| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.021902

ARTICLE

Analysis of Lateritic Soil Reinforced with Palm Kernel Shells for Use as a Sub-Base Layer for Low-Traffic Roads

1LEMA, University of Abomey-Calavi, Cotonou, Benin

2GC2D, University of Limoges, 17 Bd Jacques Derche, Egletons, France

3National University of Sciences, Technologies, Engineering and Mathematics, Abomey, Benin

*Corresponding Author: Joel Koti. Email: joelkoti@yahoo.fr

Received: 11 February 2022; Accepted: 02 March 2022

Abstract: In tropical areas, palm oil production generates significant amounts of waste, including palm kernel shells. The use of this waste in the civil engineering sector, presents a very challenging task. In the present study, the production of lateritic soil (A-2 in GTR classification and A-7-6 (9) in HRB classification) reinforced with palm kernel shells is considered. In order to improve their performances, these materials are mixed using the Fuller’s parabolic law. Moreover, experimental tests are used to characterize the physical and mechanical geotechnical properties of the lateritic soil. After characterizing the matrix (i.e., lateritic soil) and the inclusions (i.e., palm kernel shells) in their natural state, it is found that Avrankou’s lateritic soil has a high level of fine particles (56.6%), high plasticity (PI = 21%) and low lift (ICBR = 17%); which makes it unusable in the pavement layer. Results also prove that the mixture composed of 39% of lateritic soil volume and 61% of PKS with a CBR index equals to 30 and the mixture composed of 45% of lateritic soil, 40% PKS and 15% of lagoon sand with a CBR index equals to 41 can be used as sub-base layer for roads for low and medium traffic, respectively.

Keywords: Palm kernel shell; lateritic soil; subbase layer; low-traffic roads

Nomenclature

| CEBTP | “Experimental Center for Research and Studies of Buildings and Public Works: Centre Experimental de Recherches et d’Etudes du Bâtiments et des Travaux Publics’’ |

| HRB | Highway Research Board |

| ICBR | index California Bearing Ratio |

| LS | Lateritic Soil |

| MDD | Maximum Dry Density |

| OMC | Optimum Moisture Content |

| OPM | Optimum Proctor Modified |

| PI | Plasticity Index |

| PKS | Palm kernel shell |

| SL | sand |

| MAEP | “Ministry of Agriculture, Livestock and Fisheries: Ministère de l’agriculture, de l’élevage et de la pêche’’ |

In southern Benin, rural oil palm production areas are inaccessible due to the limited capacity of public investment. The maintenance or development of these roadways requires the extraction of millions of cubic meters of road material every year. These road materials, before their use in road construction, must present certain well-defined technical requirements. The lateritic gravel is the most classical and valuable road material widely used in Africa in pavement layers [1,2]. Their systematic use as construction materials is beginning to make them a scarce resource in some regions in Africa. Some of these depleted pockets require, even before their use, specific treatment with cement, lime [2], lagoon sand [3] or crushed materials [4,5] to give the materials the necessary technical requirements.

In Benin, this conventional road material is depleted and is only available in very limited quantities (724,806 m3) in the north part, mainly in Banikoara and Tchaourou cities [6]. Therefore, it becomes necessary to assess the available resources and to study the idea of extending the acceptable properties range for these soils or use alternative natural materials. In the south of Benin, where oil palms are produced, one solution consists in pouring palm kernel shells on tracks, which form with the soil on site (lateritic soil) a composite material promoting circulation, especially in rainy periods. Palm kernel shells are non-putrescible waste resulting from the exploitation and production of oil, which is one of the world’s fatty substances [7]. These residues, which represent 7% to 8% of the weight of the bunch, are generated in large quantities in tropical countries [8] and constitute in some regions an environmental nuisance. They are used in small quantities for combustion by hearths and cement industry; which has a serious issues and critical consequences on the environment. According to an MAEP report [9], over 300,000 tons of palm kernel shells are generated each year in Benin. This quantity will be constantly increasing in view of the various actions carried out by successive governments to relaunch this sector which currently contributes only 43% of the demand and needs of fatty substances of plant origin in Benin [10,11]. Recently, several studies have dealt with the problem of the use of PKS as large aggregates to replace gravel for making structural concrete for buildings [12–15]. To date, few studies have been interested in the recovery of this waste (aggregates) in road engineering. Amu and al. studied the effect of PKS in laterite stabilized with asphalt to reduce plasticity, by varying the proportions of the different components [16].

Figure 1: Entrance of treated house using the PKS

Concluding that no mixture can be used as a pavement layer, it is observed that certain characteristics such as the compressive strength of the asphalt stabilized optimal mixture (by weight of 75% of lateritic soil and 25% of PKS) was greater than that of the asphalt stabilized lateritic soil [16]. Madjadoumbaye concluded that PKS improves CBR index by 26% (95% of OPM) when it mixed (20% of PKS and 80% of gravel laterite) [17]. No author has yet been interested in the mixture of fine soil (clay soil) and PKS for use as sub-base layer. Inspired by studies of improvement of lateritic soils with crushed and the traditional technique of treatment of the population (Fig. 1), this work reports on the experimentation and development of a composite based on the lateritic soil of Avrankou and the PKS of Misserete in order to produce a composite (alternative material) that can be used as a subbase layer based on locally available natural resources.

2 Properties of the Composite Components

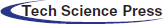

In Benin, the oil palm is widely cultivated in the southern coastal fringe (Fig. 2). PKS are obtained using traditional processes by crushing palm nuts with artisanal machines. For this study, they are collected at “Gome Sota’’ (Misserete city) 6°35′39.0″N; 2°35′20.5″E. This zone is favorable to the cultivation of oil palm because of its pedology located in the seven plateaus of South Benin. These plateaus are rich in lateritic soil (commonly called bar soil) in large quantities (minimum 10,410,949 m3) [6]. The lateritic soil is taken about ten kilometers from “Misserete’’ in a quarry at Avrankou 6°32′24.5″N and 2°39′3.6″E.

Figure 2: a) Oil palm cultivation area in Benin [18]; b) Pile of PKS in Misserete

At first glance, the initial and natural characteristics and properties of the basic materials were studied.

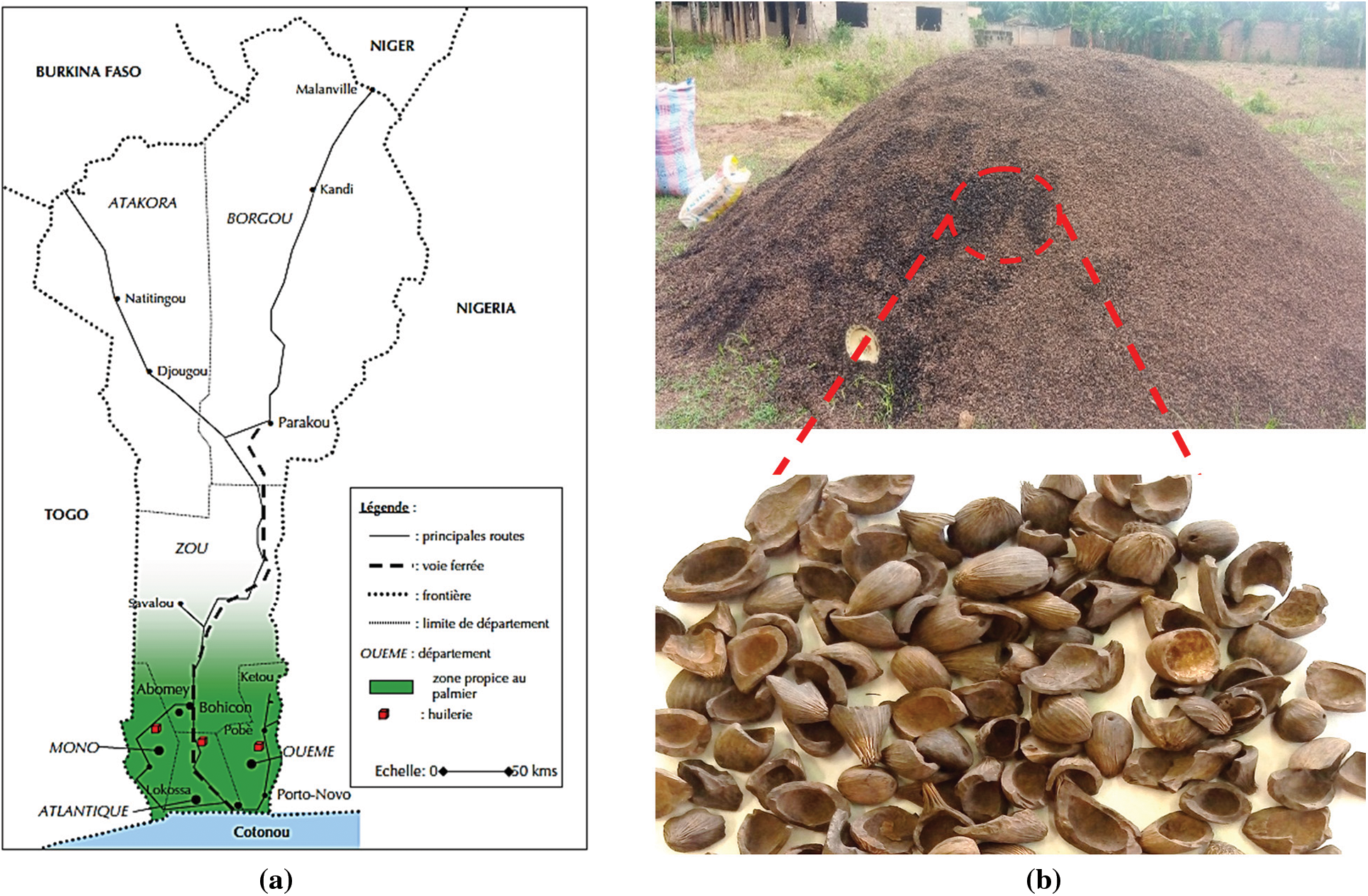

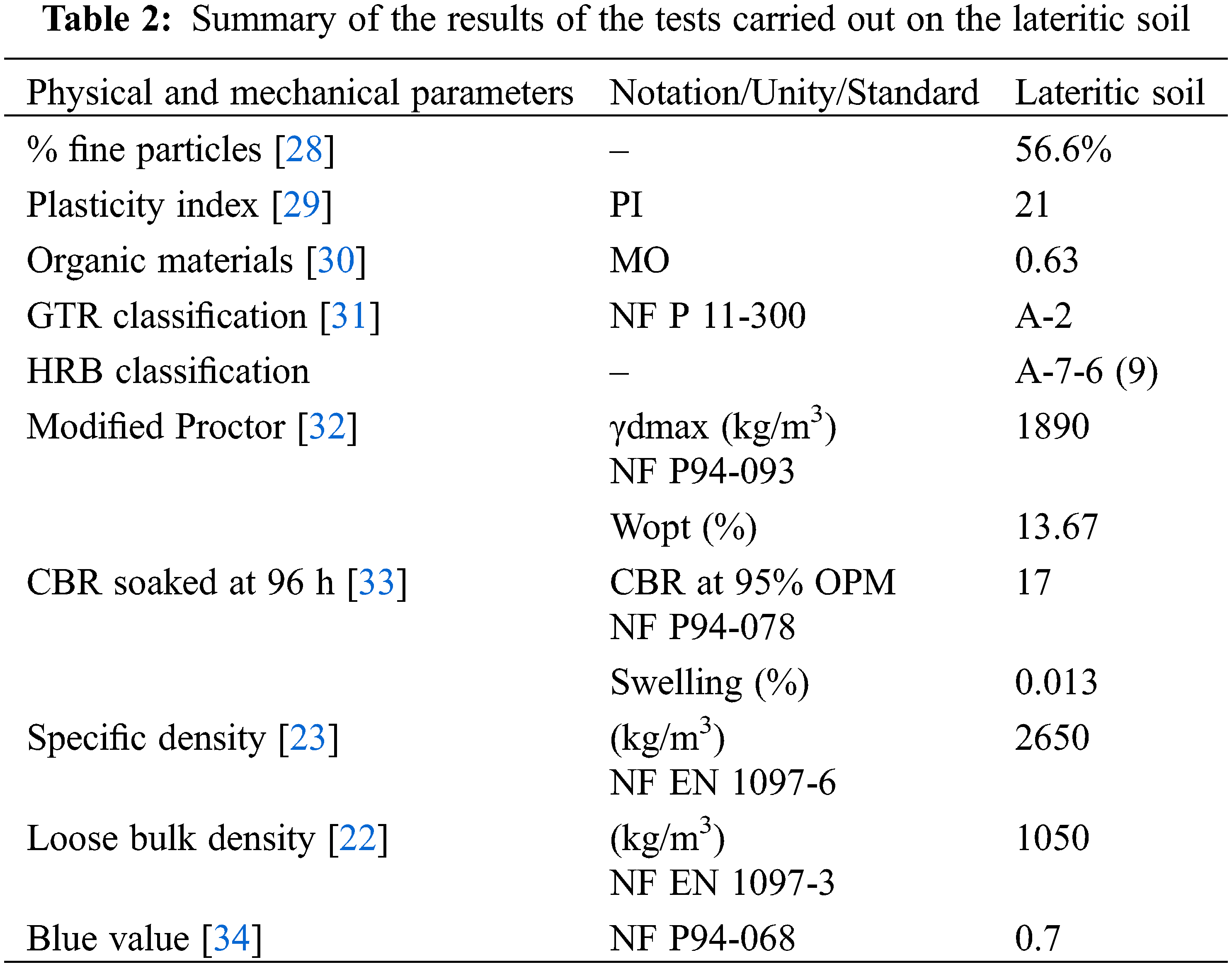

The results of the identification tests for palm kernel shells and lateritic soil are presented in Tables 1 and 2, respectively.

Palm kernel shells (PKS) are coarse aggregates, the identification parameters are generally: granular distribution, specific weight, apparent weight and water absorption after 24 h after immersion [12,14,19]. PKS has an thickness rang of 1.50 to 2.5 mm, a specific weight 1370 kg/m3, an apparent weight 5300 kg/m3 and 620 kg/m3. These different parameters show that PKS are light aggregates, 50% to 60% lighter than conventional aggregates [8,20]. The granular distribution conducted in accordance with standard NF EN 933-1 [21], the apparent weight with standard NF EN 1097-3 [22], specific weight, and water absorption with standard NF EN 1097-6 [23].

The laterite soil is identified with the habitual geotechnical road test namely: distribution granular, soil limits liquidity and plasticity, water content and dry density for Optimum Proctor Modified (OPM), bearing CBR, after 4 days of immersion and swelling after immersion [24–27].

3 Mixture Proportioning for the Composite

Granular mixtures, especially in the field of road materials, are generally produced by the trial and error technique [3–5,16,17]. This technique consists in varying the proportion of a component, then carrying out physico-mechanical tests on the mixtures in order to retain the mixtures with the best results. This groping technique leads to a lot of unnecessary testing. To overcome these difficulties, studies have been carried out on particle size distribution functions [35] in order to find optimal mixtures. For each system considered, there are parameters to optimize the distribution and lead to the most compact stack. But at this stage the difficulty is to set one of these real distribution functions, particularly for large grain sizes [36]. In 1907, the influence of particle size distribution on the density of granular materials was studied by Fuller et al. [37] and expressed as Eq. (1).

where P(d) the percentage of material passing a sieve with opening d; Dmax maximum size of particle in grading; n is a variable exponent, taken as 0.5 for maximum density.

With an exponent set at 0.5, this model lacks versatility. This is why it was improved by Andreasen and Andersen in 1929 which replaced the constant 0.5 by a variable q [38]. Even though Andreasen and Andersen came to the conclusion that the exponent q must be between 0.33 and 0.5 to obtain a dense mixture, the value of q which must be considered in this light constitutes a real debate [36]. For Peronius et al. [39], the porosity decreases when q evolves from 3 to 0.5 then begins to increase for q from 0.5 to 0.4 [39]. Aberg [40] and Tsirel [41] have shown that a decrease in q leads to a decrease in voids. In summary, the authors agree that it is produces a decrease in porosity when q goes from 3 to 0.5. Below 0.5, opinions diverge.

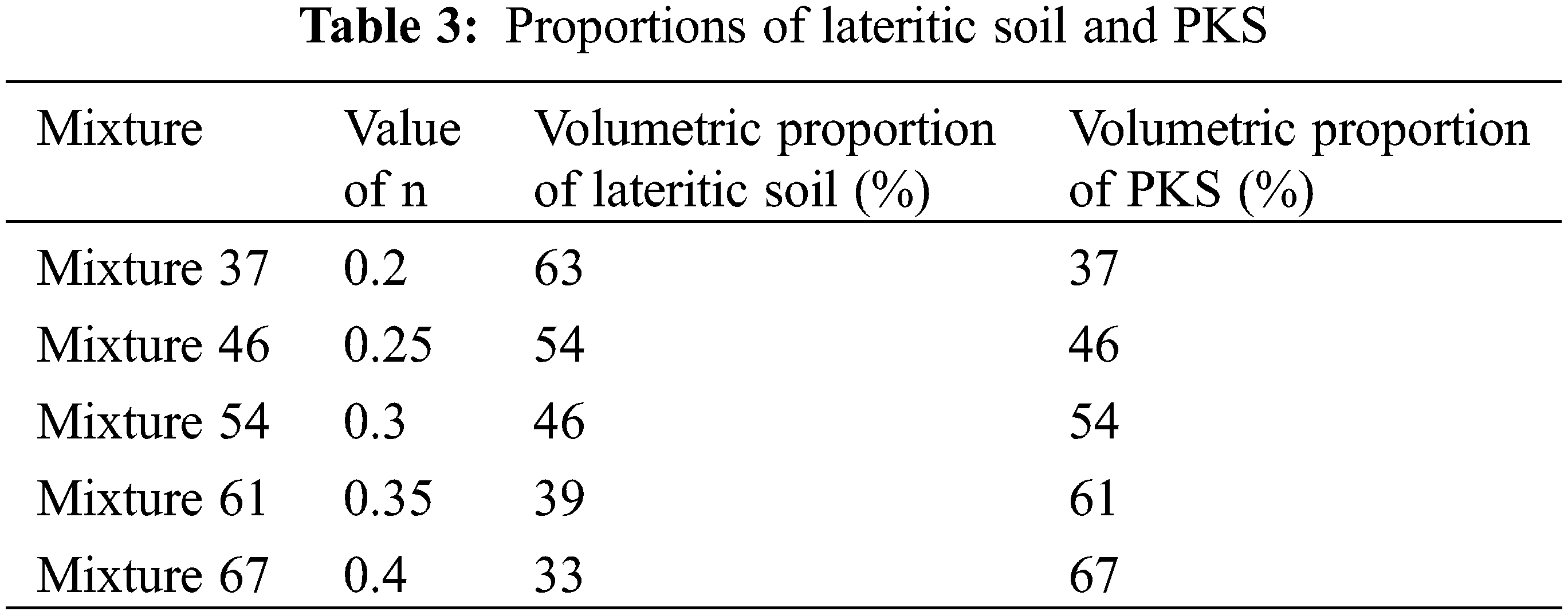

In view of these variations on the exponent, a parametric study was carried out on the variation of “n’’ in this paper. The method used consisted in finding the volume proportions of components forming the densest possible mixture. The maximum diameter D of the aggregates is fixed and known. For a given variable n, the study percentage P is determined corresponding to the passing of the granular fraction of mean diameter d. A parametric optimization study is carried out by varying “n”. It appears that for n less than 0.2 the proportion of PKS is very low and for values of n superior to 0.5 the proportion of PKS is high, which would make the mixture incompressible. For values of n between 0.2 and 0.4, we obtain the following five mixtures (see Table 3):

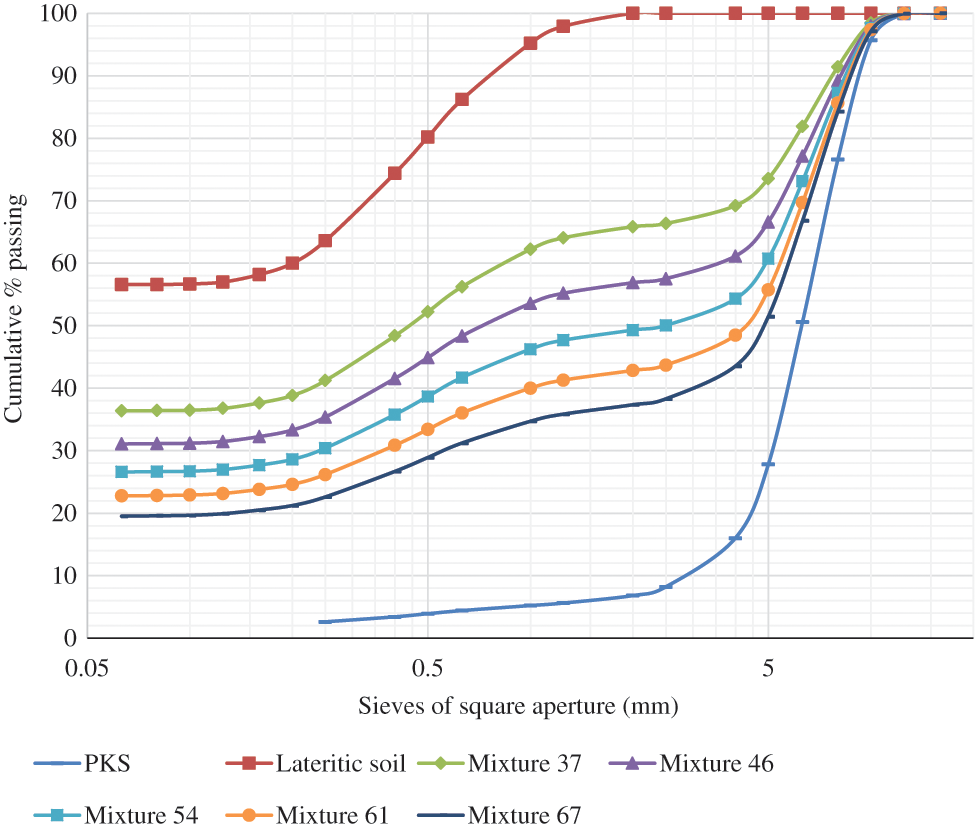

Each mixture is designated by its proportional volume of PKS. The different grain size curves are shown in Fig. 4 and it is noted that the curves of the different mixtures lie between the curve of the PKS and that of the lateritic. PKS being light aggregates, the objective sought here is to have mixtures with better compactness (see Eq. (2)) and with better geotechnical characteristics.

Figure 4: Sieves of PKS, Lateritic soil and the 5 mixtures

The mixes are done manually; PKS and lateritic soil being dry (illustrated in Fig. 3). Geotechnical tests are carried out with each mixing (granular distribution, soil limits liquidity and plasticity, water content and dry density for Optimum Proctor Modified (OPM), bearing CBR, after 4 days of immersion and swelling after immersion).

Figure 3: Study images of mixtures (lateritic soil + PKS)

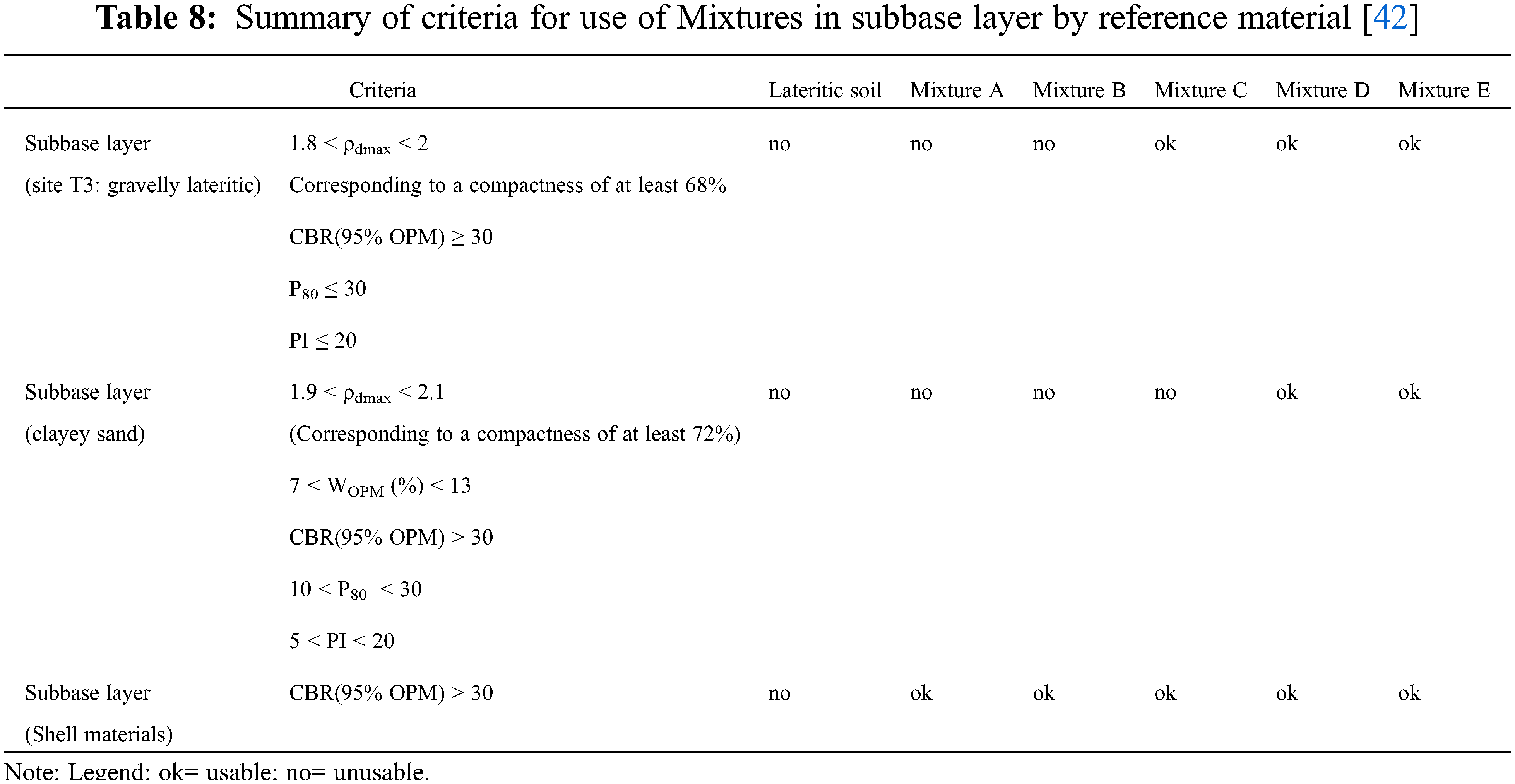

The recommendations of the specifications related to road materials depend on the nature of said materials, the standards and regulations in force in the country, the traffic, the considered layer and the type of treatment. In West Africa, the CEBTP guideline [42] is considered as the most widely used material in the civil engineering of roads; which has evolved over time (1972, 1980 and 1984). The major criteria are the CBR index and the plasticity index (PI). Based on the shape of PKS (polygonal shapes with angular edges, surfaces smooth enough for concave and convex faces), the composite (Lateritic soil + PKS) could be assimilated or compared to conventional materials such as lateritic gravelly (if the PKS play the role of lateritic nodules), clayey sand or shell materials from the CEBTP guideline.

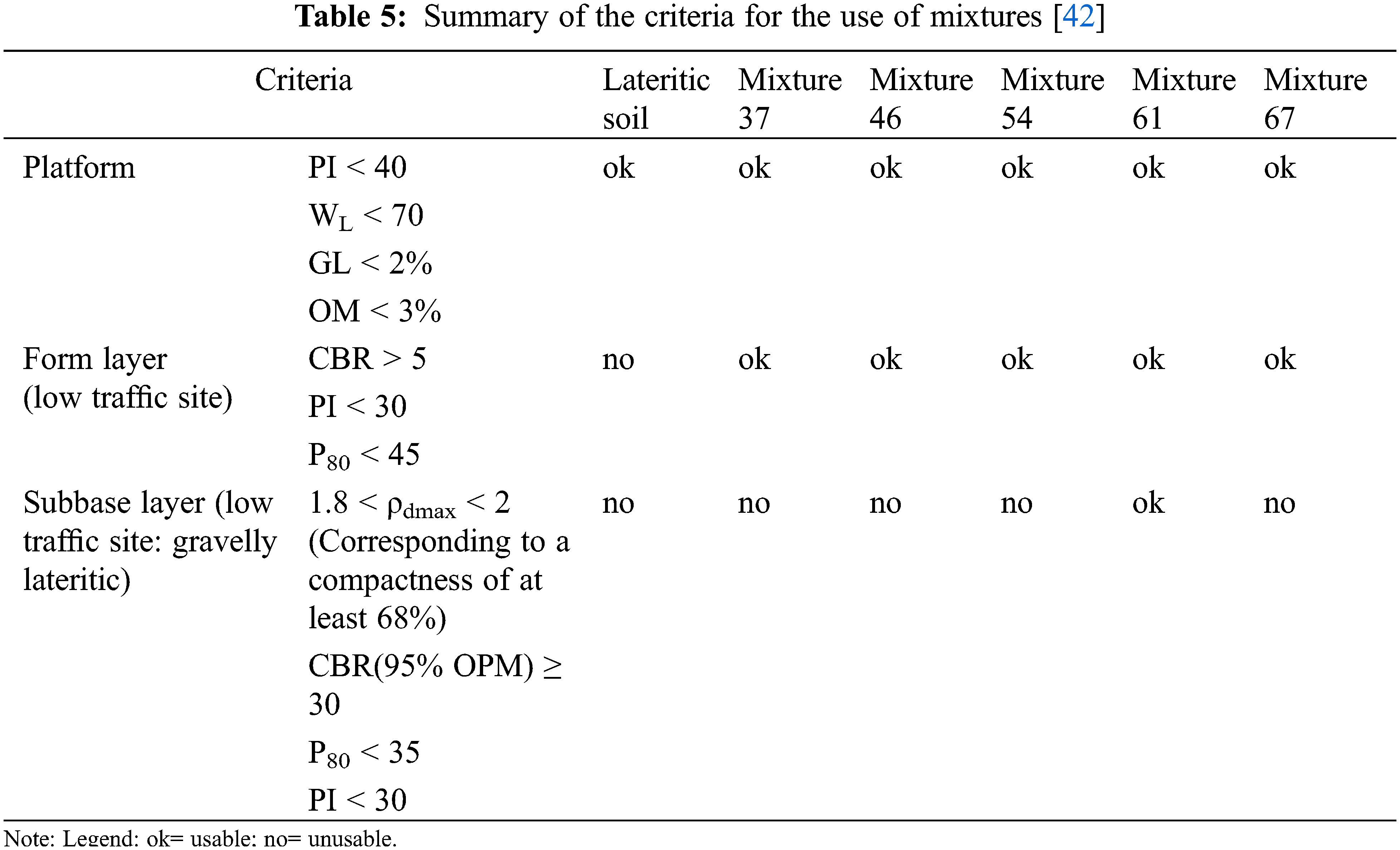

The geotechnical characteristics of the various mixtures are presented in Table 4 and the various criteria for the use of natural soils, according to the CEBTP approach, are summarized in Table 5.

The lateritic soil used is a fine soil with 56.6% fines. It is class A-2: clay soil (GTR classification) and A-7-6 (9) and (HRB classification) with a CBR index after immersions of 17.

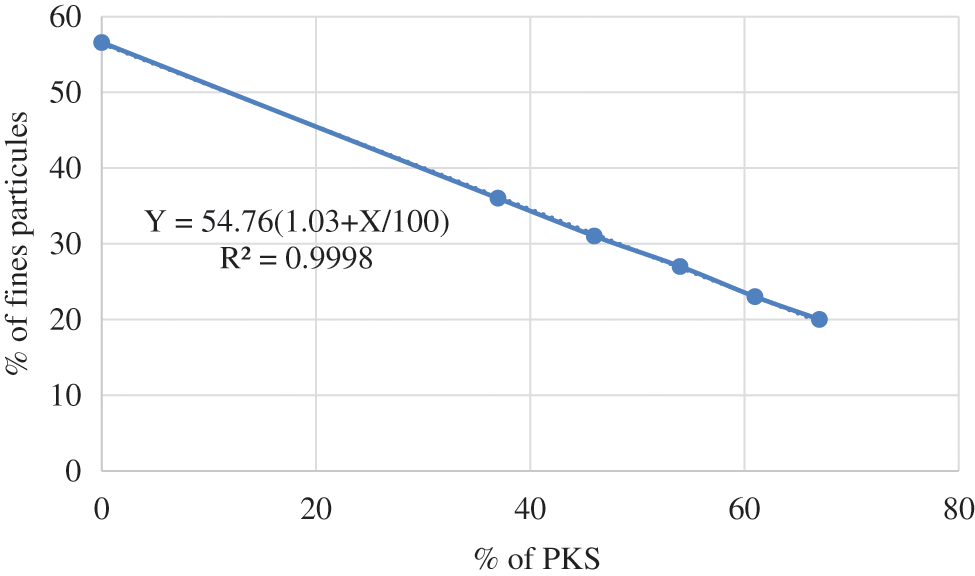

The evolution of the proportions of fine particles (passing to 80 µm) is linear (Fig. 5). The absolute linearity is that the distributions of the different granular mixtures were reconstructed from the sizes of the two materials. It is noted that the percentage of fines in the lateritic soil decreases by 10% for 10% of PKS added.

Figure 5: Evolution of the proportion of fines particles in function of PKS

4.2 Maximum Dry Density and Compactness

The maximum dry density is determined as a function of the wet density and the optimum water content. The compactness, for its part, represents the ratio between the maximum dry density and the density of the solid grains.

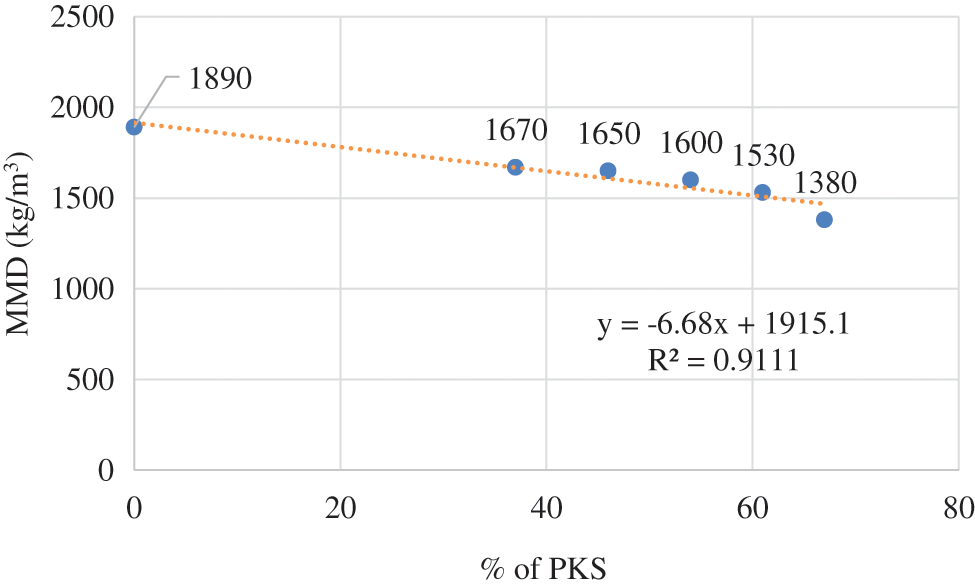

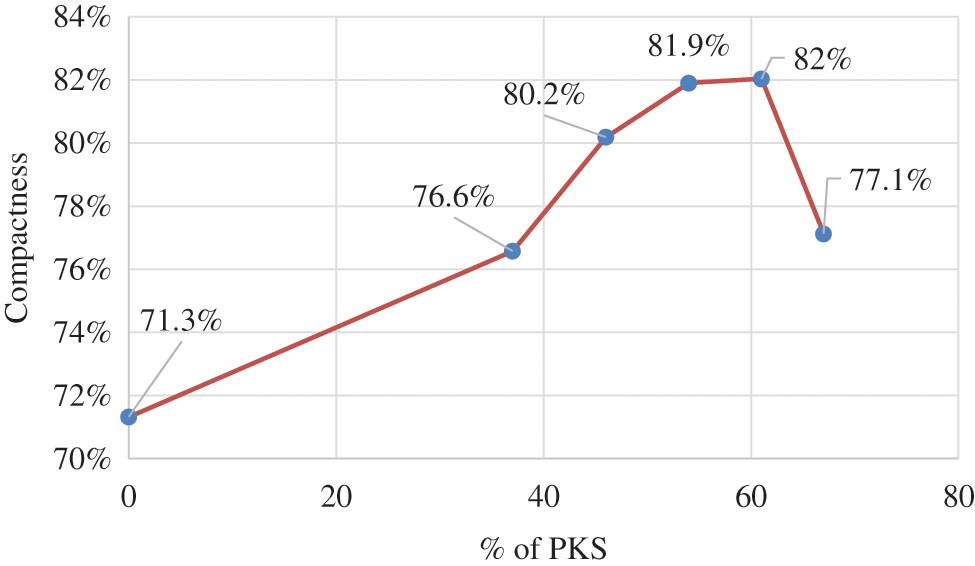

Unlike what is observed with mixtures of conventional materials (lateritic gravel and alluvial gravel) [5], the maximum dry density decreases when the proportion of PKS increases (Fig. 6). Its evolution is almost linear. The trend line of equation y = –6.68x + 1915.1 and its coefficient correlation of 0.9111. This observed decrease in the maximum dry density of composites is due to the fact that PKS is twice as light as lateritic soil. Despite the decrease in maximum dry densities, the compactness of composites is greater than that of lateritic soil in its natural state. This phenomenon is explained by the arrangement of fine grains in coarse grains thus forming dense mixtures. All five have a compactness greater than 72%, which gives them a usable material density in the pavement body. The compactness (Fig. 7) seems to stabilize for mixtures 46, 51 and 61. This means that the optimum proportion of PKS is between 46% and 61% (i.e., between 30% and 45% by mass proportion).

Figure 6: Evolution of maximum dry density (MMD) in function of % PKS

Figure 7: Evolution of compactness in function of % PKS

4.3 CBR after Immersion and Swelling

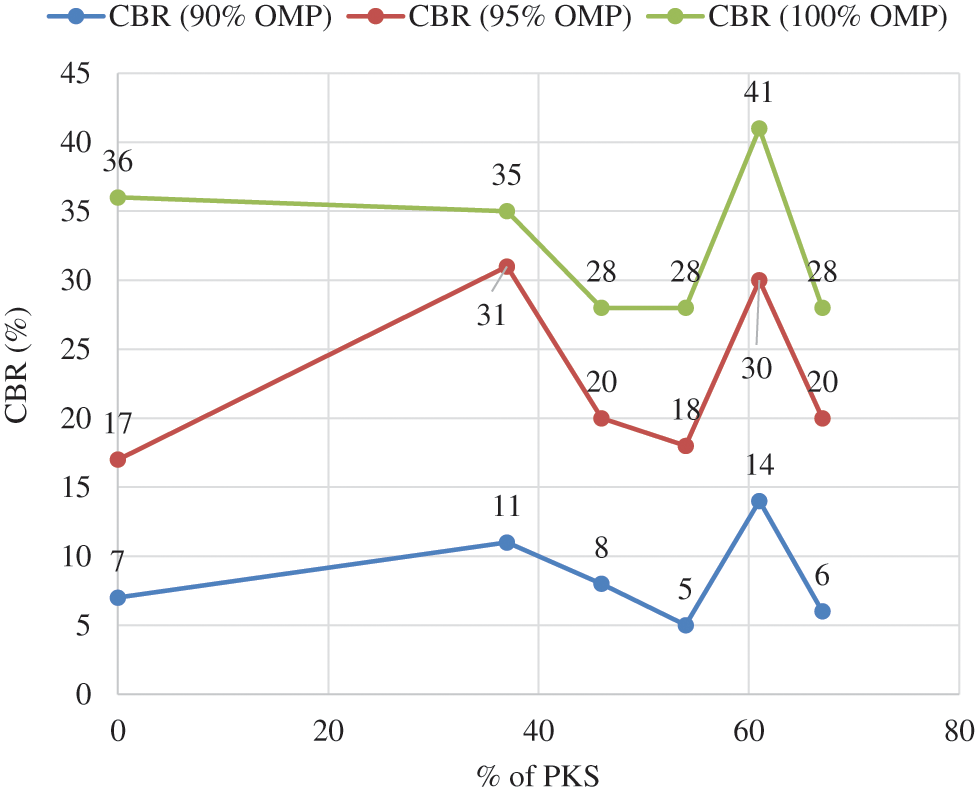

The curves in Fig. 8 show the variation of CBR (90%, 95% and 100% of the OPM corresponding respectively to 10, 25 and 56 strokes) as a function of the proportion of PKS. The curves look the same. Above 90% of the OPM, all composites have a higher CBR than the lateritic soil. However, the mixture 61 (with the best compactness) offers a considerable improvement in the CBR index compared to the CBR of lateritic soil with gains of 100%, 76% and 14% for respectively 90%, 95% and 100% of the OPM.

The linear swellings at 95% of the OPM are 0.013% for the lateritic soil against 0.16% for the mixture 61. These swellings are lower than the maximum allowable for the use of the composite in base and sub-base layers of low traffic pavements.

Figure 8: Evolution of CBR after immersion in function of PKS

4.4 Use of Composites in Road Construction

According to the technical recommendations of CEBTP [42] summarized in Table 5, the five mixtures can be used as materials for the platform and for subgrade for low and medium traffic sites.

Whatever the nature of the structure, the materials used in the sub-base layer must have a CBR at least equal to 30 obtained for a dry density corresponding to 95% of the OPM (25 may be accepted for low traffic, T1). The mixture 61 is the most dense and compact mix with a compactness of 82% with CBR 30 (at 95% of OPM) and 41 (at 100% of OPM). In view of these different technical requirements, only the mixture 61 (39% lateritic soil + 61% PKS) has all the characteristics as a sub-base layer materials for low traffic roads (T1 < 300 vehicles per day).

The optimal composite 61% of PKS (45% by weight) is different that of Amu (25% of PKS and 75% of laterites), that of Madjadoumbaye (20% of PKS and 80% of grave lateritic) and of Ahouet (30% alluvial gravel and 70% lateritic gravel [5,16,17]. These differences demonstrate that the optimum of composites and their geotechnical characteristics strongly depend on intrinsic characteristics of the matrix (type of laterites) and inclusion.

4.5 Composite PKS/Lateritic Soil/Sand

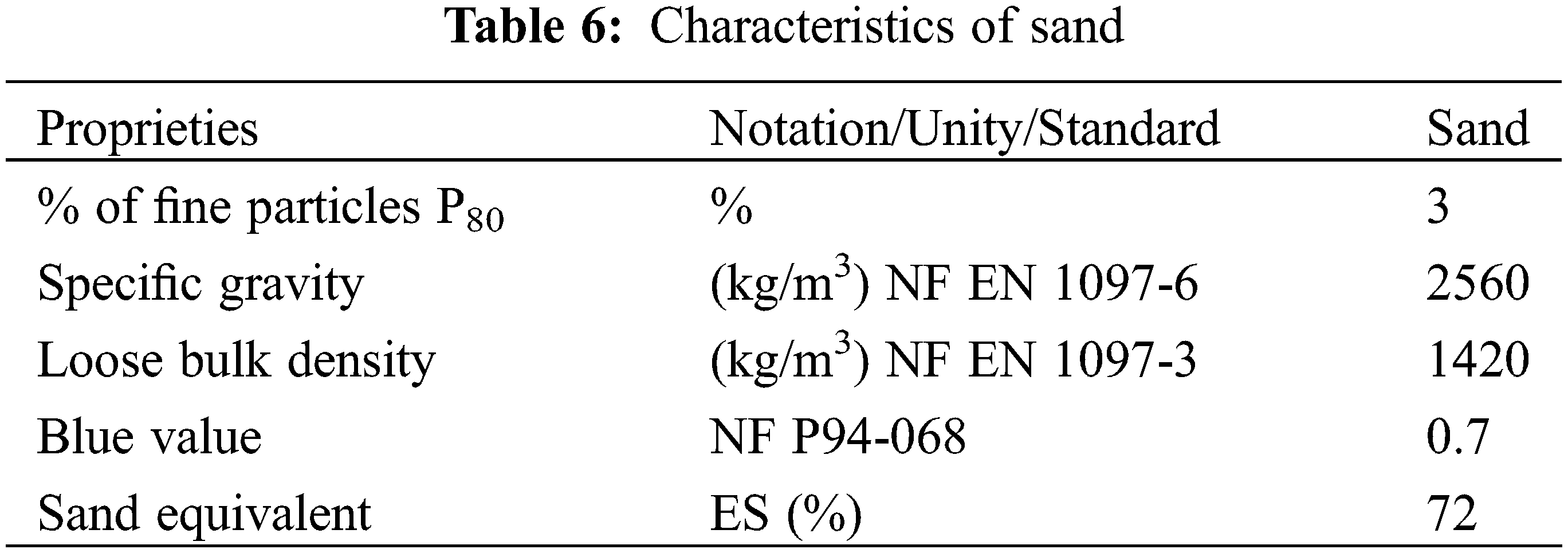

In order to consider their use as a subbase layer for medium traffic (T2 and T3), it will be necessary to degrease by reducing the plasticity index. The addition of sand is considered as one of the less expensive mechanical treatment improvements, recommended by CEBTP guideline. This solution was chosen in this work because of the availability of river sand in the study environment. This solution was adopted by Ndiaye et al. [3] as part of his lithostabilization study in which he has concluded that the sand not only reduces the plasticity index but also helps in increasing lift. The proportion of sand was fixed and kept constant (15%). The used sand is taken from Agassa-Godomey in the municipality of Abomey-Calavi, in which their physical and mechanical characteristics are summarized in Table 6.

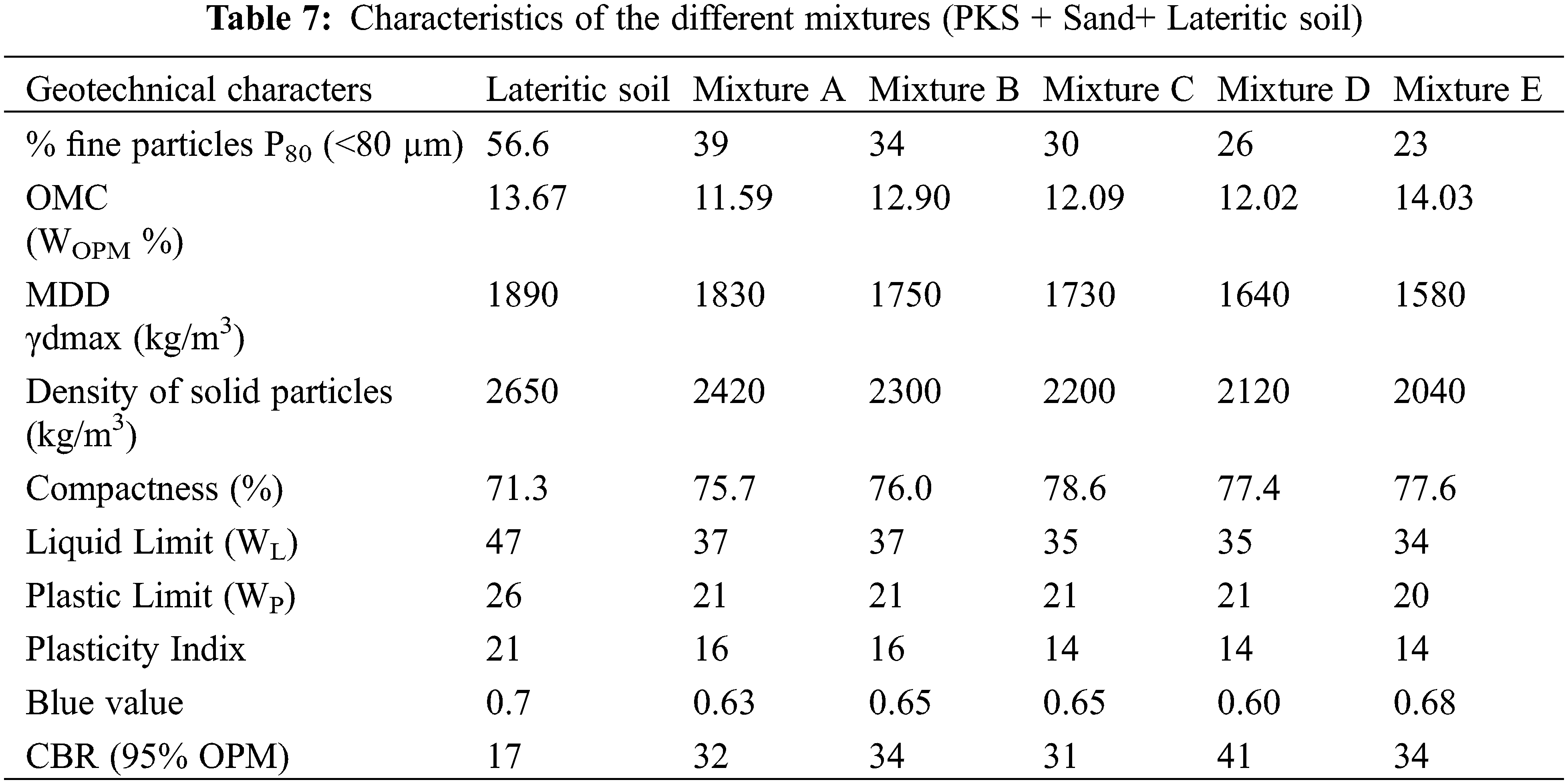

Using the same methodology (3), the following five mixtures are obtained:

- Mixture A: 68% LS + 15% SL + 17% PKS

- Mixture B: 59% LS + 15% SL + 26% PKS

- Mixture C: 51% LS + 15% SL + 34% PKS

- Mixture D: 45% LS + 15% SL + 40% PKS

- Mixture E: 38% LS + 15% SL + 47% PKS

** LS: Lateritic soil; SL: sand; PKS: palm kernel shell.

The results of the Modified Proctor and CBR tests, carried out on the three-phase mixtures of lateritic soil, of sand and PKS are presented in Table 7. It is observed that the addition of 15% of sand improves significantly the bearing capacity of the mixtures (i.e., their CBR index is greater than 30) and their plasticity limit (i.e., less than 20). It is noticed also that the compactness of the various mixtures is stabilized between 75% and 78%.

The CBR index of the composites mix with PKS is greater than that of the lateritic soil. Therefore, the CBR index is improved by adding PKS to lateritic soil. Unlike the work of Amu et al. [16], the mixture D (45% LS + 15% SL + 40% PKS) and the mixture E (38% LS + 15% SL + 47% PKS) with a plasticity index less than 20, the fines percentage being less than 30 and a CBR index greater than 30 can be used as a subbase layer (Table 8) for medium traffic roads (T2 and T3). The mixture D (by weight of 26.1% of PKS, 55.8% of lateritic soil and 18.1% of lagoon sand) comparable to that optimal from Amu’s study (25% PKS and 75% lateritic soil), confirms the reliability of the optimization method used.

In Benin, as in many African countries, the selection criteria for materials in road construction are based on the recommendations of the “pavement sizing guideline for tropical countries” of the CEBTP of 1972 and of 1980 (revised 1984). These recommendations are generally based on the Plasticity Index (PI) and the CBR Index.

In this work, an experimental study is presented to improve the geotechnical properties of lateritic soil (i.e., unusable in its natural state in the body of the road) by adding palm kernel shells.

According to the findings, the minimum input of 37% of PKS (by volume) enhances the clay material for its use in subgrade and road platform. The addition of PKS to the lateritic soil reduces the percentage of fines to less than 35 and increases the CBR index. Thus, the mixture composed of 39% of lateritic soil and 61% of PKS with CBR index equals 30 and the mixture composed of 40% of PKS, 45% of lateritic soil and 15% of lagoon sand with CBR index equals 41 can be used as a subbase layer for roads for low and medium traffic respectively, in the case of new constructions as well as rehabilitations.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Bohi, Z. P. B. (2008). Caractérisation des sols latéritiques utilisés en construction routière: Cas de la région de l’Agneby (Côté d’Ivoire) (Ph.D. Thesis). Ecole Nationale des Ponts et Chaussées, France. [Google Scholar]

2. Tankpinou Kiki, S. Y. (2016). Caractérisation minéralogique, thermique et microscopique de sols fins en technique routière (Ph.D. Thesis). Université de Bordeaux et Université d’Abomey-Calavi. [Google Scholar]

3. Ndiaye, M., Magnan, J. P., Cissé, I. K., Cissé, L. (2013). Étude de l’amélioration de latérites du Sénégal par ajout de sable. Bulletin des Laboratoires des Ponts et Chaussées, 280, 123–137. [Google Scholar]

4. Babaliye, O., Houanou, K. A., Vianou, A., Tchehouali, A., Foudjet, A. E. (2020). Litho stabilization of the lateritic gravelly by granite crushed for their use in flexible pavement in Benin. International Journal of Advanced Research, 8(4), 1008–1016. DOI 10.21474/IJAR01/10871. [Google Scholar] [CrossRef]

5. Ahouet, L., Elenga, R. G., Bouyila, S., Ngoulou, M., Kengue, E. (2019). Amélioration des propriétés géotechniques du graveleux latéritique par ajout de la grave alluvionnaire concassée 0/31,5. Revue RAMReS– Sciences Appliquées et de l’Ingénieur, 3(1), 1–6. [Google Scholar]

6. Gbaguidi, V. S., Tankpinou Kiki, Y., Zevounou, C., Vedogbeton, N., Zankpe, M. (2018). Identification of the strata of lateritic soils and alterites in Benin. International Journal of Advanced Research, 6(9), 282–293. DOI 10.21474/ijar01/7674. [Google Scholar] [CrossRef]

7. FAOSTAT (2017). Production du palmier à huile au Bénin. Rome, Food and Agriculture Organization of the United Nations. http://www.fao.org/faostat/fr/#home. [Google Scholar]

8. Okpala, D. C. (1990). Palm kernel shell as a lightweight aggregate in concrete. Building and Environment, 25(4), 291–296. DOI 10.1016/0360-1323(90)90002-9. [Google Scholar] [CrossRef]

9. MAEP (2010). Plan stratégique de Relance du Secteur Agricole.Benin: Ministère de l’agriculture et de la Pêche. [Google Scholar]

10. Toffa, J. A. H. (2009). Renforcement des capacités organisationnelles et techniques des producteurs du palmier à huile sélectionné dans la commune d’Adjarra: Cas de la CVPPH de Lindja-Dangbo. Abomey-Calavi, University of Abomey-Calavi. [Google Scholar]

11. MAEP (2017). Plan stratégique de développement du secteur agricole (PSDSA) 2025 et plan national d’Investissements agricoles et de sécurité alimentaire et nutritionnelle PNIASAN, 2017–2021.Benin: Ministère de l’agriculture et de la Pêche. [Google Scholar]

12. Gibigaye, M., Godonou, G. F., Katte, R., Degan, G. (2017). Structured mixture proportioning for oil palm kernel shell concrete. Case Studies in Construction Materials, 6, 219–224. DOI 10.1016/j.cscm.2017.04.004. [Google Scholar] [CrossRef]

13. Teo, D. C. L., Mannan, M. A., Kurian, V. J. (2006). Structural concrete using oil palm shell (OPS) as lightweight aggregate. Turkish Journal of Engineering and Environmental Sciences, 30(4), 251–257. [Google Scholar]

14. Traore, Y. B., Messan, A., Hannawi, K., Gerard, J., Prince, W. et al. (2018). Effect of oil palm shell treatment on the physical and mechanical properties of lightweight concrete. Construction and Building Materials, 161, 452–460. DOI 10.1016/j.conbuildmat.2017.11.155. [Google Scholar] [CrossRef]

15. Ogundipe, K. E., Ogunbayo, B. F., Olofinnade, O. M., Amusan, L. M., Aigbavboa, C. O. (2021). Affordable housing issue: Experimental investigation on properties of eco-friendly lightweight concrete produced from incorporating periwinkle and palm kernel shells. Results in Engineering, 9(1), 100193. DOI 10.1016/j.rineng.2020.100193. [Google Scholar] [CrossRef]

16. Amu, O., Adeyeri, J., Haastrup, A., Eboru, A. (2008). Effects of palm kernel shells in lateritic soil for asphalt stabilization. Research Journal of Environmental Sciences, 2(2), 132–138. DOI 10.3923/rjes.2008.132.138. [Google Scholar] [CrossRef]

17. Madjadoumbaye, J., Kamdjo, G., Mbessa, M., Defo, F. E. H., Tamo, T. T. (2013). Possibilities for improving the bearing capacity of laterite with a vegetable shell: The shell of palm kernels. Electronic Journal of Geotechnical Engineering, 18, 1917–1928. [Google Scholar]

18. Fournier, S., Ay, P., Jannot, C., Okounlola-Biaou, A., Pédé, E. (2001). La transformation artisanale de l’huile de palme au Bénin et au Nigeria. Berlin: CERNA, CIRAD, SRPH. [Google Scholar]

19. Alengaram, U. J., Muhit B. A., A., bin Jumaat, M. Z., (2013). Utilization of oil palm kernel shell as lightweight aggregate in concrete–A review. Construction and Building Materials, 38(7), 161–172. DOI 10.1016/j.conbuildmat.2012.08.026. [Google Scholar] [CrossRef]

20. Okafor, F. O. (1988). Palm kernel shell as a lightweight aggregate for concrete. Cement and Concrete Research, 18(6), 901–910. DOI 10.1016/0008-8846(88)90026-9. [Google Scholar] [CrossRef]

21. NF EN 933-1 (2012). Tests for geometrical properties of aggregates—Part 1 : Determination of particle size distribution-Sieving method. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

22. NF EN 1097-3 (1998). Tests for mechanical and physical properties of aggregates—Part 3 : Determination of loose bulk density and voids. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

23. NF EN 1097-6 (2014). Tests for mechanical and physical properties of aggregates—Part 6: Determination of particle density and water absorption. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

24. Autret, P. (1983). Latérites et graveleux latéritiques. France: Laboratoire des ponts et chaussées de Paris. [Google Scholar]

25. Houben, H., Guillaud, H. (1989). Traité de construction en terre, pp. 21. 1ère Edition. Marseille: Editions Parenthèses. [Google Scholar]

26. Onana, V. L., Ngo’o Ze, A., Medjo Eko, R., Ntouala, R. F. D., Nanga Bineli, M. T. et al. (2017). Geological identification, geotechnical and mechanical characterization of charnockite-derived lateritic gravels from Southern Cameroon for road construction purposes. Transportation Geotechnics, 10(2), 35–46. DOI 10.1016/j.trgeo.2016.12.001. [Google Scholar] [CrossRef]

27. Nzabakurikiza, A., Onana, V. L., Ngo’o Ze, A., Mvindi, A. T., N., Ekodeck, G. E. (2017). Geological, geotechnical, and mechanical characterization of lateritic gravels from Eastern Cameroon for road construction purposes. Bulletin of Engineering Geology and the Environment, 76(4), 1549–1562. DOI 10.1007/s10064-016-0979-y. [Google Scholar] [CrossRef]

28. NF EN ISO 17892-4 (2018). Geotechnical investigation and testing-Laboratory testing of soil—Part 4: Determination of particle size distribution. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

29. NF P94-051 (1993). Sols: Reconnaissance et essais-Détermination des limites d’Atterberg-Limite de liquidité à la coupelle-Limite de plasticité au rouleau. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

30. XP P 94-047 (1998). Sols: Reconnaissance et essais-Détermination de la teneur pondérale en matières organiques d’un matériau-Méthode par calcination. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

31. NF P 11-300 (1992). Classification des matériaux utilisables dans la construction des remblais et des couches de forme d’infrastructures routières. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

32. NF P 94-093 (2014). Soils: Investigation and testing—Determination of the compaction reference values of a soil type—Standard Proctor Test—Modified Proctor Test. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

33. NF P 94-078 (1997). Soils: Investigation and tests. CBR after immersion. Immediate CBR. Immediate bearing ratio. Measurement on sample compacted in CBR mould. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

34. NF P 94-068 (1998). Sols: Reconnaissance et essais-Mesure de la capacité d’adsorption de bleu de méthylène d’un sol ou d’un matériau rocheux-Détermination de la valeur de bleu de méthylène d’un sol ou d’un matériau rocheux par l’essai à la tâche. La Plaine Saint-Denis Cedex, AFNOR. [Google Scholar]

35. Yu, A. B., Standish, N. (1990). A study of particle size distributions. Powder Technology, 62(2), 101–118. DOI 10.1016/0032-5910(90)80073-8. [Google Scholar] [CrossRef]

36. Roquier, G. (2016). Etude de la compacité optimale des mélanges granulaires binaires: Classe granulaire dominante, effet de paroi, effet de desserrement (Ph.D. Thesis). Université Paris Est, France. [Google Scholar]

37. Fuller, W. B., Thompson, S. E. (1907). The laws of proportioning concrete. Transactions of the American Society of Civil Engineers, 59(2), 67–143. DOI 10.1061/TACEAT.0001979. [Google Scholar] [CrossRef]

38. Andreasen A. H., M., Andersen, J. (1930). ÜBer die beziehung zwischen kornabstufung und Zwischenraum in produkten aus losen Körnern (mit einigen Experimenten). Kolloid-Zeitschrift, 50(3), 217–228. DOI 10.1007/BF01422986. [Google Scholar] [CrossRef]

39. Peronius, N., Sweeting, T. J. (1985). On the correlation of minimum porosity with particle size distribution. Powder Technology, 42(2), 113–121. DOI 10.1016/0032-5910(85)80043-7. [Google Scholar] [CrossRef]

40. Aberg, B. (1992). Void ratio of non-cohesive soils and similar materials. Journal of Geotechnical Engineering, 118(9), 1315–1334. DOI 10.1061/(ASCE)0733-9410(1992)118:9(1315). [Google Scholar] [CrossRef]

41. Tsirel, S. V. (1997). Methods of granular and fragmented material packing density calculation. International Journal of Rock Mechanics and Mining Sciences, 34(2), 263–273. DOI 10.1016/S0148-9062(96)00029-0. [Google Scholar] [CrossRef]

42. CEBTP (1984). Guide pratique de dimensionnement des chaussées pour les pays tropicaux. France: Ministère des Rélations Exterieurieures Coopération et Développement. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |