Open Access

Open Access

ARTICLE

Engine Performance Using Blended Fuels of Biodiesel and Eco Diesel

1 Study Program of Mechanical Engineering, Universitas Medan Area, Medan, 20156, Indonesia

2 Study Program of Mechanical Engineering, Politeknik Negeri Medan, Medan, 20156, Indonesia

3 Study Program of Industrial Engineering, Universitas Harapan Medan, Medan, 20156, Indonesia

4 Department of Mechanical Engineering Education, Universitas Sebelas Maret, Surakarta, 57126, Indonesia

* Corresponding Authors: Muhammad Idris. Email: ; Nugroho Agung Pambudi. Email:

Energy Engineering 2023, 120(1), 107-123. https://doi.org/10.32604/ee.2023.019203

Received 08 September 2021; Accepted 05 July 2022; Issue published 27 October 2022

Abstract

Diesel engines is an internal combustion engine with high thermal efficiency, which also uses biodiesel fuel, an environmentally friendly, non-toxic, and low sulfur content. Biodiesel has been around for a long time due to its similar characteristics to diesel fuels which has limited availability. However, several disadvantages are associated with biodiesel, such as poor volatility and high viscosity, which reduces engine performance. Therefore, this study was carried out to improve the diesel engine performance by mixing biodiesel with ecodiesel (ED), an additive produced from natural ingredients that is dissolvable in biodiesel. The biodiesel fuel properties used are density 860 kg/, dynamic viscosity 4.50E-06 /s, cetane number 45, and flashpoint 52°C. The results showed that biodiesel-ED mixture could improve engine performance and the optimum performance was at a speed of 3000 rpm on 43.30 (kW), 124.93 (N.m) of the engine torque, and 2.45E−5 (kg/kW.s) of the specific fuel consumption. According to paired sample t-test, the difference in the engine performance is only experienced in the torque, which has a significant increase in the composition of the biodiesel+ED by 0.07 gr mixture.Keywords

Nomenclature

| BMEP | brake means effective pressure | |

| BP | brake power | |

| BSFC | brake-specific fuel consumption | |

| BTE | brake thermal efficiency | |

| CI | compression ignition | |

| CO | carbon monoxide | |

| DEE | diethyl ether | |

| DI | decision intelligence | |

| ED | eco diesel | |

| GVL | γ-valero lactone | |

| HC | hydrocarbons | |

| MORF-1 | Monoraphidium contortum | |

| SFC | specific fuel consumption | |

| Symbols | road load power | |

| coefficient of rolling resistance | ||

| mass of vehicle | ||

| ambient air density (1.184 kg/ | ||

| drag coefficients | ||

| frontal area of vehicle ( | ||

| vehicle speed (km/h) | ||

| engine torque ( | ||

| N | crankshaft rotational speed (rpm) | |

| specific fuel consumption (kg/kW.s) | ||

| fuel mass rate (kg/s) | ||

| engine power (kW) | ||

| relative uncertainty | ||

| DS | deviation standard | |

| e | exponential number | |

| calculated value | ||

| number of data | ||

| sample mean | ||

| data value |

Diesel engines are widely used in various sectors, such as transportation, industry, and agriculture because they are internal combustion engines with high thermal efficiency [1,2]. The diesel engine production all over the world is very significant [3]. The diesel fuel is used, the availability is limited [4–7]. However, the diesel engine can also use biodiesel, a fuel with environmentally friendly, non-toxic, and low sulfur characteristics [8–11]. The use of biodiesel also has been around for a long time due to its similar characteristics with diesel fuels [12]. When biodiesel is used in the diesel engine, it does not need significant modifications [13]. Another advantage, biodiesel is an abundant renewable energy source with progressive growth in production and demand [14].

However, biodiesel has several disadvantages, such as poor volatility and high viscosity that reduce the engine’s performance [15,16]. Furthermore, Biodiesel from vegetable oils has energy content close to petro-diesel and is regarded as inexhaustible because of its renewable energy source [17,18]. Abdollahi et al. [19] examined the effects of nano-emulsion biodiesel on engine efficiency, as well as the gas emission and combustion parameters of a single-cylinder air-cooled diesel engine. The results showed that the power and torque using nano-emulsion fuel improved by approximately 4.84% and 4.65%, respectively, compared to standard emulsion [19]. With the increase in load, nano fuel blends also show lower HC emission than diesel [20].

There are various disadvantages associated with biodiesel, therefore a lot of research tries to make its improvement. Xiao et al. investigated the effect of ethanol-biodiesel and n-butanol-biodiesel blends. The results showed the combustion performed is better at low engines load [21]. Wei et al. carried out research to determine the combustion performance and emission characteristics of a diesel engine powered by isobutanol/biodiesel, which was experimentally studied under different loads at the engine speed of 1800 rpm [22]. The result showed that the combustion duration decreased with a rise in the isobutanol ratio when the engine loads exceeded 0.38 MPa brake means effective pressure (BMEP).

Currently, chemical and biological catalysts are being investigated to improve engine performance, and both have their advantages and disadvantages [23]. Akos et al. stated that γ-valero lactone (GVL) is a C5-cyclic ester produced from biomass and used to provide a potentially renewable fuel for transportation and feedstock of the chemical industry [24]. Furthermore, Yordanaka et al. examined the hydroesterification process for the production of Biodiesel from Monoraphidium contortum (MORF-1) microalgae biomass and stated that it is a sustainable alternative to petroleum diesel fuel due to its economic, environmental, and ecological attributes [25].

To increase biodiesel performance, eco diesel (ED) is used for their mixture. Eco Diesel is a new biofuel derived from a mixture of monoglycerides (MG) and fatty acid methyl esters (FAME) which can be applied to diesel engines [26–28]. ED is a bio additive produced from natural ingredients, consisting of citronella oil, graniol, granile acetate, and citronellal acetate [29]. It is produced in solid form, making it easier for the engine to easily consume 40 liters of biodiesel. ED dissolves easily within a limited period, thereby increasing engine performance.

Previous studies related to mixing biodiesel with various substances have been carried out with the results affecting engine performance. Gaur et al. [30] found that mixing of nanoparticles and polymer waste in biodiesel affects engine performance by increasing BTE, lowering BSFC, and reducing emissions of certain pollutants such as CO, HC, NOx. Meanwhile, Sekhar et al. [31] found that mixing Pithecellobium dulce seed oil methyl ester increased BSFC and decreased BTE. Sharudin et al. [32] found that Palm Oil Methyl Esters (POME) addition into algae-diesel blended fuels has lower BSFC compared to diesel fuel. The CO and HC emissions were less for bauhinia variegata biodiesel test blends (0%, 25%, 50%, 75%) (except B100) but NOx emissions increased with closer engine performance when compared with diesel [33]. Furthermore, Singh et al. [34] predicted a future blend of Jatropha biodiesel B20 (20 percent biodiesel and 80 percent diesel) with the addition of a nano-catalyst will improve its thermo-physical properties and emit emissions within permissible limits. Elkelawy et al. [35] found that biodiesel from sunflower oil and soybean oil is able to refuel and operate DI engines without modifications to the engine’s original fuel system because it can be mixed with pure diesel up to 70%. Moreover, Sekhar et al. [36] found that Pithecellobium dulce biodiesel 20% blends could be used as an alternative fuel for CI engines with no modifications in engine design. Reang et al. [37] found that blending D75B20RW5 with biodiesel shows 8% higher brake thermal efficiency and 3.33% lower BSFC compared to diesel. Whereas Dey et al. [38] found that the D85B10E5 was the most optimal mix at 100% engine loading performance. Based on the gray-fuzzy approach with the Taguchi method, the most optimum engine parameter is found in the D85B10E5 mixture at 100% [39]. While Reang et al. [40] using the Taguchi-Fuzzy optimization method found that BD10DEE10 has maximum brake thermal efficiency (BTHE) of 4.48% higher than that of diesel. Studies on biodiesel-ethanol diesel-palm mixtures also show that they have an effect on the performance of BSEC emissions, nitrogen oxides (

Mixing biodiesel with other substances and mixing ED with other substances have an effect on the performance of diesel engines, but it is not yet known how they will affect the performance of mixing biodiesel and ED. Therefore, this study aims to examine the mixture of biodiesel and ED to reduce some of the disadvantages of fuel properties and increase engine performance. Furthermore, it also aims to determine the influence of ED on engine performances.

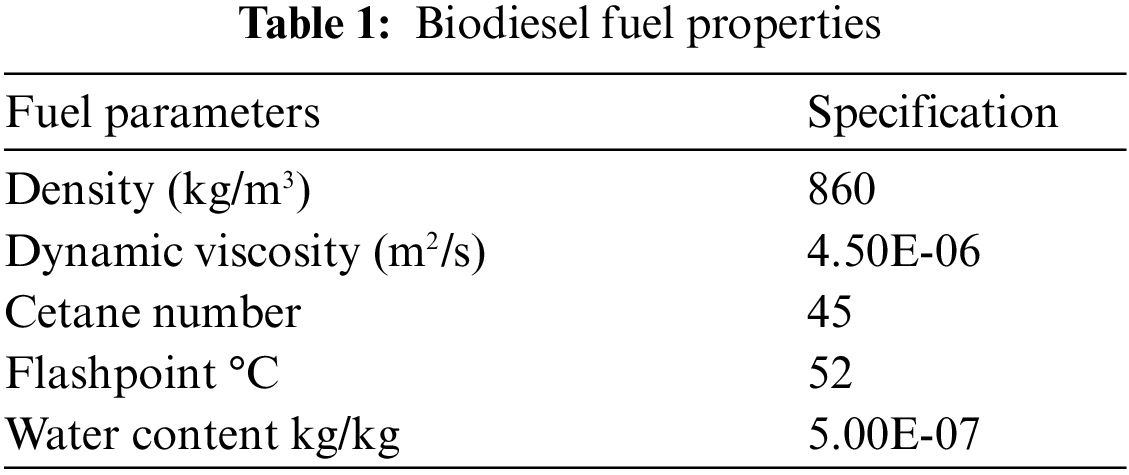

The fuel used in this study is biodiesel, with the properties shown in Table 1. For every 1 liter of biodiesel, three variations of 0.03, 0.04, and 0.07 (gr. ED) are added, respectively.

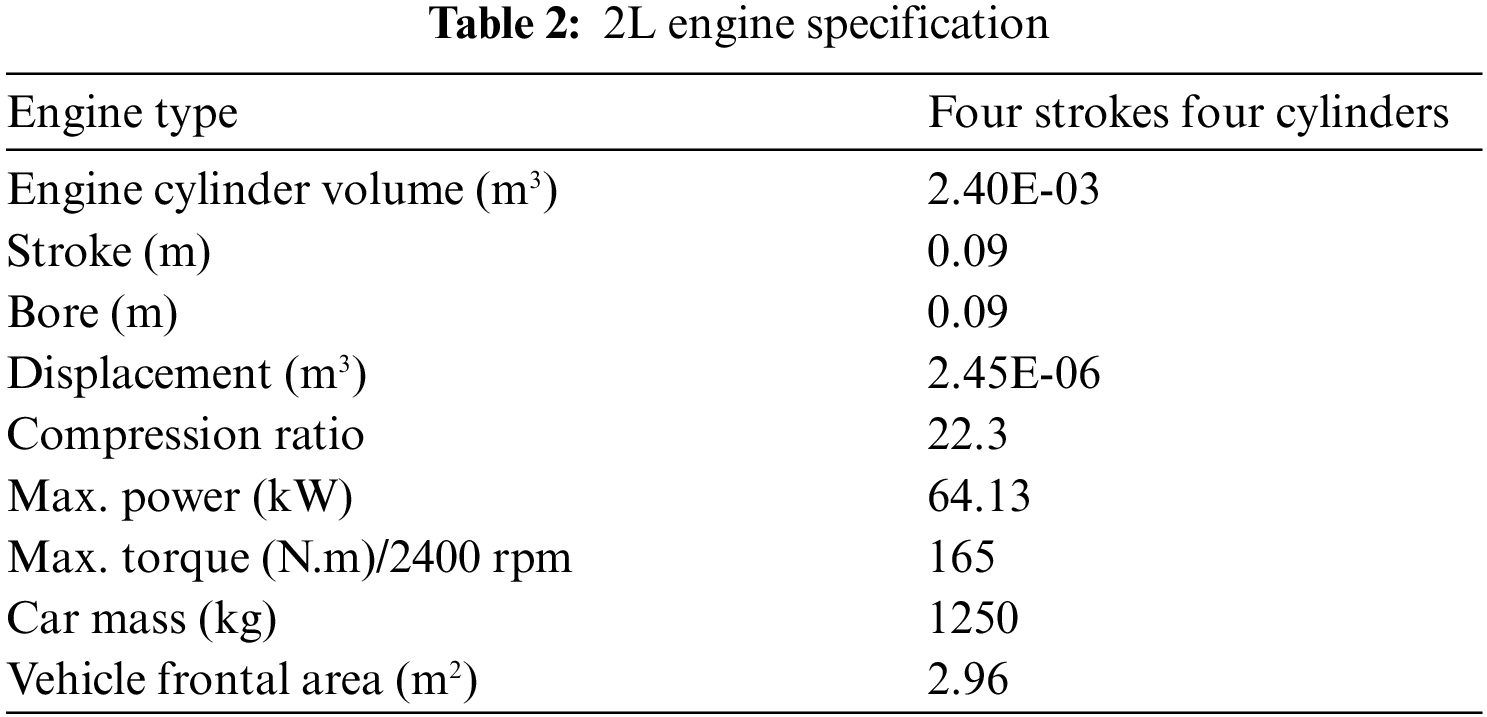

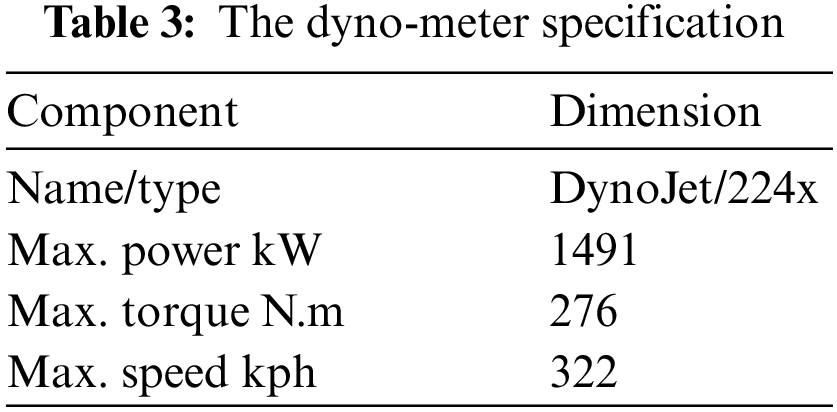

Experiments were carried in a 2L Toyota diesel engine unit car, as shown in Table 2. Furthermore, Table 3 shows the dyno-meter used to examine the engine performance and the characteristics of the biodiesel fuel.

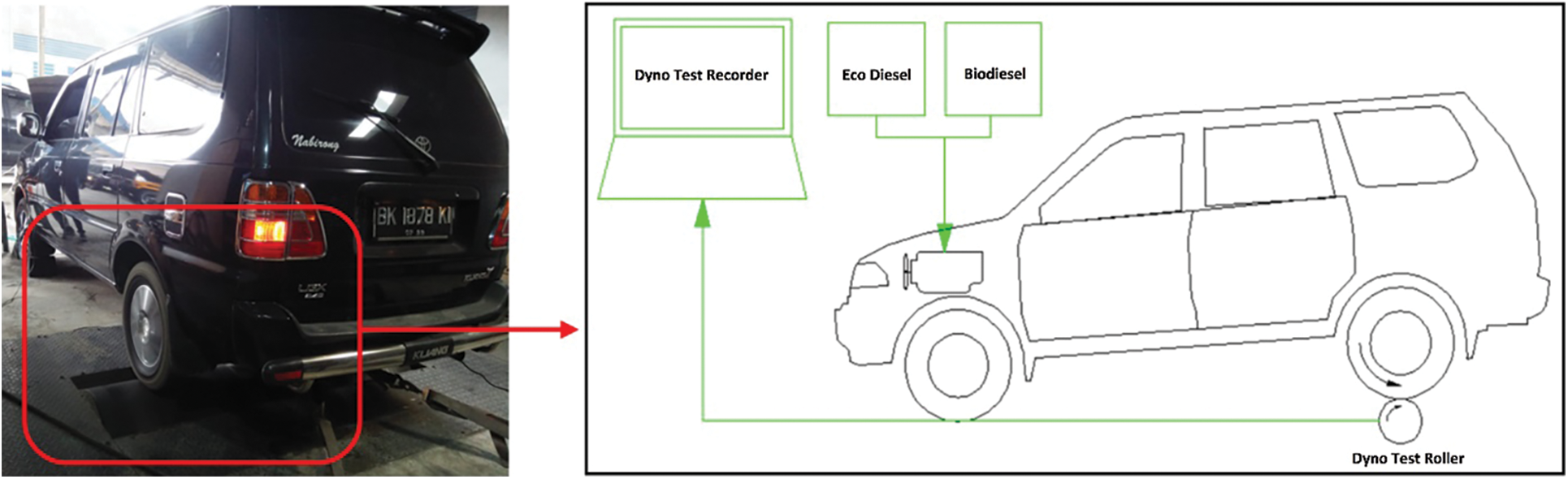

The initial test of ED on engine performance used pure biodiesel, while subsequent tests three variations of mixtures. The engine diesel unit uses a rear-wheel-drive which is connected directly to the dyno-meter roller at various engine speeds, as shown in Fig. 1. Power measurement is done by assuming the vehicle is in a running position at a steady speed (road load power). The aero dynamic drag frictions that occur on the surface in contact between the wheel and the roller dyno meter [42], so that the road load power is determined by an empirical approach in the Eq. (1):

Figure 1: Experimental set up diesel engine performance procedures

where

Meanwhile, the specific fuel consumption is calculated using Eq. (1) and measured directly during the test by placing the fuel in a measuring cup and recorded during the testing process.

SFC is a specific fuel consumption (kg/kW. s),

To prove that the addition of ED has an effect on engine performance, statistical tests are carried out using the normality test in Eq. (3) and the paired sample test in Eqs. (4)–(6). Both of these tests are based on the 0.95 confidence level, therefore, in making decisions in the normality test, ifthe significance value is >0.05, then the hypothesis is accepted, if the significance value is <0.05, the hypothesis is rejected. On the other hand, in the paired sample t-test, if sig. (2-tailed) <0.05, the hypothesis is accepted, and if sig. (2-tailed) >0.05, the hypothesis is rejected [43].

where DS as deviation standard e as an exponential number, t as calculated value n as the number of data.

Machine operation and physical parameters cause some uncertainty in the experimental results [44] so that uncertainty analysis is needed [45]. Uncertainty error analysis is a type of characteristic analysis which is analogous to the deviation of the experimental output response that can be solved effectively [46]. Therefore, uncertainty analysis can be a useful approach for communicating the researcher’s level of confidence in the results and their main conclusions [47]. In this study, the uncertainty of the dependent variable was calculated using the errors involved in measuring independent parameters using Eq. (7) [48].

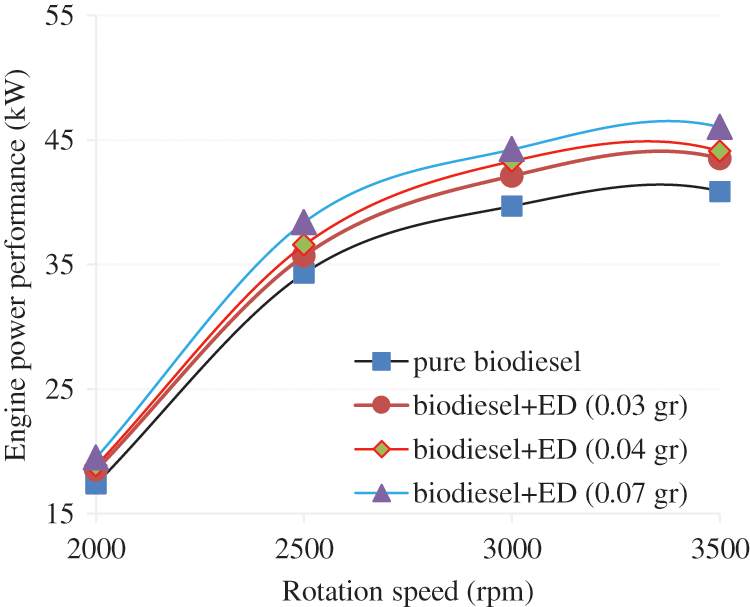

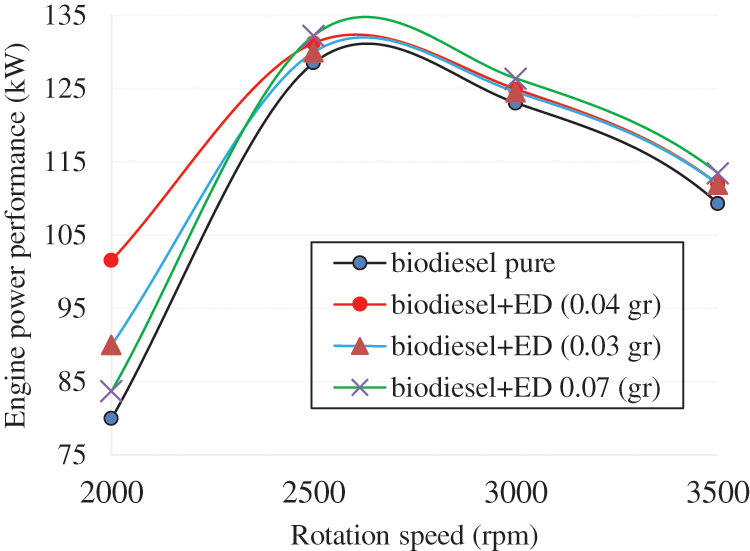

The engine performances are presented in four rotation speed variations, as shown in Figs. 2 and 3. These figures show that ED affects engine power and torque at each rotation speeds variation. The increased power in each composition is 1.1–2.6 (kW/ED 0.03 gr), 1.6–3.6 (kW/ED 0.04 gr) and 2.1–5.2 (kW/ED 0.07 gr). Furthermore, torque increases in the first, second, and last mixingby 1.5–10 N.m, 1.9–21.6 N.m, and 3.72–16.43 N.m, respectively. The optimum engine performances for pure biodiesel and the respective mixture at 3000 rpm, are 39.7 kW/123.0 N.m, 43.3 kW/124.5 N.m, 43.3 kW/124.9 N.m and 44.3 kW/126.4 N.m. Several studies stated that the addition of natural additives to fuel increases in engine performance [49–51].

Figure 2: Engine power

Figure 3: Engine torque

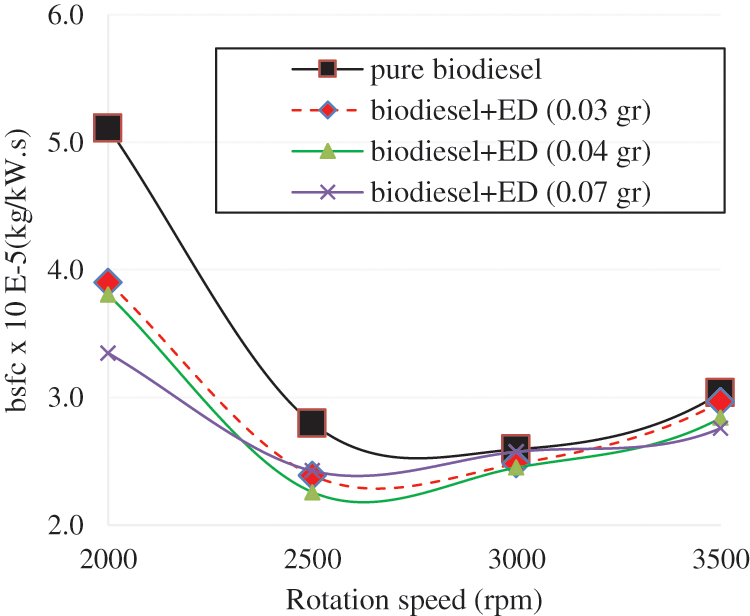

Fig. 4 is a graph of specific fuel consumption. In these three figures, the specific fuel consumption of pure diesel increases first at 2000 rpm by 5.1E−5 kg/kW.s, while ED mixed with biodiesel rises in three different variations of 3.9E−5; 3.8E−5 and 3.3E−5 (kg/kW.s), respectively. The figures show that the three variations of the ED mixture of biodiesel have an effect that causes a decrease in the specific fuel consumption at each variation of rotation speed. The most efficient BSFC at optimum engine performance generally occurs at 3000 rpm engine speed [52–55].

Figure 4: Break specific fuel consumption

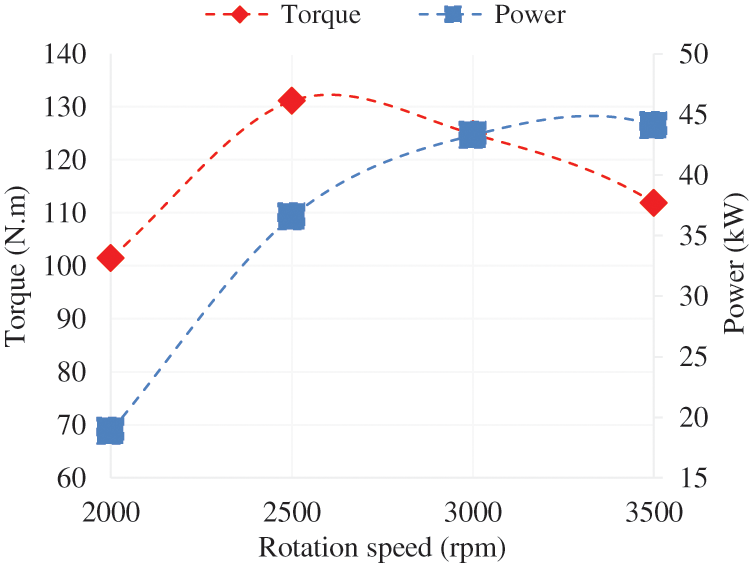

Approximately 0.04 grams of ED in 1 liter of biodiesel when the engine performance was tested using a dyno-meter, thereby producing optimum engine performance as shown in Fig. 5. The engine power, torque and specific fuel consumption were 43.30 (kW), 124.93 (N.m) and

Figure 5: Optimum engine performance fueled by biodiesel ED 0.04 gr blended

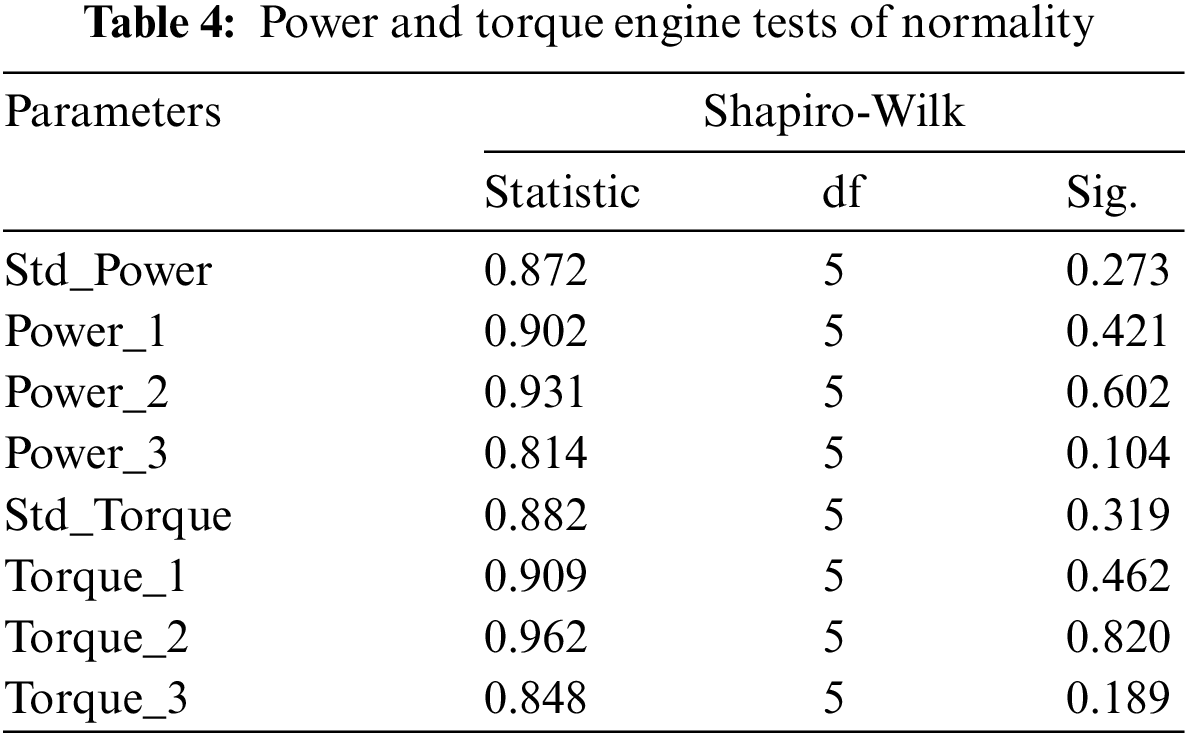

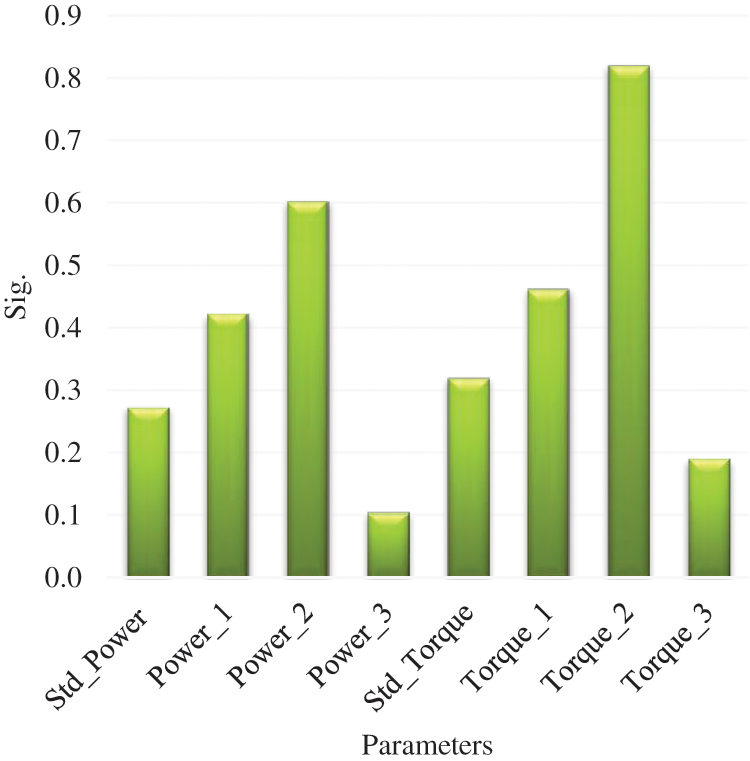

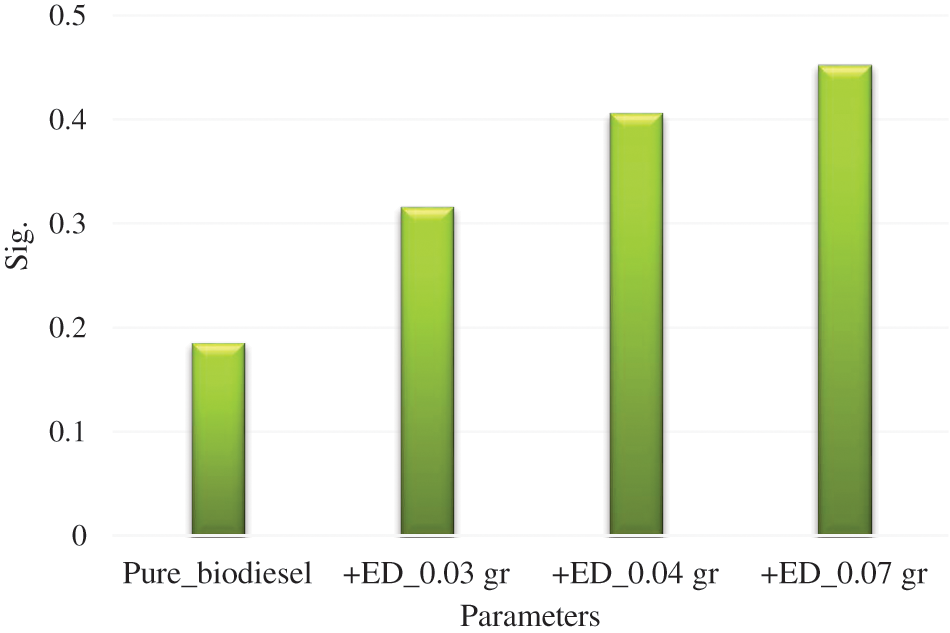

The first step to determine the effect of adding ED to engine performance, is testing each data with a normality test based on Shapiro Wilk’s theory, as shown in Eq. (2), where the results of these tests are shown in Table 4 and Fig. 5. The std_power as a power fueled by biodiesel without ED blend and the power_1 to power_3 and the torque_1 to torque_3 as power and torque fueled by biodiesel ED blend explained before.

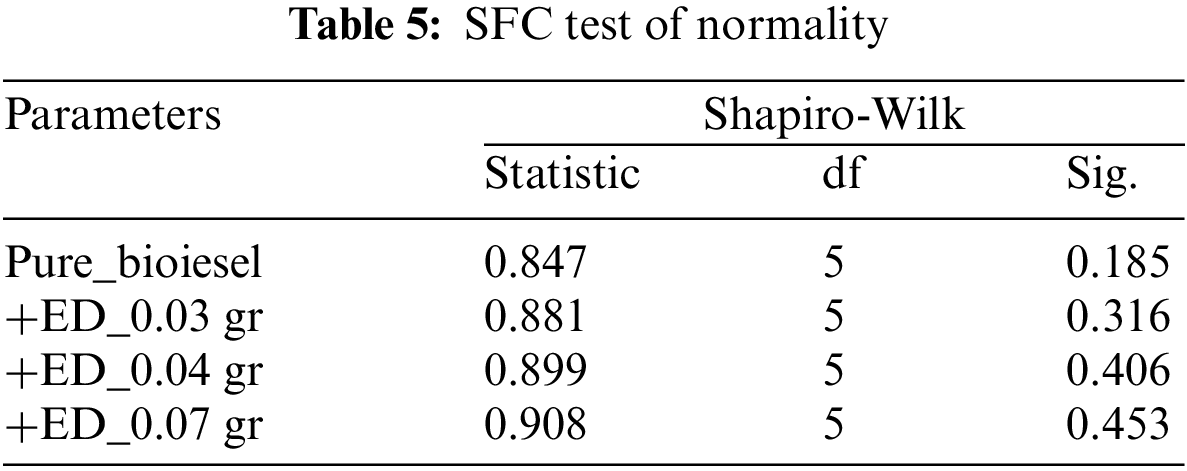

The theory in taking decisions previously mentioned that if sig. > 0.05, then the hypothesis is accepted, therefore the engine power and torque data changes are normally distributed. This is similar to the normality test on the SFC, shown in Table 5, and Fig. 6 with a significant result above 0.05.

Figure 6: Power and torque engine tests of normality

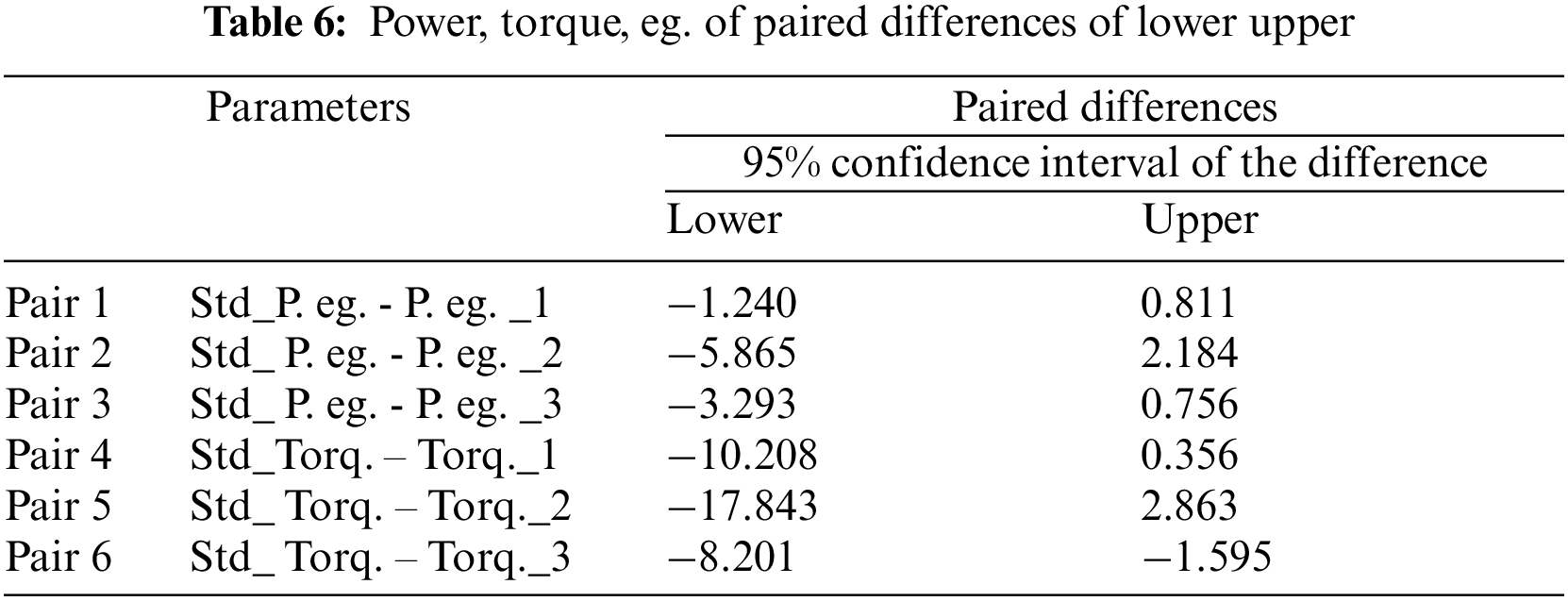

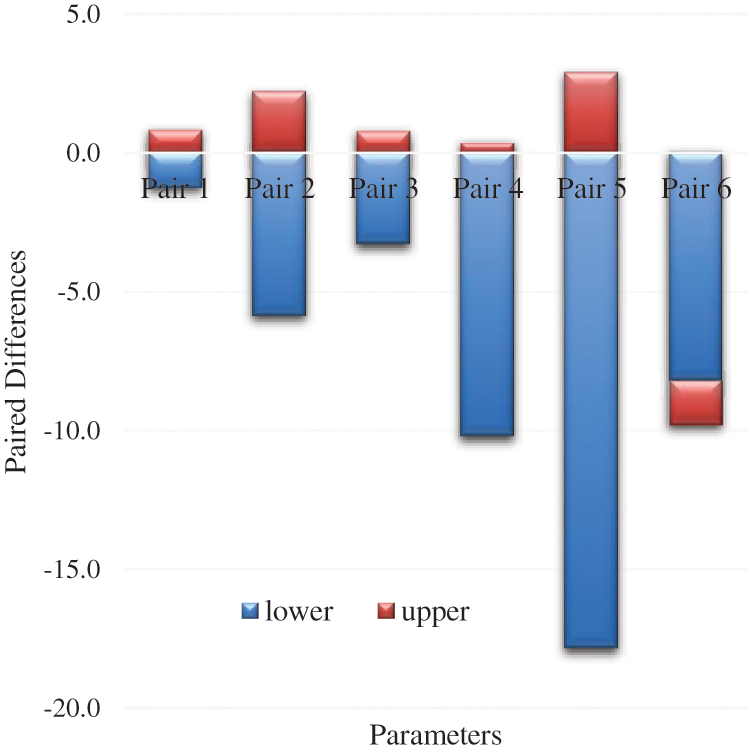

After the normality test, the paired test is carried out to determine the power, torque, and specific fuel consumption variables of Eqs. (3) and (4). The results of these tests are shown in Table 6, and Fig. 7. These data illustrate an average difference between engine power and torque before using ED as a fuel additive with engine power and torque after using ED in each mixture variation. The difference in engine power and torque are 2051–4049 (kW), and 10,565–6,606 (N.m), respectively.

Figure 7: SFC tests of normality

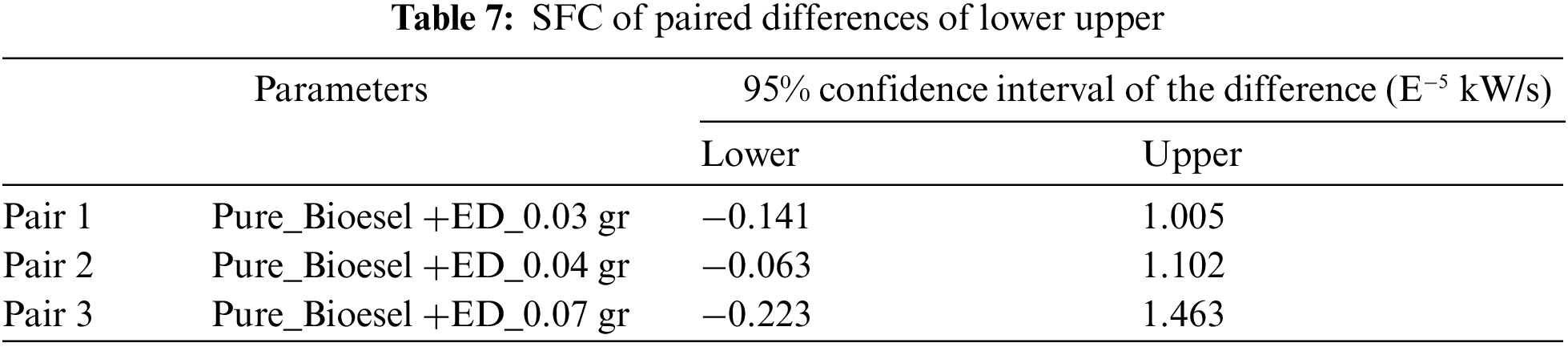

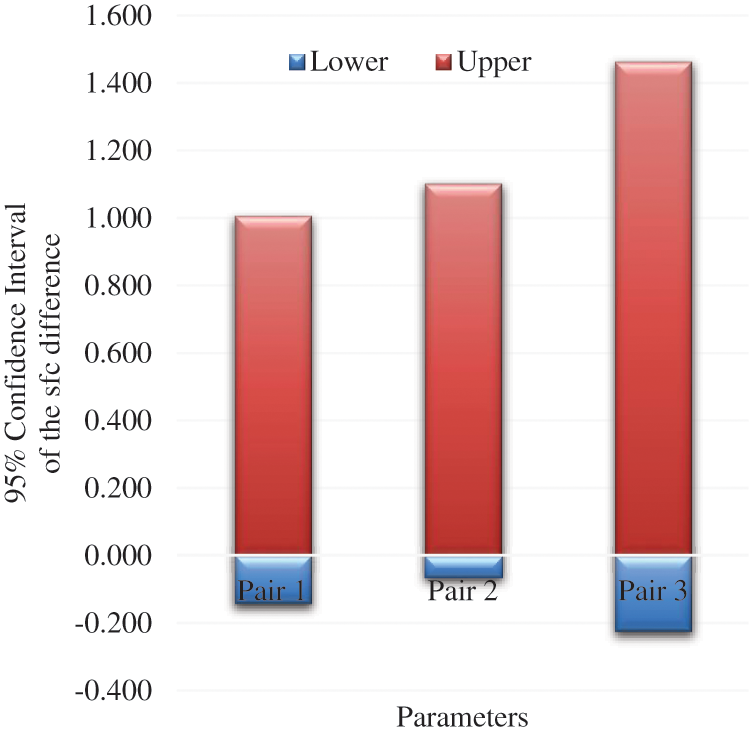

Table 7 and Fig. 8 show that each ED mixture of biodiesel tends to differ in the specific fuel consumption between 1.14–1.68 (E−5 kW/s). This indicates that there is a saving effect in the use of fuel, even in small amounts.

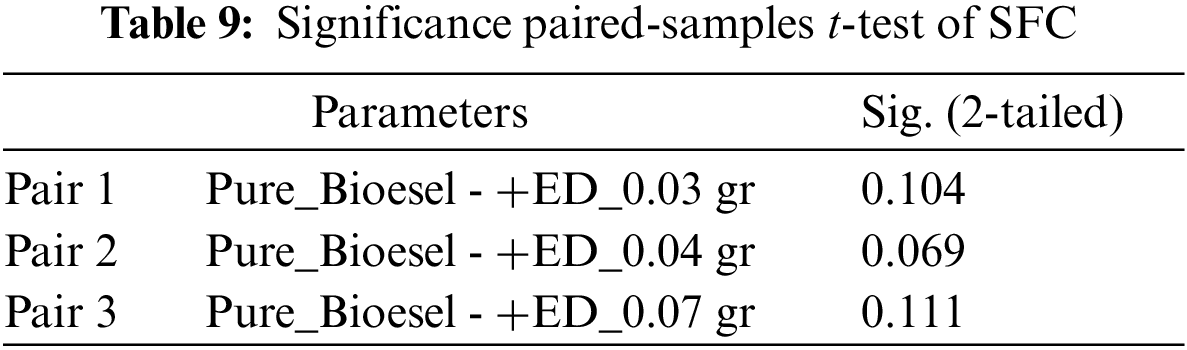

Figure 8: Differences of lower upper

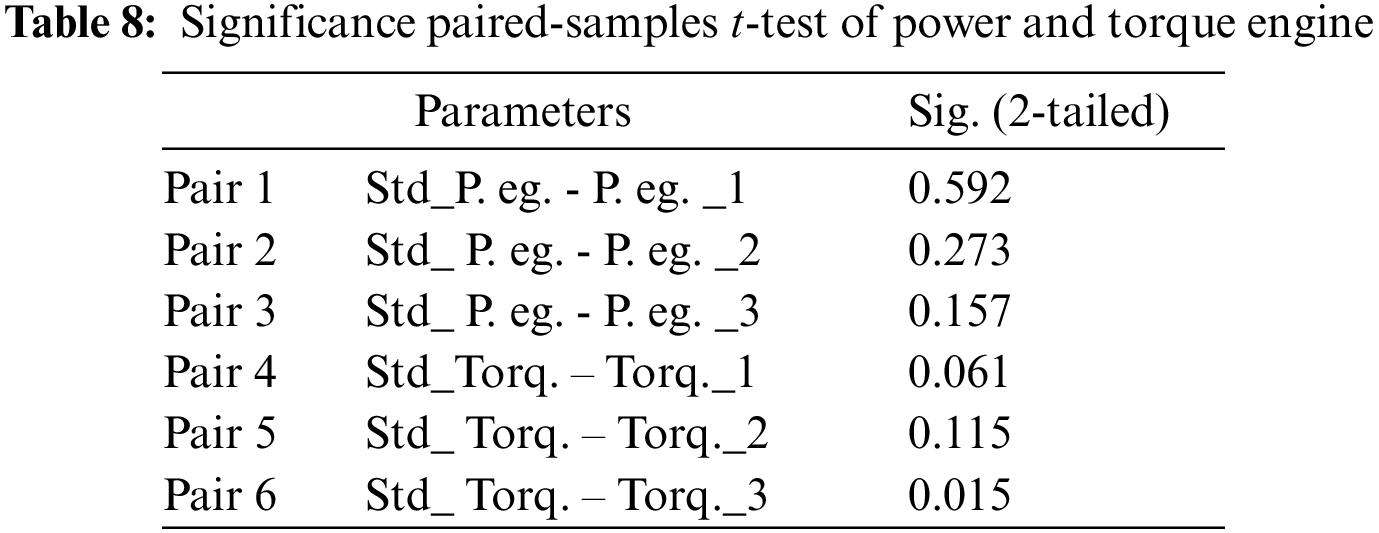

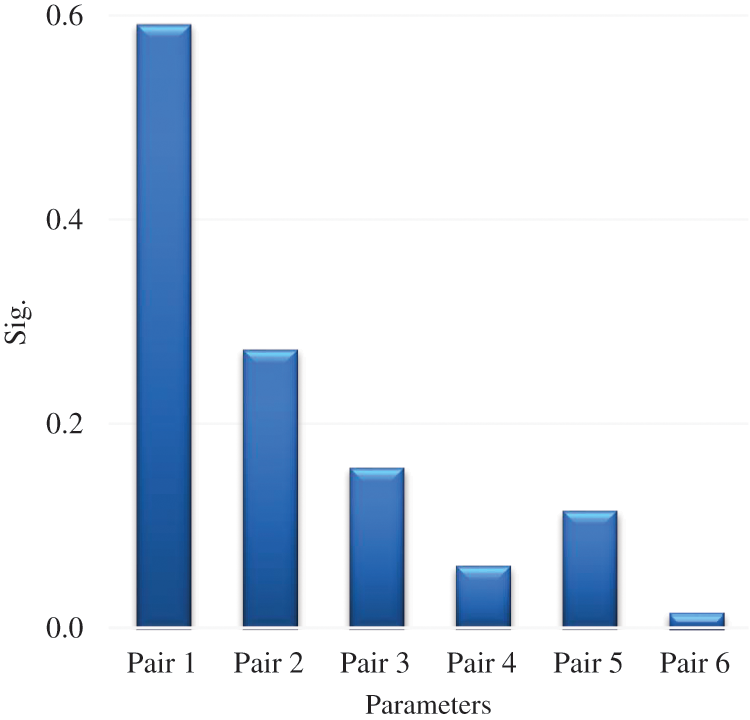

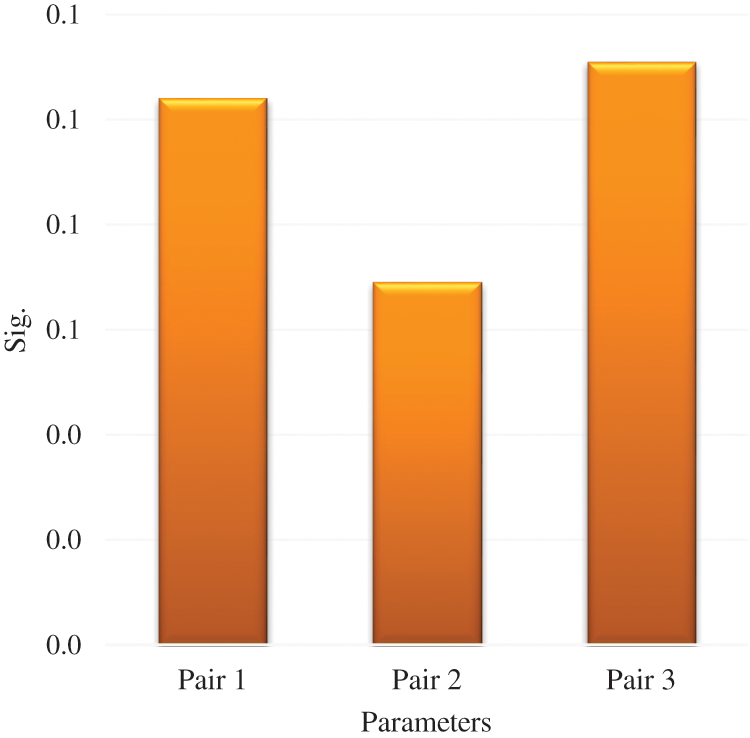

The significant difference of adding ED to engine performance is determined by the paired-sample t-test method, with the hypothesis result smaller than the significant 2-tailed, shown in Table 9. Tables 8, as well as Figs. 9 and 10 are the results of paired sample t-test. These results illustrate that only the torque significance in pair 6 has a biodiesel composition rate of +ED_0.07 gr as shown in Fig. 11.

Figure 9: SFC of paired differences of lower upper

Figure 10: Significance paired-samples t-test of power and torque engine

Figure 11: Significance paired-samples t-test of SFC

In conclusion, ED mixture in biodiesel fuel has a positive effect on improving engine performance as follows:

1. The maximum engine power fueled by pure biodiesel at 40.86 kW increased after biodiesel is mixed with ED, in percentages of 38.8%, 34.4%, and 35.5%, with a maximum engine power of 3500 rpm.

2. The maximum engine torque at 3000 rpm for pure biodiesel is 123.04 N.m with an increase in ED mixtures by 1.2%, 1.5%, 2.7%.

3. The most efficient specific fuel consumption at 2500 rpm using pure biodiesel was2.59 E−5 (kg/kW.s), decreasing 4%, 6%, and 1%, respectively.

4. The optimum engine performance at 3000 rpm, fueled by a mixture of 1 litter biodiesel with ED 0.04 gr, where the engine power, torque, and specific fuel consumption values are 43.30 (kW), 124.93 (N.m), and 2.45E−5 (kg/kW.s), respectively.

Engine performance testing was carried out by direct measurement using a dyno-meter and the paired-sample t-test method. The results obtained from the dyno-meter tend to increase power, torque, and SFC before and after using the ED. However, the difference in the engine performance of the three variables is only experienced in the torque, which has a significant increase in the composition of the biodiesel+ED by 0.07 gr mixture.

Acknowledgement: The authors are grateful to the team for their help and moral support in completing this research.

Funding Statement: The authors are also grateful to the Universitas Medan Area and the Haji Agus Salim Foundation for their financial assistance.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Xiao, H., Guo, F., Li, S., Wang, R., Yang, X. (2019). Combustion performance and emission characteristics of a diesel engine burning biodiesel blended with n-butanol. Fuel, 258(7), 1–7. DOI 10.1016/j.fuel.2019.115887. [Google Scholar] [CrossRef]

2. Aydin, H., Ilkiliç, C. (2010). Effect of ethanol blending with biodiesel on engine performance and exhaust emissions in a CI engine. Applied Thermal Engineering, 30(10), 1199–1204. DOI 10.1016/j.applthermaleng.2010.01.037. [Google Scholar] [CrossRef]

3. Finkin, E. (2019). Manufacturing progress: 1 Million heavy-duty diesel engines are good for. https://medium.com/diesel-direct/one-million-new-heavy-duty-diesel-engines-good-for-the-environment-and-u-s-economy-37a454c6d4ce. [Google Scholar]

4. Pawar, R., Patil, S., Jagadale, K., Gujar, P., Barade, V. (2021). An experimental investigation on performance, combustion, emission and vibration analysis of diesel engine fuelled with rice bran biodiesel and n-butanol additive. Journal of Engineering Research, 1, 1–16. DOI 10.36909/jer.13511. [Google Scholar] [CrossRef]

5. Mahlia, T. M. I., Syazmi, Z. A. H. S., Mofijura, M., Abas, A. E., Bilad, M. R. et al. (2020). Patent landscape review on biodiesel production: Technology updates. Renewable and Sustainable Energy Reviews, 118(16), 1–9. DOI 10.1016/j.rser.2019.109526. [Google Scholar] [CrossRef]

6. Mofijur, M., Atabani, A. E., Masjuki, H. H., Kalam, M. A., Masum, B. M. (2013). A study on the effects of promising edible and non-edible biodiesel feedstocks on engine performance and emissions production: A comparative evaluation. Renewable and Sustainable Energy Reviews, 23, 391–404. DOI 10.1016/j.rser.2013.03.009. [Google Scholar] [CrossRef]

7. Mofijur, M., Masjuki, H. H., Kalam, M. A., Atabani, A. E. (2013). Evaluation of biodiesel blending, engine performance and emissions characteristics of Jatropha curcas methyl ester: Malaysian perspective. Energy, 55, 879–887. DOI 10.1016/j.energy.2013.02.059. [Google Scholar] [CrossRef]

8. Temizer, İ., Cihan, Ö., Eskici, B. (2020). Numerical and experimental investigation of the effect of biodiesel/diesel fuel on combustion characteristics in CI engine. Fuel, 270(1), 1–9. DOI 10.1016/j.fuel.2020.117523. [Google Scholar] [CrossRef]

9. Zahan, K., Kano, M. (2018). Biodiesel production from palm oil, its by-products, and mill effluent: A review. Energies, 11(8), 1–25. DOI 10.3390/en11082132. [Google Scholar] [CrossRef]

10. Singh, D., Sharma, D., Soni, S. L., Sharma, S., Sharma, P. K. et al. (2020). A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel, 262, 116553. DOI 10.1016/j.fuel.2019.116553. [Google Scholar] [CrossRef]

11. Simsek, S. (2020). Effects of biodiesel obtained from Canola, sefflower oils and waste oils on the engine performance and exhaust emissions. Fuel, 265(12–15), 1–6. DOI 10.1016/j.fuel.2020.117026. [Google Scholar] [CrossRef]

12. Venkateswarlu, K., Murthy, B. S. R., Subbarao, V. V. (2012). An experimental investigation on performance, combustion and emission characteristics of diesel-biodiesel blends with isobutanol as an additive. SAE Technical Papers, 1, 1–9. DOI 10.4271/2012-28-0011. [Google Scholar] [CrossRef]

13. Goh, B. H. H., Ong, H. C., Cheah, M. Y., Chen, W. H., Yu, K. L. et al. (2019). Sustainability of direct biodiesel synthesis from microalgae biomass: A critical review. Renewable and Sustainable Energy Reviews, 107(Supplement C), 59–74. DOI 10.1016/j.rser.2019.02.012. [Google Scholar] [CrossRef]

14. Dey, S., Reang, N. M., Das, P. K., Deb, M. (2021). A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. Journal of Cleaner Production, 286(1), 1–26. DOI 10.1016/j.jclepro.2020.124981. [Google Scholar] [CrossRef]

15. Bhale, P. V., Deshpande, N., Thombre, S. B. (2009). Improving the low temperature properties of biodiesel fuel. Renewable Energy, 34(3), 794–800. DOI 10.1016/j.renene.2008.04.037. [Google Scholar] [CrossRef]

16. Liu, Y., Li, J., Jin, C. (2015). Fuel spray and combustion characteristics of butanol blends in a constant volume combustion chamber. Energy Conversion and Management, 105(5938), 1059–1069. DOI 10.1016/j.enconman.2015.08.047. [Google Scholar] [CrossRef]

17. John, C. B., Raja, S. A., Deepanraj, B., Ong, H. C. (2021). Palm stearin biodiesel: Preparation, characterization using spectrometric techniques and the assessment of fuel properties. Biomass Conversion and Biorefinery, 12(5), 1679–1693. DOI 10.1007/s13399-020-01265-0. [Google Scholar] [CrossRef]

18. Estevez, R., Aguado-Deblas, L., López-Tenllado, F. J., Luna, C., Calero, J. et al. (2022). Biodiesel is dead: Long life to advanced biofuels—A comprehensive critical review. Energies, 15, 1–39. [Google Scholar]

19. Abdollahi, M., Ghobadian, B., Najafi, G., Hoseini, S. S., Mofijur, M. et al. (2020). Impact of water–biodiesel–diesel nano-emulsion fuel on performance parameters and diesel engine emission. Fuel, 280(8), 1–10. DOI 10.1016/j.fuel.2020.118576. [Google Scholar] [CrossRef]

20. Dey, S., Reang, N. M., Deb, M., Das, P. K. (2021). Experimental investigation on combustion-performance-emission characteristics of nanoparticles added biodiesel blends and tribological behavior of contaminated lubricant in a diesel engine. Energy Conversion and Management, 244(6), 1–13. DOI 10.1016/j.enconman.2021.114508. [Google Scholar] [CrossRef]

21. Xiao, H., Guo, F., Wang, R., Yang, X., Li, S. et al. (2020). Combustion performance and emission characteristics of diesel engine fueled with iso-butanol/biodiesel blends. Fuel, 268(6), 1–8. DOI 10.1016/j.fuel.2020.117387. [Google Scholar] [CrossRef]

22. Wei, L., Cheung, C. S., Ning, Z. (2018). Effects of biodiesel-ethanol and biodiesel-butanol blends on the combustion, performance and emissions of a diesel engine. Energy, 155, 957–970. DOI 10.1016/j.energy.2018.05.049. [Google Scholar] [CrossRef]

23. Thangaraj, B., Solomon, P. R., Muniyandi, B., Ranganathan, S., Lin, L. (2019). Catalysis in biodiesel production–A review. Clean Energy, 3(1), 2–23. DOI 10.1093/ce/zky020. [Google Scholar] [CrossRef]

24. Bereczky, Á., Lukács, K., Farkas, M., Dóbé, S. (2014). Effect of γ-valerolactone blending on engine performance, combustion characteristics and exhaust emissions in a diesel engine. Natural Resources, 5(5), 177–191. DOI 10.4236/nr.2014.55017. [Google Scholar] [CrossRef]

25. Ong, H. C., Milano, J., Silitonga, A. S., Hassan, M. H., Shamsuddin, A. H. et al. (2019). Biodiesel production from Calophyllum inophyllum-Ceiba pentandra oil mixture: Optimization and characterization. Journal of Cleaner Production, 219, 183–198. DOI 10.1016/j.jclepro.2019.02.048. [Google Scholar] [CrossRef]

26. Calero, J., Luna, D., Luna, C., Bautista, F. M., Romero, A. A. et al. (2020). Optimization by response surface methodology of the reaction conditions in 1,3-selective transesterification of sunflower oil, by using CaO as heterogeneous catalyst. Molecular Catalysis, 484, 1–7. DOI 10.1016/j.mcat.2020.110804. [Google Scholar] [CrossRef]

27. Luna, C., Luna, D., Bautista, F. M., Calero, J., Romero, A. A. et al. (2018). Evaluation of lipases from wild microbial strains as biocatalysts in biodiesel production. Separations, 5(4), 1–13. DOI 10.3390/separations5040053. [Google Scholar] [CrossRef]

28. Hurtado, B., Posadillo, A., Luna, D., Bautista, F. M., Hidalgo, J. M. et al. (2019). Synthesis, performance and emission quality assessment of ecodiesel from castor oil in diesel/biofuel/alcohol triple blends in a diesel engine. Catalysts, 9(40), 1–21. DOI 10.3390/catal9010040. [Google Scholar] [CrossRef]

29. Hartanto, S., Ihsan, A. M., Yuliana, G. C. (2019). Pemanfaatan bioaditif serai wangi-etanol pada kendaraan roda dua berbahan bakar pertalite. Jurnal Teknik Mesin ITI, 3(2), 35–40. DOI 10.31543/jtm.v3i2.264. [Google Scholar] [CrossRef]

30. Gaur, A., Dwivedi, G., Baredar, P., Jain, S. (2022). Influence of blending additives in biodiesel on physiochemical properties, engine performance, and emission characteristics. Fuel, 321(1), 1–14. DOI 10.1016/j.fuel.2022.124072. [Google Scholar] [CrossRef]

31. Sekhar, S. C., Karuppasamy, K., Vedaraman, N., Kabeel, A. E., Sathyamurthy, R. et al. (2018). Biodiesel production process optimization from Pithecellobium dulce seed oil: Performance, combustion, and emission analysis on compression ignition engine fuelled with diesel/biodiesel blends. Energy Conversion and Management, 161, 141–154. DOI 10.1016/j.enconman.2018.01.074. [Google Scholar] [CrossRef]

32. Sharudin, H., Mat, S. C., Pahmi, M. A. A. H., Ismail, N. I., Salleh, M. F. M. et al. (2022). Effect of POME additive in algae-diesel fuel blends on fuel consumptions and emissions characteristics of a single diesel engine. Pertanika Journal of Science and Technology, 30(2), 1309–1326. DOI 10.47836/pjst. [Google Scholar] [CrossRef]

33. Yatish, K. V., Lalithamba, H. S., Suresh, R., Hebbar, H. R. H. (2018). Optimization of bauhinia variegata biodiesel production and its performance, combustion and emission study on diesel engine. Renewable Energy, 122, 561–575. DOI 10.1016/j.renene.2018.01.124. [Google Scholar] [CrossRef]

34. Singh, A., Sinha, S., Choudhary, A. K., Panchal, H., Elkelawy, M. et al. (2020). Optimization of performance and emission characteristics of CI engine fueled with Jatropha biodiesel produced using a heterogeneous catalyst (CaO). Fuel, 280, 118611. DOI 10.1016/j.fuel.2020.118611. [Google Scholar] [CrossRef]

35. Elkelawy, M., Bastawissi, H. A. E., Esmaeil, K. K., Radwan, A. M., Panchal, H. et al. (2020). Maximization of biodiesel production from sunflower and soybean oils and prediction of diesel engine performance and emission characteristics through response surface methodology. Fuel, 266(1), 1–17. DOI 10.1016/j.fuel.2020.117072. [Google Scholar] [CrossRef]

36. Sekhar, S. C., Karuppasamy, K., Sathyamurthy, R., Elkelawy, M., Bastawissi, H. A. E. D. et al. (2019). Emission analysis on compression ignition engine fueled with lower concentrations of Pithecellobium dulce biodiesel-diesel blends. Heat Transfer—Asian Research, 48(1), 254–269. DOI 10.1002/htj.21381. [Google Scholar] [CrossRef]

37. Reang, N. M., Dey, S., Debbarma, B., Deb, M., Debbarma, J. (2020). Experimental investigation on combustion, performance and emission analysis of 4-stroke single cylinder diesel engine fuelled with neem methyl ester-rice wine alcohol-diesel blend. Fuel, 271(1), 1–13. DOI 10.1016/j.fuel.2020.117602. [Google Scholar] [CrossRef]

38. Dey, S., Reang, N. M., Das, P. K., Deb, M. (2021). Comparative study using RSM and ANN modelling for performance-emission prediction of CI engine fuelled with bio-diesohol blends: A fuzzy optimization approach. Fuel, 292, 120356. DOI 10.1016/j.fuel.2021.120356. [Google Scholar] [CrossRef]

39. Dey, S., Deb, M., Das, P. K. (2019). Application of fuzzy-assisted grey Taguchi approach for engine parameters optimization on performance-emission of a CI engine. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 1, 1–17. DOI 10.1080/15567036.2019.1697392. [Google Scholar] [CrossRef]

40. Reang, N. M., Dey, S., Debbarma, J., Deb, M. (2022). Effect of linseed methyl ester and diethyl ether on the performance-emission analysis of a CI engine based on Taguchi-Fuzzy optimization. International Journal of Ambient Energy, 43(1), 471–485. DOI 10.1080/01430750.2019.1653969. [Google Scholar] [CrossRef]

41. Dey, S., Reang, N. M., Majumder, A., Deb, M., Das, P. K. (2020). A hybrid ANN-Fuzzy approach for optimization of engine operating parameters of a CI engine fueled with diesel-palm biodiesel-ethanol blend. Energy, 202, 1–17. DOI 10.1016/j.energy.2020.117813. [Google Scholar] [CrossRef]

42. Grimaldi, C. N., Millo, F. (2015). Internal combustion engine (ICE) fundamentals. In: Handbook of clean energy systems, vol. 1, pp. 1–32. DOI 10.1002/9781118991978.hces077. [Google Scholar] [CrossRef]

43. Montgomery, D. C., Runger, G. C. (2018). Applied statistics and probability for engineers, 7th Edition. USA: Wiley. [Google Scholar]

44. Tang, Z. C., Xia, Y., Xue, Q., Liu, J. (2018). A non-probabilistic solution for uncertainty and sensitivity analysis on techno-economic assessments of biodiesel production with interval uncertainties. Energies, 11(3), 1–17. DOI 10.3390/en11030588. [Google Scholar] [CrossRef]

45. Venu, H., Raju, V. D., Lingesan, S., Soudagar, M. E. M. (2021). Influence of Al2O3 nano additives in ternary fuel (diesel-biodiesel-ethanol) blends operated in a single cylinder diesel engine: Performance, combustion and emission characteristics. Energy, 266(2), 1–12. DOI 10.1016/j.energy.2020.119091. [Google Scholar] [CrossRef]

46. Sai, B. A. V. S. L., Subramaniapillai, N., Mohamed, M. S. B. K., Narayanan, A. (2020). Optimization of continuous biodiesel production from rubber seed oil (RSO) using calcined eggshells as heterogeneous catalyst. Journal of Environmental Chemical Engineering, 8(1), 1–17. [Google Scholar]

47. Scown, C. D., Baral, N. R., Yang, M., Vora, N., Huntington, T. (2021). Technoeconomic analysis for biofuels and bioproducts. Current Opinion in Biotechnology, 67, 58–64. DOI 10.1016/j.copbio.2021.01.002. [Google Scholar] [CrossRef]

48. Dinesha, P., Kumar, S., Rosen, M. A. (2021). Effects of particle size of cerium oxide nanoparticles on the combustion behavior and exhaust emissions of a diesel engine powered by biodiesel/diesel blend. Biofuel Research Journal, 8(2), 1374–1383. DOI 10.18331/BRJ2021.8.2.3. [Google Scholar] [CrossRef]

49. Yesilyurt, M., Yilbasi, K. Z., Aydin, M. (2020). The performance, emissions, and combustion characteristics of an unmodified diesel engine running on the ternary blends of pentanol/safflower oil biodiesel/diesel fuel. Journal of Thermal Analysis and Calorimetry, 140(6), 2903–2942. DOI 10.1007/s10973-020-09376-6. [Google Scholar] [CrossRef]

50. Rathinam, G. S., Sajin, J. B., Ganesan, S., Yuvarajan, D. (2018). Performance and emission study on the effect of oxygenated additive in neat biodiesel fueled diesel engine. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 41(16), 2017–2027. DOI 10.1080/15567036.2018.1549148. [Google Scholar] [CrossRef]

51. Santos, B. S., Capareda, S. C., Capunitan, J. A. (2013). Engine performance and exhaust emissions of peanut oil biodiesel. Journal of Sustainable Bioenergy Systems, 3(4), 272–286. DOI 10.4236/jsbs.2013.34037. [Google Scholar] [CrossRef]

52. Ileri, E., Karaoglan, A. D., Akpinar, S. (2020). Optimizing cetane improver concentration in biodiesel-diesel blend via grey wolf optimizer algorithm. Fuel, 273(139), 1–9. DOI 10.1016/j.fuel.2020.117784. [Google Scholar] [CrossRef]

53. Razzaq, L., Imran, S., Anwar, Z., Farooq, M., Abbas, M. M. et al. (2020). Maximising yield and engine efficiency using optimised waste cooking oil biodiesel. Energies, 13(22), 1–16. DOI 10.3390/en13225941. [Google Scholar] [CrossRef]

54. Ashok, B., Usman, K. M., Vignesh, R., Umar, U. A. (2022). Model-based injector control map development to improve CRDi engine performance and emissions for eucalyptus biofuel. Energy, 246(3), 1–16. DOI 10.1016/j.energy.2022.123355. [Google Scholar] [CrossRef]

55. Simsek, S., Uslu, S., Simsek, H., Uslu, G. (2021). Multi-objective-optimization of process parameters of diesel engine fueled with biodiesel/2-ethylhexyl nitrate by using Taguchi method. Energy, 231, 1–10. DOI 10.1016/j.energy.2021.120866. [Google Scholar] [CrossRef]

56. Kasaby, M. E., Nemit, M. A. (2013). Experimental investigations of ignition delay period and performance of a diesel engine operated with Jatropha oil biodiesel. Alexandria Engineering Journal, 52(2), 141–149. DOI 10.1016/j.aej.2012.12.006. [Google Scholar] [CrossRef]

57. Qi, D. H., Chen, H., Geng, L. M., Bian, Y. Z. (2010). Experimental studies on the combustion characteristics and performance of a direct injection engine fueled with biodiesel/diesel blends. Energy Conversion and Management, 51(12), 2985–2992. DOI 10.1016/j.enconman.2010.06.042. [Google Scholar] [CrossRef]

58. Li, R., Wang, Z., Ni, P., Zhao, Y., Li, M. et al. (2014). Effects of cetane number improvers on the performance of diesel engine fuelled with methanol/biodiesel blend. Fuel, 128, 180–187. DOI 10.1016/j.fuel.2014.03.011. [Google Scholar] [CrossRef]

59. Paneerselvam, P., Venkadesan, G., Panithasan, M. S., Alaganathan, G., Wierzbicki, S. et al. (2021). Evaluating the influence of cetane improver additives on the outcomes of a diesel engine characteristics fueled with peppermint oil diesel blend. Energies, 14(10), 1–15. DOI 10.3390/en14102786. [Google Scholar] [CrossRef]

60. Chauhan, B. S., Kumar, N., Cho, H. M. (2012). A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy, 37(1), 616–622. DOI 10.1016/j.energy.2011.10.043. [Google Scholar] [CrossRef]

61. Rao, P. V., Chary, D. P. (2018). Characteristics comparison of biodiesel-diesel blend (B20) fuel with alcohol additives. International Journal of Advanced Engineering Research and Science, 5(8), 128–132. DOI 10.22161/ijaers.5.8.17. [Google Scholar] [CrossRef]

62. Miron, L., Chiriac, R., Brabec, M., Bădescu, V. (2021). Ignition delay and its influence on the performance of a Diesel engine operating with different Diesel-biodiesel fuels. Energy Reports, 7(7), 5483–5494. DOI 10.1016/j.egyr.2021.08.123. [Google Scholar] [CrossRef]

63. Pham, P. X., Pham, N. V. T., Pham, T., Nguyen, V. H., Nguyen, K. T. (2021). Ignition delays of biodiesel-diesel blends: Investigations into the role of physical and chemical processes. Fuel, 303(1), 1–13. DOI 10.1016/j.fuel.2021.121251. [Google Scholar] [CrossRef]

64. Pachiannan, T., Zhong, W., Xuan, T., Li, B., He, Z. et al. (2019). Simultaneous study on spray liquid length, ignition and combustion characteristics of diesel and hydrogenated catalytic biodiesel in a constant volume combustion chamber. Renewable Energy, 140, 761–771. DOI 10.1016/j.renene.2019.03.063. [Google Scholar] [CrossRef]

65. Kumbhar, V. S., Pandey, A., Varghese, A., Patil, V. (2021). Comparative assessment of performance, combustion, and emission of compression ignition engine fuelled with different generations of biodiesel. International Journal of Sustainable Engineering, 14(6), 2082–2096. DOI 10.1080/19397038.2021.1943043. [Google Scholar] [CrossRef]

66. Yaqoob, H., Teoh, Y. H., Sher, F., Farooq, M. U., Jamil, M. A. et al. (2021). Potential of waste cooking oil biodiesel as renewable fuel in combustion engines: A review. Energies, 14(9), 1–20. DOI 10.3390/en14092565. [Google Scholar] [CrossRef]

67. Mujtaba, M. A., Kalam, M. A., Masjuki, H. H., Razzaq, L., Khan, H. M. et al. (2021). Development of empirical correlations for density and viscosity estimation of ternary biodiesel blends. Renewable Energy, 179(1), 1447–1457. DOI 10.1016/j.renene.2021.07.121. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools