Open Access

Open Access

ARTICLE

Exploring Win-Wins from Trade-Offs? Co-Benefits of Coalbed Methane Utilization for the Environment, Economy and Safety

1 Center for Sustainable Development and Energy Policy Research, School of Energy and Mining Engineering, China University of Mining and Technology-Beijing, Beijing, 100083, China

2 Beijing Key Laboratory for Precise Mining of Intergrown Energy and Resources, China University of Mining and Technology-Beijing, Beijing, 100083, China

* Corresponding Author: Bing Wang. Email:

(This article belongs to the Special Issue: Innovative Energy Systems Management under the Goals of Carbon Peaking and Carbon Neutrality)

Energy Engineering 2022, 119(6), 2469-2487. https://doi.org/10.32604/ee.2022.021171

Received 30 December 2021; Accepted 08 April 2022; Issue published 14 September 2022

Abstract

With policy incentives for the coalbed methane in energy industry, coalbed methane from coal production has been effectively improved by technology innovations in coalbed methane extraction and utilization. The progress of coalbed methane promotes the clean construction of energy system and contributes to carbon neutrality target. To quantitatively measure the contributions of the coalbed methane in energy industry, this paper builds a carbon emissions accounting system for coalbed methane in China and assesses the historical co-benefits of coalbed methane utilization from the aspects of emissions reduction, safety and economy. By using the parameters of gas content, raw coal production, gas extraction rate and utilization rate over the years, emissions reduction potential and economic viability of coal seam gas are estimated and the safety benefits of coal mine gas extraction are analyzed by using data for gas accidents and economic losses. The results reveal that with the increase in raw coal production, the great emission reduction potential of coalbed methane is expected to benefit clean energy system and the development of carbon neutrality by means of policy incentives and technology innovations. The co-benefit evaluation indicates the huge profitability of coalbed methane from 2012 to 2015 and the significance of emissions reduction and safety gain internalization. Safety benefits are obvious in the negative exponential function between the annual drainage quantities of coalbed methane and annual death tolls from coal mine gas accidents. Based on these results, relevant suggestions are put forward for sustainable development of the coalbed methane in energy industry.Keywords

Natural gas will become an essential part of China’s clean energy system on the road to carbon neutrality. According to opinions on accelerating the utilization of natural gas for energy diversification, the proportion of natural gas in the primary energy consumption structure will reach at least 10% by 2020, and approximately 15% in 2030 [1]. As a relatively low-carbon energy source, natural gas produces less carbon dioxide than other fossil fuels during combustion, and results in reduced greenhouse effects [2]. However, with increasing demand and insufficient natural gas reserves, China’s dependence on foreign natural gas is also increasing rapidly from being a net importer in 2006 to an external dependence degree of 44.5% in 2018 [3]. It is therefore vital to develop the Chinese domestic natural gas supply to ensure the security of China and its natural gas supply.

Coalbed methane (CBM) can be used as a supplement to conventional natural gas to address the high external dependence on natural gas, and also helps to realize the sustainable energy development in China [4,5]. According to the resource assessment report in China, the geological reserves of conventional natural gas are 90 trillion m3, and recoverable reserves are 50 trillion m3, while the geological reserves of CBM buried at a depth of 2,000 meters in the ground are 30 trillion m3 with recoverable reserves of 12.5 trillion m3 [6]. In 2019, China’s natural gas output was 176.17 billion m3 and its foreign trade dependency of approximately 43.4% exhibited a slight decline for the first time [3]. The production of unconventional natural gas increased significantly and shale gas production became a major source that contributed to this decline, which was subsequently followed by the contributions derived from CBM production. There is no doubt that the development of unconventional natural gas sources will be an important policy direction for natural gas security in China.

CBM not only fills the gap between natural gas supply and demand, but also brings social benefits from carbon emissions reduction and coal mine safety. CBM is a typical greenhouse gas whose main component is methane (CH4) with strong greenhouse effects [7]. The caloric value of CH4 per cubic meter is equivalent to 1.21 kg of standard coal and its combustion power, combined with its lower carbon dioxide emissions is more environmentally friendly than other fossil fuels [8]. Hong et al. [9] found that a cost-effectiveness greater than approximately about 0.04 USD/kWh could be achieved by utilizing CBM in China, and could address the environmental burden posed by coal-fired power generation. The past fifteen years have seen increasingly rapid advances in CBM development in the Fuxin coal basin with a total cumulative CBM supply of 215 million m3 with an output value of nearly 967.5 million CHY. This project can supply 20 million m3 of CBM every year and meet the needs of one-third of the residents and 4,000 taxis in Fuxin [10]. Dong et al. [11] found that 54.5 million m3 of gas drainage could be used based on a 60% utilization rate and reduce 57.6% of the greenhouse effect compared with direct emissions. Furthermore, coal mine gas is still one of the main hazards to coal mine safety. Casualties and economic losses caused by gas accidents account for a high proportion of coal mine accidents. Therefore, it is necessary to extract CBM prior to mining activities for mine safety and for postmining management. When coal mine gas during coal production is reduced by 70%–85%, the frequency of major accidents caused by gas during coal mining can be reduced as well [12].

The government has set goals for CBM exploitation through supportive policies [13]. During the 12th Five-Year Plan, many policies including tax breaks, subsidies, and waivers on imported equipment, have been implemented for CBM development. The subsidy policy has been strengthened for the CBM industry, with standard price subsidies of 0.2 CHY/m3 in 2007 to 0.3 CHY/m3 in 2016. The State Council has also published several opinions on promoting the coordinated and stable development of natural gas plans, and has facilitated incentives for unconventional natural gas development during the period of the 14th Five-Year Plan [14]. These facts reveal that the national development plan for the CBM industry continues to take firm steps to improve its economic viability and realize its sustainable development.

However, the development of the CBM industry has not reached the expected prosperity quite yet. Although the extraction volume of CBM continues to increase yearly, the yields in 2010 and 2015 were 9.1 and 18 billion m3, respectively, which were less than the planned development goals [15]. In the 13th Five-Year Plan for the development and utilization of CBM (coal mine gas), China has reduced the previous planning goal of 24 billion m3 of extraction by 2020, including 10 billion m3 of surface CBM production. It will be a difficult task for a 12.6% increase in CBM utilization in 2020 to achieve the 13th Five-Year Plan target. This shows that the current investments in the CBM industry and national policy support are not sufficient and more funds should be allocated. Therefore, apart from the income generated by CBM innovations, the other benefits of CBM development should be evaluated to reflect their potential for improving CBM profitability.

Previous studies of the benefits of CBM have been conducted with a rough framework. According to the economic, social and environmental externalities of coal mine gas, a model is established to evaluate the comprehensive benefits of coal mine gas development and utilization [16]. Gao [17] quantitatively assessed the industrial investment benefit and safety benefit to reflect the development value of CBM and finally obtained the value of CBM development benefits. Even though these benefits assessments have been conducted for CBM development, a systematic evaluation of CBM emission reduction benefits (RB), safety benefits (SB), and economic benefits (EB) remains essential for tracking the development trend of CBM benefits from the macro perspective. Traditionally, these co-benefits have not been fully included in the decision-making processes for sustainable management of the CBM industry [18,19]. The first step towards greenhouse gas (GHG) reduction is to establish a practical estimate framework [20]. Therefore, calculations of coal mine methane emissions are employed in this research to evaluate the emissions reduction potential of CBM, and a comprehensive CBM benefit accounting system is established to evaluate the co-benefits of the CBM industry. Based on the above, this paper attempts to address the following questions:

1. What is the total amount of CBM that escaped from Chinese coal mines in China from 2005 to 2018? How can we assess the emissions reduction potential of CBM in the near future?

2. What are the main factors affecting emission reduction benefits, economic benefits, and the safety benefits of CBM generally speaking? What are the emission reduction benefits, economic benefits, and safety benefits of CBM in China?

3. What are the trends of comprehensive benefits and sustainable development prospects of CBM in China for 2050?

The co-benefits of CBM development should be evaluated to highlight the importance of the CBM industry. The next section will introduce models for estimating CBM emissions and calculation methods for benefit assessments. Policy scenarios are also designed in Section 2 to test the future contributions of CBM development. Section 3 discusses the evaluation results and analyzes the scenarios for 2050. Conclusions and policy suggestions are described in Section 4.

2.1 Research Framework for Co-Benefits Assessment of CBM Utilization

The comprehensive benefits of CBM utilization are evaluated from a macro perspective. The research framework is shown in Fig. 1. CBM plays a significant role in different circumstances. As a greenhouse gas source, it could aggravate the greenhouse effect, but as an unconventional natural gas, it could become a supplementary energy source for the natural gas supply [21]. Additionally, coal mine gas is a major cause of coal mine accidents which threaten the safety of coal mine workers and their production. Therefore, only by pumping and utilizing CBM can it play a positive role in society. This research builds an integrated accounting model to calculate the emission reduction benefits, economic benefits, and safety benefits of CBM from 2005 to 2018 and forecasts the sustainable development prospects of CBM through scenario analysis.

Figure 1: Research framework of this research

2.2 Fugitive Emission Estimations for Coalbed Methane

In the process of coal exploitation, large amounts of fugitive CBM emissions come from coal seams. CBM emissions can be contained in open mining processes, underground mining processes, and even in washing, transportation and crushing processes before coal combustion. Therefore, large quantities of CBM emissions are released and become a second source of global greenhouse gas emissions [22]. Therefore, CH4 emissions caused by coal mining have attracted worldwide attention and many scholars have conducted estimates by using different models. Maasakkers et al. [23] used detailed emission information and combined this with the Tier 2 and Tier 3 methods of the Intergovernmental Panel on Climate Change (IPCC) to prepare an anthropogenic CH4 emissions list for the U.S. Wang et al. [24] established the output emission regression function model to obtain the gas emission coefficients of different types of mines in China and calculated province-level CH4 emission factors (EFs). Estimation methods of CH4 emissions from many coal mines were introduced. It is an inaccurate estimation process if the coal production process is used to estimate the amount of CBM emissions or if the actual measurement parameters of a specific coal mine are used. Therefore, this research compares and analyzes the coal mine methane emission inventory by literature review and establishes an estimation method for CBM emissions.

The estimation method is a portfolio combination of the IPCC method and coal seam gas content by employing the values of raw coal outputs and CH4 emission flows. Total CH4 emissions from coal mines include the direct fugitive emissions of CBM, fugitive emissions of gas drainage, and utilization quantities of gas drainage [25]. CH4 emissions were calculated by formulas (1) to (3).

M: Raw coal outputs by t/year

EF: Emission factor by m3/t

R: Unit conversion factor by 0.67E-9 Tg per m3

The main parameter is the regional emission factor of CBM for different coal seams. According to research on regional EFs of Wang et al. [26] and Zhu et al. [27], coal mines are divided into three categories: low CH4 content mines, high CH4 content mines and outburst CH4 content mines. These three types have different CBM emission coefficients and are calculated by the formula (4).

REIF: Regional CBM emission intensity factors by m3/t

n: n types of coal mines by

M: Total coal production by t/year

According to a comparative analysis, it was found that the measured CH4 emissions of 798, 787 and 10,000 coal mines were used in the analysis of coal mine methane emissions and these mines were distributed in the major coal-producing provinces of China. The data of the Chinese State Administration of Coal Mine Safety database are usually regarded as a consistent data source to minimize uncertainty in EFs data. Based on the detailed monitoring data of CH4 emissions from coal mines in 2010 and 2011, the actual data from 2010 in the study of Zhu et al. [27] and the predicted data for 2011 were compared with those from Wang et al. [26]. According to the comparative analysis of three studies, the province-level CBM CH4 EFs are shown in Fig. 2.

Figure 2: Comparison of province-level CH4 EFs for 24 major coal-producing provinces

As shown in Fig. 2, the study of Sheng et al. [28] provided a much wider range of CH4 EFs for coal mines than had been previously obtained. The results of Wang et al. [26] and Zhu et al. [27] showed that the EFs of three provinces (Beijing, Anhui, and Chongqing) were greater than the highest CH4 EFs of Sheng et al. [28] and the EFs of some provinces (e.g., Beijing, Fujian, Inner Mongolia, Guangxi, Shandong, and Gansu) were smaller than the lowest CH4 EFs of Sheng et al. [28]. Therefore, some high EFs in the research of Sheng et al. [28] were replaced by the results of Wang et al. [26] and Zhu et al. [27]. Province-level CH4 EFs were calculated by formula (4) and the EF was kept unchanged. By using formula (3), the CH4 emissions from coal mines can be calculated.

2.3 Integrated Evaluation for Co-Benefits of CBM Development

2.3.1 Emission Reduction Benefits from CBM Utilization

It is obvious that the development of unconventional natural gas can guarantee the benefits of greenhouse gas emission reductions and play an important role in coping with climate change [29]. CBM development can reduce direct fugitive emissions of CBM into the atmosphere which is conducive to reducing air pollution and achieving environmental protection [30,31]. In this research, the emission reduction benefit of CBM refers to the economic value that can be achieved by carbon trading of CBM in the carbon market. CBM includes surface and underground drainage gas. The drained gas concentrations at the surface are generally more than 90%, and those underground are approximately 5%−30% with large fluctuations [32]. To simplify the calculation process, the concentration of surface drainage gas was set at 90% and the concentration of underground drainage gas was set to 30%. Additionally, the average carbon trading price in 2018 was 22.43 CHY/t. Finally, these parameters were input to formula (5) to calculate the emission reduction benefits of CBM utilization in China from 2005 to 2018.

RB: Emission reduction benefits of CBM utilization

C: Drained gas concentrations at the surface are 90%, and those underground are 30%

F: Global warming potential of CH4 by 21–34 tons Carbon Dioxide Equivalent (CO2e)

2.3.2 Measurement of Economic Benefits of CBM

Although the proportion of CBM production in the present natural gas market is still small, CBM production and utilization are increasing each year with the support of government policies. The economic benefits of CBM continue to gradually improve and this study analyzes the economic benefits of CBM development from the perspective of market economic value. The economic benefit of CBM is the economic value generated by selling CBM in the natural gas market. The market price of CBM includes the civil price and automobile fuel price; the prices of CBM in different areas vary greatly due to provincial support policies. This research chose the price in Shanxi province due to the large utilization scale of CBM in Shanxi Province. In recent years, the lowest selling price of CBM was 2.30 CHY/m3 and the highest price was 3.40 CHY/m3 in Shanxi. By using formula (6), the economic benefits of CBM in China from 2005 to 2018 can be calculated

EB: Economic benefits of CBM utilization

2.3.3 Safety Benefits Assessment of CBM

Coal mine gas is one of the main hazards in coal mine safety [33]. Methane-related accidents often cause serious casualties and economic losses [34]. Therefore, it is beneficial to reduce gas accidents, guarantee the safety of mining processes and improve the safety benefits of the mine to extract gas before mining [35,36]. Drainage of coal mine gas brings safety benefits to coal mine production [37]. This study analyzes the relationship between the death toll of gas accidents, the quantity of gas drainage, and the loss of personnel caused by gas accidents, and evaluates the relative safety benefits. Safety benefit is the contribution of a quantity of gas drainage to coal mine safety to avoid economic losses from gas accidents and is measured by the death tolls from gas accidents, per capita death compensations, and by the direct fugitive emissions of CBM. Years 2003 and 2004 were set as the base years and the difference between the death compensation per unit of fugitive gas emissions in the base year and target year represents the safety benefit of CBM drainage. Finally, the safety benefit was obtained by multiplying the quantity of drainage and safety benefit of the unit drainage, as is shown in formulas (7) to (10).

SB: Safety benefits of CBM utilization

y: Death tolls of gas accident

D: Drainage quantities of CBM by m3

According to the target of energy structure adjustment and CBM development in China, the co-benefits and development situation of CBM utilization were analyzed. A low utilization rate (pessimistic) scenario, medium utilization rate (benchmark) scenario, and high utilization rate (optimistic) scenario of CBM were defined to predict the CBM development trend in China. Specific definitions of the three scenarios are described as follows:

(1) Low utilization rate (pessimistic) scenario: According to the current development trend of comprehensive CBM benefits, no measures are taken to control CBM utilization. The general development parameters mainly refer to the utilization and market value of CBM in the most recent 10 years in China.

(2) Medium utilization rate (benchmark) scenario: This scenario considers the impact of environmental change and measures that are taken to cause CBM development in China to extend beyond the planning goals. For example, the goals are from the 13th Five-Year Plan target for CBM development and utilization, as well as certain energy structure optimization policies to promote CBM development and utilization in China.

(3) High utilization rate (optimistic) scenario: Under the premise of achieving the CBM development goal in China, the government further pursues a high-efficiency development mode for CBM to facilitate co-benefits and investment in the research and development of CBM technology and other incentives.

The CBM utilization rates under the above three scenarios are shown in Table 1. The growth rate of CBM utilization under the pessimistic scenario is based on the growth trend from 2010 to 2018. The settings of the benchmark scenario comes from planning goals related to CBM. Additionally, the optimistic scenario is generally designed to be 5% higher than the goals of the benchmark path. The benchmark drainage rates of CBM in China are set to 67.6% in 2020, 80% in 2030, and 90% in 2050. According to the trend of the proportion of surface CBM production and underground CBM production over the years, the proportion of underground CBM production to total CBM production is set to 60.2% in 2020, 39% in 2030, and just 3.21% in 2050. It is assumed that the drainage rates and specific gravity parameters in the pessimistic scenario are 90% of the baseline scenario, and those for the optimistic prediction are 110% of the baseline scenario.

Moreover, the main parameters that determine high CBM utilization rates in the future are coal production, average EFs (8.95 m3/t), CBM market price, and carbon price. These parameters were taken from the 13th Five-Year Plan for the development of the coal industry, China’s medium- and long-term coals for 2030, prediction of coal production in 2050 development strategy research, and China’s carbon price survey report in 2019. Predictions of China’s CBM prices are also Europe’s natural gas prices in 2019. In addition, the per capita death compensation for gas accident deaths in 2020 was set to 181,000 CHY and this compensation will double every ten years. The number of gas accident deaths is determined by the extraction volume in 2020 and will be approximately zero due to intelligent mining. Finally, the pessimistic forecast is 90% of the benchmark while the optimistic forecast is 110% of the benchmark; the benchmark scenario is shown in Table 2.

In this study, raw coal output by region and death compensations for coal mine accidents from 2005 to 2018 were sourced and assessed from the China energy statistical yearbook 2010–2018. Death compensations were 20 times the disposable income of urban residents, as shown in Table A. 1 [38]. CBM extraction and utilization levels from 2000 to 2018 were collected from the official website of the National Bureau of Statistics and the 13th Five-Year Plan for CBM (coal mine gas) development and utilization. The numbers of coal mine accidents and deaths were obtained from the websites of the national and provincial coal mine safety production supervision bureaus and relevant literature.

3.1 Estimation of Fugitive Emissions Results

Province-level CH4 EFs of coal mining in 25 major coal-producing provinces were calculated, and the results are shown in Fig. 3. Total CH4 emissions from coal mines were calculated from province-level CH4 EFs and provincial raw coal production of 2005–2018, as shown in formula (1).

Figure 3: Province-level CH4 EFs for CBM emissions

The total CBM emissions from coal mines are shown in Fig. 4. Fig. 4 shows that total CH4 emissions from coal mines in China have significantly increased yearly and reached a maximum of 19.3 million tons in 2012 and then declined slightly to 12.5 million tons in 2018. This trend was largely affected by changes in raw coal production in China for the highest coal production in 2012. With the increased proportion of extraction and utilization of CBM in China, the proportion of fugitive emissions continues to decrease each year. However, although the total amount of gas drainage has increased each year, the utilization rate was at a lower level and the CBM utilization rate just exceeded 50% in 2016 which led to higher total CH4 emissions from coal mines. At the same time, the large quantities of direct fugitive CBM emissions reflect the great emissions reduction potential in the development and utilization of CBM in China. While coal will occupy the first energy position in China for a long period to come, we predict very high levels of carbon emissions caused by CH4 will be released from coal mines in the future as well [39]. It is also necessary to adhere to the development and utilization of CBM in the future and reduce coal mine methane emissions.

Figure 4: Total CH4 emissions from coal mining activities in 2005–2018

3.2 Estimation of Benefits Results

3.2.1 Results of Greenhouse Gas Emission Reduction Benefits

Bu using the results from Section 3.1, this section calculates the emission reduction benefits generated by CBM utilization in China from 2005 to 2018 and the development trend of emission reduction benefits due to CBM over the years as shown in Fig. 5a. The range of global warming potentials of CH4 can reflect the range of CBM emission reduction benefits. Due to the updating of the global warming potential of CH4 data by the IPCC and other data sources, the possible range of emission reduction benefits is calculated to reflect the monetary value of CBM utilization in the carbon trading market.

Figure 5: Co-benefits of CBM utilization from 2005 to 2018

Note: The CB, RB, EB, and SB are the abbreviations of comprehensive benefits, emission reduction benefits, economic performance, and safety benefits, respectively.

3.2.2 Results of Economic Benefits

The scope and development trend of the economic benefits of CBM are shown in Fig. 5b. The economic benefit interval in the figure continues to increase each year at a relatively gentle pace. The greater the utilization amount, the greater the economic benefit of CBM. As mentioned in Section 3.2.1, after 2015, CBM utilization has not maintained the growth rate of previous years and has slowed significantly. The reason may be rooted in a lack of national incentives and that the CBM industry in some regions is not competitive in terms of commercial and traditional gas prices [40,41]. As a result, the CBM industry has not actively produced and utilized CBM. However, the findings of Marcos-Martinez et al. [42] show that household incomes in areas with coal seam gas activity are higher than those in areas without coal seam gas mining. It is important for local governments to develop the CBM industry due to its considerable profits. In 2012, and 2015, clear increases in economic benefits amounted to 12–17.7 billion CHY and 19.8–29.2 billion CHY, respectively, with an increase of 65% over three years. After 2015, the growth rate of economic benefits fell due to the uncertainty of the state’s subsidy policies. CBM has gradually been established in the natural gas market and its cumulative output value has reached tens of billions. Therefore, with the gradual improvement of the industrial chain of CBM, its economic benefits can be achieved by the effects of scale.

3.2.3 Results of Safety Benefits

Coal mine safety has always been a focal point for all interested parties in the coal mining industry, and remains a major issue for coal mine operations. With more attention being paid to safety issues, measures such as safety investment, supervision and emergency response capacity have been implemented and the national coal mine safety situation has gradually improved too. Since 2002, it has shown a decreasing trend in terms of the numbers of coal mine accidents and numbers of gas accidents. However, before 2008, the numbers of coal mine gas accidents accounted for no less than 10% of the number of coal mine accidents and the death toll from gas accidents accounted for no less than 25% of the death toll from all coal mine accidents. It is meaningful therefore, to explore whether coal mine gas drainage can contribute to greater coal mine safety [43].

Curve fitting was conducted to examine the death tolls from gas accidents and gas drainage quantities from 2000 to 2015. A linear model, quadratic model, and index model were used in SPSS25.0 software. The best-fitting model was selected to show the relationship between death tolls from gas accidents and gas drainage quantities. When comparing the curve fitting results shown in Table A. 2 and Fig. 6, it was found that the goodness of fit of the exponential model was highest at 0.950.

Figure 6: Gas drainage quantities and death tolls from gas accidents from 2000 to 2015

Death tolls from gas accidents over the years were calculated by the formula in Fig. 6 and were used to calculate the safety benefits of CBM drainage with the quantity of gas drainage. The safety benefits from the pre-drainage of CBM are shown in Fig. 5c. This figure clearly reveals that the safety benefits of coal mines from CBM drainage before 2015 were increasing compared with the reference year of 2003–2004. The first decline in safety benefits took place in 2016 and increased again in 2018. The highest value of 405.06 million CHY was reached in 2015. Before 2015, the CBM drainage rate was the main parameter for determining the safety benefits of CBM. After 2015, drainage rate is only a secondary parameter and is followed by compensation. The reason is that CBM drainage rates after 2015 were able to maintain coal mine gas concentrations within a safe mining range. As long as the CBM drainage rate exceeds the 55.9% value for 2015, the probability of gas accidents will be very low. When the influence of drainage parameters gradually exceeds the drainage rate parameters, a decreasing trend for safety benefits will occur and begin to show an increasing trend again. For example, if an extra 3.683 billion m3 had been extracted in 2015, the drainage volume would have played a major role regarding safety benefits in 2015.

3.3 Scenario Analysis for Future Trends of Co-Benefits of CBM

Based on the CBM utilization rates under the three scenarios, the development prospects of CBM in 2020, 2030, and 2050 are analyzed and the final forecast results are shown in Fig. 7. It is evident that the economic benefits of CBM exhibit a rapid increase due to increased CBM market prices. The increased production capacity of CBM can promote its market competitiveness which will profoundly affect the natural gas market in the future. Similarly, with the maturity of China’s carbon trading market and increased CBM production capacity, the emission reduction benefits of CBM will also increase even though the growth rate is lower than that of economic benefits.

Figure 7: Scenario results of CBM co-benefits predictions

The safety benefits of CBM drainage for coal mine operations have low growth rates and are lower than for other benefits. The safety benefit is measured here as a relative benefit value compared to the benchmark year of 2002 and is determined by the death compensation and CBM extraction parameters. However, with the gradual realization of complete mechanization and intelligence in coal mining activities, the coal mining industry is expected to achieve zero or near-zero casualties. If zero deaths are achieved in 2050, the safety benefit of the baseline scenario in 2050 is expected to be 806.5 million CHY. At this time, the relative benefit is entirely determined by the level of CBM extraction. The safety benefits will remain at a stable level when coal mine gas concentrations due to increased CBM drainage are still lower than the upper-limit concentrations for safe production.

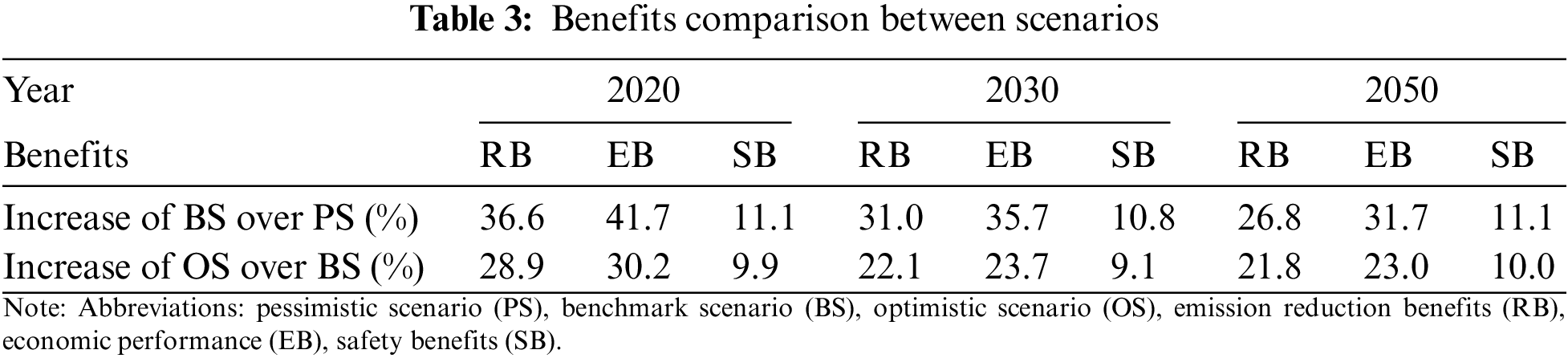

The three dimensions of co-benefits in the three scenarios are compared in Table 3. In 2020, the three kinds of benefits in the pessimistic scenario are lower than those of the benchmark scenario by more than 10%. This fact demonstrates that CBM development in China is highly dependent on development investment and policy support contained in the planning. To achieve the benchmark scenario in 2020, strong intervention is needed. If we want to achieve the optimistic scenario in 2050, the CBM industry not only requires policy and financial support but also should overcome technical restrictions on CBM exploitation and utilization.

4 Conclusions and Policy Implications

Fully understanding the broad and specific advantages and benefits of coalbed methane development is of great importance regarding the implementation of proper policy support for it, while offsetting the high cost of coalbed methane utilization at the same time. This research investigates the environmental, economic, and safety benefits of China’s coalbed methane industry from 2005 to 2018 and forecasts future trends by scenario analysis. Based on the modeling results, the following conclusions were determined:

(1) High outputs of raw coal and low utilization rates of CBM in China lead to high CH4 emissions in coal mines. The large amounts of coal mine methane emissions demonstrate the emissions reduction potential of China’s CBM development and utilization. Under the prospect that coal will be the primary energy source for a long period, total CH4 emissions from coal mines will also be an increasingly valuable source for greenhouse gas emission reductions. The estimated historical CBM emissions also indicate that the CBM utilization rate cannot catch up with that of fugitive CBM emissions. Scenario analysis suggests that there are many challenges to the control and utilization of these fugitive emissions in the future. To reduce emissions, it is necessary to strengthen innovations in CBM extraction and utilization and improve the CBM utilization rate to facilitate the profitability of the CBM industry.

(2) Economic benefits have occupied a major part of CBM co-benefits and there was rapid growth in CBM co-benefits from 2013 to 2015 due to the implementation of a CBM industrial development policy in 2013. Therefore, the co-benefits results confirmed the development of the CBM industry. From the monetary analysis of co-benefits, it can be seen that the co-benefits of CBM are fluctuating and rising. These fluctuations have occurred because the productivity and utilization rate of CBM are both limited by technology, capital, and markets. Only when the CBM production capacity increases and the market competitiveness of the CBM industry strengthens itself can CBM subsidies be reduced. When the price of CBM approaches the market value, the industry could achieve success in CBM industrialization.

(3) Coal mine gas prevention and control measures have contributed greatly to safeguarding coal mine operations and avoiding negative impacts. There is a negative relationship between the death tolls from gas accidents and gas drainage quantities which shows that CBM drainage effectively maintains the safety of coal mine production. CBM drainage rates and drainage quantities are the main parameters that determine the safety benefits of CBM before 2015 and after 2015, respectively. When the methane concentrations in coal seams decrease and can maintain a state of low gas levels in coal mines, changes in the decisive factors of safety benefits lead to a trend of a decreasing benefit curve and rising again. As long as the CBM drainage rate is not below that of 2015, the probability of gas accidents will be very low. Moreover, only direct personnel losses are considered in this study. If other property losses from coal mine and mining accidents are evaluated, the safety benefit from CBM will be much higher and more valuable.

(4) The CBM industry is expected to prosper in the future due to the stable support and earnings from safety and emissions reduction. This can be seen from the scenario prediction results that the growth rate of the economic benefit of CBM is the most rapid and is followed by the growth rate of emission reduction benefits and safety benefits. The CBM development goals were not sufficiently achieved in 2020 and should be emphasized by facilitating policy support and capital investment. CBM enterprises and coal enterprises should work together to actively participate in clean development mechanisms and shoulder the burden of sharing the co-benefits of CBM. There is still a gap of more than 10% in the co-benefits between the planned benchmark scenario and the pessimistic scenario. Based on the results of the historical co-benefits of coalbed methane, it is essential to take funding measures to improve coalbed methane utilization from different aspects.

Based on the above conclusions, policy implications are suggested to enhance coalbed methane profitability and facilitate the prosperity of the coalbed methane industry.

(1) The government can provide special policy subsidies and technical support for CBM utilization to different coal mines with high EFs to reduce the cost of CBM extraction and utilization. For example, the subsidy policy should be designed to assist coal mine owners in building production modes of pre-drainage or simultaneous coal and gas extraction to fulfill the emission reduction potential of CBM by using actual geological conditions and gas source conditions of CBM mines. Targeted research on CBM mining and utilization technology needs to be carried out to overcome the technical problems of low utilization rates of CBM extraction, improve CBM development and utilization levels and promote innovative solutions for CBM development.

(2) Coal enterprises should pay more attention to the utilization of coal mine gas and obtain support from coal safety management and environmental agencies. For example, enterprises could adopt distributed electricity generation systems fueled by onsite coal mine gas combustion. It is beneficial to reduce the concentration of coal mine gas by the measures of pre-drainage of CBM or coal and gas simultaneous extraction. These two measures could not only reduce the investment of coal mine safety construction, but also provide the energy supply for production and operation. In this way, the utilization of CBM could bring safety benefits and reduce CH4 emissions as well as electricity costs.

(3) The CBM industry should exploit financing channels for social capital investment to engage in CBM extraction and utilization. By expanding the scale of the CBM industry, the integration of CBM could be promoted in the carbon market, enhance the competitiveness of CBM in the natural gas market, and share carbon emission reduction benefits with social investors. CBM utilization is the main factor for determining safety benefits and could be funded by the proposed national coal mining safety insurance.

This study analyzes the development and prospects of the CBM industry from a market-value perspective by fully considering the direct economic benefits of CBM and indirect benefits of safety and greenhouse gas emissions reductions. However, because the safety benefits of CBM utilization are measured by contrasting benefit analyses, safety benefits cannot be compared with emission reduction benefits and economic benefits. The emphasis should focus on directions rather than exact figures. The present research merely reflects the monetary benefit value, and the next direction could be cost accounting for the cost-benefit analysis of CBM development.

Funding Statement: The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (No. 71704178), Beijing Excellent Talent Program (No. 2017000020124G133) and the Fundamental Research Funds for the Central Universities (Nos. 2022SKNY01, 2022YJSNY04). The suggestions from the Workshop of the Chinese Academy of Engineering are also appreciated.

Conflicts of Interest: The authors declare they have no conflicts of interest to report regarding the present study.

References

1. National Development and Reform Commission (2017). Notice on printing and distributing opinions on accelerating the utilization of natural gas. https://www.ndrc.gov.cn/xxgk/zcfb/tz/201707/t20170704_963000.html. [Google Scholar]

2. Jiang, T., Huang, S., Yang, J. (2019). Structural carbon emissions from industry and energy systems in China: An input-output analysis. Journal of Cleaner Production, 240, 118116. DOI 10.1016/j.jclepro.2019.118116. [Google Scholar] [CrossRef]

3. National Bureau of Statistics (2020). National database. http://data.stats.gov.cn//. [Google Scholar]

4. Wang, L., Cheng, Y. P., Liu, H. Y. (2014). An analysis of fatal gas accidents in Chinese coal mines. Safety Science, 62, 107–113. DOI 10.1016/j.ssci.2013.08.010.z. [Google Scholar] [CrossRef]

5. Yang, J., Wu, J. L., He, T., Li, L. Y., Han, D. Z. et al. (2016). Energy gases and related carbon emissions in China. Resources, Conservation and Recycling, 113, 140–148. DOI 10.1016/j.resconrec.2016.06.016. [Google Scholar] [CrossRef]

6. Ministry of Natural Resources (2018b). The successful attempt of green transformation of mining city. http://www.mnr.gov.cn/dt/ywbb/201810/t20181030_2284823.html. [Google Scholar]

7. Zhou, A. T., Hu, J. Y., Wang, K. (2020). Carbon emission assessment and control measures for coal mining in China. Environmental Earth Sciences, 79, 461. DOI 10.1007/s12665-020-09189-8. [Google Scholar] [CrossRef]

8. Hu, Q. T., Liang, Y. P., Wang, H. (2017). Intelligent and integrated techniques for coalbed methane (CBM) recovery and reduction of greenhouse gas emission. Environmental Science & Pollution Research, 24, 17651–17668. DOI 10.1007/s11356-017-9335-4. [Google Scholar] [CrossRef]

9. Hong, J. M., Yu, Z. H., Fu, X., Hong, J. L. (2019). Life cycle environmental and economic assessment of coal seam gas-based electricity generation. Life Cycle Assessment, 24, 1828–1839. DOI 10.1007/s11367-019-01599-6. [Google Scholar] [CrossRef]

10. Ministry of Natural Resources (2018a). China mineral resources, pp. 1–58. Beijing, China: Geological Publishing House. http://www.gov.cn/xinwen/2018-10/22/5333589/files/01d0517b9d6c430bbb927ea5e48641b4.pdf. [Google Scholar]

11. Dong, J., Cheng, Y. P., Chang, T. Y., Zhang, J. J., Guo, S. F. (2015). Coal mine methane control cost and full cost: The case of the luling coal mine, Huaibei coalfield, China. Natural Gas Science & Engineering, 26, 290–302. DOI 10.1016/j.jngse.2015.05.040. [Google Scholar] [CrossRef]

12. Hou, J. C., Wang, Z. W., Liu, P. K. (2018). Current states of coalbed methane and its sustainability perspectives in China. Energy Research, 42, 3454–3476. DOI 10.1002/er.4085. [Google Scholar] [CrossRef]

13. Cheng, Y. P., Wang, L., Zhang, X. L. (2011). Environmental impact of coal mine methane emissions and responding strategies in China. Greenhouse Gas Control, 5, 157–166. DOI 10.1016/j.ijggc.2010.07.007. [Google Scholar] [CrossRef]

14. The State Council (2018). Opinions of the state council on promoting coordinated and stable development of natural gas. http://www.gov.cn/zhengce/content/2018-09/05/content_5319419.htm. [Google Scholar]

15. National Energy Administration (2016). The 13th five year plan for the development and utilization of coalbed methane (coal mine gas). http://zfxxgk.nea.gov.cn/auto85/201612/t20161202_2326.htm?keywords=. [Google Scholar]

16. Zheng, C. S., Jiang, B. Y., Xue, S., Chen, Z. Q., Li, H. (2019). Coalbed methane emissions and drainage methods in underground mining for mining safety and environmental benefits: A review. Process Safety and Environmental Protection, 127, 103–124. DOI 10.1016/j.psep.2019.05.010. [Google Scholar] [CrossRef]

17. Gao, X. (2017). Study on comprehensive benefit evaluation of coal mining in China. Modern Industrial Economy and Informationization, 21, 426. DOI 10.16525/j.cnki.14-1362/n.2017.07.01. [Google Scholar] [CrossRef]

18. Fan, Y., Mo, J. L., Zhu, L. (2013). Evaluating coal bed methane investment in China based on a real options model. Resources Policy, 38, 50–59. DOI 10.1016/j.resourpol.2012.08.002. [Google Scholar] [CrossRef]

19. Martina, N., Riceb, J. (2019). Coal seam gas projects: Proposed policy model for compensation and benefits sharing. Resources Policy, 63, 101458. DOI 10.1016/j.resourpol.2019.101458. [Google Scholar] [CrossRef]

20. Javadi, P., Yeganeh, B. J., Abbasi, M., Alipourmohajer, S. (2021). Energy assessment and greenhouse gas predictions in the automotive manufacturing industry in Iran. Sustainable Production and Consumption, 26, 316–330. DOI 10.1016/j.spc.2020.10.014. [Google Scholar] [CrossRef]

21. Zhang, N., Pan, Z., Zhang, Z. E., Zhang, W. X., Zhang, L. et al. (2020). CO2 capture from coalbed methane using membranes: A review. Environmental Chemistry Letters, 18, 79–96. DOI 10.1007/s10311-019-00919-4. [Google Scholar] [CrossRef]

22. Kholod, N., Evans, M., Pilcher, R. C., Roshchanka, V., Ruiz, F. et al. (2020). Global methane emissions from coal mining to continue growing even with declining coal production. Cleaner Production, 256, 120489. DOI 10.1016/j.jclepro.2020.120489. [Google Scholar] [CrossRef]

23. Maasakkers, J. D., Jacob, D. J., Sulprizio, M. P., Turner, A. J., Weitz, M. et al. (2016). Gridded national inventory of U.S. methane emissions. Environmental Science & Technology, 50, 12123–13133. DOI 10.1021/acs.est.6b02878. [Google Scholar] [CrossRef]

24. Wang, N., Zhu, T., Chen, S., Luo, D. W. (2013). Study on the interprovincial emission factor of Chinese coal mine methane. Applied Mechanics and Materials, 295--298, 3354–3358. DOI 10.4028/www.scientific.net/AMM.295-298.3354. [Google Scholar] [CrossRef]

25. IPCC (Intergovernmental Panel on Climate Change) (2006). IPCC guidelines for national greenhouse gas inventories. https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol2.html. [Google Scholar]

26. Wang, N., Wen, Z. G., Zhu, T. (2015). An estimation of regional emission intensity of coal mine methane based on coefficient-intensity factor methodology using China as a case study. Greenhouse Gases Science & Technology, 5, 437–448. DOI 10.1002/ghg.1485. [Google Scholar] [CrossRef]

27. Zhu, T., Bian, W. J., Zhang, S. Q., di, P. K., Nie, B. S. (2017). An improved approach to estimate methane emissions from coal mining in China. Environmental Science & Technology, 51, 12072–12080. DOI 10.1021/acs.est.7b01857. [Google Scholar] [CrossRef]

28. Sheng, J. X., Song, S. J., Zhang, Y. Z., Prinn, R. G., Janssens-Maenhout, G. (2019). Bottom-up estimates of coal mine methane emissions in China: A gridded inventory, emission factors, and trends. Environmental Science & Technology Letters, 6, 473–478. DOI 10.1021/acs.estlett.9b00294. [Google Scholar] [CrossRef]

29. Smith, D. C. (2018). Unconventional gas development 2.0: Reducing the ‘environmental footprint’ through new technologies. https://ssrn.com/abstract=3165144. [Google Scholar]

30. Ji, Z. M., Chen, Z. J., Pan, J. N., Niu, Q. H. (2017). A novel method for estimating methane emissions from underground coal mines: The Yanma coal mine, China. Atmospheric Environment, 170, 96–107. DOI 10.1016/j.atmosenv.2017.09.052. [Google Scholar] [CrossRef]

31. Wu, H. T., Xu, L. N., Ren, S. Y., Hao, Y., Yan, G. Y. (2020). How do energy consumption and environmental regulation affect carbon emissions in China? New evidence from a dynamic threshold panel model. Resources Policy, 67, 101678. DOI 10.1016/j.resourpol.2020.101678. [Google Scholar] [CrossRef]

32. Ren, J., Xie, C. J., Lin, J. Y., Li, Z. (2014). Co-utilization of two coal mine residues: Non-catalytic deoxygenation of coal mine methane over coal gangue. Process Safety and Environmental Protection, 92, 896–902. DOI 10.1016/j.psep.2013.10.002. [Google Scholar] [CrossRef]

33. Wang, K., Zhang, J. J., Cai, B. F., Yu, S. M. (2019). Emission factors of fugitive methane from underground coal mines in China: Estimation and uncertainty. Applied Energy, 250, 273–282. DOI 10.1016/j.apenergy.2019.05.024. [Google Scholar] [CrossRef]

34. Wang, T., Lin, B. Q. (2014). Impacts of unconventional gas development on China’s natural gas production and import. Renewable & Sustainable Energy Reviews, 39, 546–554. DOI 10.1016/j.rser.2014.07.103. [Google Scholar] [CrossRef]

35. Zhou, H. X., Yang, Q. L., Cheng, Y. P., Ge, C. G., Chen, J. X. (2014). Methane drainage and utilization in coal mines with strong coal and gas outburst dangers: A case study in Luling mine, China. Natural Gas Science & Engineering, 20, 357–365. DOI 10.1016/j.jngse.2014.07.023. [Google Scholar] [CrossRef]

36. Yang, X., Krul, K., Sim, D. (2020). Uncovering coal mining accident coverups: An alternative perspective on China's new safety narrative. Safety Science, 148, 105637. DOI 10.1016/j.ssci.2021.105637. [Google Scholar] [CrossRef]

37. Zhou, H. X., Dai, H., Ge, C. G. (2016). Quality and quantity of pre-drainage methane and responding strategies in Chinese outburst coal mines. Arabian Journal of Geosciences, 9, 445. DOI 10.1007/s12517-016-2488-5. [Google Scholar] [CrossRef]

38. The State Council (2011). Work injury insurance regulations.http://www.gov.cn/flfg/2010-12/24/content_1772226.htm. [Google Scholar]

39. Ju, Y. W., Sun, Y., Sa, Z. Y., Pan, J. N., Wang, J. L. et al. (2016). A new approach to estimate fugitive methane emissions from coal mining in China. Science of the Total Environment, 543, 514–523. DOI 10.1016/j.scitotenv.2015.11.024. [Google Scholar] [CrossRef]

40. Evans, N., Jones, C., Munday, M., Song, M. (2018). Economic effects in the UK periphery from unconventional gas development: Evidence from wales. Energy, 166, 1037–1046. DOI 10.1016/j.energy.2018.10.060. [Google Scholar] [CrossRef]

41. Hummel, J. A., Ruiz, F. A., Kelafant, J. R. (2018). Quantifying the benefits of coal mine methane recovery and use projects: Case study on the application of in-mine horizontal pre-drainage boreholes at gassy coal mines in India and the optimization of drainage system design using reservoir simulation. Environmental Technology & Innovation, 10, 223–234. DOI 10.1016/j.eti.2018.03.003.1. [Google Scholar] [CrossRef]

42. Marcos-Martinez, R., Measham, T. G., Fleming-Muñoz, D. A. (2019). Economic impacts of early unconventional gas mining: Lessons from the coal seam gas industry in New South Wales, Australia. Energy Policy, 125, 338–346. DOI 10.1016/j.enpol.2018.10.067. [Google Scholar] [CrossRef]

43. Wang, L., Cheng, Y. P. (2012). Drainage and utilization of Chinese coal mine methane with a coal-methane co-exploitation model: Analysis and projections. Resources Policy, 37, 315–321. DOI 10.1016/j.resourpol.2012.06.013. [Google Scholar] [CrossRef]

Appendix A

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools