| Energy Engineering |  |

DOI: 10.32604/EE.2021.014703

ARTICLE

Design and Analysis of a Small Sewage Source Heat Pump Triple Supply System

1College of Urban Construction, Wuhan University of Science and Technology, Wuhan, 430065, China

2City College, Wuhan University of Science and Technology, Wuhan, 430083, China

*Corresponding Author: Chunxue Gao. Email: gaochunxue@wust.edu.cn

Received: 21 October 2020; Accepted: 10 December 2020

Abstract: Based on the characteristics of sewage from beauty salons, a simulation model of a small sewage source heat pump triple supply system that can be applied to such places is established to optimize the operating conditions of the system. The results show that with the increase of sewage temperature and flow, the performance of the system also increases. In summer conditions, the system provides cooling, recovers waste heat and condensed heat from sewage, with a COP value of 8.97; in winter conditions, the system heats and produces hot water, with a COP value of 2.44; in transitional seasons, only hot water is produced. The COP value is 2.75. Compared with the traditional systems which refers to the air source heat pump and hot water boiler system currently used in beauty salons, this system can save energy by 50.9%.

Keywords: Triple supply system of small sewage source heat pump; simulation; system optimization; energy saving and environmental protection

With the gradual advancement of urbanization and the vigorous development of the construction industry, it has also brought about a sharp increase in building energy consumption. From 2010 to 2017, the proportion of building energy consumption in our country’s total energy consumption rose from 17.73% to 21.11% [1,2]. In the proportion of building energy consumption, the energy consumption of hot water, heating and cooling accounts for more than 50% [3,4], and it is of great significance to study the use of low-level energy, such as sewage and industrial waste heat, to replace high-level energy to alleviate the energy crisis [5]. Among them, the sewage from the beauty salon is used as a good source of cold and heat. It usually prepares domestic hot water, provides heating in winter and cooling in summer, and has high recycling and utilization values.

Domestic and foreign scholars have carried out in-depth research on sewage source heat pumps. Sara et al. [6] made statistics on the transformation of sewage flow in the sewage treatment plant and the laws of people’s activities, and based on this, improved the design of the waste heat recovery system. Hepbasli et al. [7] studied the economic and environmental benefits of sewage source heat pump systems in detail through experiments and simulation methods, and provided guidance in all aspects of design, analysis, simulation and evaluation. Culha et al. [8] improved the heat exchanger and sewage transportation channel of the sewage source heat pump system. Nam et al. [9] conducted different studies on the performance of water source heat pumps. Fu Yunkun et al. established transfer function and fuzzy neural network controller based on the principles of thermodynamics and fuzzy neural network, and studied energy-saving control methods for sewage source heat pump systems [10]. Professor Sun Dexing’s scientific research team proposed a complete sewage source heat pump technology and formed a number of new technical ideas and products, and obtained national patents [11]. Li et al. took an indirect primary sewage source heat pump system in severe cold areas as the research object, analyzed the operating conditions of the unit and the influencing factors of the operating effect of the unit [12]. Wang et al. [13] designed a kind of shell and tube heat exchanger suitable for sewage source heat pump.

Although scholars at home and abroad have carried out a lot of researches, there are few researches on the application of sewage from beauty salons. The sewage drainage temperature of the beauty salon club is high, and the existing treatment method is directly discharged into the sewage pipe network, causing a lot of waste heat. Based on the characteristics of sewage from beauty salons, this paper designs a small sewage source heat pump triple supply system to recover waste heat from sewage to save energy, and uses TRNSYS software to simulate the system, aiming to provide guidance and reference for the waste heat recovery and utilization of this kind of sewage in the future.

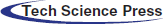

Before designing a small-scale sewage source heat pump triple-supply system, it is assumed that the sewage in the beauty salon has been treated to the domestic miscellaneous water standard. The system aims to solve the problem of heat recovery from sewage discharge in beauty salons and to effectively use water resources. To achieve this goal, the system is mainly composed of evaporative heat exchangers, compressors, condensers, thermal expansion valves, heat preservation water tanks, circulating water pumps, electric valves and other basic components. The system diagram is shown in Fig. 1. It is assumed that the beauty salons can continuously produce sewage during working hours and the demand for hot water is also continuous in this paper.

Figure 1: Sewage source heat pump triple supply system diagram. 1-Compressor 2-Condenser 1 3-Condenser 2 4-Throttling mechanism 5-Evaporator 1 6-Evaporator 2 7-Electric valve 1 8-Electric valve 2 9-Circulating pump 1 10-Circulating pump 2 11-Water supply pump 12-Sewage pump 13-Sewage filter 14-Sewage treatment equipment 15-User terminal 16-Insulation water tank 17-Sewage tank

The small sewage source heat pump triple supply system uses the sewage of the beauty salon club as the heat source, recovers the condensing heat at the end of the air conditioner, and can meet the requirements of cooling, heating and hot water in the club’s usual business. The annual operation mode of the system realizes the conversion of different functions through the automatic control of the unit control panel and the opening of the valve. Several functional modes are as follows:

1. Separate cooling

2. Separate heating

3. Separate hot water

4. Cooling and hot water production

5. Heating and hot water production

The specific function operation principle is relatively simple and will not be repeated.

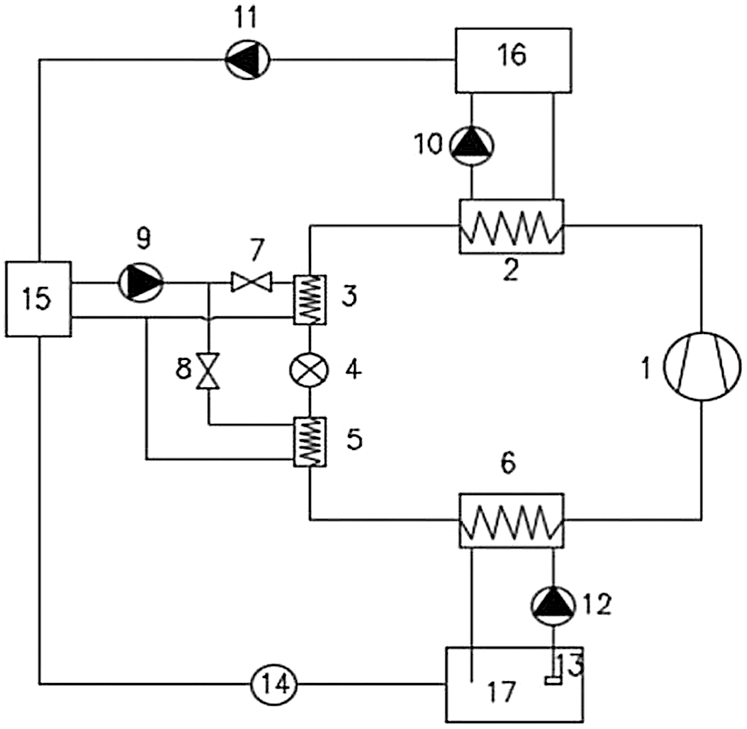

After completing the basic design of the triple-supply system diagram, the heat transfer calculation of the condensing heat exchanger and evaporating heat exchanger in the system is now performed, and the compressor is matched and designed according to the operating parameters of the system. Assuming that the room size of the beauty salon is 7 m × 12 m × 4 m, according to the Code for Design of Heating, Ventilation and Air Conditioning of Civil Buildings (GB50736-2012), the calculation parameters of the triple-supply system design are shown in Tab. 1.

Table 1: Design and calculation parameters of triple supply system

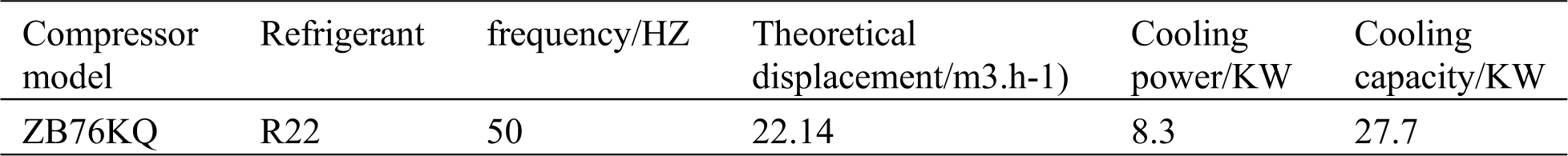

Use TRNSYS (Transient System Simulation Program) simulation software to calculate room cooling, heating and hot water loads based on the meteorological parameters and room building structure parameters in Wuhan. It is calculated that the heat taken away by the room evaporator in summer, that is, the maximum cooling load Qm of the room is 12.6 kW; the maximum heat load of the room is 7.84 kW; the heat exchange of the sewage side evaporator, that is, the sewage heat load Qh is 13.53 kW. The maximum heat that the system can theoretically recover, that is, the cooling capacity Q = 13.53 + 12.6 = 26.13 kW. The theoretical input power of the compressor is calculated to be 6.02 kW. The compressor is selected accordingly, and its characteristic parameters are shown in Tab. 2.

Table 2: Compressor characteristic parameters

The condenser chooses φ203 × 6 mm seamless steel pipe as the shell and tube heat exchanger, and the heat transfer tube chooses φ12 × 1 mm copper pipe, 2 processes, 30 per process.

Choose the Hongsen thermal expansion valve suitable for refrigerant R22, the model is ERF22-φ7.0, the inlet and outlet interface size is 16 × 15 mm, and the rated cooling capacity is 29.9 KW.

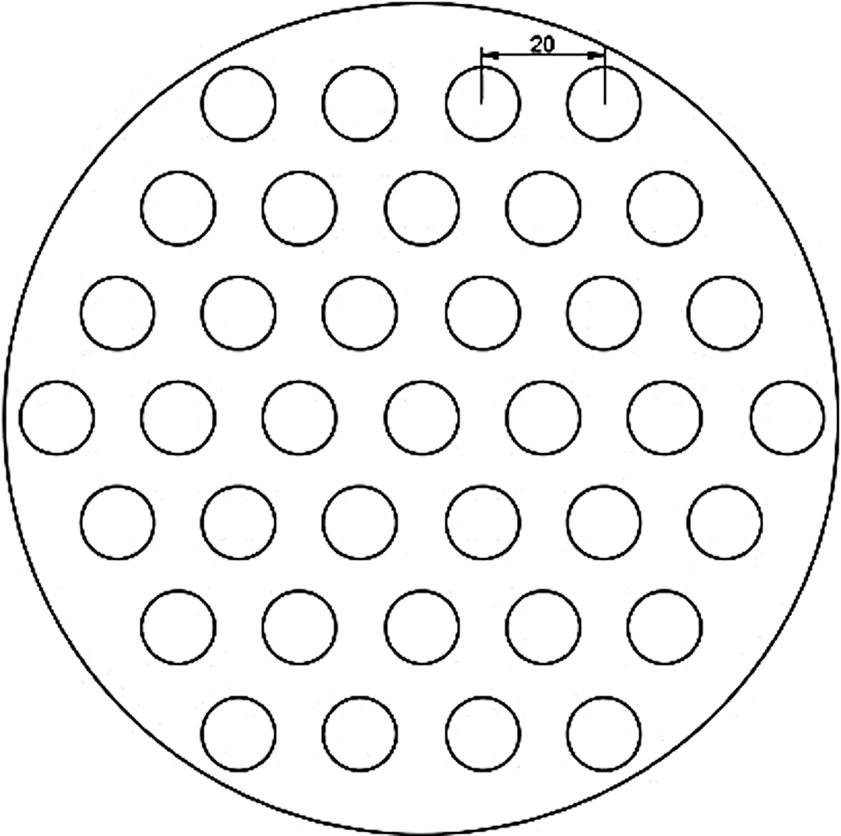

The sewage evaporator chooses φ146 × 4.5 mm seamless steel tube as the shell and tube heat exchanger. The size of the heat transfer tube is the same as the basic size of the condenser heat exchange tube. There are 37 heat exchange tubes. The tube bundle arrangement is shown in Fig. 2.

Figure 2: Schematic diagram of evaporator heat transfer tube bundle layout

This paper aims to simulate a typical small single experimental building in Wuhan. Its size is 7 m (length) × 12 m (width) × 4 m (height). There is no thermal zone inside the building, three sides are exterior walls, and the other is glass exterior walls, and the building has no sunshade. Measures, thermal parameters and interior design parameters of the envelope structure refer to Code for Thermal Design of Civil Buildings (GB50176-2019) and Code for Design of Heating, Ventilation and Air Conditioning of Civil Buildings (GB50736-2012), respectively. The various components and parameters of the system refer to the above.

In order to reduce the impact of the sewage source heat pump system, the simulation system is simplified as follows:

1. Ignore the heat gain and heat dissipation of system equipment;

2. Ignore the heat loss during system pipeline transportation;

3. The hydraulic characteristics of the system pipe network are stable.

This article will establish a mathematical model and use TRNSYS software to simulate the heating, cooling and hot water supply of the small sewage source heat pump triple supply simulation system throughout the year, and analyze the system stability under fixed sewage temperature and tap water temperature. And reliability, by calculating the COP (heating energy efficiency ratio) of the triple heat pump system, the energy consumption of the system for heating, cooling and hot water production throughout the year is simulated and calculated.

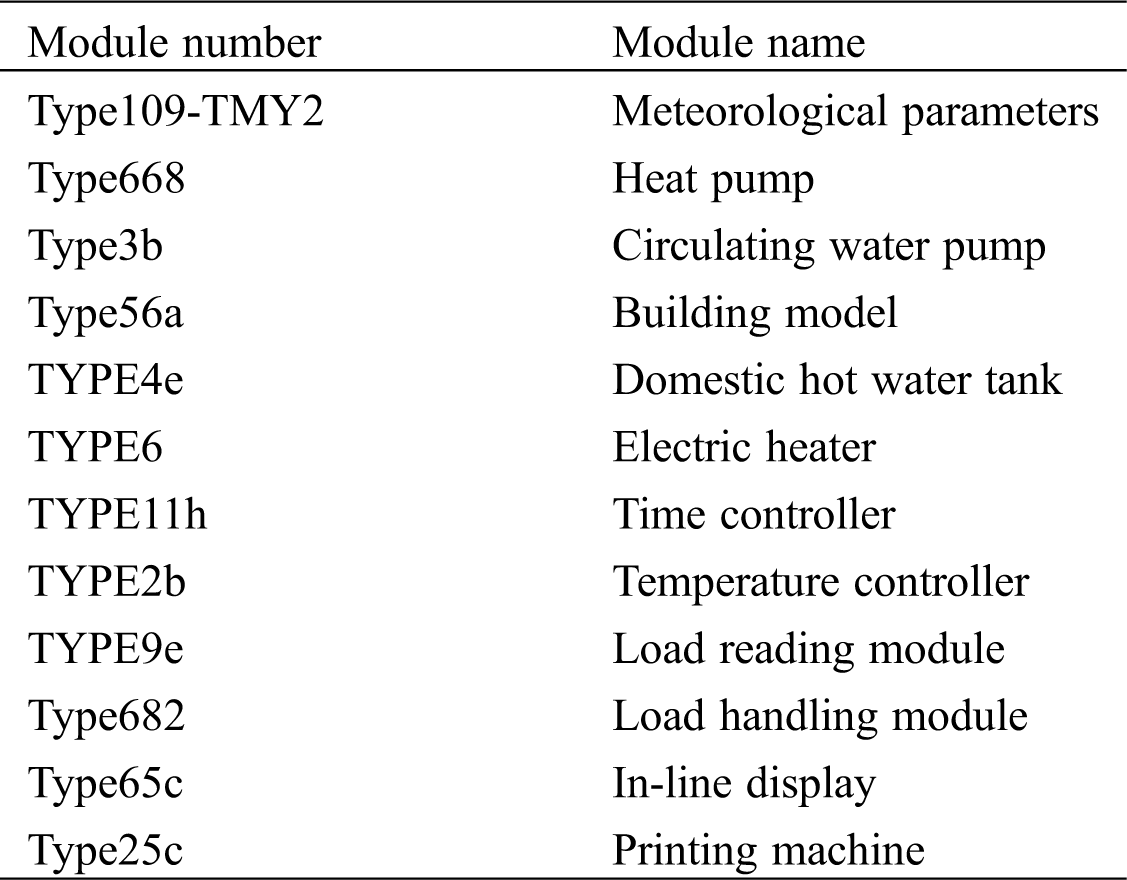

The modules used in TRNSYS software are shown in Tab. 3.

Table 3: The modules used in TRNSYS

The main module used in the system simulation was water source heat pump module, Type668, which has two control signals: Cooling and heating. Type668 can calculate the operating power and heating power of the unit at any time based on the input inlet water temperature at the source side and the inlet water temperature at the load side.

Mathematical model formula under heating condition

which Qheating was the heating capacity, kW; Pheating was the power consumption, kW; Qabsorbed was the heat absorption capacity, kW; Tsource,in was the inlet temperature at source side, °C; Tload,in was the inlet temperature at load side, °C; msource was the mass flow rate at source side, kg/s; mload was the mass flow rate at load side , kg/s; Cpsource was the specific heat capacity of water at source side, kJ/kg·°C; Cpload was the specific heat capacity of water at load side, kJ/kg·°C.

Mathematical model formula under cooling condition

which Qcooling was the cooling capacity, kW; Pcooling was the power consumption, kW; Qrejected was the heat release capacity, kW; Tsource,out was the outlet temperature at source side, °C; Tload,out was the outlet temperature at load side, °C; msource was the mass flow rate at source side, kg/s; mload was the mass flow rate at load side, kg/s; Cpsource was the specific heat capacity of water at source side, kJ/kg·°C; Cpload was the specific heat capacity of water at load side, kJ/kg·°C.

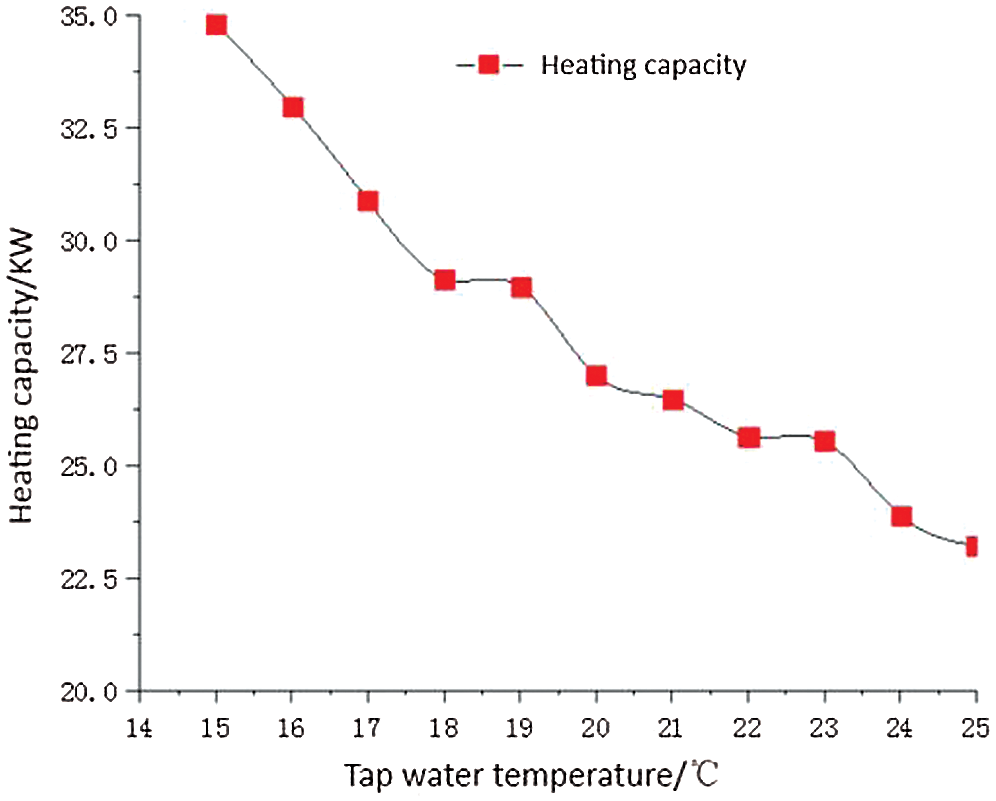

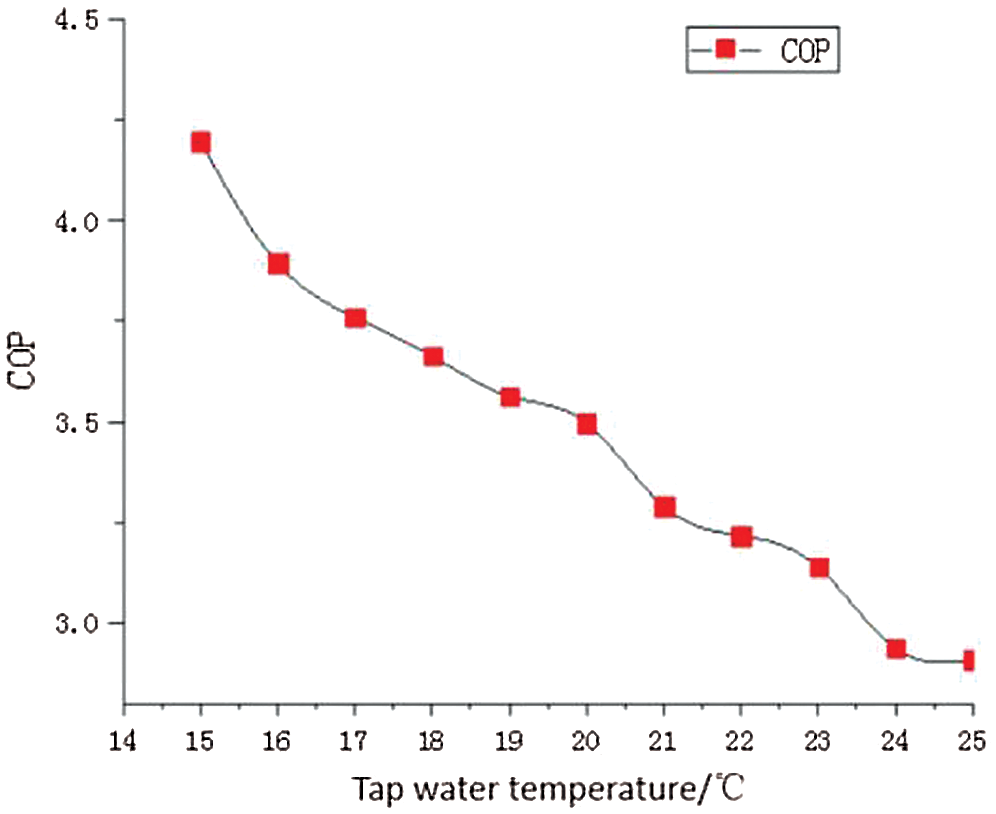

3.1 Analysis on the Influence of Tap Water Temperature on the System

Keep the sewage temperature and flow constant, the hot water on the condenser side will be heated to 40°C, and the tap water flow will not change. The change in the initial temperature of the tap water has a great impact on the performance of the system. When the tap water temperature changes, the heating performance of the system is shown in Figs. 3 and 4. The tap water temperature in Wuhan measured was within the range of 15–25°C. Therefore, the temperature in the range of 15°C to 25°C is used for analysis.

Figure 3: The influence of tap water temperature on heating capacity

Figure 4: The influence of tap water temperature on system performance coefficient

It can be seen from Figs. 3 and 4 that when the tap water flow rate remains constant, as the tap water temperature gradually increases, the system’s heating capacity and COP value show a downward trend; as the tap water temperature increases, the heat flowing through the condensing heat exchanger remains unchanged. It is equivalent to reducing the temperature difference flowing through the condenser. Since the water flow rate is rated, the heating capacity of the system must be reduced. Because the system refrigerant flow rate, evaporating temperature, condensing temperature and compressor power remain unchanged, the heating capacity is reduced, and the coefficient of performance of the system is reduced. When the tap water temperature is 15°C, the heating capacity of the system reaches the maximum value, reaching 34.84 KW. At this time, the system COP value also reaches the maximum value, reaching 4.19. The lower the tap water temperature during hot water production, the greater the system performance, but at the above tap water temperature In the change interval, the system average COP value is 3.46.

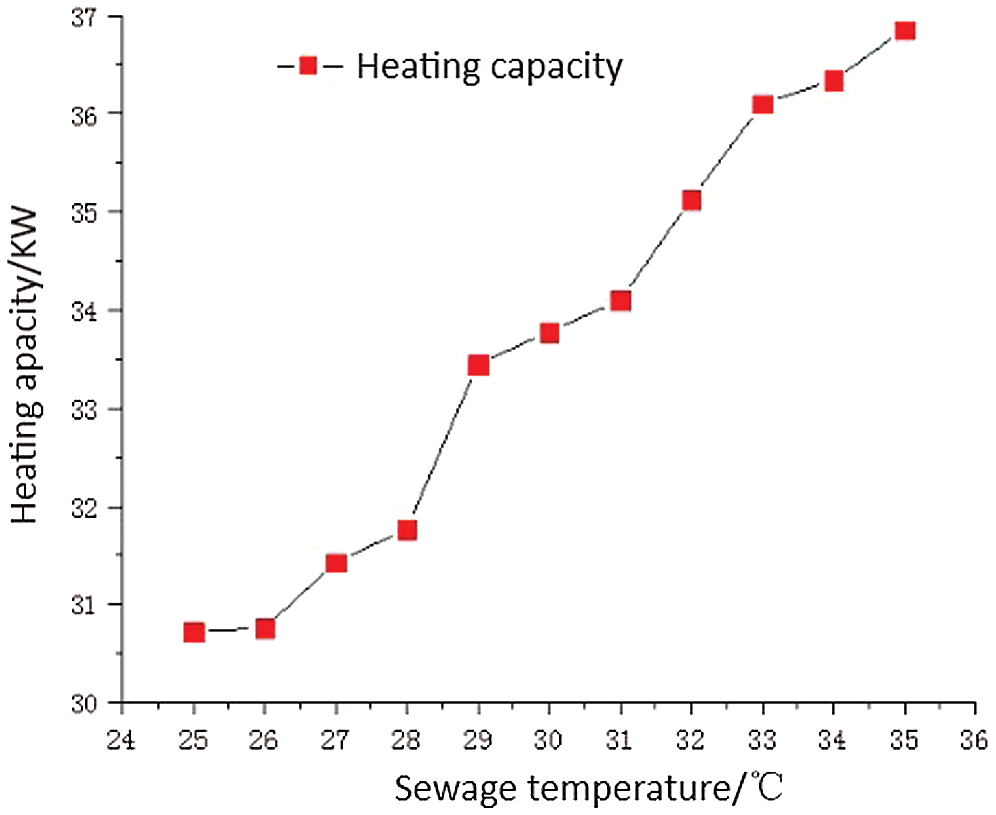

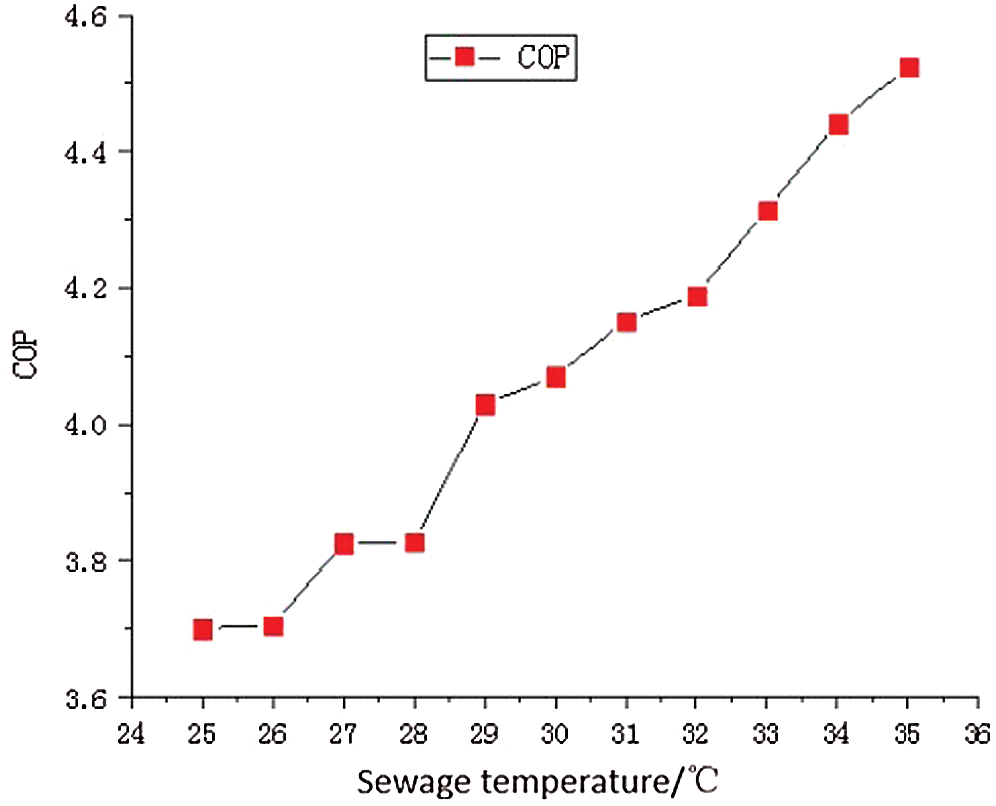

3.2 Analysis of the Influence of Sewage Temperature on the System

Keep the tap water temperature and flow stable, and at the same time keep the sewage flow of the beauty salon unchanged, change the sewage temperature and analyze the influence of the sewage temperature on the system, which is beneficial to the optimization of the system performance. The annual average air temperature in Wuhan is 17.7°C and the annual average temperature of urban sewage pipe network is 16.4°C which both lower than the sewage temperature from beauty salons. The measured effluent temperature from beauty salons and the temperature at the entrance of the sump were in the range of 25–36°C. Therefore, the temperature in the range of 25°C to 36°C is used for analysis, as shown in Figs. 5 and 6.

Figure 5: Influence of sewage temperature on system heating capacity

Figure 6: The influence of sewage temperature on system performance coefficient

It can be seen from Figs. 5 and 6 that when the load side temperature, flow, and sewage flow are kept constant, as the sewage temperature increases, the heating capacity and COP value of the system show an increasing trend; this is due to the increase in sewage temperature. The more, the more heat absorbed by the refrigerant on the evaporator side, and the more heat taken away by the tap water flowing through the condenser side, the more the system heating capacity increases with the temperature of the sewage. When the refrigerant flow rate, evaporating temperature, condensing temperature and compressor power in the system remain unchanged, the heating capacity increases and the system COP increases. When the sewage temperature is 35°C, the heating capacity reaches the maximum, which is 38.3 KW. At this time, the COP is 4.54 and the average COP value is 4.2, indicating that the higher the sewage temperature within the measured temperature range, the better the system performance.

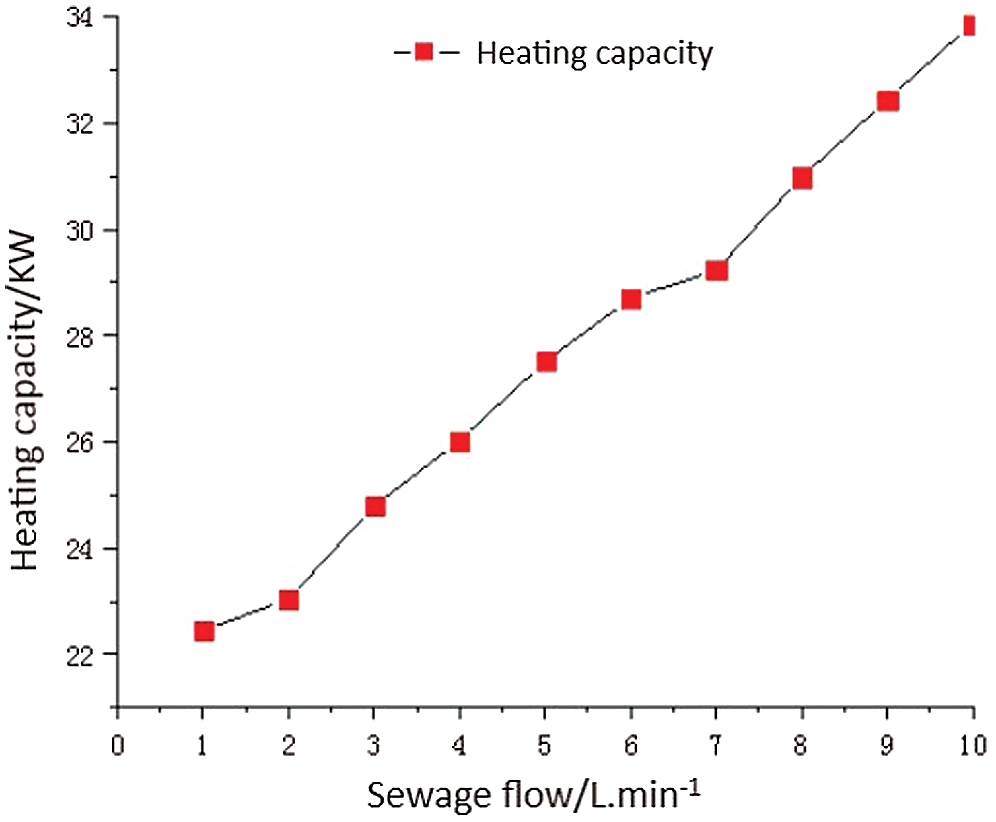

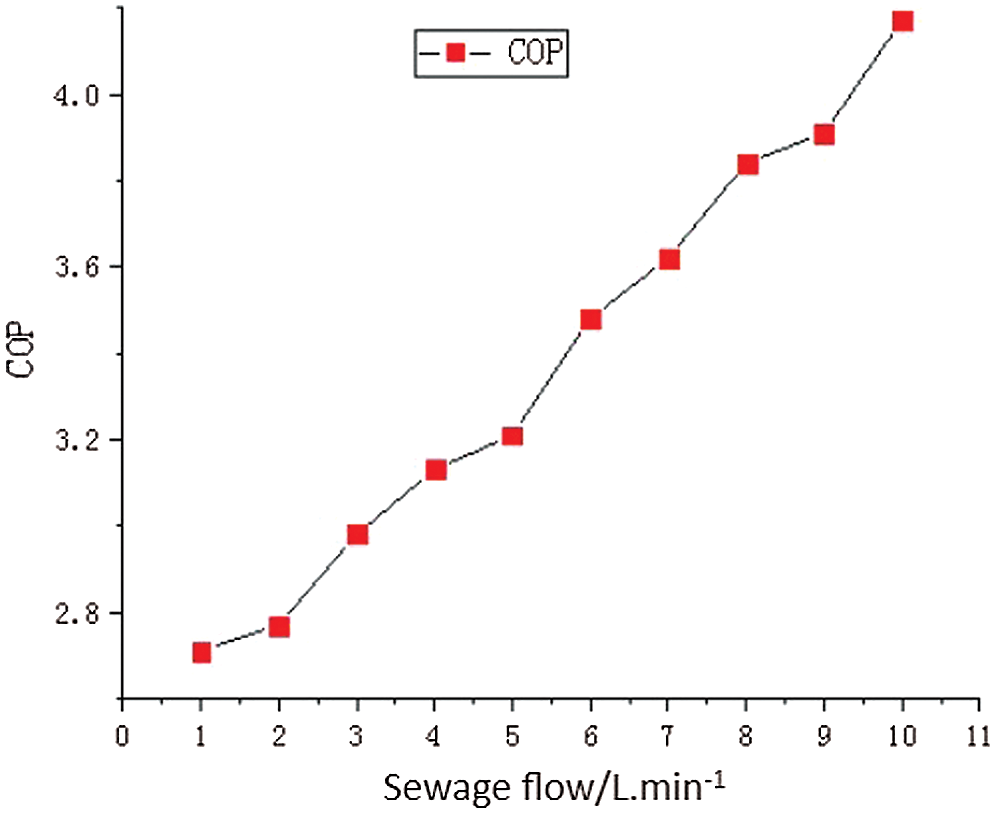

3.3 Analysis on the Impact of Sewage Flow on the System

Keep the load side temperature, flow and sewage temperature stable, change the sewage flow, and the influence of the sewage flow change on the stability of the system is shown in Figs. 7 and 8.

Figure 7: Influence of sewage flow on system heating

Figure 8: Influence of sewage flow on system performance coefficient

As can be seen from Figs. 7 and 8, as the sewage flow increases, the heating capacity of the system is gradually increasing. Due to the increase in sewage flow, the heat and COP value of the evaporative heat exchanger through the system also increase non-linearly, resulting in the more heat taken away by the refrigerant, and the more heat exchanged at the condensing heat exchanger. The outlet water temperature will increase, which will increase the heating capacity of the system. During the operation of the system, the refrigerant flow rate and system power remain unchanged, and the system COP will increase with the increase of the sewage flow rate. The heating capacity of the system reaches the maximum when the sewage flow is 10 L/min, the heating capacity is 36.4kW, the COP value is 4.17, and the average system COP is 3.38.

The simulation results in this paper were basically similar to previous researches on small sewage source heat pump. In the experiment of recycling shower with sewage source heat pump, Lei [14], from Harbin Institute of Technology, concluded that in a certain range, the system had the better performance with lower tap water temperature, higher sewage temperature and larger sewage flow, which was similar to the research results in this paper.

3.4 System Performance Analysis throughout the Year

The optimal tap water temperature, sewage temperature and flow rate were obtained by analyzing the heating performance of the system under different conditions. According to the basis of system performance optimization and the flow analysis of beauty salon sewage, the system would be analyzed under the basic conditions which the tap water temperature is 15°C, the sewage temperature is 30°C, and the sewage flow rate is 8.97 L/min.

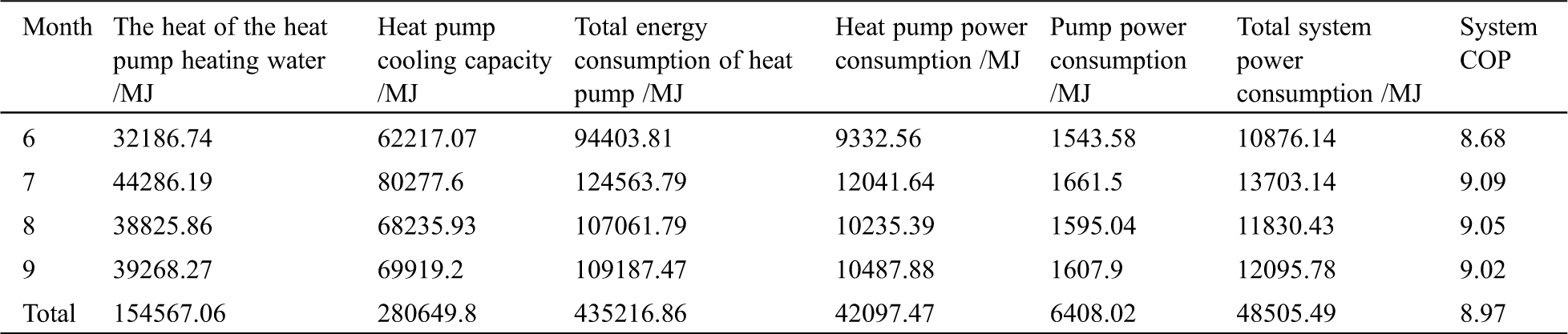

3.4.1 Summer System Operation Performance Analysis

The cooling season in Wuhan is generally from June 1st to September 30th, with a cooling period of 122 days and a total of 2928 hours. In the process of simulation calculation of the system simulation model, the initial setting of the system running time is 3624 hours, and the end time is 6552 hours. The parameters of the system during working hours are selected to simulate the system under the dynamic load of the room and the sewage under the rated state, The heat pump system performs heat recovery in the cooling season to heat the heat of the water, the total power consumption of the heat pump and the coefficient of performance of the system. The simulation calculation results of the cooling season system are shown in Tab. 4.

Table 4: Simulation results of cooling season

It can be seen from Tab. 4 that the cooling season system recovers the condensation heat of the room and the heat of beauty and hairdressing sewage. In the cooling season, the amount of heat that can be produced is 154567.06 MJ, the total energy consumption of the heat pump is 435216.86 MJ, and the total power consumption of the system is 48505.49 MJ, the average COP of the system is 8.97. This is the COP value obtained under the optimal operation condition of the triple supply system. It is reliability that the modules of TRNSYS software used have been verified by experiments.

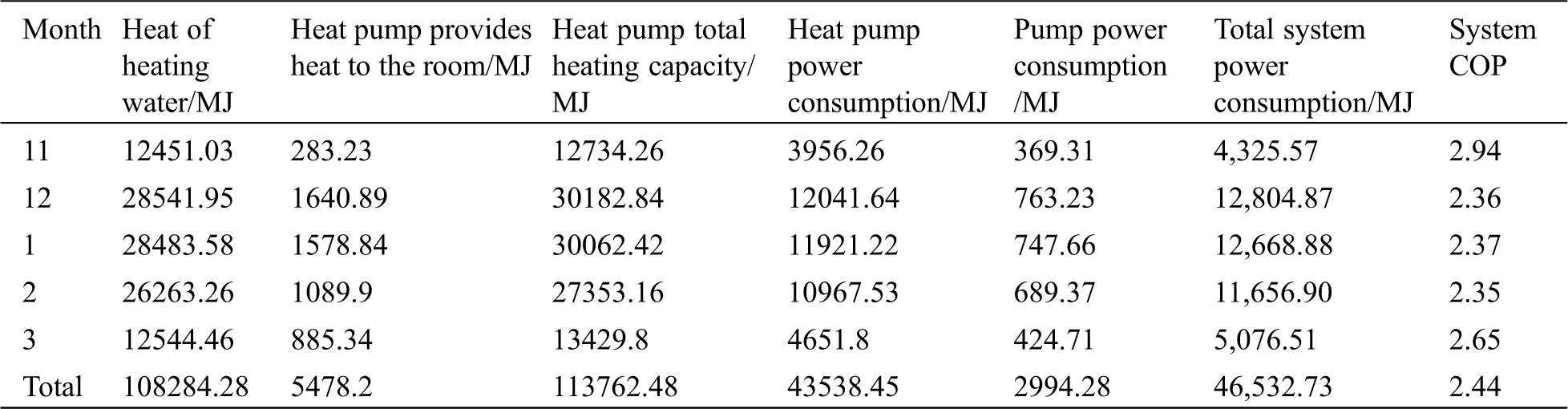

3.4.2 Analysis of System Operation Performance in Winter

The heating season in Wuhan is generally from November 16th to March 15th of the following year, with 120 heating days and a total of 2,880 h. Since the maximum heat load in winter is 7.84 kW and the load provided by sewage is 13.53 kW, when the system is operating in winter, the heat recovered from the sewage can not only meet the room load, but also part of the waste heat can be used to heat hot water. In the calculation of the system operation, the typical parameters of the sewage source heat pump triple supply system in the operating time range of the operation are analyzed, and the system’s heat recovery, heat pump power consumption, water pump power consumption and system COP are obtained. Tab. 5 shows the calculation results of energy consumption during the heating season.

Table 5: Simulation results of heating season

It can be seen from Tab. 5 that during the whole winter operation of the system, the heat for producing hot water is 108284.28 MJ, the heat supply to the room is 5478.20 MJ, the total heat pump heat is 113762.48 MJ, and the total system power consumption is 46532.73 MJ. The average COP value in winter is 2.44.

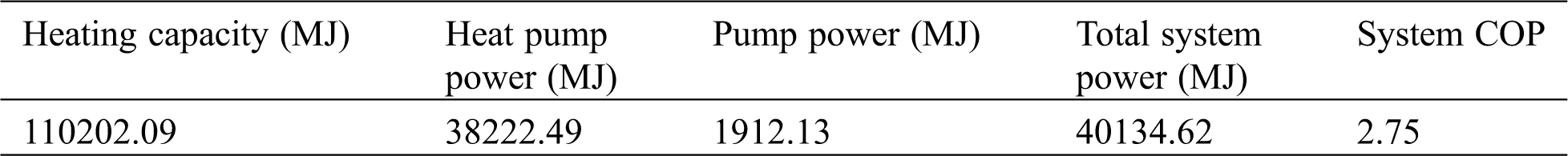

3.4.3 Analysis of System Operation Performance in Transition Season

The transition season in Wuhan is from March 16 to May 31, and from October 1 to November 15, totaling 123 days. In the transition season, the heat pump system recovers the heat in the sewage to produce hot water, without the need for an additional heater to assist in heating the water, so that the waste heat of the sewage can be recycled. During the operation of the system, the results of energy consumption during the transition season are shown in Tab. 6 within the time frame of the system operation.

Table 6: Simulation results of the transition season

4 Energy Saving and Environmental Protection Analysis

At present, hairdressing clubs generally use air source heat pump systems for cooling in summer and heating in winter. Electric boilers or gas boilers are used to produce hot water. In the single experimental building simulated above, the annual electricity consumption is 275056.644 MJ, which is equivalent to 23.46 tons of standard coal. Using the sewage source heat pump triple supply system designed in this paper, the annual electricity consumption is 135172.84 MJ (48505.47 + 40134.62 + 135172.82), which is equivalent to 11.52 tons of standard coal. Compared with the current commonly used systems, the annual energy saving is 139883.8 MJ, which is equivalent to 11.94 tons of standard coal, and the energy saving efficiency of the system is 50.9%.

A beauty salon with a construction area of 84 m2 can save 139883.8 MJ of electricity a year, which not only reduces the operating cost of the club, improves the economic efficiency of the club, but also saves energy for the society and contributes to environmental protection.

According to the characteristics of the sewage discharged from the beauty salon, this paper designs a small sewage source heat pump triple supply system. The room model is built through TRNSYS simulation software and the system is simulated, and the system is optimized. The optimization results show that:

1. When the temperature of the tap water changes from 15°C to 25°C, the COP value of the system drops from 4.19 to 2.93, a drop of 30.1%, and the average COP value is 3.46; when the temperature of the sewage changes from 25°C to 35°C, The system COP value increased from 3.71 to 4.54, an increase of 22.4%, and the average COP value was 4.2; when the sewage flow rate varied from 1 to 10 L/min, the system COP value increased from 2.78 to 4.17, an increase of 50%, the average COP The value is 3.38.

2. The small sewage source triple supply system recovers heat from sewage and air-conditioning circulating water in the cooling season. The energy consumption of the system is 48505.49 MJ, and the average COP value of the system is 8.97; the heat pump system in the heating season also heats and prepares the room. For hot water, the energy consumption of the system is 46532.73 MJ, and the average COP of the system is 2.44; the heat energy of the sewage is recovered during the transition season to heat the water, the power consumption of the system is 40134.62, and the average COP of the system is 2.75.

3. Compared with the conventional system, this design system can save 139883.8 MJ of electric energy in one year, and the system energy saving efficiency is 50.9%. It has significant effects in energy saving, economy and environmental protection, and it is worthy of widespread promotion.

Funding Statement: This research was funded by the Science and Technology Program Project of the Ministry of Housing and Urban-Rural Development “Research on Indoor Thermal Environment Based on Zero Energy Building Technology in Hot Summer and Cold Winter Area” (2017-K1-014). Hubei Provincial Natural Fund Youth Fund “Technology and Evaluation of Multi-energy Complementary Energy Supply for Rural Residential Buildings in Hubei” (2017CFB311).

Conflicts of Interest: The authors declare that they have no conflicts of interest.

1. China Building Energy Association (2017). China Building Energy Research Report (2016). https://www.efchina.org/Reports-zh/report-20170710-1-zh. [Google Scholar]

2. China Building Energy Association (2020). 2019 China Building Energy Research Report. Building, 7, 30–39. [Google Scholar]

3. Li, Z. M. (2010). Energy-saving plan for hospital refrigeration, heating and hot water combined supply. Director of Chinese Hospital, 19, 67. [Google Scholar]

4. Liu, Y. J., Wu, W. Z., Lu, C. H., Li, Z. X. (2019). Optimized design of operation mode of water source heat pump air conditioning system in a five-star hote. Light Industry Technology, 35(10), 112–113,138. [Google Scholar]

5. Zhang, R. B. (2016). Low-carbon-saving construction engineering technology. Engineering Technology, 10, 34. [Google Scholar]

6. Sara, I. C., Marco, M. N. (2014). Heat recovery from urban wastewater: analysis of the variability of flow rate and temperature in the sewer of Bologna, Italy. Energy Procedia, 45, 288–297. DOI 10.1016/j.egypro.2014.01.031. [Google Scholar] [CrossRef]

7. Hepbasli A., Biyik E., Ekren O., Gunerhan H., Araz M. (2014). A key review of wastewater source heat pump (WWSHP) systems. Energy Conversion and Management, 88, 700–722. DOI 10.1016/j.enconman.2014.08.065. [Google Scholar] [CrossRef]

8. Culha, O., Gunerhan, H., Biyik, E., Ekren, O., Hepbasli, A. (2015). Heat exchanger applications in wastewater source heat pumps for buildings: A key review. Energy and Buildings, 104, 215–232. DOI 10.1016/j.enbuild.2015.07.013. [Google Scholar] [CrossRef]

9. Nam, Y., Ooka, R., Shiba, Y. (2010). Development of dual-source hybrid heat pump system using groundwater and air. Energy and Buildings, 42(6), 909–916 4. DOI 10.1016/j.enbuild.2009.12.013. [Google Scholar] [CrossRef]

10. Fu Y. K., Pan, L., Liu, Y. T., Liang, Y. (2020). Research on energy-saving control method of sewage source heat pump system. Thermal Power Engineering, 9, 80–88. [Google Scholar]

11. Zhang, C. H., Liu, X. X., Zhuang, Z. Y. (2010). Key technologies and engineering applications of urban sewage source heat pumps. HVAC, 10(6), 21–23. [Google Scholar]

12. Li, M. Z., Li, Y. A. (2020). Analysis of operation effect of sewage source heat pump heating system in severe cold area. Journal of Jilin Jianzhu University, 2, 59–64. [Google Scholar]

13. Wang, Y. S., Han, J. T., Liu, Y. J., Li, K., Jiang, Y. L. (2019). Design and analysis of heat exchanger for sewage source heat pump. Refrigeration and Air Conditioning, 19(9), 32–35. [Google Scholar]

14. Lei, B. (2014). Experimental study on domestic shower sewage source heat pump water heater. Harbin Institute of Technology. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |