| Energy Engineering |  |

DOI: 10.32604/EE.2021.014866

ARTICLE

Reliability Based Multi-Objective Thermodynamic Cycle Optimisation of Turbofan Engines Using Luus-Jaakola Algorithm

1Centre for Modelling and Simulation, Faculty of Engineering, Built Environment and Information Technology, SEGi University, Petaling Jaya, Selangor, 47810, Malaysia

2Mechanical Engineering Department, Faculty of Engineering, Built Environment and Information Technology, SEGi University, Petaling Jaya, Selangor, 47810, Malaysia

3Lee Kong Chian Faculty of Engineering and Science, Universiti Tunku Abdul Rahman, Kajang, Selangor, 43200, Malaysia

*Corresponding Author: Vin Cent Tai. Email: taivincent@segi.edu.my

Received: 04 November 2020; Accepted: 18 March 2021

Abstract: Aircraft engine design is a complicated process, as it involves huge number of components. The design process begins with parametric cycle analysis. It is crucial to determine the optimum values of the cycle parameters that would give a robust design in the early phase of engine development, to shorten the design cycle for cost saving and man-hour reduction. To obtain a robust solution, optimisation program is often being executed more than once, especially in Reliability Based Design Optimisations (RBDO) with Monte-Carlo Simulation (MCS) scheme for complex systems which require thousands to millions of optimisation loops to be executed. This paper presents a fast heuristic technique to optimise the thermodynamic cycle of two-spool separated flow turbofan engines based on energy and probability of failure criteria based on Luus-Jaakola algorithm (LJ). A computer program called Turbo Jet Engine Optimiser v2.0 (TJEO-2.0) has been developed to perform the optimisation calculation. The program is made up of inner and outer loops, where LJ is used in the outer loop to determine the design variables while parametric cycle analysis of the engine is done in the inner loop to determine the engine performance. Latin-Hypercube-Sampling (LHS) technique is used to sample the design and model variations for uncertainty analysis. The results show that optimisation without reliability criteria may lead to high probability of failure of more than 11% on average. The thrust obtained with uncertainty quantification was about 25% higher than the one without uncertainty quantification, at the expense of less than 3% of fuel consumption. The proposed algorithm can solve the turbofan RBDO problem within 3 min.

Keywords: Multi-objective design optimisation; reliability based design optimisation; turbofan engines; luus-jaakola algorithm

Aircraft engine design is a complex process as it involves tens of thousands of components [1]. It begins with parametric cycle analysis, which includes the determination of compression and expansion ratios, burner outlet temperature, bypass ratio, air-fuel ratio, etc. In early stage of the design development, there are too many uncertainties involved. Low fidelity models such as empirical models are used to predict the design performance, due to many variables are not yet determined or available at this design stage. Therefore, determining the optimum values of these parameters that would lead to a robust design in the early phase of engine development is crucial, as it can shorten the design cycle and eventually lead to cost saving and man-hour reduction. Failure to account for uncertainty can result in significant shortcomings in performance when the engine is initially tested [2].

Over the years, various performance indicators have been proposed and used to evaluate the performance of aircraft engines such as energy, exergy and propulsive efficiencies, specific thrust, and fuel consumption [1,3–5]. While the world is growing concerns on the impact of aviation on the environment, emissions have since become an important performance indicator [6,7]. The performance indicators were often being used alone to form single-objective optimisation (SO) problems, or in combination with other indicators to form multi-objective optimisation (MO) problems [1,4–8]. Optimisation problems that involve only single discipline is called single-discipline optimisation (SDO) while multi-discipline optimisation (MDO) involves problems that involve multiple disciplines (e.g., thermodynamics, aerodynamics, structure, acoustic, etc.). MDO is inherently more difficult to solve than SDO, due to large search space and inter-disciplinary coupling of components involved (see references [3,7,9–14]. Evolutionary Algorithm (EA) methods such as Genetic Algorithm (GA) [1,3,5,7,8], Differential Evolution (DE) [10], Particle Swarm Optimization (PSO) [4,15] are favoured over deterministic optimisation methods such as gradient based optimisation [9,13] and Sequential Quadratic Programming (SQP) [6], due to EA is more capable in handling discontinuous, non-differential, and multi-modal functions [16].

However, optimisation in such way may lead to high sensitivity to failure when used in practical situations, due to too many uncertainties involved in the early phase of design. This has called for the needs to incorporate uncertainties in design optimisation to obtain robust optimum solutions. In [17], Mavris et al. examined ways to apply probabilistic design methods in preliminary aeroengine design and analytically determined the impacts of component performance on engine overall performance. To reduce the computational burden incurred by MCS, the authors utilised Fast Probability Integration (FPI) method to approximate Monte-Carlo analysis, in conjunction with Response Surface Method (RSM) to construct the design space. Then, Tong [18] presented the application of probabilistic method to assess the reliability of a new aeroengine system. Differ from [17], analytical equations were used to describe the functional relationships between the design variables and response variables. Roth et al. [19] presented a probabilistic based optimisation method that utilised GA and MCS to find optimum combination of technologies for aeroengines. The authors concluded that such GA-MCS technique can applied to any engine design problem for robust solution. Chen et al. [20] proposed a probabilistic model of turboshaft engine to quantify the impact of uncertainty in engine performance based on Monte-Carlo probabilistic design method. Their work demonstrated the uncertainties in component performance can significantly impact the engine overall performance prediction and concluded that probabilistic design approach is more credible and reliable in assigning the design space for a target engine performance. In recent year, Cao et al. [21] presented a study on aeroengine conceptual design considering multi-mission reliability. To save computation time, the authors employed Artificial Neural Network (ANN) to construct surrogate models to replace MCS for reliability calculation. PSO was used to optimise the engine design.

Although metaheuristic method such as GA and PSO is known to be robust in searching for optimum solution, optimisation that involves large number of calculations for RBDO with MCS schemes is prohibitively slow. In view of this, this research is dedicated to close the loop, by introducing an efficient optimisation method with MCS scheme to optimise the energy efficiency and reliability of two-spool turbofan engines considering the variable and model uncertainties in the early design stage.

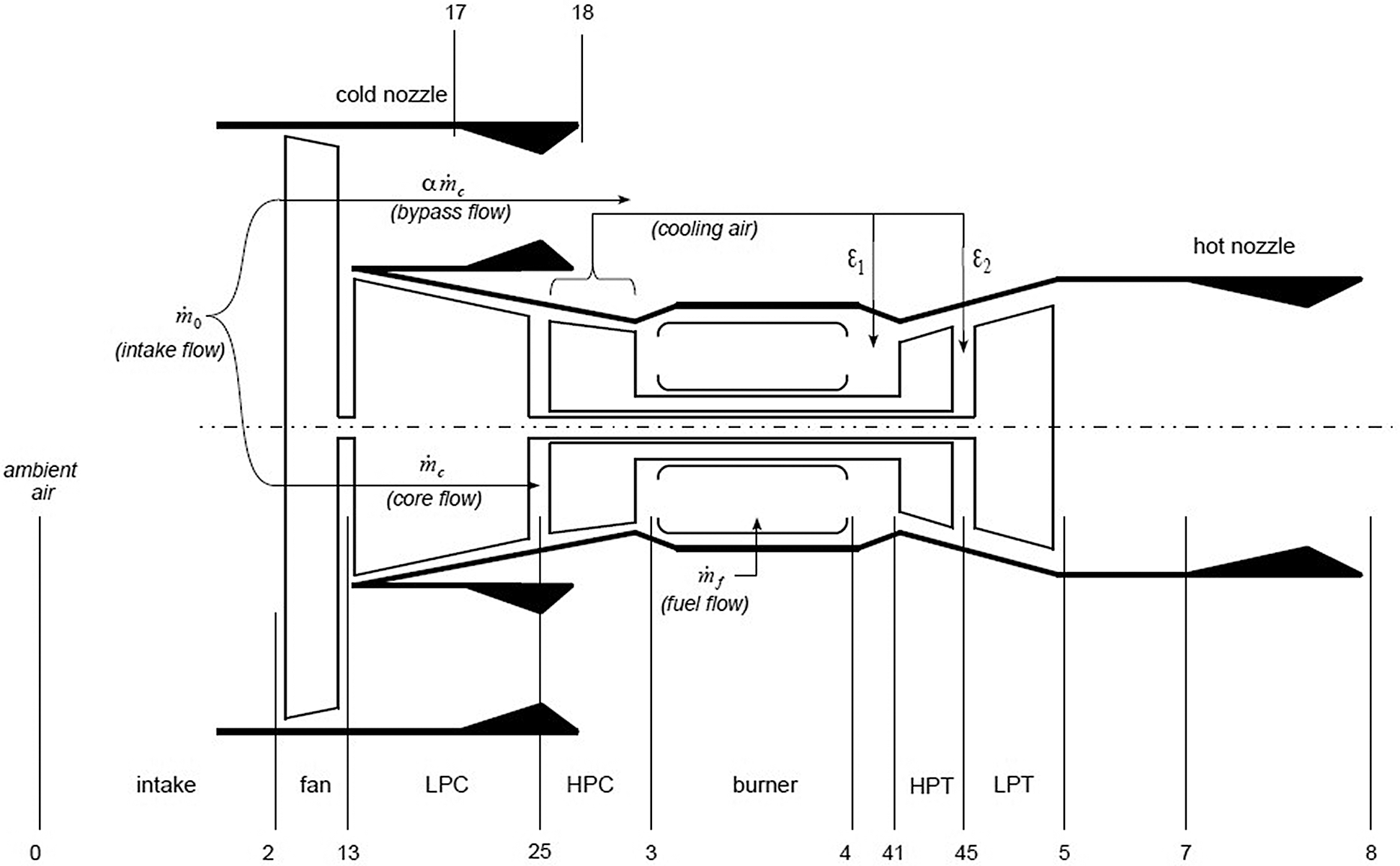

2 Modelling of Turbofan Engines

Turbofan Model. The turbofan engine model used in this work is identical to the one presented by Tai et al. [8], as illustrated in Fig. 1. It is a two-spool separated flow turbofan engine, consists of a high-pressure spool where high-pressure turbine (HPT) is connected to high-pressure compressor (HPC), and a low-pressure spool where low-pressure turbine (LPT) is connected to fan and low-pressure compressor (LPC). The cooling air fractions ɛ1 and ɛ2 are bled from the HPC, for cooling of HPT and LPT, respectively. The mathematical models and algorithms that describe the thermodynamic cycle of a turbofan engine are identical to the one developed by Tai et al. [8], where zero-dimensional thermodynamic model described in [22] was used to calculate the turbofan performance. Liquid kerosene with chemical equation C12H23.5 was assumed in this study. The lower heating value (hL) of the kerosene is 43124 kJ/kg.

Figure 1: Schematic diagram of the two-spool separated flow turbofan engine used in this study

Uncertainty Quantification. In conventional design optimisation formulation, only one value from each variable is used for performance evaluation. However, in RBDO formulation, a set of Ns number of variations from each variable is required for use in performance and reliability evaluations. The way of modelling the variations is called uncertainty quantification.

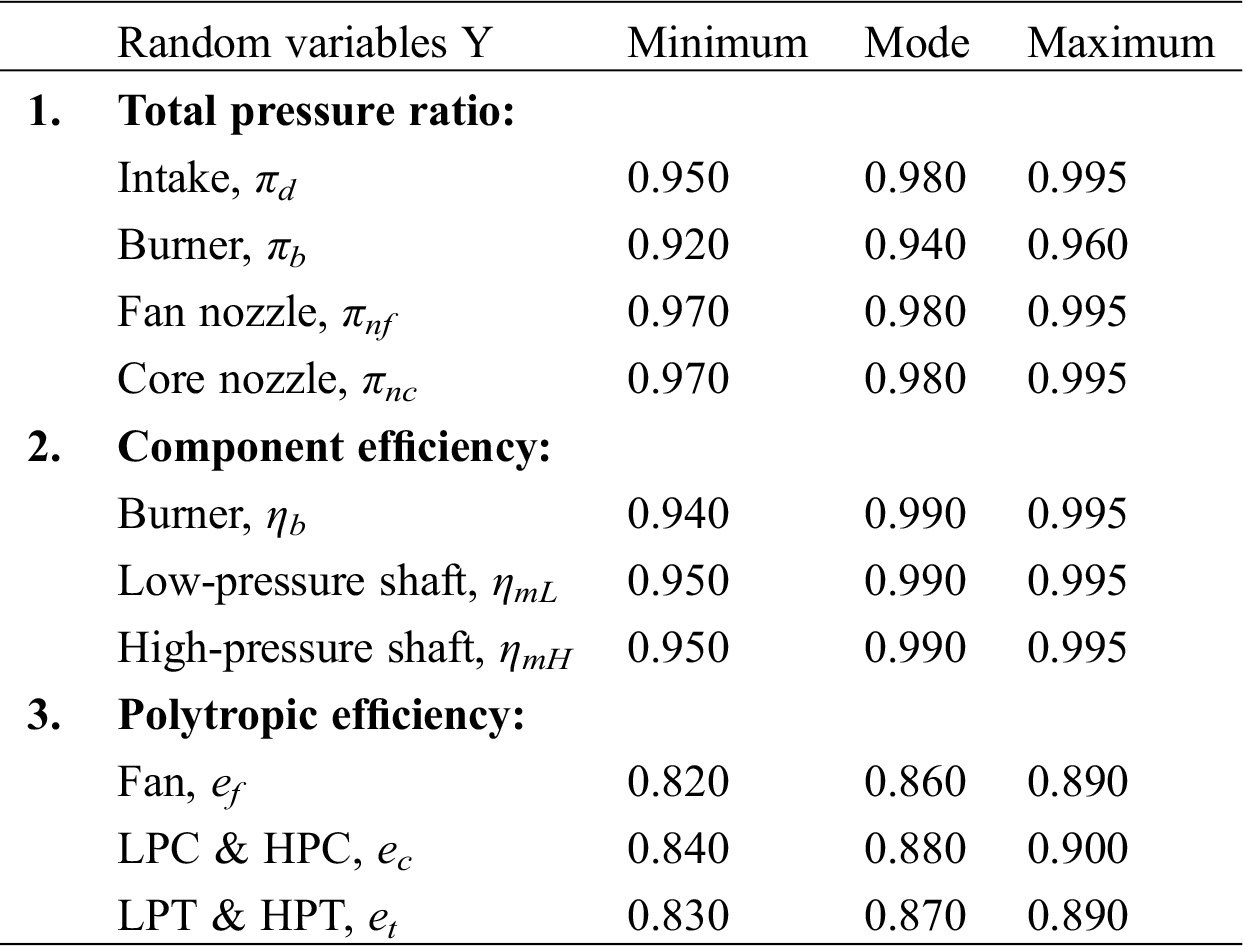

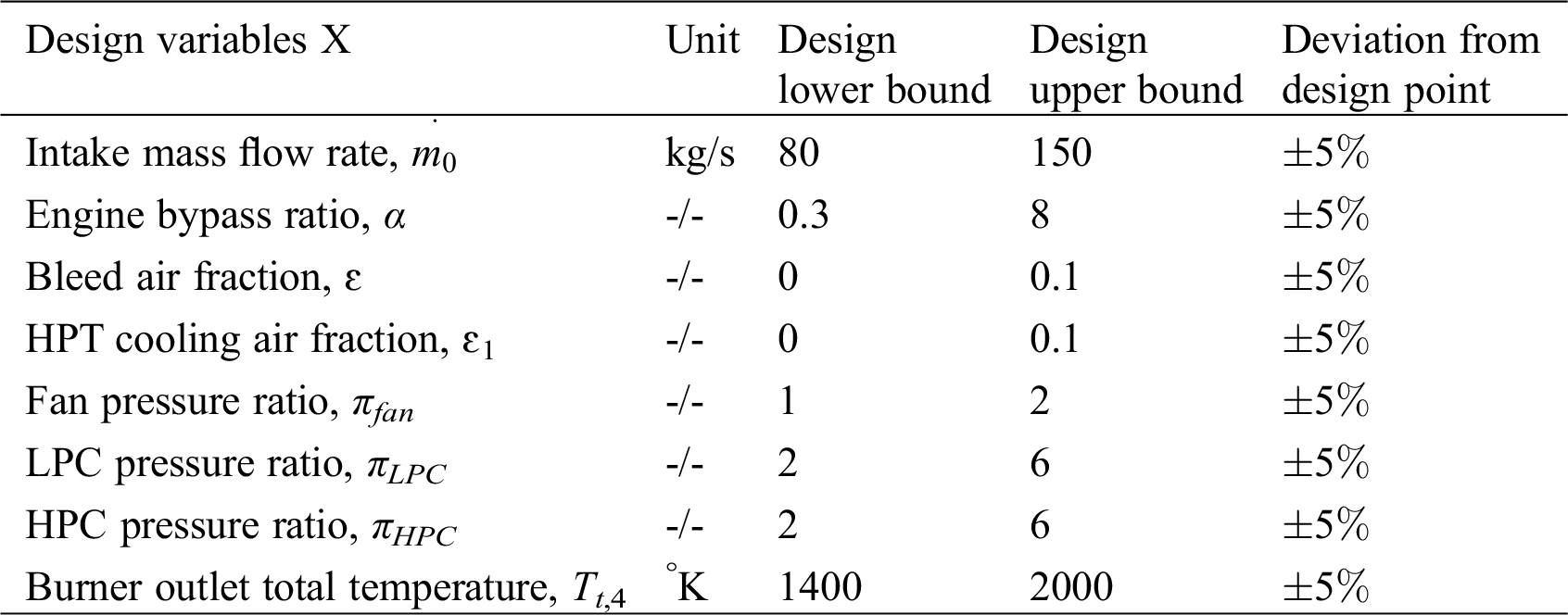

Uncertainty in component technology can be modelled with probability distribution function [2]. In this study, triangular probability function had been employed to model the technology level of an aeroengine component, where the most likely value was represented by the mode, and the upper and lower bounds described the best and worst scenarios respectively. The same type of probability distribution was used to model the uncertainty of design variables. The detailed descriptions of both the technology level and design variables are presented in Tabs. 1 and 2, respectively.

Table 1: Uncertainty quantification of turbofan components

Table 2: Upper and lower bounds and uncertainty quantification of design variables

As all variables are independent of each other, the combination of them formed a high-dimensional joint probability distribution. LHS had been used to sample Ns number of variations from the distribution at each optimisation iteration. The convergence of optimisation results with respect to Ns is presented in Section 4.

Reliability Based Design Optimisation. In general, the mathematical formulation of RBDO can be described as follows:

where, X ∈ ℝn is the design vector (e.g., the input design variables that define the aeroengine), Y ∈ ℝm is vector of random variables (see Tab. 1), and μX and μY are the means of X and Y, respectively. J(⋅) is the objective function and G(⋅) is the function that defines failure. The formulation of J(⋅) is presented in Section. All Ng number of hard constraints were treated as G(⋅) and its detailed formulation is presented in this Section.

where, fx, y (⋅) is the joint probability distribution of X and Y. As there is no simple analytical way to evaluate Eq. (2), Monte-Carlo Simulation (MCS) based on Latin Hypercube Sampling (LHS) method has been used to approximate the solution.

Objective Function. The combinatorial objective function J(⋅) was designed according to Filatovas et al. [23], to obtain Pareto optimal solutions for k number of objective functions f (⋅):

where, subscript i denotes the ith objective, w is the weight factor, ρ > 0 is called augmentation coefficient.

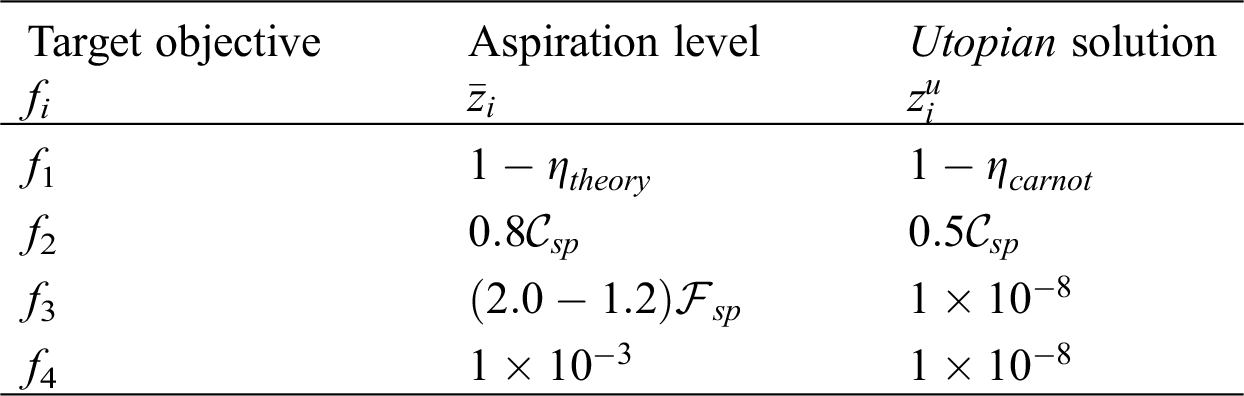

where, f1 to f3 evaluate the mean values of the design’s thermal efficiency (ηth), thrust specific fuel consumption (

Penalty Function. There are a total of six constraints to this optimisation problem, denoted

The failure function G1(X, Y) in Eqs. (1) and (2), defined by the six hard constraints in Eqs. (8)–(13), is as follows:

This way, Eq. (14) returns 0 if all the constrains are met and 1 otherwise. Therefore, f4 in Eq. (4) is simply the ratio of failure runs to total number of Ns runs for an engine configuration of interest. Following the work by Tai et al. [8], the constraint values for minimum thrust (

4 Luus-Jaakola Algorithm for RBDO

Luus-Jaakola optimisation algorithm is easy to apply as it does not require additional auxiliary variables or transformations [25]. This makes the direct search optimisation procedure comparatively fast compared with other direct search methods such as GA [26]. This feature is important for use in RBDO as many variations of a design are generally required to compute its reliability. Modified from the original version presented in [25] and [26], the optimisation procedure is summarised as follows, with double asterisk marks (**) to indicate the modified codes:

1. Set number of design samples Ns.

2. Generate Ns number of design vector d using LHS. **

3. Set the number of iterations for external and internal loops (next and nint).

4. Choose a region size contraction factor γ and region collapsed parameter ɛ (= 10−4 in this study).

5. Initialise the input vector x* and search size vector r(0).

6. For i = 1 to next:

a) For j = 1 to nint:

i. x(j) = x∗ + D(j)r(j); where D is a diagonal matrix with element values chosen randomly between [−1, + 1].

ii. For each element in x(j), truncate the value if the element bound constraint is violated.

iii. Using x(j) as mean, generate Ns number of input vectors X(j) using LHS. **

iv. Evaluate the objective function J (d, X).

v. If J(j) < J∗: store x∗ = x(j).

vi. Update r(j+1) = γr(j).

b) Choose new search region size r(i+1) = |x∗(i) − x∗(i−1)|.

c) If

d) After five external loops, if J does not change for three consecutive loops, reduce ε by half.

e) Terminate the program if ε < 10−8.

7. Interpret the results.

Running on a 64-bit Windows 10 equipped with Intel(R) Core(TM) i5-3330 CPU at 3.00 GHz, the optimisation procedure requires only about 3 min for number of samples Ns = 500. The parameters next, nint, and γ are 50, 100, and 0.95, respectively.

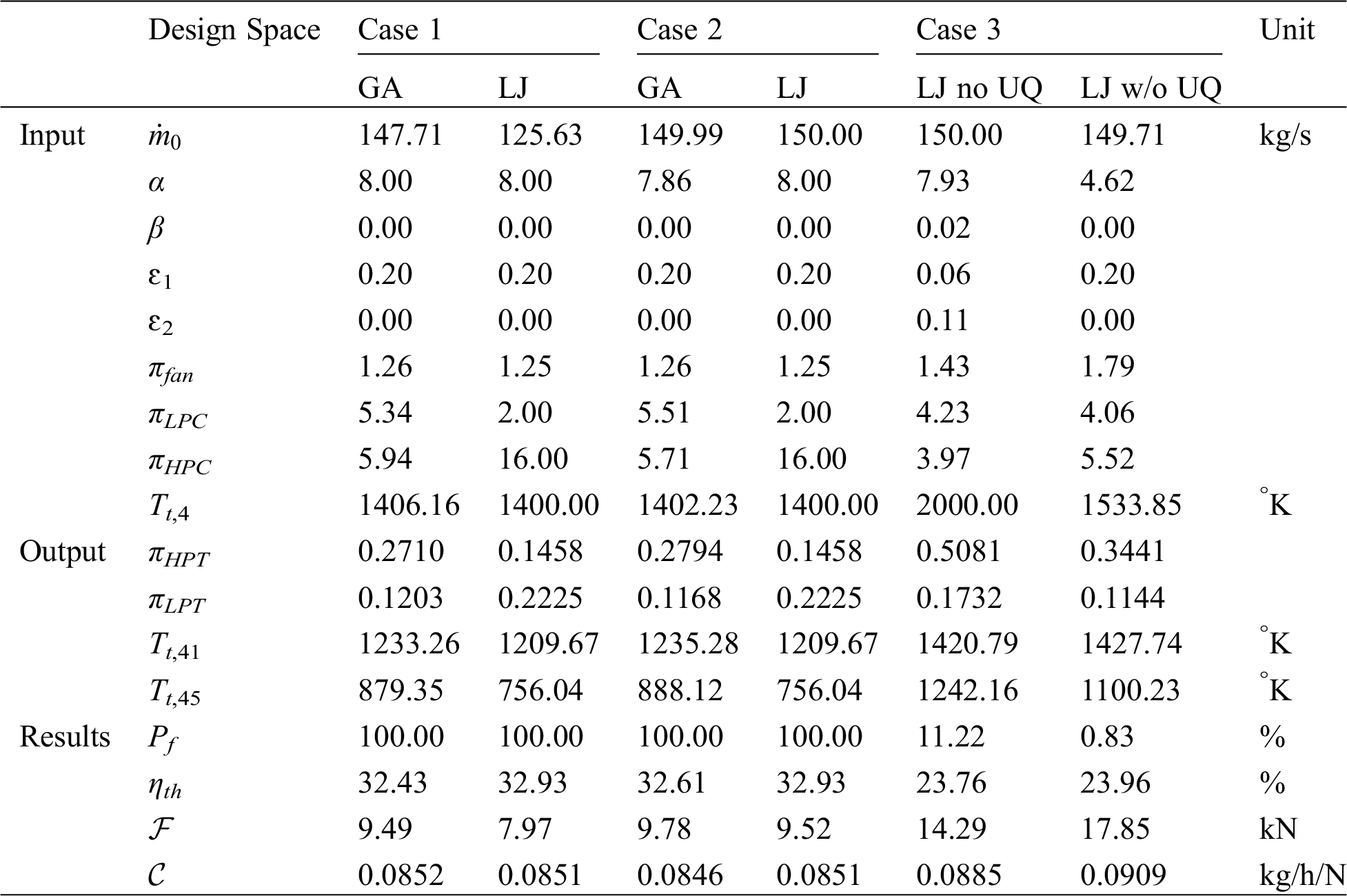

A total of 3 optimisation cases have been studied in this work. Case 1 is a single objective optimisation problem designed to compare the performance of the proposed optimisation algorithm with genetic algorithm. Case 2 presents a multi-objective optimisation case study without considering variable and model uncertainties, while Case 3 is a multi-objective optimisation case with variable and model uncertainties considered. For Cases 2 and 3, their optimised design variables were re-sampled and re-evaluated for 10000 times to obtain their respective probability of failure and objective score. Presented in Fig. 2 is the plot of success probability (Psuccess) and objective score against Ns for Case 3, to study the number of sample required in RBDO that would yield reasonably reliable results. The results show that more than 500 LHS samples were required to give reliable results with Pf < 1%. For the cases without uncertainty modelling, the mode values were used (see Tab. 1).

Figure 2: Sampling convergence study

The objective of Case 1 was to maximise the thermal efficiency ηth, without the thrust constraint

1. Roulette wheel selection of chromosomes for crossover operation, and

2. population size, generation size, crossover rate and mutation probability were 25, 2000, 0.85, and 0.06, respectively.

The values of objective score, ηth,

Case 2 seeked to optimise 3 conflicting objectives (i.e., ηth,

The optimisation problem for Case 3 was similar to Case 2, but with

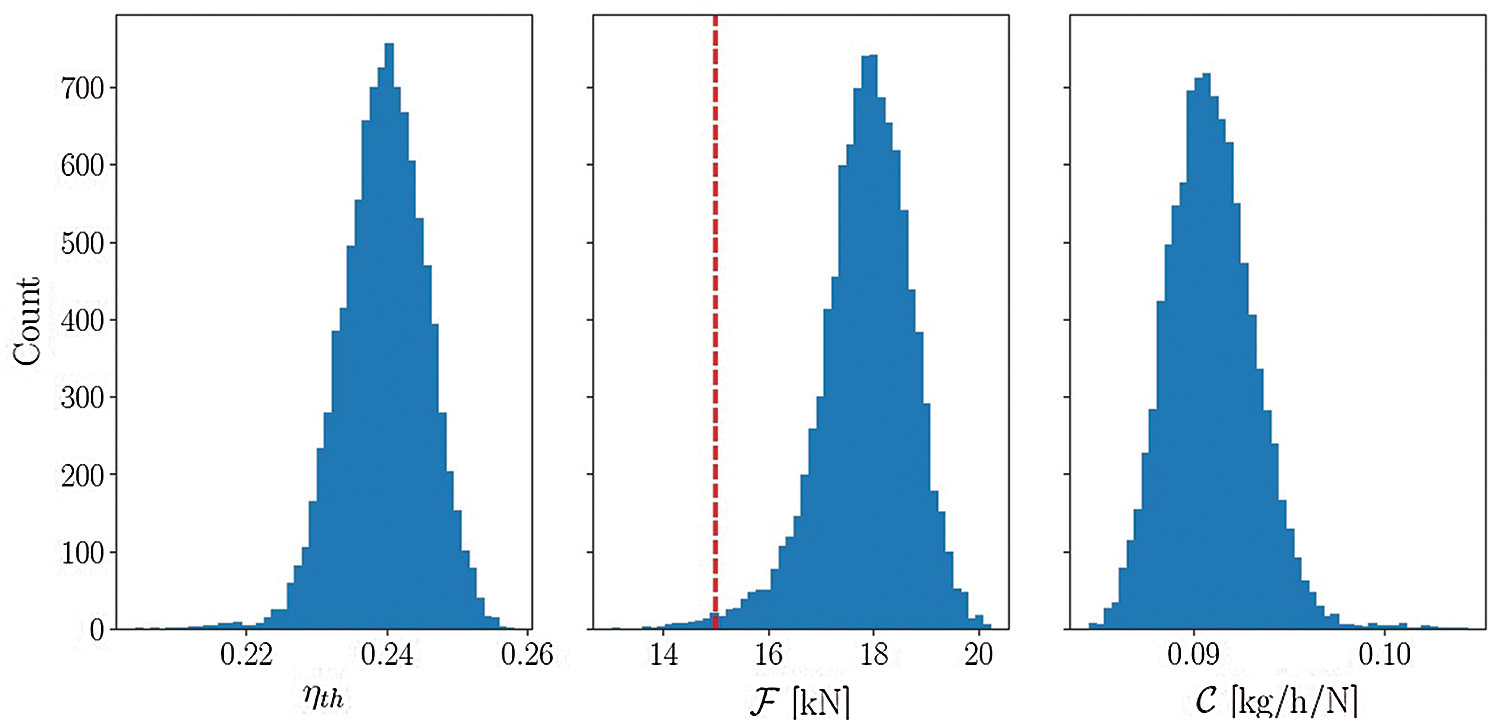

Figure 3: Performance of aeroengine optimised with 500 LHS samples

With uncertainty quantification, the ηth for Case 3 was slightly less than Case 2, about 23.96%. However, its probability of not meeting

Table 3: Objective function parameter values

Fig. 4 shows the convergence plots of the proposed method for Case 3 with different LHS sample sizes used in the optimisation processes. The objective scores presented in Figs. 4a to 4d were obtained with the number of samples reported in their respective optimisation process. Note that the final objective score shown in Fig. 4a is the lowest among the four solution candidates. This is due to only 100 samples were used in the optimisation calculation. When subjected to 10000 LHS samples, the Psuccess was only 97% (see Fig. 2). This indicates that the design is sensitive to failure, although the objective score of the design is the lowest (i.e., the best) among the four solution candidates. In Fig. 4b, the sample size was increased to 200 samples and the resultant final objective score was also increased, from 11.56 for 100 sample size to 11.65. The Psuccess for this solution was 99% according to Fig. 2. When the sample size is increased to 500 samples and subsequently to 1000 samples, Figs. 4c and 4d show there is improvement in the objective score, from 11.645 to 11.59. The probability of success for the 2 solution candidates are around 99.90% and 99.95% when subjected to 10000 LHS samples. In short, the results presented in Fig. 4 indicate the proposed method can produce optimisation solution with low sensitivity of failure, provided the number of LHS samples is large enough.

Figure 4: Convergence of solution to Case 3 with different sample sizes. (a) 100 samples (b) 200 samples (c) 500 samples (d) 1000 samples

Table 4: Performance of solution candidates with aligned units

In the field of thermodynamic cycle optimisation, the traditional deterministic design optimisation is widely used. Although uncertainty is an inherent property existing in early engine development stage, the deterministic design could yield unreliable solutions. Optimisation considering uncertainty factors in thermodynamic cycles is rare in studies for the time being. Integrating MCS in the popular metaheuristic methods to realise RBDO in aeroengine design is prohibitive due to time constraint and limited computation resource. Therefore, this paper aims to propose a faster RBDO method for two-spool separated flow turbofan engine cycle optimisation using Luus-Jaakola algorithm and LHS MCS scheme.

The proposed algorithm was validated against a simple genetic algorithm scheme to verify its ability to obtain global optimum solutions. When tested with single objective and multi-objective case studies without uncertainty modelling, the results showed that the proposed algorithm is reliable and about 4 to 10 times faster than a simple GA in searching for optimum solutions. When subjected to uncertainty, the solution without considering uncertainty and thrust constraint yielded 41% of not meeting the design specifications. Sampling convergence study revealed that more than 500 samples are required to reach robust results with probability of failure of less than 1% with the proposed method. Increasing the number of samples can lead to more robust solutions, with the cost of longer solution time.

For the turbofan model used in this study, the RBDO formulation in study revealed that thrust constraint is important to ensure the thrust design requirement is met. Incorporating thrust in the objective function alone is not enough to ensure the final solution to meet the design requirement. With uncertainty modelling and thrust constraint, the ηth obtained was only 23.96% with Pf < 0.1%, compared with 23.76% and Pf > 11% without uncertainty quantification. The

The proposed algorithm can achieve satisfactory optimisation solutions within reasonable time frame for the turbofan RBDO problem formulated in this study. The use of surrogate modelling in RBDO to save computation time such as the one presented in [21] is very interesting. In the future version of TJEO program, integrating surrogate models in the proposed method is expected to further reduce the computation time needed to yield robust optimum solutions.

Funding Statement: The project is funded by the Ministry of Higher Education Malaysia, under the Fundamental Research Grant Scheme (FRGS Grant No. FRGS/1/2017/TK07/SEGI/02/1).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Homaifar, A., Lai, H. Y., McCormick, E. (1994). System optimization of turbofan engines using genetic algorithms. Applied Mathematical Modelling, 18(2), 72–83. DOI 10.1016/0307-904X(94)90162-7. [Google Scholar] [CrossRef]

2. Younghans, J. L., Johnson, J. E., Csonka, S. J. (1995). A methodology to assess design uncertainty in selecting affordable Gas turbine technology. Journal of Engineering for Gas Turbines and Power, 117(4), 666–672. DOI 10.1115/1.2815451. [Google Scholar] [CrossRef]

3. Asako, T., Miyagawa, H., Miyata, S., Kudo, K. (2002). Conceptual design of aircraft engine using multidisciplinary design optimization technique. 23rd Congress of International Council of the Aeronautical SciencesToronto, Canada. [Google Scholar]

4. Niknamian, S. (2020). The optimization of a jet turbojet engine by PSO and searching algorithms. Journal of Applied Science, Engineering Technology, and Education, 3(1), 7–11. DOI 10.35877/454RI.asci3195. [Google Scholar] [CrossRef]

5. Atashkari, K., Nariman-Zadeh, N., Pilechi, A., Jamali, A., Yao, X. (2005). Thermodynamic pareto optimization of turbojet engines using multi-objective genetic algorithms. International Journal of Thermal Sciences, 44(11), 1061–1071. DOI 10.1016/j.ijthermalsci.2005.03.016. [Google Scholar] [CrossRef]

6. Chandrasekaran, N., Guha, A. (2012). Development and optimization of a sustainable turbofan aeroengine for improved performance and emissions. Proceedings of the Institution of Mechanical Engineers. Part G: Journal of Aerospace Engineering, 227(11), 1701–1719. DOI 10.1177/0954410012462183. [Google Scholar] [CrossRef]

7. Celis, C., Sethi, V., Singh, R., Pilidis, P. (2015). An optimisation of environmentally friendly aircraft engine cycles. Journal of Aerospace Technology and Management, 7(2), 143–156. DOI 10.5028/jatm.v7i2.406. [Google Scholar] [CrossRef]

8. Tai, V. C., See, P. C., Mares, C., (2014). Optimisation of energy and exergy of turbofan engines using genetic algorithms. International Journal of Sustainable Aviation, 1(1), 25–42. DOI 10.1504/IJSA.2014.062866. [Google Scholar] [CrossRef]

9. Hearn, T., Hendricks, E., Chin, J., Gray, J., Moore, K. T. (2016). Optimization of turbine engine cycle analysis with analytic derivatives. 17th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference. AIAA AVIATION ForumWashington DC, USA. [Google Scholar]

10. Zhang, X., Wang, Z., Zhou, L., Liu, Z. (2016). Multidisciplinary design optimization on conceptual design of aero-engine. International Journal of Turbo & Jet-Engines, 33(2), 195–208. DOI 10.1515/tjj-2015-0024. [Google Scholar] [CrossRef]

11. Xu, L., Kyprianidis, K. G., Grönstedt, T. U. G. (2013). Optimization study of an intercooled recuperated aero-engine. Journal of Propulsion and Power, 29(2), 424–432. DOI 10.2514/1.B34594. [Google Scholar] [CrossRef]

12. Verstraete, D., Tacconi, J., Visser, W. P. J. (2019). Multi-objective optimisation of semi-closed cycle engines for high-altitude UAV propulsion. The Aeronautical Journal, 123(1270), 1938–1958. DOI 10.1017/aer.2019.62. [Google Scholar] [CrossRef]

13. Thoma, E. M., Grönstedt, T., Zhao, X. (2020). Quatifying the environmental design trades for a state-of-the-art turbofan engine. Aerospace, 7(10), 148. DOI 10.3390/aerospace7100148. [Google Scholar] [CrossRef]

14. Chen, M., Jia, Z., Tang, H., Xiao, Y., Yang, Y. et al. (2019). Research on simulation and performance optimization of mach 4 civil aircraft propulsion concept. International Journal of Aerospace Engineering. DOI 10.1155/2019/2918646. [Google Scholar] [CrossRef]

15. Choi, J. W., Sung, H. -G. (2014). Performance analysis of an aircraft gas turbine engine using particle swarm optimization. International Journal of Aeronautical & Space Sciences, 15(4), 434–443. DOI 10.5139/IJASS.2014.15.4.434. [Google Scholar] [CrossRef]

16. Fortuna, L., Rizzotto, G., Lavorgna, M., Nunnari, G., Xibilia, M. G. et al. (2001). Evolutionary optimization algorithms, Soft computing. Advanced textbooks in control and signal processing. London: Springer. [Google Scholar]

17. Mavris, D. N., Macsotai, N. I., Roth, B. A. (1998). A probabilistic design methodology for commercial aircraft engine cycle selection. SAE Transactions,1432–1441. [Google Scholar]

18. Tong, M. T. (2000). A probabilistic approach to aeropropulsion system assessment. Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, vol. 78545, American Society of Mechanical Engineers. Munich, Germany. [Google Scholar]

19. Roth, B., Graham, M., Mavris, D. (2004). Adaptive selection of aircraft engine technologies in the presence of risk. Journal of Engineering for Gas Turbines and Power, 126(1), 40–44. DOI 10.1115/1.1639006. [Google Scholar] [CrossRef]

20. Chen, M., Zhang, K., Tang, H. (2014). A probabilistic design methodology for a turboshaft engine overall performance analysis. Advances in Mechanical Engineering, 6, 976853. DOI 10.1155/2014/976853. [Google Scholar] [CrossRef]

21. Cao, D., Bai, G. (2020). A study on aeroengine conceptual design considering multi-mission performance reliability. Applied Sciences, 10(13), 4668. DOI 10.3390/app10134668. [Google Scholar] [CrossRef]

22. Walsh, P. P., Fletcher, P. (2004). Gas turbine performance, 2nd edition. Oxford, UK: Blackwell Science. [Google Scholar]

23. Filatovas, E., Kurasova, O., Sindhya, K. (2015). Synchronous R-nSGA-iI: An extended preference-based evolutionary algorithm for multi-objective optimization. Informatica, 26(1), 33–50. DOI 10.15388/Informatica.2015.37. [Google Scholar] [CrossRef]

24. Svoboda, C. (2000). Turbofan engine database as a preliminary design tool. Aircraft Design, 3(1), 17–31. DOI 10.1016/S1369-8869(99)00021-X. [Google Scholar] [CrossRef]

25. Luus, R., Sabaliauskas, K., Harapyn, I. (2006). Handling inequality constraints in direct search optimization. Engineering Optimization, 38(4), 391–405. DOI 10.1080/03052150500431642. [Google Scholar] [CrossRef]

26. Liao, B., Luus, R. (2005). Comparison of the luus-jaakola optimisation procedure and the genetic algorithm. Engineering Optimization, 37(4), 381–398. DOI 10.1080/03052150512331328312. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |