Open Access

Open Access

ARTICLE

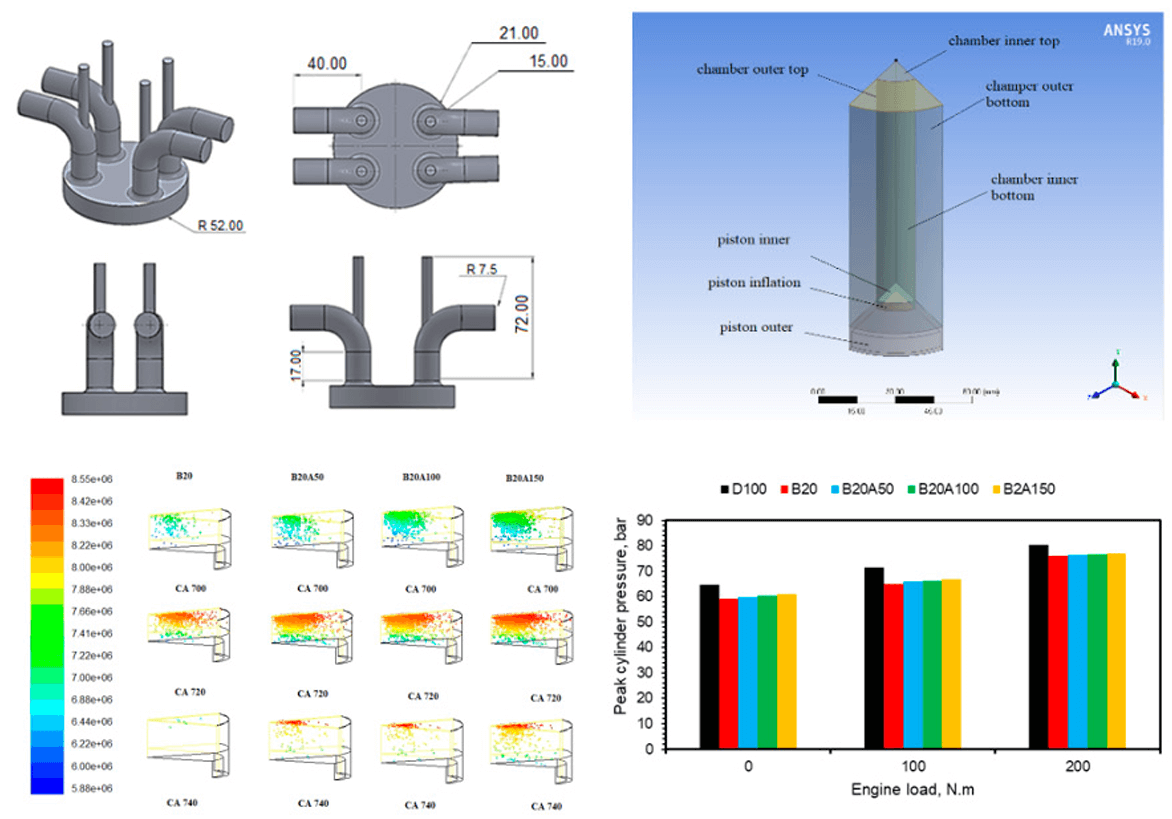

Nanoparticle Distribution in Compression Ignition Engines Using Rapeseed Methyl Ester

1 Mechanical Engineering Department, University of Technology-Iraq, Baghdad, 10001, Iraq

2 Energy and Renewable Energies Technology Centre, University of Technology-Iraq, Baghdad, 10001, Iraq

3 Training and Workshop Center, University of Technology-Iraq, Baghdad, 10001, Iraq

4 Centre for Advanced Powertrain and Fuels Research School of Engineering and Design, Brunel University, London, UB 83PH, UK

* Corresponding Author: Miqdam T. Chaichan. Email:

(This article belongs to the Special Issue: Advancements in Energy Resources, Processes, Systems, and Materials-(ICSSD2024))

Energy Engineering 2025, 122(4), 1249-1264. https://doi.org/10.32604/ee.2025.061617

Received 28 November 2024; Accepted 13 January 2025; Issue published 31 March 2025

Abstract

One of the most important of these emissions is fine particulate matter, which is a harmful emission of diesel engines, leading to the imposition of strict regulations. Biodiesel, with its high oxygen content, is an effective alternative to significantly reduce these emissions. In this study, rapeseed methyl ester (RME) was used as a diesel engine fuel and the emitted particulate matter was compared with ultra-low sulfur diesel (ULSD). In most experimental studies, the emission of soot was measured. In this work, the effects of injection timing, injection pressure (IP), and engine load on fine particulate matter in both nucleation and accumulation modes were studied. The results show that IP increases the number of particles in the accumulation mode while the number of particles in the crystallization mode is higher for rapeseed methyl ester (RME) than for ultra-low sulfur diesel (ULSD). Conversely, the formation rates of particles in the accumulation mode are higher for ULSD. Cumulative concentration numbers (CCN) are generally higher for RME in crystallization mode but higher for ULSD in accumulation mode. Increasing the IP reduces the CCN values. The particle size in crystallization mode reaches a maximum of 22 nm at IPs of 800 and 1000 bar but decreases to 15 nm at 1200 bar. Most fine particles fall in the 5–100 nm diameter range. High engine loads reduce the particle size distribution in nucleation mode for both fuels, with a slight increase in particle size in nucleation mode. The study concluded that the use of rapeseed methyl ester as an engine fuel benefits the environment and improves air quality due to the significant reduction in the size, number, and concentration of nano-soot particles and total particles emitted from the engine.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools