Materials Processing

| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2021.015478

ARTICLE

Experimental Analysis of a Pneumatic Drop-on-Demand (DOD) Injection Technology for 3D Printing Using a Gallium-Indium Alloy

1College of Mechatronics, Xuchang University, Xuchang, 461000, China

2College of Mechanical and Vehicle Engineering, Chongqing University, Chongqing, 400044, China

3State Key Laboratory of Mechanical Transmissions, Chongqing University, Chongqing, 400044, China

*Correspondence Author: Hao Yi. Email: haoyi@cqu.edu.cn

Received: 21 December 2020; Accepted: 11 February 2021

Abstract: Many liquid metals have a high boiling point, strong electrical conductivity, high thermal conductivity, and non-toxic properties, which make them ideal targets for applications in different fields such as optics, microcircuits, electronic switches, micro-electromechanical System (MEMS) devices and 3D printing manufacturing. However, owing to the generally high surface tension of these liquids, achieving uniform micro-droplets is often a challenge due to the inherent difficulties in controlling their size and shape. In this study, a gallium indium alloy (GaIn24.5) has been used in combination with a pneumatic drop-on-demand (DOD) injection technology to carry out a series of experiments. The micro-droplet forming process has been explored for different pressure and pulse width conditions. Uniform metal droplets (diameter 1080 μm) have been obtained with a 1.5 kPa jet pressure, 100 ms pulse width, and 50% duty ratio. The standard deviation of the measured metal droplets diameter has been found to be approximately 20 μm.

Keywords: Liquid metal; drop-on-demand; micro-droplet; pulse width; gallium indium alloy

Low melting point alloys [1], such as gallium, bismuth, indium, tin, and zinc-based alloys in general have a melting point below 183°C. These alloys have low melting point, viscosity and resistivity, and are primarily used in solder, fuse and mold manufacturing [2]. Liquid metal is a novel low-melting point alloy with unique physical and chemical properties, and is mainly composed of gallium and indium alloys [3]. Liquid metal is liquid at room temperature (25°C), and has high boiling point, strong electrical conductivity, high thermal conductivity, and non-toxic properties. Owing to good fluidity and strong surface tension, when the jet is ejected from the nozzle, liquid metal easily breaks into multiple spherical droplets. This unique characteristic endows it with broad range of application prospects in the field of optics, microcircuits, cooling liquid, electronic switches, MEMS devices and 3D printing manufacturing [4–6].

Metal droplet preparation technology has become a research hotspot in both academia and industry. In recent years, multiple methods for producing metal micro-droplets have been developed. Continuous Ink-Jet (CIJ) technology [7] and drop-on-demand (DOD) injection technology [8] are two typical methods for the preparation of metal micro-droplets. In comparison with CIJ technology, DOD technology injection frequency is low and computer-controlled, has decent single tiny droplet controllability, which has enormous potential in the field of microelectronics packaging, metal parts printing, etc [9,10].

A pneumatic driven droplet on-demand injection device was developed by Cheng [11]. By applying a pressure pulse to the fluid in the crucible, the fluid flowed out of the jet hole and broke into a single droplet, and the 100–300 μm solder metal (tin, lead, and zinc) droplets were successfully sprayed. The millimeter scale micro-parts were printed by controlling the layer by layer stacking.

A piezoelectric actuated micro-droplet injection device was developed by Lee et al. [12]. A stable ejection of droplets between 100 and 300 μm [13] could be achieved, using this device. The tilted column structure was successfully printed on the substrate. Luo et al. [14] used a pneumatic DOD system to produce solder droplets (also called solder bumps) for the electronics packages. The pneumatic driving, stress wave drive, and piezoelectric actuation device have been developed to obtain on demand Pb/Sn, Al, Cu micro-droplets [15–17]. Tang et al. used Acoustic Waves drive technology to produce liquid metal droplets with controllable size on chip [18]. Ming et al. used piezoelectric film-piston jet technology to produce solder droplets with a controllable size [19].

However, the above works mainly used Pb/Sn alloy with low melting point as the injection material, and the injection temperature is mostly above 180°C. There are some reports on the micro-droplet injection technology using gallium, bismuth, indium alloy and other liquid metals as test materials [20]. Liu et al. discovered an extremely low voltage induced liquid metal jet phenomenon, which opens a new route for the rapid preparation and precise control of liquid metal droplets [21]. Although this technique can be used to rapidly prepare liquid metal droplets, the size accuracy of metal droplets is not ensured. This is because the process needs to be conducted in a specific solution, and the jet is dispersed into droplets rapidly. Microfluidic channel technology is also a common method for producing micro-droplets.

In the above studies, droplets take shapes by flow focusing, and the key factors controlling the fabrication include fluid velocity, viscosity and surfactant properties. By controlling the shape of various micro-channels and the velocity, viscosity and surfactant properties, different sizes and non-spherical liquid metal droplets can be produced [22,23]. However, the microfluidic channels are required to have high shape and size precision, but in these processes, the manufacturing process is cumbersome, and the size control precision of liquid metal micro-droplet is poor.

Herein, the gallium indium alloy (GaIn24.5) liquid metal was used as the research material, and the pneumatic DOD injection technology was adopted to conduct experiments. The micro-droplet forming principle and dimension characteristics under different pressure, pulse width and injection frequency have been discussed. This work provides a reference for liquid metal micro-droplet preparation and customized printing of flexible circuits, and has important application prospects.

2 Process Principle and Experiment System

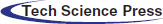

Fig. 1 shows a schematic illustration of the process principle and experimental setup of pneumatic drop-on-demand jetting of liquid metal. The experimental system mainly included a printing head, three-dimensional (3D) motion platform, high-speed CCD camera, deposition substrate, power module, trigger module, temperature controller, pressure valve, and heating furnace. The 3D motion platform was used to form complex trajectory patterns via data control. It consists of a multi-axis motion controller (GOOGOL), deposition substrate and three axis (X, Y, Z) servo motors (Panasonic). A process monitor system was used to observe the spraying and deposition process of droplets, which consists of a high speed CCD camera (Uniq 610), a microscope (Optem Zoom 65) and an image acquisition card (GIE62+). The crucible was made of stainless steel, and an injection needle was inserted into the bottom plate of the crucible. The heating furnace around the crucible maintained its temperature above the melting point of droplet material. A T-junction was connected to the solenoid valve, and one of its outlet was installed into the top plate of the crucible, while a vent valve was connected to the other outlet of the T-junction. A pressure pulse was generated in the droplet generator chamber by opening and closing of the solenoid valve connecting the gas source and the droplet generator chamber.

Figure 1: Schematic diagram of process and experimental set-up

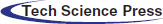

As shown in Fig. 2, according to the basic principle of air pressure driven droplet-on-demand injection system, the main parameters that affect the droplet injection are the air supply pressure P, pulse parameters and opening size of vent valve. The primary function of the vent valve is to form negative pressure in the crucible cavity when the solenoid valve is in turn on-off state. The oscillating pressure wave is generated, driving the generation of droplet and retraction of jet. The ball valve spool can be used to adjust the ratio of opening in the vent valve. When the opening size of air vent valve is fixed, the air supply pressure P should be suitable. Under a large air supply pressure P, the jet velocity is too high to break into micro-droplets. P is too low to eject the liquid metal jet from the nozzle. When the air supply pressure P and the opening size of air vent valve are fixed, Pulse parameters (pulse frequency H, pulse width Pw, and duty ratio R) are the main factors, which affect the change of pulse pressure and the generation of metal droplet.

Figure 2: Schematic diagram of pressure fluctuation curve in crucible cavity

The value of Pp is primarily related to the air supply pressure P. The value of pulse width Pw and duty cycle R determine the droplet formation of liquid metal jet. When the duty ratio R is unchanged, the pulse width Pw is too large, and the liquid metal jet cannot break into micro-droplets. With the decrease pulse width Pw, the phenomenon of multiple or single micro-droplet fracture forming appears. Therefore, the experimental research of liquid gallium indium alloy pneumatic DOD injection under different pulse parameters is of great significance.

In this process, the gas pulse pressure inside the droplet generator chamber was a driver, which was produced by switching on and off the solenoid valve. When the solenoid valve was switched on, the high-purity argon gas entered into the crucible chamber. The gas pressure in the crucible was increased, and the molten metal liquid was extruded through the nozzle to form a jet. Under the action of gravity and surface tension, the tip of the jet was separated into individual droplets. When the solenoid valve was switched off, the argon inside the cavity escaped through the vent on top of the droplet generator, and the pressure inside the droplet generator dropped rapidly below the atmospheric pressure. The liquid metal was pulled back into the nozzle and no more droplets were formed until another pressure pulse was applied.

Under the action of pulse pressure, the liquid metal fluid was ejected from the nozzle at the bottom of the crucible. The droplet formation process is influenced by the action of gravity, surface tension and gas resistance. The magnitude of these forces is related to the properties of the material such as surface tension, viscosity, and density. Herein, Gallium Indium Alloy (GaIn24.5) Liquid Metal was selected as the experimental material. Its melting point is 15.7°C, viscosity is 0.23cSt, and surface tension is 0.60 N.m-1. In order to reproduce the dynamic process of liquid metal forming droplets on demand, a high-speed CCD was used to capture the process at the rate of 600 Hz. Then the process of liquid metal micro-droplet was analyzed frame by frame. In the experiment, the material was heated to 40°C. By adjusting the injection process parameters such as injection pressure and pulse width, the droplets were obtained.

As per the principle of pneumatic on-demand injection technology, a pulse pressure was applied to the cavity when the solenoid valve was turn on and off once. At this time, the liquid metal in the crucible was ejected from the pinhole nozzle under the action of pulse pressure. However, not under each pulse pressure excitation, a single micro-droplet was produced, sometimes the phenomenon of many droplets or no droplet ejection also occurred.

The pinhole nozzle diameter (D) was 280 μm, air supply pressure (P) was set at 2 kPa, injection frequency (H) was set at 1 Hz, and duty ratio (R) was 80%. The effect of control parameters on the injection state was investigated by changing the high-level pulse width of the signal.

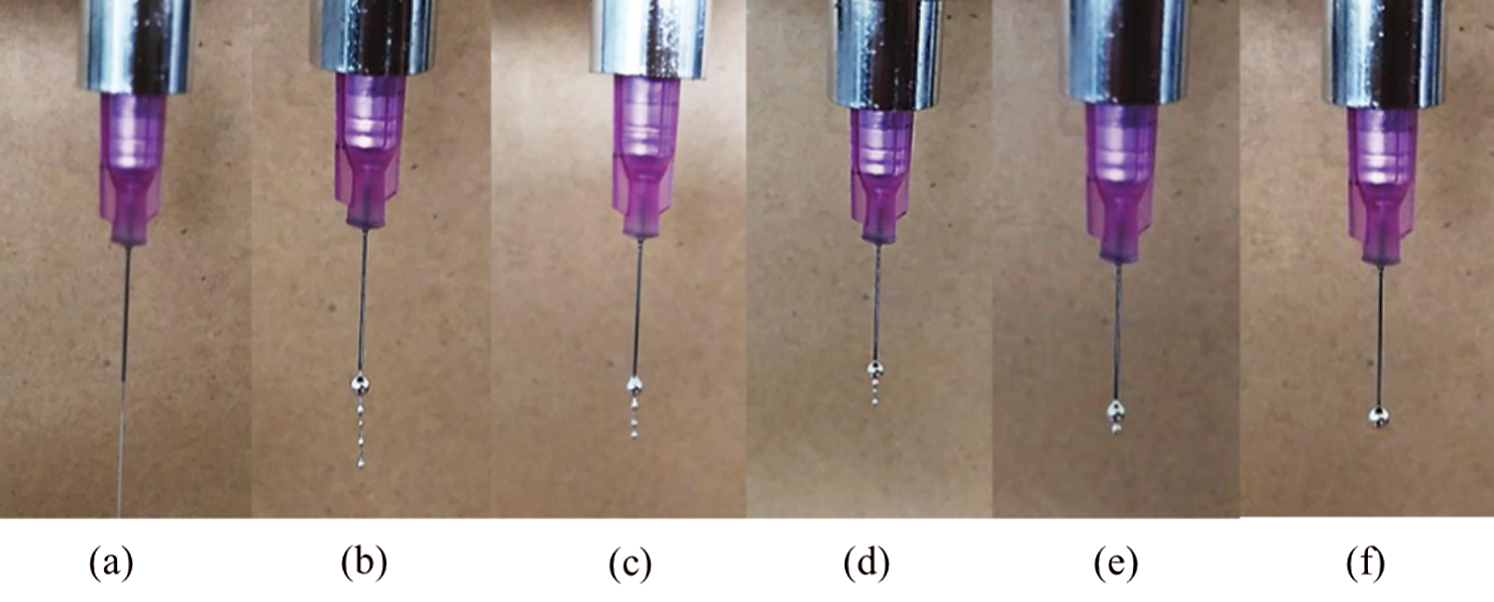

Fig. 3 display the experimental results of ejected liquid metal micro-droplets under different pulse width with as captured by high speed CCD. When the pulse width (Pw) was 1000 ms, only the jet flow was generated and no liquid metal micro-droplet was formed. When the pulse width was 650 ms, the jet broke into forming 4 small droplets in series. The main reasons were improper injection pressure, pulse width and duty cycle parameters. Which resulted in oxidation of the surface of liquid metal. When the liquid metal jet is ejected from the nozzle, liquid metal jet forms an oxide film with oxygen, which hinders the breakage of the jet and, prolongs the breaking time of the jet. Due to the relatively large pulse width (650 ms) and duty cycle (80%), the length of the liquid metal jet becomes longer, and the fracture process occurs in multiple areas, which eventually leads to the phenomenon that the jet breaks into 4 small droplets in series. When the pulse widths were 450 ms, 300 ms, and 200 ms, the jet broke into forming 3, 2, and 1 small droplets in series, respectively. When the pulse width was 100 ms, a large suspended droplet was formed at the nozzle. The primary reason for the phenomenon is that: the liquid metal viscosity and surface tension were relatively large, and the air supply pressure was relatively high.

Figure 3: Liquid metal micro-droplets under different pulse width: (a) 1000 ms; (b) 650 ms; (c) 450 ms; (d) 300 ms; (e) 200 ms; (f) 100 ms

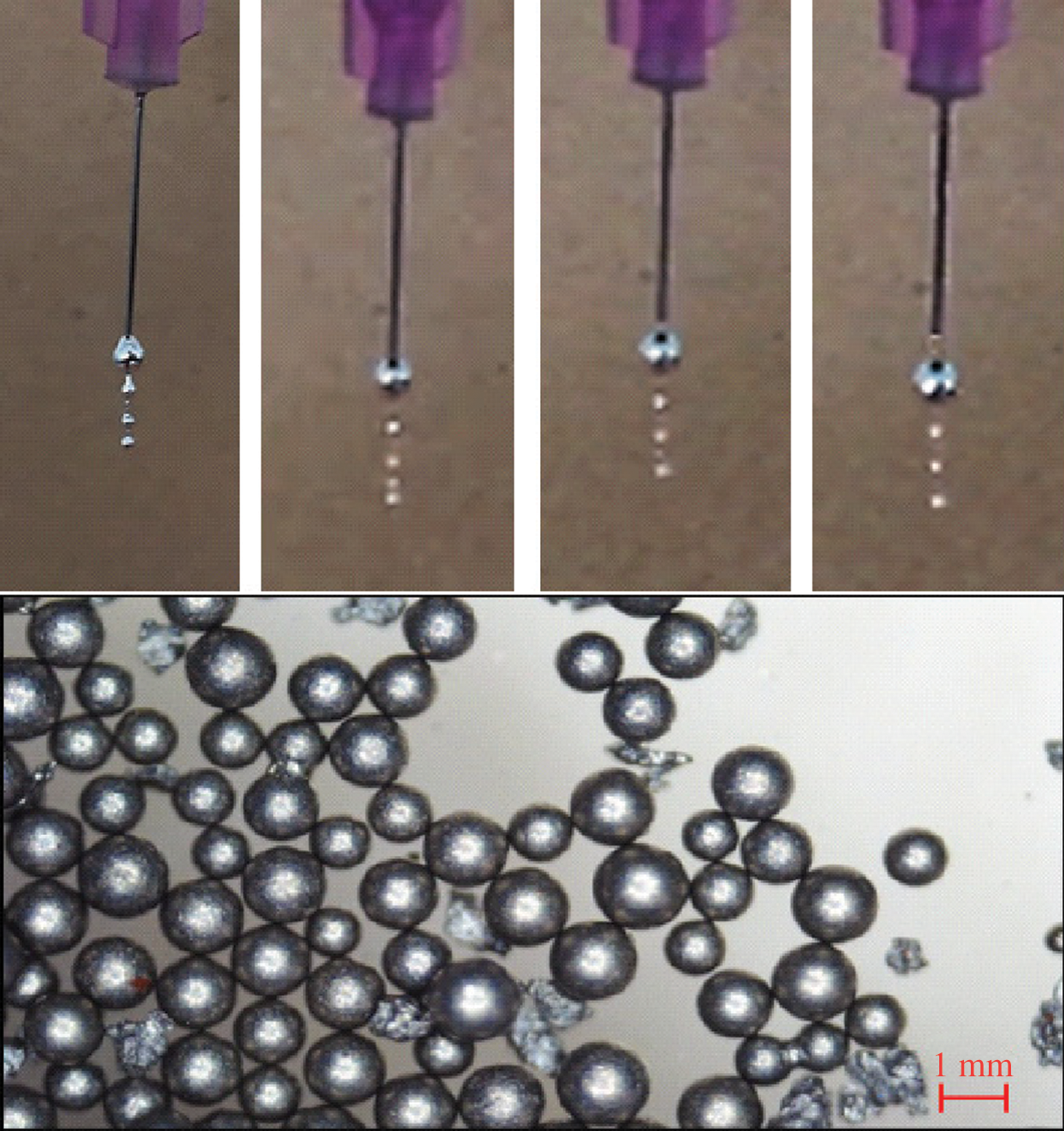

For further analysis, the formed droplets after liquid metal jet fracture were deposited into ice water at 0°C. Fig. 4 shows the collected particles after the solidification of liquid metal droplets. The diameter of the droplets was extremely uneven, diameter deviation was relatively large, and there were irregular shapes in the droplets.

Figure 4: Collected uneven particles after solidification of liquid metal droplets

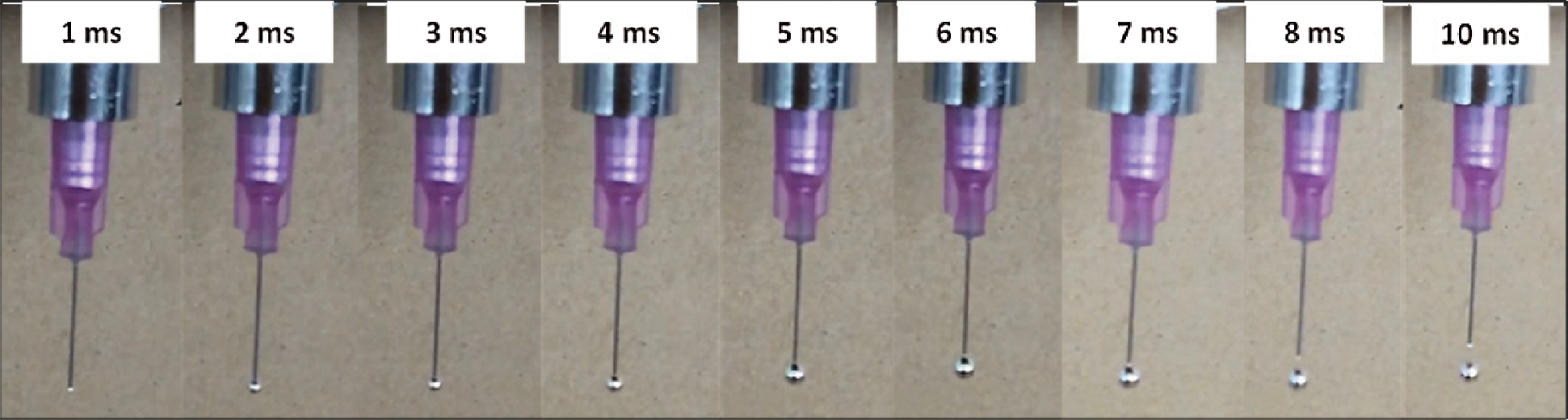

To obtain a single uniform liquid metal droplet, the jet pressure was adjusted to 1.5 kPa, the pulse width was set to 100 ms, and the duty ratio was set to 50%. Fig. 5 presents the fracture and forming process of liquid metal droplets as captured by high-speed CCD under the above process parameters. A single uniform liquid metal droplet was finally obtained and; the whole forming process took about 10 ms. Within 1–6 ms, the metal droplet hung the bottom of the nozzle, and the size gradually increased. At 7–10 ms, the hanging liquid metal droplet broke into a single uniform droplet under the action of surface tension, gravity, and the retraction of metal jet.

Figure 5: Formation process of single liquid metal micro-droplet as captured by high speed CCD

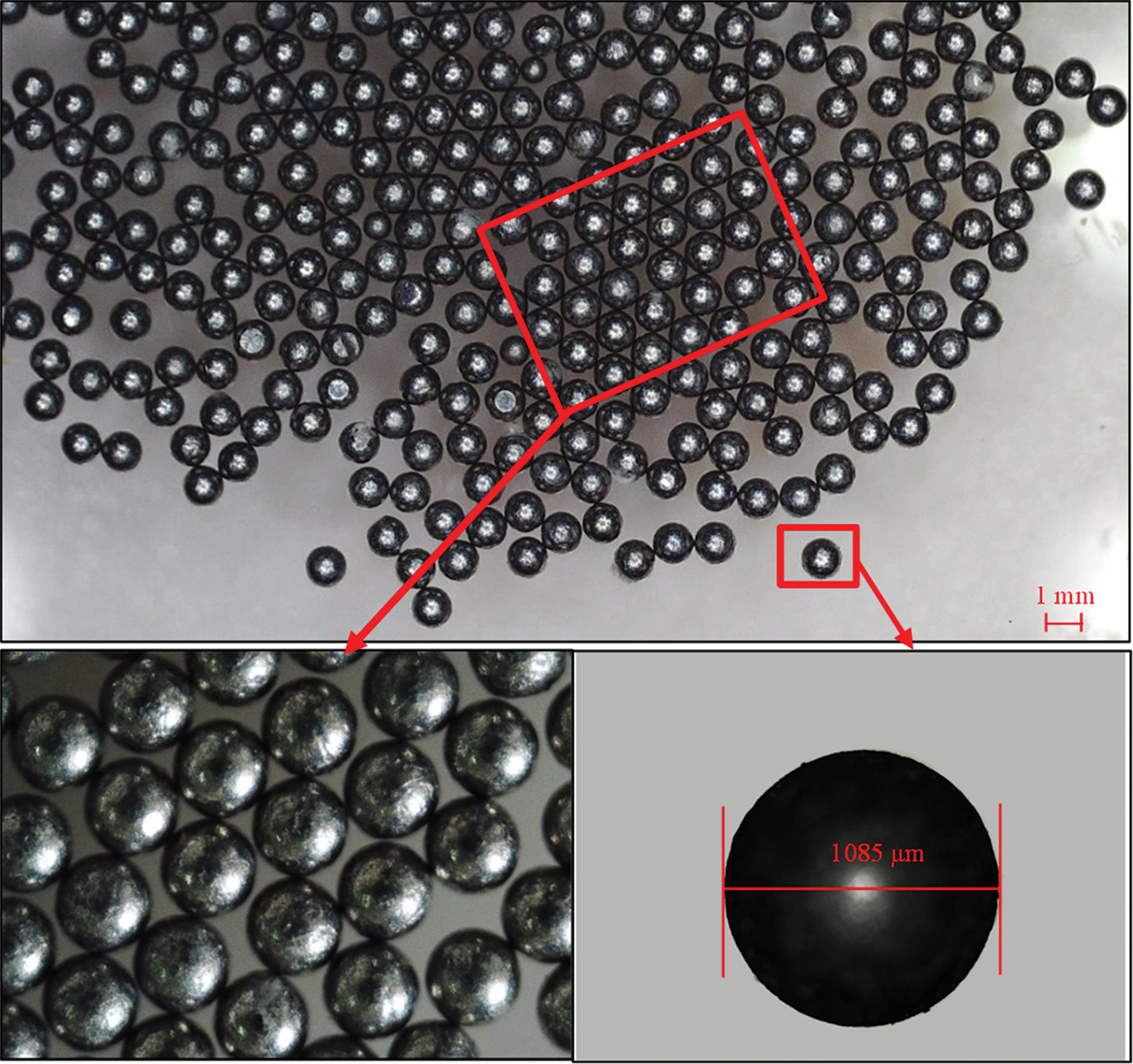

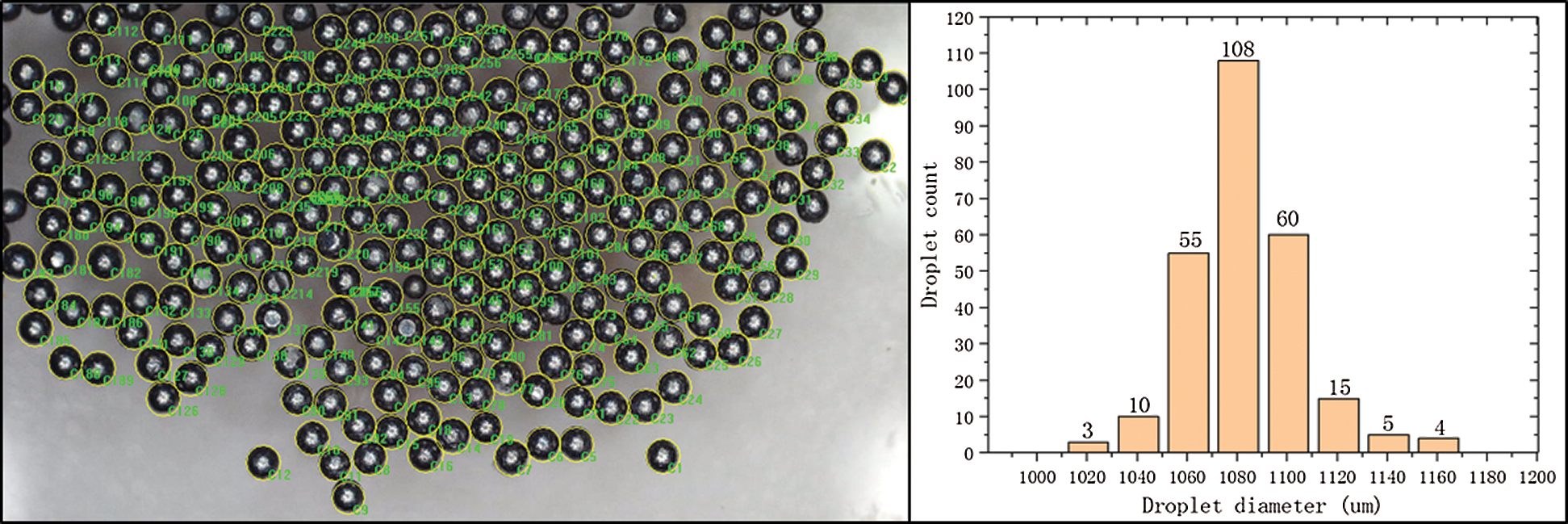

Fig. 6 shows the collected particles after the solidification of liquid metal droplets. The diameters of the droplets were extremely even. There were no irregularly shaped particles and the individual metal particles had a high roundness.

Figure 6: Collected even particles after solidification of liquid metal droplets

The diameter of collected uniform metal droplets was assessed. Fig. 7 shows the statistical results of diameters of 260 uniform metal droplets. The number of droplets between 1060 and 1100 μm in diameter was more than 85% of the total number of droplets. The standard deviation of the measured metal droplets diameter was approximately 20 μm. These results show that the size distribution of the droplets was concentrated and uniform.

Figure 7: Statistical analysis of uniform metal droplets diameter

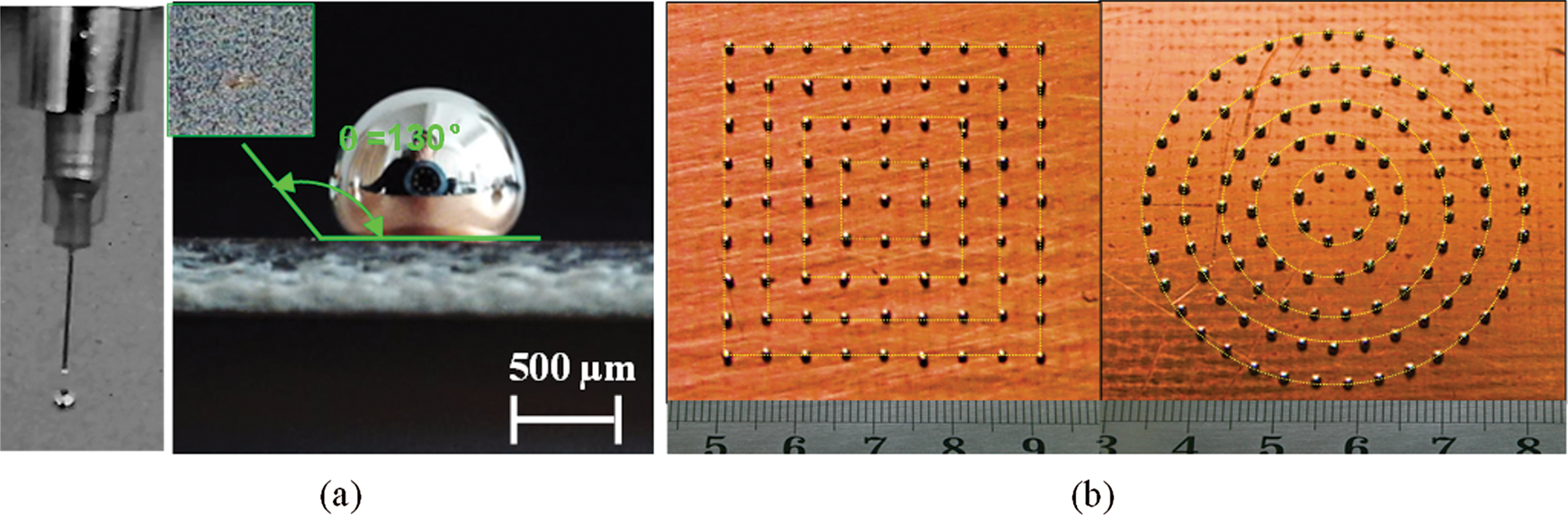

Considering the above results, the liquid metal micro-droplets were deposited on the copper-clad plate surface of the substrate. Fig. 8 shows the deposition result. The morphology of a liquid metal micro-droplet deposited on the copper-clad plate surface is shown in Fig. 8(a). The wetting angle between liquid metal and substrate was about 130°. As shown in Fig. 8(b), the square and circular point arrays were printed successfully. The deviation of position of droplet deposition was relatively small, and there was no prominent divergence and deviation.

Figure 8: Liquid metal on the copper-clad plate surface (a) morphology of liquid metal and (b) printed array points

1. The experimental system of a pneumatic drop-on-demand jetting of liquid metal was developed, which mainly included a print head, 3D motion platform, high-speed CCD camera, deposition substrate, a power module, trigger module, temperature controller, pressure valve, and heating furnace.

2. The influence mechanism of parameters (jet pressure, pulse width, and duty ratio) was explored in the droplet pneumatic -on-demand spraying process, and a single uniform liquid metal droplet was stably produced.

3. The uniform metal droplets (diameter 1080 μm) were obtained under 1.5 kPa jet pressure, 100 ms pulse width, and 50% duty ratio. The standard deviation of the measured metal droplets diameter was approximately 20 μm.

Funding Statement: This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51305128 and 52005059), the China Postdoctoral Science Foundation (Grant No. 2020M673127), the Natural Science Foundation of Chongqing (Grant No. cstc2020jcyj-bshX0008), and the Fundamental Research Funds for the Central Universities of China (Grant No. 2020CDJQYA035), the key scientific and technological project of Henan province (Grant No. 192102210055), the “Construction of double city economic circle in Chengdu Chongqing area” scientific and technological innovation project (Grant No. KJCXZD2020011), the key scientific research projects of the colleges and universities of Henan province (Grant No. 18A4600050), and Outstanding Young Backbone Teachers projects of Xuchang University.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Yu, Y. Z., Liu, F. J., Liu, J. (2017). Direct 3D printing of low melting point alloy via adhesion mechanism. Rapid Prototyping Journal, 23(3), 642–650. DOI 10.1108/RPJ-12-2015-0185. [Google Scholar] [CrossRef]

2. Li, H., Yang, Y., Liu, J. (2012). Printable tiny thermocouple by liquid metal gallium and its matching metal. Applied Physics Letters, 101(7), 073511–0731–3. DOI 10.1063/1.4746397. [Google Scholar] [CrossRef]

3. Siegel, A. C., Phillips, S. T., Dickey, M. D., Lu, N., Suo, Z. G. et al. (2010). Foldable printed circuit boards on paper substrates. Advanced Functional Materials, 20(1), 28–35. DOI 10.1002/adfm.200901363. [Google Scholar] [CrossRef]

4. Yu, Y. Z., Liu, F. J., Zhang, R. C., Liu, J. (2017). Suspension 3D printing of liquid metal into self-healing hydrogel. Communication, 1–6. [Google Scholar]

5. Zheng, Y., He, Z. Z., Gao, Y. X., Liu, J. (2013). Direct desktop printed-circuits-on-paper flexible electronics. Scientific Reports, 3(1), 911. DOI 10.1038/srep01786. [Google Scholar] [CrossRef]

6. AlOmari, S. A. B., Elnajjar, E. (2013). An experimental study on enhancing cooling rates of low thermal conductivity fluids using liquid metals. Fluid Dynamics & Materials Processing, 9(2), 91–109. [Google Scholar]

7. Orme, M., Smith, R. F. (2000). Enhanced aluminum properties by means of precise droplet deposition. Journal of Manufacturing Science and Engineering, 122(3), 484–493. DOI 10.1115/1.1285914. [Google Scholar] [CrossRef]

8. Prokhorov, V. E. (2020). Acoustic shock emission in a collision of a drop with water surface. Fluid Dynamics & Materials Processing, 16(4), 737–746. DOI 10.32604/fdmp.2020.08988. [Google Scholar] [CrossRef]

9. Vaughn, B. S., Tracey, P. J., Trevitt, A. J. (2016). Drop-on-demand micro droplet generation: a very stable platform for single-droplet experimentation. RSC Advances, 6(65), 60215–60222. DOI 10.1039/C6RA08472A. [Google Scholar] [CrossRef]

10. Chekifi, T., Dennai, B., Khelfaoui, R. (2017). Computational investigation of droplets behaviour inside passive microfluidic oscillator. Fluid Dynamics & Materials Processing, 13(3), 173–187. [Google Scholar]

11. Cheng, S. X., Li, T., Chandra, S. (2005). Producing molten metal droplets with a pneumatic droplet-on-demand generator. Journal of Materials Processing Technology, 159(3), 295–302. DOI 10.1016/j.jmatprotec.2004.05.016. [Google Scholar] [CrossRef]

12. Lee, T., Kang, T. G., Yang, J. S., Jo, J. D., Kim, K. Y. et al. (2008). Drop-on-demand solder droplet jetting system for fabricating microstructure. IEEE Transactions on Electronics Packaging Manufacturing, 31(3), 202–210. DOI 10.1109/TEPM.2008.926285. [Google Scholar] [CrossRef]

13. Sohn, H., Yang, D. Y. (2005). Drop-on-demand deposition of superheated metal droplets for selective infiltration manufacturing. Materials Science and Engineering: A, 392(1–2), 415–421. DOI 10.1016/j.msea.2004.09.049. [Google Scholar] [CrossRef]

14. Luo, J., Qi, L. H., Zhong, S. Y., Zhou, J. M., Li, H. J. (2012). Printing solder droplets for micro devices packages using pneumatic drop-on-demand (DOD) technique. Journal of Materials Processing Technology, 212(10), 2066–2073. DOI 10.1016/j.jmatprotec.2012.05.007. [Google Scholar] [CrossRef]

15. Zuo, H. S., Li, H. J., Qi, L. H., Luo, J., Zhong, S. Y. et al. (2014). Effect of wetting behavior on generation of uniform aluminum droplets obtained by pneumatic drop-on-demand technique. Journal of Materials Processing Technology, 214(11), 2566–2575. DOI 10.1016/j.jmatprotec.2014.05.017. [Google Scholar] [CrossRef]

16. Chekifi, T., Dennai, B., Khelfaoui, R. (2015). Numerical simulation of droplet breakup, splitting and sorting in a microfluidic device. Fluid Dynamics & Materials Processing, 11(3), 205–220. [Google Scholar]

17. Yi, H., Qi, L. H., Luo, J., Zhang, D. C., Li, N. (2019). Direct fabrication of metal tubes with high-quality inner surfaces via droplet deposition over soluble cores. Journal of Materials Processing Technology, 264, 145–154. DOI 10.1016/j.jmatprotec.2018.09.004. [Google Scholar] [CrossRef]

18. Tang, S. Y., Ayan, B., Nama, N., Bian, Y. S., Lata, J. P. et al. (2016). On-chip production of size-controllable liquid metal microdroplets using acoustic waves. Small, 12(28), 3861–3869. DOI 10.1002/smll.201600737. [Google Scholar] [CrossRef]

19. Ma, M., Wei, X. F., Shu, X. Y., Zhang, H. H. (2019). Producing solder droplets using piezoelectric membrane-piston-based jetting technology. Journal of Materials Processing Tech, 263, 233–240. DOI 10.1016/j.jmatprotec.2018.08.029. [Google Scholar] [CrossRef]

20. Shi, J. T., Shu, Q. Q., Tong, B. X., Fu, J. H., Tang, S. S. et al. (2020). Fabrication of BiInSn alloy powder via the combination of ultrasonic crushing with dispersants. Powder Technology, 373, 614–619. DOI 10.1016/j.powtec.2020.07.015. [Google Scholar] [CrossRef]

21. Fang, W. Q., He, Z. Z., Liu, J. (2014). Electro-hydrodynamic shooting phenomenon of liquid metal stream. Applied Physics Letters, 105(13), 4104. [Google Scholar]

22. Chekifi, T. (2019). Droplet breakup regime in a cross-junction device with lateral obstacles. Fluid Dynamics & Materials Processing, 15(5), 545–555. DOI 10.32604/fdmp.2019.01793. [Google Scholar] [CrossRef]

23. Jin, T. M., Edward, M. H., Zhao, N., Duan, Z. Y., Wang, J. T. (2019). Generation and analysis of axiolitic liquid-metal droplets in a t-junction microfluidic device. Chemistry Select, 4, 3926–3935. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |