Open Access

Open Access

ARTICLE

Optimal Scheduling Method of Cogeneration System with Heat Storage Device Based on Memetic Algorithm

1 Key Laboratory of Energy Saving and Controlling in Power System of Liaoning Province, Shenyang Institute of Engineering, Shenyang, 110136, China

2 Jinzhou Power Supply Company, State Grid Liaoning Electric Power Co., Ltd., Jinzhou, 121009, China

* Corresponding Author: Haibo Li. Email:

Energy Engineering 2023, 120(2), 317-343. https://doi.org/10.32604/ee.2023.023715

Received 11 May 2022; Accepted 20 July 2022; Issue published 29 November 2022

Abstract

Electric-heat coupling characteristics of a cogeneration system and the operating mode of fixing electricity with heat are the main reasons for wind abandonment during the heating season in the Three North area. To improve the wind-power absorption capacity and operating economy of the system, the structure of the system is improved by adding a heat storage device and an electric boiler. First, aiming at the minimum operating cost of the system, the optimal scheduling model of the cogeneration system, including a heat storage device and electric boiler, is constructed. Second, according to the characteristics of the problem, a cultural gene algorithm program is compiled to simulate the calculation example. Finally, through the system improvement, the comparison between the conditions before and after and the simulation solutions of similar algorithms prove the effectiveness of the proposed scheme. The simulation results show that adding the heat storage device and electric boiler to the scheduling optimization process not only improves the wind power consumption capacity of the cogeneration system but also reduces the operating cost of the system by significantly reducing the coal consumption of the unit and improving the economy of the system operation. The cultural gene algorithm framework has both the global evolution process of the population and the local search for the characteristics of the problem, which has a better optimization effect on the solution.Keywords

Nomenclature

| The coal burning cost of the system, ten thousand yuan | |

| The operation cost of the heat storage device, ten thousand yuan | |

| The operation cost of the electric boiler, ten thousand yuan | |

| Wind abandonment penalty cost, ten thousand yuan | |

| The coal-fired cost of cogeneration units, ten thousand yuan | |

| The coal-fired cost of thermal power units, ten thousand yuan | |

| Coal price, yuan/ton | |

| Dispatching cycle, hours | |

| The power output of the unit, MW | |

| The thermal output of the unit, MW | |

| The operating cost coefficient of the heat storage device, yuan/MWh | |

| The operating power of the heat storage device, MW | |

| The operating cost coefficient of the electric boiler, yuan/MWh | |

| The operating power of the electric boiler, MW | |

| The penalty coefficient of abandoning the wind, yuan/MWh | |

| The abandoned wind volume of the system, MW | |

| The output of the wind turbine, MW | |

| Electrical load, MW | |

| The electric heat conversion efficiency of the electric boiler | |

| Heat load, MW | |

| Wind turbine output upper limit, MW | |

| The heat value in the heat storage device, MW | |

| The upper limit of the maximum output of the electric boiler, MW | |

| Evaluation function | |

| Punishment factor | |

| Penalty item | |

| The number of constraints | |

| A violation of the constraint function | |

| Penalty level | |

| Crossover probability | |

| Mutation probability | |

| Initial temperature, °C |

With the “dual carbon” goal-carbon peaking and the concept of carbon neutrality, the vigorous development of clean energy and gradual replacement of non-renewable energy sources such as coal, oil, and natural gas have been put on the agenda. Wind power generation is favoured because of its wide distribution, short construction period, and high utilization rate. However, the wind power output is random and fluctuating, which causes difficulty in integrating into the grid. Wind energy resources are abundant, especially in China’s “Three North” regions. However, due to the operating mode of “setting electricity by heat” during the heating season and the electric-heat coupling characteristics of the cogeneration system itself, the unit generates a large amount of wind energy when the heat load demand is high. Forced power output seriously occupies the wind power grid space, which not only causes a large amount of wind energy not to be effectively utilized but also has high system operation costs. Therefore, optimizing the operation of the cogeneration system is significant to improving the wind power consumption capacity and operation economy.

To improve the wind power consumption capacity and economical operation of the cogeneration system, literature [1] confirmed through the economic model predictive control framework that adding heat pump and electric boiler to traditional cogeneration systems can improve system flexibility and economy while balancing the district heating network. Literature [2] integrated the energy storage battery with the cogeneration system through the power electronic interface, which enhances the flexibility and frequency response of the system. It stabilizes the unit’s output power fluctuation while considering the operating economy. Literature [3,4] added energy storage devices to enhance the system’s peak regulation capability and economy. Literature [5] effectively improved wind adaptability by quantitatively assessing and utilizing the available spare capacity of cogeneration units. Literature [6,7] added an absorption heat pump to the system to recover the waste heat from the exhaust gas of the steam turbine to improve the heating effect and reduce the coal consumption of the system. Literature [8] proposed using low-temperature storage tanks, high-temperature storage tanks, and electric heat pumps to coordinate heating, which enhances the peak-shaving capability of the system and expands the space for wind power grids. Literature [9] integrated phase-change material buildings as heat storage devices for heat storage, reducing system heat supply and forced electricity output. Literature [10–12] proposed a new type of solar heat and power cogeneration system composed of solar collectors to alleviate the heating load of buildings. Literature [13] used cogeneration units, auxiliary heat boilers, and heat pumps to coordinate heat supply and improve the structure of traditional cogeneration units. Literature [14,15] proposed configuring electric boilers on the load side through the electric-heat conversion of electric boilers and using abandoned wind to supply heat to improve the utilization rate of wind power. Literature [16] proposed configuring a heat storage device on the side of the cogeneration unit to decouple the rigid constraints of “determining electricity by heat” and improve the grid-connection capability of wind power. Literature [17] used battery packs as energy storage devices to smooth wind power fluctuations while absorbing excess wind power.

To obtain high-quality optimal solutions and improve the solution efficiency, the literature [18] used the genetic algorithm to solve the optimal scheduling problem of the cogeneration system to minimize the system’s operating cost. Literature [19] used the improved ant colony optimization algorithm to solve the optimal energy scheduling of the cogeneration system. Literature [20] established a cogeneration simulation tool based on mixed-integer quadratic programming techniques to solve the optimal scheduling problem of the cogeneration system. Literature [21] proposed a practical model of efficiency data obtained from equipment manufacturers or machine testing to optimize cogeneration units’ thermal and electrical output to minimize system costs. Literature [22] adopted particle swarm optimization (PSO) to minimize the microgrid’s operating cost to realize the microgrid’s economic dispatch. Literature [23] proposed an improved PSO algorithm that combines reverse learning and differential evolution algorithms and applies it to the economic dispatch problem of the power system considering multiple constraints. In literature [24], a wind-power central heating model based on the immune genetic Lagrange relaxation hybrid algorithm is constructed for the wind power volatility and stability of the electric-thermal system. Literature [25] used the quadratic mixed-integer method to optimize the dispatching of the cogeneration system, which alleviates the fluctuation of the power grid and prolongs the service life of the energy storage device. In literature [26], the scheduling problem of a multi-period multi-energy system is reformulated as a mixed-integer second-order cone programming, and the sequential second-order cone programming method is used to solve it, which improves the operating economy of the system and the utilization rate of renewable energy. Literature [27] combined mixed-integer linear programming scheduling and greedy search method to solve the optimal scheduling problem of combined electric and heat systems, which minimized greenhouse gas emissions and improved the environmental benefits of scheduling. Literature [28,29] combined probability distribution with information gap decision theory to improve the robustness of optimal scheduling results for cogeneration systems. Literature [30,31] applied the robust stochastic optimization method to the economic dispatch of the integrated energy system, which has high computational efficiency while considering the economic and environmental benefits of dispatch. In literature [32], the modified grasshopper optimization algorithm and the improved harris hawks optimizer were applied to the economic scheduling of cogeneration system. In literature [33], an adaptive cuckoo search with differential evolution mutation was proposed to solve the economic scheduling problem of the cogeneration system.

Among the many intelligent algorithms, the memetic algorithm combined global evolution with local search and had been successfully applied to many fields because of its excellent optimization ability and wide applicability. Literature [34,35] applied the memetic algorithm to the flow shop scheduling problem, designed an optimization strategy that fully considers the problem’s characteristics. In literature [36], the memetic algorithm was applied to the research of uncrewed air-to-ground vehicle cooperative detection systems. In literature [37], the memetic algorithm was applied to the iron and steel production system’s wire and bar rolling process. Literature [38] applied the memetic algorithm to detect SNP-SNP interactions related to complex diseases and proposed a memetic algorithm for advanced screening.

Based on the abovementioned discussion, few studies consider coordinating heat supply between heat storage devices and electric boilers to improve the grid space of wind power. Furthermore, the solving process of the mathematical method is relatively complicated, and obtaining an accurate solution is complex. A single intelligent algorithm can obtain the optimal solution quickly and, at the same time, guarantee that the quality of the solution is difficult.

This study constructs a cogeneration system, including a heat storage device and electric boiler. It establishes a system with the minimum operating cost as the goal and the real-time output distribution of each unit, real-time heat change of thermal storage, and real-time output of electric boiler as decision variables. An optimal scheduling model is established considering constraints such as electrical balance, thermal balance, and electrical equipment standard operating conditions. The Memetic algorithm program is designed and optimized based on a numerical example. The global evolution process of the algorithm adopts the genetic operator, and the local search strategy adopts simulated annealing. Finally, the feasibility of the proposed scheme is proved by comparing the system operating costs before and after the system structure improvement. The effectiveness of the cultural gene algorithm is verified through comparison with the optimization results of the improved artificial bee colony algorithm and particle swarm algorithm.

The cogeneration system with the heat storage device and electric boiler aims to install the heat storage device on the heat source side and the electric boiler on the load side based on the traditional cogeneration system by optimizing the output distribution of each part of the system to minimize the operating cost while absorbing wind power as much as possible. The electrothermal energy flow of the cogeneration system is shown in Fig. 1.

Figure 1: Schematic of electrothermal energy flow in cogeneration system

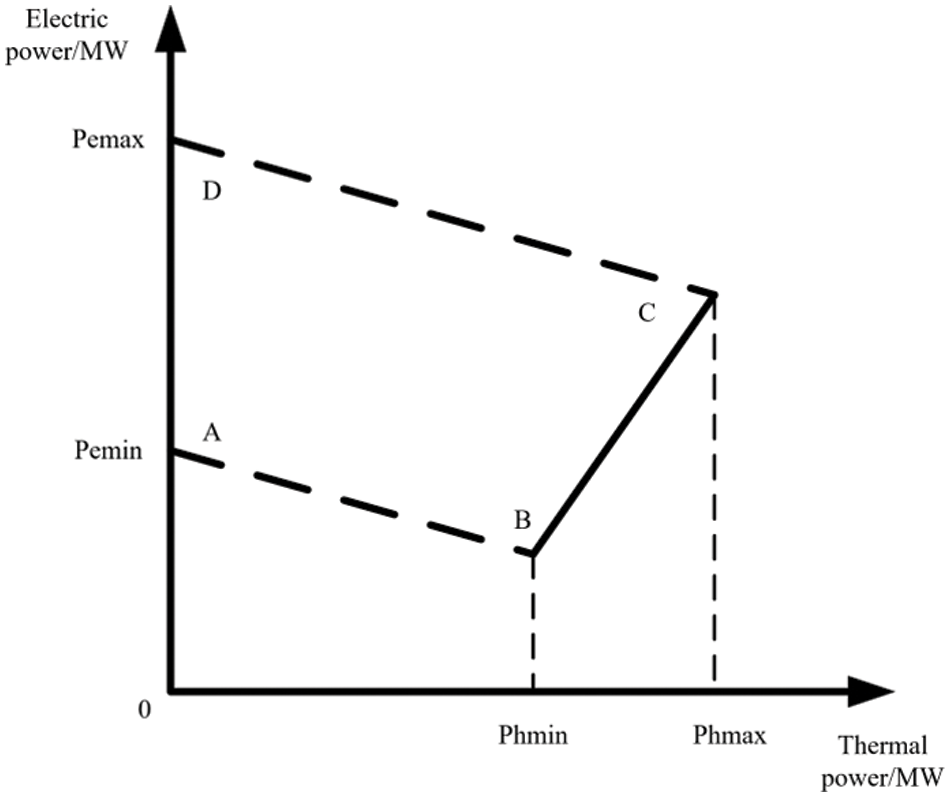

With the addition of a heat storage device and electric boiler, the electrothermal characteristic curve of the cogeneration system also changes. The electrothermal characteristic curve of the traditional cogeneration system is shown in Fig. 2. In practice, cogeneration systems primarily work under back pressure (BC section). According to the relevant requirements of thermostatic electricity, when the thermal output is determined, the system’s adjustable range of power output is fixed. Moreover, when the heat load demand increases, the adjustable range of electricity output becomes smaller, and the peak regulation capacity of the system is extremely limited, which may lead to an abandoned wind phenomenon.

Figure 2: Electrothermal characteristic curve of traditional cogeneration system

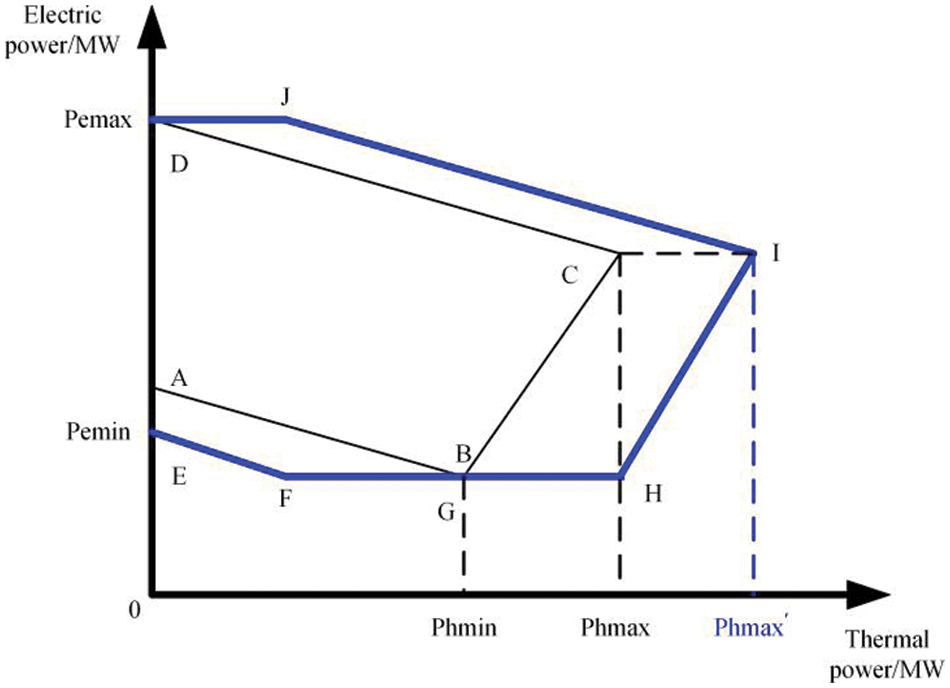

The electrothermal characteristic curve of the cogeneration system after adding the heat storage device is shown in Fig. 3. After adding the heat storage device, when the electric power provided by the unit is constant, due to the heat release effect of the heat storage device, heating power range is enlarged so that the BC section of the electrothermal characteristic curve shifts to the right to the HI section, and the CD section to the right translation to the IJ section. The auxiliary thermoelectric unit with a heat storage device meets the demand of thermal load through a certain degree of thermal-electrolytic decoupling and expanding the system’s operating range. At this time, the operating area of the cogeneration system is expanded from ABCD to EFGHIJ. The heat release effect of the heat storage device increases the maximum thermal output of the system. At the same time, the adjustable range of the electric output corresponding to the same thermal output is expanded, and the system’s peak regulation capacity is improved, providing space for the wind power grid.

Figure 3: Electrothermal characteristic curve of cogeneration system with heat storage device

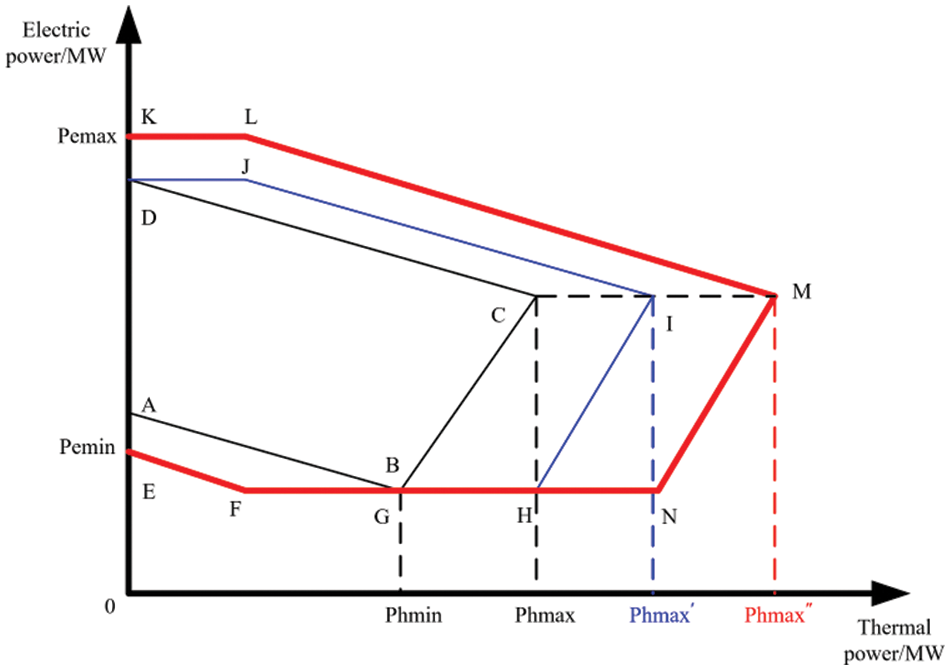

If adding the heat storage device cannot meet the needs of abandoned wind absorption, the use of electric boilers should be considered to absorb the remaining wind power. The electrothermal characteristic curve of the cogeneration system with a heat storage device and electric boiler is shown in Fig. 4. The DKLMNHIJ area represents the increased operating area of the cogeneration system with heat storage devices due to the existence of electric boilers. An electric boiler has the dual properties of electric load and heat source, which can assist in meeting the heating demand while absorbing excess wind power in the system. The value of KD depends on the amount of wind power that can be absorbed by the electric boiler when abandoning the wind, which increases the power output limit of the cogeneration system. The electric heating of the electric boiler further breaks the thermal output limit of the cogeneration system so that the HI section of the electric-thermal characteristic curve of the system is translated to the right to the NM section, and the IJ section to the right to the ML section. At this time, the operating area of the system is further expanded to KLMNHGFE. When the electric boiler works, on the one hand, it acts as a part of the power load in the system, which plays a role in increasing the upper limit of the power output of the system; on the other hand, the electric boiler can convert electrical energy into heat for heating, which plays a role in improving the upper limit of the thermal output of the system.

Figure 4: Electrothermal characteristic curve of cogeneration system with heat storage device and electric boiler

During the daytime heating season, the wind power output is smaller, the power load is larger, and the heat load is smaller. During this period, there is little abandonment of the wind phenomenon, and the cogeneration unit can increase the power output due to the electrothermal coupling characteristics of the cogeneration unit itself. The thermal output of the unit also increases and stores the excess heat. At night during the heating season, the wind power output is larger, the electricity load is smaller, and the heat load is larger. During this period, to meet the demand for heating, cogeneration units produce a large number of forced power output, which seriously occupies the Internet space of wind power, resulting in a waste of wind power. At this time, the heat stored in the heat storage device during the day can be released to reduce the output of cogeneration units, creating opportunities for wind power to be connected to the grid, and if there is abandoned wind, the electric boiler can convert excess abandoned air into heat to participate in heating.

The goal of optimal scheduling of a cogeneration system with a heat storage device and the electric boiler is to minimize the system’s total operating cost in one scheduling cycle while absorbing abandoned wind as much as possible. The system’s operating cost mainly comes from the coal-fired cost of the unit, operating cost of the heat storage device, operating cost of the electric boiler, and wind abandonment cost. The small cost of wind power generation is ignored.

Total operating cost of cogeneration system:

where

The coal-fired cost of the system includes two parts: coal-fired cost of cogeneration units and coal-fired cost of thermal power units [39].

where

The operating cost of the thermal storage device can be expressed as the product of the operating cost coefficient of the thermal storage device and the real-time operating power of the thermal storage device.

where

The operation cost of the electric boiler can be expressed as the product of the operation cost coefficient of the electric boiler and the real-time output power [39].

where

The wind curtailment cost represents the penalty cost caused by the waste of wind power due to the limited capacity of the system to absorb wind power. It can be expressed as the product of the wind curtailment penalty coefficient and the total amount of curtailed wind in the dispatch period [40].

where d represents the penalty coefficient of abandoning the wind, which is 233 yuan/MWh; and

(1) Power balance constraint

where

(2) Thermal constraint

where

(3) Output constraint of cogeneration unit

The output constraints of cogeneration units include upper and lower limit constraints and climbing power constraints. The first item of formula (8) represents that the electric output of the unit should be within its allowable range. The second item represents that the thermal output of the unit should not exceed its upper limit. The third item represents that the increase of the electric output of the unit should not exceed the upward climbing power. Finally, the fourth item represents that the reduction of the electric output of the unit shall not exceed the downward climbing power.

(4) Output constraint of thermal power units

The output constraints of thermal power units include upper and lower limit constraints and climbing power constraints. In formula (9), the first item represents that the electric output of the unit should be within its allowable range, the second item represents that the increase of the electric output of the unit should not exceed the upward climbing power, and the third item represents that the reduction of the electric output of the unit shall not exceed the downward climbing power.

(5) Wind turbine output constraint

The real-time output of the wind turbine should not exceed the upper limit of the wind turbine itself [39].

where

(6) Operation constraint of heat storage device

The first term of formula (11) represents the real-time heat storage of the heat storage device, which should not exceed the capacity of the heat storage device. The second item represents the real-time release (storage) heat power of the heat storage device, which does not exceed its maximum operating power.

where

(7) Operation constraint of electric boiler

The real-time output of electric boiler should not exceed its maximum output limit [41].

where

The decision variables are output of cogeneration unit at each time

3 Solving Method Based on Memetic Algorithm

The objective function is a high-order nonlinear function, and the mathematical method is more complex and difficult to obtain an accurate solution. Thus, a swarm intelligence algorithm is more suitable for obtaining a practical optimal solution. This study adopts a more advanced memetic algorithm to solve this problem.

The memetic algorithm is a bionic intelligent algorithm that combines global evolution with local search. After the initial population is generated, the optimal solution satisfying the problem is found through global evolution and local search and repeatedly iterated until the termination condition of the algorithm is met. The memetic algorithm introduces selection, crossover and mutation operators into the global evolution process to ensure the algorithm’s convergence. Local search can effectively prevent the algorithm from falling into local optimization, and the quality of the optimal solution obtained by the algorithm is also excellent while improving efficiency. More importantly, for optimization problems in different fields, the memetic algorithm can be solved by changing the strategies of global evolution and local search, which has broad applicability. In this paper, according to the scheduling characteristics of the cogeneration system, the memetic algorithm is applied to the scheduling optimization process to obtain a scheduling scheme that considers the system’s wind power consumption capacity and economy.

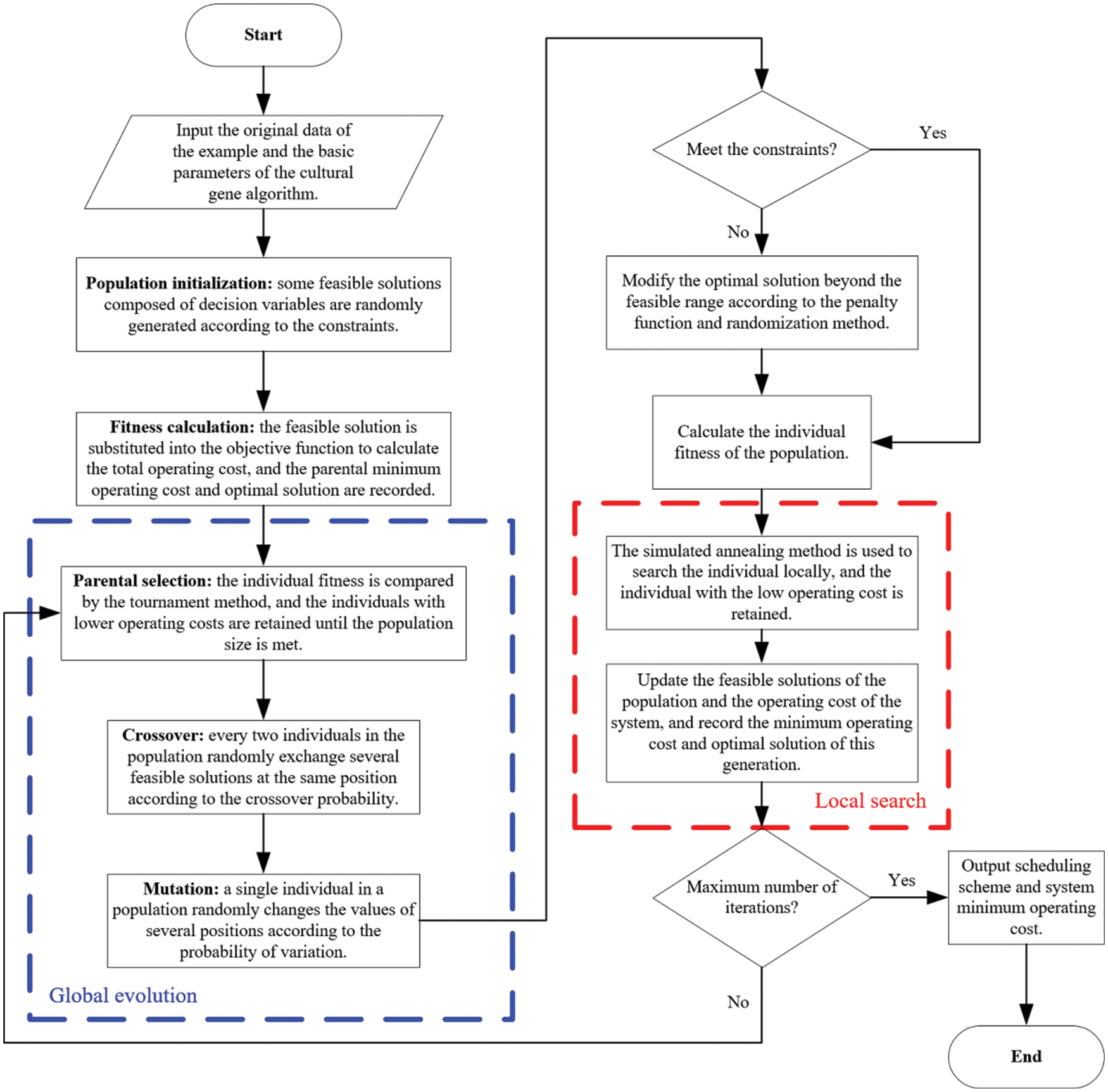

The solving process of the memetic algorithm is as follows:

1. Population initialization: under the premise of satisfying the constraints, several feasible solutions composed of decision variables are randomly generated as the iterative initial solution set.

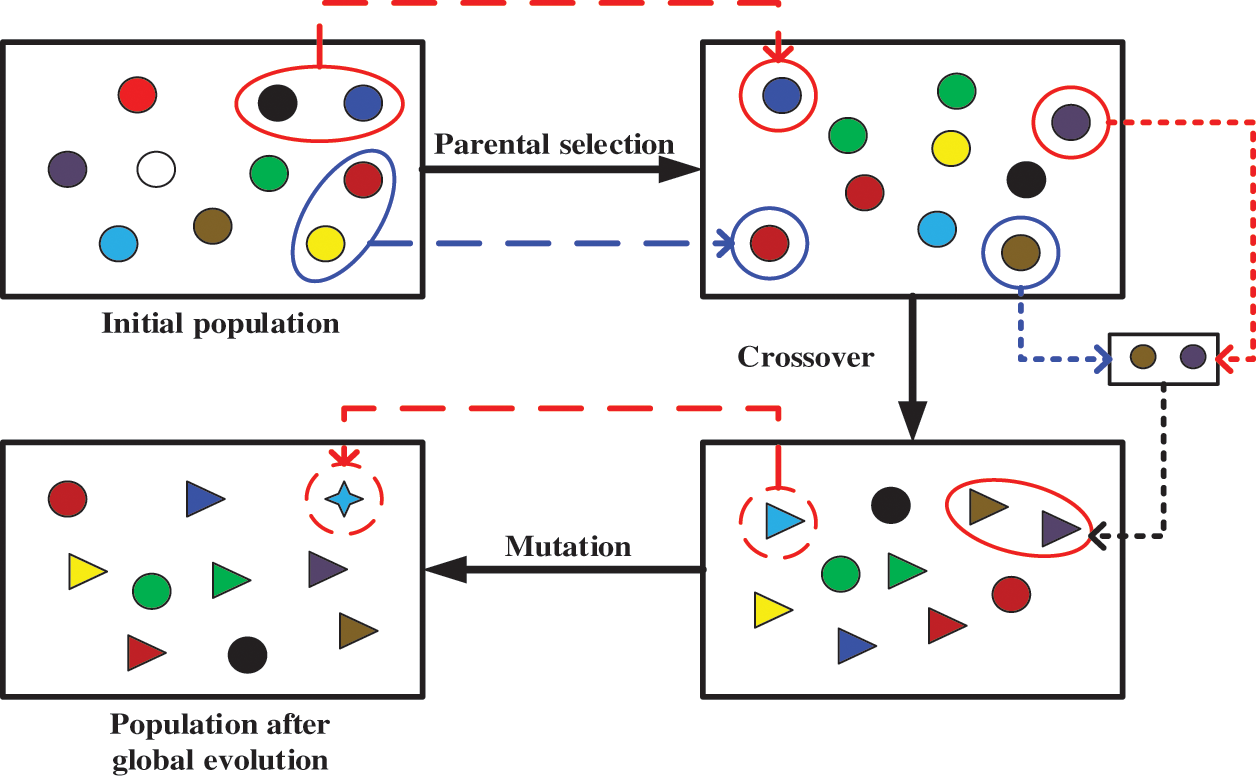

2. Global evolution: the initial feasible solution set is generated by three genetic operators: parental selection, crossover, and mutation. The constraint condition tests whether the new individual is still a feasible solution. If it is beyond the feasible range, the randomization method combined with constraint modification is used to make it back to the feasible range.

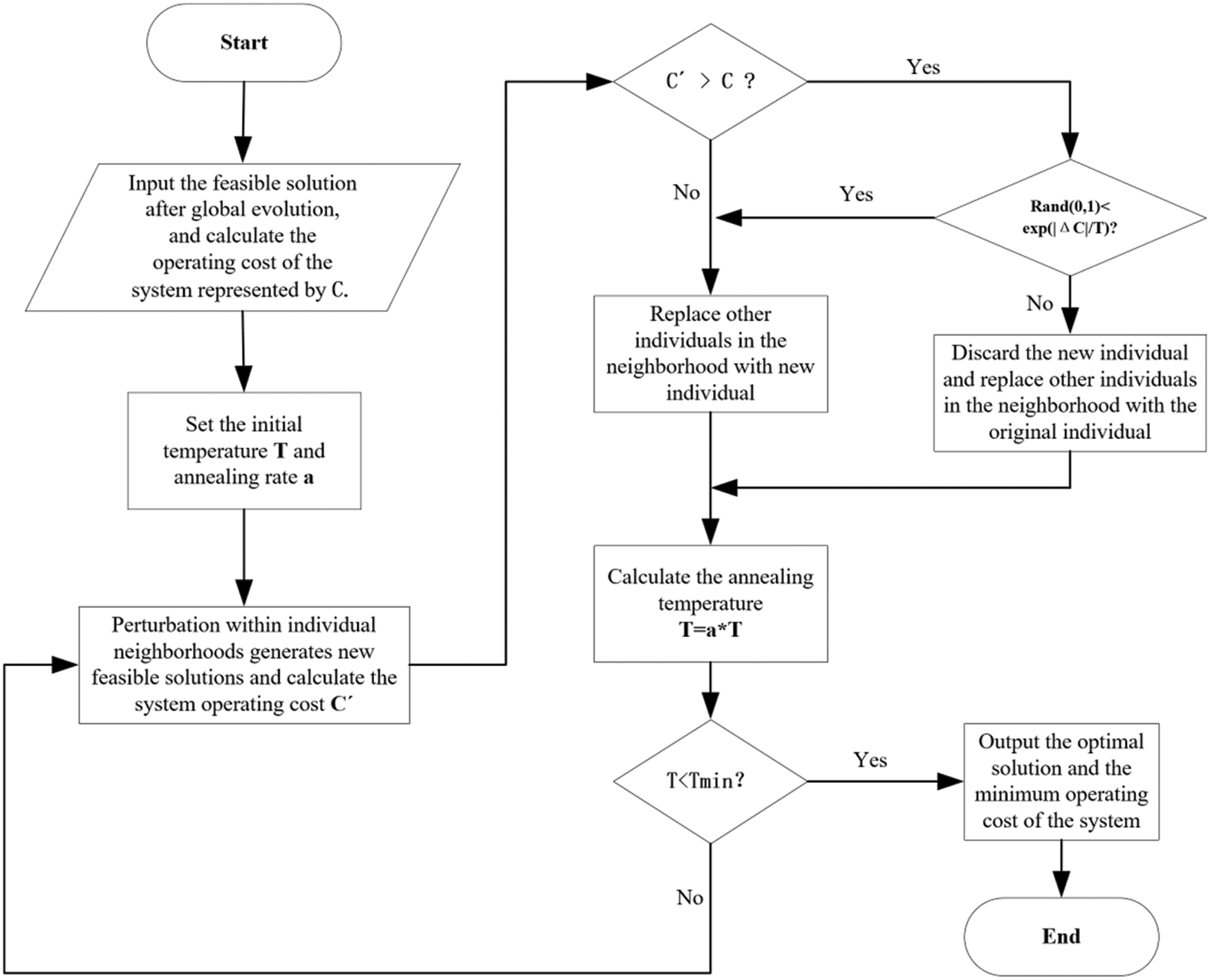

3. Local search: the evolved new population is selected by simulated annealing method to select the optimal individual with the lowest system operating cost in each individual field to form a progeny population.

4. Algorithm termination: when the evolution process reaches the maximum number of iterations, output the value of optimization solution and minimum operating cost of the system.

The solving process of the memetic algorithm is shown in Fig. 5.

Figure 5: Flowchart of Memetic algorithm operation

Constraint handling is the key to forming the initial solution set and ensuring the iterative process’s effectiveness. In this study, the most widely used penalty function method is intended to construct an augmented objective function with parameters by combining the objective function and constraints in a certain way, reducing the number of constraints as much as possible, and gradually approaching the optimal solution of the original problem [23].

The memetic algorithm is combined with the penalty function method, that is, the memetic algorithm is used as the main method to solve the problem, and the penalty function method is used to construct the evaluation function to calculate the optimal value of the individual in the population.

Evaluation function:

where F represents the evaluation function (optimal value); C represents the objective function (minimum operating cost of the system), 10,000 yuan;

Violation of constraint function [42]:

where

The value rule of function

Global evolution involves three steps: parental selection, crossover, and mutation. First, the individuals in the initial population are substituted into the evaluation function (13) to calculate the optimal value. Then the tournament method is used to retain the individuals with a lower optimal value of each randomly selected two individuals until the population size is satisfied as to the population after parental selection. Then, according to the rules of crossover probability and crossover operator, two individuals in the population selected by parents are randomly selected to generate the crossover population. Finally, individuals in the crossover population are randomly selected to perform mutation operation according to the mutation probability and mutation operator rules, and a new population that satisfies the stability and diversity of the population is obtained.

The global evolution operators are designed as follows:

1. Selection operator: Randomly select two individuals and compare their optimal values; the one with the smaller optimal value is taken out as the parent. Repeat the above procedure until the number of individuals removed is the same as the population size.

2. Crossover operator: According to the population crossover probability, randomly select the participating individuals, starting point and crossover length, and calculate the gene exchange within the length backwards from the starting point to another offspring.

3. Mutation operator: According to the mutation probability of the population, randomly select the individuals involved in the mutation, the starting point and the mutation length, and reverse the order of the genes within the length calculated from the starting point.

The global evolution process is shown in Fig. 6.

Figure 6: Schematic of global evolution process

To prevent the optimization solution from falling into the optimal local situation, the local search of the population should be conducted after the completion of global evolution. The local search begins at the end of the global evolution process and is realized by a simulated annealing strategy. First of all, the optimal value of the population after global evolution is calculated in the evaluation function, and some possible new solutions in the neighbourhood are generated by the random disturbance method for each individual in the population. Then, the optimal value is calculated. The optimal value comparison operation is carried out: if the optimal value of the feasible solution produced by the disturbance is smaller, the new individual is used to replace other individuals in the neighbourhood. Otherwise, whether to accept the new feasible solution is considered according to the probability. Finally, when the annealing temperature reaches the minimum temperature set in advance, the optimal solution after local search and the minimum operating cost of the system are output. The local search operation process is shown in Fig. 7.

Figure 7: Local search operation flow chart

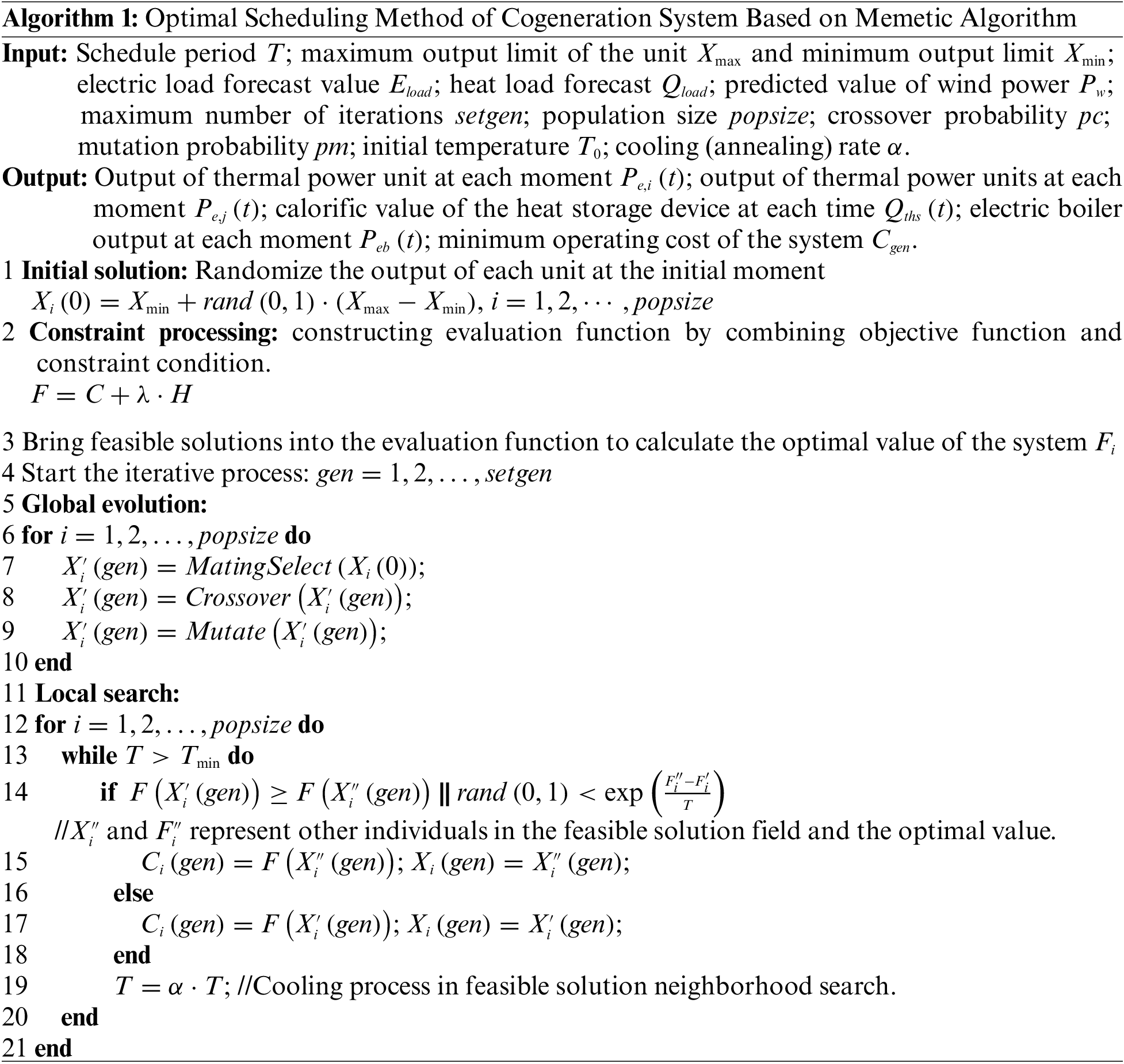

Optimal scheduling method of cogeneration system based on memetic algorithm is given in Algorithm 1.

Algorithm 1 : Optimal Scheduling Method of Cogeneration System Based on Memetic Algorithm

To verify the effectiveness of the scheme proposed in this paper, the power grid structure in a certain northern region is selected as an example, the scheduling period is 24 h, and the scheduling interval is 1 h. The system includes 6 cogeneration units, 2 thermal power units, and 1 wind turbine.

In the follow-up system structure improvement, a heat storage tank with a maximum capacity of 1000 MW is arranged on the heat source side, and the maximum operating power is 200 MW. An electric boiler with maximum power of 100 MW is arranged on the load side, and the electric-heat conversion efficiency is 0.95.

The original data required for the simulation mainly includes two parts: predicted power of the system and parameters of the unit. Among them, the system predicted power includes thermal load, electrical load and wind power; the unit parameters include cogeneration unit parameters, thermal power unit parameters, and wind turbine installed capacity. The original data used in this study are from [43].

(1) System power prediction

It is assumed that the heat load in the heating area of the system remains unchanged (1,000 MW) during the scheduling period.

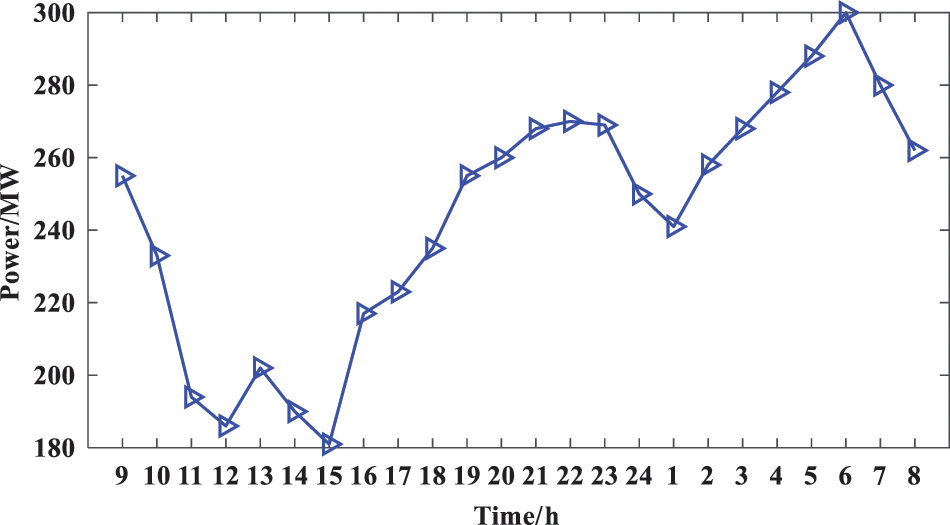

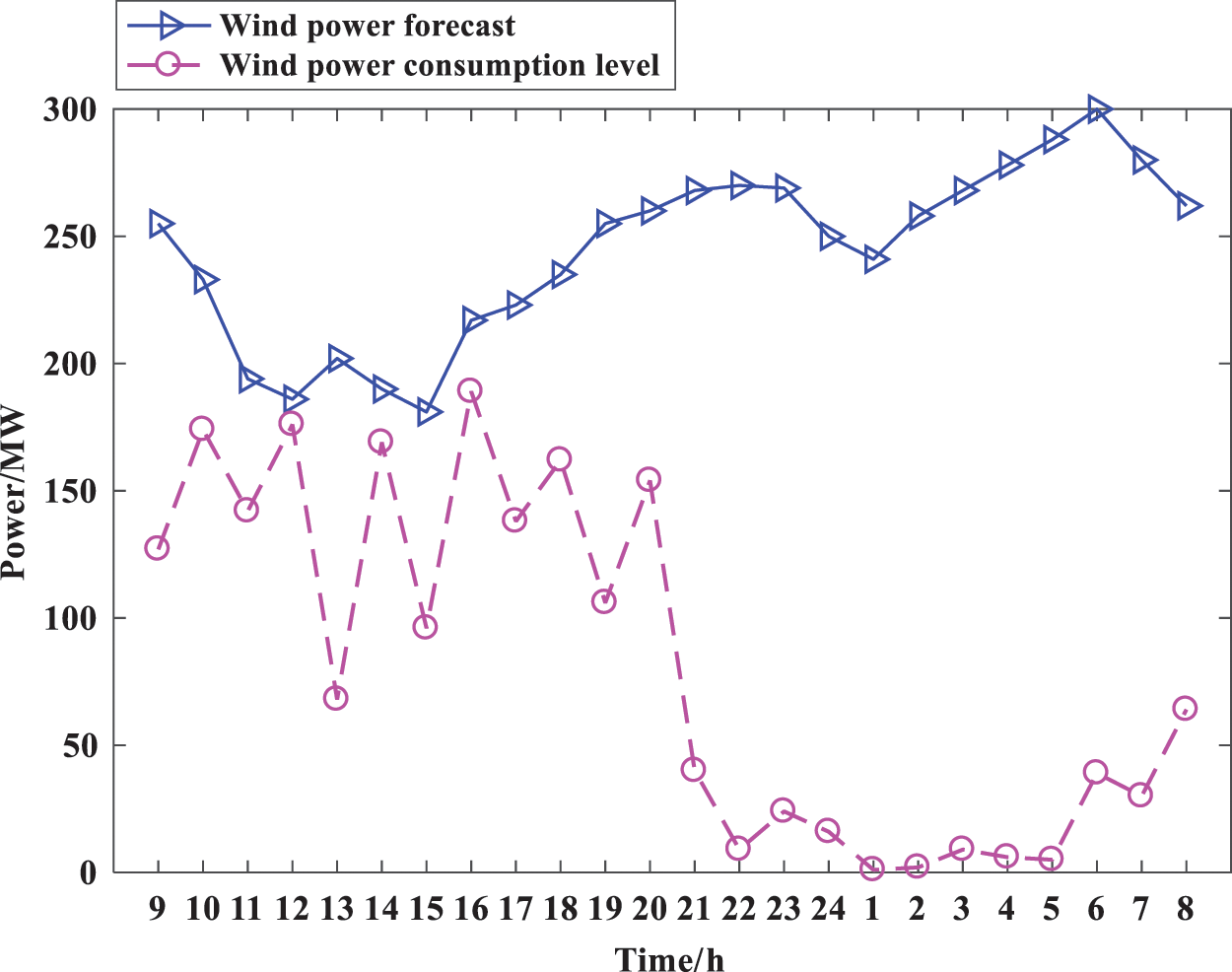

Fig. 8 shows the predicted electricity load in a dispatch period (9:00 to 8:00 the next day) in a certain area. The prediction of wind power during the scheduling cycle is shown in Fig. 9.

Figure 8: Electric load forecast

Figure 9: Prediction of wind power

(2) Unit parameters

The parameters of the cogeneration unit and thermal power unit are shown in Tables 1 and 2. The installed capacity of the wind turbine is 300 MW.

(3) Parameters setting

In order to test the effect of the algorithm in the optimal scheduling of cogeneration, the matlab 2016b platform is used under the Intel i7 processor, 8 GB memory and Windows10 operating system. The parameters of the memetic algorithm (MA) are as follows: the population size is 100; the number of iterations is 500, the crossover probability is 0.8, the mutation probability is 0.1, the initial temperature is 500, and cooling (annealing) rate is 0.9. In the selection of artificial bee colony algorithm parameters: the number of bees is 100; the maximum number of iterations is 500; the crossover probability is 0.6. In the selection of the parameters of the particle swarm algorithm: the number of particles is 100; and the maximum number of iterations is 500; the learning factor is 0.6.

4.2 Analysis of Simulation Results of Traditional Cogeneration System

After the simulation of the example by memetic algorithm, the wind power consumption of the traditional cogeneration system in this dispatch period can be obtained, as shown in Fig. 10.

Figure 10: Wind power consumption level under reference mode without heat storage device and electric boiler

The traditional cogeneration system is restricted by its own thermal-electric coupling characteristics and the working mode of “fixing electricity by heat”, so its wind power absorption capacity is very limited. The usual case is that wind energy is not fully utilized. The heating demand is huge especially on cold nights during the heating season. To meet the heating demand, the cogeneration system is bound to produce a large amount of forced power output, which occupies the online space of wind power. In this example, the wind energy is sufficient from 20:00 to 8:00 (the next day), and when the electric load is small, the obvious phenomenon of abandoning the wind is inevitable.

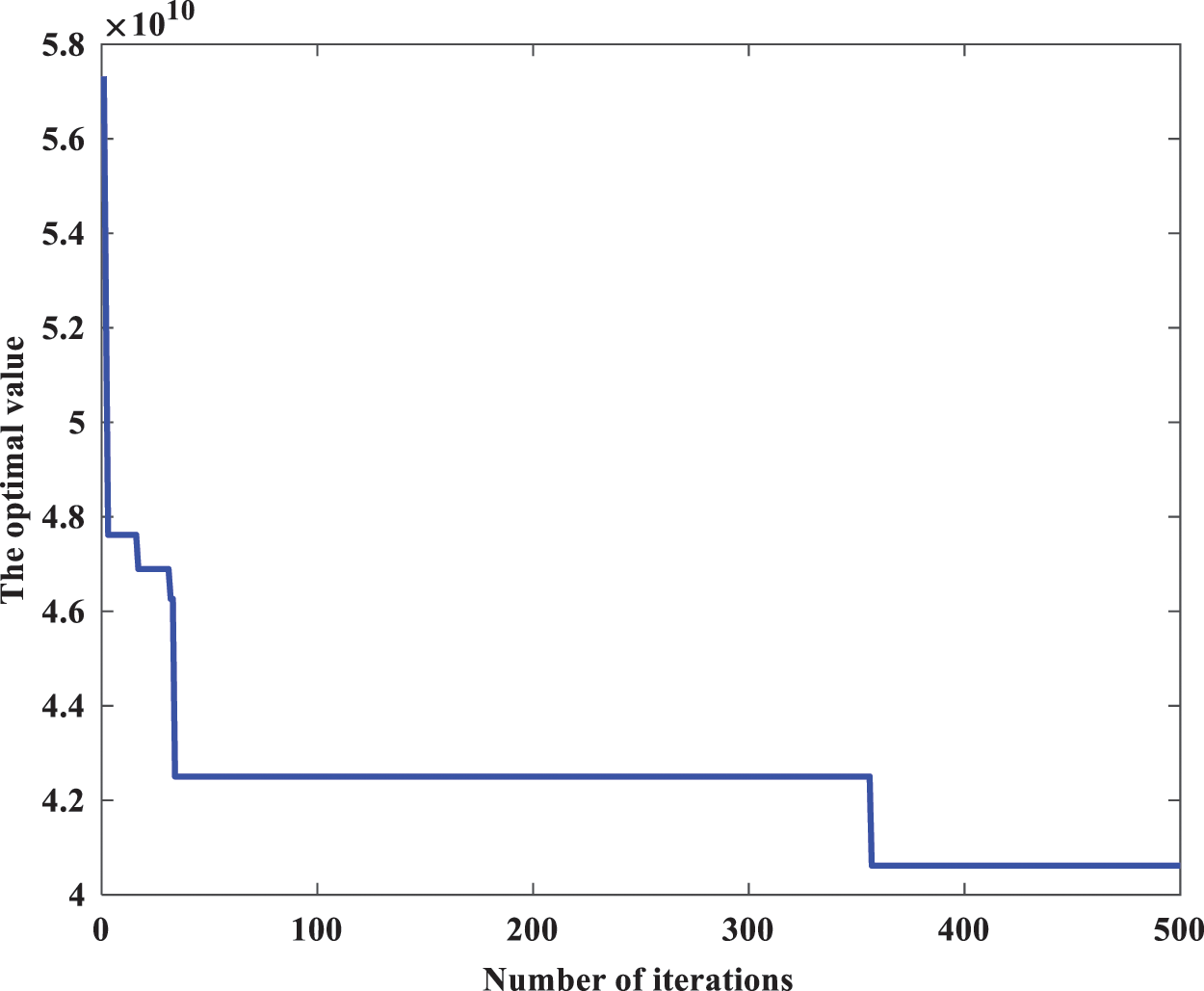

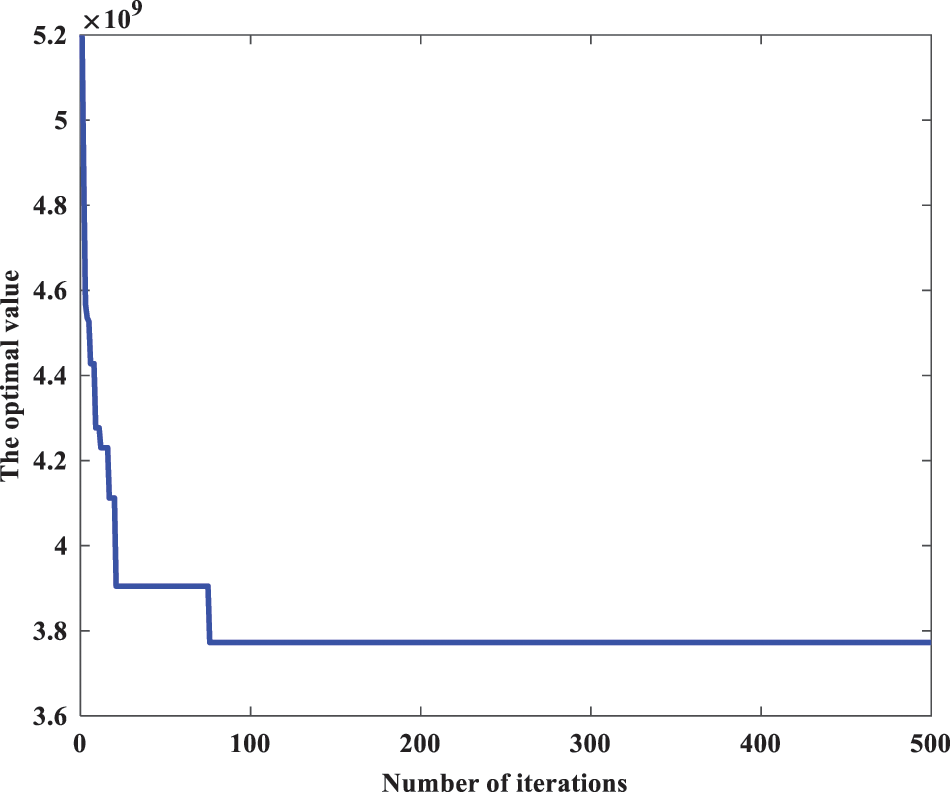

In the process of applying the memetic algorithm to optimize the traditional cogeneration system, the change of the optimal value of the system can be obtained, as shown in Fig. 11.

Figure 11: Optimal value of the system without heat storage device and electric boiler

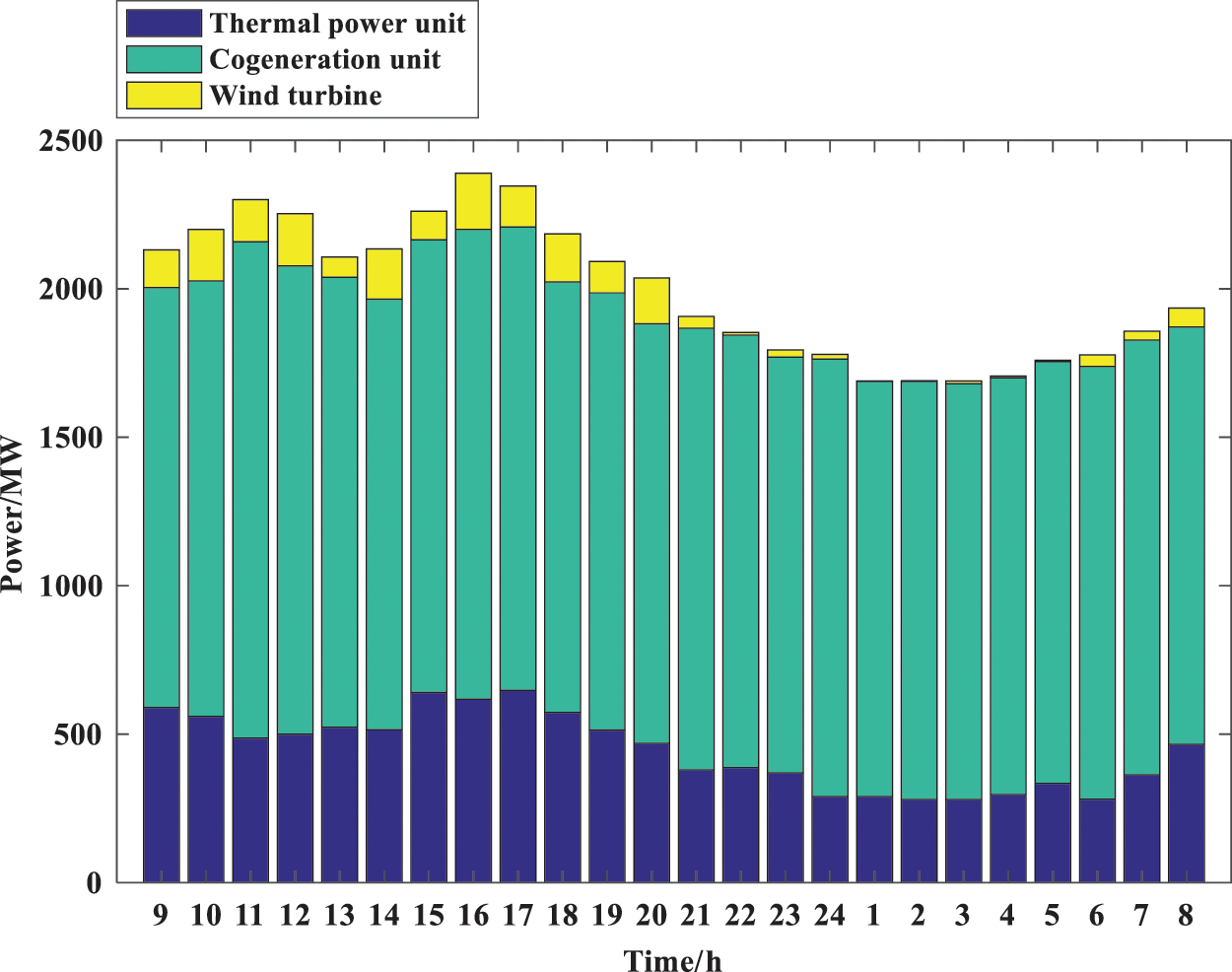

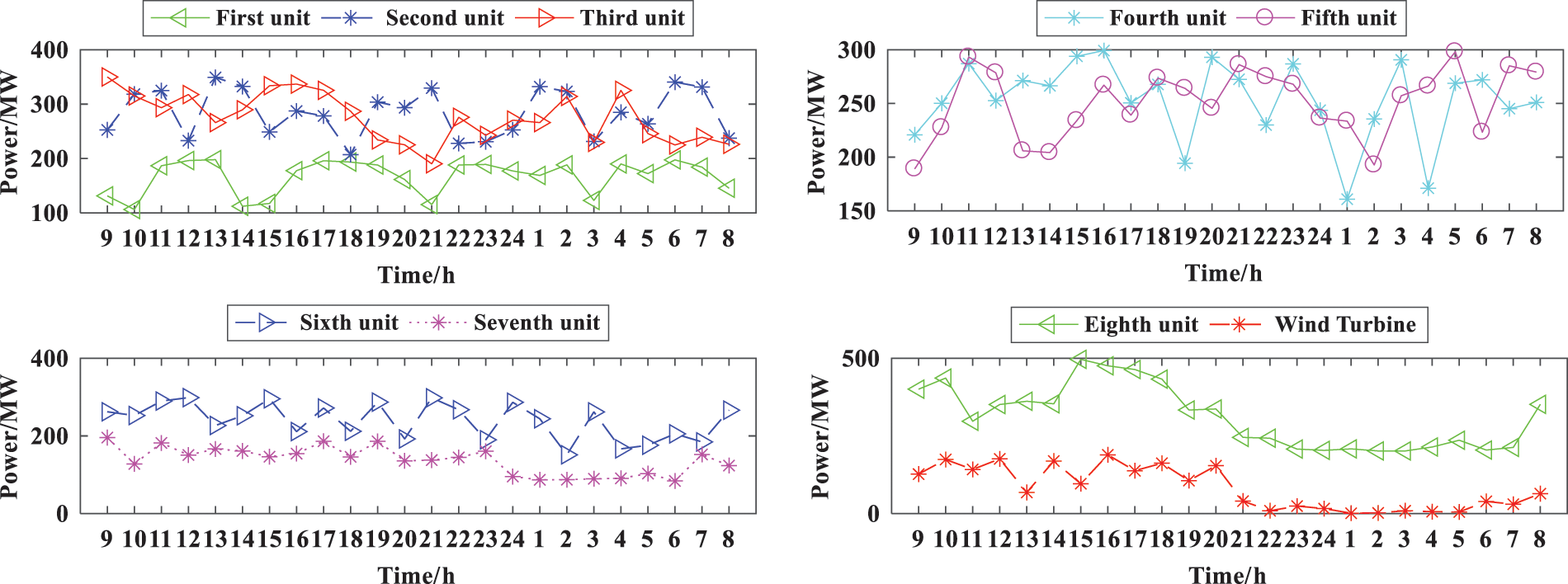

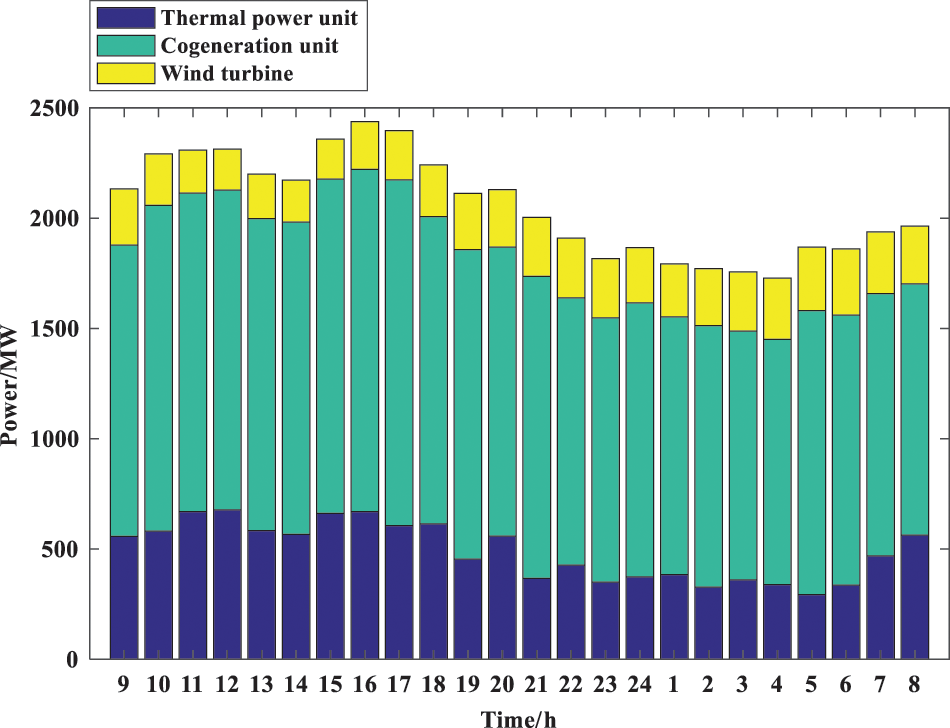

The real-time output of each unit in the system is shown in Figs. 12 and 13.

Figure 12: Real-time output of each unit in the system

Figure 13: Output of a single unit at each time

Due to the absence of heat storage devices and electric boilers, the ability of the system to absorb excess wind power is very limited, resulting in uneven output of wind turbines, which not only causes waste of wind energy but also has a negative impact on the stability of the system.

At this time, the operating cost of the system only includes the coal-fired cost and wind abandonment cost of the unit. By substituting the evaluation function, the optimal value in the scheduling cycle is 4.06 × 1010, the minimum operating cost of the system is 10.8885 million yuan, and the coal-burning cost of the system is 10.4468 million yuan.

4.3 Analysis of Simulation Results of Cogeneration System with Heat Storage Device and Electric Boiler

To improve the wind power consumption capacity of the system and the economy of system operation, the structure of the traditional cogeneration system is improved in this study. The heat storage device is added to the heat source side of the system, and the electric boiler is added to the load side. The function of the heat storage device is to store excess heat when the power supply load is large or wind energy resources are sufficient, and participate in heating when the heating demand is large, reduce the output of cogeneration units, and indirectly provide space for the wind power grid. On the one hand, the electric boiler can store the excess wind power into heat or supply the load directly to achieve the purpose of directly absorbing the wind power. On the other hand, as a part of the power load of the system, the electric boiler increases the electricity load in the period of low electric load and indirectly improves the calorific value of the system to meet the heating demand.

The memetic algorithm is used to optimize the simulation of the cogeneration system with heat storage devices and electric boilers, and the change of the optimal value of the system can be obtained, as shown in Fig. 14. The simulation results show that improving the system structure can improve the economy of the system.

Figure 14: Optimal value of the system including heat storage device and electric boiler

The real-time output of each unit in the system is shown in Fig. 15. After the heat storage device and electric boiler are added, the output of the wind turbine in the abandonment period is significantly increased, indicating that the ability of the system to absorb wind power has beenimproved. At the same time, the fluctuation of wind turbine output is also obviously weakened, which is conducive to maintaining the stability of the entire system.

Figure 15: Real-time output of each unit in the system including heat storage device and electric boiler

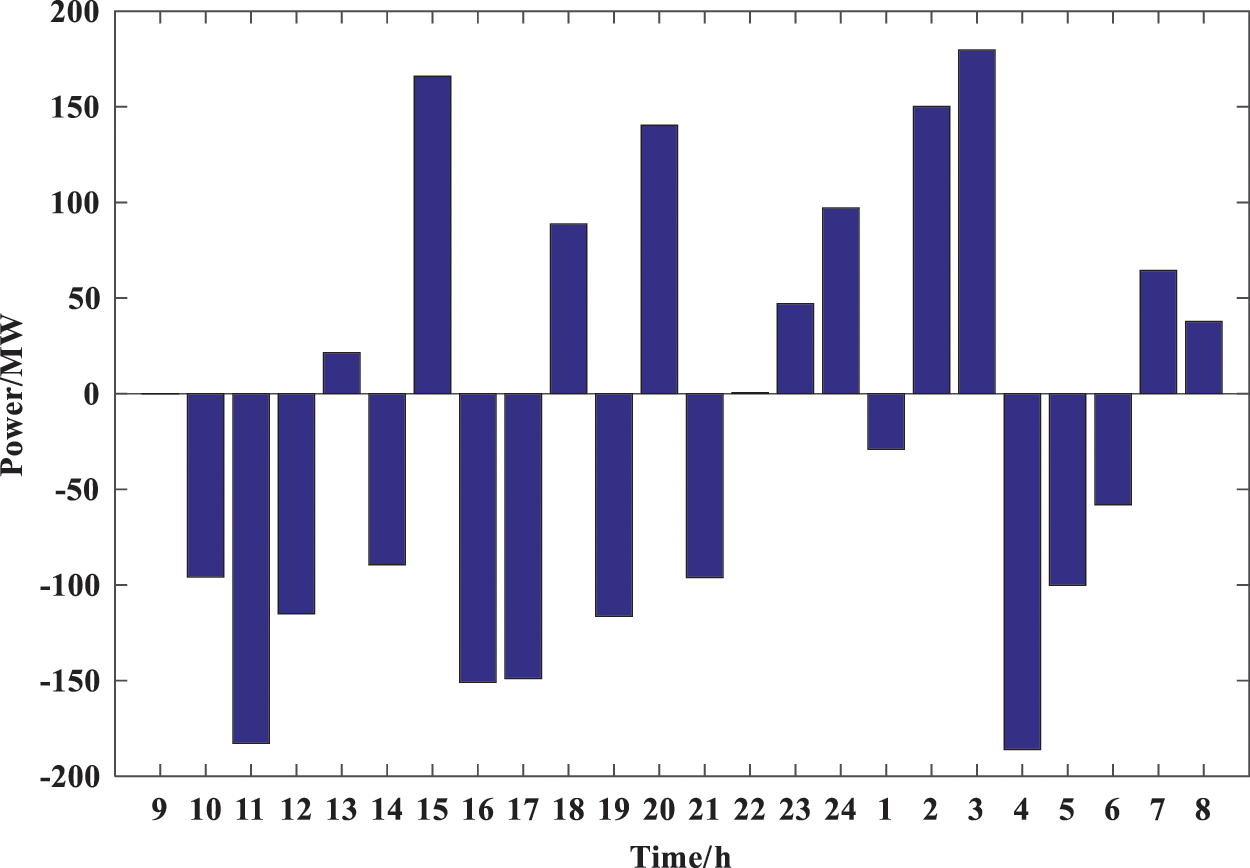

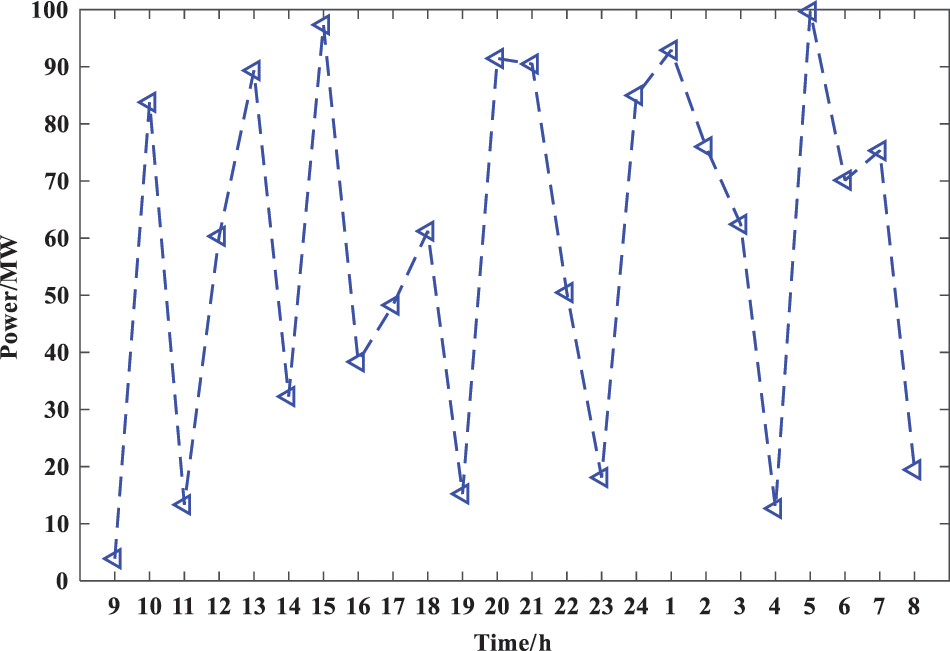

Applying the memetic algorithm to the calculation example can obtain the real-time output of a single unit of the system, the real-time output of the heat storage device and the electric boiler, as shown in Figs. 16–18. When they are substituted into the system evaluation function, the optimal value of the system in the scheduling period can be obtained as 3.77 × 109, the minimum operating cost of the system is 9.9515 million yuan, and the system coal-burning cost is 9.9263 million yuan.

Figure 16: Real-time output change of heat storage device

Figure 17: Real-time output of a single unit in the system including heat storage device and electric boiler

Figure 18: Real-time output of electric boiler

4.4 Validation of the Algorithm

Given that the intelligent algorithm has a certain degree of randomness, this study performs 30 iterations and saves the data to make a box plot to verify the reliability of the running results of the algorithm. The interval of unit output operation is shown in Fig. 19.

Figure 19: Box diagram of unit output

The addition of heat storage devices and electric boilers enhances the flexibility of the cogeneration system, and the output of the unit is maintained at a low level from 20:00 to 6:00 (the next day), providing space for wind power grid-connected consumption, effectively improving the wind power consumption capacity of the system.

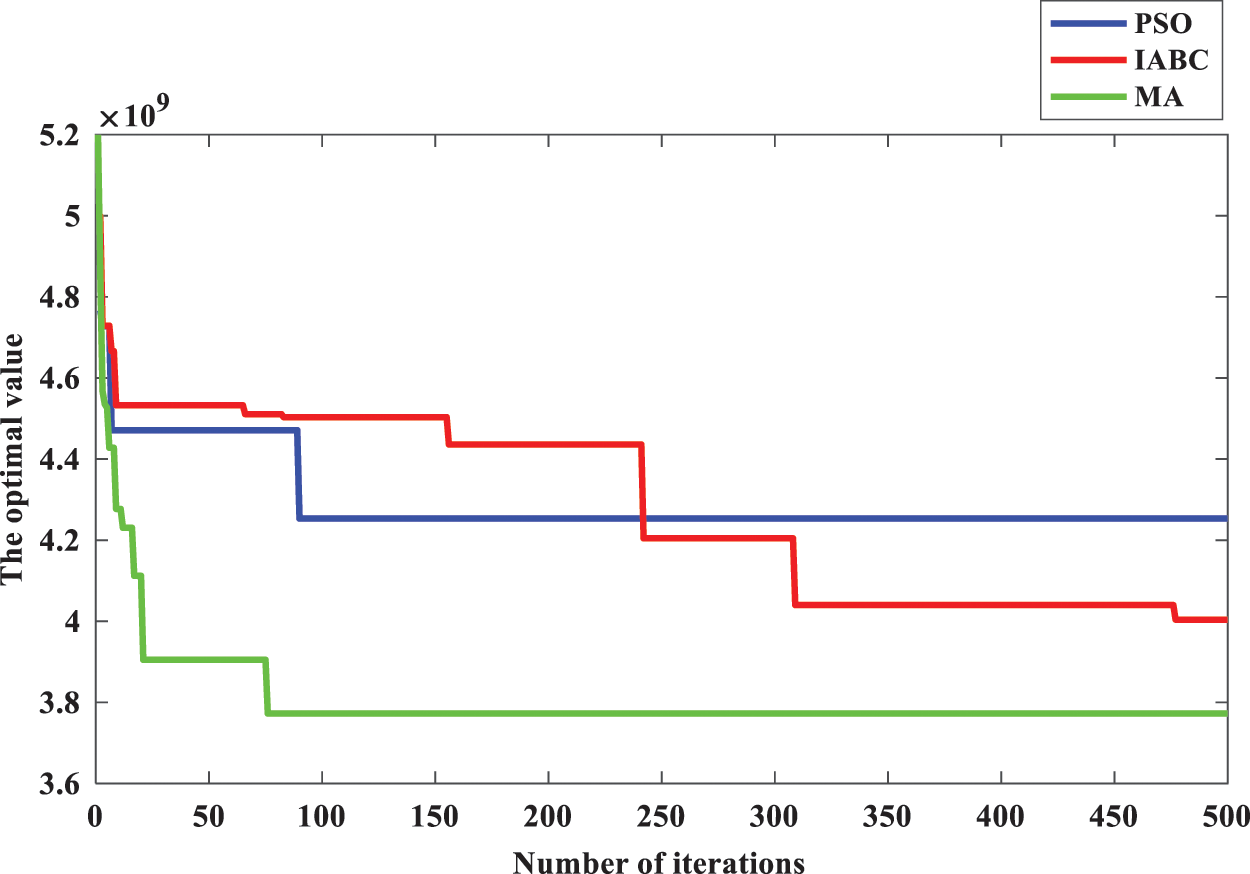

To further verify the feasibility of the scheme, the PSO and the improved artificial bee colony algorithm commonly used in solving such problems in the past are selected for comparison and are also applied to this example. The optimal value of the system is obtained as shown in Fig. 20.

Figure 20: Comparison of optimal values (including heat storage device and electric boiler)

To more intuitively reflect the improvement of system economy brought by the improvement of system structure and optimization algorithm, the scheduling optimization solutions are compared, as shown in Table 3.

The comparison shows the following: (1) No matter what kind of optimization algorithm is adopted, the economy of the cogeneration system with improved system structure is improved in varying degrees, which shows that the scheme is feasible. (2) Almost the entire operation cost of the system comes from the coal-burning cost of the unit, while the influence of the operation cost of the heat storage device and electric boiler is negligible, indicating that the system optimization is mainly achieved by adjusting the output of the unit. (3) Compared with the improved artificial bee colony algorithm and PSO algorithm, the memetic algorithm has a higher quality of optimal solution and less average iterative times.

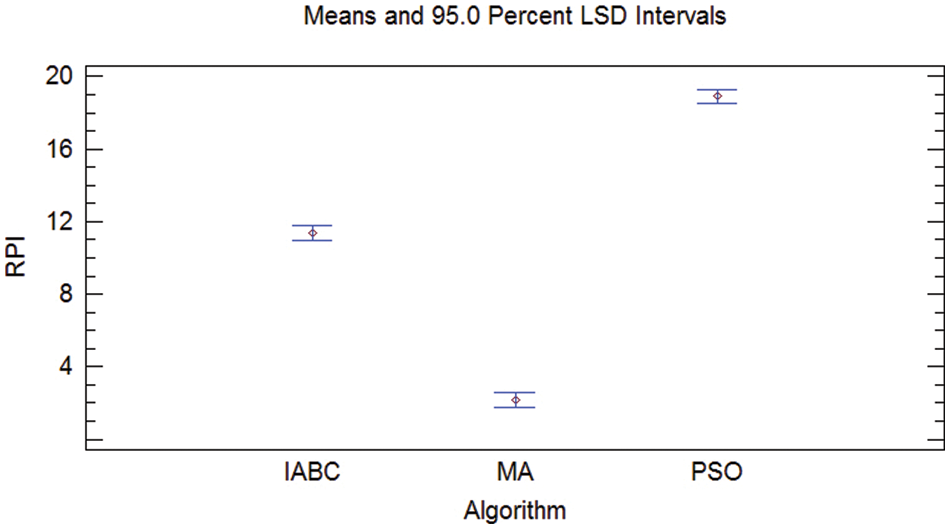

To further verify the superior performance of the memetic algorithm in the scheduling of the cogeneration system, this paper implements the above three algorithms (PSO, IABC and MA) to explore the same objective function. They are operated on the same computer, and three methods independently operate ten times for every instance, and the RPI is calculated for the replication. The compared results are shown in Table 4. The relative percentage increase (RPI) is given to measure the performance, which is shown in the following:

where

To verify the observed distinguishes in statistics from Table 4, a “multifactor analysis of variance (ANOVA)” is carried out where the type of algorithm is defined as factors. The result is given in Fig. 21 at a 95% confidence level. It can be analyzed from this figure that the MA algorithm reflects significantly better performance.

Figure 21: Compare the results of different algorithms

Considering the limited wind power absorption capacity and high operating cost of the traditional cogeneration system, this study improves the system structure and optimal scheduling method. An optimal scheduling method for the cogeneration system with heat storage device and electric boiler based on memetic algorithm is proposed. The scheme’s feasibility is verified by taking the actual power grid in a specific area as an example. The effectiveness of the scheduling method is proved by comparing the memetic algorithm with the improved artificial bee colony algorithm and PSO algorithm, which belong to the same intelligent algorithm.

Through further analysis, the following conclusions can be drawn:

(1) Adding heat storage devices and electric boilers can remove the rigid shackles between the power supply and heat generation of the cogeneration system, thus enhancing the system’s flexibility. In the period of rich wind energy resources, it provides space for large-scale wind power grid consumption, which can not only effectively solve the problem of wind abandonment but also reduce the consumption of fossil fuels, thus ensuring the economy and low-carbon environmental protection of the system operation.

(2) This paper proposes an optimal scheduling method for a cogeneration system based on a memetic algorithm to ensure the scientific nature of scheduling planning. The memetic algorithm combines global evolution with local search so that the algorithm can find the optimal global solution with a higher probability. Compared with the intelligent methods commonly used in the scheduling field, the memetic algorithm has higher optimal solution quality and fewer iterations.

Funding Statement: This work was partly supported by the National Natural Science Foundation of China (61773269), China Scholarship for Overseas Studying (CSC No. 202008210181), Department of Education of Liaoning Province of China (LJKZ1110), the Natural Science Foundation of Liaoning Province of China (2019-KF-03-08), and the Program for Shenyang High Level Innovative Talents (RC190042).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Khatibi, M., Bendtsen, J. D., Stoustrup, J., Mølbak, T. (2021). Exploiting power-to-heat assets in district heating networks to regulate electric power network. IEEE Transactions on Smart Grid, 12(3), 2048–2059. DOI 10.1109/TSG.2020.3044348. [Google Scholar] [CrossRef]

2. Xu, X. D., Ming, W. L., Zhou, Y. (2021). Unlock the flexibility of combined heat and power for frequency response by coordinative control with batteries. IEEE Transactions on Industrial Informatics, 17(5), 3209–3219. DOI 10.1109/TII.2020.3012495. [Google Scholar] [CrossRef]

3. Shen, Z. R., Wu, C. L., Wang, L. (2021). Real-time energy management for microgrid with EV station and CHP generation. IEEE Transactions on Network Science and Engineering, 8(2), 1492–1501. DOI 10.1109/TNSE.2021.3062846. [Google Scholar] [CrossRef]

4. Dou, C. X., Zhou, X. H., Zhang, T. F. (2020). Economic optimization dispatching strategy of microgrid for promoting photoelectric consumption considering cogeneration and demand response. Journal of Modern Power Systems and Clean Energy, 8(3), 557–563. DOI 10.35833/MPCE.2019.000214. [Google Scholar] [CrossRef]

5. Zhou, Y. F., Hu, W., Min, Y. (2019). Integrated power and heat dispatch considering available reserve of combined heat and power units. IEEE Transactions on Sustainable Energy, 10(3), 1300–1310. DOI 10.1109/TSTE.2018.2865562. [Google Scholar] [CrossRef]

6. Zhang, H. S., Liu, Y. F., Liu, X. G., Duan, C. H. (2020). Energy and exergy analysis of a new cogeneration system based on an organic Rankine cycle and absorption heat pump in the coal-fired power plant. Energy Conversion and Management, 223(4), 113293. DOI 10.1016/j.enconman.2020.113293. [Google Scholar] [CrossRef]

7. Li, W. T., Li, Y. (2020). Configuration optimization of the novel cogeneration heating system with multi turbine units. Energy Conversion and Management, 221, 113140. DOI 10.1016/j.enconman.2020.113140. [Google Scholar] [CrossRef]

8. Wu, Y. T., Fu, L., Zhang, S. G. (2019). Study on a novel co-operated heat and power system for improving energy efficiency and flexibility of cogeneration plants. Applied Thermal Engineering, 163(3), 114429. DOI 10.1016/j.applthermaleng.2019.114429. [Google Scholar] [CrossRef]

9. Wang, Z. X., Sun, S. T., Lin, X. G., Liu, C., Tong, N. et al. (2019). A remote integrated energy system based on cogeneration of a concentrating solar power plant and buildings with phase change materials. Energy Conversion and Management, 187(7), 472–485. DOI 10.1016/j.enconman.2019.02.094. [Google Scholar] [CrossRef]

10. Ghorbani, B., Shirmohammadi, R., Mehrpooya, M. (2020). Development of an innovative cogeneration system for fresh water and power production by renewable energy using thermal energy storage system. Sustainable Energy Technologies and Assessments, 37(10), 100572. DOI 10.1016/j.seta.2019.100572. [Google Scholar] [CrossRef]

11. Zhang, H. F., Lei, B., Yu, T., Zhao, Z. D. (2019). Form and operation mode analysis of a novel solar-driven cogeneration system with various collector types. International Journal of Photoenergy, 2019, 5329086. DOI 10.1155/2019/5329086. [Google Scholar] [CrossRef]

12. Zhang, H. F., Lei, B., Yu, T. (2018). Exergy analysis of two kinds of solar-driven cogeneration systems in Lhasa, Tibet, china. International Journal of Photoenergy, 2018, 6702049. DOI 10.1155/2018/6702049. [Google Scholar] [CrossRef]

13. Ancona, M., Bianchi, M., Branchini, L. (2019). Combined heat and power generation systems design for residential houses. Energy Procedia, 158(1), 2768–2773. DOI 10.1016/j.egypro.2019.02.036. [Google Scholar] [CrossRef]

14. Zhou, Y., Wei, M., Li, Z. (2020). Distributional robust co-optimization of energy and reserve for combined distribution networks of power and district heating. IEEE Transactions on Power Systems, 35(3), 2388–2398. DOI 10.1109/TPWRS.2019.2954710. [Google Scholar] [CrossRef]

15. Cheng, H., Wu, J., Luo, Z. (2019). Optimal planning of multi-energy system considering thermal storage capacity of heating network and heat load. IEEE Access, 7, 13364–13372. DOI 10.1109/ACCESS.2019.2893910. [Google Scholar] [CrossRef]

16. Johar, D. K., Sharma, D., Soni, S. L. (2020). Comparative studies on micro cogeneration, micro cogeneration with thermal energy storage and micro trigeneration with thermal energy storage system using same power plant. Energy Conversion and Management, 220, 113082. DOI 10.1016/j.enconman.2020.113082. [Google Scholar] [CrossRef]

17. Li, Z., Zhang, R., Zhang, L. P. (2020). Scheduling optimization of wind power system based on cogeneration. International Transactions on Electrical Energy Systems, 30(8), 1–19. DOI 10.1002/2050-7038.12435. [Google Scholar] [CrossRef]

18. Huang, L. X. (2020). Optimal scheduling of cogeneration microgrid with wind energy and energy storage devices. IOP Conference Series: Earth and Environmental Science, 558(5), 052010. DOI 10.1088/1755-1315/558/5/052010. [Google Scholar] [CrossRef]

19. Lin, W. M., Yang, C. Y., Tu, C. S. (2019). The optimal energy dispatch of cogeneration systems in a liberty market. Energies, 12(15), 1–15. DOI 10.3390/en12152868. [Google Scholar] [CrossRef]

20. Stefano, M., Sean, O., Alessandro, R. (2019). Cogeneration power plants for smart-district optimal operations-CO2 and primary energy savings in a real industrial application. AIP Conference Proceedings, 020099. Beirut, Lebanon. [Google Scholar]

21. Santos, M. I., Uturbey, W. (2018). A practical model for energy dispatch in cogeneration plants. Energy, 151(1), 144–159. DOI 10.1016/j.energy.2018.03.057. [Google Scholar] [CrossRef]

22. Dou, C. X., Zhou, X. H., Zhang, T. F. (2020). Economic optimization dispatching strategy of microgrid for promoting photoelectric consumption considering cogeneration and demand response. Journal of Modern Power Systems and Clean Energy, 8(3), 557–563. DOI 10.35833/MPCE.2019.000214. [Google Scholar] [CrossRef]

23. Jing, L., Ge, S. L., Qu, B. Y. (2020). Improved particle swarm optimization algorithm for solving power system economic dispatch problem. Control and Decision, 35(8), 1813–1822. [Google Scholar]

24. Su, K. (2013). Research on power system optimal dispatch with wind power central heating, China (Master Thesis). Dalian University of Technology, China. [Google Scholar]

25. Garmabdari, R., Moghimi, M., Yang, F. (2020). Multi-objective optimisation and planning of grid-connected cogeneration systems in presence of grid power fluctuations and energy storage dynamics. Energy, 212, 118589. DOI 10.1016/j.energy.2020.118589. [Google Scholar] [CrossRef]

26. Xu, D., Wu, Q. W., Zhou, B. (2020). Distributed multi-energy operation of coupled electricity, heating, and natural gas networks. IEEE Transactions on Sustainable Energy, 11(4), 2457–2469. DOI 10.1109/TSTE.2019.2961432. [Google Scholar] [CrossRef]

27. Rémy, R. M., Zhang, C., Alessandro, R. (2020). A combined cycle gas turbine model for heat and power dispatch subject to grid constraints. IEEE Transactions on Sustainable Energy, 11(1), 448–456. DOI 10.1109/TSTE.2019.2894793. [Google Scholar] [CrossRef]

28. Amirhossein, D., Mohammad, J., Behnam, M. I. (2019). Short-term scheduling strategy for wind-based energy hub: A hybrid stochastic/igdt approach. IIEEE Transactions on Sustainable Energy, 10(1), 438–448. DOI 10.1109/TSTE.2017.2788086. [Google Scholar] [CrossRef]

29. He, Y. L., Yuan, L. Y., Che, Y. R. (2022). Operational optimization of combined cooling, heat and power system based on information gap decision theory method considering probability distribution. Sustainable Energy Technologies and Assessments, 51(10), 101977. DOI 10.1016/j.seta.2022.101977. [Google Scholar] [CrossRef]

30. Liu, G., Qin, Z. F., Diao, T. Y. (2022). Low carbon economic dispatch of biogas-wind-solar renewable energy system based on robust stochastic optimization. International Journal of Electrical Power and Energy Systems, 139(2), 108069. DOI 10.1016/j.ijepes.2022.108069. [Google Scholar] [CrossRef]

31. Jiang, Y. B., Wan, C., Botterud, A. (2021). Efficient robust scheduling of integrated electricity and heat systems: A direct constraint tightening approach. IEEE Transactions on Smart Grid, 12(4), 3016–3029. DOI 10.1109/TSG.2021.3066449. [Google Scholar] [CrossRef]

32. Murugan, R., Seyedali, M., Morteza, N. H., Deiva, S. P., Arunachalam, S. et al. (2022). A hybrid grasshopper optimization algorithm and harris hawks optimizer for combined heat and power economic dispatch problem. Engineering Applications of Artificial Intelligence, 111, 104753. [Google Scholar]

33. Yang, Q. D., Liu, P., Zhang, J., Dong, N. (2022). Combined heat and power economic dispatch using an adaptive cuckoo search with differential evolution mutation. Applied Energy, 307(1), 118057. DOI 10.1016/j.apenergy.2021.118057. [Google Scholar] [CrossRef]

34. Zhang, G. H., Ma, X. J., Wang, L. (2022). Elite archive-assisted adaptive memetic algorithm for a realistic hybrid differentiation flowshop scheduling problem. IEEE Transactions on Evolutionary Computation, 26(1), 100–114. DOI 10.1109/TEVC.2021.3094542. [Google Scholar] [CrossRef]

35. Wang, J. J., Wang, L. (2021). A bi-population cooperative memetic algorithm for distributed hybrid flow-shop scheduling. IEEE Transactions on Emerging Topics in Computational Intelligence, 5(6), 947–961. DOI 10.1109/TETCI.2020.3022372. [Google Scholar] [CrossRef]

36. Li, J. Q., Sun, T., Huang, X. P. (2021). A memetic path planning algorithm for unmanned air/ground vehicle cooperative detection systems. IEEE Transactions on Automation Science and Engineering, 19(7), 2724–2737. DOI 10.1109/FASE.2021.3061870. [Google Scholar] [CrossRef]

37. Zhao, Y. Z., Liu, S. X., Zhou, M. C. (2021). Dual-objective mixed integer linear program and memetic algorithm for an industrial group scheduling problem. IEEE/CAA Journal of Automatica Sinica, 8(6), 1199–1209. DOI 10.1109/JAS.2020.1003539. [Google Scholar] [CrossRef]

38. Guan, B. X., Zhao, Y. H., Yin, Y. (2022). Detecting disease-associated SNP-SNP interactions using progressive screening memetic algorithm. IEEE/ACM Transactions on Computational Biology and Bioinformatics, 19(2), 878–887. [Google Scholar]

39. Li, J. H., Fu, Y. N., Li, C. P., Xing, Z. T. (2020). Economic optimal configuration of hybrid energy storage system for improving wind power consumption. Power System Technology, 44(12), 4547–4555. [Google Scholar]

40. Chen, L., Lin, H., Cheng, H. L. (2021). Electrothermal combination dispatching based on additional heat source improving wind power consumption. Acta Energiae Solaris Sinica, 42(10), 258–264. [Google Scholar]

41. Dai, Y. C., Wang, X. J., Ge, K. K., Xiao, Q., Liang, G. J. (2021). Day-ahead optimization scheduling of thermoelectric storage system considering user satisfaction. Hydroelectric Power, 47(12), 92–97. [Google Scholar]

42. Yang, Y. F. (2012). The method of partical swarm optization solving constrained problems, China (Master Thesis). China University of Geosciences (BeijingChina. [Google Scholar]

43. Lv, Q., Chen, T. Y., Wang, H. X., Li, L., Lv, Y. et al. (2014). Electric and heating integrated dispatching model of power system with heat storage. Electric Power Automation Equipment, 34(5), 79–85. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools