| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.018995

ARTICLE

Analysis of Highway Asphalt Modified With Recycled Rubber and Waste Plastics

Building Engineering B.O. of CCCC Third Highway Engineering Co., Ltd. (Beijing), Beijing, 100015, China

*Corresponding Author: Mingzhi Lu. Email: bjhzzl@163.com

Received: 28 August 2021; Accepted: 03 November 2021

Abstract: In this study, it is shown how recycled rubber and waste plastics can modify the softening point and penetration of asphalt traditionally used for highways. It is shown that the modified asphalt can meet the performance index requirements when the components are present with a certain proportion or relative ratio (1:3.5). The dispersion process of the masterbatch in base asphalt can effectively be implemented, with good results and a smaller mixing time. The proposed approach may be regarded as a good strategy to achieve energy savings and protection of the environment.

Keywords: Recycled rubber; low-density polyethylene; waste polyethylene; polymer materials; modified asphalt

With the continuous development of the domestic economy, highways have become a vital link to promote economic development. Excellent performance, cost reduction, and simple processes have become the main trends in the development of the asphalt industry. Modified asphalt with excellent performance, such as Styrene-butadiene-styrene block copolymer (SBS), is made by adding rubber, resin, high molecular polymer, ground rubber powder or other fillers and other admixtures (modifiers), or adopting measures such as mild oxidation processing of asphalt to make asphalt or asphalt mixture. The performance of the asphalt binder can be improved, see reference [1]. Modified asphalt, etc., have disadvantages such as high cost, complex production process, and high construction intensity. In recent years, many high-grade domestic highways have made SBS gradually pay attention to asphalt modification [1]. At present, SBS modified asphalt in Europe is in modified asphalt; the share of China has exceeded 40%. The SBS modified asphalt of the United States is its main component. SBS modified asphalt is also widely used in high-grade highways and airports such as the Capital Airport Expressway in China. The good effect of SBS modified asphalt is mainly due to its hard and soft two-phase structure. This can effectively improve the temperature performance, tensile performance, elastic cohesive adhesion performance, storage stability, and aging resistance of the asphalt. However, the differences in relative molecular mass and chemical structure between asphalt and SBS are thermodynamically incompatible. Therefore, SBS is physically dispersed in the asphalt. The complete compatibility of SBS and asphalt is the key to the modification effect. But in fact, phase separation is still the main reason that affects the performance of modified asphalt. Using recycled polymer materials to modify the compatibility of asphalt, the preparation of recycled polymer material modified asphalt masterbatch has become the focus and difficulty of future research. Low-density polyethylene (LDPE) has low crystallinity and low melting point conducive to blending with asphalt and low cost. It can significantly improve the high-temperature performance of asphalt. Therefore, LDPE occupies an important position in polymer-modified asphalt.

Because asphalt is a viscoelastic material, the elastic properties of asphalt gradually decrease under high-temperature conditions. After its transformation into a plastic body, its resistance to deformation gradually decreases. It is easy to flow at high temperatures and is prone to permanent deformation under external force. Polymer-modified asphalt is also a viscoelastic material. However, this material has a wide range of viscoelastic properties and has elasticity or delayed elasticity at high temperatures. After the external force is removed, the stress and deformation can be recovered quickly or slowly. Asphalt is prone to brittle fracture in a long-term low-temperature environment, so polymer modification is required. In turn, it helps to improve the high and low-temperature performance of the asphalt [2]. The main advantage of the masterbatch method is that the modifier can be blended and pre-dissolved with the asphalt. Therefore, the prepared modified asphalt masterbatch can be better dispersed in the base asphalt. The dissolution time of this operation is short, the preparation process is simple, and the production cost is low. It has good practical value.

In this article, we have improved the processing technology of asphalt through composite recycled rubber (WR) and low-density polyethylene. In addition, the modifier was prepared concerning the modification mechanism of SBS modified asphalt, and the processing conditions, preparation temperature, and basic performance of the asphalt were improved. The modified asphalt preparation process is simplified, the high-performance modified asphalt masterbatch is prepared, and the process technology is effectively improved.

2.1 Experimental Materials and Instruments

100# petroleum asphalt was purchased from Panjin Heima Rubber Co., Ltd. (Panjin, China) Extrusion reclaimed rubber (WR) was purchased from Panjin Heima Rubber Co., Ltd. (Panjin, China) Extrusion reclaimed rubber. Type 50I LDPE was purchased from Yanjing Petrochemical (Beijing, China) [3]. Coumarone resin was purchased from the market. Waste polyethylene plastic (WPE) comes from waste mulch film within two years.

XSS-300 torque rheometer was purchased from Haikechuang Rubber and Plastic Machinery Equipment Co., Ltd. (China) SYD2806F computer control asphalt softening point tester from Beijing Aerospace Keyu Testing Instrument Co., Ltd. (China). HDLz-IV automatic asphalt penetration meter was purchased from Nanjing Huada Electronic Application Research Institute (China). MH-200A digital display electronic hydrometer.

2.2.1 Preparation of Modified Masterbatch

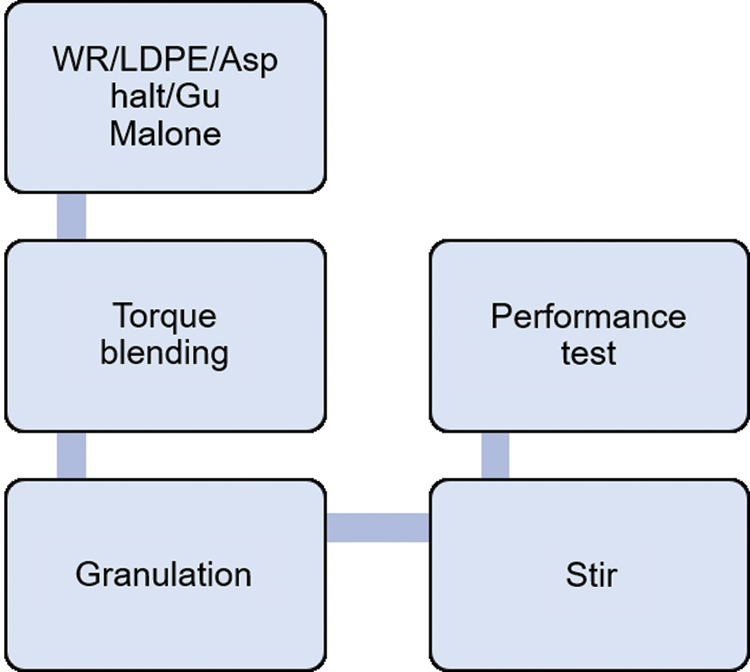

Add recycled rubber, LDPE, and Gumarone in the torque rheometer in sequence. After the three raw materials are completely blended, we add the base asphalt. This is mainly because the melting temperature of LDPE is 120°C, but the asphalt has become fluid at this temperature. If the asphalt is added in advance, the torque will be almost zero. Under such conditions, the modifier cannot be fully mixed and pre-blended with the base asphalt [4]. This will not achieve the best results. The experimental process is shown in Fig. 1.

Figure 1: Experimental process

2.2.2 Performance Test of Masterbatch

Melt index measurement: We express it in MFR. The unit is g/10 min. The melt index refers to the quality of the thermoplastic material that passes through the standard die capillary tube every 10 min under a load of 2.16 kg at 120°C.

Density determination: The density is measured by a digital electronic hydrometer.

2.2.3 Performance Test of Modified Asphalt

According to the GB/T4507 specification, we use the ring and ball method to test the softening point. First, the asphalt sample is injected into the standard copper ring, and a standard quality steel ball is placed on the top of the copper ring. We place the copper ring and the sample at (5 ± 0.5). The temperature will start to rise after 1~1.5 h in distilled water [5]. The heating rate is set to 5 °C/min. As the temperature rises, the sample falls under heat, and after falling to the contact plate, the temperature (°C) is read as the softening point. The penetration test is carried out according to the GB/T4509 specification. The experimental temperature is set at 25°C, load 100 g. Penetration index PI calculates the value obtained according to the penetration test at different temperatures and the corresponding temperature value. The calculation formula is

In the formula:

2.2.4 Parametric Modeling of the Lightweight Lattice Structure

To make the lightweight lattice structure composed of 5 different cells have the same geometric shape, shape size, and quality, it is necessary to ensure the same cell spatial density. Its space density formula is

The subscript

It can be seen from formula (4) that the pillar value of the edge structure cell is smaller than that of the other four structures. The edge structure cell is used as the basic structure for data comparison research. The size of the rectangular parallelepiped space occupied by the cells is set to

The rectangular parallelepiped specimens were designed with the cell as mentioned earlier structure. The formulas for the dimensions of the shape, length, width, and height of the specimen

3.1 The Influence of Heating Temperature on the Solubility of Masterbatch in Asphalt

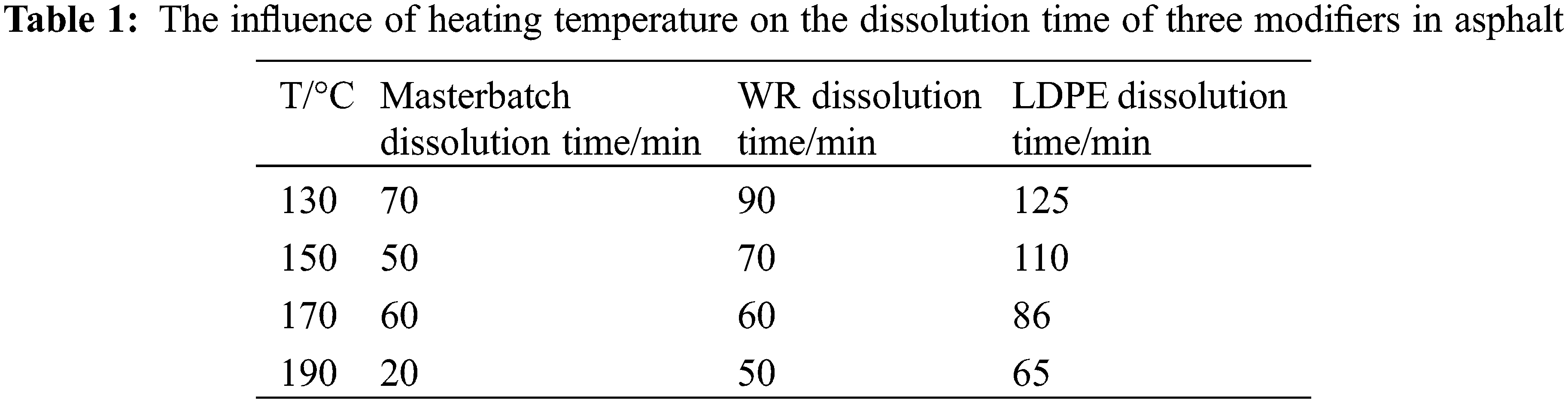

We use a common mechanical mixing method to dissolve 4 g masterbatch, 4 g WR, 4 g LDPE in 14 g base asphalt. At the same time, record the dissolution time at 130°C, 150°C, 170°C, and 190°C. The results are shown in Table 1.

It can be seen from Table 1 that the three modifiers all show the law of shortening the dissolution time in the asphalt with the increase of the dissolution temperature. However, the experiment found that when the temperature exceeds 170°C, the matrix asphalt will produce a lot of smoke and pollute the environment, so the experiment choose 150°C as the best dissolution temperature. The dissolution time of the masterbatch is the shortest (50 min) at 150°C dissolution temperature [7]. Followed by WR dissolution time (70 min). The dissolution time of LDPE is the longest (110 min). The masterbatch is a blend of asphalt, coumarone resin, WR, and LDPE in a certain proportion. Therefore, the dissolution time of the masterbatch in the matrix asphalt is the shortest, and the dissolution effect is the best.

3.2 The Effect of Mixing Time on the Solubility of Masterbatch in Base Asphalt

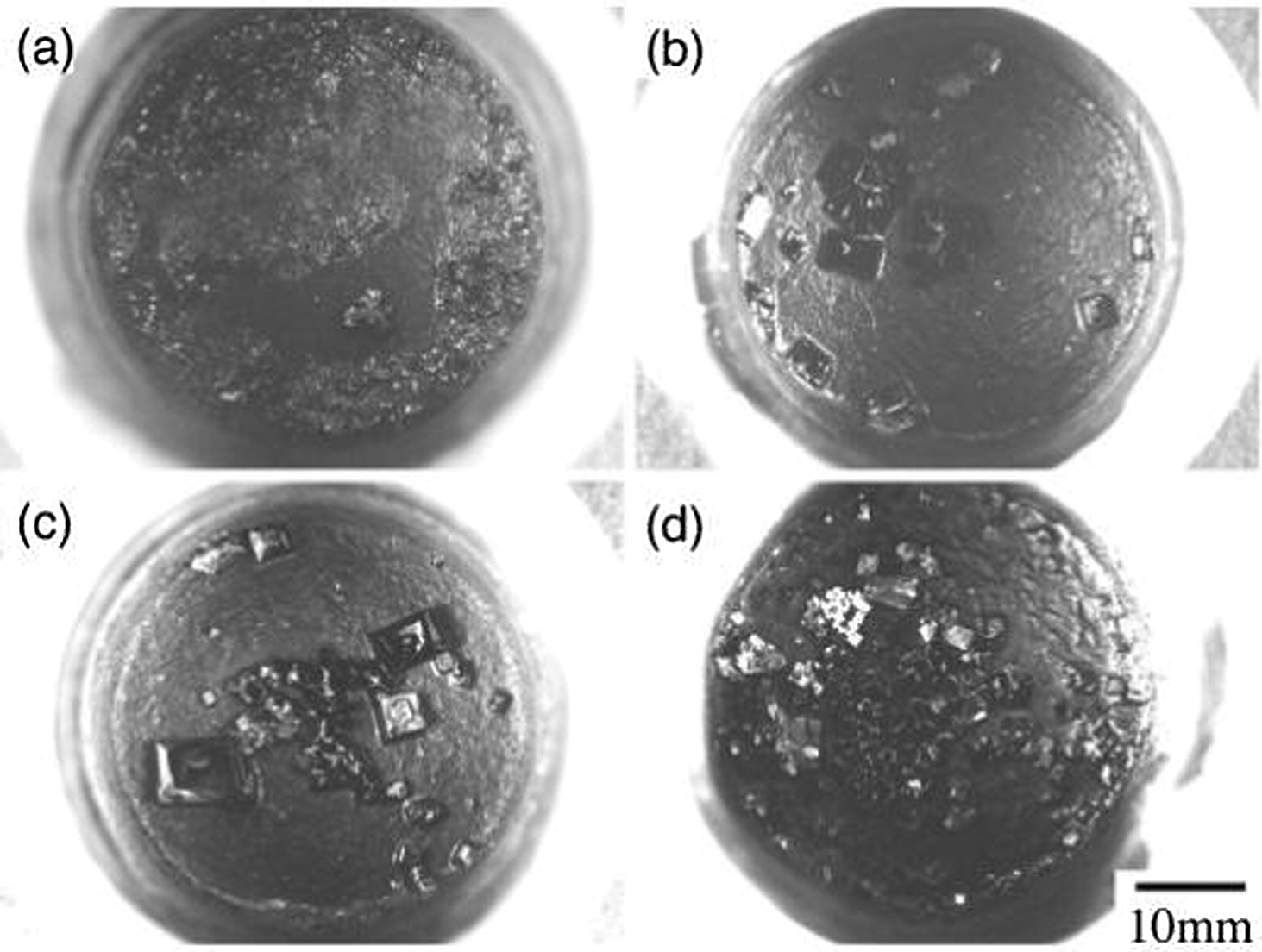

We weighed 4 g bitumen modified masterbatch and put it into 14 g base bitumen heated to 150°C. Take out a small amount of modified asphalt every 10 min and observe its dispersibility. The results are shown in Fig. 2. It can be seen from Fig. 2 that the masterbatch hardly dissolves in the base asphalt for 10 min. Most of it dissolves at 20 min, and the remaining masterbatch also swells. There are tiny masterbatch particles in the asphalt at 30 min. The masterbatch can be completely dissolved in the base asphalt at 50 min.

Figure 2: The dispersion of modified masterbatch in base asphalt at different periods among them (a) dissolve 10 min. (b) dissolve 20 min. (c) dissolve 30 min. (d) dissolve 50 min

3.3 The Influence of WR Dosage on the Performance of Masterbatch and Masterbatch Modified Asphalt

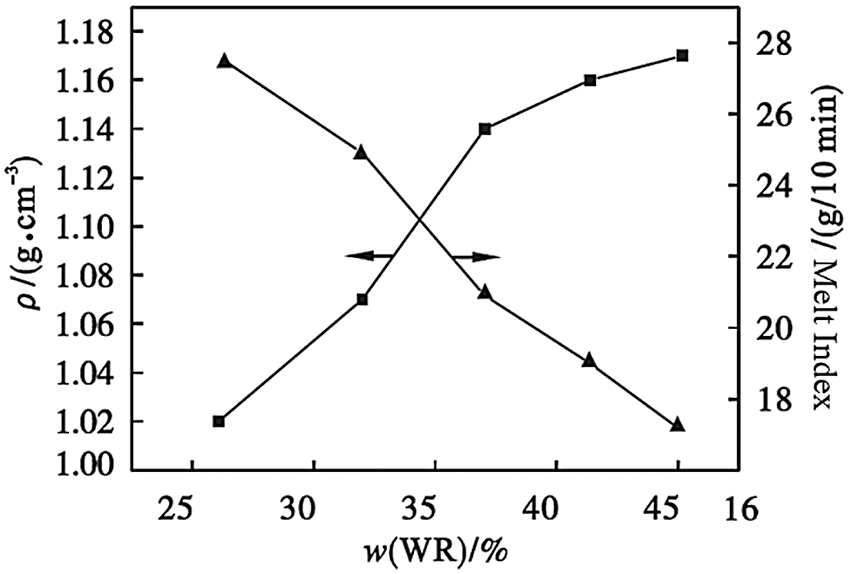

Under the condition of 20 parts of basic asphalt, 20 parts of LDPE, and 2.5 parts of Coumarone, the influence of WR in the masterbatch on the masterbatch’s performance and the modified performance asphalt was studied. The results are shown in Figs. 3 to 5.

Figure 3: The effect of WR addition on the density and melt index of masterbatch

It can be seen from Fig. 3 that the density of the masterbatch increases with the increase of the WR content. The melt index decreases with the increase of WR content [8]. The reclaimed rubber has a relatively large molecular weight and contains a large amount of carbon black inside to make it dense (1.45 g/cm3), resulting in poor fluidity.

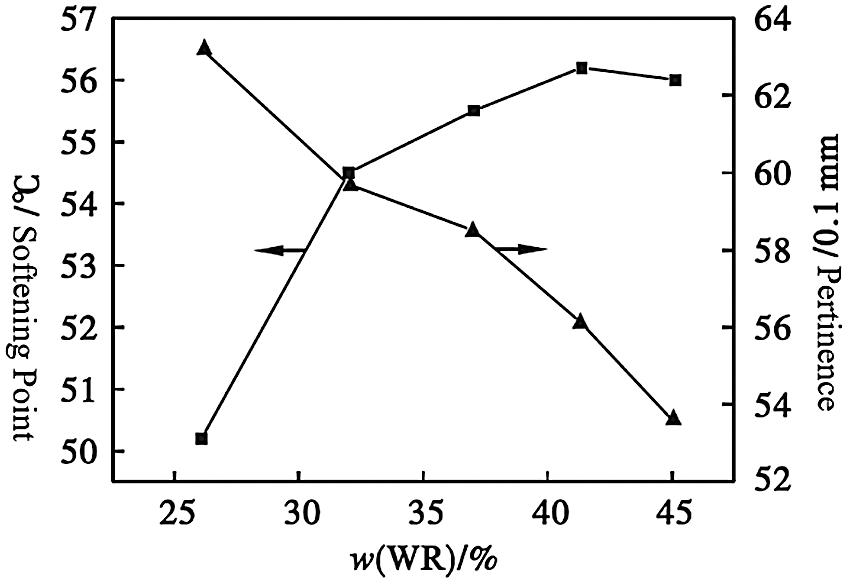

It can be seen from Fig. 4 that the softening point of modified asphalt increases with the increase of the WR content in the masterbatch, but when the mass fraction of WR in the masterbatch reaches 37%, increasing the amount of WR has a smaller effect on the softening point of the modified asphalt. This is because recycled rubber molecules can form a network structure in the asphalt matrix. The network structure limits the plastic flow of asphalt molecules and thus increases the softening point of the modified asphalt. When the mass fraction of WR in the masterbatch reaches 37%, the network structure has been formed, so when the mass fraction of WR in the masterbatch exceeds 37%, the increase in the softening point of the modified asphalt will be reduced [9]. The penetration of modified asphalt decreases significantly with the increase of WR in the masterbatch. This may be due to the large molecules of recycled rubber and many branches, which can effectively bond with the asphalt molecules to improve the bulk strength of the modified asphalt. In addition, by comparing the comprehensive influence of WR on the penetration and softening point of modified asphalt, it is found that WR has superior performance when the mass fraction of the masterbatch is 37% (30 parts).

Figure 4: The effect of WR addition on the softening point and penetration of masterbatch modified asphalt

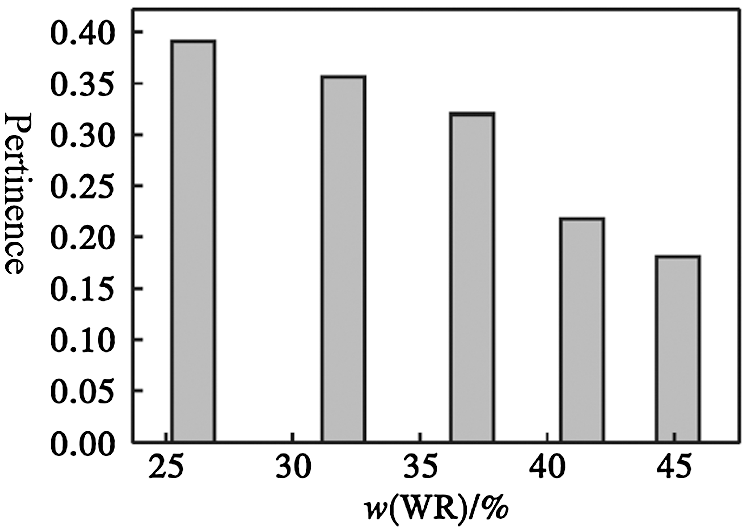

It can be seen from Fig. 5 that the temperature sensitivity index penetration index (PI value) of the modified asphalt decreases with the increase of the WR content in the masterbatch. This shows that the temperature change has a reduced impact on the performance of the modified asphalt. This is because reclaimed rubber can transform the colloidal structure of the asphalt from a sol-gel type to a gel-type structure.

Figure 5: Influence of WR content in masterbatch on penetration index of masterbatch modified asphalt

3.4 The Influence of LDPE Dosage on the Performance of Masterbatch and Masterbatch Modified Asphalt

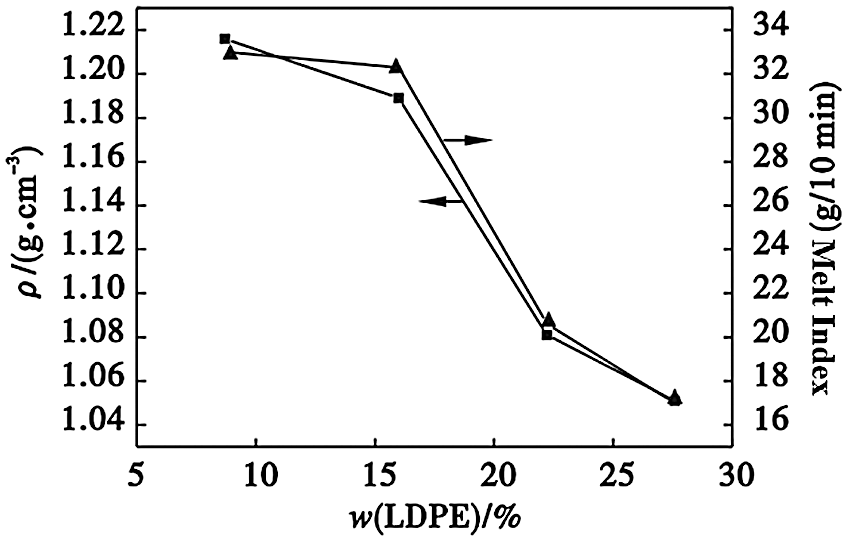

Under the same conditions of basic formula WR30 parts, asphalt 20 parts, and Gumarone 2.5 parts, the influence of the amount of LDPE in the masterbatch on the performance of the masterbatch and the performance of the masterbatch modified asphalt was studied. The results are shown in Figs. 6 to 8.

It can be seen from Fig. 6 that the density and melt index of the masterbatch decrease with the increase of LDPE content. This is because the density of LDPE is 0.92 g/cm3. It has a lower density than other substances in the masterbatch. The melt index of the masterbatch is measured at 120°C. LDPE has poor fluidity at this temperature, so the density and melt index of the masterbatch decrease with the increase of LDPE content.

Figure 6: The effect of LDPE addition on the density and melt index of masterbatch

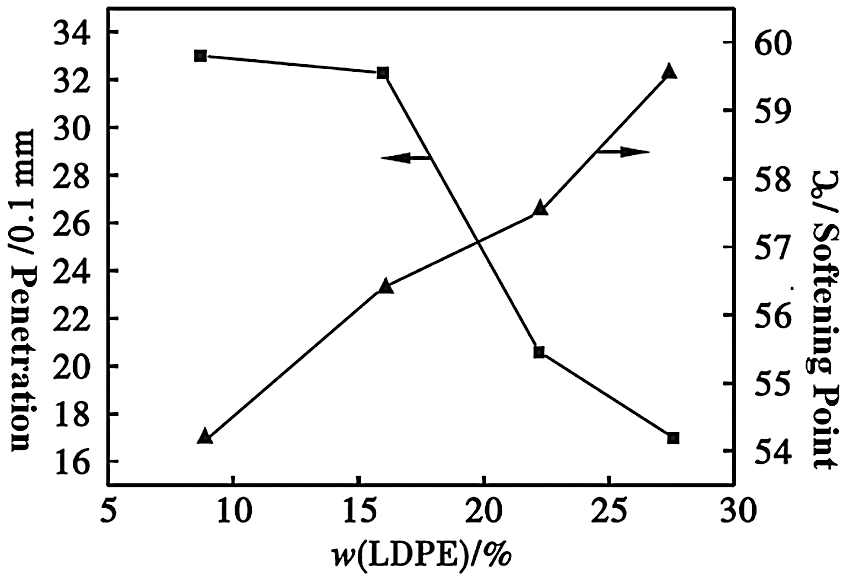

It can be seen from Fig. 7 that LDPE can also increase the softening point of the modified asphalt and reduce the penetration. But the additional amount should not be too large. When the mass fraction of LDPE in the masterbatch increases to 27%, the modified asphalt will segregate. LDPE is a crystalline plastic with better toughness, and its molecular chain structure is relatively regular. It is very easy to crystallize, the hardness and strength increase after crystallization, and the compatibility with asphalt decreases [10]. Therefore, when the content of LDPE is small, LDPE is uniformly dispersed in the asphalt in the form of tiny crystals. However, as the mass fraction of LDPE increases, LDPE crystals will separate from the asphalt when they grow to a certain size. Considering comprehensively, the mass fraction of LDPE in the masterbatch should be 22.2% (20 parts). At this time, the modified asphalt has a high softening point, low penetration, and good compatibility.

Figure 7: The effect of LDPE addition on the softening point and penetration of masterbatch modified asphalt

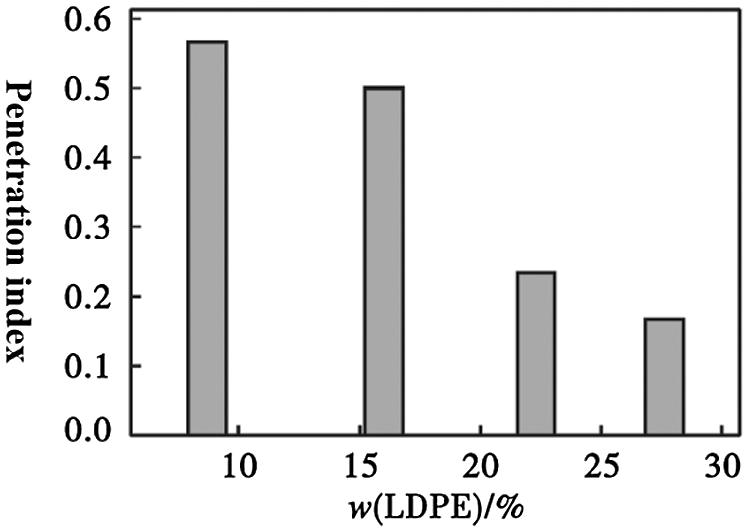

It can be seen from Fig. 8 that as the content of LDPE increases, the penetration index decreases, and the sensitivity of the modified asphalt to temperature decreases. A uniform network structure can be formed in the asphalt, the load-carrying capacity is increased, and the hardness is increased. It is also not sensitive to temperature changes.

Figure 8: Influence of LDPE content in masterbatch on penetration index of masterbatch modified asphalt

3.5 The Influence of Asphalt Dosage on the Performance of Masterbatch and Masterbatch Modified Asphalt

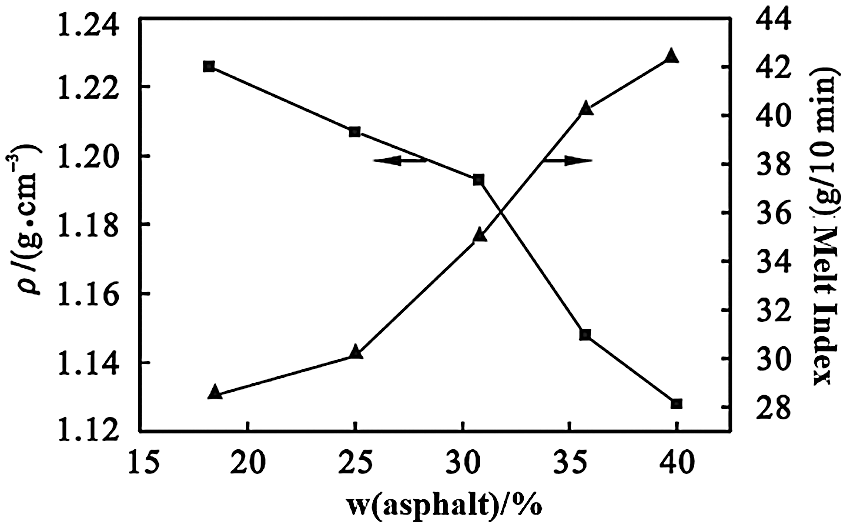

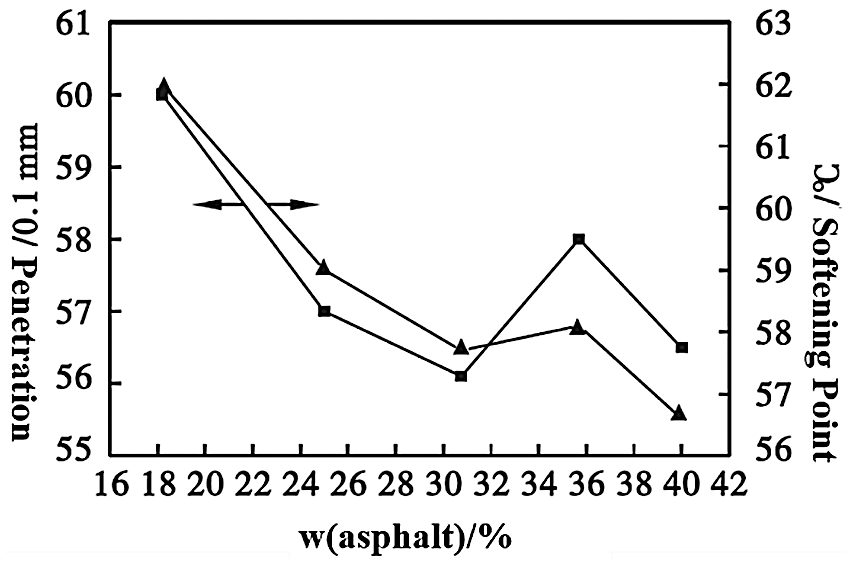

Under the condition of the basic formula of 20 parts WR, 20 parts of LDPE, and 2.5 parts of Coumarone, the influence of the amount of asphalt in the masterbatch on the performance of the masterbatch and the performance of the modified asphalt of the masterbatch was studied. The results are shown in Figs. 9 and 10. The greater the amount of asphalt added, the greater the melt index of the masterbatch and the better the fluidity. Its dissolution time in the base asphalt is shorter, but the amount of asphalt added is not easy to be too large [11]. When the amount of asphalt added is too large, WR, LDPE, and asphalt are not easy to blend, and the masterbatch is easy to stick, and at the same time, the amount of masterbatch added to the asphalt is increased.

Figure 9: The effect of asphalt addition on the density and melt index of the masterbatch

The amount of asphalt in the masterbatch has a greater impact on the properties of the masterbatch and has a certain impact on the performance. From Fig. 10, it can be seen that when the asphalt mass fraction in the masterbatch is ≤31%, as the asphalt content increases, the penetration of modified bitumen is reduced [12]. This is because the main function of bitumen in the masterbatch is to enable the masterbatch to dissolve in the matrix bitumen in a short time. At the same time, the modifiers WR and LDPE are well dispersed in the asphalt. Too little asphalt content in the masterbatch will affect the dispersion effect of WR and LDPE in the modified asphalt, thereby affecting the modification effect of the asphalt. That is the additional amount of 20 servings in this recipe.

Figure 10: The effect of asphalt addition on the softening point and penetration of masterbatch modified asphalt

3.6 Performance Analysis of WR and WPE Composite Modified Asphalt

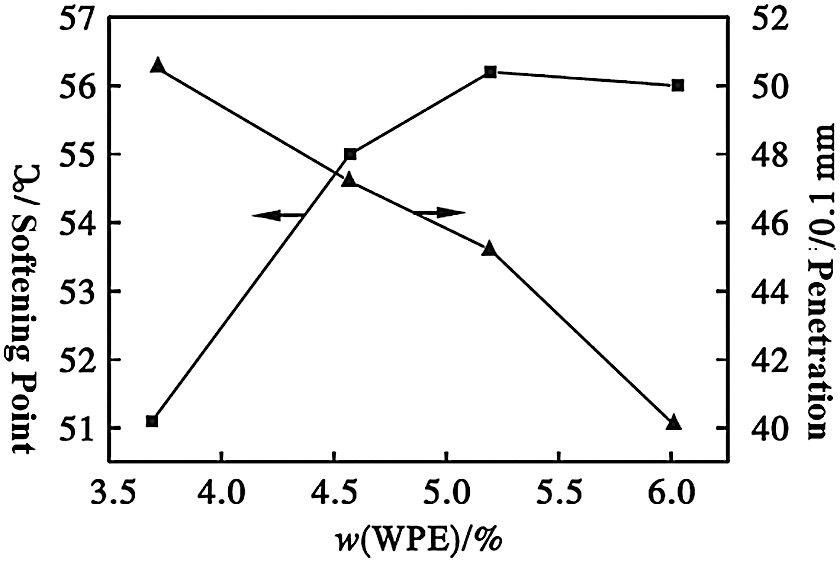

“White pollution” has gradually evolved into a severe social and economic problem, and plastic waste recycling has reached a point where it cannot be ignored [13]. Waste plastic (WPE) modified asphalt has greater economic benefits and has better social benefits. Refer to the amount of LDPE in the masterbatch to determine the optimal content of WPE in the modified asphalt masterbatch. The result is shown in Fig. 11. The standard deviation of the data in the figure is within 1%.

Figure 11: The influence of WPE content in the masterbatch on the softening point and penetration of the modified asphalt

It can be seen from Fig. 11 that the penetration and softening points of WPE and WR composite modified asphalt are similar to the results of WR and LDPE composite modified asphalt mentioned above. The difference is that the dispersing effect of WPE in asphalt is not as good as LDPE, so the additional amount should not be too large [14]. This may be because the waste film used in the experiment contains other resins, resulting in poor masterbatch dispersion in the base asphalt. However, when the content of WPE in the masterbatch is 15 parts, the indicators are similar to recycled rubber and LDPE composite modified asphalt.

3.7 Performance and Cost Comparison of WR/LDPE and WR/WPE Composite Modified Asphalt

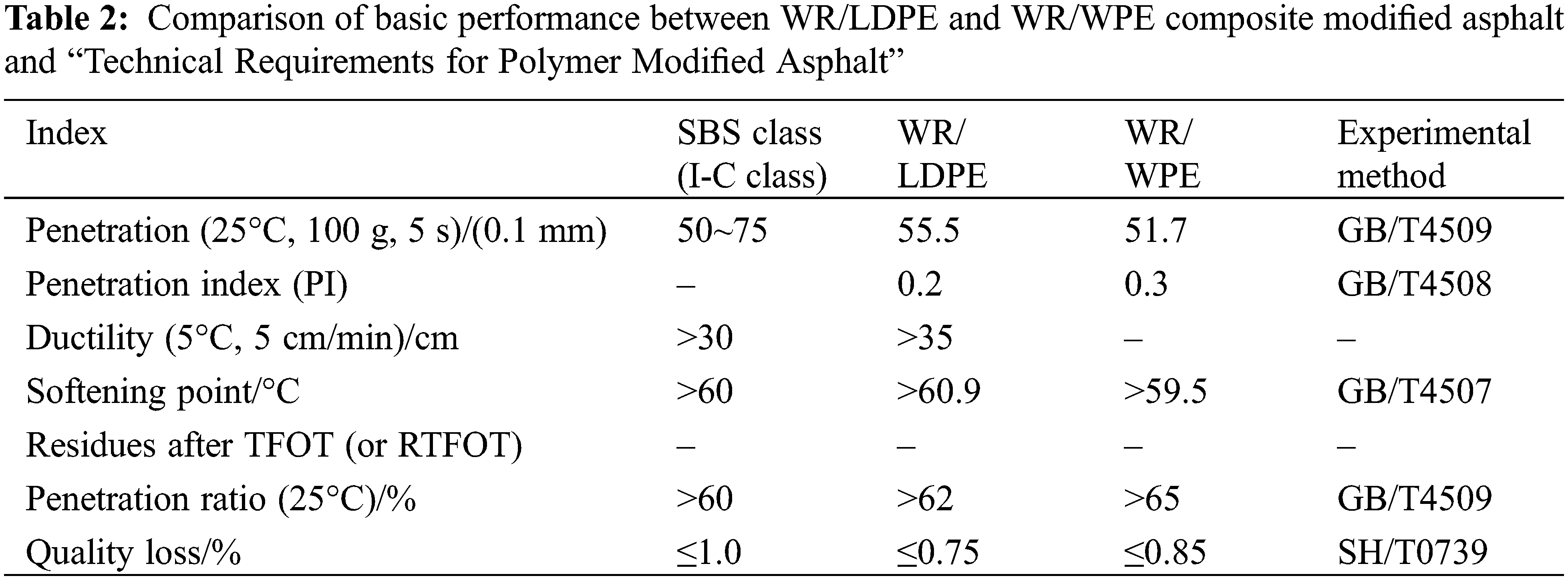

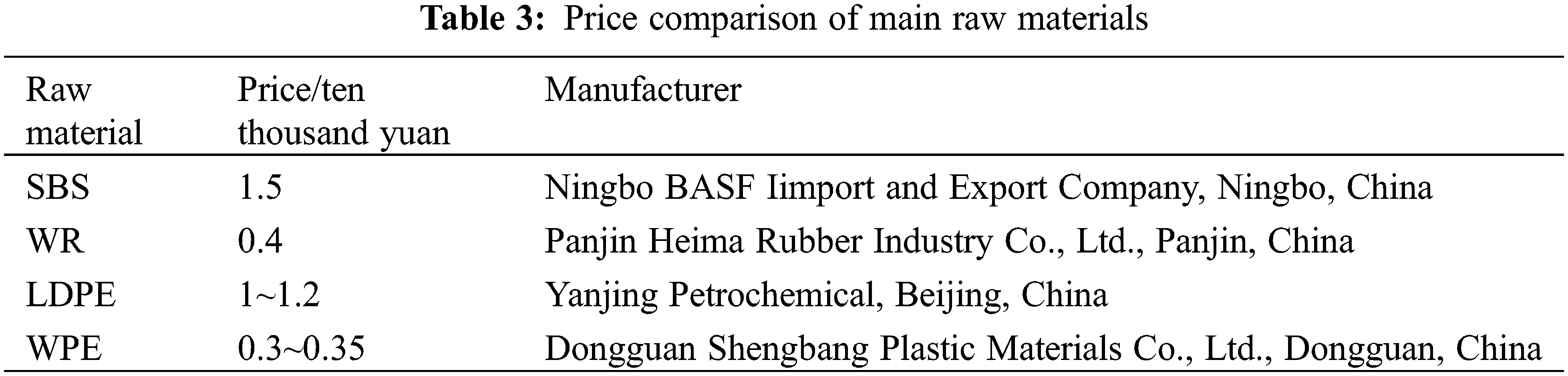

One method is to prepare WR/LDPE composite modified asphalt masterbatch with a formula of 30 parts of WR, 20 parts of LDPE, 20 parts of asphalt, and 2.5 parts of Coumarone. The modified asphalt is prepared according to the mixing ratio of masterbatch and base asphalt of 1:3.5. Another method is to replace LDPE with WPE, using 30 parts of WR, 15 parts of WPE, 20 parts of asphalt, and 2.5 parts of Coumarone to prepare WR/WPE composite modified asphalt [15]. The modified asphalt is also prepared according to the mixing ratio of masterbatch and base asphalt of 1:3.5. The basic performance comparison results of the modified asphalt prepared by the above two methods and the SBS (IC) category of “Polymer Modified Road Asphalt” are shown in Table 2. The raw material cost comparison is shown in Table 3.

From the data in Table 2, the main performance indexes of the modified asphalt prepared with WR/LDPE composite modified masterbatch have reached the basic performance index requirements of the SBS category (I-C category) of “Polymer Modified Road Asphalt”. The basic performance index of modified asphalt prepared with WR/WPE composite modified asphalt masterbatch is close to the basic performance index requirements of the SBS category (I-C category) of “Polymer Modified Road Asphalt”.

Because SBS has the superior properties of plastic and rubber simultaneously and SBS modified asphalt has good high and low-temperature performance. It is the main modifier for asphalt used in many high-temperature and high-cold areas at home and abroad [16]. However, the cost of SBS is higher, and WR the cost price only accounts for one-third of SBS. The cost of WPE is lower than that of WR (see Table 3). In addition, the dispersion process of composite modified masterbatch in base asphalt is simpler than that of SBS in base asphalt. Its mixing time is shorter [17], so it has a greater application value [18].

This paper uses recycled rubber and waste plastics to modify the asphalt used on highways to study its performance. It can meet the requirements of asphalt performance index and meet the high and low-temperature performance requirements. Realize the secondary utilization of recycled rubber and waste plastics, which can meet the requirements of energy-saving and environmental protection. WR, LDPE, and other additives can be mixed to prepare an asphalt-modified masterbatch. This kind of masterbatch in the base asphalt can increase the softening point of the asphalt and reduce the penetration and penetration index of the asphalt. It also has the characteristics of low cost and easy dispersion in asphalt. It has very good application prospects. WR/LDPE and WR/WPE composite modified asphalt can meet asphalt’s high and low-temperature performance. China’s global market share of SBS modified asphalt production has reached 40%, surpassing European countries and American countries. The dispersion process of the masterbatch in the base asphalt is simple, the dispersion is good, and the mixing time is shortened. The modified material realizes the secondary utilization of reclaimed rubber and waste plastics.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Bala, N., Kamaruddin, I., Napiah, M., Sutanto, M. H. (2019). Polymer nanocomposite-modified asphalt: Characterization and optimization using response surface methodology. Arabian Journal for Science and Engineering, 44(5), 4233–4243. DOI 10.1007/s13369-018-3377-x. [Google Scholar] [CrossRef]

2. Azimi Alamdary, Y., Singh, S., Baaj, H. (2021). Effect of aggregates containing iron sulfide on asphalt aging. Road Materials and Pavement Design, 22(3), 623–638. DOI 10.1080/14680629.2019.1610477. [Google Scholar] [CrossRef]

3. Joni, H. H., Zghair, H. H., Mohammed, A. A. (2020). Rutting parameters of modified asphalt binder with micro and nano-size of metakaolin powder. Journal of Engineering Science and Technology, 15(5), 3465–3480. [Google Scholar]

4. Han, S., Zhang, Z., Zhang, Y., Cheng, X., Ren, W. (2019). Changes in rheological properties during asphalt aging. Petroleum Science and Technology, 37(13), 1539–1547. DOI 10.1080/10916466.2019.1587454. [Google Scholar] [CrossRef]

5. El Atrash, K. S., Assaf, G. J. (2020). Performance testing of asphalt paving mixtures for hot conditions using tension-compression test. Innovative Infrastructure Solutions, 5(1), 1–10. DOI 10.1007/s41062-019-0252-x. [Google Scholar] [CrossRef]

6. Liu, H., Zeiada, W., Al-Khateeb, G. G., Shanableh, A., Samarai, M. (2020). Characterization of the shear-thinning behavior of asphalt binders with consideration of yield stress. Materials and Structures, 53(4), 1–13. DOI 10.1617/s11527-020-01538-0. [Google Scholar] [CrossRef]

7. Liu, G., Jia, Y., Pan, Y., Yang, T., Zhao, Y. et al. (2020). Quantitative comparison of evaluation indices for asphalt-filler interaction ability within filler critical volume fraction. Road Materials and Pavement Design, 21(4), 906–926. DOI 10.1080/14680629.2018.1531054. [Google Scholar] [CrossRef]

8. Wang, Y., Wu, R., Feng, M., Zhang, G., Zhang, C. et al. (2020). Synthesis of microcapsules with waste oil core and application in self-healing asphalt. Petroleum Science and Technology, 38(3), 203–209. DOI 10.1080/10916466.2019.1702679. [Google Scholar] [CrossRef]

9. Wang, T., Wang, J., Hou, X., Xiao, F. (2021). Effects of SARA fractions on low-temperature properties of asphalt binders. Road Materials and Pavement Design, 22(3), 539–556. DOI 10.1080/14680629.2019.1628803. [Google Scholar] [CrossRef]

10. Gao, M., Xue, Y., Guan, P., Yuan, F. (2020). Influence mechanism of epoxy resin and curing agent on high-temperature performance of asphalt. Sains Malaysiana, 49(3), 661–669. DOI 10.17576/jsm-2020-4903-21. [Google Scholar] [CrossRef]

11. Graziani, A., Mignini, C., Bocci, E., Bocci, M. (2019). Complex modulus testing and rheological modeling of cold-recycled mixtures. Journal of Testing and Evaluation, 48(1), 120–133. DOI 10.1520/JTE20180905. [Google Scholar] [CrossRef]

12. Alas, M., Ali, S. I. A. (2019). Prediction of the high-temperature performance of a geopolymer modified asphalt binder using artificial neural networks. International Journal of Technology, 10(2), 417–427. DOI 10.14716/ijtech.v10i2.2421. [Google Scholar] [CrossRef]

13. Seitllari, A., Kumbargeri, Y. S., Biligiri, K. P., Boz, I. (2019). A soft computing approach to predict and evaluate asphalt mixture aging characteristics using asphaltene as a performance indicator. Materials and Structures, 52(5), 1–11. DOI 10.1617/s11527-019-1402-5. [Google Scholar] [CrossRef]

14. Carret, J. C., di Benedetto, H., Sauzeat, C. (2020). Linear viscoelastic behavior of asphalt mixes from dynamic frequency response functions. International Journal for Numerical and Analytical Methods in Geomechanics, 44(7), 1019–1031. DOI 10.1002/nag.3045. [Google Scholar] [CrossRef]

15. Guo, F., Zhang, J., Pei, J., Zhou, B., Hu, Z. (2019). Study on the mechanical properties of rubber asphalt by molecular dynamics simulation. Journal of Molecular Modeling, 25(12), 1–8. DOI 10.1007/s00894-019-4250-x. [Google Scholar] [CrossRef]

16. Nie, X., Li, Z., Yao, H., Hou, T., Zhou, X. et al. (2020). Waste bio-oil as a compatibilizer for high content SBS modified asphalt. Petroleum Science and Technology, 38(4), 316–322. DOI 10.1080/10916466.2019.1703741. [Google Scholar] [CrossRef]

17. Zhang, C., Dong, H. J., Yan, Z. L., Yu, M., Wang, T. (2021). SBS modified bitumen with organic layered double hydroxides: Compatibility and aging effects on rheological properties. Materials, 7(27), 30–35. DOI 10.3390/ma14154201. [Google Scholar] [CrossRef]

18. He, Y. H., Cao, Z. L., Ge, Y. Y., Liu, Z. Y., Li, J. T. (2021). Effect of heat aging on properties and structure of SBS modified bitumen waterproof membrane. Materials Science Forum, 7(21), 45–48. DOI 10.4028/www.scientific.net/MSF.1035.951. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |