| Energy Engineering |  |

DOI: 10.32604/EE.2021.015467

ARTICLE

Aging Characteristics and Influencing Factors of the Sheds of Composite Insulators in Karst Regions of China

1Tianshengqiao Bureau, Southern Power Grid EHV Power Transmission Company, Guizhou, 562400, China

2School of Electrical and Electronic Engineering, Huazhong University of Science & Technology, Wuhan, 430074, China

*Corresponding Author: Lee Li. Email: leeli@hust.edu.cn

Received: 20 December 2020; Accepted: 11 March 2021

Abstract: In recent years, more and more high-voltage overhead transmission lines were built passing through the karst regions in southwestern China. This type of special landform seems to have an adverse effect on the aging of the sheds of the line suspension composite insulators, which may lead to unexpected flashover and line tripping. In order to find out the particularity of the aging characteristics of insulators operating in the karst regions, samples in operation were selected from both the karst regions and the flatlands. Hydrophobicity, amount of surface contamination, and contaminant composition of the sheds were studied, then a comparison of performance between the two was made, and the possible influencing factors that cause such differences were discussed. The results show that the overall aging of the sheds of the composite insulators operating at the karst regions is more aggravated, which is caused by the combined influence of factors including the special topography, climate, and pollution in the area. The strong wind crossing the col will bring about the mutual scraping on the edges and stress concentration at the root of the sheds, leaving scratches and root cracks; the infiltration from these rupture of acid liquid, if any, will accelerate the aging and corroding of the internal silicone rubber material; moreover, the carbonates enriched on the surface of the sheds will gradually transform into more corrosive sulfates in an acidic environment, leading to further deterioration and chalking of the sheds of the insulators. The research work in this paper can provide guidance for the current operation and maintenance of composite insulators in the karst areas, as well as having important reference values for the layout design and insulation configuration of transmission lines to be built across karst landforms in the future.

Keywords: Composite insulator; silicone rubber; aging characteristics; karst region; contamination; carbonate

In the past decade, China has made great progress in the field of high-voltage direct-current (HVDC) power transmission. With more and more overhead transmission lines being built, the insulators, which serve as an indispensable mechanical component of the lines, were also put into use in large quantities. Composite insulators were particularly favored due to its small size, light weight, easy installation and free of maintenance, thus newly built HVDC lines are mostly equipped with composite insulators [1,2]. However, the biggest weakness of this kind of insulator is that its sheds, which are made of organic silicone rubber material, are prone to deteriorate over time, resulting in a decline in its insulation strength [3,4]. Especially when being applied in harsh environment, the performance degradation may be greatly exacerbated, and even malfunction during its normal service life [5]. Therefore, it is of great significance to research on the operation status and aging characteristics of composite insulators applied in special environments.

In the early 2000s, China has started an unprecedented large-scale power construction project nationwide, namely the West-to-East Electricity Transmission Project, to ease the problem of imbalanced distribution of energy resources. The southwest of China, abundant in hydroelectric resources, has undertaken the task of transmitting electricity to the southeast coast, thus quite a number of HVDC lines have been built there. Coincidentally, this area, including Guangxi Province, Guizhou Province and part of Eastern Yunnan Province, happens to be widely covered by a special type of landform called “the Karst” [6]. It refers to a type of natural landform formed by a series of geological processes including the chemical dissolution, erosion and suffosion of carbonate rocks by groundwater, whose landmark features are gully rock strata, peak-forest and peak-cluster on the ground surface. Although this situation was not well realized at the time the lines were built, after they have been operating for these years, it is found that the composite insulators operating in the karst regions were more likely to have a shorter service life than those operating in normal landforms, and the failure rate such as flashover and fracture of the core rod is also a bit higher, based on field experience and on-site statistics. It seems that the karst environment exerts an adverse effect on the operation status of the insulators, yet the possible reasons and the mechanism behind this remain unclear.

There have been some studies concerning the aging characteristics of composite insulators under the effects of special environments, such as plateaus with high altitude and strong ultraviolet radiation [7], coastal areas with high temperature and high humidity [8], saline-alkali lands [9], etc. However, the environmental characteristics of the karst are somewhat different from those mentioned above, thus the conclusions in the literatures cannot be directly applied in the karst regions. On the other hand, the distribution of karst landforms around the world is too less extensive than that of common landforms to arouse attention, let alone the karst regions with transmission lines passing through. For this reason, as of now there have been no relevant studies on the effect of karst on the aging of composite insulators, whether at home or abroad. Hence we consider it necessary and valuable to fill the gap in the research of the above-mentioned issues.

In this paper, we sampled a few composite insulators from currently operative transmission lines located in both the karst regions and the normal plain areas. Their operation statuses including hydrophobicity of the sheds, amount of contamination and contaminant composition were tested, followed by a comparison of the aging characteristics between them. Based on the experimental results, we analyzed the reasons for the abnormal aging of the sheds of insulators operating in the karst regions, and discussed several possible influencing factors. The work in this paper provides a forward-looking reference for the design, operation and maintenance of transmission lines across karst landforms in the future.

According to a preliminary investigation, there have been a total of 8 main high voltage transmission channels constructed in the southwestern China in the West-to-East Electricity Transmission Project, of which 5 are HVDC transmission lines. Among them, there are 2 lines, the DC ± 500 kV Tian-Guang Line and the DC ± 500 kV Xing-An Line, that mainly lies in Guizhou Province, which is one of the largest karst mountainous areas in China, and their corridors pass across a vast tract of karst regions. Although the other lines have also passed the karst more or less, they are either small in area or scattered in distribution, which is not suitable for systematic sampling and research. Therefore, in this paper we mainly sampled composite insulators from the two lines mentioned above. Nevertheless, the results of this paper can still be applied in other lines with similar situations.

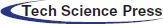

To make the research more persuasive, about thirty composite insulator samples were selected from the DC ± 500 kV Tian-Guang Line and the DC ± 500 kV Xing-An Line, with their towers located both in karst mountainous regions and in the plain areas nearby, as a comparison. After basic testing of all the samples, it is found that the aging characteristics of the insulators under similar environments and the same service life are very similar. Therefore, we did not list all the samples and their aging conditions, but selected the 8 most representative samples of the insulators for briefer and better illustration. They are divided in groups A and B, according to the terrains they are operated. Basic information of the samples was shown in Tab. 1.

All the insulators were operated in the same climate zone, which is the subtropical monsoon climate zone, with an annual average temperature 16∼25, annual average humidity 70%∼85% RH, and an annual average wind speed 2.6∼3.8 m/s. This ensured that the aging characteristics of all the insulators will not have substantial differences affected by environmental implication.

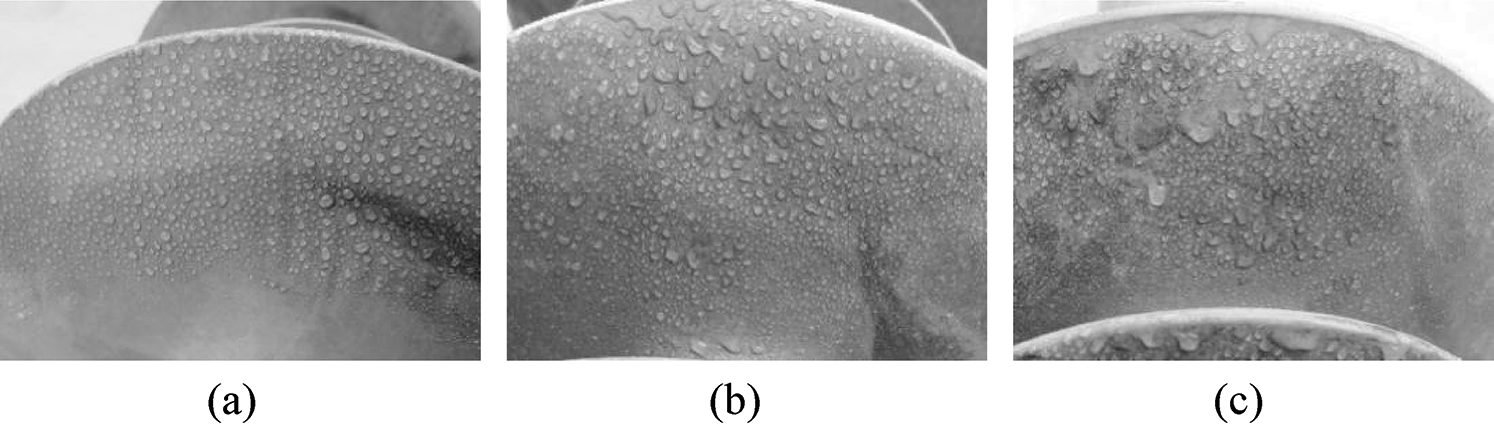

The water spray classification method was used to test the hydrophobicity of the rubber sheds of the insulator samples. According to standard [10], the hydrophobic state of the material surface is divided into seven grades, i.e., HC1∼HC7, where grade HC1 corresponds to highly hydrophobic surfaces, and grade HC7 corresponds to completely hydrophilic surfaces. Hydrophobicity tests were carried out on the sheds at the high voltage (HV) end, middle and low voltage (LV) end of all the eight insulator samples. The results are shown in Fig. 1, and some of the site images are shown in Fig. 2.

Figure 1: Hydrophobicity of the sheds of the insulator samples

Figure 2: Images of the sheds in the hydrophobicity test. (a) sample B-1, LV end, HC2; (b) sample A-4, middle, HC3; (c) sample A-2, HV end, HC4

It can be seen from Fig. 1 that the hydrophobicity of all the eight insulators is classified as grade HC4 and below, which indicates that the sheds remain not bad water repellency after 8 years of operation. Specifically, the hydrophobicity of the insulator samples in group A is classified HC3∼HC4, while the hydrophobicity of the insulator samples in group B is classified HC2∼HC3, indicating that for the insulators operating in the karst mountainous regions, the sheds would have a faster loss of hydrophobicity and more serious aging process. Besides, samples A-1, A-4 and B-4 have got worse hydrophobicity of the sheds at the HV end than in the middle and at the LV end. This is because the electric field around the HV end is higher, which exerts a more unfavorable effect on the aging of the sheds, resulting in greater loss of their hydrophobicity.

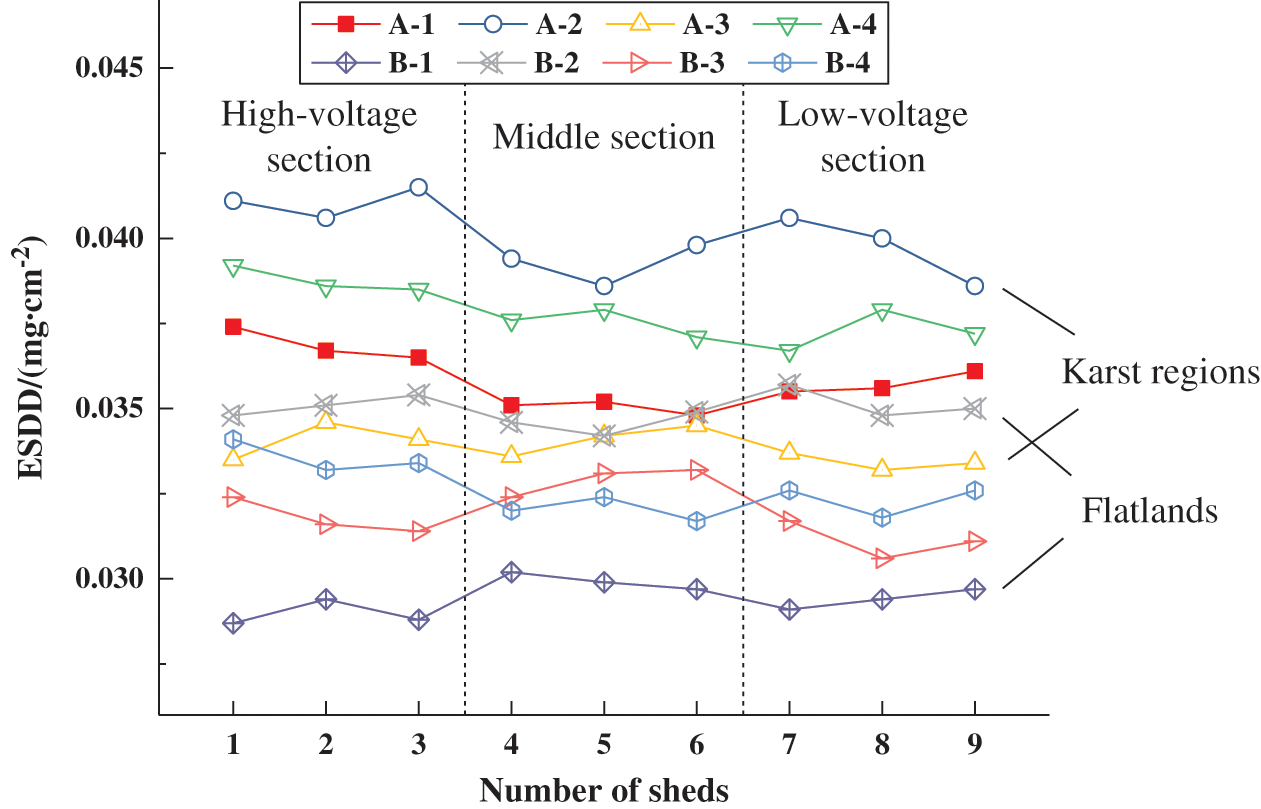

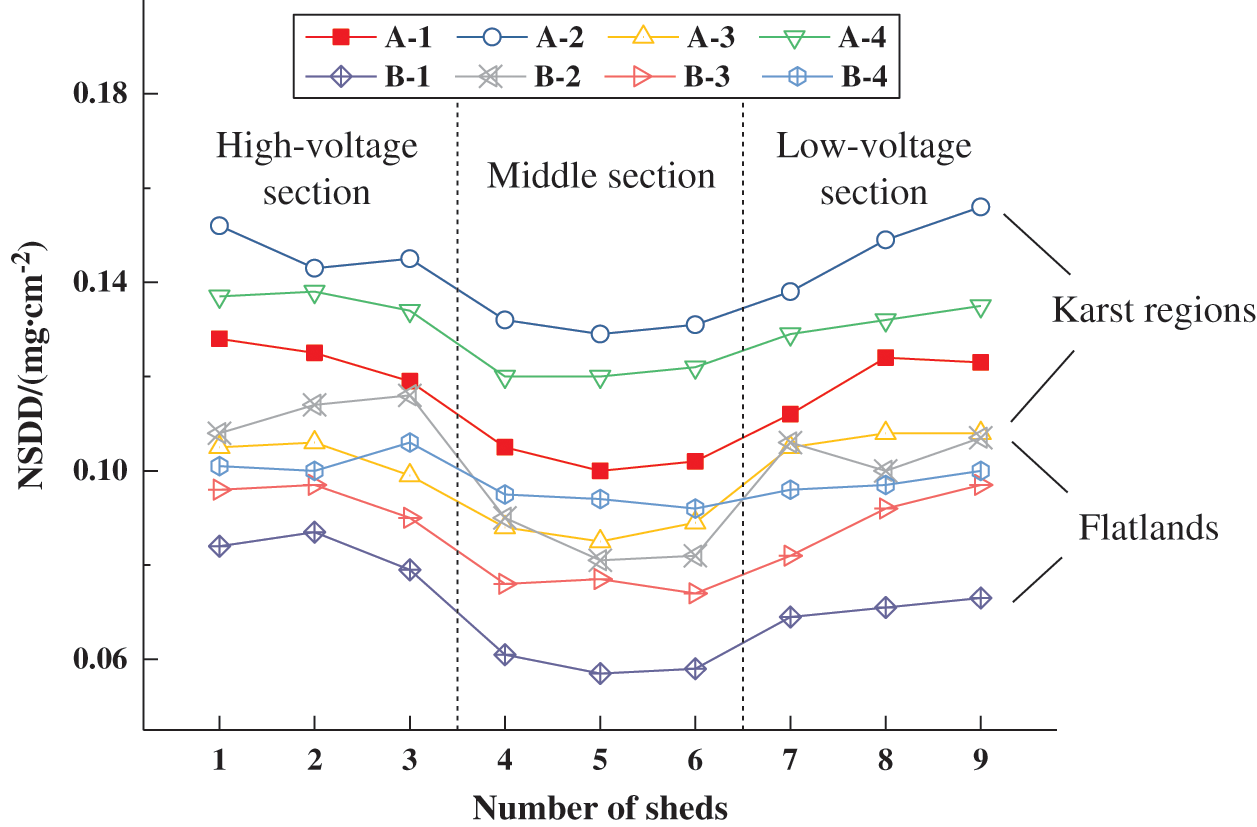

The amount of surface contamination is an important indicator reflecting the degradation of the sheds of an insulator. With the degradation of hydrophobicity and hydrophobicity migration, the self-cleaning ability of the shed surface against dirt particles is weakened, and the consequent performance is that the amount of contamination increases. The equivalent salt deposit density (ESDD) and non-soluble deposit density (NSDD) of the eight insulators are measured. Each insulator is divided into three sections: the high-voltage section, the middle section, and the low-voltage section. Three adjacent sheds in each section are taken for measurement, totaling 9 measurement points. The measurement results are shown in Figs. 3 and 4.

Figure 3: Measurement results of ESDD of the insulator samples

Figure 4: Measurement results of NSDD of the insulator samples

It can be seen from Figs. 3 and 4 that, the insulators in group A have overall higher values of both ESDD and NSDD than those in group B, indicating that there exists some differences in the contaminating process between insulators operated in the karst regions and those operated in the plain areas. Among all the samples, sample A-2 has the highest ESDD and NSDD, which is consistent with intuitive perception, since A-2 has been operated in the karst region and for the longest time (8 years). So is true in other situations, where samples A-1 and A-3 (karst regions for 6 years) have roughly the same amount of contamination as B-2 and B-4 (plain areas for 8 years), and samples B-1 and B-3 (plain areas for 6 years) are least contaminated. The contaminant accumulation on the sheds is closely related to their aging, for the aging and degradation of the shed will worsen its insulating performance, leading to an increase in the electric field, which will then exert a more obvious drawing force on the contaminants towards its surface [11].

Also, it is noticed in Fig. 4 that, the NSDD in different sections of a same insulator is quite varied. The NSDD in the HV section and the LV section is larger than in the middle section, presenting a “U”-shaped distribution along the suspension direction of the insulator. This is because of the polarization effect of the DC electric field, where places with higher field intensity are more likely to adsorb dirt particles [12]. And it is known that the axial electric field distribution of a composite insulator is saddle-shaped, with two ends high and the middle low [13], thus the distribution characteristics of the NSDD and the electric field are basically agreed.

2.3 Contaminant Composition Analysis

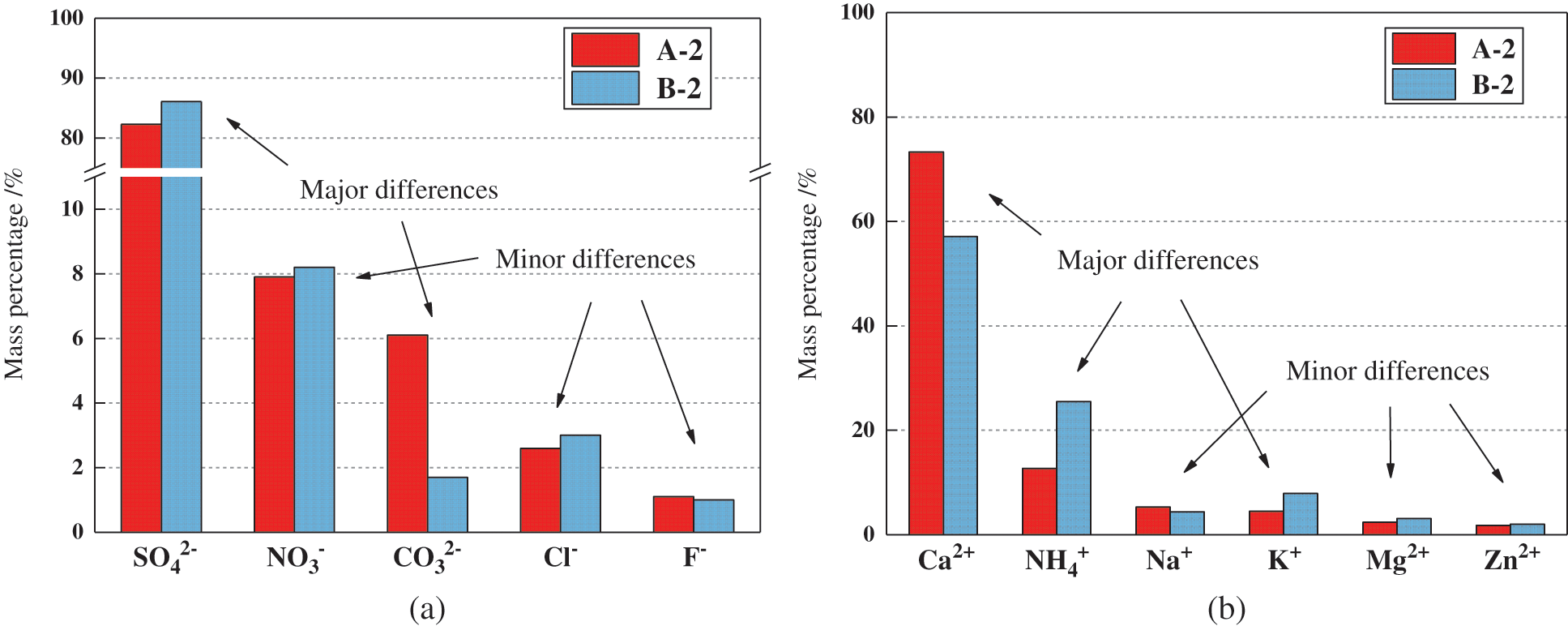

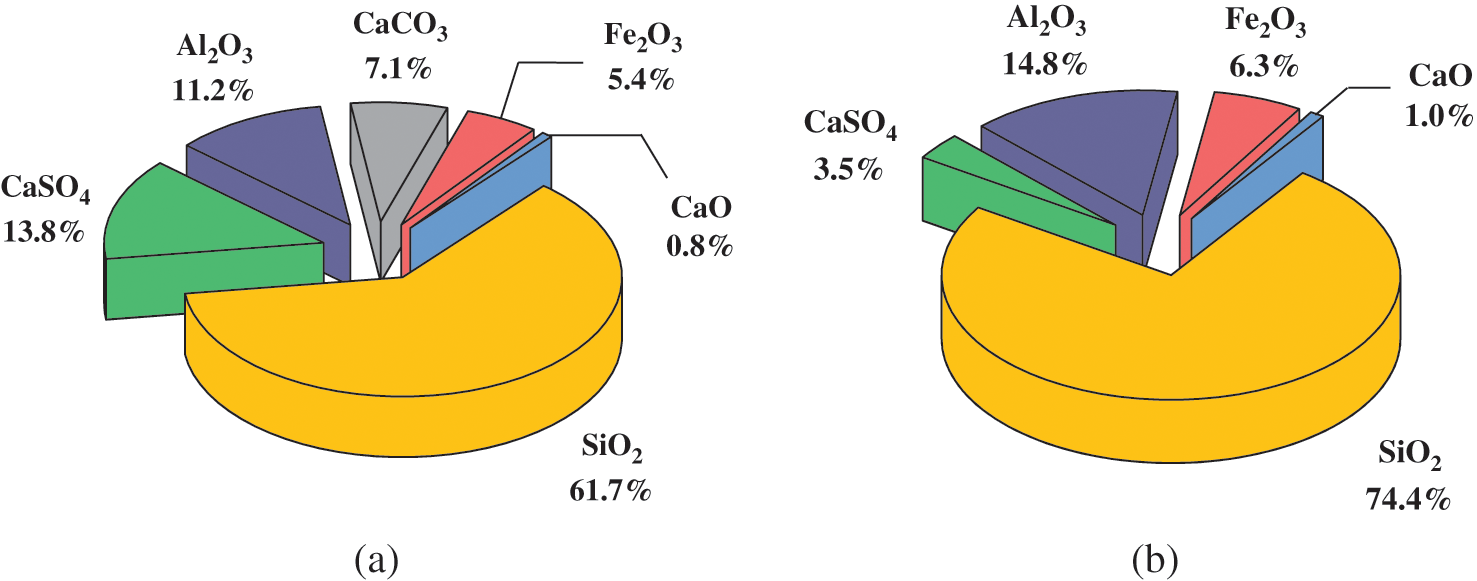

To dig further, we take measures to determine the composition and content of the contaminants on the sheds of the insulator samples. The contaminants consists of soluble ionic composition and insoluble particles, which are tested and analyzed by an ion chromatograph and an infrared spectrometer, respectively. The detection method is as follows: First, place the contaminants collected from the shed surface of the insulators in an oven at 80°C for 24 h, then dissolve them in a proper amount of distilled water, and filter the solution with quantitative filter paper after 30 min’ standing. Finally, we separate the solution containing only soluble composition and the insoluble residual particles for detecting separately [14,15]. In order to focus on the possible differences in the contaminant composition between insulators operated in the karst regions and in the plain areas, we picked samples A-2 and B-2, which have the greatest amount of contamination in their group, to carry out the composition analysis. The results are shown in Figs. 5 and 6.

Figure 5: Composition and contents of the soluble ion in the contaminants of the insulators (a) Anions (b) Cations

Figure 6: Composition and contents of the insoluble matter in the contaminants of the insulators (a) Sample A-2 (b) Sample B-2

Fig. 5 shows the anions and cations of the soluble compositions and their mass percentages of the contaminants of the two insulator samples. It can be found that the ionic compositions of the contaminants are just the same, the anions mainly SO2−4 and NO−3, and the cations mainly Ca2+ and NH+4, whether the insulator is applied in karst regions or flatlands. However, there are some certain differences in the mass fractions of the ions. The insulators used in plain areas have more contents of NH+4 and K+, which is closely related to the wide farmlands near the tower, where the volatilization of fertilizers containing nitrogen and potassium gradually results in an enrichment of ammonium and potassium ions in the area [16]. As for insulators operating in karst mountainous regions, their contamination is hardly affected by human activities thanks to its inaccessibility, thus their contaminating is mostly a reflection of the local natural pollution characteristics. It is noticed that, the mass fraction of Ca2+ and CO2-3 ions of sample A-2 is greatly more than that of sample B-2, indicating that the contamination of insulators in the karst regions is distinctly dominated by the particularity of the local rock and soil, which happen to be made of calcium carbonate. Yet, the absolute content of CO2−3 ion is not very high, as can be seen in Fig. 5a. This is because of the frequent acid rain in the karst regions. The gaseous SO2 in the air will slowly transform into H2SO4 under acidic conditions, and it will react with CaCO3 and CO2-3 ions deposited on the insulator. The ion reaction finally exists on the surface of the sheds in the form of chemical stable CaSO4 particles and SO2-4.

Fig. 6 shows the composition and content of insoluble matter in the contaminants of two insulator samples. It is clearly noticed that there exists CaCO3 deposits on the sheds of the insulator operating in the karst regions, which no corresponding component is found on the surface of the insulator operating in the plain areas. It is naturally deduced, based on this obvious fact, that the composition comes from weathered residue of limestone, which is unique to karst landforms. As illustrated before, CaCO3 will gradually transform into CaSO4 during contamination, and this explains the also rather high content of CaSO4 in the insoluble contaminants. Excluding calcium-containing compounds, the other composition of the insoluble matter in two samples is nearly the same, most of which are SiO2 from soil and sand, as well as some common metal oxides, including a small amount of Al2O3, Fe2O3, and a trace of CaO.

3 Influencing Factors Analysis

From the test results above, we have learned that, the composite insulators operating in the karst regions are more degraded in terms of hydrophobicity and fouling than those operating in the flatlands under the same service life. In order to explore the reasons for this specificity, we are now going to dig out the possible influencing factors that may be responsible, how the influence is implemented, and put forward practical measures for improvement.

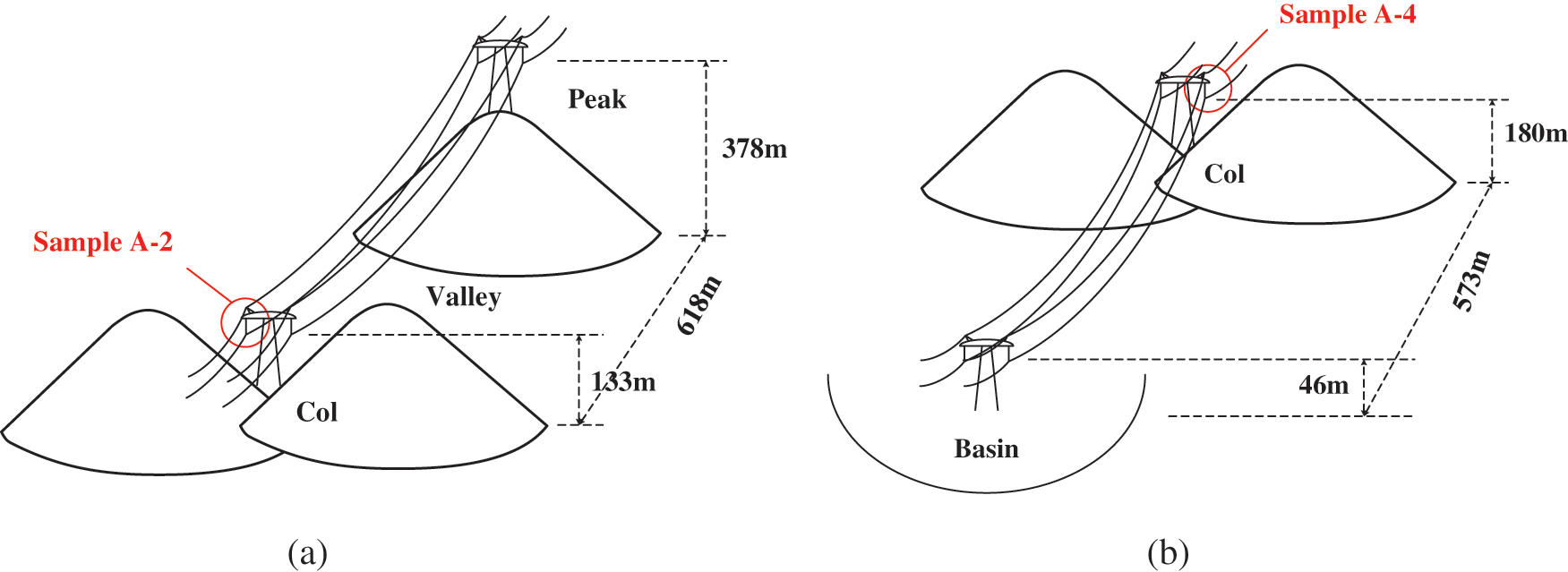

When it comes to the most conspicuous distinction between karst regions and flatlands, the first thing that comes to mind is their difference in topography. The karst landscapes are iconically characterized by vertical and horizontal ravines and rolling peaks and valleys on the land surface, which is a typical kind of natural micro-topography region [6]. According to site inspection of the Tian-Guang Line and Xing-An Line, it was found that dozens of towers were located at the col, which refers to a relatively flat and low-lying valley between consecutive mountains, also known as a saddle. In terms of the overall layout design of the transmission line, the passage of the line corridor through the col is very reasonable as it can avoid stepping directly over the mountains. However, for the towers and insulators suspended working on this very spot, their long-term performance is bound to be adversely affected by this special terrain. Taking sample A-2 and A-4 for examples, the geographical layouts of the towers they were suspended are shown in Fig. 7.

Figure 7: Geographical layout of the towers in the vicinity of the col (a) Sample A-2: col-peak (b) Sample A-4: basin-col

Fig. 7 reveals two typical layouts of the line corridor crossing through the col, where the towers adjacent to the tower located at the col are either located on the top of a mountain or in a basin. What is certain is that in either case, there will always be an altitude difference between the tower at the col and its adjacent bases, which will increase the vertical span and the arc sag of the wire. Thus, the towers at both ends of the wire are unevenly stressed, bringing the insulators an additional horizontal tensile load, whose effect is equal to a bending moment. As suspended insulators has poor bending moment capability, the long-term mechanical performance of the insulator is inevitably being adversely affected.

Since the effect of micro-topography on the insulators is mainly reflected in the additional bending moment, it is practicable to replace the suspended insulators with strain insulators to avoid the effect, as strain insulators are able to withstand bending moments. On the other hand, for new lines to be built in the karst regions, it is suggested not to put up the tower right at the col of the mountains, so as to avoid an excess of altitude difference of the adjacent towers.

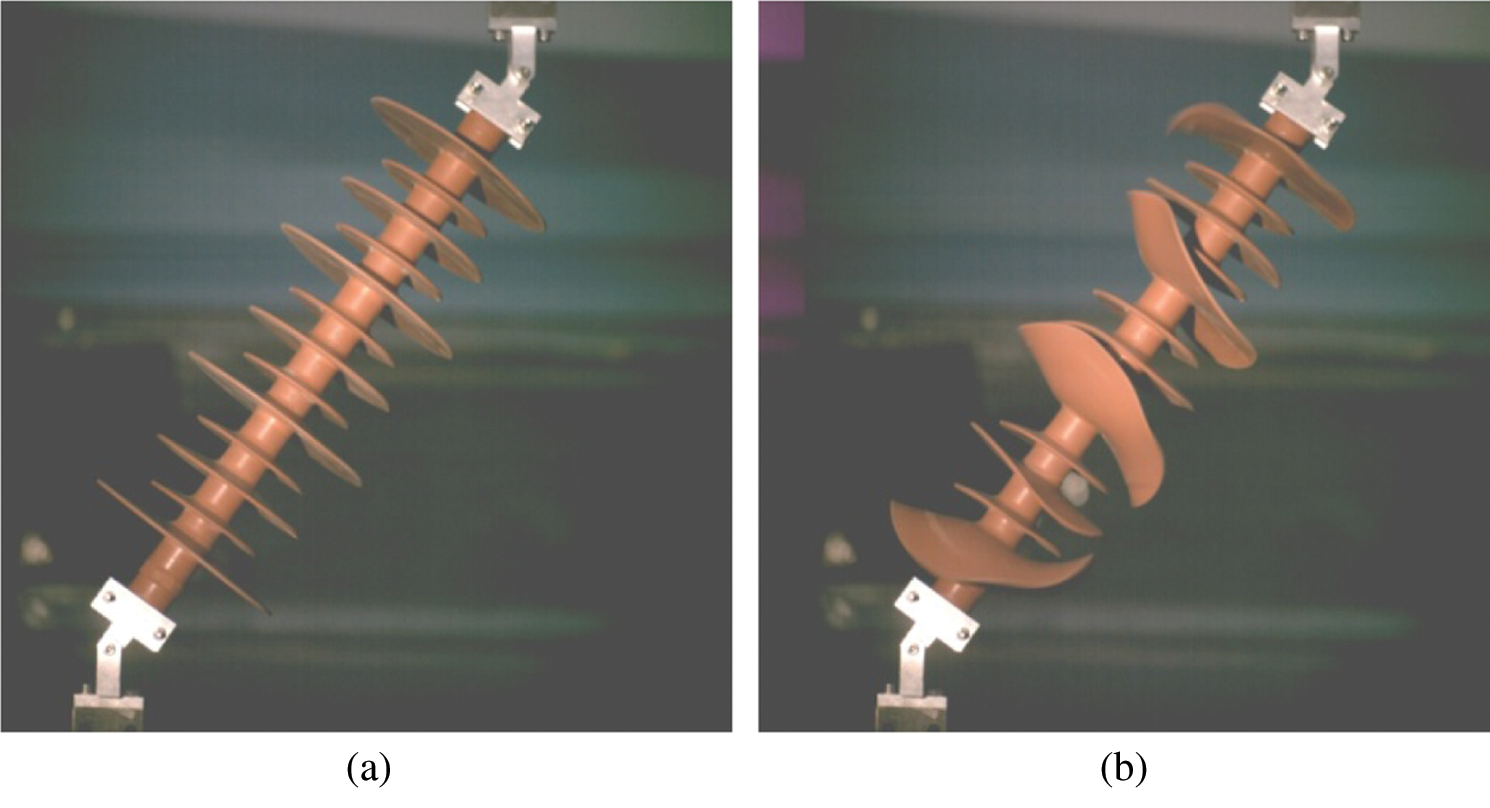

The particularity of the micro-climate in karst regions is mainly reflected in the abnormally strong wind across the col. According to funneling effect [17], when a mass of airflow comes from an open area into a narrow area such as a col-pass, the airflow will accelerate because of the conservation of mass, causing a significant increase in wind speed. Zhang et al. [18] have proved that the maximum wind speed on the central axis of a mountain col can be 33% higher than that on flatlands, a value far exceeds the 10% requirement in the current design specifications of transmission lines. The wind tunnel test in literature [19] directly observed the drastic swing of the sheds under strong airflow, as shown in Fig. 8. In such harsh conditions, the edges of the sheds scraped each other, and the surface performance of the silicone rubber material will soon be permanently damaged.

Figure 8: Behavior of the insulator sheds in wind tunnel experiment (a) Wind speed = 0 m/s (b) Wind speed = 40 m/s

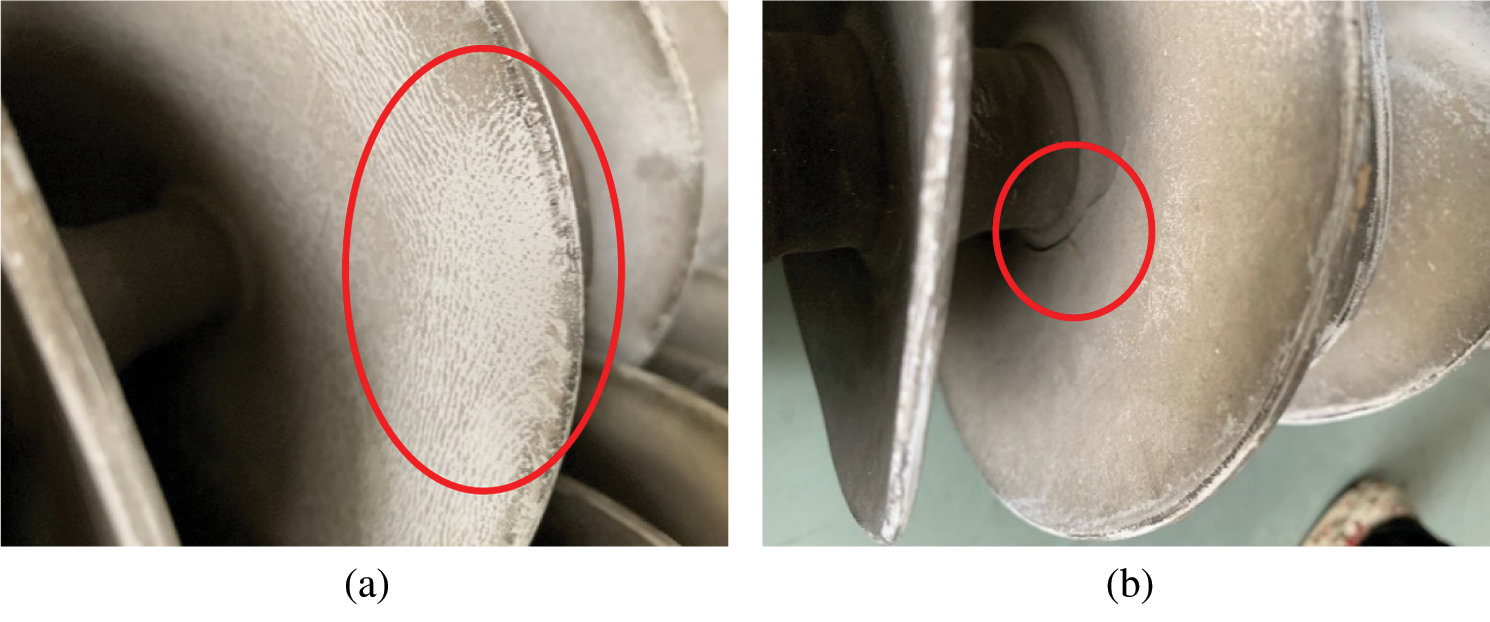

In actual situation, the short-term damage of the sheds may not be as exaggerated as in the wind tunnel test shown in Fig. 8, still the long-term effect of strong wind on the sheds should not be underestimated. Due to the complex structure of the shed, the fluid will be partly blocked by it when flowing through, leading to a sharp change in the flow field distribution at the edge of the shed. The windward side of the shed is subjected to greater wind pressure, which causes the separation of the turbulence and the vortex shedding at the margin, resulting in a certain degree of vibration at the edge of the shed. As wind speed becomes faster, the vibration frequency correspondingly increases, and gradually turns into high-frequency and large-scale vibration, finally periodic stress concentration occurs at the root of the shed. If subjected to long-term periodic cyclic loads, the root of the shed will be damaged in the form of stress fatigue, causing rupture and cracks on the surface of the silicone rubber material [20,21].

The real images of the two types of damages (surface scratches and root cracks) are shown in Fig. 9, which were found and taken from sample A-4. It is worth mentioning that more or less scrapes and cracks can be found on the sheds of all insulator samples in Group A, while few breakages are found on that of in Group B. This fact convincingly proves that the strong wind across the col of the karst mountains indeed adversely affect the surface properties of the sheds of insulators.

Figure 9: Scratch and crack on the sheds of sample insulators (a) Scratches at the edge (b) Crack at the root

Moreover, strong wind might also cause wire galloping as well as other problems. The horizontal wind load of the wire is transmitted through the connecting hardware fittings to the composite insulator, imposing tensile and bending loads on the sheds, the sheath and the crimping end fittings, and flexing the glass fiber core rod [22]. This is undoubtedly detrimental to the performance of the rubber sheds, and even the long-term mechanical tolerance properties of the entire insulator.

The adverse effect of strong wind on the aging of composite insulators seems devastating and inevitable, still there are some countermeasures to minimize its negative consequences. For example, installing spacers and anti-vibration dampers on the wire could well prevent it from galloping. Also, the structure of insulators applied in high wind speed areas can be redesigned, such as widening the distance of adjacent sheds to avoid scraping each other. However, the most important thing is to pay close attention to the insulators operated under strong wind conditions, and increase the frequency of routine inspections so that they can be immediately replaced once they were found severely damaged and aging.

The unique geological structure of the karst landform determines the particularity of the contamination characteristics of the composite insulators operating there. As mentioned before, the main composition of the rocks of the karst surface layer is CaCO3, which is inclined to decompose into fine particles under long-term weathering. Along with the fugitive dust from local soil and the floating dust from atmosphere, together they constitutes the sources of the contaminants on an insulator in the karst region. Since carbonate is a weak acid ion, the accumulation of carbonate itself on the sheds may not have that much effect on the performance of the sheds; yet unfortunately, the karst regions in Guizhou Province have always been the worst-hit areas by acid rain pollution, with serious acidification of precipitation [23]. In a long-term acidic environment, the CO2−3 ions gradually transform to SO2−4 ions, the enrichment of which will have an adverse influence on the sheds, including an acceleration of chalking of silicone rubber and a decrease on the pollution flashover voltage of the insulator. The chalking refers to the appearance of a powder layer on the surface of the sheds of the composite insulator, which is regarded as a kind of malignant aging. Chalking is caused by the breaking of molecular bonds in the main chain of the silicone rubber material, and it would make it easier for small molecules and ions to seep into the interior [24]. Worse still, if the surface of the sheds have already cracked or ruptured, the SO2−4 ions may penetrate into the inner sheath in the form of acid solution, which will then corrode the inner silicone rubber and even the epoxy resin core, thereby awfully worsening the aging characteristics of the composite insulator.

Regular cleaning of the contaminants is the most direct and commonly used way to solve the problem of insulator contamination. As long as the sheds are not cracked or ruptured, their aging characteristics could be greatly improved after the contaminants are removed. However, if the sheds have already been damaged, and corrosive ions may have penetrated into the inner sheath and the core rod, then the aging of the entire insulator may have deteriorated. Under such circumstances, it is recommended to replace the defected insulator as soon as possible.

1. Compared with composite insulators used in plain areas with the same service life, the composite insulators used in the karst mountainous regions have worse hydrophobicity and more serious pollution on their sheds, indicating that the karst environment is more unfavorable to the aging characteristics of the insulator sheds.

2. Affected by the longstanding strong wind at the col of the mountains, the edges of the sheds scrape each other, and the root is prone to stress fatigue, leaving surface scratches and root cracks on the sheds, which deteriorate the surface performance of the silicone rubber material. If acidic liquid in the external environment infiltrates from the cracks, it may further corrode the inside of the material and greatly aggravate the aging of the silicone rubber.

3. In the contaminants on the sheds of insulators used in the karst regions, the contents of Ca2+, CO2−3 ions and insoluble CaCO3 are relatively higher, compared with that in flatlands. Enriched carbonates are gradually converted into more corrosive sulfates in acidic rain environment, aggravating the deterioration and chalking of the surface of the insulator sheds.

4. There are several practical ways to improve the aging characteristics of the composite insulators used in the karst regions, including replacing suspended insulators with strain insulators, redesign of their structure, regular cleaning, and so on. The point is to have a thorough and up-to-date awareness of the operation status and aging condition of the insulators, so as to take timely and effective measures to prevent them from further aging and deterioration.

Funding Statement: This study was supported by Science and Technology Project of Southern Power Grid EHV Transmission Company of China (010700KK52190003).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Song, W., Shen, W. W., Zhang, G. J., Song, B. P., Lang, Y. et al. (2015). Aging characterization of high temperature vulcanized silicone rubber housing material used for outdoor insulation. IEEE Transactions on Dielectrics and Electrical Insulation, 22(2), 961–969. DOI 10.1109/TDEI.2015.7076797. [Google Scholar] [CrossRef]

2. Akbar, M., Ullah, R., Alam, S. (2019). Aging of siliconerubber-based composite insulators under multi-stressed conditions: anoverview. Materials Research Express, 6(10), 102003. DOI 10.1088/2053-1591/ab3f0d. [Google Scholar] [CrossRef]

3. Wieczorek, K., Fleszynski, J., Bretuj, W. (2012). Effect of shape of insulator housings and positions of composite insulators on ageing resistance under high voltage and precipitation. IEEE Transactions on Dielectrics and Electrical Insulation, 19(3), 1044–1052. DOI 10.1109/TDEI.2012.6215111. [Google Scholar] [CrossRef]

4. Baker, A. C., Bernstorf, R. A., Cherney, E. A., Christman, R., Gorur, R. S. et al. (2012). High-voltage insulators mechanical load limits–Part II: Standards and recommendations. IEEE Transactions on Power Delivery, 27(4), 2342–2349. DOI 10.1109/TPWRD.2012.2200509. [Google Scholar] [CrossRef]

5. Wang, S. H., Wu, Y. L. (2019). Effect of salty fog on flashover characteristics of OCS composite insulators. Chinese Journal of Electrical Engineering, 5(3), 59–66. DOI 10.23919/CJEE.2019.000021. [Google Scholar] [CrossRef]

6. Sun, W. J., Song, J. X., Yang, W. K., Zheng, Y. J., Li, C. Y. et al. (2020). Distribution of carbonate rocks and variation analysis of karst water resources in China. Carbonates and Evaporites, 35(4). DOI 10.1007/s13146-020-00657-7. [Google Scholar] [CrossRef]

7. Hu, Y. X., Liu, X. D., Li, Y. W., Sun, W. J. (2019). Research of influence of corona discharge on surface hydrophobicity of contaminated composite insulators in high altitude areas. Power System Technology, 43(4), 1487–1494. DOI 10.13335/j.1000-3673.pst.2018.1523. [Google Scholar] [CrossRef]

8. Zhou, J., Fang, Y. H., Deng, Y., Wang, J., Xu, J. et al. (2020). Ageing characteristics of silicone rubber for composite insulator in southeast coastal area. Insulating Materials, 53(3), 14–21. DOI 10.16790/j.cnki.1009-9239.im.2020.03.003. [Google Scholar] [CrossRef]

9. Liu, Y. (2020). Study on pollution flashover prediction and operation of catenary insulator in saline-alkali area, Lanzhou Jiaotong University. [Google Scholar]

10. GB/T 10299–2011 (2011). Test method for hydrophobic nature of thermal insulation, Beijing: Standard Press of China. [Google Scholar]

11. Jiang, Y. P., Li, L., Lu, M., Wang, R. M., Jiang, Y. W. et al. (2019). Statistical characteristics and mechanism analysis of adhered particle on surface under strong electric field. Particuology, 43, 110–122. DOI 10.1016/j.partic.2018.03.016. [Google Scholar] [CrossRef]

12. Colbeck, I., Lazaridis, M. (2013). Aerosol science: technology and applications. USA: John Wiley & Sons, Ltd. [Google Scholar]

13. Phillips, A. J., Kuffel, J., Baker, A., Burnham, J., Carreira, A. et al. (2008). Electric fields on AC composite transmission line insulators. IEEE Transactions on Power Delivery, 23(2), 823–830. DOI 10.1109/TPWRD.2007.911127. [Google Scholar] [CrossRef]

14. Gao, F., Li, Y. Q., Li, L., Lu, M., Du, Z. X. et al. (2015). Analysis on contamination components of energized insulator of hami-Zhengzhou overhead line in henan and influence of install height on pollution accumulation. Power System Technology, 39(10), 2923–2928. DOI 10.13335/j.1000-3673.pst.2015.10.036. [Google Scholar] [CrossRef]

15. GB/T 26218.1–2010 (2010). Selection and dimensioning of high-voltage insulators intended for use in polluted conditions–Part 1: Definitions, information and general principles. Beijing: Standard Press of China. [Google Scholar]

16. Song, Y. H., Liu, G., Li, H. Z. (2010). Comparative analysis of natural contamination composition on insulators at highway area and highway-farmland area. High Voltage Apparatus, 46(5), 22–25. DOI 10.13296/j.1001-1609.hva.2010.05.007. [Google Scholar] [CrossRef]

17. Li, Z. H., Lou, W. J., Zhang, L. G., Bian, R., Duan, Z. Y. (2016). Numerical simulation of effects of topographic factors on wind speed in col. Journal of Zhejiang University (Engineering Science50(5), 848–855. DOI CNKI:SUN:ZDZC.0.2016-05-006. [Google Scholar]

18. Zhang, H. J., Zhao, J. F., Cai, D. Z., Niu, H. W. (2014). Wind tunnel test on the influence of col features on wind speed distribution. Journal of Experiments in Fluid Mechanics, 28(4), 25–30. DOI 10.11729/syltlx20130044. [Google Scholar] [CrossRef]

19. Zhu, Z. Y., Jia, Z. D., Ma, G. X., Wang, X. L., Guan, Z. C., (2014). Analysis on fracture failure mechanism of 750 kV composite insulator sheds utilized in a storm-hit region. Proceedings of the CSEE, 34(6), 947–954. DOI 10.13334/j.0258-8013.pcsee.2014.06.017. [Google Scholar] [CrossRef]

20. Li, Q. F., Wei, J., Yin, Y., Gao, H. F., Su, Z. Y. et al. (2012). Research on aeolian vibration caused fatigue properties of strain composite insulator string. Power System Technology, 36(12), 269–275. DOI 10.13335/j.1000-3673.pst.2012.12.015. [Google Scholar] [CrossRef]

21. Mars, W. V., Fatemi, A. (2002). A literature survey on fatigue analysis approaches for rubber. International Journal of Fatigue, 24(9), 949–961. DOI 10.1016/S0142-1123(02)00008-7. [Google Scholar] [CrossRef]

22. Anderson, J., Gubanski, S. M., Hillborg, H. (2008). Properties of interfaces between silicone rubber and epoxy. IEEE Transactions on Dielectrics and Electrical Insulation, 15(5), 1360–1367. DOI 10.1109/TDEI.2008.4656245. [Google Scholar] [CrossRef]

23. Ao, Z. Q., Qu, L. Y., Lin, W. J., Zhao, Y. Z., Peng, S. S. (2007). Study on chemical features of acid rain in luchongguan and leigongshan regions. Guizhou Province. Carsologica Sinica, 1, 61–66. DOI CNKI:SUN:ZGYR.0.2007-01-010. [Google Scholar]

24. Deng, T., Yang, D., Tao, W. B., Zhou, K., Zhang, X. J. et al. (2016). The relationship between microstructure and hydrophobicity of pulverized composite insulator sheds. Power System Technology, 40(1), 328–334. DOI 10.13335/j.1000-3673.pst.2016.01.046. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |