| Energy Engineering |  |

DOI: 10.32604/EE.2021.016867

ARTICLE

Multiple Phase Change Materials for Performance Enhancement of a Solar Dryer with Double Pass Collector

Engineering Technical College, Middle Technical University, Baghdad, Iraq

*Corresponding Author: Ahmed J. Hamad. Email: ahmed.elhamad99@gmail.com

Received: 04 March 2021; Accepted: 27 May 2021

Abstract: The fluctuation in drying temperature influences the food products’ quality and drying time significantly during the drying process using an indirect solar dryer. One of the effective methods to reduce these variations in the temperature is based on thermal storage materials to control the drying temperature. An experimental investigation is presented in this study to evaluate the performance of an indirect solar dryer with air double pass using multiple phase change materials (PCM) as thermal storage materials. Two PCMs with different melting points are used to store the available heat energy during peak sunshine periods and reduce the drying temperature fluctuations. Drying tests on a food product sample are conducted in three cases, the first was without PCMs using natural convection. The second and third cases are based on forced convection with and without using multiple PCMs under Baghdad city conditions. The results showed that; approximately a steady temperature of hot drying air was obtained during relatively low ambient temperatures when the dryer was incorporated with multiple PCMs. The drying time of the product sample for the natural, forced convection without PCMs and forced with PCMs was 87, 72 and 47 h, respectively. The higher performance of the dryer was for the forced convection with PCMs. The reduction percentage in drying time was about 17.2% and 46% for the forced convection without and with PCMs respectively compared with natural convection. The average drying rate for the natural, forced without PCMs and forced convection with PCMs was 0.0093, 0.0135 and 0.0172 kg/h, respectively. The enhancement in thermal efficiency of the solar collector and drying chamber with multiple PCMs was 43% and 25.5%, respectively, compared with a typical solar dryer.

Keywords: Solar dryer; double pass; indirect dryer; multiple PCM; drying rate

Nomenclature

| Ac: | area of the absorber plate (m2) |

| Cpa: | air specific heat (J/kg.°C) |

| Fr: | heat removal factor for the collector |

| hfg: | water latent heat of evaporation (J/kg) |

| I: | solar irradiance (W/m2) |

| k: | thermal conductivity (W/m.°C) |

| Lt1: | latent heat of fusion of PCM1 (J/kg) |

| Lt2: | latent heat of fusion of PCM2 (J/kg) |

| ma: | air mass flow rate (kg/s) |

| mdr: | drying rate of the product sample (kg/h) |

| mpr: | mass of the food product sample (kg) |

| mpri: | initial mass of the food product sample (kg) |

| mprf: | final mass of the food product sample after drying (kg) |

| mp1: | mass of PCM1 (kg) |

| mp2: | mass of PCM2 (kg) |

| msd: | moisture content on a dry basis (%) |

| msw: | moisture content on a wet basis (%) |

| mw: | mass of the water removed from the product sample (kg) |

| Qp1: | rate of heat transfer to the first PCM (W) |

| Qp2: | rate of heat transfer to the second PCM (W) |

| Qa: | rate of heat transfer to the air (W) |

| Tam: | ambient temperature (°C) |

| Ta1: | temperature of inlet air to the collector channel (°C) |

| Ta2: | temperature of the outlet air from the collector channel (°C) |

| Tcs: | temperature of the collector absorber plate (°C) |

| Tp1: | temperature of PCM1 (°C) |

| Tp2: | temperature of PCM2 (°C) |

| Tw: | wet bulb temperature (°C) |

| tc1: | charging time of PCM1 (s) |

| tc2: | charging time of PCM2 (s) |

| td: | drying time (s) |

| td1: | discharging time of PCM1 (s) |

| td2: | discharging time of PCM2 (s) |

| U: | overall heat transfer coefficient (W/m2. °C) |

Greek Symbols

| α: | absorptivity of the absorber plate |

| τ: | transmissivity of the collector glass cover |

| ηc: | thermal efficiency of the indirect solar collector (%) |

| ηdc: | thermal efficiency of the drying chamber (%) |

Acronyms

| PCM1: | first phase change material |

| PCM2: | second phase change material |

Drying of food products using solar energy as an environmentally friendly and sustainable energy source represents an effective and economical method to preserve the food products for a sustainable world. Sustainable energy technologies such as solar drying can significantly contribute to developing the processing systems of agricultural products to enhance economic growth, particularly in developing countries. Therefore, continuous research activities are required to develop the solar drying equipment, specifically direct and indirect dryers. The indirect solar dryer’s thermal performance can be feasibly improved if the dryer is incorporated with thermal storage material such as phase change materials (PCM). Using single or multiple PCMs with different melting temperatures will feasibly utilize the solar energy and at the same time prevents the fluctuations in temperature of the drying chamber that occurred in case of using a conventional solar dryer. In the extreme hot region like Baghdad city in Iraq (Latitude 33° 19′ N and longitude 44° 25′ E), where the solar radiation is available during relatively long light hours, there is a large difference between the ambient temperatures through the sunlight period. Therefore, during peak sun hours, the available heat energy could be lost if it is not stored using a heat storage device. Additionally, the variation in drying temperatures resulting from weather fluctuations will affect the drying quality of the food products. These disadvantages can be reduced by using multiple PCMs. The previous relative studies on solar air collectors and thermal systems without and with PCMs were reviewed by many researchers [1–4]. They have focused on PCMs as more efficient heat storage materials than sensible heat storage materials and reviewed the utilization of PCMs in different thermal systems applications. Numerous experimental studies are reported to investigating the thermal performance of solar dryers with and without PCM. Aiswarya et al. [5] developed a solar dryer incorporated with Paraffin as PCM to evaluate the agricultural products’ drying performance experimentally. An economic analysis was conducted in this work based on the payback period method which uses the dyer’s operating costs and the dried product’s cost in the analysis. Shalaby et al. [6] investigated the indirect solar dryer experimentally using 12 kg of paraffin wax as PCM for drying the Nerium Oleander at 50 ± 2.5°C. The experimental results showed that, the drying chamber temperature was kept at about 50°C for 7 consecutive hours when the PCM was incorporated with the solar dryer. Many experimental studies have focused on using different phase change materials in the drying chamber to enhance the performance of a solar dryer. Bhardwaj et al. [7] used Paraffin RT-42 as PCM to reduce the moisture content of medicinal herb from 89% to 9% through 5 days. Ashish et al. [8] used two types of Paraffin wax for drying the Potato chips with an estimated thermal efficiency of 52%. Vaibhav et al. [9] developed a forced convection solar dryer incorporated with Paraffin wax to evaluate experimentally the performance of drying the chilies and to investigate the effect of drying time and air mass flow rate on temperatures of the collector and dryer chamber. Research works investigating the forced convection indirect solar dyer performance without and with using PCM were conducted by many scholars [10–12]. Numerous effective parameters such as drying rate, collector and drying chamber temperatures, air flowrate and dryer efficiency were investigated experimentally in these works. Pankaew et al. [13] studied a large-scale solar dyer’s performance and exergy analysis based on a greenhouse incorporated with PCM for drying the chili. The results revealed that the exergy efficiency was 11.4% and 13.1% for the drying chamber without and with PCM respectively. Vijay et al. [14] and Sreerag et al. [15] used multiple PCMs in the solar dryer to enhance the solar dyer’s performance at various ambient temperatures and environmental conditions. The solar collector efficiency was increased to about 60.40% by using two PCMs, and a continuous heat supply at the drying chamber was achieved even at evening hours which make the products dry faster. Many researchers [16–19] have conducted numerical and theoretical analysis to improve the efficiency of the solar dryer and air heater based on MATLAB and computational fluid dynamics (CFD) simulation models. Research works to investigate the modified structures of the air heater using Ansys Fluent software and experimental work have been conducted by [20–21]. These modified design of the solar dryers have based on using iron mesh assisted tube heater and convex type solar absorber to enhance the thermal performance of the solar dryers. Experimental and numerical studies for improving the design of solar dryer were reported by several authors [22–26]. Feasible enhancement in thermal energy storage, drying rate and quality of dried products were achieved using single or multiple PCMs in the solar air heater and drying chamber. As reviewed, most of the previous research works have focused on the performance investigation of the indirect solar dryers with and without using a single PCM as thermal energy storage materials. The gap in research area of the indirect solar dryers with multiple PCMs is not sufficiently covered and still needs more investigation. The present work aims to evaluate the thermal performance of the active indirect solar dryer with double air pass incorporated with two phase change materials of different thermophysical properties.

2.1 Solar Dryer and PCM Analysis

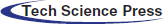

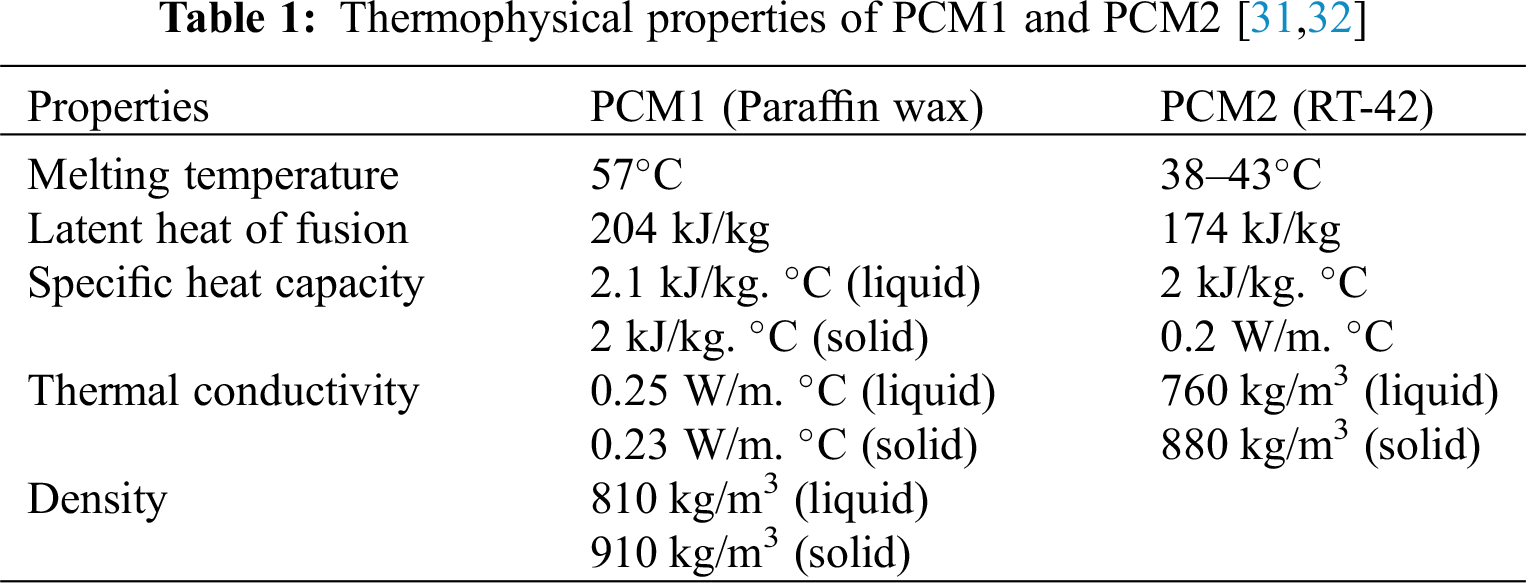

Two phase change materials (PCM) of different thermophysical properties are used to improve the performance of an indirect solar dyer with air double pass. The first material (PCM1) is used to store the excess heat energy through the peak sunshine hours, while the second material (PCM2) is utilized to reduce the fluctuations in temperature of the drying chamber and keep it at the desired point. The thermophysical properties of PCM1 and PCM2 are illustrated in the Tab. 1.

Referring to Fig. 1, the estimated mass of two PCMs and drying process characteristics of the food product can be determined as follows:

Figure 1: Schematic diagram of the air double pass indirect solar dryer with two phase change materials

The rate of heat transfer (Qp1) to the PCM1 placed under the absorber plate of the solar collector during a sunshine period can be determined from the following equation [27]:

where the values of Fr, τ, and α, are approximated to 0.9, 0.85 and 0.9 respectively in the current work [5].

Overall heat transfer coefficient (U) of the flat plate solar collector can be expressed by:

where the rate of heat (Qa) gained by air flowing in the collector channel can be determined as follows:

Mass (mp1) of PCM1 and charging time (tc1) during melting process through a peak sunshine period(s) is approximated using Eq. (4):

Discharging time (td1) of PCM1 during solidification process through a relatively low solar radiation period can be estimated by:

The rate of heat transfer (Qp2) to the PCM2 in the drying chamber during a peak sunshine period is determined as follows:

where td is drying time(s), and Ew is the estimated heat energy (J) to remove the moisture content of food product sample, which can be approximated using Eq. (7):

where mw is mass of the water removed from the product sample; hfg is determined at 100°C from the steam tables.

Charging time (tc2) of PCM2 during the melting process through a peak sunshine period(s) can be approximated using Eq. (8):

The mass (mpc2) of PCM2 required for drying the product sample can be estimated by:

Discharging time (td2) of PCM2 during the solidification process through a relatively low solar radiation period is approximated as follows:

where Tdr is the required temperature for drying the food product sample in the drying chamber (40–43°C).

The mass of water (mw) removed from the initial food product sample (wet material) is estimated by [28]:

where msw and msd are the moisture content on a wet and dry basis respectively and expressed as follows:

The moisture ratio (MR) can be expressed as follows [11]:

where: mswt is the moisture content on wet basis at any time, and mswi is the initial moisture content on wet basis.

The drying rate (mdr) of the food product sample during a drying time td (h) can be expressed by:

Thermal efficiency of the air double pass indirect solar collector (ηc) is given by [29,30]:

Thermal efficiency of the drying chamber (ηdc) can be evaluated as follows:

2.2 Experimental Setup and Methodology

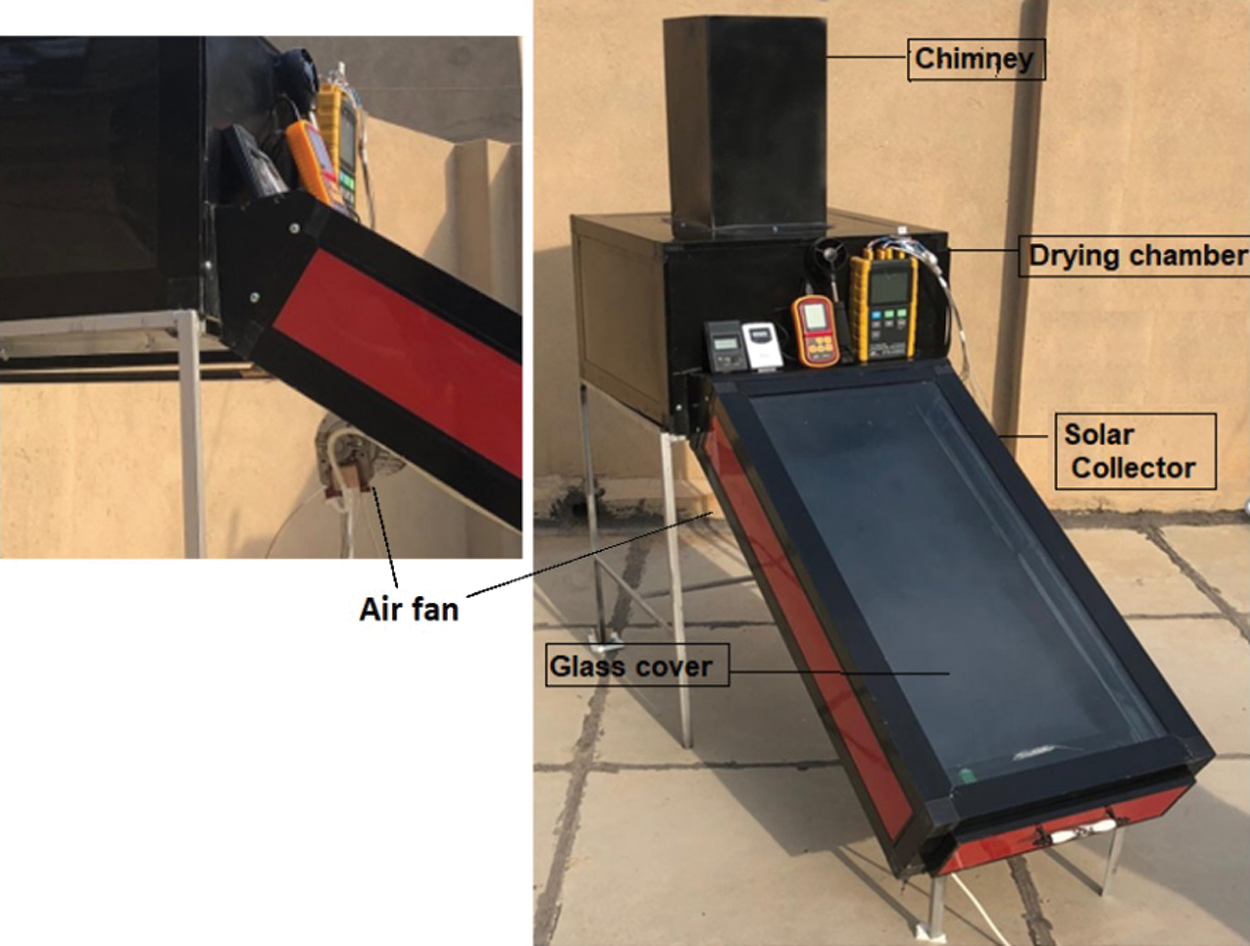

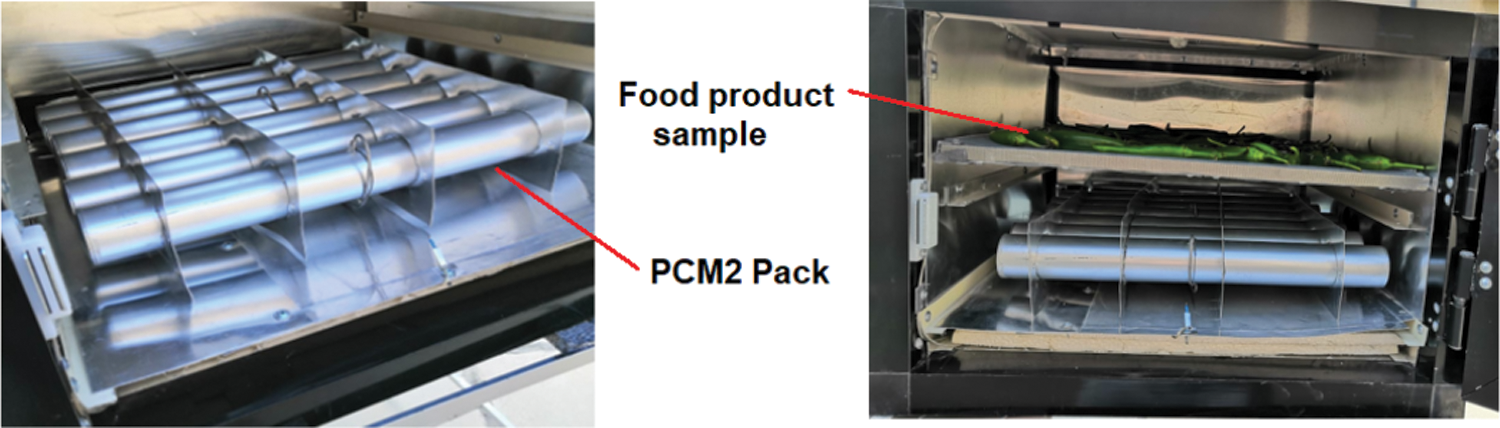

An indirect solar dryer with air double pass using multiple PCMs based on forced convection was used to conduct the experimental work in the present study. The solar dryer rig is fabricated during the current study, consisting of two main parts, solar collector for heating the air and drying chamber for drying the food product sample, as shown in Fig. 2. The flat plate solar collector is fabricated from Aluminum sheets (k = 232 W/m. °C) with dimensions, 1000 mm length, 500 mm width and 200 mm height. The collector is insulated from the bottom and sides by glass wool (k = 0.038 W/m. °C) for minimizing heat loss to the surrounding and covered at the top with 4 mm thick glass sheet. The absorber plate is a black coated Aluminum sheet of 900 mm long, 400 mm wide and 2 mm thick. To facing the solar radiation, the solar collector is installed on a supporting stand inclined at an angle of 45° with the horizontal and oriented to west south direction [33]. The drying chamber is of dimensions 600 mm × 600 mm × 500 mm, fabricated from insulated Aluminum sheets and connected from the top with a chimney. Paraffin wax of mass 3.8 kg as PCM1 is placed in 900 mm × 400 mm × 20 mm container under the absorber plate of the collector. The Paraffin RT-42 of mass 3 kg as PCM2 is filled at liquid state in six Aluminum cylinders of 450 mm length and 50 mm diameter and placed in the drying chamber. Four Aluminum panels of dimensions 500 mm × 100 mm and 0.5 mm thickness are installed at PCM2 cylinders to direct the air across the cylinders and work as extended surfaces to enhance the heat transfer, as illustrated in Fig. 3.

Figure 2: Indirect solar dryer with measurement devices

Figure 3: Drying cahamber with PCM2 cylinders

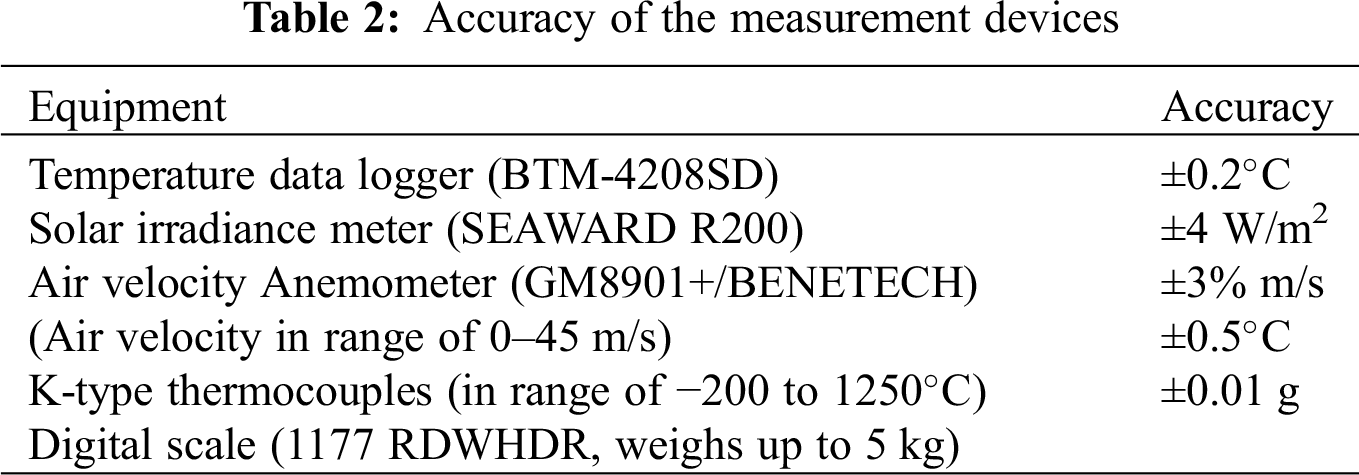

A centrifugal air fan of 25W capacity, model AKS 680–180 with power regulator, is used to supply the air with flowrate 0.005–0.012 kg/s in the solar dryer. The air fan is installed under the solar collector to circulate the air around the PCM1 container and over the absorber plate for heating the air before entering into the drying chamber, as shown in Fig. 1. Nine K-type thermocouples in the range of −200 to 1250°C are fixed at many locations in the solar dryer setup and used with a temperature recorder of model BTM-4208SD to measure and display the temperatures. The velocity of air flowing through the dryer was measured using a digital Anemometer, and the solar irradiance was recorded using the irradiance meter of model SEAWARD R200 with a measuring range of 100–1250 W/m2. The experimental work was conducted in November 2020, where the temperatures and other measurements are taken during sunshine hours from 9.00 am to 5.00 pm through the testing days, under Baghdad city conditions. The food product sample used in the drying tests is 800 g of chili pieces with an initial moisture content of 87%. The initial moisture content of the product was determined by heating 200 g of the product sample using an electric oven at 105°C until thoroughly dried. The difference between the initial and final mass of the product sample represents the water content in the product. The initial moisture content represents the percentage of water mass to the product mass before drying. The product sample is weighed before and after drying through time interval of one hour using a digital balance. The temperatures of ambient air, absorber plate, PCM1, PCM2, dry bulb and wet bulb of inlet and outlet air at different locations in the dryer rig are recorded through time interval of one hour during the test period. The drying tests are conducted in three cases; the first case was without PCMs based on natural convection as a baseline case for comparison. While the second and third cases were based on forced convection with and without using multiple PCMs. The accuracy of measurement devices is illustrated in Tab. 2.

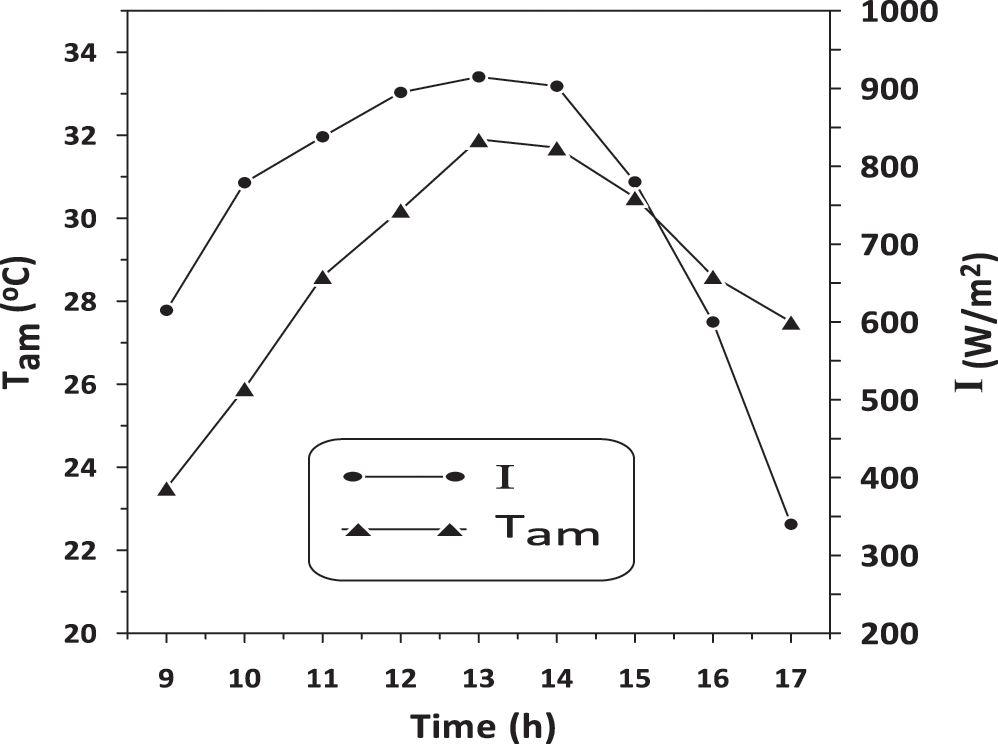

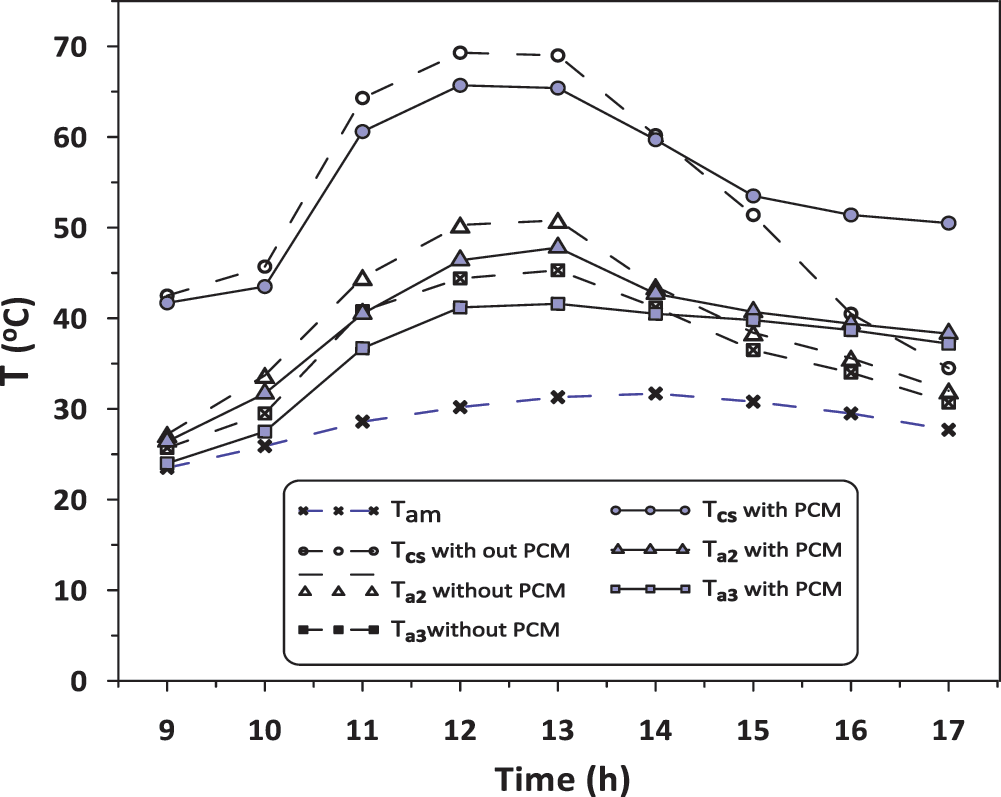

Experimental work is conducted in November 2020 through sunshine hours from 9 am to 5 pm under Baghdad city conditions (Latitude 33° 19′ N and longitude 44° 25′ E). Variations of ambient temperature and solar irradiance with day time are illustrated in Fig. 4. During the test period, the ambient temperature was in range of 23–32°C, and the solar intensity was in range of 350–915 W/m2. Temperature variations with day sunshine hours at different locations in the solar dryer for forced convection case with and without PCM are shown in Fig. 5. It can be observed that the maximum values of temperature were at day hours from 12 to 14, where the absorber plate temperature reaches about 69°C. Relatively steady temperatures for air outlet from air heater (solar collector) and drying chamber can be observed during a relatively low irradiance an ambient temperature period after hour 14 of drying time. This trend in temperature is attributed to the effect of thermal storage materials PCM1 and PCM2 placed in the collector container and drying chamber respectively, which work as heat supply during discharging cycles of PCMs at low temperature periods.

Figure 4: Variation of the average ambient temperature and solar irradiance with the sunshine hours

Figure 5: Variation of the temperature with sunshine hours at forced convection with and without PCM

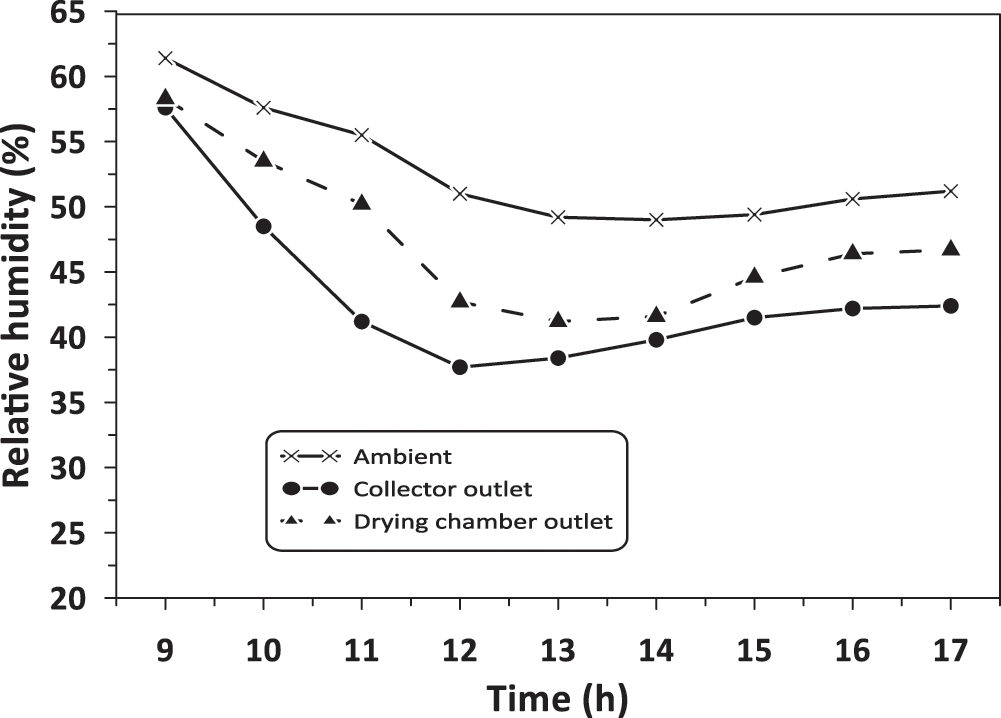

Fig. 6 shows the variations of relative humidity of air at different locations in the solar dryer as a function of day sunshine hours for the forced convection with PCM. Air relative humidity was determined based on dry bulb and wet bulb temperatures measured at different locations in the solar dryer. The relative humidity of the inlet ambient air was higher, particularly at morning hours, and gradually decreases with day time to reach lower values at hours 12 and 13. The humidity of air is significantly reduced during flowing in the solar collector channel due to heating by the absorber plate. Then, it increases gradually as a result of the water evaporation from the food product in the drying chamber.

Figure 6: Relative humidity of air as a function of the drying time at forced convection with PCM

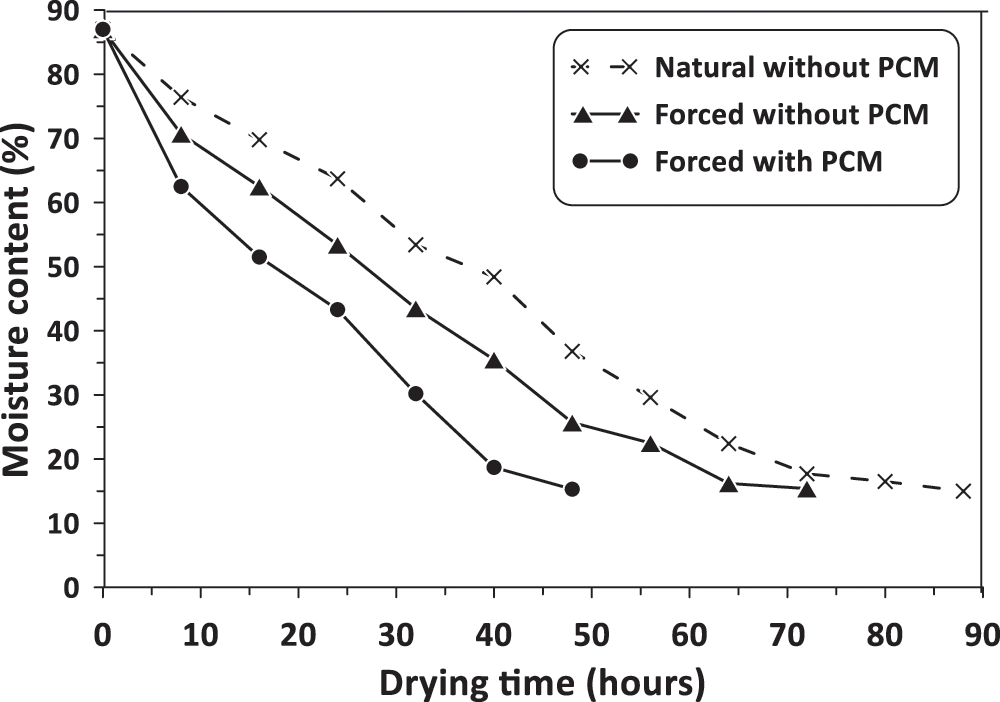

The performance of the drying process depends on a reduction in moisture content of the food product sample (chili pieces) during sunshine hours. The initial moisture content of the sample was 87% and gradually reduced with time at various ranges to reach about 15% as a final desired content of the moisture for the product sample, as shown in Fig. 7. The drying time for the three cases of drying, natural, forced convection without PCMs and forced convection with PCMs was 87, 72 and 47 h, respectively. Drying process of the product sample has reflected a higher performance for forced convection with PCMs than that for other cases. The reduction percentage in drying time was about 17.2% and 46% for forced convection without and with PCMs respectively compared with natural convection.

Figure 7: Variation of the moisture content of the food product with total drying time

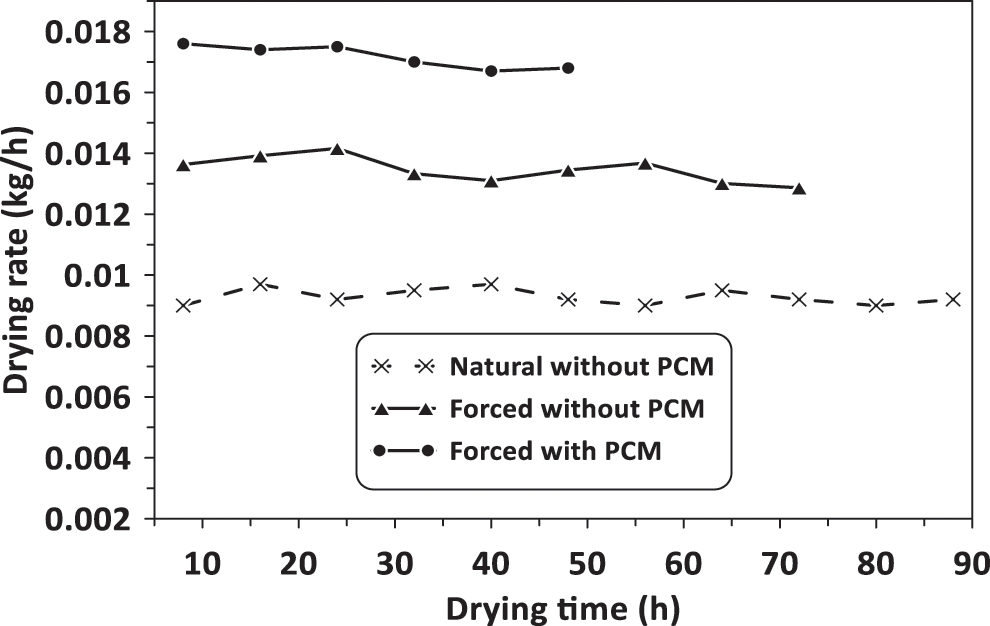

Fig. 8 shows the variations of the drying rate of the product sample with the drying time. It can be observed that, the average drying rate for the three cases, natural, forced without PCMs and forced convection with PCMs was 0.0093, 0.0135 and 0.0172 kg/h, respectively. Utilizing thermal storage materials PCM1 and PCM2 incorporated with solar collector and drying chamber has significantly improved the food product’s drying rate. During peck solar radiation at sunshine hours 11 to 14, PCMs pack works as a storage of excess thermal energy through charging cycle. In contrast, it works as heat supply during discharging cycles of PCMs at relatively low ambient temperatures during a low irradiance to prevent the fluctuations in temperatures of the drying chamber and to improve the quality of dried product.

Figure 8: Drying rate of the product as a function of the total drying time

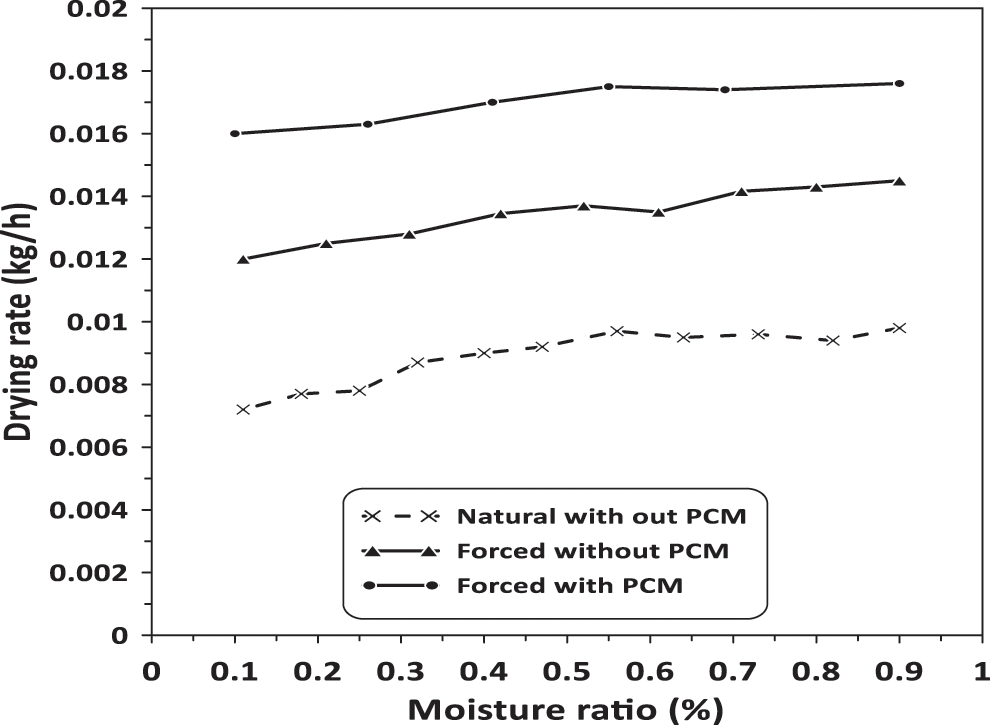

The variations of drying rate with the moisture ratio of the product sample is depicted in Fig. 9. It can be noticed that the drying rate increases with the increase in the moisture ratio. High moisture content of the product sample at the beginning of the drying period compared with hot drying air will make the evaporation of water faster than that for a low moisture ratio.

Figure 9: Drying rate as a function of moisture ratio of the product sample

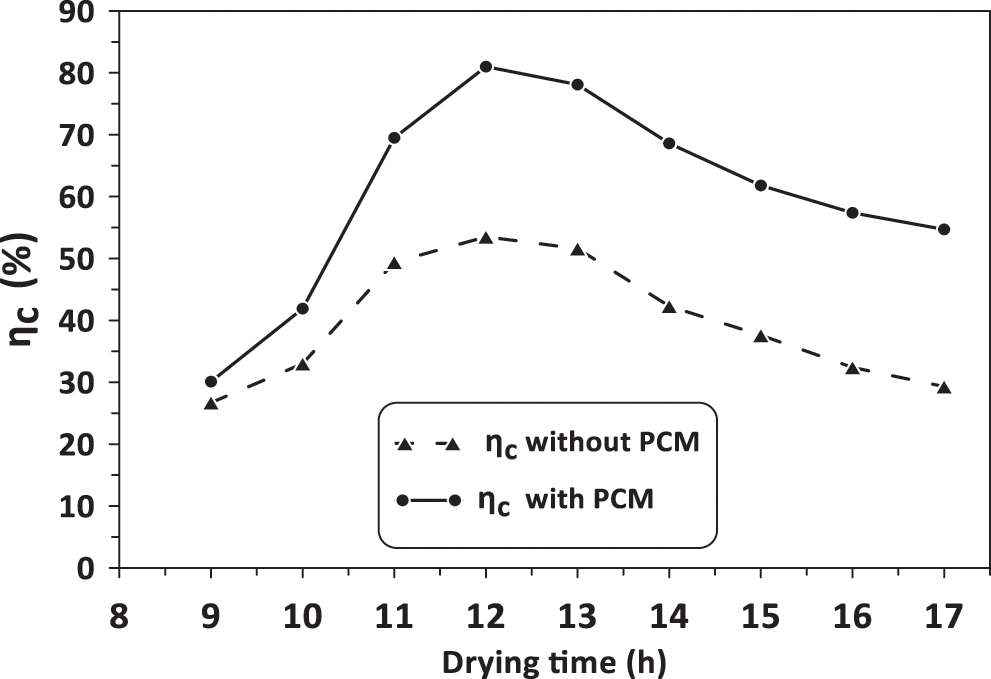

Fig. 10 shows the variation of solar collector efficiency with day time for the two forced convection cases, with and without PCM incorporated with the collector’s absorber plate. Higher efficiency can be observed at a relatively higher solar radiation period during peak sunshine hours from 11 to 14. The enhancement in the efficiency of the collector with PCM was about 43% compared with that for the solar collector without PCM. This difference in the efficiency is attributed to the effect of PCM1 in controlling the fluctuations in the air temperature.

Figure 10: Variation of the solar collector efficiency with drying time

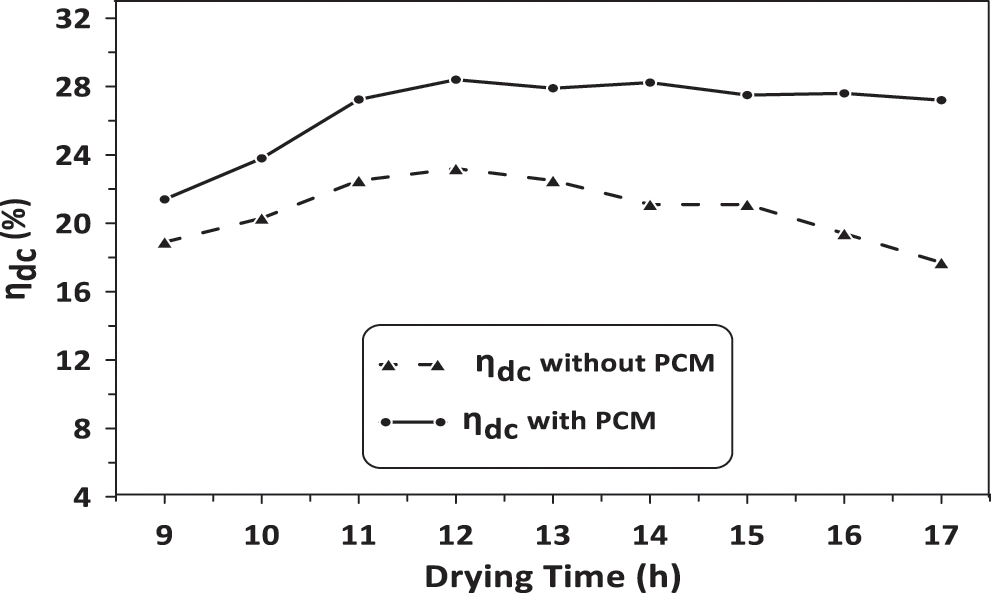

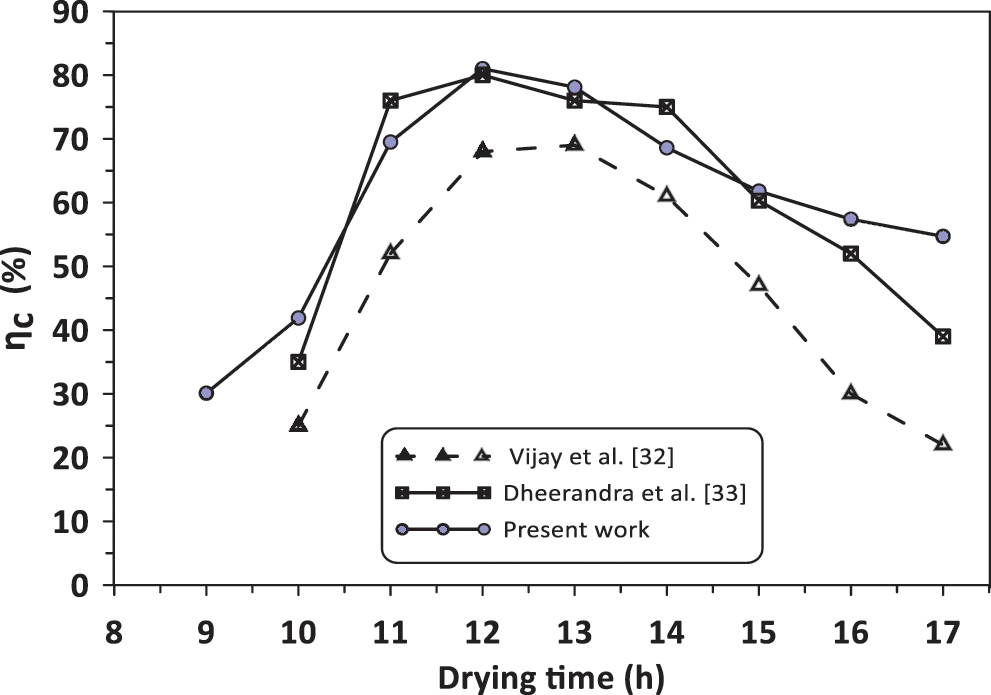

Comparing the efficiency of the drying chamber with and without PCM during drying time is shown in Fig. 11. The efficiency was improved by about 25.5% using PCM, particularly at low ambient temperatures and irradiance period after the hour 14 of day time. During this period, the PCM2 works as a heat source to compensate for the drop in thermal energy and extend the drying time. This change in values of drying chamber efficiency is obviously indicated in the figure, where the values of drying efficiency with PCM are approximately steady after the hour 14 of the drying period. The present study results of the solar collector efficiency are validated with the experimental results of the previous research works of Vijay et al. [34], Dheerandra et al. [35], as shown in Fig. 12. Comparison of the results revealed that the average deviation of collector efficiency is 22.5% and 2.2% compared to the previous investigators [34] and [35], respectively. This deviation in the results can be attributed to the variations in the operating conditions and design parameters approximations of the solar collector.

Figure 11: Variation of the drying chamber efficiency with drying time

Figure 12: Comparison of the solar collector efficiency of present study with previous research works

An indirect solar dryer’s thermal performance with and without multiple PCMs as thermal storage materials has been investigated in the current study. Drying tests are conducted in three cases, the first case was without PCMs based on natural convection as baseline case for comparison, while the second and third cases are based on forced convection with and without multiple PCMs. Steady air outlet temperatures from the solar collector and drying chamber are obtained during relatively low ambient temperatures and irradiance after the hour 14 of day time due to the effect of multiple PCMs. The drying time of the product sample at the three cases, natural, forced without PCMs and forced with PCMs, was 87, 72 and 47 h, respectively. Higher performance of the dryer was for the case of forced convection with PCMs. The reduction percentage in drying time was about 17.2% and 46% for the cases of forced without and with PCMs respectively compared to natural convection. The enhancement in the efficiency of solar collector and drying chamber with PCM was about 43% and 25.5% respectively compared to that without PCM. For the three cases, natural, forced without PCMs and forced with PCMs, the average drying rate was 0.0093, 0.0135 and 0.0172 kg/h, respectively.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Alkilani, M. M., Sopian, K., Alghoul, M. A., Sohif, M., Ruslan, M. H. (2011). Review of solar air collectors with thermal storage units. Renewable and Sustainable Energy Reviews, 15, 1476–1490. DOI 10.1016/j.rser.2010.10.019. [Google Scholar] [CrossRef]

2. Shalaby, S. M., Bek, M. A., El-Sebaii, A. A. (2014). Solar dryers with PCM as energy storage medium: A review. Renewable and Sustainable Energy Reviews, 33, 110–116. DOI 10.1016/j.rser.2014.01.073. [Google Scholar] [CrossRef]

3. Yagnesh, B. C., Pravin, P. R. (2018). A comprehensive review on solar dryer. International Journal of Ambient Energy, 41(3), 348–367. DOI 10.1080/01430750.2018.1456960. [Google Scholar] [CrossRef]

4. Mofijur, M., Teuku, M. I., Arridina, S. S., Hwai, C. O., Mahyar, S. et al. (2019). Phase change materials (PCM) for solar energy usages and storage: An overview. Energies, 12(16), 3167. DOI 10.3390/en12163167. [Google Scholar] [CrossRef]

5. Aiswarya, M. S., Divya, C. R. (2015). Economic analysis of solar dryer with PCM for drying agricultural products. International Research Journal of Engineering and Technology, 2(4), 1948–1953. [Google Scholar]

6. Shalaby, S. M., Bek, M. A. (2015). Drying nerium oleander in an indirect solar dryer using phase change material as an energy storage medium. Journal of Clean Energy Technologies, 3(3), 176–180. DOI 10.7763/JOCET.2015.V3.191. [Google Scholar] [CrossRef]

7. Bhardwaj, A. K., Ranchan, C., Raj, K., Muneesh, S., Adit, R. (2017). Experimental investigation of an indirect solar dryer integrated with phase change material for drying valeriana jatamansi (medicinal herb). Case Studies in Thermal Engineering, 10, 302–314. DOI 10.1016/j.csite.2017.07.009. [Google Scholar] [CrossRef]

8. Ashish, C., Sanjay, S. (2015). Performance enhancement of a drying chamber of solar Air dryer with phase change material as thermal energy storage. International Engineering Research Journal, (Special Issue 2), 1873–1877. [Google Scholar]

9. Vaibhav, V. P., Sanjay, P. S. (2016). Design and development of solar dryer cabinet with thermal energy storage for drying chilies. International Journal of Current Engineering and Technology, (Special Issue 5), 358–362. [Google Scholar]

10. Virendra, V. B., Vaibhav, P. P., Krantikumar, K. B., Sandip, P. K. (2017). Experimental analysis of a solar air dryer with thermal energy storage unit (PCM). International Advanced Research Journal in Science, Engineering and Technology, (Special Issue, 2, 4), 1873–1877. DOI 10.17148/IARJSET/NCDMETE.2017.39. [Google Scholar] [CrossRef]

11. Prashant, M., Dheerandra, S. (2018). Comparative study of performance of indirect mode with PCM and mixed mode solar dryer for coriander leaves. International Journal of Applied Engineering Research, 13(8), 5909–5919. [Google Scholar]

12. Salah, M. S., Jalal, M. J., Saleh, E. N. (2019). Experimental and numerical analysis of double-pass solar Air heater utilizing multiple capsules PCM. Renewable Energy, 143, 1053–1066. DOI 10.1016/j.renene.2019.05.050. [Google Scholar] [CrossRef]

13. Pankaew, P., Aumporn, O., Janjai, S., Pattarapanitchai, S., Sangsan, M. et al. (2020). Performance of a large-scale greenhouse solar dryer integrated with phase change material thermal storage system for drying of chili. International Journal of Green Energy, 17(11), 1–12. DOI 10.1080/15435075.2020.1779074. [Google Scholar] [CrossRef]

14. Vijay, T. B., Anil, S. D. (2018). Performance evaluation of indirect solar dryer. International Journal of Applied Engineering Research, 13(5), 58–63. [Google Scholar]

15. Sreerag, T. S., Fithish, K. S. (2016). Experimental investigations of a solar dryer with and without multiple phase change materials (PCM’s). World Journal of Engineering, Emerald Insight, 13(3), 210–217. DOI 10.1108/WJE-06-2016-028. [Google Scholar] [CrossRef]

16. Messaoud, S., Abdelghani, B., Abderrahmane, B., Belkhir, S., Daoud, H. et al. (2017). A simulation study of a solar collector using phase change materials for Air heating application needs. Technologies and Materials for Renewable Energy, Environment and Sustainability, AIP Conference Proceedings, vol. 1814, no. 1, 020010. AIP Publishing LLC. DOI 10.1063/1.4976229. [Google Scholar] [CrossRef]

17. Salve, S. P., Fulambarkar, A. M., Khune, P. D. (2020). Solar drying system integrated with phase change material (PCM). International Journal of Engineering and Advanced Technology, 9(3), 1897–1902. DOI 10.35940/ijeat.2249-8958. [Google Scholar] [CrossRef]

18. Akanksha, G., Shukla, S. K., Srivastava, A. K. (2013). Analysis of solar drying unit with phase change material storage systems. International Journal of Agile Systems and Management, 6(2), 164–176. DOI 10.1504/IJASM.2013.053804. [Google Scholar] [CrossRef]

19. Martin, Z., Lubomír, K., Pavel, C. (2020). Design optimization of a solar Air collector integrating a phase change material. Chemical Engineering Transactions, 81, 211–216. DOI 10.3303/CET2081036. [Google Scholar] [CrossRef]

20. Adnan, S., Ceylin, S., Ataollah, K., Azim, D. T., Emine, Y. G. (2020). Thermal performance enhancement of tube-type alternative indirect solar dryer with iron mesh modification. Elsevier, Solar Energy, 207, 1269–1281. DOI 10.1016/j.solener.2020.07.072. [Google Scholar] [CrossRef]

21. Azim, D. T., Adnan, S. F. A., Ataollah, K., Ceylin, S., Afsin, G. (2020). Testing of a novel convex-type solar absorber drying chamber in dehumidification process of municipal sewage sludge. Journal of Cleaner Production, 272, 122862. DOI 10.1016/j.jclepro.2020.122862. [Google Scholar] [CrossRef]

22. Ramin, M., Ali, K., Somchai, W. (2017). Optimization of a solar air heater with phase change materials: Experimental and numerical study. Experimental Thermal and Fluid Science, 89, 41–49, DOI 10.1016/j.expthermflusci.2017.07.011. [Google Scholar] [CrossRef]

23. Tesfay, A. H., Hagos, F. Y., Yohannes, K. G., Nydal, O. J., Kahsay, M. B. (2015). Preparing side charging of PCM storage: Theoretical and experimental investigation. IOP Conference Series: Materials Science and Engineering, vol. 100, no. 1, 012021. IOP Publishing. DOI 10.1088/1757-899X/100/1/012021. [Google Scholar] [CrossRef]

24. Yue, H., Heiselberg, P. K., Hicham, J., Rui, G. (2020). Experimental and numerical study of a PCM solar air heat exchanger and its ventilation preheating effectiveness. Renewable Energy, 145, 106–115. DOI 10.1016/j.renene.2019.05.115. [Google Scholar] [CrossRef]

25. Murugan1, P., Dhanushkodi, S., Sudhakar, K., Vincent, H. W. (2020). Industrial and small-scale biomass dryers: An overview. Energy Engineering, 118(3), 435–446. DOI 10.32604/EE.2021.013491. [Google Scholar] [CrossRef]

26. Zheng, B. H., Qian, W., Zhen, Y. W., Jia, L. Z., Song, L. Y. (2019). The numerical simulation and experimental study of heat release in a heat storage system with various diameters of aluminum tubes. Heliyon, 5(10), 1–10. DOI 10.1016/j.heliyon.2019.e02651. [Google Scholar] [CrossRef]

27. Maundu, N. M., Kosgei, S. K., Nakajo, Y. (2016). Design and analysis of solar dryer for mid-latitude region. elsevier. Energy Procedia, 100, 98–110. DOI 10.1016/j.egypro.2016.10.145. [Google Scholar] [CrossRef]

28. Kilanko, O., Ilori, T. A., Leramo, R. O., Babalola, P. O., Eluwa, S. E. et al. (2019). Design and performance evaluation of a solar dryer. Journal of Physics: Conference Series, vol. 1378, no. 3, 032001. IOP Publishing. DOI 10.1088/1742-6596/1378/3/032001. [Google Scholar] [CrossRef]

29. Erick, C. L., Lilia, L. M., Juan, R. R. (2013). Efficiency of a hybrid solar-gas dryer. Elsevier, Solar Energy, 93, 23–31. DOI 10.1016/j.solener.2013.01.027. [Google Scholar] [CrossRef]

30. Promise, J. E., Akachukwu, B. E., Kayode, J. S. (2020). Design and development of an active indirect solar dryer for cooking banana. Elsevier, Scientific African, 8, 1–10. DOI 10.1016/j.sciaf.2020.e00463. [Google Scholar] [CrossRef]

31. Kaviarasu, C., Prakash, D. (2016). Review on phase change materials with nanoparticle in engineering applications. Journal of Engineering Science and Technology Review, 9(4), 26–386. DOI 10.25103/jestr. [Google Scholar] [CrossRef]

32. Wisam, A. D., Nabeel, S. D., Tahseen, A. A. (2020). Experimental investigation of the horizontal double pipe heat exchanger utilized phase change material. IOP Conference Series: Materials Science and Engineering, vol. 671, no. 1, 012148. IOP Publishing. DOI 10.1088/1757-899X/671/1/012148. [Google Scholar] [CrossRef]

33. Khosravi, A., Oscar, R. S. R., Behnam, T., Timo, L., Juan, J. G. P. et al. (2020). New correlations for determination of optimum slope angle of solar collectors. Energy Engineering, 117(5), 249–265. DOI 10.32604/EE.2020.011024. [Google Scholar] [CrossRef]

34. Vijay, T. B., Anil, S. D. (2018). Performance evaluation of indirect solar dryer. International Journal of Applied Engineering Research, 13(5), 58–63. [Google Scholar]

35. Dheerandra, S., Prashant, M. (2020). Experimental investigation of thermal performance of indirect mode solar dryer with phase change material for banana slices. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 1–18. DOI 10.1080/15567036.2020.1810825. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |