| Energy Engineering |  |

DOI: 10.32604/EE.2022.017356

ARTICLE

The Use of Single-Phase Immersion Cooling by Using Two Types of Dielectric Fluid for Data Center Energy Savings

Energy and Society Laboratory, Mechanical Engineering Education, Universitas Sebelas Maret, Surakarta, 57126, Indonesia

*Corresponding Author: Nugroho Agung Pambudi. Email: agung.pambudi@staff.uns.ac.id

Received: 04 May 2021; Accepted: 17 August 2021

Abstract: Data centers are recognized as one of the most important aspects of the fourth industrial revolution since conventional data centers are inefficient and have dependency on high energy consumption, in which the cooling is responsible for 40% of the usage. Therefore, this research proposes the immersion cooling method to solving the high energy consumption of data centers by cooling its component using two types of dielectric fluids. Four stages of experimental methods are used, such as fluid types, cooling effectiveness, optimization, and durability. Furthermore, benchmark software is used to measure the CPU maximum work with the temperature data performed for 24 h. The results of this study show that the immersion cooling reduces 13°C lower temperature than the conventional cooling method which means it saves more energy consumption in the data center. The most optimum variable used to decrease the temperature is 1.5 lpm of flow rate and 800 rpm of fan rotation. Furthermore, the cooling performance of the dielectric fluids shows that the mineral oil (MO) is better than the virgin coconut oil (VCO). In durability experiment, there are no components damage after five months immersed in the fluid.

Keywords: Single-phase; immersion cooling; data center; dielectric fluid; mineral oil; virgin coconut oil

| Nomenclature | |

| CPS | Cyber-Physical System |

| CPU | Central Processing Unit |

| CRAC | Computer Room Air Conditioning |

| VCO | Virgin coconut oil |

| IT | Information Technology |

| ITU | International Telecommunications Union |

| TWh | Terra Watt Hour |

| PSU | Power Supply Unit |

| LPM | Liter Per Minutes |

| RPM | Rotation per Minutes |

| PCB | Printed Circuit Board |

| UPS | Uninterruptible Power Supply |

The rise of the fourth industrial revolution, in which any technology can interact using the same data, has increased the data center across the world. As a platform for combining the actual and digital worlds, an integration of computation, networking, and physical processes called the Cyber-Physical System (CPS) had been created. Consequently, the yearly percentage increase in the level of energy consumption, has now amounted to 2 percent of global electricity demand, which is expected to rise by 15–20 percent annually [1]. Data centers have several components such as backup generators, power distribution devices (UPS), cooling systems such as fans, air circulation regulating units, pumps, CRAC, lighting, cooling towers, and other additional facilities [2]. The level of energy consumption by the cooling system and the server constitute the majority of the electrical energy and accounts for 40 percent of overall energy consumption in the data center [3].

As shown in Fig. 1, the breakdown of the data center's energy consumption is evaluated as 38% to the cooling system, while the auxiliary equipment is responsible for the remaining 10% [4]. The major technical challenges in cooling systems are sufficient heat transfer from heat changes and uneven disappearance of power. Most of the cooling of data center utilize air or liquid medium [5]. Using air is called the conventional cooling system. However, the increasing efficiency and ability of heat transfer is still a big challenge [5]. The heat from data center devices is absorbed and carried to the environment, mixed with the atmospheric air of lower temperature or through refrigerants [6].

Figure 1: Electricity distribution in the data center [4]

Cooling demand for server data center needs tremendous electricity, which is the reason to reduce its cooling load. Therefore, the liquid of the cooling process is formulated as a substitute for the air medium. Furthermore, liquids have more conductivity than air, make it more efficient in heat transfer. With the introduction of the immersion cooling method, more prospective solution for cooling data center is available. Furthermore, multiple tests and projects have been conducted to minimize the energy consumption of data centers.

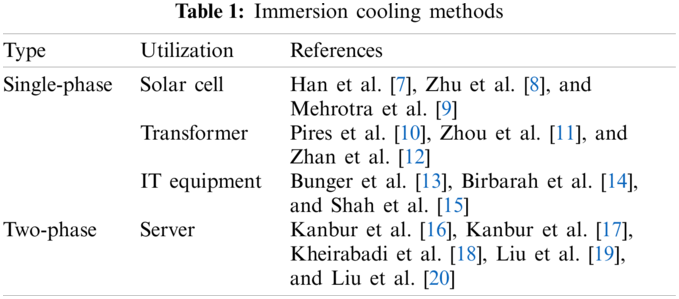

For several years, the immersion cooling method has been employed for cooling various electronic devices, few of the recorded and broadcast analyses are shown in Table 1. It consists of several hardware such as solar cell, transformer, IT equipment as well as sever.

In a Single-phase immersion cooling, the use of coolants to exchange heat without any phase is used. The cooling mechanism does not contain any gas or vapor, making this process safer. As a result, the system is protected from explosion due to under pressure. However, it is more adaptable than air cooling. In two-phase immersion cooling, the liquid-vapor phase changes, coolants are used to exchange heat. Two-phase immersion cooling has the advantage of reducing environmental impacts, having a simple model, increasing power density by up to ten times, and being economical.

Numerous studies adopted the immersion cooling method, which has been proved to reduce the energy consumption in the data center. Levin et al. designed the promising re-configurable computer system using immersion cooling [21]. The methods with liquid cooling have considerable advantage of such parameters as real and specific performance, energetic efficiency, mass, and dimensions characteristics. Tuma discussed the economic and environmental merits of passive 2-phase immersion in semi-open baht of dielectric fluid for cooling the server [22]. Kuncoro et al. used the Taguchi method to determine the interaction of several variables measured [23]. The result shows that the costs and greenhouse gas emissions associated with conservative annual fluid emission estimates are realized to be lesser than those associated with the electrical power required for conventional chassis fans and liquid pumps [23].

Previous research show an adoption of immersion cooling on a computer data center, they use two phases in which the dielectric liquid was circulated by dripping from above with the open system [16–20]. During an operation, the dielectric fluid stores heat and this makes damaged the material and evaporates quickly. With this open system, the material was also easily dirty and its fluid thickens faster, increasing its viscosity because it binds to dust scattered in the room. The more viscosity of dielectric fluid affects to lowering the convection heat transfer [24]. To overcome this situation, a combination of immersion cooling is needed with a closed system method, such as in a car engine radiator application. Heat release acceleration is carried out by the radiator assisted by fan blowing. Furthermore, previous studies using the single-phase immersion cooling method have been carried out by some research, but it mainly uses a natural convection [25,26]. In this research, two dielectric fluids were use namely mineral oil (MO) and virgin coconut oil (VCO).

With the method, some variables were eliminated because the best method has been investigated in the previous experiment. There were four stages research experiment to reduce the number of test variables, therefore data were obtained quickly and precisely. The first stage was to examine the two dielectric fluid of mineral oil and VCO. The second stage was an examination of cooling Effectiveness with the dependent variables

Figure 2: Experimental design

To represent the amount of work assigned to the CPU, the load was performed with benchmark software. The CPU temperature rises due to the benchmark load, therefore, temperature was used as control variable.

While collating the data, the CPU was placed in an empty glass container measuring 39 cm × 14 cm × 25 cm, where it was activated, and the results were obtained through a conventional cooling supplied by a blowing fan. To evaluate the similarities and differences, the next step was to put the oil in the container until it penetrates through the container for maximum heat absorption. Furthermore, the experiment was carried out with each variable with a factorial combination.

To increase the heat transfer rate, the coolant was used to penetrate and circulate through the radiator. The coolant was further passed to the outflow to the container again. To measure the accurate flow rate, a flow meter was installed in the outflow to determine the volume of the passing fluids. The loading software was installed and run on the CPU during measurement for the workload. In addition, the software also measured the computer temperature using a monitor chip, determines the voltage, and adjusts the fan speed.

The experimental scheme and results are presented in Figs. 3 and 4. It is showed that the CPU temperature by cooling using the immersion method was better than the conventional. At a stable temperature reached at 8.10–17.20, while the conventional method was 60°C. The temperature of immersion cooling was lower, 51°C for VCO and 47°C for MO. The difference of the two temperatures were not significantly different at the early operation shown, as shown in Fig. 4.

Figure 3: Scheme experimental of immersion cooling

Figure 4: CPU Temperature with cooling method comparison

This experiment showed that the cooling method by immersion was more effective than the conventional. However, the results of the difference between MO and VCO were not significant. It was important to note that the performance of dielectric fluids were measured based on their effectiveness.

3.2 Immersion Cooling Effectiveness

The inlet, outlet, and wet bulb cooling temperatures were measured to determine the effectiveness of the system. The inlet temperature was measured in the location of the liquid pumped from the vessel to the condenser for the cooling process as shown in Fig. 6. Meanwhile, the outlet temperature was measured from the coolant in the condenser outlet. Furthermore, Wet-bulb temperature was measured when the coolant was in the condenser.

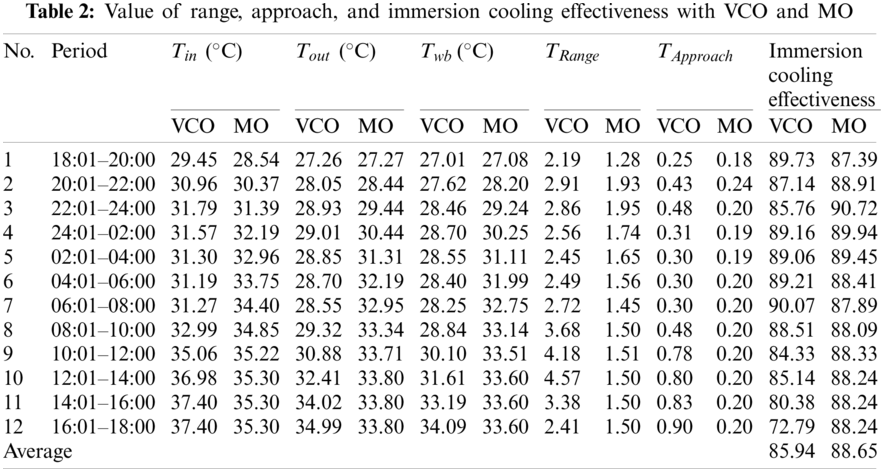

A thermocouple recorded data every minute, and its average was calculated every 2 h to facilitate the data presented. The value of the range,

From the experiment, it was known that MO's effectiveness was better than VCO. As shown in Fig. 5, the VCO was fluctuate, where at the 16th to 24th-h, there was a drastic decrease. This indicated that the VCO's ability to cool was damaged. The low VCO's effectiveness was related to its high viscosity that affect in a convention reduction of heat transfer rate [24]. It also has a high-water vapor absorption capacity, resulting in fluctuate water content [24,27]. However, the VCO's viscosity at operating temperature (40–100°C) was better than sunflower oil and soya oil based on other research [28]. Therefore, this fluid has more potential to be used as a dielectric fluid than others. Furthermore, VCO's viscosity stability can be improved by a special treatment in the manufacturing process [27]. After five month immersed, we do not find any significant damage to the components visually as shown in Fig. 7.

Figure 5: The immersion cooling effectiveness by using VCO and MO

Figure 6: Inlet and outlet temperature using mineral oil. (a) inlet temperature of 0.5 lpm (b) outlet temperature of 0.5 lpm (c) inlet temperature of 1 lpm (d) outlet temperature of 1 lpm (e) inlet temperature of 1.5 lpm (f) outlet temperature of 1.5 lpm

Figure 7: Fan, processor, motherboard, and PSU after five months of immersion

3.3 Immersion Cooling Optimization

In the second stage, it had known that MO's effectiveness was better than VCO. Therefore, the third stage focused on MO's performance. The results at the beginning of the experiment showed that the graphs tend to overlap, revealing that the variables of flowrate and fan rotation have no significant effect on temperature at the time of set-up. During it operation, it was more than 14 h, the results substantially impact the temperature by fan rotation and flow rate. During the experiment, each fan rotation variable has a stability point. A larger flow rate and fan rotation result in an earlier stable temperature than the lower flow rate and fan rotation. According to the a research, using natural convection heat sink, Cheng et al. found that coolant flow was the most influential, and heat sink material did not significantly affect the performance [26]. This experiment showed different results where the coolant flow velocity and wind speed from the fan rotation forced a convection effect, substantially lowers cooling performance. This was simply mean that increased flow rate and fan rotation, improve heat release and in the earlier stages. It was more stable, such as at 0.5 lpm was slower stable at 14 h than at 1.5 lpm was stable at 10 h.

Approximately five months after the immersion process, necessary deductions were made to determine any destructive physical changes. The results of observations were as follows:

For five months, the conditions of the immersed CPU were monitored to evaluate what damages or physical effects on each of the components. This was also to establish if there were any negative adverse effects due to the mineral oil fluid used. The possible damages were delaminating (detachment of the motherboard), warpage (bending on the Printed Circuit Board- PCB), and swelling of the PCB [5]. The state of the CPU after it was soaked for five months has no difference from the early conditions, and each component worked well. This result recommends the future use of immersion cooling capable of solving the existing problem. It provided an overview of the immersion cooling usage of individuals and organizations that have something to do with computer devices.

This research provided a more prominent and better way of cooling a data center through the immersion cooling method to solving the high energy consumption of data centers, which, according to several reports were considered not a modern technique. Immersion Cooling was a system that employs the principle of convection heat transfer to immerse CPU components. The heat generated from the CPU was absorbed by the mineral oil and pumped to be cooled in the radiator before being poured back into the container.

This study showed that heat loss occurrence at 13°C is lower than conventional cooling with air. The reason for this was because the heat absorption capacity of mineral oil was greater than air. The effect of the flow rate and rotation had a significant influence on temperature reduction. The lowest temperature can be achieved with the highest flow rate and fan rotation variable of 1.5 lpm and 800 rpm. This was more influential in reducing CPU temperature compared to VCO. This was confirmed by the maximum temperature the CPU produces when using a 47°C mineral oil coolant, lower than the VCO coolant of 51°C. Inflow temperature and liquid mineral oil outflow were lower than VCO, meaning that CPU heat absorption using mineral oil is much preferred to a temperature of 35.3°C mineral oil inlet, while VCO 37.4°C, and 33.8°C, at 35°C, respectively. In this study, CPU components also were immersed for five months, with the effects ranging from delaminating, warpage, and swelling. This shows that the immersion method of cooling is an appropriate cooling system and meets technological development and progress demands.

More analysis will be considered to investigate the data center's ability to leverage the capacities of electronic devices and the impact this approach as well as for the environment as a whole. Immersion cooling was also found to reduce component temperature, simplify data center layout, and allow for higher power density. Therefore, immersion cooling can reduce energy consumption in the data center which leads to more energy saving.

Funding Statement: This work is financially supported by the Ministry of Research and Technology of Indonesia (BRIN) in the project called “Penggunaan Immersion Cooling untuk Meningkatkan Efisiensi Energi Data Center”.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Capozzoli, A., Primiceri, G. (2015). Cooling systems in data centers: State of art and emerging technologies. Energy Procedia, 83, 484–493. DOI 10.1016/j.egypro.2015.12.168. [Google Scholar] [CrossRef]

2. Zhang, H., Shao, S., Xu, H., Zou, H., Tian, C. (2014). Free cooling of data centers: A review. Renewable and Sustainable Energy Review, 35, 171–182. DOI 10.1016/j.rser.2014.04.017. [Google Scholar] [CrossRef]

3. Rong, H., Zhang, H., Xiao, S., Li, C., Hu, C. (2016). Optimizing energy consumption for data centers. Renewable and Sustainable Energy Reviews, 58, 674–691. DOI 10.1016/j.rser.2015.12.283. [Google Scholar] [CrossRef]

4. Nadjahi, C., Louahlia, H., Lemasson, S. (2018). A review of thermal management and innovative cooling strategies for data center. Sustainable Computing: Informatics and Systems, 19, 14–28. DOI 10.1016/j.suscom.2018.05.002. [Google Scholar] [CrossRef]

5. Ni, J., Bai, X. (2017). A review of air conditioning energy performance in data centers. Renewable and Sustainable Energy Reviews, 67, 625–640. DOI 10.1016/j.rser.2016.09.050. [Google Scholar] [CrossRef]

6. Coles, H., Herrlin, M. (2016). Immersion cooling of electronics in DoD installations. USA: Ernest Orlando Lawrence Berkeley National Laboratory. [Google Scholar]

7. Han, X., Wang, Q., Zheng, J., Qu, J. (2015). Thermal analysis of direct liquid-immersed solar receiver for high concentrating photovoltaic system. International Journal of Photoenergy, 2015, 1–9. DOI 10.1155/2015/321350. [Google Scholar] [CrossRef]

8. Zhu, L., Boehm, R. F., Wang, Y., Halford, C., Sun, Y. (2011). Water immersion cooling of PV cells in a high concentration system. Solar Energy Materials and Solar Cells, 95(2), 538–545. DOI 10.1016/j.solmat.2010.08.037. [Google Scholar] [CrossRef]

9. Mehrotra, S., Rawat, P., Debbarma, M., Sudhakar, K., Centre, E. et al. (2014). Performance of a solar panel with water immersion, International Journal of Science, Environment, and Technology, 3(3), 1161–1172. DOI 10.1016/j.solmat.2010.08.037. [Google Scholar] [CrossRef]

10. Pires, I. A., Silva, R. Á., Pereira, I. T. O., Faria, O. A., Maia, T. A. C. et al. (2020). An assessment of immersion cooling for power electronics: An oil volume case study. IEEE Transactions on Industry Applications, 56(3), 3231–3237. DOI 10.1109/TIA.2020.2975762. [Google Scholar] [CrossRef]

11. Zhou, S., Iannuzzi, D. (2019). Immersion photoacoustic spectrometer (iPAS) for arcing fault detection in power transformers. Optics Letters, 44(15), 3741–3744. DOI 10.1364/ol.44.003741. [Google Scholar] [CrossRef]

12. Zhan, W., Goulart, A. E., Falahi, M., Rondla, P. (2015). Development of a low-cost self-diagnostic module for oil-immerse forced-air cooling transformers. IEEE Transactions on Power Delivery, 30, 129–137. DOI 10.1109/TPWRD.2014.2341454. [Google Scholar] [CrossRef]

13. Bunger, R., Day, T. (2020). Comparison of dielectric fluids for immersive liquid cooling of IT equipment, pp. 1–13. French: Schneider Electric–Data Center Science Center. [Google Scholar]

14. Birbarah, P., Gebrael, T., Foulkes, T., Stillwell, A., Moore, A. et al. (2020). Water immersion cooling of high power density electronics. International Journal of Heat and Mass Transfer, 147, 1–13. DOI 10.1016/j.ijheatmasstransfer.2019.118918. [Google Scholar] [CrossRef]

15. Shah, J. M., Eiland, R., Siddarth, A., Agonafer, D. (2016). Effects of mineral oil immersion cooling on IT equipment reliability and reliability enhancements to data center operations. 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, pp. 316–325. DOI 10.1109/ITHERM.2016.7517566. [Google Scholar] [CrossRef]

16. Kanbur, B. B., Wu, C., Fan, S. Tong, W., Duan, F. (2020). Two-phase liquid-immersion data center cooling system: Experimental performance and thermoeconomic analysis. International Journal of Refrigeration, 118, 290–301. DOI 10.1016/j.ijrefrig.2020.05.026. [Google Scholar] [CrossRef]

17. Kanbur, B. B., Wu, C., Fan, S., Duan, F. (2021). System-level experimental investigations of the direct immersion cooling data center units with thermodynamic and thermoeconomic assessments. Energy, 217, DOI 10.1016/j.energy.2020.119373. [Google Scholar] [CrossRef]

18. Kheirabadi, A. C., Groulx, D. (2016). Cooling of server electronics: A design review of existing technology. Applied Thermal Engineering, 105, 622–638. DOI 10.1016/j.applthermaleng.2016.03.056. [Google Scholar] [CrossRef]

19. Liu, C., Yu, H. (2020). Experimental study on Two-phase liquid-immersion cooling system. International Conference on Applied Energy, pp. 1–6. [Google Scholar]

20. Liu, C., Yu, H. (2021). Evaluation and optimization of a Two-phase liquid-immersion. Energies, 14, 1–21. DOI 10.3390/en14051395. [Google Scholar] [CrossRef]

21. Levin, I. I., Dordopulo, A. I., Doronchenko, Y. I., Raskladkin, M. K., Fedorov, A. M. et al. (2016). Immersion liquid cooling FPGA-based reconfigurable computer system. IFAC–PapersOnLine, 49(25), 366–371. DOI 10.1016/j.ifacol.2016.12.070. [Google Scholar] [CrossRef]

22. Tuma P. E. (2010). The merits of open bath immersion cooling of datacom equipment. 26th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, pp. 123–131. DOI 10.1109/STHERM.2010.5444305. [Google Scholar] [CrossRef]

23. Kuncoro, I. W., Pambudi, N. A., Biddinika, N. A., Budiyanto, C. W. (2020). Optimization of immersion cooling performance using the Taguchi Method. Case Studies in Thermal Engineering, 21, 1–9. DOI 10.1016/j.csite.2020.100729. [Google Scholar] [CrossRef]

24. Sauki, S. S. M., Muhamad, N. A., Rasid, Z. A. (2019). Virgin coconut oil dielectrical properties as electrical insulation material. Bulletin of Electrical Engineering and Informatics, 8(3), 1154–1161. DOI 10.11591/eei.v8i3.1603. [Google Scholar] [CrossRef]

25. Matsuoka, M., Matsuda, K., Kubo, H. (2017). Liquid immersion cooling technology with natural convection in data center. IEEE 6th International Conference on Cloud Networking, pp. 1–7. DOI 10.1109/CloudNet.2017.8071539. [Google Scholar] [CrossRef]

26. Cheng, C. C., Chang, P. C., Li, H. C., Hsu, F. I. (2020). Design of a single-phase immersion cooling system through experimental and numerical analysis. International Journal of Heat and Mass Transfer, 160, 1–12. DOI 10.1016/j.ijheatmasstransfer.2020.120203. [Google Scholar] [CrossRef]

27. Ansyori, Z., Nawawi, M., Siddik, A., Verdana, I. (2019). Analysis of dielectric strength of virgin coconut oil as an alternative transformer liquid insulation. Journal of Physics: Conference Series, 1198, 052003. DOI 10.1088/1742-6596/1198/5/052003. [Google Scholar] [CrossRef]

28. Das, A. K., Shill, D. C., Chatterjee, S. (2020). Potential of coconut oil as a dielectric liquid in distribution transformers. IEEE Electrical Insulation Magazine, 36(6), 36–46. DOI 10.1109/MEI.2020.9222633. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |