| Energy Engineering |  |

DOI: 10.32604/EE.2021.016738

ARTICLE

Performance Analysis of Multi-Energy Hybrid System Based on Molten Salt Energy Storage

School of Energy Engineering, Tianjin Sino-German University of Applied Sciences, Tianjin, 300350, China

*Corresponding Authors: Xin Xu. Email: xuxin@tsguas.edu.cn; Lian Zhang. Email: zhanglian@tsguas.edu.cn

Received: 23 March 2021; Accepted: 24 June 2021

Abstract: This paper briefly summarizes the current status of typical solar thermal power plant system, including system composition, thermal energy storage medium and performance. The thermo-physical properties of the storage medium are some of the most important factors that affect overall efficiency of the system, because some renewable energy sources such as solar and wind are unpredictable. A thermal storage system is therefore necessary to store energy for continuous usage. Based on the form of storage or the mode of system connection, heat exchangers of a thermal storage system can produce different temperature ranges of heat transfer fluid to realize energy cascade utilization. Founded upon the review, a small hybrid energy system with a molten-salt energy storage system is proposed to solve the problems of heating, cooling, and electricity consumption of a 1000 m2 training hall at school. The system uses molten-salt storage tank, water tank and steam generator to change the temperature of heat transfer fluid, in order to realize thermal energy cascade utilization. Compared to the existing heating and cooling system, the proposed system needs more renewable energy and less municipal energy to achieve the same results according to simulation analysis. Furthermore, by improving the original heating and cooling system, PMV has been improved. The comprehensive efficiency of solar energy utilization has been increased to 83%.

Keywords: Solar thermal power; thermal energy storage; storage medium; energy cascade utilization

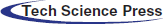

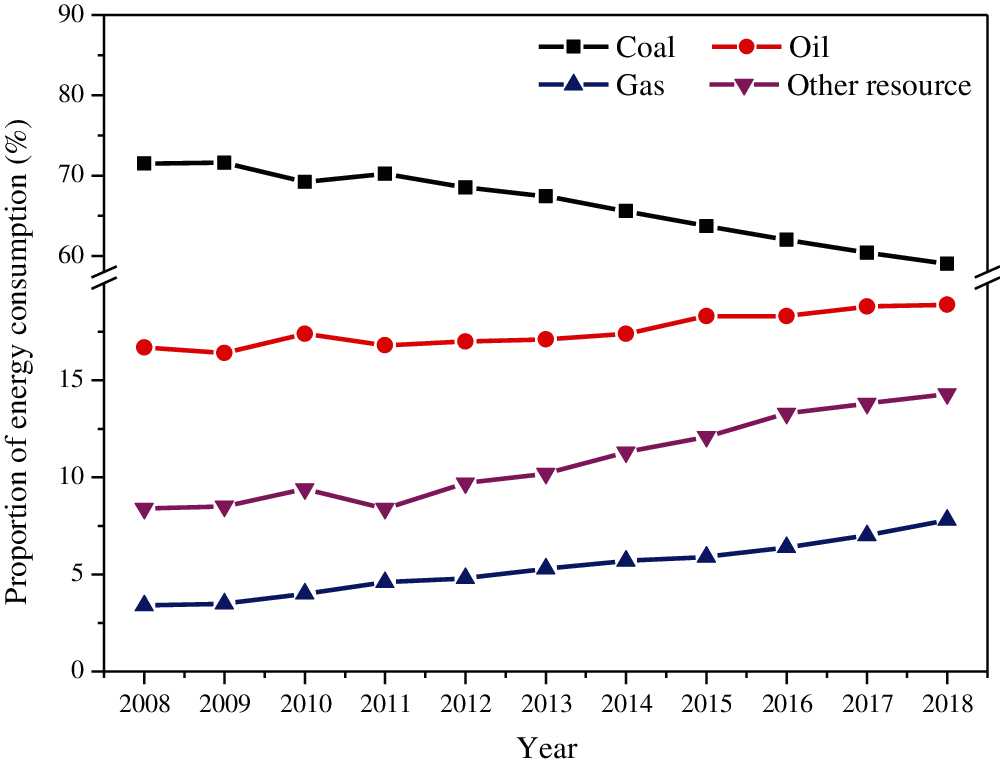

Over the past decade, the utilization of fossil fuel has decreased in China. Meanwhile, the utilization of natural gas and other renewable (or clean) energy has increased [1], as shown in Fig. 1. Based on 2017 data, energy consumption of buildings in China amounted to 947 million tons of standard coal equivalent (TCE), accounting for 21.11% of the total energy consumption in the country [2]. Fig. 2 shows that energy consumption of public buildings was 363 million tce, urban residential buildings 361 million tce, and rural residential buildings 223 million tce. Heating and cooling systems for buildings consume a significant amount of energy. Clean energy systems, such as solar collectors, wind turbines, and ground-source heat pump systems, are increasingly being used to decrease fossil fuel consumption. As the most widely available renewable energy source, solar energy can be easily collected and used for space heating, cooling and hot water usage. However, because of the fluctuation of solar irradiance, the systems combining solar energy and the other renewable sources like geothermal energy were proposed [3]. This paper reviews typical solar based hybrid systems, the performance of thermal energy storage, and effect of thermal energy cascaded using by combined cooling, heating and power system (CCHP). For the training room in school, a new CCHP hybrid system and operation strategy is proposed.

Figure 1: Energy consumption in China [1]

Figure 2: Energy consumption ratio of typical buildings [2]

2 Hybrid System with Thermal Storage

2.1 Traditional Energy-Based Hybrid System

Electricity is the most common secondary energy source used in buildings for heating, cooling, lighting, and other domestic and industrial requirements. In Northern China, hot water produced by the district heating system boiler supplies heat to buildings in winter. In most parts of China, electricity is produced through thermal power or hydropower plants. Ahn suggested a combined cooling, heating, and power system (CCHP), which includes a thermal power plant, absorption chiller, electric chiller, and heat exchanger for buildings [4]. However, a coal-fired power plant creates air pollution, greenhouse effects, and other problems. Therefore, natural gas, hydro, nuclear, and other traditional clean energies should be used as the primary energy source of the power plant.

2.2 Solar Energy-Based Hybrid System

Solar energy is one of the most important renewable energy resources because of its distribution characteristics, safety, and flexibility. Some studies investigated solar heating and cooling as two separate systems [5], even though overall system performance can be improved by several techniques. For example, heat obtained from central industrial waste and local solar collectors [6] can replace 32% of the electricity from the former district heating system. Arsalis proposed a hybrid system using gas as raw material and photovoltaic (PV) as auxiliary energy for power generation combined with a hybrid chiller [7]. Beha used a concentrating solar collector to produce auxiliary heat for increased efficiency [8]. Tian designed a hybrid solar district heating plant with 5960 m2 flat plate collectors (FPC) and 4039 m2 parabolic trough collectors (PTC) in series. It was built in Taars, Denmark, and has an annual energy output of 1289 kWh/m2 [9]. A hybrid system with solar energy usually includes a compressor chiller, adsorption chiller or absorption chiller [10] to realize both heating and cooling supply simultaneously or according to seasonal requirements [11].

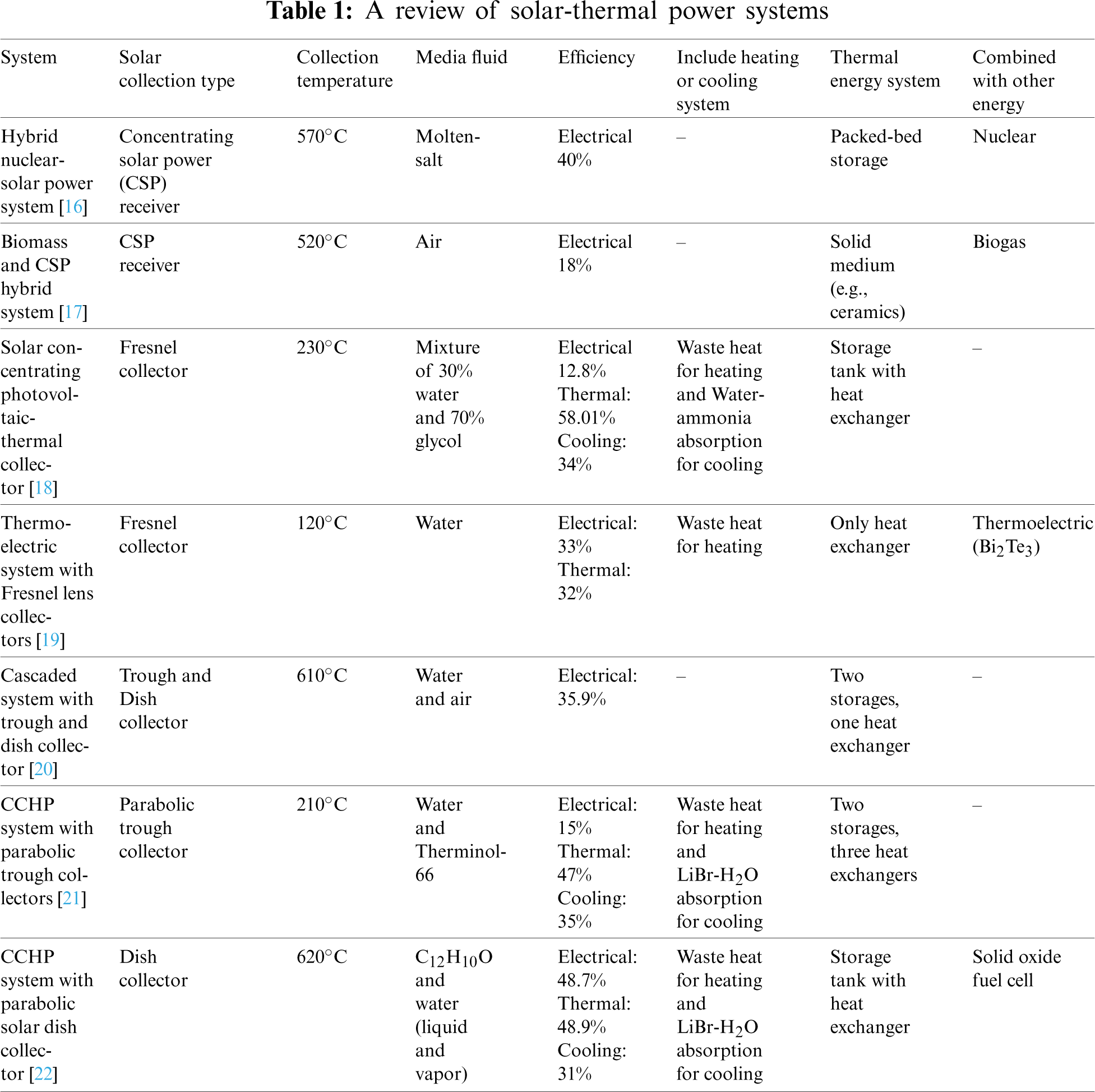

These kinds of district heating and cooling systems have received attention, owing to their benefits in terms of efficiency, greenhouse gas reduction, flexibility to use renewable energy sources, and economic benefits. For cascaded arrangement a domestic water heating system combining photovoltaic thermal (PVT) solar collectors with two heat pumps was presented, which has an annual thermal energy output improvement of 37%–68% [12]. Carotenutoa et al. combined an evacuated-tube solar collector, geothermal heat exchanger, biomass boiler, adsorption chiller, and storage system to achieve a significant saving of primary energy, collector efficiency of approximately 40%, and adsorption chiller performance coefficient of 0.51 [13]. By combining solar thermal and PV, Buonomano used PVT (Combined Photovoltaic Panel with thermal collector) to increase the comprehensive efficiency [14]. By utilizing PV and fuel cells for generating power, researchers used a solar collector for heating water to increase comprehensive efficiency. Once designed, researchers used experiments and simulation analysis [15] (e.g., TRNSYS or HOMER) for examining the solar CCHP system's performance in order to commercialize it. There are several types of solar thermal power plants. Some of them are hybrid systems with several energy sources or with several thermal cascades. Tab. 1 shows some typical systems. Compared to the single plant, hybrid systems have higher overall efficiency.

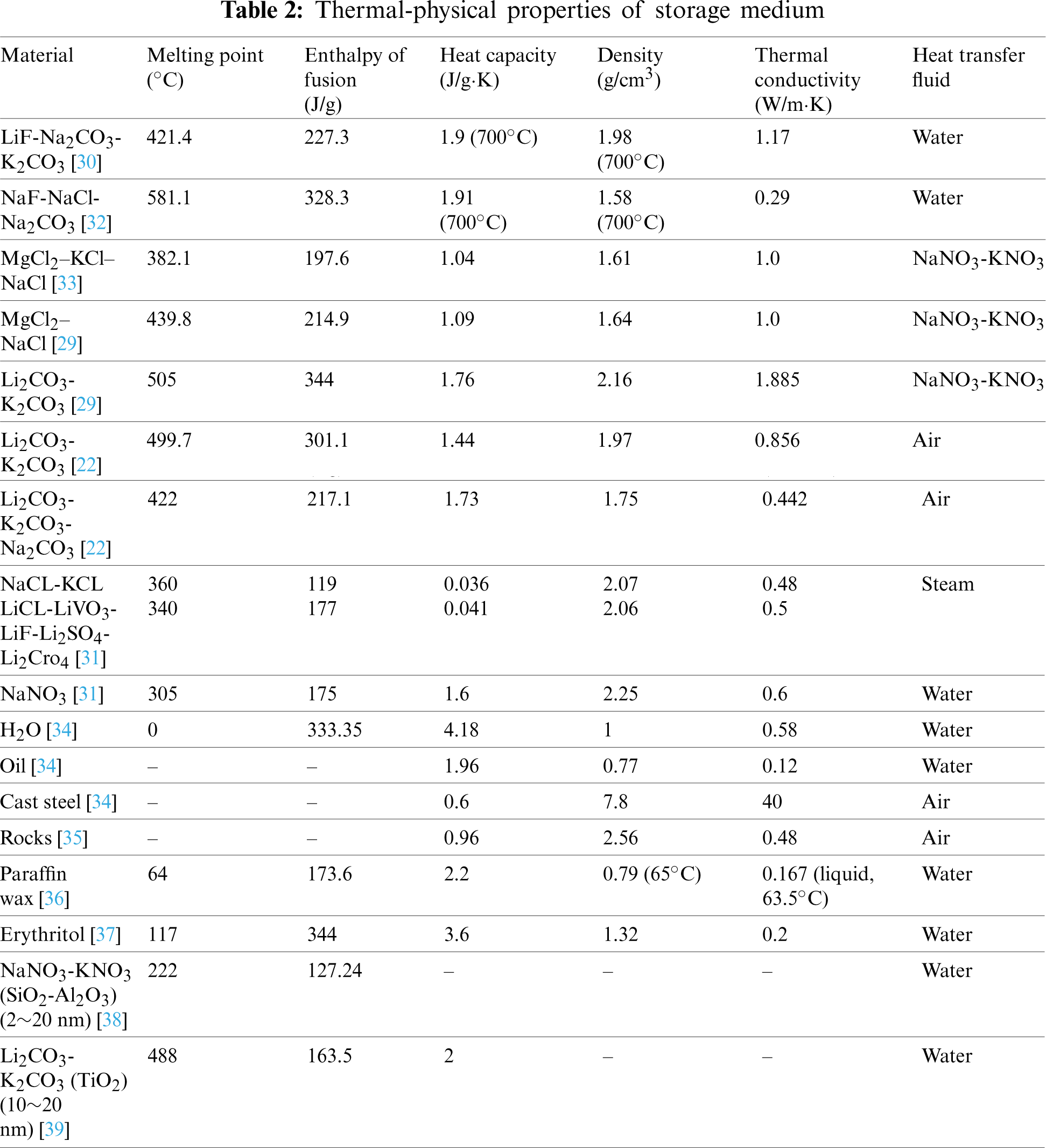

Owing to the unpredictability of solar energy, thermal storage is necessary. Numerous studies focused on improvement of the structure or choice of a suitable storage medium for the thermal storage system, in order to increase the efficiency of storage and heat exchange.

Former storage structures were just tanks without any tubes inside. However, for improved energy efficiency, storage with tubes, fins or unusual structures is widely used in solar thermal power plants.

Esapour shows the ratio of heat transfer in fluid tubes and storage mediums differs, the efficiency of heat storage and exchange differs, and improvement in melting and solidification rates of the storage medium are 41% and 23%, respectively [23]. Niedermeier shows a storage system of which the performance is influenced by bed porosity, tank diameter-to-height ratio, and filler size [24]. Amagour shows a storage system with encapsulated phase changing material (PCM) filled between fins to increase efficiency to 71% [25]. Normally, relative heat storage sizes are determined by annual heat supply into networks [26].

Recent studies reveal that HTF, which is a significant element of solar thermal systems, include liquids, solids, and PCMs. Liquid mediums, such as oils and alcohols, need less space, but have lower storage efficiencies. Solid mediums, such as rocks, concrete, and silica fire bricks need more space and normally use air as heat transfer fluid. PCM mediums, such as H2O, paraffin, and molten salt, has large heats of fusion, which increase storage and heat exchange efficiency. There are many types of PCMs for different solar heating and cooling systems with different working temperatures [27]. Some mixed nanomaterials have a great potential for thermal management applications owing to their excellent thermo-physical properties [28]. For increasing the overall efficiency of solar thermal power plants, researchers studied the performance of hybrid PCMs and a variety of storage systems. Yuan et al. used a novel PCM (22.0 wt% Li2CO3-62.0 wt% K2CO3–16.0 wt% Na2CO3) to store air heat from a solar collector. They found an increase in overall heat storage and release capacities of 18.48% and 7.55%, respectively [29]. Elfeky used three types of PCM in one storage system, which can significantly improve the heat transfer rate and effectively shorten the heat storage time. Charging efficiency was 91% and discharging efficiency 84% [30]. Kargar et al. combined three storage components (super heater, steam generator, and preheater) as a thermal storage system to decrease the charging time from 12 h to 4 h and significantly increase the energy storage efficiency [31]. Tab. 2 shows some typical heat storage mediums and their thermo-physical properties. According to different forms of energy cascade utilization, suitable heat storage systems and mediums should be selected to improve the efficiency of whole systems.

3 Hybrid System for Training Hall

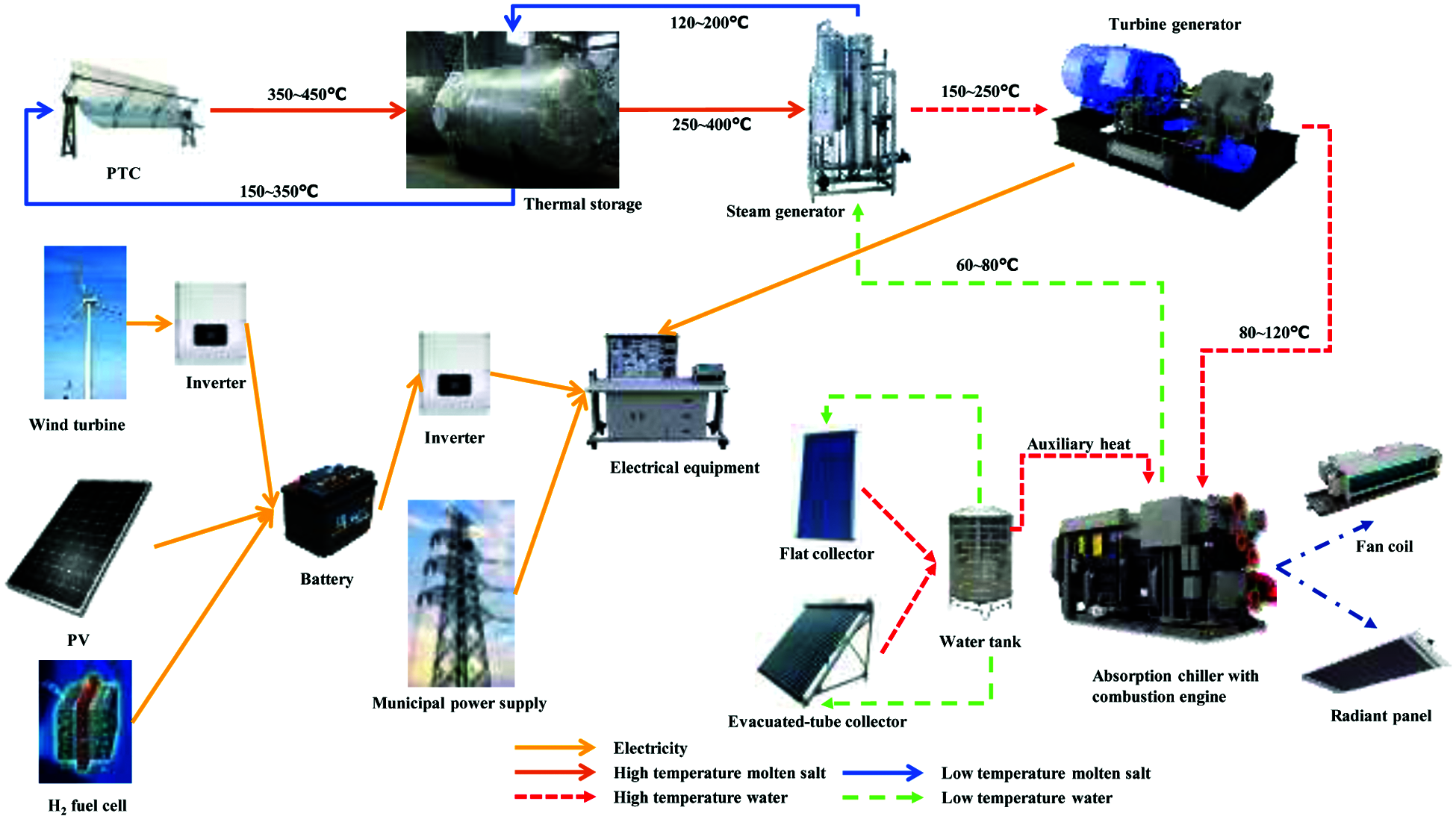

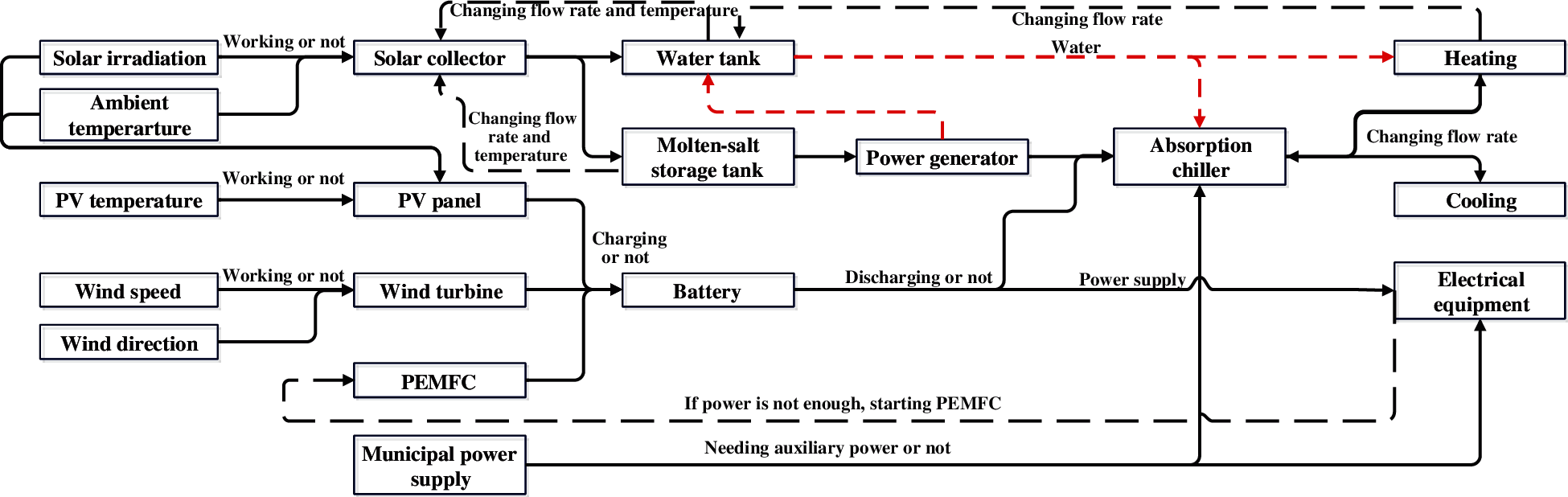

At school, there is a 1000 m2 training hall. Solar-wind hybrid power system with 4 kW (including monocrystalline silicon PV and vertical axis wind turbine), solar flat collector heating system with 20 m2, and traditional electrical cooling and heating system with 61.5 kW cooling and 69 kW heating capacity (Central air-conditioning) already exist. However, these former systems cannot meet the requirements for indoor comfort and consumes a significant amount of electricity. A small hybrid energy system based on molten-salt energy storage is proposed. As illustrated in Fig. 3, the novel system includes solar thermal power generation system, solar hot water system, multi-energy hybrid power generation system, absorption chiller and energy storage system.

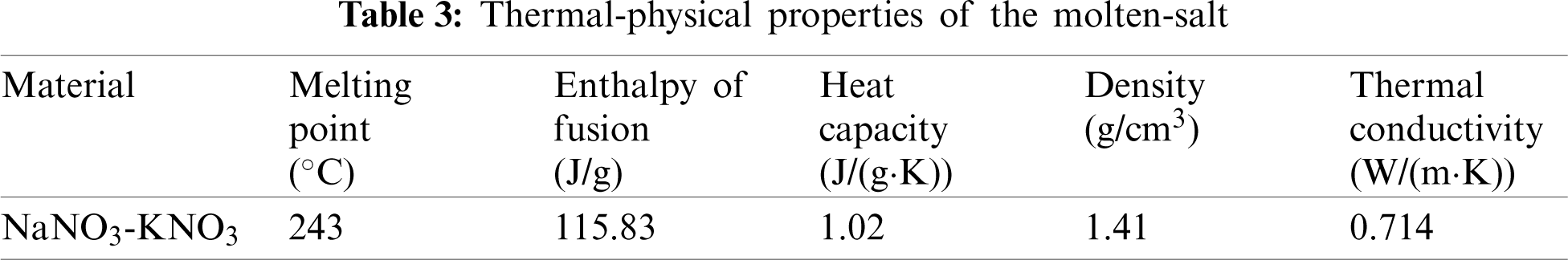

Solar thermal power generation system includes PTC collectors (20 m2), thermal storage tank, steam generator and turbine generator. Considering cost, safety, building load-bearing, and floor area, one 1.5 m3 thermal storage cylinder with electric heating is chosen. Thermal insulation material covers pipes and thermal storage tank. For improving storing and heat transferring efficiency, the storage is directly connected with PTC. Considering cost, toxicity, corrosion, preparation, and thermo-physical properties, 50% NaNO3 + 50% KNO3 is chosen as molten-salt in the loop of PTC system, shown in Tab. 3. Solar hot water system includes flat collectors (15 m2), evacuated-tube collectors (15 m2), and the exiting water tank (1 m3) used as auxiliary storage for low temperature water. Water is used as HTF in the loop of solar hot water system and power generating system. PTC collectors can produce 350∼450°C molten-salt, which is sent to the thermal storage tank for thermal storage, or sent to the steam generator through the tank for heat-exchanging with the waste heat water (60∼80°C) after the generator of the absorption chiller with combustion engine (refrigeration capacity 116 kW; heating capacity 90 kW), to produce 150∼250°C medium-high temperature steam to meet the needs of the turbine. Steam passing through the turbine, which turns into 80∼120°C medium-low temperature waste heat water, will be transmitted to absorption chiller as heat source, to promote refrigeration and heat pump cycle. At the same time, solar water heating system can also provide auxiliary heat for absorption chillers. The cascaded utilization of solar thermal energy can be realized. The terminals include radiant panels and fan coils. Multi-energy hybrid power generation system includes solar PV system (3 kW monocrystalline silicon cells), wind power generation system (5 kW), fuel cell power generation system (Proton exchange membrane fuel cell-PEMFC 3 kW), inverter, and battery (10 kW). The system uses municipal power supply as auxiliary electricity.

Figure 3: Hybrid system for training hall

The power system uses inverters changing AC power generated by wind turbine into DC power to store, and stored DC power into AC power. For power load, some researches reviewed the control strategies for hybrid system [40]; for thermal load, some researches reviewed energy management strategies (EMS) [41] (including power and thermal control), such as linear programming, intelligent techniques, fuzzy logic controllers and so on. Considering maturity, reliability, stability, and operation cost, the control method based on PID regulation is used, based on systematic simulation analysis of energy supply part, energy storage part and energy consumption part. The operation of hybrid energy system is adjusted according to the relationship between supply and demand of heating, cooling and electricity, and environment impacts (e.g., ambient temperature, solar irradiation, and wind velocity). Fig. 4 illustrates the system control process. The performance of solar collectors and PV cells mainly depends on solar irradiance and ambient temperature. By changing the flow rate of HTF, the working condition of the system varying with load demand can be realized. The performance of wind power generation system mainly depends on wind speed and direction. Adjusting the charge and discharge rate of battery can be realized according to the power demand of customers. PEMFC as an auxiliary power unit begins to supply power when power is not enough, furthermore, municipal power begins to supply. Power from solar thermal power generator and batteries can provide energy for absorption chiller and electrical equipment. Absorption chiller can provide cooling or heating according to demand of customers. Meanwhile, in order to realize thermal energy cascade utilization, by adjusting the flow rate of HTF among steam generator, water tank, thermal storage tank and generator of absorption chiller, energy supply can be adjusted in real time according to the load demand.

Figure 4: Basic system control process

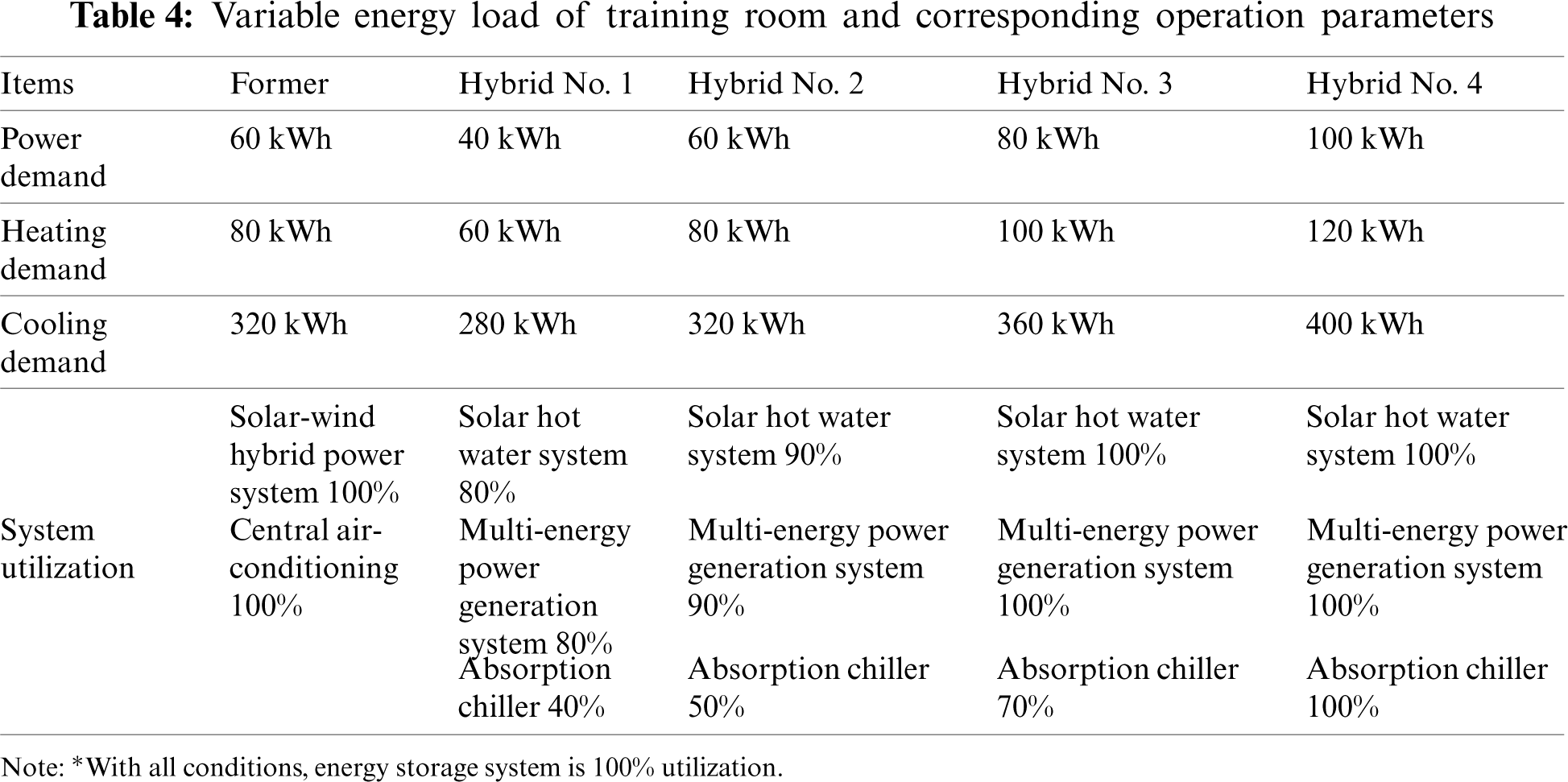

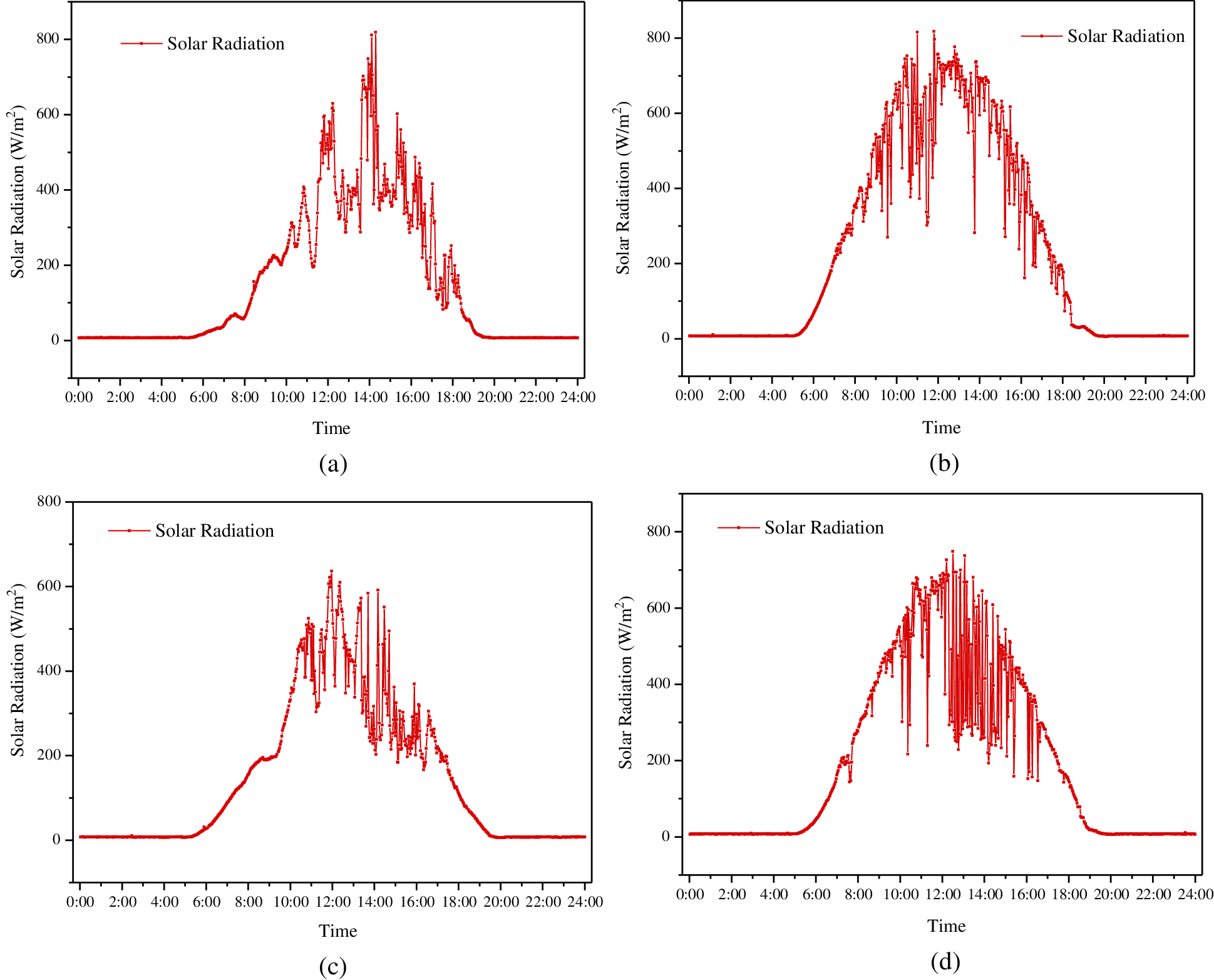

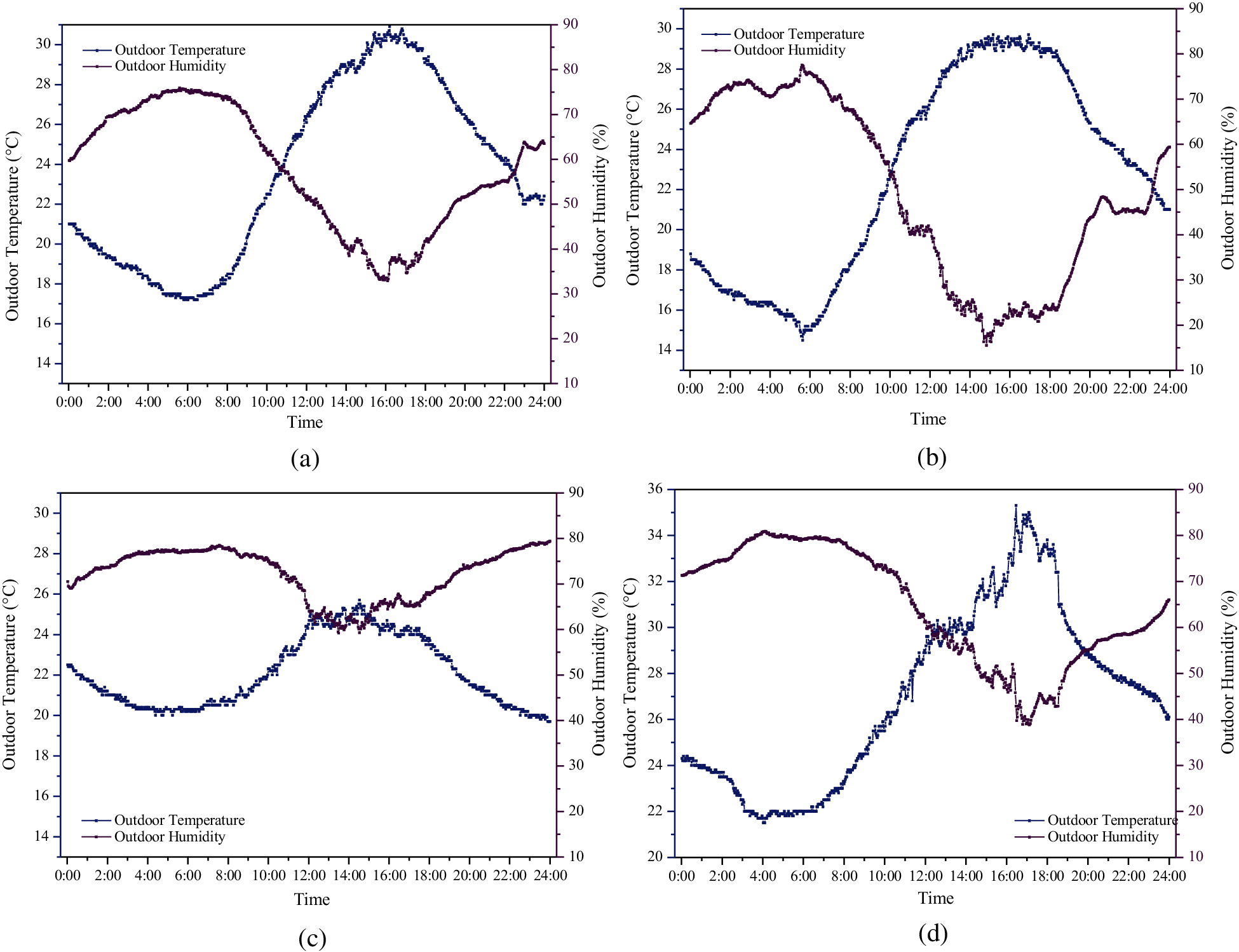

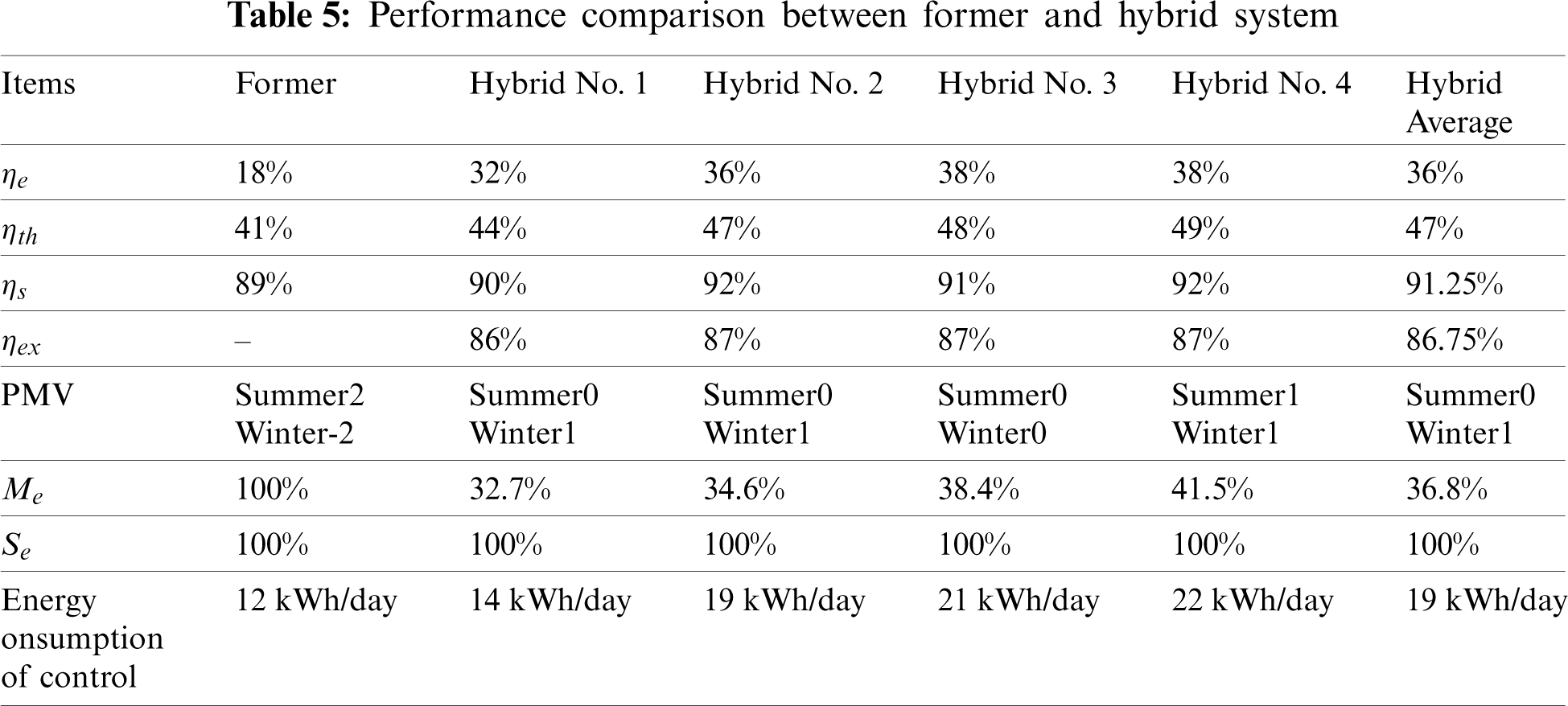

Energy Plus is used to simulate the performance of former and designed system. Firstly, the building model is established according to the training room. Then, the corresponding energy supply modules are selected, and the operation parameters, environmental parameters and variable energy load of training room are inputted. Specifically, the former system is chosen PV cells, wind turbine and central air-conditioning as energy supply modules. The designed system is chosen solar collectors (flat collectors, evacuated-tube collectors and PTC), wind turbine (vertical), PV (monocrystalline silicon solar cell), fuel cell (PEMFC), and combustion engine as heating and power supplying devices, chosen thermal storage tank (molten-salt) and battery (lead-acid battery) as energy storage and buffer devices, and chosen absorption chiller as cooling supplying devices. The operation parameters and variable energy load are listed in Tab. 4. The corresponding actual environmental parameters in May in Tianjin are showed in Figs. 5 and 6. The performance of the chosen PV system is shown in Fig. 7. Finally, through simulation and calculation based on Eqs. (1)–(7), the results showed that, designed system can increase the efficiency of solar energy utilization, as described in Tab. 5.

Figure 5: Solar radiation parameters (a) Hybrid No. 1 (b) Hybrid No. 2 (c) Hybrid No. 3 (d) Hybrid No. 4

As shown in Tab. 5, the performance of the suggested novel hybrid system is better than that of the former system. Because of the better control logic and complementary energy supply mechanism of multiple energy sources,

Figure 6: Outdoor temperature and humidity (a) Hybrid No. 1 (b) Hybrid No. 2 (c) Hybrid No. 3 (d) Hybrid No. 4

Figure 7: Performance of PV system in the year (a) Irradiation on horizonal and tilted (30°) plane (b) PV system output energy

This paper reviews the typical solar thermal power plant with energy cascade utilization system. A CCHP system can produce cooling, heating, and power simultaneously. Owing to unpredictable solar energy supply, storage is necessary. Through reviewing the hybrid system and storage form, we determined that the mode of system connection and thermal storage system characteristics can affect the temperature range of heat transfer fluid to realize different efficiency levels of energy cascade utilization. We chose several existing energies at the school as resources, proposing a small hybrid energy system based on molten salt for energy storage to solve the problems of heating, cooling, and electricity consumption of a 1000 m2 training room. According to simulation analysis, PMV improved, usage of municipal electricity decreased, and the overall energy efficiency increased to 83%.

Availability of Data and Materials: All data, models, and code generated or used during the study appear in the submitted article. However, the raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Funding Statement: This research was funded by 2017 Research Project of Tianjin Sino-German University of Applied Sciences (Project No. zdkt2017-001), The Science & Technology Development Fund of Tianjin Education Commission for Higher Education (Project No. 2018KJ260), and The Science & Technology Development Fund of Tianjin Education Commission for Higher Education (Project No. 2020ZD03).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. National Bureau of Statistics of China (2019). China statistical yearbook 2019. China: China Statistics Press. [Google Scholar]

2. China Association of Building Energy Efficiency (2019). Research report on building energy consumption in China. [Google Scholar]

3. Guo, S. P., Liu, Q. B., Sun, J., Jin, H. G. (2018). A review on the utilization of hybrid renewable energy. Renewable and Sustainable Energy Reviews, 91, 1121–1147. DOI 10.1016/j.rser.2018.04.105. [Google Scholar] [CrossRef]

4. Ahn, H., Rim, D., Freihaut, J. D. (2018). Performance assessment of hybrid chiller systems for combined cooling, heating and power production. Applied Energy, 225, 501–512. DOI 10.1016/j.apenergy.2018.05.045. [Google Scholar] [CrossRef]

5. Ge, T. S., Wang, R. Z., Xu, Z. Y., Pan, Q. W., Du, S. et al. (2018). Solar heating and cooling: Present and future development. Renewable and Sustainable Energy Reviews, 126, 1126–1140. DOI 10.1016/j.renene.2017.06.081. [Google Scholar] [CrossRef]

6. Vandermeulen, A., Heijde, B., Helsen, L. (2018). Controlling district heating and cooling networks to unlock flexibility: A review. Energy, 151, 103–115. DOI 10.1016/j.energy.2018.03.034. [Google Scholar] [CrossRef]

7. Arsalis, A., Alexandrou, A. N., Georghiou, G. E. (2018). Thermo-economic modeling of a small-scale gas turbine-photovoltaic-electrolyzer combined-cooling-heating-and-power system for distributed energy applications. Journal of Cleaner Production, 188, 443–455. DOI 10.1016/j.jclepro.2018.04.001. [Google Scholar] [CrossRef]

8. Beha, O. (2018). Solar thermal power plants—A review of configurations and performance comparison. Renewable and Sustainable Energy Reviews, 92, 608–627. DOI 10.1016/j.rser.2018.04.102. [Google Scholar] [CrossRef]

9. Tian, Z. Y., Perers, B., Furbo, S. (2018). Thermo-economic optimization of a hybrid solar district heating plant with at plate collectors and parabolic trough collectors in series. Energy Conversion and Management, 165, 92–101. DOI 10.1016/j.enconman.2018.03.034. [Google Scholar] [CrossRef]

10. Arabkoohsar, A., Andresen, G. B. (2017). Supporting district heating and cooling networks with a bifunctional solar assisted absorption chiller. Energy Conversion and Management, 148, 184–196. DOI 10.1016/j.enconman.2017.06.004. [Google Scholar] [CrossRef]

11. Sanaye, S., Sarrafi, A. (2015). Optimization of combined cooling, heating and power generation by a solar system. Renewable Energy, 80, 699–712. DOI 10.1016/j.renene.2015.02.043. [Google Scholar] [CrossRef]

12. Fine, J. P., Friedman, J., Dworkin, S. B. (2017). Detailed modeling of a novel photovoltaic thermal cascade heat pump domestic water heating system. Renewable Energy, 101, 500–513. DOI 10.1016/j.renene.2016.08.063. [Google Scholar] [CrossRef]

13. Carotenutoa, A., Figaja, R. D., Vanoli, L. (2017). A novel solar-geothermal district heating, cooling and domestic hotwater system: Dynamic simulation and energy-economic analysis. Energy, 141, 2652–2669. DOI 10.1016/j.energy.2017.08.084. [Google Scholar] [CrossRef]

14. Buonomano, A., Calise, F., Palombo, A. (2018). Solar heating and cooling systems by absorption and adsorption chillers driven by stationary and concentrating photovoltaic/thermal solar collectors: Modelling and simulation. Renewable and Sustainable Energy Reviews, 82, 1874–1908. DOI 10.1016/j.rser.2017.10.059. [Google Scholar] [CrossRef]

15. Ramos, A., Chatzopoulou, M. A., Guarracino, I., Freeman, J., Markides, C. N. (2017). Hybrid photovoltaic-thermal solar systems for combined heating, cooling and power provision in the urban environment. Energy Conversion and Management, 150, 838–850. DOI 10.1016/j.enconman.2017.03.024. [Google Scholar] [CrossRef]

16. Zhao, B. C., Cheng, M. S., Liu, C., Dai, Z. M. (2018). Conceptual design and preliminary performance analysis of a hybrid nuclear-solar power system with molten-salt packed-bed thermal energy storage for on-demand power supply. Energy Conversion and Management, 166, 174–186. DOI 10.1016/j.enconman.2018.04.015. [Google Scholar] [CrossRef]

17. Coelho, B., Oliveira, A., Schwarzbözl, P., Mendes, A. (2015). Biomass and central receiver system (CRS) hybridization: Integration of syngas/biogas on the atmospheric air volumetric CRS heat recovery steam generator duct burner. Renewable Energy, 75, 665–674. DOI 10.1016/j.renene.2014.10.054. [Google Scholar] [CrossRef]

18. Moaleman, A., Kasaeian, A., Aramesh, M., Mahian, O., Sahota, L. et al. (2018). Simulation of the performance of a solar concentrating photovoltaic-thermal collector, applied in a combined cooling heating and power generation system. Energy Conversion and Management, 160, 191–208. DOI 10.1016/j.enconman.2017.12.057. [Google Scholar] [CrossRef]

19. Banakar, A., Motevali, A., Emad, M., Ghobadian, B. (2017). Co-generation of heat and power in a thermoelectric system equipped with fresnel lens collectors using active and passive cooling techniques. Renewable Energy, 112, 268–279. DOI 10.1016/j.renene.2017.05.052. [Google Scholar] [CrossRef]

20. Zhang, C., Zhang, Y. P., Arauzo, I., Gao, W., Zou, C. Z. (2017). Cascade system using both trough system and dish system for power generation. Energy Conversion and Management, 142, 494–503. DOI 10.1016/j.enconman.2017.03.073. [Google Scholar] [CrossRef]

21. Al-Sulaiman, F. A., Hamdullahpur, F., Dincer, I. (2012). Performance assessment of a novel system using parabolic trough solar collectors for combined cooling, heating, and power production. Renewable Energy, 48, 161–172. DOI 10.1016/j.renene.2012.04.034. [Google Scholar] [CrossRef]

22. Moradi, M., Mehrpooy, M. (2017). Optimal design and economic analysis of a hybrid solid oxide fuel cell and parabolic solar dish collector, combined cooling, heating and power (CCHP) system used for a large commercial tower. Energy, 130, 530–543. DOI 10.1016/j.energy.2017.05.001. [Google Scholar] [CrossRef]

23. Esapour, M., Hamzehnezhad, A., Darzi, A. R., Jourabian, M. (2018). Melting and solidification of PCM embedded in porous metal foam in horizontal multi-tube heat storage system. Energy Conversion and Management, 171, 398–410. DOI 10.1016/j.enconman.2018.05.086. [Google Scholar] [CrossRef]

24. Niedermeier, K., Marocco, L., Flesch, J., Mohan, G., Coventry, J. et al. (2018). Performance of molten sodium vs. molten salts in a packed bed thermal energy storage. Applied Thermal Engineering, 141, 368–377. DOI 10.1016/j.applthermaleng.2018.05.080. [Google Scholar] [CrossRef]

25. Amagour, M. H., Rachek, A., Bennajah, M., Touhami, M. E. (2018). Experimental investigation and comparative performance analysis of a compact finned-tube heat exchanger uniformly filled with a phase change material for thermal energy storage. Energy Conversion and Management, 165, 137–151. DOI 10.1016/j.enconman.2018.03.041. [Google Scholar] [CrossRef]

26. Gadd, H., Werner, S. (2015). Advances in thermal energy storage systems-methods and applications. Woodhead Publishing Series in Energy, 18, 467–478. DOI 10.1533/9781782420965.4.467. [Google Scholar] [CrossRef]

27. Settino, J., Sant, T., Micallef, C., Farrugia, M., Staines, C. S. et al. (2018). Overview of solar technologies for electricity, heating and cooling production. Renewable and Sustainable Energy Reviews, 90, 892–909. DOI 10.1016/j.rser.2018.03.112. [Google Scholar] [CrossRef]

28. Banakar, A., Motevali, A., Emad, M., Ghobadian, B. (2017). Co-generation of heat and power in a thermoelectric system equipped with fresnel lens collectors using active and passive cooling techniques. Renewable Energy, 112, 268–279. DOI 10.1016/j.renene.2017.05.052. [Google Scholar] [CrossRef]

29. Yuan, F., Li, M. J., Ma, Z., Jin, B., Liu, Z. B. (2018). Experimental study on thermal performance of high-temperature molten salt cascaded latent heat thermal energy storage system. International Journal of Heat and Mass Transfer, 118, 997–1011. DOI 10.1016/j.ijheatmasstransfer.2017.11.024. [Google Scholar] [CrossRef]

30. Wang, T., Mantha, D., Reddy, R. G. (2015). Novel high thermal stability LiF-Na2CO3-K2CO3 eutectic ternary system for thermal energy storage applications. Solar Energy Materials and Solar Cells, 140, 366–375. DOI 10.1016/j.solmat.2015.04.033. [Google Scholar] [CrossRef]

31. Kargar, M. R., Baniasadi, E., Mosharaf-Dehkordi, M. (2018). Numerical analysis of a new thermal energy storage system using phase change materials for direct steam parabolic trough solar power plants. Solar Energy, 170, 594–605. DOI 10.1016/j.solener.2018.06.024. [Google Scholar] [CrossRef]

32. Li, X., Wu, S., Wang, Y., Xie, L. D. (2018). Experimental investigation and thermodynamic modeling of an innovative molten salt for thermal energy storage (TES). Applied Energy, 212, 516–526. DOI 10.1016/j.apenergy.2017.12.069. [Google Scholar] [CrossRef]

33. Elfeky, K. E., Ahmed, N., Wang. Q. W. (2018). Numerical comparison between single PCM and multi-stage PCM based high temperature thermal energy storage for CSP tower plants. Applied Thermal Engineering, 139, 609–622. DOI 10.1016/j.applthermaleng.2018.04.122. [Google Scholar] [CrossRef]

34. Gil, A., Medrano, M., Martorell, I., Potau, X., Cabeza, L. F. (2010). State of the art on high temperature thermal energy storage for power generation. Part 1—Concepts, materials and modellization. Renewable and Sustainable Energy Reviews, 14, 31–55. DOI 10.1016/j.rser.2009.07.035. [Google Scholar] [CrossRef]

35. Hänchen, M., Brückner, S., Steinfeld, A. (2011). High-temperature thermal storage using a packed bed of rocks–heat transfer analysis and experimental validation. Applied Thermal Engineering, 31, 1798–1806. DOI 10.1016/j.applthermaleng.2010.10.034. [Google Scholar] [CrossRef]

36. Farid, M. M., Khudhair, A. M., Razack, S. A. K., Al-Hallaj, S. (2004). A review on phase change energy storage: Materials and applications. Energy Conversion and Management, 45, 1597–1615. DOI 10.1016/j.enconman.2003.09.015. [Google Scholar] [CrossRef]

37. Alva, G., Liu, L. K., Huang, X., Fang, G. Y. (2017). Thermal energy storage materials and systems for solar energy applications. Renewable and Sustainable Energy Reviews, 68, 693–706. DOI 10.1016/j.rser.2016.10.021. [Google Scholar] [CrossRef]

38. Shin, D., Banerjee, D. (2011). Experimental investigation of molten salt nanofluid for solar thermal energy application. ASME/JSME 2011 Proceedings of the 8th Thermal Engineering Joint Conference, pp. 1–6. Hawaii. [Google Scholar]

39. Chieruzzi, M., Cerritelli, G. F., Miliozzi, A., Kenny, J. M. (2013). Effect of nanoparticles on heat capacity of nanofluids based on molten salts as PCM for thermal energy storage. Nanoscale Research Letters, 8, 448. DOI 10.1186/1556-276X-8-448. [Google Scholar] [CrossRef]

40. Arul, P. G., Ramachandaramurthy, V. K., Rajkumar, R. K. (2015). Power control strategies for a hybrid renewable energy system: A review. Renewable and Sustainable Energy Reviews, 42, 597–608. DOI 10.1016/j.rser.2014.10.062. [Google Scholar] [CrossRef]

41. Olatomiwa, L., Mekhilef, S., Ismail, M. S., Moghavvemi, M. (2016). Energy management strategies in hybrid renewable energy systems: A review. Renewable and Sustainable Energy Reviews, 62, 821–835. DOI 10.1016/j.rser.2016.05.040. [Google Scholar] [CrossRef]

42. Zhu, Y. X. (2016). Built environment. China: China Architecture & Building Press. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |