Materials Processing

| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2021.013575

ARTICLE

Optimizing the Exhaust System of Marine Diesel Engines to Improve Low-speed Performances and Cylinder Working Conditions

1Science and Technology on Diesel Engine Turbocharging Laboratory, China North Engine Research Institute, Tianjin, 300400, China

2Key Laboratory for Power Machinery and Engineering of Ministry of Education, College of Mechanical and Power Engineering, Shanghai Jiaotong University, Shanghai, 200240, China

*Corresponding Author: Lei Shi. Email: shi_lei@sjtu.edu.cn

Received: 13 August 2020; Accepted: 02 March 2021

Abstract: Proper design of exhaust systems in marine high-power turbocharged diesel engines can contribute to improve the low-speed performance of these engines and make the working conditions of the cylinders more uniform. Here a high-power marine 16-cylinder V-type turbocharged diesel engine is simulated using the GT-Power software. The results reveal the differences induced by different exhaust system structures, such as an 8-cylinder-in-pipe exhaust system with single/double superchargers and a 4-cylinder-in-pipe exhaust system with a single supercharger. After a comparative analysis, the 8-cylinder type with double superchargers is determined to be the optimal solution, and the structure of the exhaust system is further optimized. The simulations show that the optimized maximum exhaust temperature difference among cylinders is reduced by 66%. Finally, the simulation results and the optimized performance of the designed exhaust system are verified through experiments.

Keywords: Exhaust system; low-speed performance; cylinder uniformity; diesel engine

An engine exhaust system is an important part of the air exchange system of an internal combustion engine and has a significant impact on the performance of an internal combustion engine [1–3]. Especially for high-power turbocharged diesel engines, to make full use of exhaust energy, reduce pumping losses, and improve the working consistency among cylinders, the design requirements for the exhaust system are further improved [4,5]. At present, an 8-cylinder supercharged diesel engine or a 16-cylinder V-type supercharged diesel engine is usually used in ship propulsion power machinery. Since a 16-cylinder V-type diesel engine has 8 cylinders on each side, this paper focuses on the optimization design of the exhaust system of an eight-cylinder in-one-row diesel engine.

For high-power marine supercharged diesel engines, to meet the performance requirements of high-power engines under high load conditions, the selection of turbochargers is usually relatively large, so the performance of diesel engines deteriorates at low-speed conditions. In addition, considering the requirement of increasing torque in low-speed conditions for marine diesel engines to increase power output, low-speed performance has become one of the most important performance evaluation indicators for high-power diesel engines. The innovative design of exhaust pipe systems is helpful for improving the low-speed performance of high-supercharge diesel engines.

The ignition interval angle of an eight-cylinder in-one-row four-stroke diesel engine is 90°CA, which can easily cause scavenging interference between two adjacent cylinders, affect the working uniformity among engine cylinders, and thus affect the engine life. The design process of the exhaust pipe of an 8-cylinder diesel engine should not only consider the simple structure and layout, but also take account of the full use of the exhaust energy and avoid scavenging interference among cylinders as much as possible to ensure the consistency of air exchange among cylinders. Therefore, improving the low-speed performance of high-power turbocharged diesel engines and the working uniformity among cylinders through exhaust system structure design has always been a research difficulty and focus.

To optimize the exhaust system and to improve the performance of internal combustion engines, scholars have done much work on exhaust system designs [6–10] and have actively explored the exhaust system design schemes of eight-cylinder in-one-row turbocharged diesel engines [11–14]. Initially, 8-cylinder or 16-cylinder diesel engines adopted the pulse converter (PC) turbocharging mode. In the PC mode, two cylinders are connected to an exhaust pipe, and the exhaust pipes are summarized at the turbine inlet. This mode can effectively avoid interference among cylinders, but its structure is too complicated to realize the layout. The modular pulse converter (MPC) exhaust system with 4 cylinders or 8 cylinders in one exhaust pipe has the advantages of a simple structure, and its modular structure design meets industrial needs. Therefore, MPC is commonly used in the exhaust system of 8-cylinder diesel engines or 16-cylinder V-type diesel engines at present [15]. The MPC turbocharging system adopts a curved exhaust manifold with necking, but it still cannot solve the problem of the excessive exhaust temperature of individual cylinders under high loads [16]. The mixed pulse conversion (MIXPC) system adopts the form of a pulse converter for 2 to 4 cylinders at the closed end of the exhaust manifold, and the other cylinders adopt an MPC structure, which can avoid large scavenging interference and greatly improve the consistency of the exhaust temperature of cylinders [17]. However, the structure is still relatively complicated, and the exhaust system components are not universal, which is not conducive to the improvement and maintenance of a diesel engine exhaust system.

In summary, there are almost no exhaust systems that can take account of both the simple structures and the working consistency among cylinders simultaneously. The modular multipurpose pulse converter (MMPC) turbocharging system has a reasonable design for the exhaust branch pipe modular necking so that the gas flow loss is small. In addition, the flow area of the exhaust gas is reduced when passing through the MMPC branch pipe port. The pressure energy of the airflow peak pressure from the upstream manifold is converted into kinetic energy when passing through the constriction so that a low-pressure area forms at the exhaust branch pipe port, which weakens the scavenging interference to the downstream cylinder [18].

This paper uses GT-Power one-dimensional engine performance simulation software to study the effects of different exhaust system structures, such as an 8-cylinder-in-pipe exhaust system with single/double superchargers and a 4-cylinder-in-pipe exhaust system with a single supercharger, on the low-speed performance of high-power diesel engines and the uniformity of the exhaust temperature of cylinders. On the basis of the MPC exhaust system currently widely used in marine turbocharged 16-cylinder V-type diesel engines, the exhaust manifold of the cylinder that interferes with the scavenging of the adjacent cylinder downstream is replaced with the MMPC module. On the premises of having a simple and reliable structure with a few exhaust system changes, the exhaust system of an 8-cylinder in-one-row diesel engine is optimized for anti-scavenging interference to improve the overall performance of high-power diesel engines.

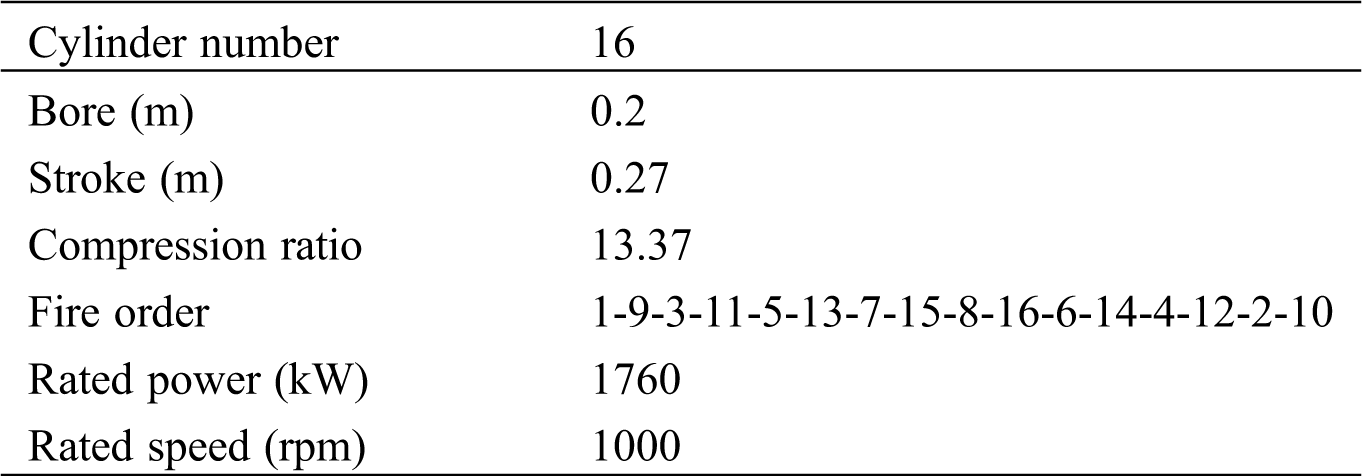

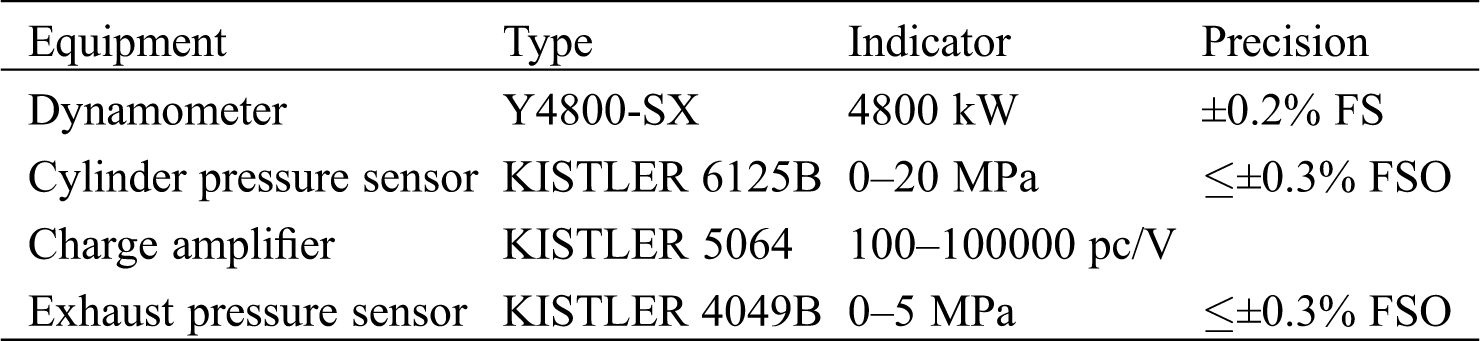

To optimize the low-speed performance of a diesel engine, this paper studies the exhaust system and turbocharging system of a 16-cylinder V-type diesel engine. Because the engine has the same exhaust system on both sides, this study mainly focuses on one side, which has 8 cylinders. Since the ignition interval angle of the eight-cylinder in-one-row diesel engine is 90°CA, there is exhaust interference between two adjacent cylinders. To ensure the simple structure of the exhaust pipe and avoid the influence of scavenging interference on the working uniformity among cylinders, this paper optimizes the exhaust pipe design of an 8-cylinder in-one-row diesel engine. The original diesel engine adopts the exhaust system scheme in which each exhaust pipe is connected to eight cylinders and a turbocharger. The engine parameters are shown in Tab. 1. The KISTLER 6125B water-cooled cylinder pressure sensor is arranged in the first cylinder. The charge signal of the sensor is converted into a voltage signal through the KISTLER 5064 charge amplifier. The exhaust pressure sensor is the KISTLER 4049B. The data are collected by the NI 9411 data acquisition system. The phase signal is obtained by the Omron E6C3-AG5C encoder. The main measurement equipment and equipment parameters used in the experiment are shown in Tab. 2. To meet the high load performance of the original engine, the turbocharger selection is relatively large, so the performance of the diesel engine deteriorates at low speeds. According to the requirement of increasing torque at low speeds, this paper improves the single-row 2-turbocharger system, optimizes the performance in low-speed conditions and improves the transient response by matching 2 small turbochargers on each side.

Table 1: Diesel engine parameters

Table 2: Main measurement equipment and parameters

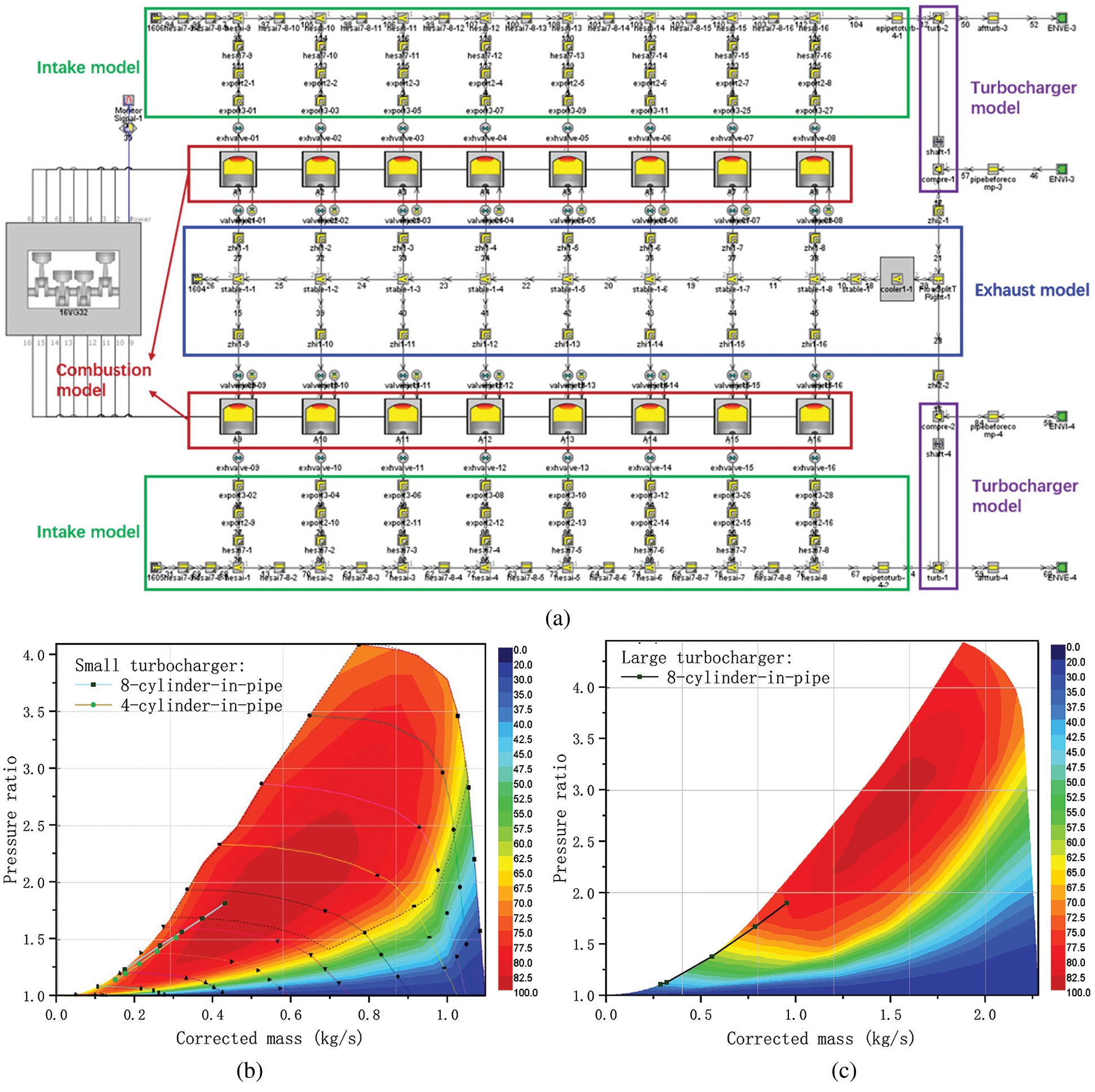

This paper uses GT-Power software to build a one-dimensional engine performance simulation model to study the influence of different exhaust pipe structures on the performance of high-power diesel engines. GT-Power focuses on the engine steady-state performance calculation and transient analysis [19,20]. In this paper, simulation software is applied to simplify and optimize the design of different exhaust pipe structures, and the state parameters of different parts of the engine and performance parameters are calculated under different structural parameters, thereby assisting the optimization design of the key parts of the engine. The GT-Power engine model mainly includes the combustion model, intake and exhaust model, and turbocharger model. The overall simulation model of the diesel engine is shown in Fig. 1a, and the above-mentioned subsystem models in the diesel engine are marked in the figure. The compressor models for the 4-turbocharger and 2-turbocharger are shown in Figs. 1b and 1c. As shown in the figure, the air flow of a single large turbocharger in the 2-turbocharger scheme is approximately twice that of a single small turbocharger in the 4-turbocharger scheme. From the joint operation line, it can be seen that both the large turbocharger and the small turbocharger can match the engine well. In this paper, the simulation and test verification calculation under 100% load conditions are carried out, and the results are shown in Tab. 3. The average error between the simulation results of the overall performance parameters and the experimental values is less than 1%, which meets the requirements of simulation accuracy.

Figure 1: Engine model (a) Original engine model (b) Compressor model of a 4-turbocharger (c) Compressor model of a 2-turbocharger

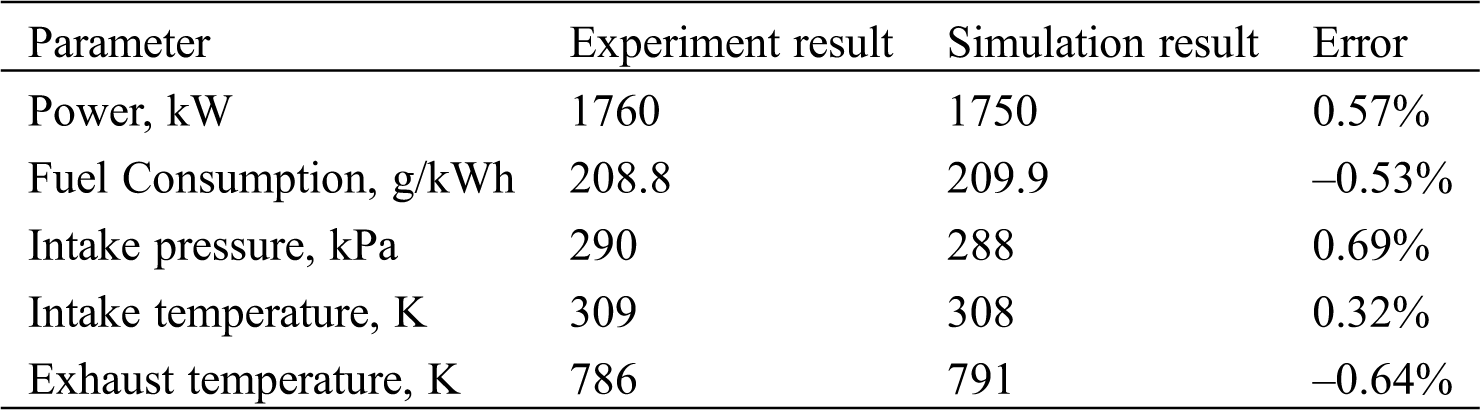

Table 3: Comparison of the experimental and simulation results at 100% load

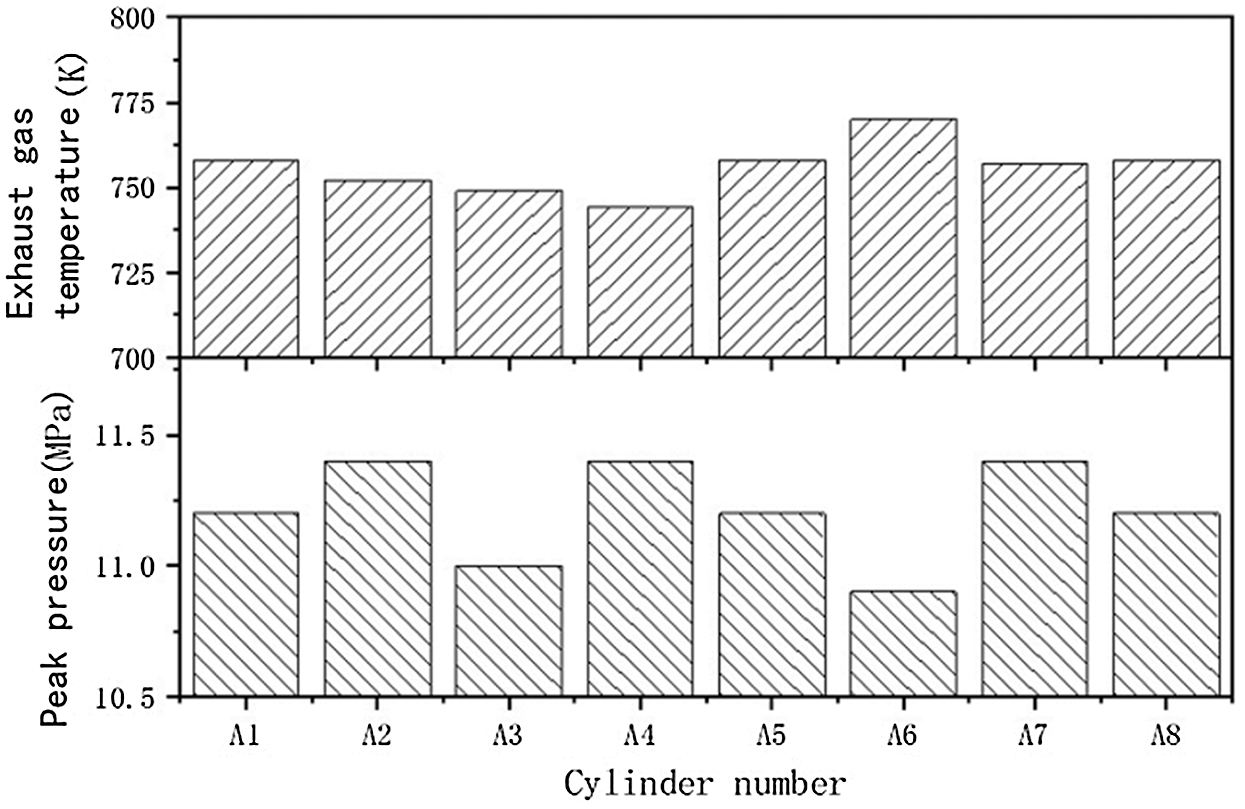

Fig. 2 shows the differences in the exhaust temperature and peak pressure of each cylinder. As shown in the figure, there are certain differences in the exhaust temperature and peak pressure among cylinders due to some structural inconsistencies in the exhaust pipes of eight cylinders. The maximum deviation in the exhaust temperature is approximately 30 K, and the maximum deviation in the peak pressure is approximately 5 bar. The main reason for the deviation in peak pressure and exhaust temperature is the interference of the exhaust gas between the cylinders. When some cylinders are exhausted, the pressure from the main exhaust pipe is relatively high, so that the residual exhaust gas in the adjacent cylinder cannot be completely discharged, which results in the problem of a high pressure rise in the cylinder.

Figure 2: Differences in exhaust temperature and peak pressure of each cylinder

3 Comparison of Low-Speed Engine Performance with Different Exhaust Systems

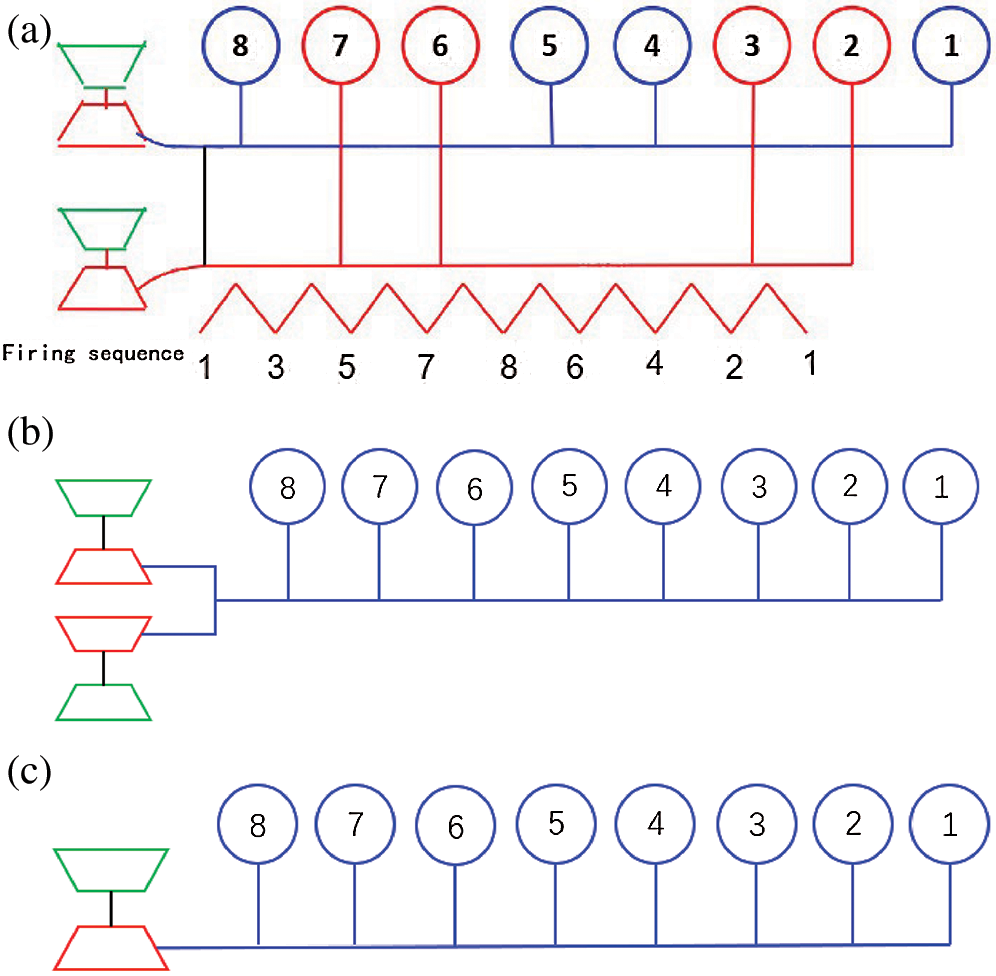

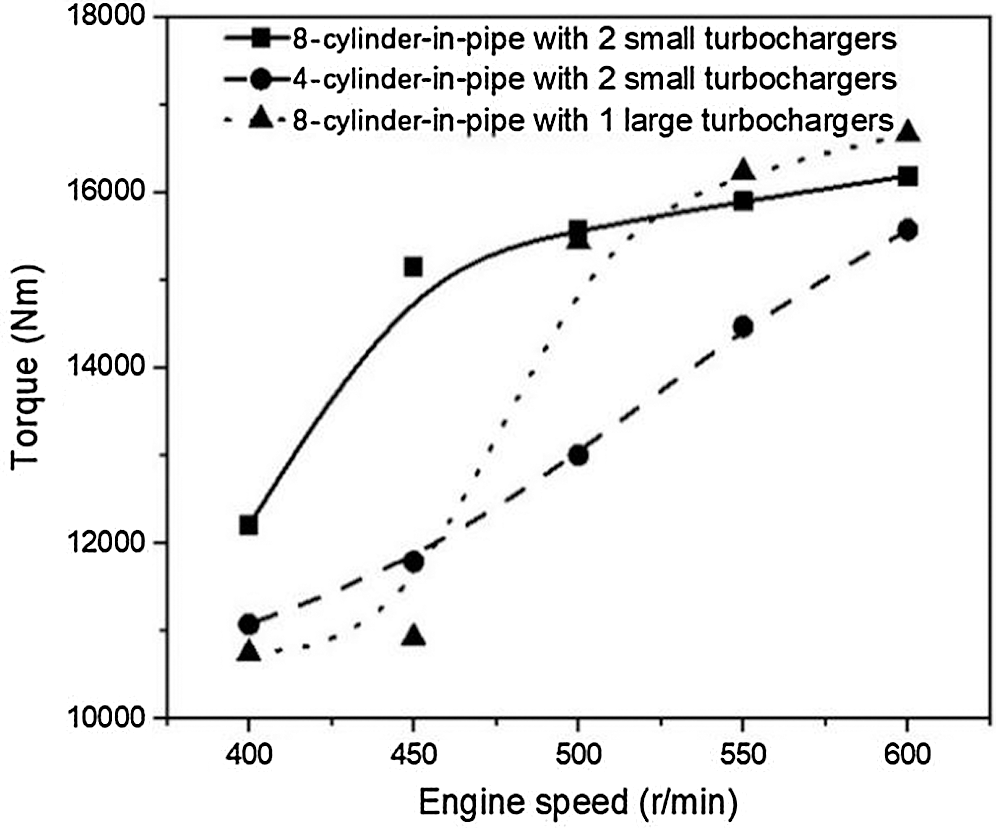

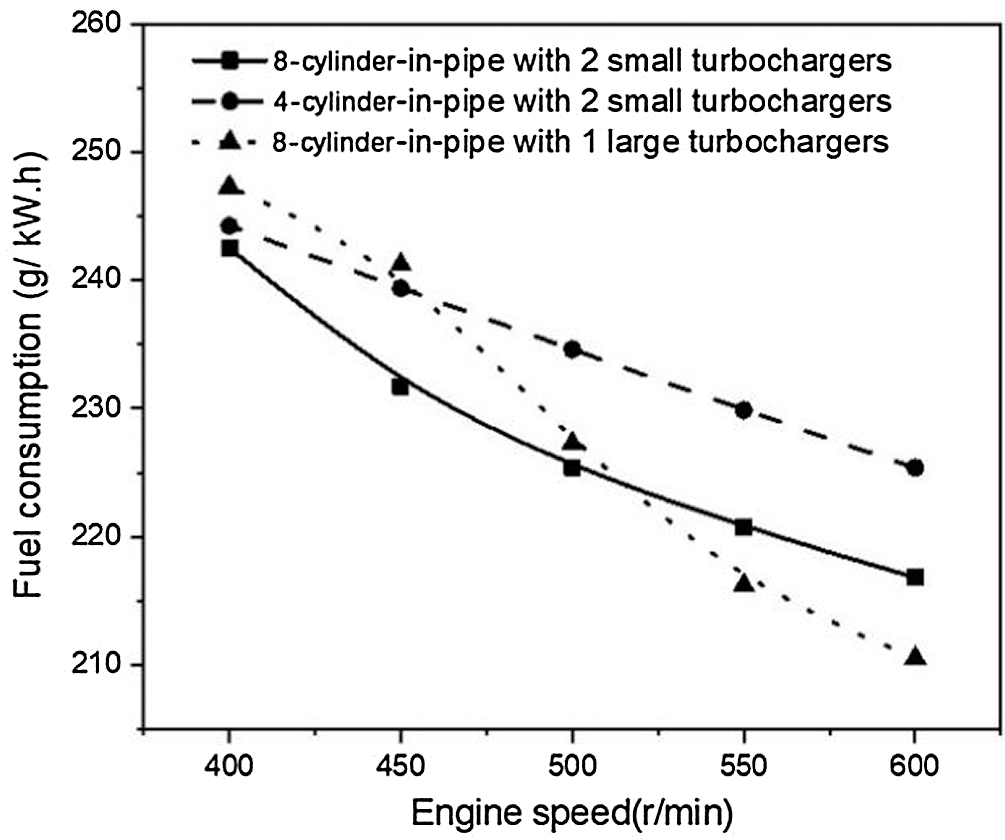

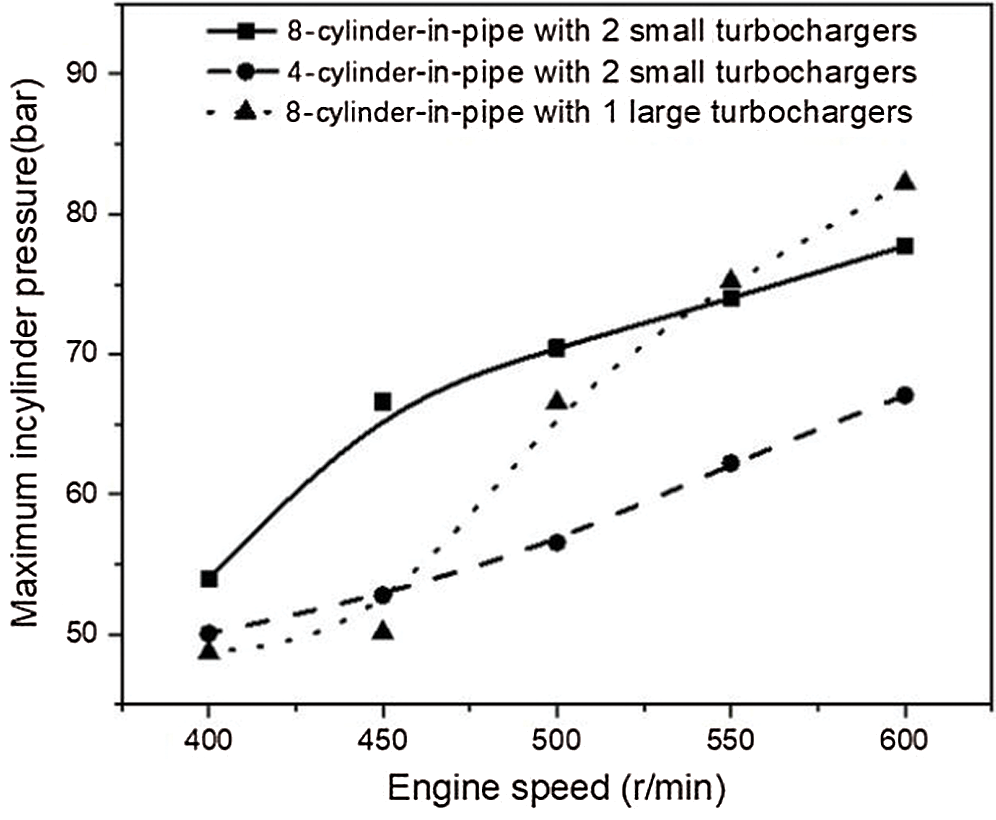

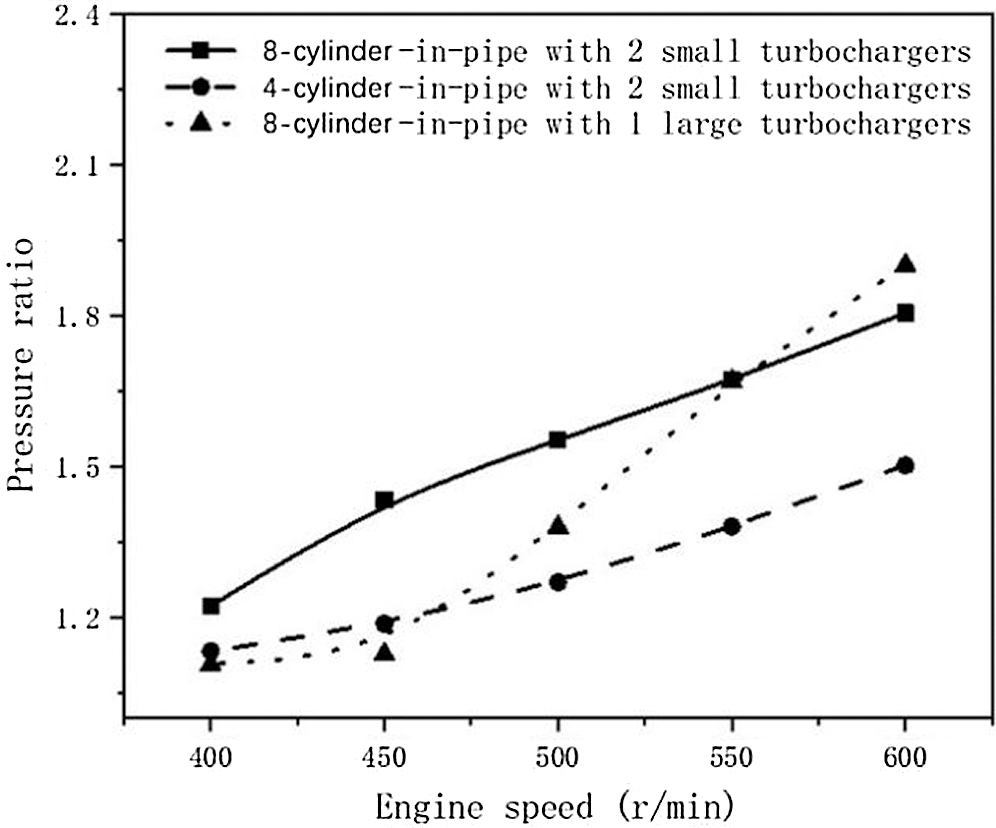

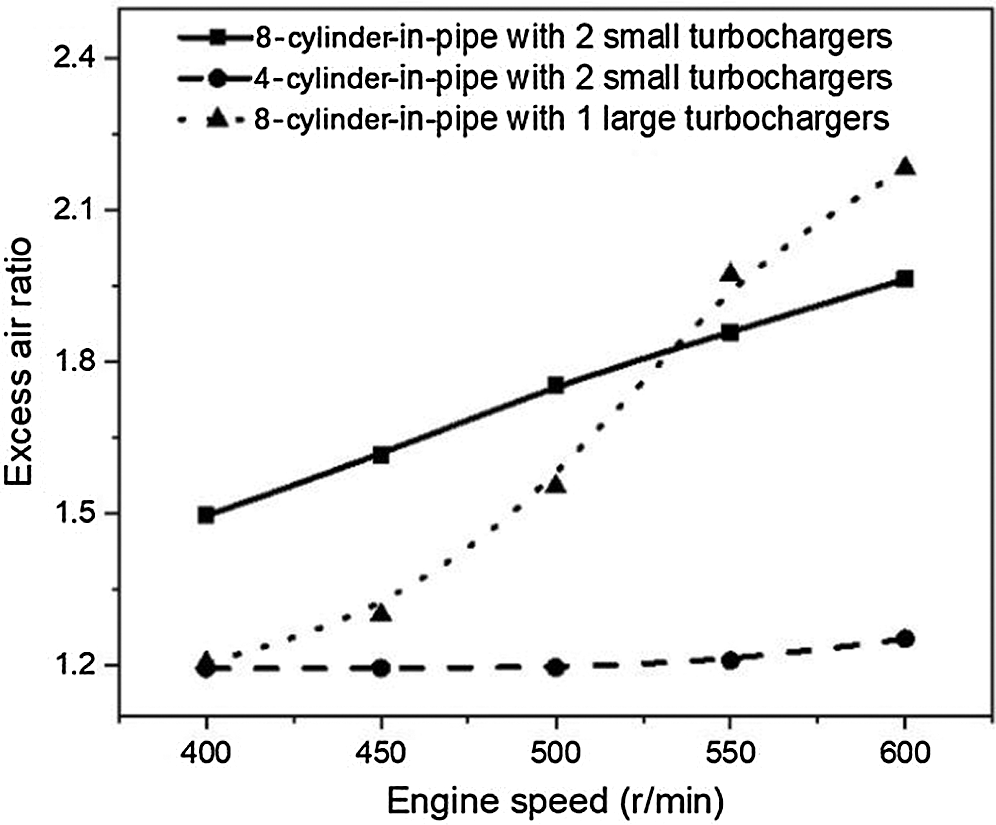

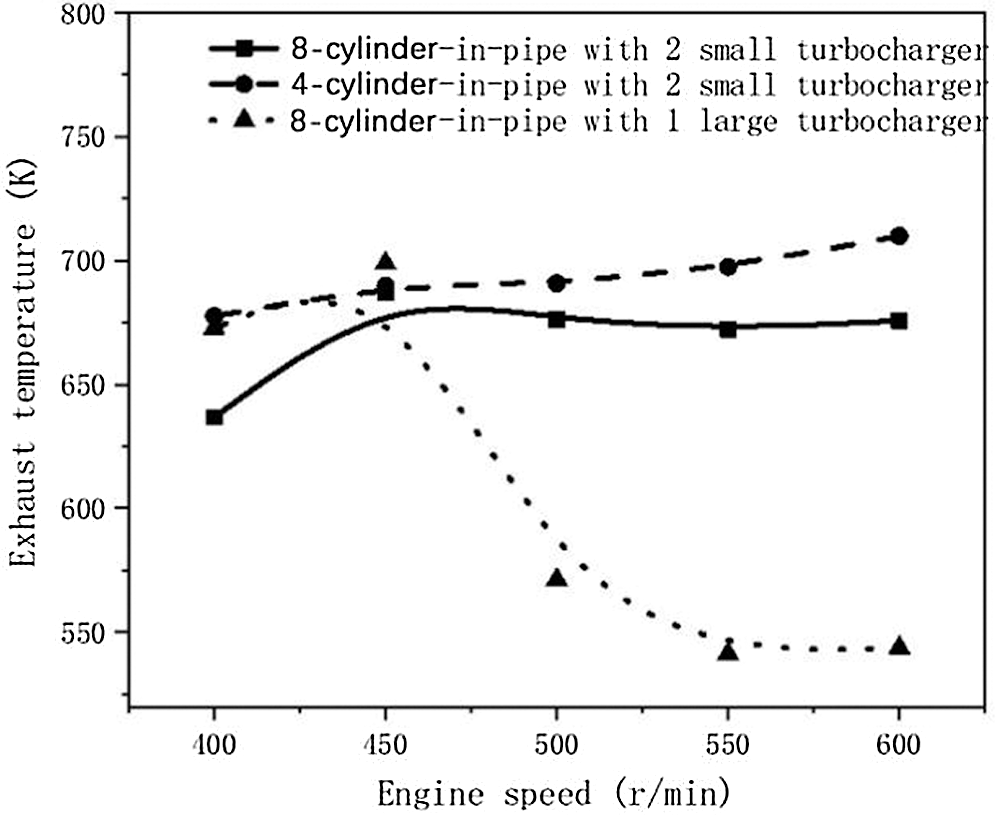

To improve the low-speed performance of high-power diesel engines, this paper studies a simulation of the low-speed performance of diesel engines with different exhaust systems. The exhaust system schemes of the 8-cylinder-in-pipe system with 1 large turbocharger, 4-cylinder-in-pipe system with 2 small turbochargers and 8-cylinder-in-pipe system with 2 small turbochargers are adopted for simulation research. The layout diagram of the three types of exhaust systems is shown in Fig. 3. The minimum value of the excess air coefficient of the diesel engine is limited to 1.2 in the simulation. When the engine runs at 400 rpm~600 rpm, the simulation results of the external characteristic parameters of each scheme are shown in Figs. 4–9.

Figure 3: Schematic diagrams of three types of exhaust systems (a) 4-cylinder-in-pipe scheme with 2 small turbochargers (b) 8-cylinder-in-pipe scheme with 2 small turbochargers (c) 8-cylinder-in-pipe scheme with 1 large turbocharger

Figure 4: Effects on the engine torque

Figure 5: Effects on the fuel consumption

Figure 6: Effects on the peak pressure

Figure 7: Effects on the pressure ratio of turbocharger

Figure 8: Effects on the excess air ratio

Figure 9: Effects on the exhaust temperature

An exhaust system with 1 turbocharger has lower boost pressure and lower excess air coefficient at low speeds. To keep the engine working normally at 400~450 rpm, the injection quantity of each cylinder must be reduced. Therefore, the external characteristic performance parameters of the diesel engine in these speed conditions deteriorate significantly.

It can be seen from the above figures that the exhaust temperature, cylinder pressure and excess air coefficient of the two 2-turbocharger exhaust system schemes under external characteristic conditions do not exceed the limit values. The advantage of pulse turbocharging over constant pressure turbocharging is that the pulse energy of the exhaust can be used in the pulse turbocharging mode under low speed conditions (low pressure ratio); hence, the supercharging effect of the pulse supercharging system is better than that of the constant pressure system. When the turbocharging ratio is high, the loss of pulse energy can be ignored. The pressure and temperature of the pulse turbocharging system in front of the turbines change periodically, and the direction of the airflow entering the blade also changes periodically, resulting in a loss of local impact energy and a reduction in the efficiency of the pulse turbocharging system.

4 Improvement in Cylinder Uniformity by Exhaust System Optimization

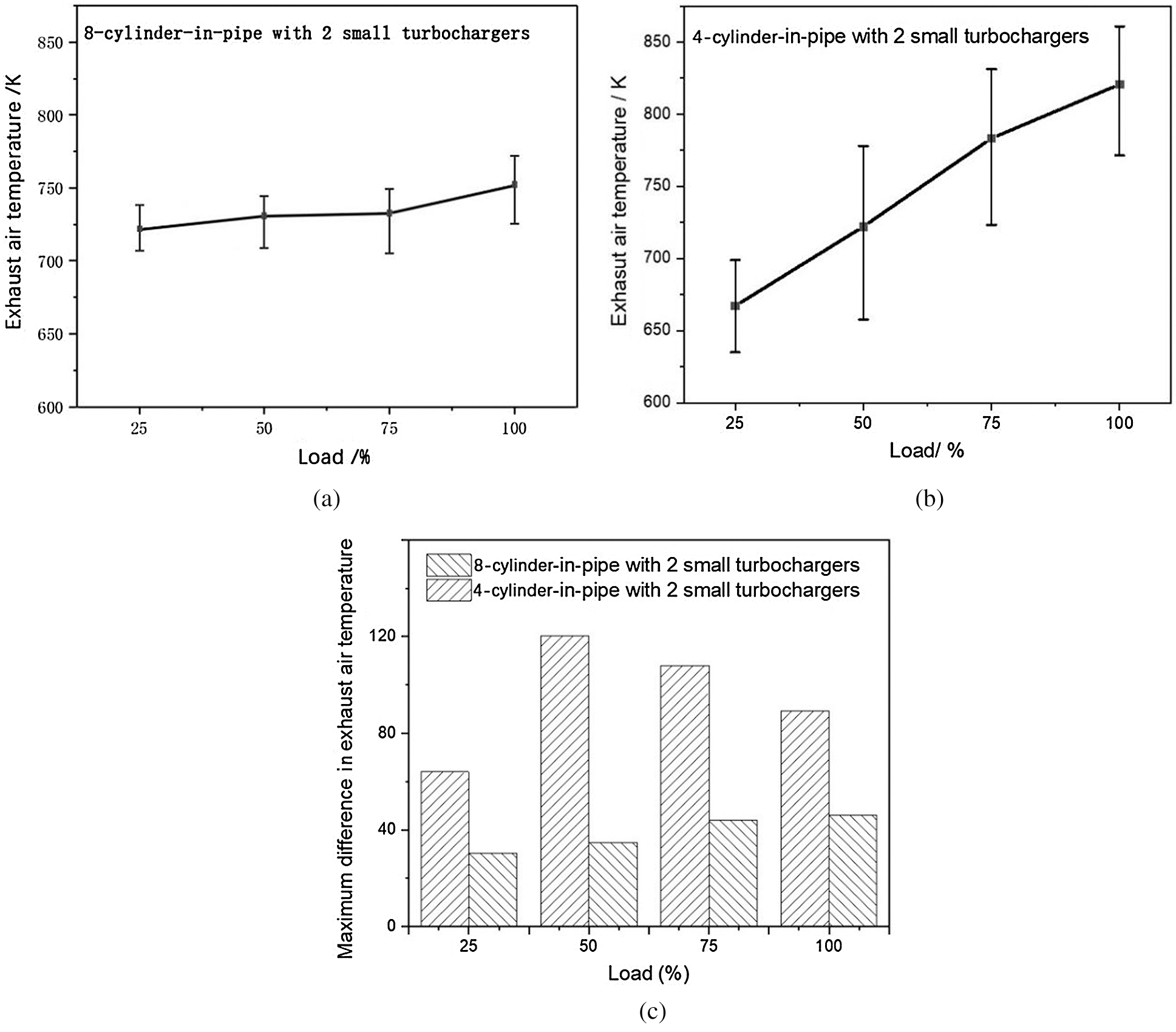

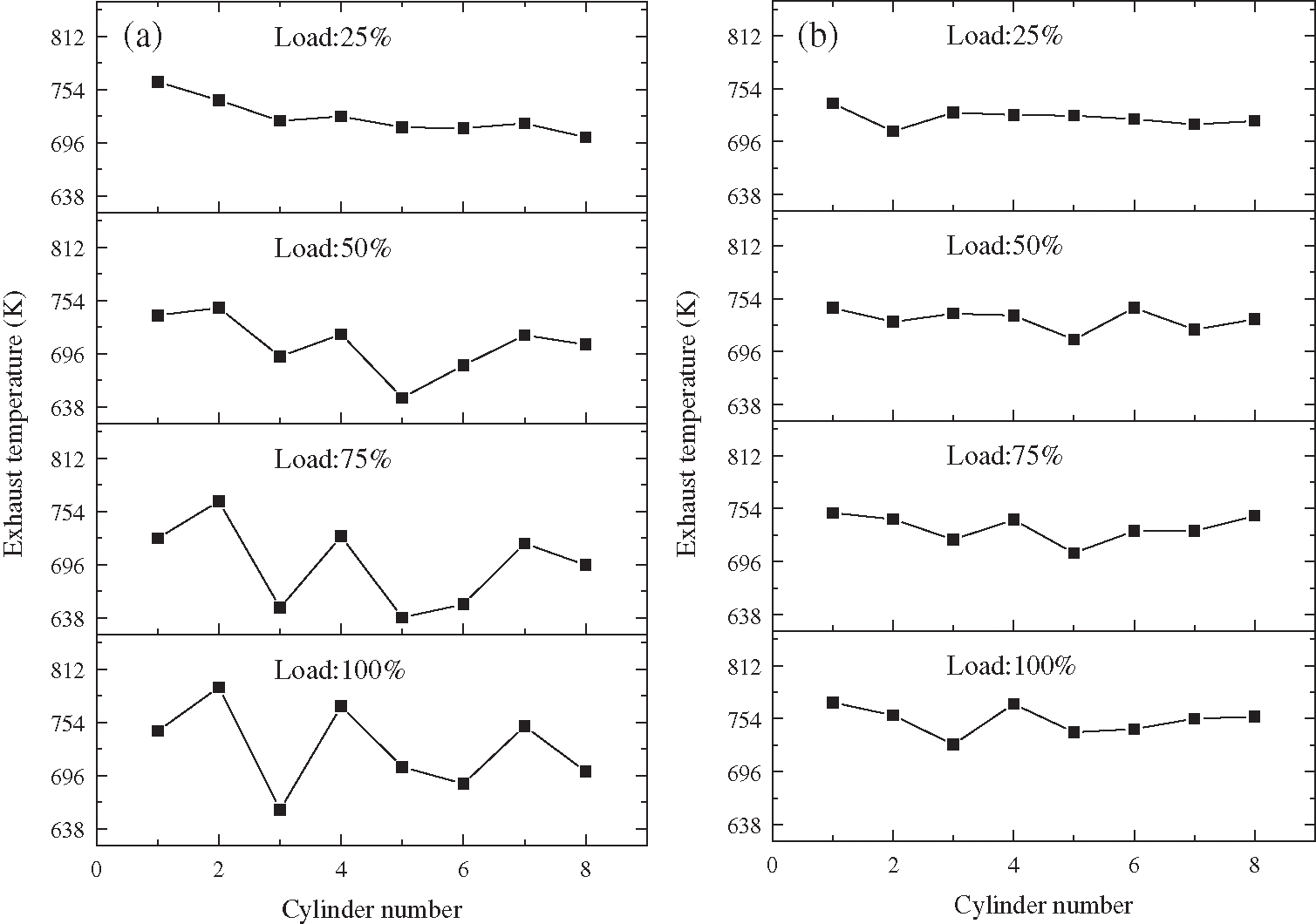

Fig. 10 shows that the exhaust uniformity of the scheme with eight cylinders sharing one exhaust pipe is better than that of the scheme with four cylinders sharing one exhaust pipe. At 100% load, the maximum exhaust temperature of the scheme with eight cylinders sharing one exhaust pipe is 771 K, while the maximum exhaust temperature of the scheme with four cylinders sharing one exhaust pipe is close to 860 K, which is close to the maximum exhaust temperature limit; hence, the exhaust temperature characteristics of the scheme with eight cylinders sharing one exhaust pipe are better. In this paper, further research on the optimization of exhaust manifolds is carried out for the 8-cylinder-in-pipe scheme with 2 small turbochargers.

Figure 10: Exhaust temperature of each cylinder of the different exhaust systems (a) Exhaust temperature of 8-cylinder-in-pipe scheme (b) Exhaust temperature of 4-cylinder-in-pipe scheme (c) Comparison of the maximum difference in the exhaust temperatures of different exhaust systems

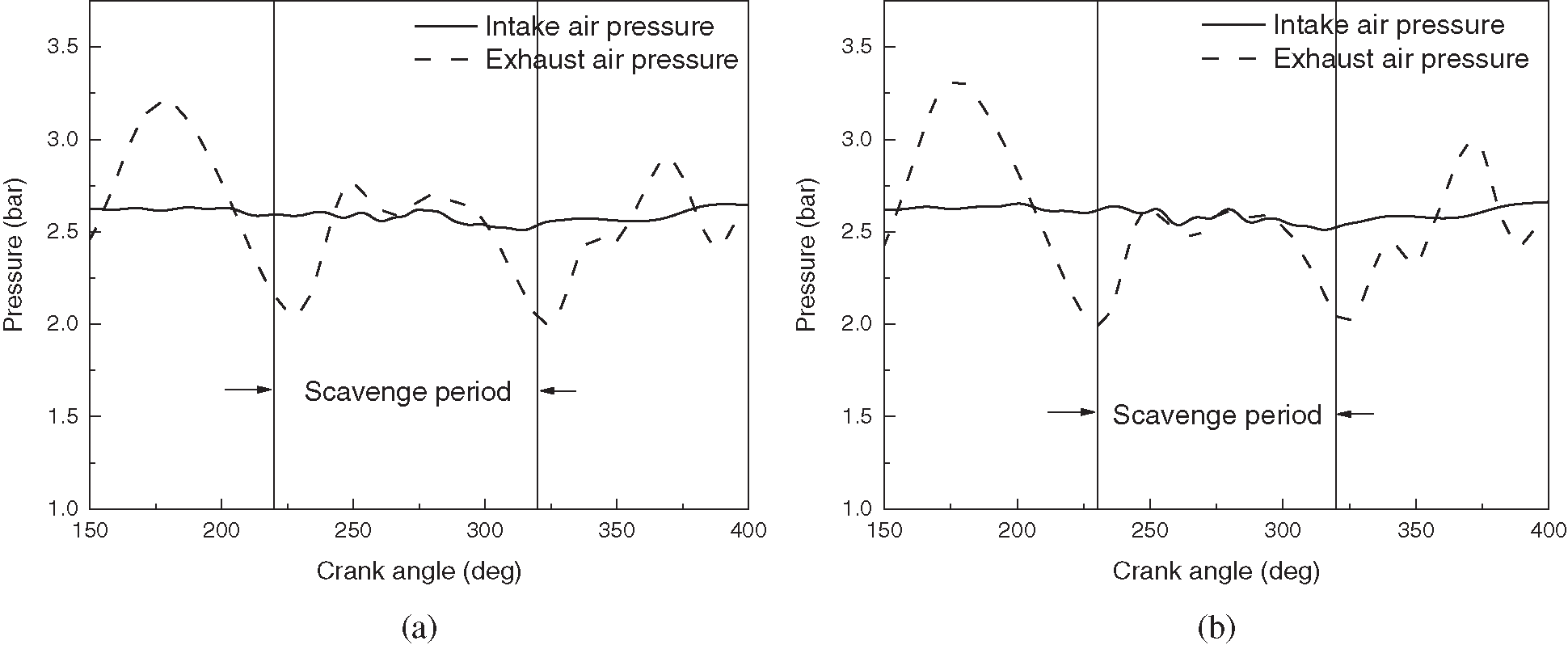

At low loads, the exhaust temperature of the diesel engine is relatively uniform. As the load increases, the exhaust temperature of cylinder 2 is relatively abnormal compared with that of the other cylinders. This is because when cylinder 3 is exhausting, cylinder 2 is just starting to scavenge. To avoid scavenging interference, the structure of the exhaust pipe of cylinder 3 is changed to an MMPC structure. To simplify the calculation, the part of MMPC inserted into the exhaust manifold should be equivalent to a circle. The specific simulation results show that with increasing MMPC diameter, the output power of the engine increases gradually, and the maximum explosion pressure of each cylinder in a single row is under the limit of 125 bar. The maximum exhaust temperature and maximum temperature difference in a single row increase first and then decrease. To keep the exhaust temperature from exceeding the limit value of 803 K, the exhaust temperature difference among the cylinders is minimized. For the convenience of processing, the optimized diameter of MMPC is set to 90 mm. The optimization results are shown in Figs. 11 and 12.

Figure 11: Intake and exhaust pressure before and after optimization (a) Before optimization (b) After optimization

Figure 12: Exhaust temperature before and after optimization (a) Before optimization (b) After optimization

It can be seen from Fig. 11 that the exhaust pressure of cylinder 2 is higher than the intake pressure during the partial scavenging stage before the structural improvement, which results in the insufficient scavenging of cylinder 2, and the exhaust temperature of cylinder 2 is higher than that of the other cylinders. After the improvement, the exhaust pressure of cylinder 2 in the scavenging stage is generally lower than the intake pressure. Therefore, the scavenging process is improved, the exhaust temperature of cylinder 2 is significantly reduced, and the uniformity of the cylinders is significantly improved.

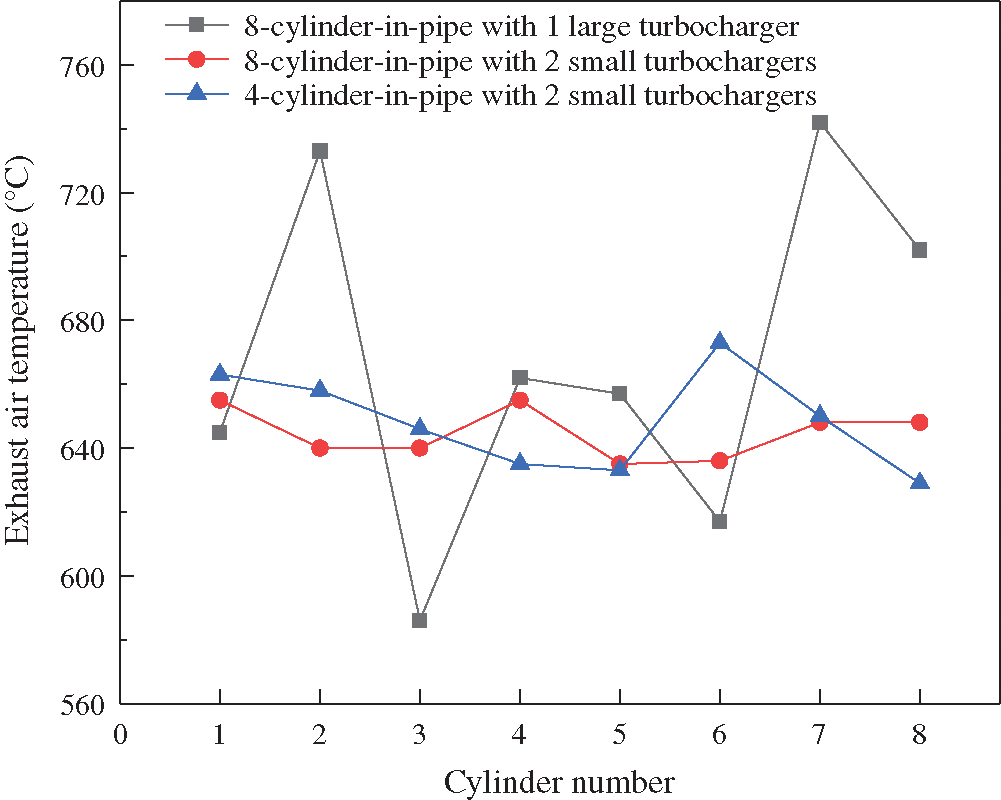

Fig. 13 shows the experimental results of the exhaust temperature of each cylinder in three typical exhaust system structures under the operating conditions of 75% load and 909 r/min. An 8-cylinder-in-pipe system with 2 small turbochargers replaced the exhaust manifold of cylinder 3 with an MMPC module; this is the final optimized structure of the exhaust system. From the experimental data in Fig. 13, it can be observed that the temperature difference among the cylinders of the original engine is large before the exhaust system is optimized, while the working uniformity among the cylinders in the 4-cylinder-in-pipe scheme with 2 small turbochargers is significantly improved. The optimized 8-cylinder-in-pipe scheme with 2 small turbochargers further reduces the difference in the exhaust temperature, the scavenging interference problem is significantly improved, and the working uniformity among cylinders is guaranteed. The laws reflected by the experimental results are consistent with the simulation calculation results, which verifies the effectiveness and reliability of the simulation method. In addition, the experiment results also demonstrate that the optimized exhaust system can solve the problem of the working consistency among cylinders with a simple structure and improved low-speed performance.

Figure 13: Experimental results of the exhaust temperature of each cylinder in different exhaust systems

For the marine high-power 16-cylinder V-type turbocharged diesel engine, one-dimensional engine performance simulation analysis is carried out with GT-Power. The effects of different exhaust systems on low-speed performance and exhaust temperature uniformity among cylinders are discussed in this paper. To avoid scavenging interference and increase the consistency of the exhaust temperature, the exhaust manifolds of certain cylinders are replaced with the MMPC structure module, and the exhaust manifold diameter is optimized. Finally, the accuracy and reliability of the simulation results are verified by experiments.

1. For a 16-cylinder V-type high-power diesel engine, a comparative analysis of 8-cylinder-in-pipe exhaust system scheme and 4-cylinder-in-pipe exhaust system scheme is carried out. The results show that the 8-cylinder-in-pipe exhaust system has advantages over the 4-cylinder-inpipe system in terms of the low-speed performance and temperature control of each cylinder.

2. The exhaust gas temperature of cylinders is different due to the exhaust disturbance. Cylinder 2 has higher exhaust back pressure. Therefore, its exhaust temperature is higher than that of the other cylinders.

3. For the 8-cylinder-in-pipe exhaust system scheme, parameter optimization of the exhaust manifold is carried out to improve the consistency of the cylinders, and the maximum exhaust temperature difference among cylinders is reduced from 134 K to 45 K.

Funding Statement: This study is supported by the High-Tech Ship Scientific Research Project [MC-201501-D01-01].

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Sun, K., Li, D., Liu, H., Bai, S. Z. (2020). Influence of diesel engine intake throttle and late post injection process on the rise of temperature in the diesel oxidation catalyst. Fluid Dynamics & Materials Processing, 16(3), 573–584. DOI 10.32604/fdmp.2020.09591. [Google Scholar] [CrossRef]

2. Shatrov, M. G., Malchuk, V. I., Dunin, A. Y. (2020). A laboratory investigation into the fuel atomization process in a diesel engine for different configurations of the injector nozzles and flow conditions. Fluid Dynamics & Materials Processing, 16(4), 747–760. DOI 10.32604/fdmp.2020.08991. [Google Scholar] [CrossRef]

3. Zhang, Y. J., Wang, C. F., Zheng, X. Q., Zhuge, W. L. (2013). Adaptive flow optimization of a turbocharger compressor to improve engine low speed performance. Journal of Mechanical Science and Technology, 27(6), 1581–1587. DOI 10.1007/s12206-013-0403-5. [Google Scholar] [CrossRef]

4. Mahabadipour, H., Srinivasan, K. K., Krishnan, S. R., Subramanian, S. N. (2018). Crank angle-resolved exergy analysis of exhaust flows in a diesel engine from the perspective of exhaust waste energy recovery. Applied Energy, 216(4), 31–44. DOI 10.1016/j.apenergy.2018.02.037. [Google Scholar] [CrossRef]

5. Kumar, K. M., Munjal, M. L. (2019). Direct estimation and experimental validation of the acoustic source characteristics of turbocharged diesel engine exhaust system. Applied Acoustics, 149(3), 171–180. DOI 10.1016/j.apacoust.2019.01.035. [Google Scholar] [CrossRef]

6. Hatami, M., Ganji, D. D., Gorji-Bandpy, M. (2015). Experimental and thermodynamical analyses of the diesel exhaust vortex generator heat exchanger for optimizing its operating condition. Applied Thermal Engineering, 75(9), 580–591. DOI 10.1016/j.applthermaleng.2014.09.058. [Google Scholar] [CrossRef]

7. Onorati, A., Montenegro, G., D’Errico, G., Piscaglia, F. (2010). Integrated 1D-3D fluid dynamic simulation of a turbocharged diesel engine with complete intake and exhaust systems. SAE Technical Papers. [Google Scholar]

8. Riegler, U., Bargende, M. (2002). Direct coupled 1D/3D-CFD-computation of the flow in the switch-over intake system of an 8-cylinder si engine with exhaust gas recirculation. SAE Technical Paper. [Google Scholar]

9. Hatami, M., Ganji, D. D., Gorji-Bandpy, M. (2015). Experimental and numerical analysis of the optimized finned-tube heat exchanger for OM314 diesel exhaust exergy recovery. Energy Conversion and Management, 97(1), 26–41. DOI 10.1016/j.enconman.2015.03.032. [Google Scholar] [CrossRef]

10. Hatami, M., Ganji, D. D., Gorji-Bandpy, M. (2014). Numerical study of finned type heat exchangers for ICEs exhaust waste heat recovery. Case Studies in Thermal Engineering, 4(9), 53–64. DOI 10.1016/j.csite.2014.07.002. [Google Scholar] [CrossRef]

11. Kaladgi, A. R., Ramis, M. K., Dafedar, M. S. (2014). CFD analysis of flow field development in a direct injection diesel engine with different manifolds. American Journal of Fluid Dynamics, 4, 102–113. [Google Scholar]

12. Rakopoulos, C. D., Andritsakis, E. C., Hountalas, D. T. (1995). The influence of the exhaust system unsteady gas flow and insulation on the performance of a turbocharged diesel engine. Heat Recovery Systems and CHP, 15(1), 51–72. DOI 10.1016/0890-4332(95)90037-3. [Google Scholar] [CrossRef]

13. Mahabadipour, H., Krishnan, S. R., Srinivasan, K. K. (2019). Investigation of exhaust flow and exergy fluctuations in a diesel engine. Applied Thermal Engineering, 147(11), 856–865. DOI 10.1016/j.applthermaleng.2018.10.109. [Google Scholar] [CrossRef]

14. Shi, L., Wang, S. M., Deng, K. Y., Cui, Y. (2012). Variable geometry exhaust manifold turbocharging system for an 8-cylinder marine diesel engine. Journal of Marine Science and Technology, 17(2), 252–259. DOI 10.1007/s00773-012-0161-6. [Google Scholar] [CrossRef]

15. Bassett, M. D., Winterbone, D. E., Pearson, R. J. (2000). Modelling engines with pulse converted exhaust manifolds using one-dimensional techniques. SAE Transactions, 109(3), 400–415. [Google Scholar]

16. Wang, S. M., Zhu, J., Deng, K. Y., Cui, Y., Xing, W. D. (2011). Preliminary study on a variable-geometry exhaust manifold turbocharging system. Proceedings of the Institution of Mechanical Engineers Part D Journal of Automobile Engineering, 225(8), 1078–1086. DOI 10.1177/0954407011404771. [Google Scholar] [CrossRef]

17. Cui, Y., Gu, H., Deng, K., Yang, S. (2010). Study on mixed pulse converter (MIXPC) turbocharging system and its application in marine diesel engines. Journal of Ship Research, 54(1), 68–77. DOI 10.5957/jsr.2010.54.1.68. [Google Scholar] [CrossRef]

18. Zhang, Z., Gu, H. Z., Guo, Z. C., Deng, K. Y. (2008). Modular multi-purpose pulse converter turbocharging system for four-stroke diesel engines. International Journal of Energy Research, 32(6), 569–580. DOI 10.1002/er.1368. [Google Scholar] [CrossRef]

19. Zhou, W. J., Cheng, J. H., Xing, W. D., Shi, L., Deng, K. Y. (2020). Switch control of sequential supercharging for diesel engine based on exhaust energy regulation. Vehicle Engine, 6, 1–6. [Google Scholar]

20. Wei, C. Y., Chen, M. Q., Jiang, Y. J. (2017). Electronic control fuel injection system based on GT-POWER and MotoTron. Procedia Engineering, 174, 773–779. DOI 10.1016/j.proeng.2017.01.221. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |