Fluid Dynamics & Materials Processing

Fluid Dynamics & Materials Processing

Fluid Dynamics & Materials Processing Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2021.013178

ARTICLE

Exergy Analysis and Thermal Optimization of a Double-Turbine Regeneration System in a Ultra-Supercritical Double-Reheat Unit

1School of Energy and Power Engineering, Shandong University, Jinan, 250061, China

2Shandong Electric Power Engineering Consulting Institute Co., Ltd., Jinan, 250061, China

3School of Thermal Engineering, Shandong Jianzhu University, Jinan, 250061, China

*Corresponding Authors: Tao Luan. Email: Prof.luantao@gmail.com; Yan Gao. Email: gaoyan.sdu@hotmail.com

Received: 28 July 2020; Accepted: 30 November 2020

Abstract: Improving the primary steam parameters is one of the most direct ways to improve the cycle efficiency of a power generation system. In the present study, the typical problem connected to the excessively high superheat degree of extraction steam in an ultra-supercritical (USC) double-reheat unit is considered. Using a 1000 MW power plant as an example, two systems (case 1 and case 2) are proposed, both working in combination with a regenerative steam turbine. The thermal performances of these two systems are compared with that of the original system through a heat balance method and an exergy balance strategy. The results reveal that the two coupled systems can significantly reduce the superheat degree of extraction steam, turbine heat rate, and coal consumption of the unit and improve the energy utilization efficiency. These results will provide useful theoretical guidance to future investigators wishing to address the general problem relating to energy conservation and modelling of the coupled extraction steam regenerative system of USC double-reheat units.

Keywords: Ultra-supercritical unit; exergy loss; thermal performance; regenerative steam turbine; superheat degree

Improving the primary steam parameters is one of the most direct ways of improving the cycle efficiency of a power generation system. In recent years, the operating parameters of double-reheat units have reached 31 MPa/600°C/620°C/620°C [1]. With the improvement of unit parameters, the superheat degree of extraction steam from high-pressure (HP) and low-pressure (LP) turbines has increased, resulting in increased irreversible heat transfer loss on the steam side and water side in the regenerative heater (RH), reducing the benefits of high steam parameters [2–4]. The conventional solution is to install an external steam cooler (ESC) [5–7] to reduce the superheat degree of extraction steam in the steam cycle. Another solution is installing a regenerative steam turbine in the double-reheat system [8,9].

Although the double-reheat system with an ESC is widely used, the extraction stage cannot be changed, and the ESC is simply added to the original extraction stage. The steam in an ESC does not have phase changes, which leads to a low heat transfer coefficient, large heat exchange area, and high installation cost [10]. Existing research reveals that, for a high-pressure/high-temperature double-reheat unit, the coupled regenerative steam turbine provides a better superheat reduction effect and thermal economy. Zhou et al. [11] and Liu et al. [12] analyzed the energy saving effect of various utilization modes of superheat degree and considered the double-turbine regeneration system as the best system. Duan et al. [13] performed a comparative analysis of different schemes of double-reheat unit Integrated with regenerative steam turbine. Qiao et al. [14] analyzed the thermal performance of RH2–RH4 heaters and a deaerator (DEA) in a double-turbine regeneration system and obtained an RH exergy loss that was 51% less than that obtained by adding a two-stage external cooler. Zhou et al. [15] carried out the thermodynamic and economic analyses of the RT system in a typical 1000 MW power plant and considered that the energy saving effect of the RT system would be decreased in off-design condition and the total exergy destruction decrement of related RHs in the RT system decreases as the load drops down. Zhou et al. [16] proposed tow schemes: The external steam cooler system and the regenerative steam turbine system for high double reheat supercritical unit and the results show that the power generation efficiency of two schemes can be improved by 0.34% and 1.87% separately, and the energy saving effect of the regeneration turbine is remarkable.

However, the above research only focused on 10-stage double-reheat systems. In this study, two system schemes for reducing extraction superheating degrees were developed for 12-stage regenerative units and higher steam parameters. The influence of different extraction stages of regenerative steam turbines was analyzed, and the thermal performance of the three system schemes were compared.

In this study, the thermodynamic cycles of the system were simulated with Thermoflex, which is widely used for the system simulation and calculation of different units. The following assumptions were made about the system: 1) The operation of the unit was in a steady state; 2) The isentropic expansion efficiencies are equal to 0.89, 0.92, 0.93 and 0.88 during the different stages of the VHP, HP, IP, and LP turbines, respectively; 3) The efficiency of the regenerative steam turbine was 0.89; 4) the boiler efficiency was 0.95; and 5) the generator efficiency was 0.99.

2.2 Thermodynamic Performance Evaluation

The heat rate and efficiency of the power plant are used in the electric power industry to evaluate the thermal performance of coal-fired units [17]. The power plant heat rate is expressed as follows:

The unit efficiency is expressed as follows:

The definition of the standard coal consumption of the power plant is expressed in the following form:

where QCP denotes the total energy entering the unit. Here, QCP is commonly defined as the chemical energy of the coal, and here that is equal to low heat value (LHV). Pe refers to the power generated by the steam turbine. Pe and QCP have the same unit of measurement (kW, MW). ηfn is the comprehensive efficiency of the unit which refers to ηqn (steam turbine efficiency), ηgd (pipe efficiency), and ηgl (boiler efficiency). The LHV of standard coal is equivalent to 29271 kg/kJ, and bCP has the unit of g/kWh.

Exergy analysis is a thermodynamic analysis technique based on the second law of thermodynamics, which reflects the substantial change in heat transfer. For the steady flow process, physical exergy is expressed as follows:

Here, the subscript 0 refers to the specified stream flow and physical values at the reference pressure and temperature. Here, P0 and T0 are 101.325 kPa and 0°C, respectively. The exergy loss of the RH can be defined as:

where Ein and Eout are the exergy input and output of the RH, respectively.

The exergy efficiency of the RH is expressed as follows:

where ΔERH,fw, ΔERH,ex, and ΔERH,dw are the exergy losses of the feed water, extraction steam, and drain water flowing through the RH, respectively.

3 Two Modes of Double-Turbine Regeneration Systems

3.1 Typical Double-Reheat USC Unit (Original System)

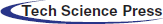

A state-of-the-art 1000 MW USC double-reheat power plant is selected as the original system in this study. The main steam parameters were 35 MPa/615°C/630°C/630°C. The main components of the original system were the VHP, HP, IP, and LP turbine groups, a boiler with two reheaters, a DEA, and high- and low-pressure RHs. 12 stages extraction steams were involved in the system. Fig. 1 presents the system flow diagram.

Figure 1: Flow diagram of the original USC system

Tab. 1 provides the major parameters of extraction steam in the original system. It shows that the superheat degree of extraction steam is very high in RH2–RH7, entirely exceeding 200°C. In RH5, that reaches 353.21°C. The extraction steam of RH2–RH4 is located in HP after the first stage of reheat, whereas the extraction steam of RH5–RH7 is located in IP after the second stage of reheat. The reheat process increases the heat of the extraction steam and lead to the high superheat degree, which causes a large temperature difference during the heat transfer process of the RH and influences the thermal performance of the system.

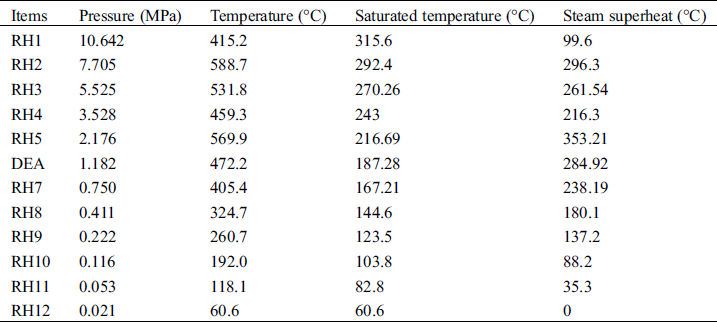

Table 1: Extraction steam parameters of the original system

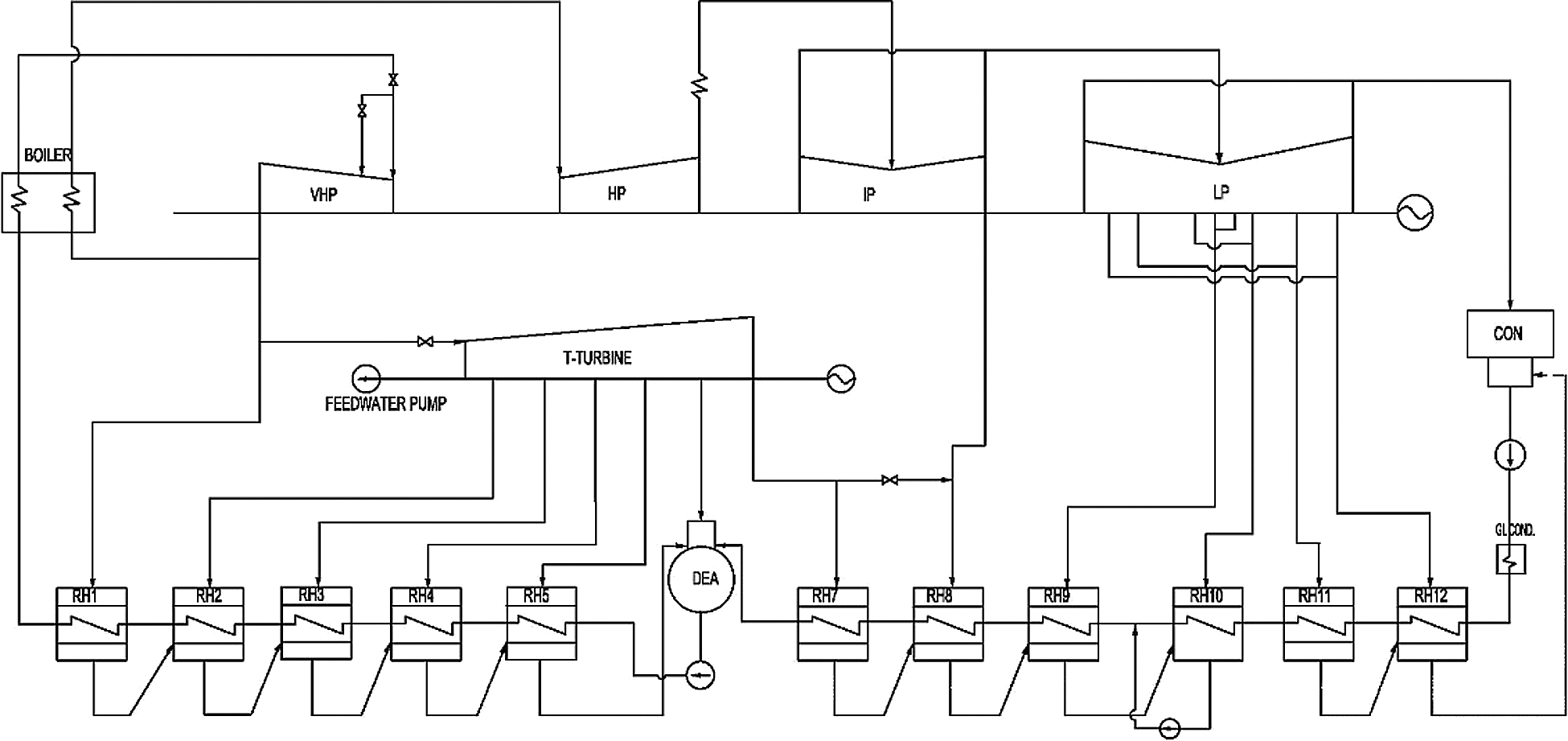

3.2 Double-Turbine System of USC Unit

For the high superheat degree of extraction steam, this study proposes two schemes: a double-turbine system with six-stage extraction steam (case 1) and a double-turbine system with seven-stage extraction steam (case 2). Here the number of the extraction steam stage is referring to that extracted from regenerative steam turbine and the main difference of the two cases is the number of extraction steam stages of the regenerative turbine. The process flow diagrams of the two schemes are shown in Figs. 2 and 3. The extraction steam of the regenerative steam turbine is produced in the VHP turbine; there is no extraction steam from the HP and LP turbines. In case 1, the regenerative steam turbine was used to drive the four-stage RH and DEA, and the exhaust steam entered RH8. In case 2, one additional extraction steam stage of the regenerative turbine was added, which drove the five-stage RH and DEA, and the exhaust steam entered RH9. The major parameters of extraction steam in case 1 system and case 2 system are provided in Tabs. 2 and 3.

Figure 2: Flow diagram of the double-turbine system with six-stage steam extraction

Figure 3: Flow diagram of the double-turbine system with seven-stage extraction steam

Table 2: Extraction steam parameters of case 1 system

Table 3: Extraction steam parameters of case 2 system

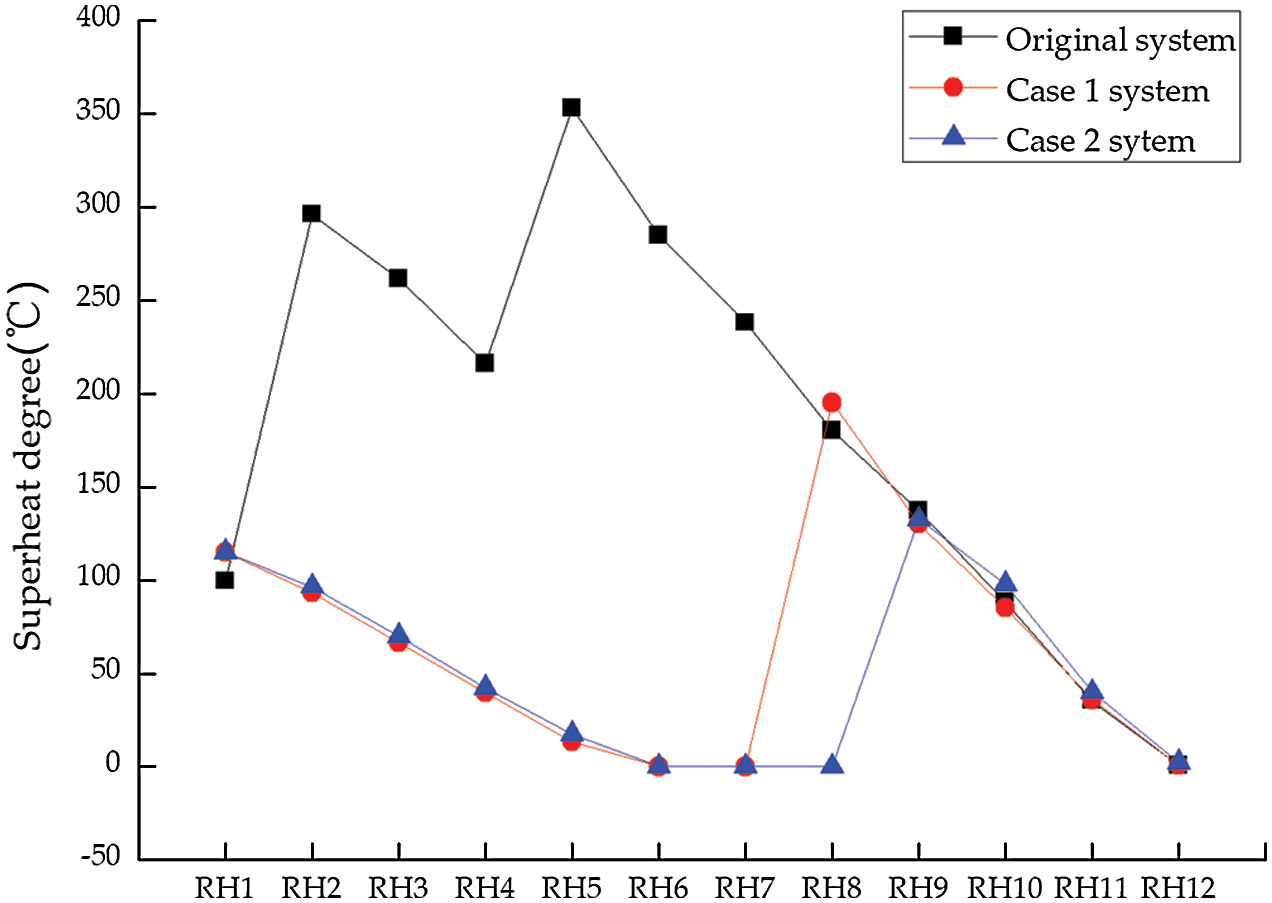

Fig. 4 shows the difference of superheat degree between the three systems in each RH. The figure shows that the superheat degree of the extraction steam in RH2–RH8 obtained from the HP and IP turbine is extremely high in the original system. There are two peak values of the superheat degree of extraction steam belong to RH2 and RH5 in the ordinary system. In case 1 and case 2, the superheat degrees of multistage extraction steams in RH2–RH8 were all obviously decreased because the related extraction steams were extracted from regenerative turbine without reheating. In the system in case 1, there are two stages of extraction steams for RH6 and RH7, with a superheat degree of 0 K. In the system of case 2, there are three stages of extraction steam for RH6–RH8. This is related to the number of extraction steams coming from regenerative steam turbine. There are six in the system in case 1 and seven in the system in case 2. The average superheat degree of the extraction steam in case 2 was the lowest.

Figure 4: Variations in the superheat degree of three systems in each RH

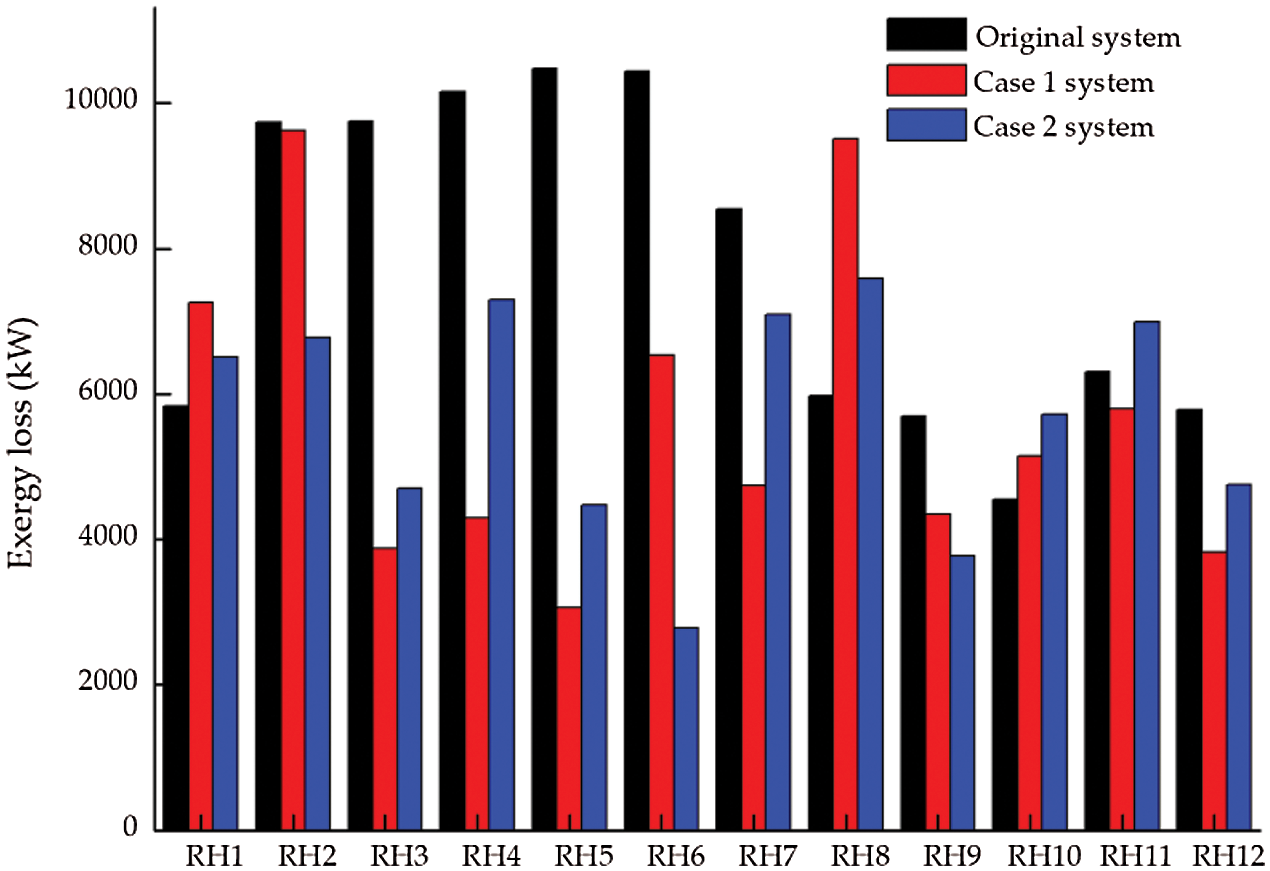

Fig. 4 shows that the decrease in superheat affects the heat transfer effect of the heater. Exergy analysis further reveals the substantial changes in heat transfer. Fig. 5 shows the exergy loss of each RH in the three systems. The exergy losses of RH2–RH7 are larger than those of the others in the ordinary system. In the double-turbine system, these are evidently reduced. Fig. 5 shows extraction losses of RH in different cases. Because of the different locations of the DEA and extraction steam stage of the regenerative steam turbine, the exergy loss of RH8 in case 2 is lower than that in case 1.

Fig. 6 shows the total exergy loss of RH1–RH8. The figure shows that the total exergy losses of RHs in the regenerative steam turbine system is significantly lower than that in the original system which was approximately 2/3 of that in a conventional system. The total exergy loss of the case 2 system is 7% higher than that of case 1. However, the exergy loss of RH1–RH8 in case 2 system decreased to 1695 kW compared with case 1. This indicates that the irreversible loss of the system was transferred to the other RHs in system, and the total exergy loss increased. With the extraction steam temperature entering the RHs decreases, the steam flow of the RHs increases. When the regenerative steam turbine is used to reduce the superheat degree of extraction steam, in addition to reducing the exergy loss of the RH, the irreversible exergy loss of the regenerative steam turbine and the coupling effect of the entire system should be considered in detail.

Figure 5: Exergy loss of different RHs

Figure 6: Exergy loss of different systems

Tab. 4 summarizes the thermal performance of each system. The main steam flow rate of the case 2 system is the highest because the extraction steam had the largest temperature decrease. The heat rate, coal consumption of the system, and exergy loss of RHs in case 1 system were the lowest, decreasing by 59 kJ/kWh, 2.15 g/kWh, and 5232 kW, respectively, compared with those of the original system. The exergy efficiency of the RHs of in case 1 system was increased by 0.25%. Those of the case 2 system were in the middle level. Although the number of extraction steam stages of the regenerative steam turbine exceeded that in case 1 system, the heat rate and coal consumption were higher than that in case 2 system. This indicates that an increasing in the number of stages driven by the regenerative steam turbine does not ensure improved overall performance of the unit. Thus, the regenerative steam turbine is effective in improving the performance of the whole unit.

Table 4: Thermal performances of the three systems

This study proposed two thermodynamic optimization schemes (case 1 and case 2) for a double-turbine regenerative system of a USC double-reheat unit. Their thermal performance and exergy were analyzed and compared with those of the original system. The results are as follows:

1. The double-turbine regenerative system can significantly reduce the superheat degree of the extraction steam of RHs in the double-reheat system, improve the energy utilization efficiency, and reduce the heat rate and coal consumption of the system. However, with an increasing of the extraction stage numbers of the regenerative steam turbine, the main steam flow and the exergy loss of the double-turbine regenerative system also increase. In case 2 system, the exergy loss of RH1–RH8 was the lowest, and the average superheat degree of extraction steam had the greatest decrease. However, the heat rate, coal consumption of the unit, and total exergy of RHs were greater than those in case 1 system. This indicates that the reduction in superheat degree is not directly proportional to the thermal economy of the unit.

2. Case 1 system has the best thermal performance among the three systems. Compared with the those of original system, the heat rate, coal consumption, and irreversible loss were reduced by 59 kJ/kWh, 2.15 g/kWh, and 25232 kW, respectively, while the average exergy efficiency of the heater increased to 92.2%. Meanwhile, the case 2 system has one additional extraction steam stage of the regenerative steam turbine compared with the case 1 system. The heat rate and coal consumption increased by 4 kJ/kWh and 0.23 g/kWh, respectively. The total exergy loss of the heater also increased.

Funding Statement: This work was supported by the Shandong Electric Power Engineering Consulting Institute science and technology project (Grant No. 37-K2014-33).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Zhao, X. J. (2016). Thermodynamic system economy of ultra-supercritical secondary reheat unit analysis (Master Thesis), Southeast University, China. [Google Scholar]

2. Zheng, P. Y., Guo, L. B., Wang, Q. L., Shi, H. C. (2018). Synchronous optimization of regenerative and reheating parameters for double reheat ultra-supercritical unit. Turbine Technology, 60(2), 99–102. [Google Scholar]

3. Liu, M., Zhao, Y. L., Wang, C. Y. (2017). Analysis on energy saving potentials of over heat recovery of steam extractions for double-reheat power unit. Thermal Power Generation, 46(8), 49–53. [Google Scholar]

4. Zhang, S. R., Li, J. T. (2019). Design and exergy analysis of 1000-MW double-reheat double-turbine regeneration system. IOP Conference Series: Earth and Environmental Science, 237(6), 062005. [Google Scholar]

5. Bo, J. R., Song, L. F., Chen, F., Wu, J. N., Cao, T. Y. (2017). Theory cost-efficiency analysis of steam extraction pressure loss of a 1000 MW double-reheat unit. Turbine Technology, 59(3), 166–168. [Google Scholar]

6. Fu, W., Shi, Y., Li, J., Yang, Y. (2017). Arrangement of outer steam coolers for a 1000 mw double reheat ultra-supercritical unit. Journal of Chinese Society of Power Engineering, 37(6), 489–494. [Google Scholar]

7. Bao, W. W., Yu, H. P., Liu, S. Y., Duan, J. P., Ren, X. N. (2015). Thermal economy analysis of a 1000 mw ultra supercritical unit with external steam cooler. Power Equipment, 29(5), 348–352. [Google Scholar]

8. Li, B. T. (2018). Economic analysis of 1000 mw ultra supercritical ec-best secondary reheat unit. Journal of Engineering for Thermal Energy and Power, 33(11), 44–49. [Google Scholar]

9. Cui, G. M., Liu, J. P. (2017). Thermal economy research for double-reheat unit equipped with heat recovery steam turbine. Thermal Power Generation, 46(8), 54–58. [Google Scholar]

10. Jing, C. C., Zhang, W., Liu, S. H. (2013). The operational economy analysis on the heater of the extraction steam system in 1000 mw ultra-supercritical unit. Power Station Auxiliary Equipment, 124(2), 521–528. [Google Scholar]

11. Zhou, L. Y., Xu, G., Bai, P., Xu, C., Yang, Y. P. (2017). Thermodynamic analysis on the superheating degree utilization modes of 1000 mw ultra-supercritical units. Journal of Chinese Society of Power Engineering, 37(6), 495–500. [Google Scholar]

12. Liu, Y. H., Gao, N., Zhou, L. Y. (2015). Optimized utilization of superheat of extraction in ultra-supercritical units. Power System Engineering, 31(4), 16–18. [Google Scholar]

13. Duan, L. L., Sun, J. (2019). Design optimization of ultra-supercritical reheating coal-fired power plant integrated with regenerative steam turbine. Journal of North China Electric Power University, 46(3), 80–89. [Google Scholar]

14. Qiao, J. F., Zhang, L., Liu, Y. H., Wang, B. B., Hao, W. (2017). Study on thermal performance of double-turbine regeneration system in double reheat unit. Thermal Power Generation, 46(8), 59–63. [Google Scholar]

15. Zhou, L., Xu, C., Xu, G., Bai, P., Yang, Y. P. (2017). Exergy analysis and economic evaluation of the steam superheat utilization using regenerative turbine in ultra-supercritical power plants under design/off-design conditions. Energy Science & Engineering, 5(3), 156–166. DOI 10.1002/ese3.158. [Google Scholar] [CrossRef]

16. Zhou, Y. L., Yang, M., Wang, D. (2018). Optimization of 1000 mw high ultra-supercritical double-reheat system. Proceeding of the CSEE, 38(S1), 137–141. [Google Scholar]

17. Suresh, M., Reddy, K. S., Kolar, A. K. (2011). Thermodynamic optimization of advanced steam power plants retrofitted for oxy-coal combustion. Journal of Engineering for Gas Turbines and Power, 133(6), 1766. DOI 10.1115/1.4002251. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |