techniques (CNRST), Morocco, Grant No. 38UM5R2020 for S.I.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Spence, R., Mulligan, H. (1995). Sustainable development and the construction industry. Habitat International, 19(3), 279–292. DOI 10.1016/0197-3975(94)00071-9. [Google Scholar] [CrossRef]

2. Pacheco-Torgal, F. (2020). Introduction to biobased materials and biotechnologies for eco-efficient construction. In: Pacheco-Torgal, F., Ivanov, V., Tsang, D. (Eds.Bio-based materials and biotechnologies for eco-efficient construction, pp. 1–16. Amsterdam: Elsevier. DOI 10.1016/B978-0-12-819481-2.00001-5. [Google Scholar] [CrossRef]

3. Danso, H., Martinson, B., Ali, M., Mant, C. (2015). Performance characteristics of enhanced soil blocks : A quantitative review. Building Research & Information, 43(2), 253-262. DOI 10.1080/09613218.2014.933293. [Google Scholar] [CrossRef]

4. Mounir, S., Khabbazi, A., Khaldoun, A., Maaloufa, Y., Elhamdouni, Y. (2015). Thermal inertia and thermal properties of the composite material clay-wool. Sustainable Cities and Society, 19, 191–199. DOI 10.1016/j.scs.2015.07.018. [Google Scholar] [CrossRef]

5. Chaib, H., Kriker, A., Mekhermeche, A. (2015). Thermal study of earth bricks reinforced by date palm fibers. Energy Procedia, 74, 919–925. DOI 10.1016/j.egypro.2015.07.827. [Google Scholar] [CrossRef]

6. Ramesh, M., Palanikumar, K., Reddy, K. H. (2017). Plant fibre based bio-composites: Sustainable and renewable green materials. Renewable and Sustainable Energy Reviews, 79, 558-584. DOI 10.1016/j.rser.2017.05.094. [Google Scholar] [CrossRef]

7. Cherki, A., Khabbazi, A., Remy, B., Baillis, D. (2013). Granular cork content dependence of thermal diffusivity, thermal conductivity and heat capacity of the composite material/granular cork bound with plaster. Energy Procedia, 42, 83–92. DOI 10.1016/j.egypro.2013.11.008. [Google Scholar] [CrossRef]

8. El Wardi, F. Z., Cherki, A., Mounir, S., Khabbazi, A., Maaloufa, Y. (2019). Thermal characterization of a new multilayer building material based on clay, cork and cement mortar. Energy Procedia, 157, 480–491. DOI 10.1016/j.egypro.2018.11.212. [Google Scholar] [CrossRef]

9. Mounir, S., Maaloufa, Y., Cherki, A. B., Khabbazi, A. (2014). Thermal properties of the composite material clay/granular cork. Construction and Building Materials, 70, 183-190. DOI 10.1016/j.conbuildmat.2014.07.108. [Google Scholar] [CrossRef]

10. Khelifa, M. R., Leklou, N., Bellal, T., Hebert, R. L., Ledesert, B. A. (2018). Is alfa a vegetal fiber suitable for making green reinforced structure concrete? European Journal of Environmental and Civil Engineering, 22(6), 686–706. DOI 10.1080/19648189.2016.1217792. [Google Scholar] [CrossRef]

11. Galán-Marín, C., Rivera-Gómez, C., Petric, J. (2010). Clay-based composite stabilized with natural polymer and fibre. Construction and Building Materials, 24(8), 1462-1468. DOI 10.1016/j.conbuildmat.2010.01.008. [Google Scholar] [CrossRef]

12. Nitcheu, M., Meukam, P., Damfeu, J. C., Njomo, D. (2018). Thermomechanical characterisation of compressed clay bricks reinforced by thatch fibres for the optimal use in building. Materials Sciences and Applications, 9(12), 913–935. DOI 10.4236/msa.2019.912066. [Google Scholar] [CrossRef]

13. Kossi, I. B., Florent, K. P., Emmanuel, O. (2014). Thermal and mechanical study of the adobe stabilized with straws and/or cement at different dosage rates. International Journal of Engineering and Innovative Technology, 4(4), 200–204. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |