| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.021831

ARTICLE

Thermodynamic Investigation of a Solar Energy Cogeneration Plant Using an Organic Rankine Cycle in Supercritical Conditions

Research Lab Energetic and Environment, National Engineering School of Tunis, Tunis El Manar University, Belvedere, Tunis, 1002, Tunisia

*Corresponding Author: Larbi Afif. Email: afif.larbi@enit.utm.tn

Received: 07 February 2022; Accepted: 01 March 2022

Abstract: In the present work, a novel Organic Rankine Cycle (ORC) configuration is used for a low-grade heat source cogeneration plant. An investigation is conducted accordingly into the simultaneous production of electricity and cold. The proposed configuration relies on concentrated solar power (as heat source) and ambient air (for cooling). Furthermore, two gas ejectors are added to the system in order to optimize the thermodynamic efficiency of the organic Rankine cycle. The results show that the thermodynamic and geometric parameters related to these ejectors have an important effect on the overall system performances. In order to account for the related environmental impact, the following working fluids are considered: HCFC-124, HFC-236fa, HFO-1234yf and HFO-1234ze. As shown by the numerical simulations, the fluid R1234yf presents the minimal heat consumption and therefore provides an optimal thermal efficiency for the ORC cycle (which is around 29%). However, the refrigerant R236fa displays the highest refrigeration performances with a performance coefficient reaching a value as high as 0.38.

Keywords: ORC; energy efficiency; solar energy; ejector

Nomenclature

| COP | Coefficient of performance |

| GWP | Global warming potential |

| ℎ | Mass enthalpy (kJ/kg) |

| M | Mass flow rate (kg/s) |

| ODP | Ozone depletion potential |

| Q | Heat power (kw) |

| W | Mechanical power (kw) |

| η | Efficiency |

Many researchers have developed several technologies to improve the energy efficiency of the combined power and refrigeration cycles [1–4] by utilizing renewable energy resources [5–7]. The Organic Rankine Cycle is well-known for being an efficient and well-suited thermal conversion technique for renewable energy applications such as geothermal [8], biomass [9], waste heat recovery [10] and solar energy [11].

In particular, solar-powered ORC technology is considered a competitive system, when operating at lower temperatures offers a lower investment cost. In the other hand, in order to achieve better energy efficiency, scholars used the ORC system for the cogeneration plants [12].

Amiri Rad et al. [13] investigated several heat sources with temperatures ranging from 120°C to 300°C, as well as the matching input temperature and pressure to the turbine, in order to find the best working fluid for ORC. They investigated many organic working fluids based on total exergy efficiency and discovered that the optimal working fluid and operating pressure for operating temperatures of 120°C, 150°C, 200°C, 250°C, and 300°C are R245fa at 6.24 bar, R152a at 2.75 bar, R141b at 8.48 bar, Benzene at 4.52 bar and water at 3.99 bar, respectively.

Sanaye et al. [14] compared ORC to Series two stage ORC and Parallel two stage ORC. They discovered that STORC generates 8.5 percent more power than ORC, but PT-ORC generates 0.3 percent less. Finally, ST-ORC was proven to boost power generation by 13.1 percent while reducing heat exchanger size by 27.9% when compared to dual cycle ORC.

Surendran et al. [15] evaluated the energetic, exergetic, and economic performance of a two-stage serial organic Rankine cycle with a double heat source and realized that it is better adapted for low-temperature heat sources, has lower power generation costs, and a shorter payback period than a two-stage serial ORC system with a single source of heat.

Wang et al. [16] investigated the utilization of gas engine exhaust waste in the operation of ORC and ERC. The cooling created by ERC was used to cool the transformer oil, improving its performance. Based on their findings, a 1.95 GW engine can typically generate 225 kW of electricity while the oil temperature is dropped by 20°C, increasing the transformer performance by 20%.

Using zeotropic mixtures, Zhu et al. [17] developed a unique ejector heat pump coupled with an organic Rankine cycle combined cooling, heating, and power system (ORC-CCHP). R141b/R134a (0.55/0.45) offers power efficiency of 4.21%, refrigeration efficiency of 14.6%, and COP of 1.12 with an optimal entrainment ratio of 0.2 and generator temperature of 78°C, which are much greater than those of pure R141b or R134a.

Moreover, based on research [18], CSP technology such as parabolic troughs is ideal for ORC plants and can offer a temperature of the heat source up to 300°C.

In this work, a novel ORC-ERC system is proposed using two gas ejectors. Several parameters were studied to highlight their influence on the system performance. On the other hand, a comparative study is developed to determine the best working fluid for the cogeneration plant.

A combined heat and power plant based on the ORC cycle is introduced in this paper and guarantees the output of energy and cooling simultaneously. An energy study is carried out by taking the following hypotheses into account:

- The adiabatic processes of the gas ejectors are postulated.

- All cycle processes have achieved a state of equilibrium.

- Kinetic and potential energies fluctuate insignificantly.

- The decrease of the heat exchanger pressure is insignificant.

- The fluid expansion process in the valve is isenthalpic.

- The heat losses into the environment are low.

Similar to the conventional Rankine cycle, an organic Rankine cycle operates by using an organic fluid rather than water. This adjustment provides many benefits that will be addressed in this paper later.

Concentrating solar power is a well-established technology in which the light of the sun is reflected into a linear or punctual collector, transmitting heat through the vapor generator to the working fluid. This heat is then used in the proposed system to generate electricity and refrigeration. In fact, concentrated solar power technologies are classified into three types: parabolic dish, solar tower, and parabolic trough. Punctual concentration systems such as parabolic dishes and solar towers present a high heat source temperature. The Stirling engine, the steam cycle and the combined cycle are the best power systems for these technologies. However, since the organic Rankine cycle is operating at a low temperature, the Parabolic trough collector is considered as the best candidate. This technology offers a low heat source temperature (300°C–400°C) and requires a lower investment cost. The process, however, is cooled by the ambient air.

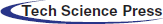

As seen in Fig. 1, the structure of the proposed system is created by coupling a modified organic Rankin cycle with an ERC process using a high-pressure turbine and a low-pressure turbine. The compressor is substituted by two gas ejectors to save energy usage compared to traditional refrigeration cycles. In fact, a gas ejector is simply able to thermally compress the secondary flow which presents a relatively low pressure by using the high-pressure primary flow.

Figure 1: Schematic of the proposed plant

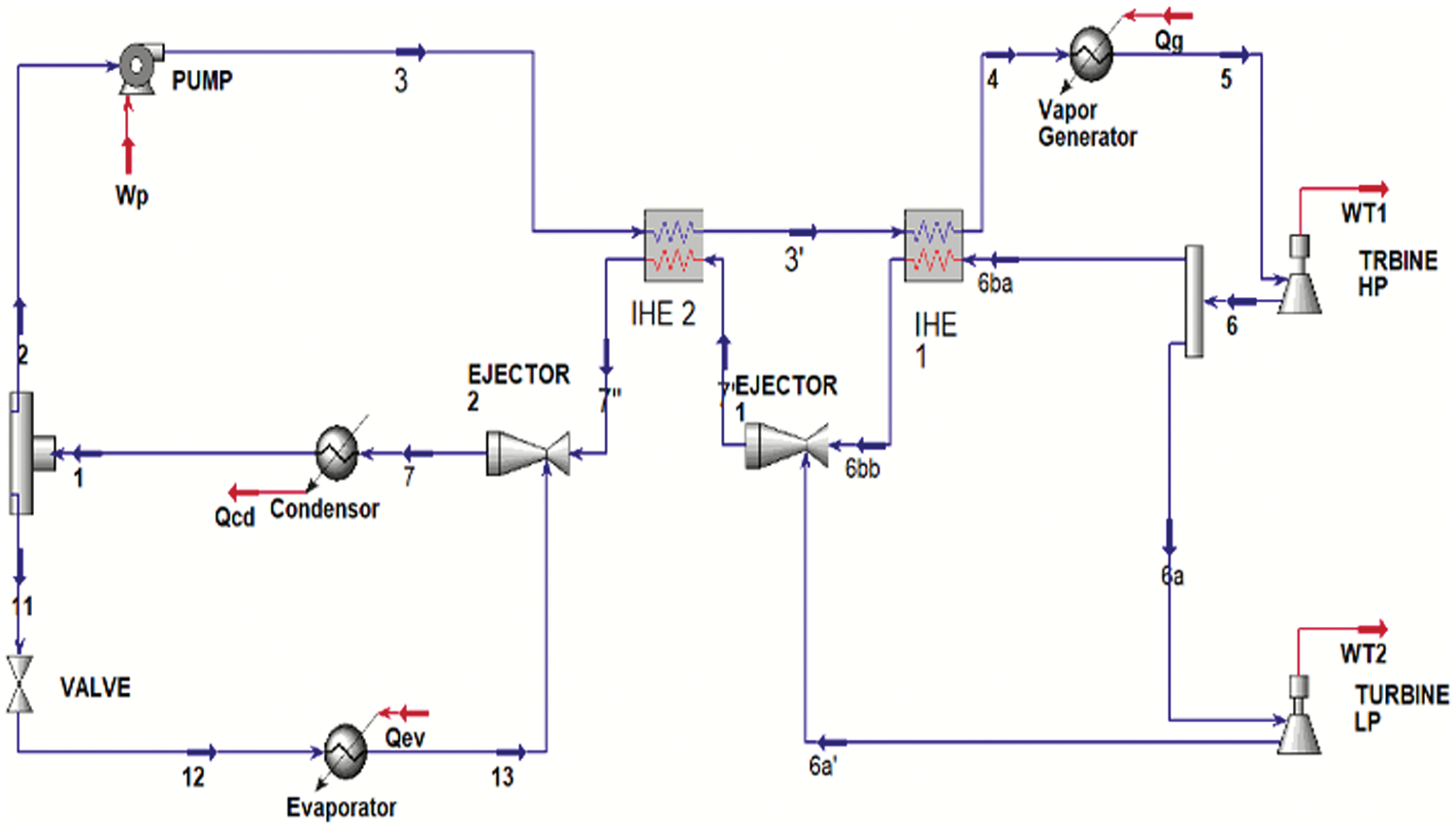

In reality, the ejector uses convergent-divergent chamber to transform enthalpy to velocity and therefore the secondary fluid is entrained by the primary fluid. The mixture fluid is recompressed at medium pressure in the diffuser chamber. Fig. 2 displays the schema of the gas ejector.

Figure 2: Schema of the gas ejector

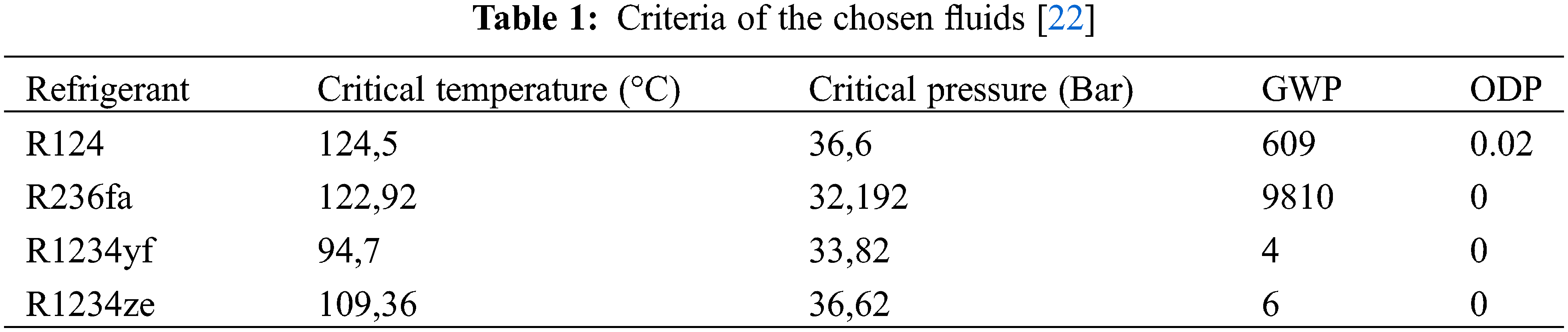

The choosing of the working fluid has a significant influence on the efficiency of the cogeneration plant. Initially, the working fluid has to be suited to the heat source temperature of the plant. Since the proposed system is operating at low temperature, the refrigerants are the best candidates. In addition, their vapor saturation curve in the T-s diagram has a positive slope, indicating that they are dry fluids [19]. As a result, the humidity created by expanding the gas in the turbine is prevented. The environmental implications, on the other hand, must be considered by selecting a fluid with a low ozone depletion potential ODP and a low global warming potential GWP [20,21]. Table 1 presents the criteria of the chosen fluids.

The Aspen Hysys software was utilized to model of the proposed cycle in this study. In order to evaluate the effectiveness of the framework, the Peng Robinson model (1) was used for the thermodynamic calculations because it is strongly suggested, necessary and quite indispensable for the two phases fluid balance calculations at hydrocarbon pressure.

where

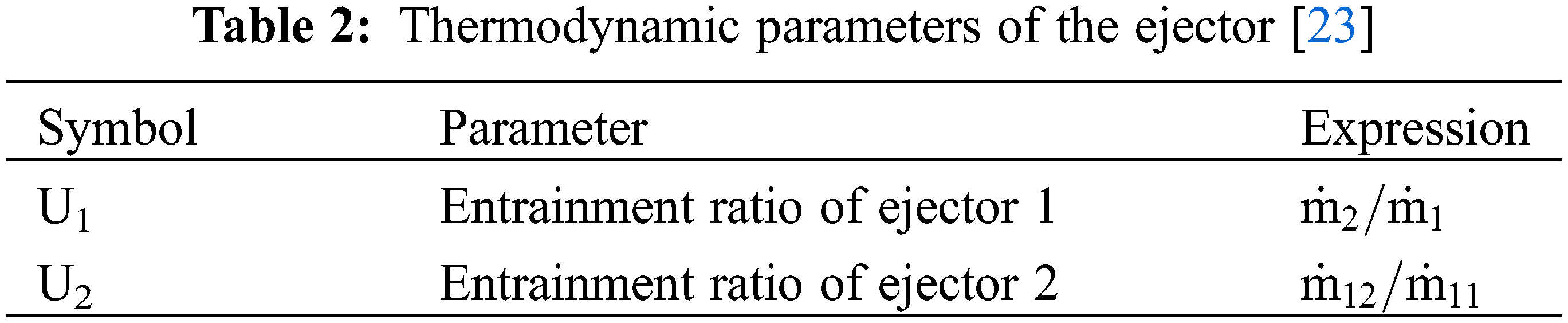

However, the data of this study has revealed that the addition of the gas ejectors influence the efficiency of the cogeneration plant by means of the entrainment ratios of these gas ejectors. The expressions of the entrainment ratios are shown in Table 2.

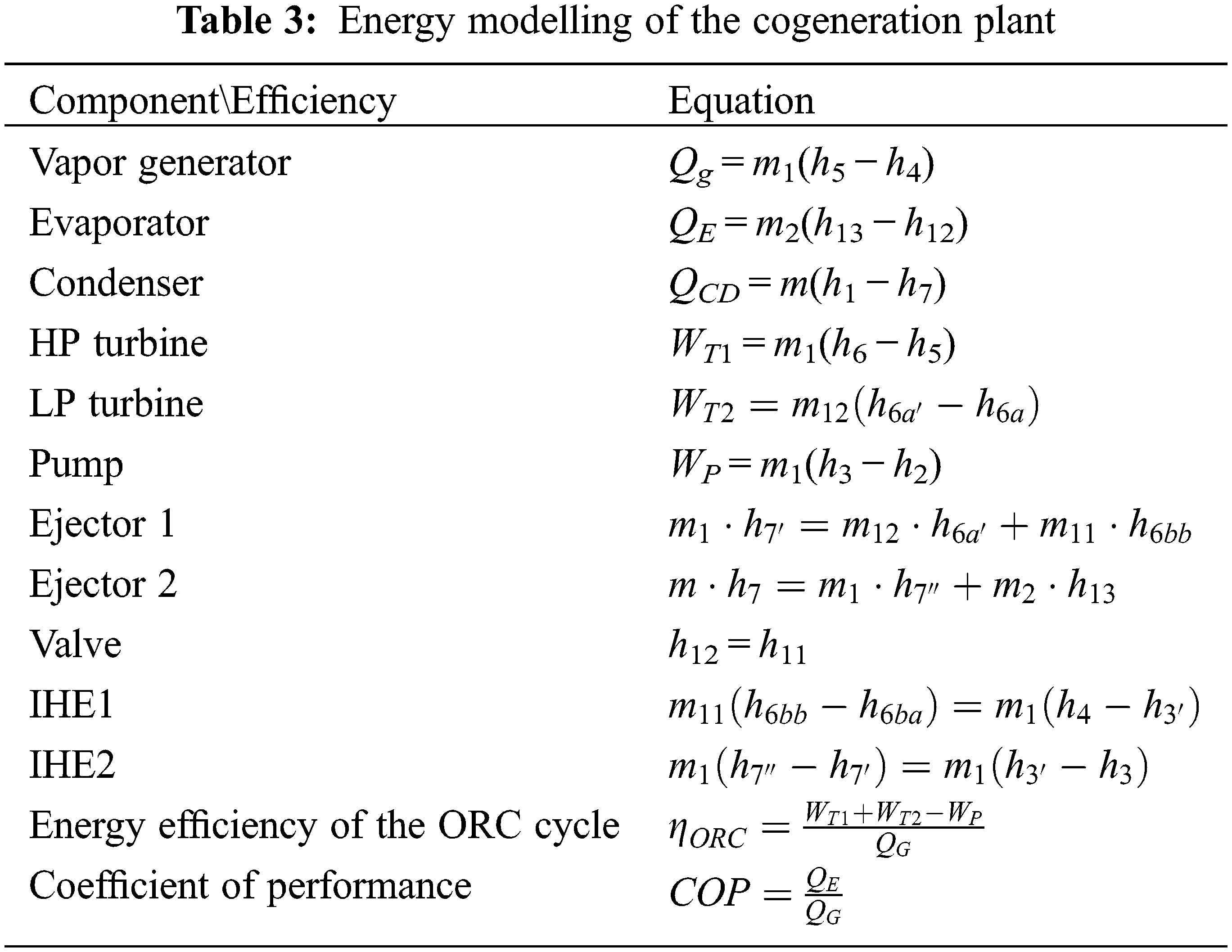

The formulas in Table 3 are used to perform an energetic assessment on the combined cycle power plant.

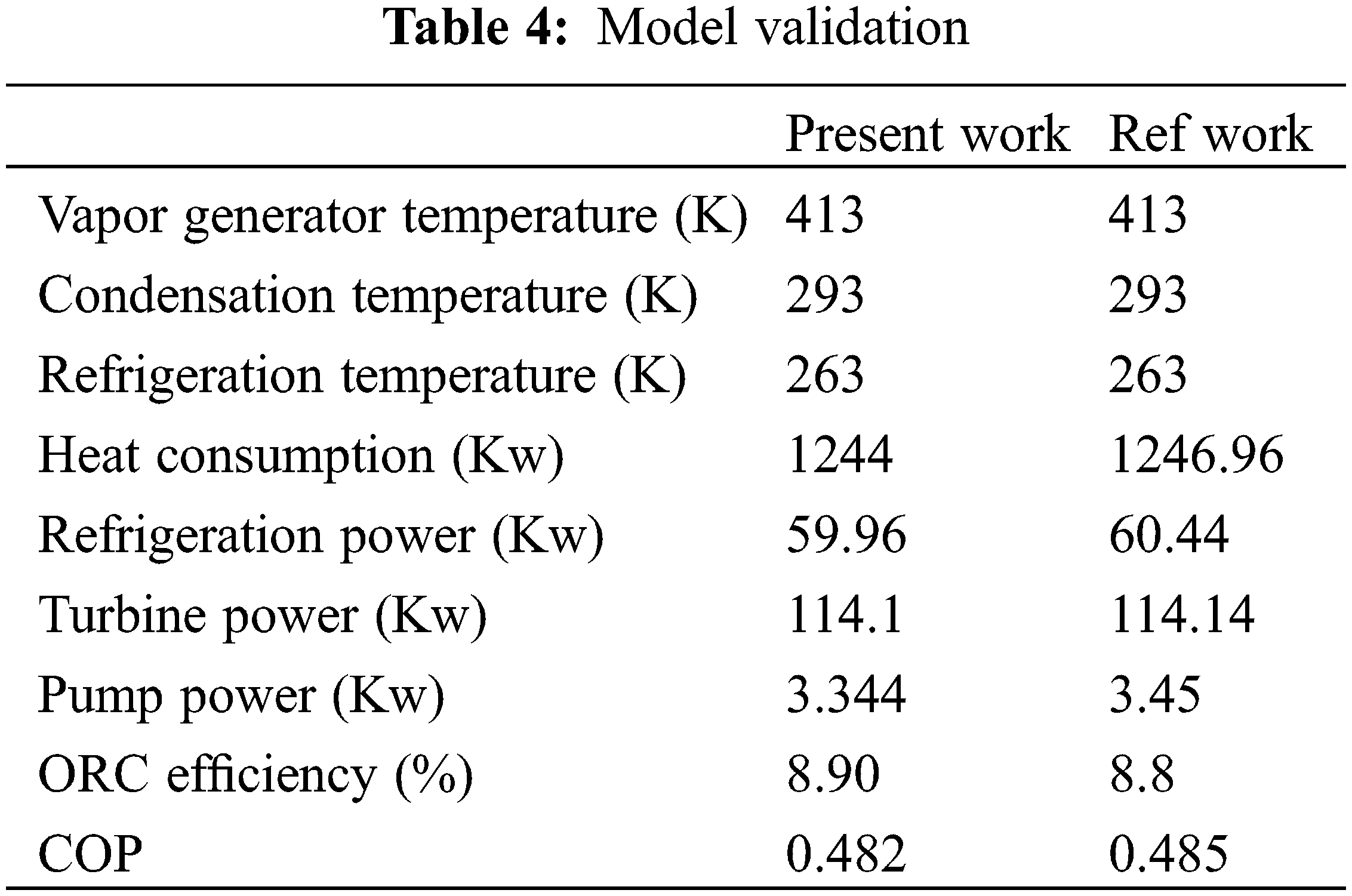

The results of this simulation are validated with a previous work using a similar cogeneration plant [24]. The comparison of results is illustrated in Table 4 where the refrigerant R123 is used as working fluid.

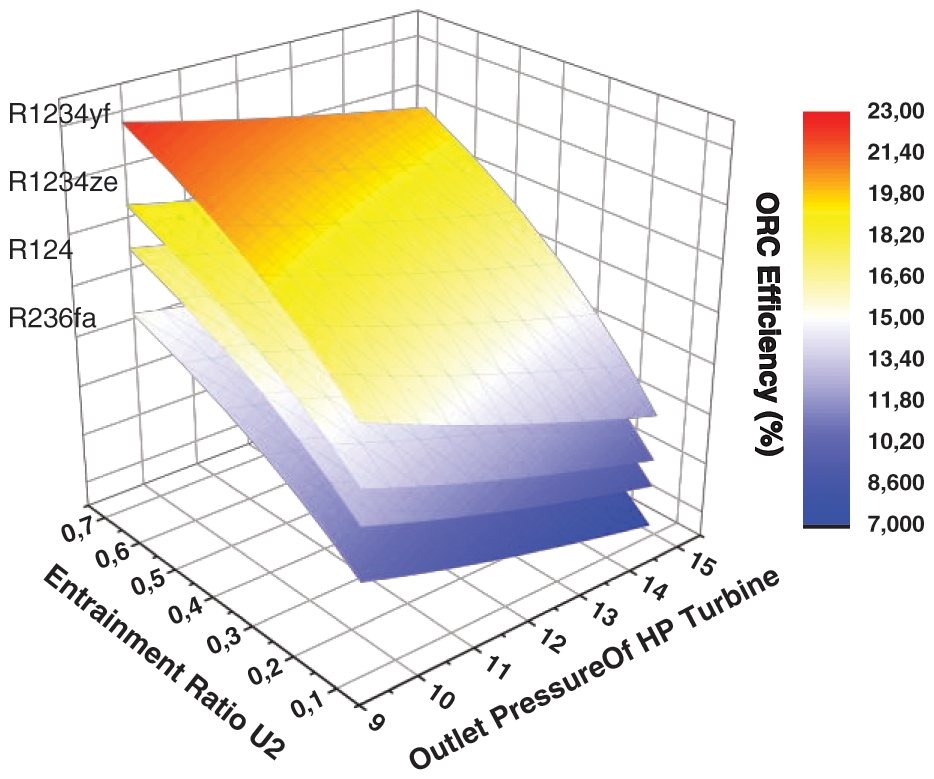

According to the results obtained in this study, the entrainment ratio of the ejector 2 and the outlet pressure of the HP turbine have an effect on the ORC thermal efficiency, as shown in Fig. 3.

Figure 3: ORC efficiency as a function of entrainment ratio U2 and HP turbine outlet pressure

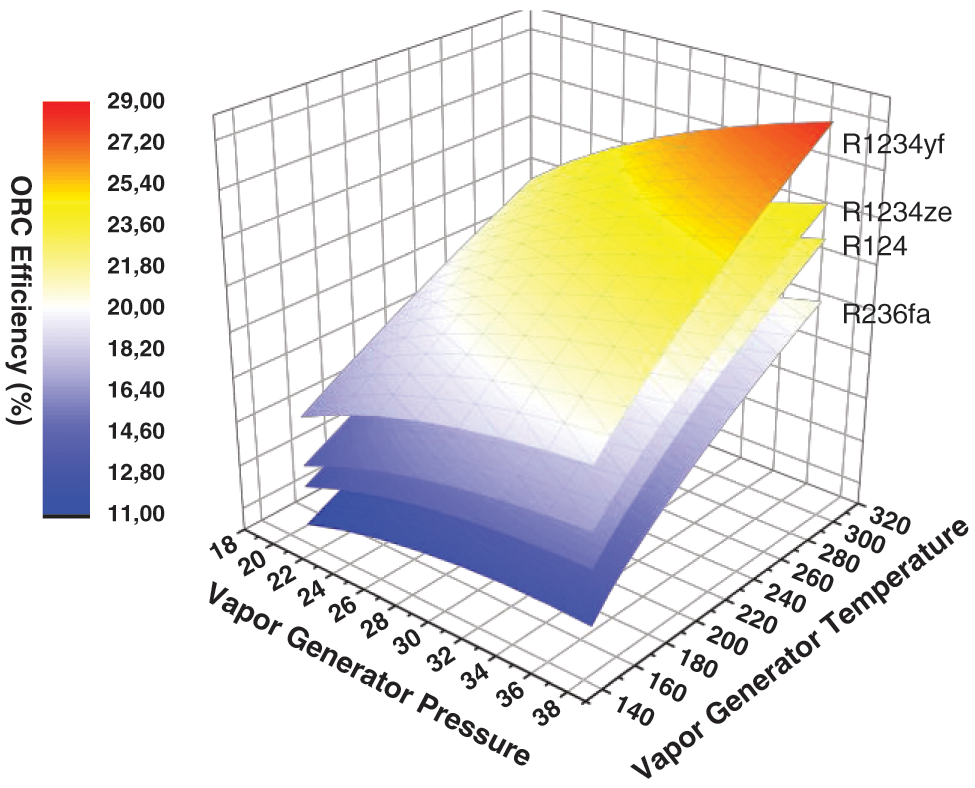

The increase of the entrainment ratio U2 has improved the ORC efficiency. However, by increasing the HP turbine outlet pressure, net power output decreases and therefore ORC performance is reduced. On the other hand, the fluid R1234yf presents the highest efficiency in comparison to other working fluids. In addition, the pressure and temperature of the vapor generator have a great influence on the system performance. As shown in Fig. 4, the increase of the pressure and temperature of the vapor generator provoke an enhancement in the ORC performance. In fact, the ORC efficiency for the R1234yf has reached a maximum of 29%.

Figure 4: ORC efficiency as a function of the pressure and the temperature of the vapor generator

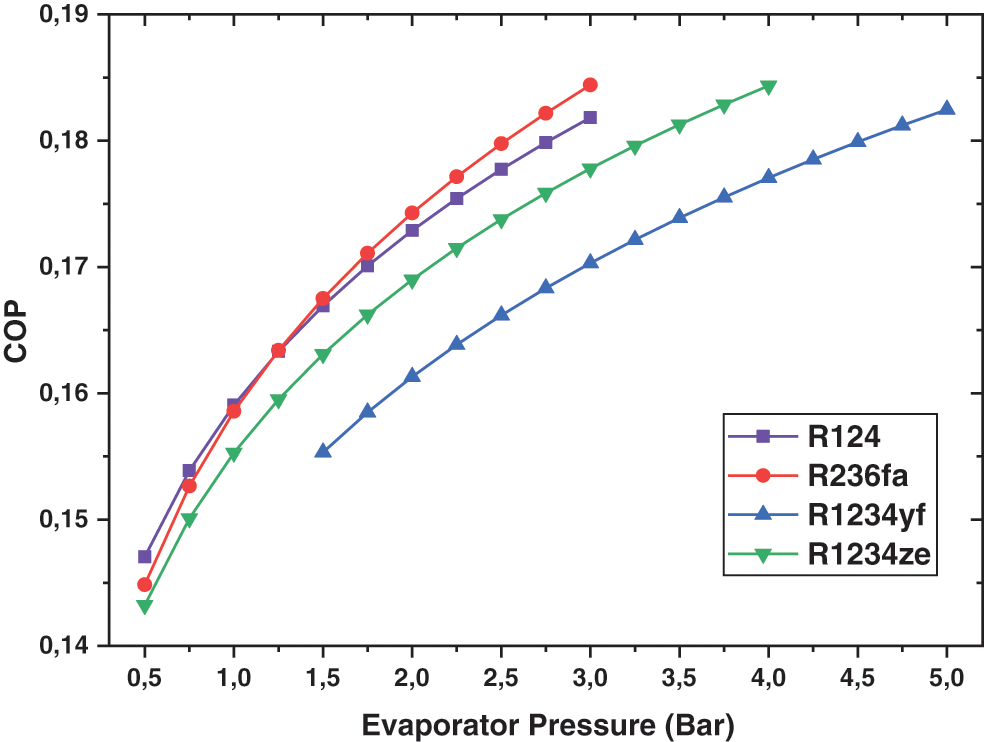

However, refrigeration performance is affected by the evaporator pressure, as shown in Fig. 5.

Figure 5: COP as a function of evaporator pressure

In fact, as we increase the evaporator pressure, the evaporator temperature increases as well. However, at the same pressure, each working fluid has a different temperature. Therefore, the refrigerant R236fa has the maximal COP but eventually all the chosen fluids reach approximately the same value at different pressures.

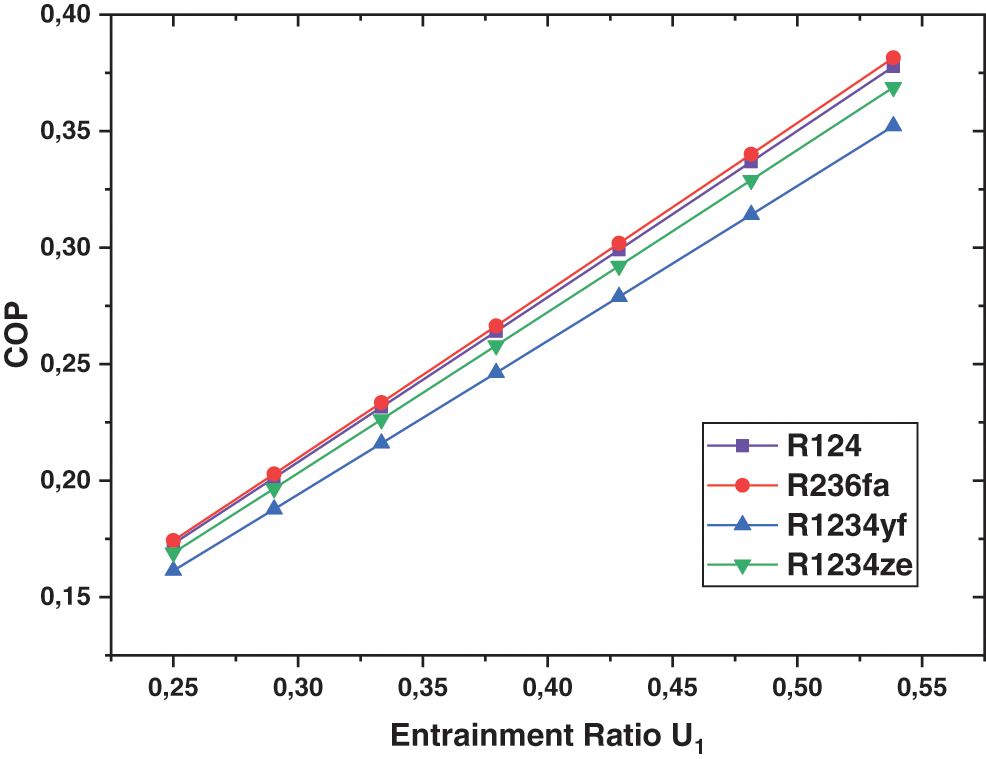

Besides, Fig. 6 shows the effect of the Entrainment ratio U1 on the refrigeration performance.

Figure 6: COP as a function of entrainment ratio U1

As plotted in Fig. 6, COP has enhanced by increasing the entrainment ratio U1. This is due to the fact the mass flow rate in the evaporator has increased and the mass flow rate in the vapor generator has decreased. Therefore, refrigeration power has increased while the heat consumption has reduced. In fact, in this case, the COP is proportional to entrainment ratio U2. Also, the working fluid R236fa has reached a maximal COP near 0.38.

The energy analysis developed in this study is carried out by taking into account the influence of the gas ejector parameters. Results have shown that the combination of two ejectors has increased the global performance of the system. In addition, the heat recuperators installed in the system have helped to save energy by recovering the extracted heat from the gas ejector. However, a comparative analysis of the chosen fluids revealed that R1234yf presented the optimal ORC efficiency, whereas R236fa had the best COP.

In fact, the fluid R1234yf presents the minimal heat consumption and therefore has the optimal thermal efficiency of the ORC cycle which is around 29%. However, the refrigerant R236fa presented the highest refrigeration performance where the COP has reached almost 0.38.

In order to more improve the performance of the proposed cogeneration plant, an exergy study is needed to complete this analysis which will help understand better which component is the most responsible for energy loss and how to reduce the system irreversibility.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Zhang, X., He, M., Zhang, Y. (2012). A review of research on the Kalina cycle. Renewable and Sustainable Energy Reviews, 16(7), 5309–5318. DOI 10.1016/j.rser.2012.05.040. [Google Scholar] [CrossRef]

2. Goswami, D. Y. (1998). Solar thermal power technology: Present status and ideas for the future. Energy Sources, 20(2), 137–145. DOI 10.1080/00908319808970052. [Google Scholar] [CrossRef]

3. Zamfirescu, C., Dincer, I. (2008). Thermodynamic analysis of a novel ammonia-water trilateral Rankine cycle. Thermochimica Acta, 477(1–2), 7–15. DOI 10.1016/j.tca.2008.08.002. [Google Scholar] [CrossRef]

4. Aghahosseini, S., Dincer, I. (2013). Comparative performance analysis of low-temperature Organic Rankine Cycle (ORC) using pure and zeotropic working fluids. Applied Thermal Engineering, 54(1), 35–42. DOI 10.1016/j.applthermaleng.2013.01.028. [Google Scholar] [CrossRef]

5. Shokati, N., Ranjbar, F., Yari, M. (2015). Comparative and parametric study of double flash and single flash/ORC combined cycles based on exergoeconomic criteria. Applied Thermal Engineering, 91, 479–495. DOI 10.1016/j.applthermaleng.2015.08.031. [Google Scholar] [CrossRef]

6. Chen, H., Goswami, D. Y., Stefanakos, E. K. (2010). A review of thermodynamic cycles and working fluids for the conversion of low-grade heat. Renewable and Sustainable Energy Reviews, 14(9), 3059–3067. DOI 10.1016/j.rser.2010.07.006. [Google Scholar] [CrossRef]

7. Patil, V. R., Biradar, V. I., Shreyas, R., Garg, P., Orosz, M. S. et al. (2017). Techno-economic comparison of solar Organic Rankine Cycle (ORC) and photovoltaic (PV) systems with energy storage. Renewable Energy, 113, 1250–1260. DOI 10.1016/j.renene.2017.06.107. [Google Scholar] [CrossRef]

8. Song, J., Wang, Y., Wang, K., Wang, J., Markides, C. N. (2021). Combined supercritical CO2 (SCO2) cycle and Organic Rankine Cycle (ORC) system for hybrid solar and geothermal power generation: Thermoeconomic assessment of various configurations. Renewable Energy, 174, 1020–1035. DOI 10.1016/j.renene.2021.04.124 [Google Scholar] [CrossRef]

9. Schuster, A., Karellas, S., Kakaras, E., Spliethoff, H. (2009). Energetic and economic investigation of organic Rankine cycle applications. Applied Thermal Engineering, 29(8–91809–1817. DOI 10.1016/j.applthermaleng.2008.08.016ï. [Google Scholar] [CrossRef]

10. Srinivasan, K. K., Mago, P. J., Krishnan, S. R. (2010). Analysis of exhaust waste heat recovery from a dual fuel low temperature combustion engine using an organic Rankine cycle. Energy, 35(6), 2387–2399. DOI 10.1016/j.energy.2010.02.018. [Google Scholar] [CrossRef]

11. Delgado-Torres, A. M., García-Rodríguez, L. (2010). Analysis and optimization of the low-temperature solar Organic Rankine Cycle (ORC). Energy Conversion and Management, 51(12), 2846–2856. DOI 10.1016/j.enconman.2010.06.022. [Google Scholar] [CrossRef]

12. Casrtelli, D., Binotti, M., Silva, P., Macchi, E., Roccaro, E. et al. (2015). Power block off-design control strategies for indirect solar ORC cycles. Energy Procedia, 69, 1220–1230. DOI 10.1016/j.egypro.2015.03.166. [Google Scholar] [CrossRef]

13. Amiri Rad, E., Mohammadi, S., Tayyeban, E. (2020). Simultaneous optimization of working fluid and boiler pressure in an organic Rankine cycle for different heat source temperatures. Energy, 194, 1–12. DOI 10.1016/j.energy.2019.116856. [Google Scholar] [CrossRef]

14. Sanaye, S., Refahi, A. (2020). A novel configuration of ejector refrigeration cycle coupled with organic Rankine cycle for transformer and space cooling applications. International Journal of Refrigeration, 115, 191–208. DOI 10.1016/j.ijrefrig.2020.02.005. [Google Scholar] [CrossRef]

15. Surendran, A., Seshadri, S. (2020). Performance investigation of two stage Organic Rankine Cycle (ORC) architectures using induction turbine layouts in dual source waste heat recovery. Energy Conversion and Management: X, 6, 1–12. DOI 10.1016/j.ecmx.2020.100029. [Google Scholar] [CrossRef]

16. Wang, Q., Wang, J., Li, T., Meng, N. (2020). Techno-economic performance of two-stage series evaporation organic Rankine cycle with dual-level heat sources. Applied Thermal Engineering, 171, 1–14. DOI 10.1016/j.applthermaleng.2020.115078. [Google Scholar] [CrossRef]

17. Zhu, Y., Li, W., Wang, Y., Li, H., Li, S. (2021). Thermodynamic analysis and parametric optimization of ejector heat pump integrated with organic Rankine cycle combined cooling, heating and power system using zeotropic mixtures. Applied Thermal Engineering, 194, 1–12. DOI 10.1016/j.applthermaleng.2021.117097. [Google Scholar] [CrossRef]

18. Quoilin, S., van den Broek, M., Declaye, S., Dewallef, P., Lemort, V. (2013). Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renewable and Sustainable Energy Reviews, 22, 168–186. DOI 10.1016/j.rser.2013.01.028. [Google Scholar] [CrossRef]

19. Mago, P. J., Chamra, L. M., Srinivasan, K., Somayaji, C. (2008). An examination of regenerative organic Rankine cycles using dry fluids. Applied Thermal Engineering, 28(8–9), 998–1007. DOI 10.1016/j.applthermaleng.2007.06.025. [Google Scholar] [CrossRef]

20. Bendig, M., Favrat, D., Maréchal, F. (2014). Methodology for identification of suitable ORC-Cycle and working-fluid using integration with multiple objectives. Chemical Engineering Transactions, 39, 1141–1146. DOI 10.3303/CET1439191. [Google Scholar] [CrossRef]

21. Bahrami, M., Pourfayaz, F., Kasaeian, A. (2022). Low global warming potential (GWP) working fluids (WFs) for Organic Rankine Cycle (ORC) applications. Energy Reports, 8, 2976–2988. DOI 10.1016/j.egyr.2022.01.222. [Google Scholar] [CrossRef]

22. Li, W., Bu, S., Yang, X., Huang, F., Tang, M. et al. (2021). Thermal performance analysis of a novel geothermal organic Rankine cycle-bypass flash system based on the latent heat proportion of working fluids. Energy Reports, 7, 6806–6819. DOI 10.1016/j.egyr.2021.10.062. [Google Scholar] [CrossRef]

23. Sun, W., Ma, X., Zhang, Y., Jia, L., Xue, H. (2021). Performance analysis and optimization of a steam ejector through streamlining of the primary nozzle. Case Studies in Thermal Engineering, 27, 1–13. DOI 10.1016/j.csite.2021.101356. [Google Scholar] [CrossRef]

24. Dai, Y., Wang, J., Gao, L. (2009). Exergy analysis, parametric analysis and optimization for a novel combined power and ejector refrigeration cycle. Applied Thermal Engineering, 29(10), 1983–1990. DOI 10.1016/j.applthermaleng.2008.09.016. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |