Energy Engineering

Energy Engineering

Energy Engineering Energy Engineering |  |

DOI: 10.32604/EE.2021.012860

ARTICLE

Development of Environmentally Friendly and Energy Efficient Refrigerants for Refrigeration Systems

1Energy Technology Program, Faculty of Engineering, Prince of Songkla University, Hat Yai, Songkhla, 90112, Thailand

2Department of Mechanical Engineering, Faculty of Engineering, Prince of Songkla University, Hat Yai, Songkhla, 90112, Thailand

*Corresponding Author: Juntakan Taweekun. Email: jantakan.t@psu.ac.th; juntakan2016@gmail.com

Received: 15 July 2020; Accepted: 18 September 2020

Abstract: This paper presents the improvement of eco-friendly and power consumption saving refrigerants for refrigeration systems. The novel azeotropic refrigerant mixtures of HFCs and HCs can replace refrigeration systems, and using the R134, R32, R125, and R1270 refrigerants in several compositions found using the decision tree function of the RapidMiner software (which came first in the KDnuggets annual software poll). All refrigerant results are mixed of POE, which is A1 classification refrigerant, non-flammable, and innocuous refrigerant, and using REFPROP software and CYCLE_D-HX software are under the CAN/ANSI/AHRI540 standards. The boiling point of the new refrigerant mix R-No.595 is 4.58%, lower than that of R404A, with a higher refrigerant effect and 50.34% lower GWP value than R404A. The proposed mix R-No.595 can be operated in hot environmental country and has high critical temperature and heat-rejection effects, due to the presence of R32 and R1270. The COPc of R463A is 13.49%, higher than R404A in freeze condition. The novel refrigerant mixes provide alternate refrigerant options mixed of 1% R1270, and which are related with the development of current refrigerants, containing a compose of HFOs and eco refrigerants for producing low-GWP, zero ODP, high-refrigerant effect, low-operating pressure, and innocuous refrigerants.

Keywords: Refrigerant; refrigeration system; energy efficiency; environmentally friendly; data mining

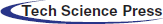

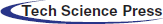

Power consumption in Thailand’s business sector has ranked second among overall power consumption in the country and should be decreased [1]. The number of retail stores in Thailand was more than 25,000 in 2020, and this number continuously increases on every year [2]. Some retail stores are open 24 hours per day and, therefore, the retail sector is the fourth largest power consumption in the business sector, consuming more energy than residences [3]. The components that contribute to the power consumption of retail stores in Thailand, rated from highest to lowest, are refrigeration systems, air-conditioning systems, electrical equipment, and lighting [4,5]. The ratio of power consumption in retail stores in Thailand have been previously rated, as shown in Fig. 1 below [6]. The excellent options for decreasing power consumption in retail stores in Thailand are novel equipment and performance power consumption control system. An excellent model of power consumption savings in refrigeration systems is shown in Fig. 2 below [7]. Power consumption savings in refrigeration systems can be achieved through decreased power consumption of the compressor, as this it is the component that benefits the most power consumption.

Figure 1: Proportions of energy use in Taiwanese convenience stores [6]

Figure 2: Examples of energy savings in refrigeration systems [7]

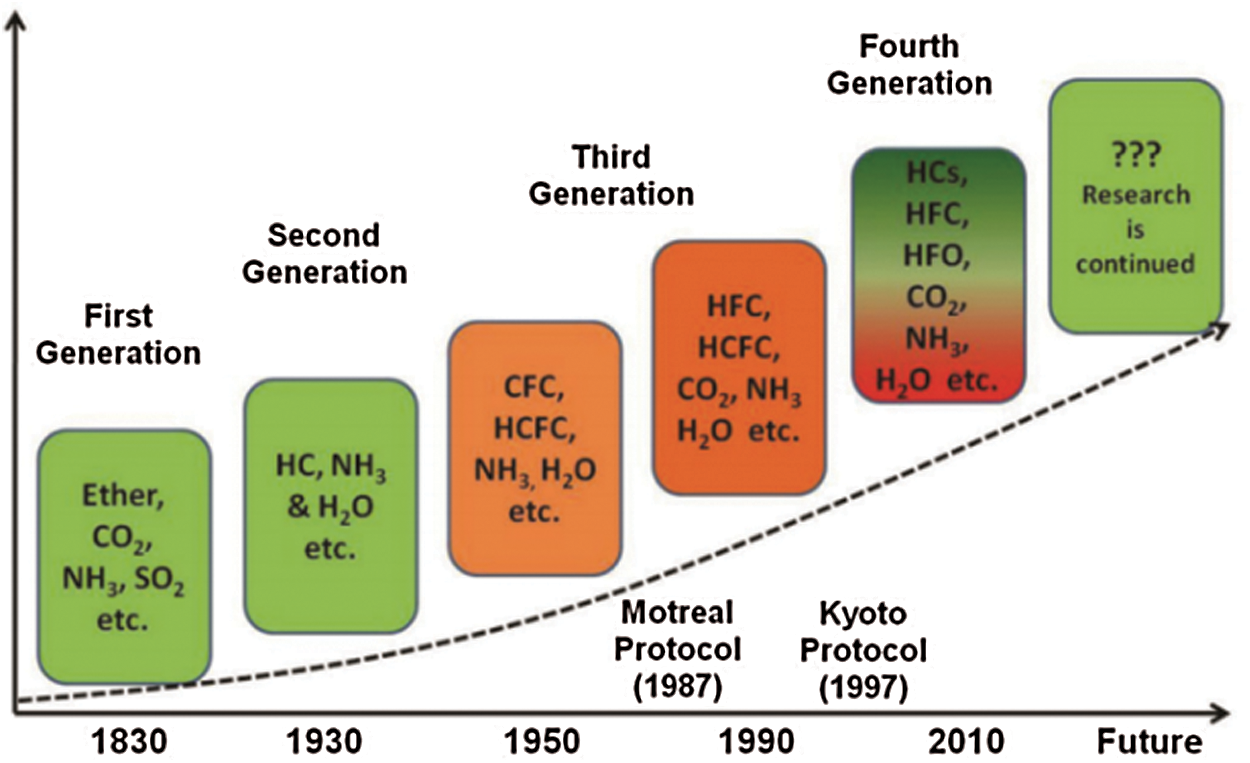

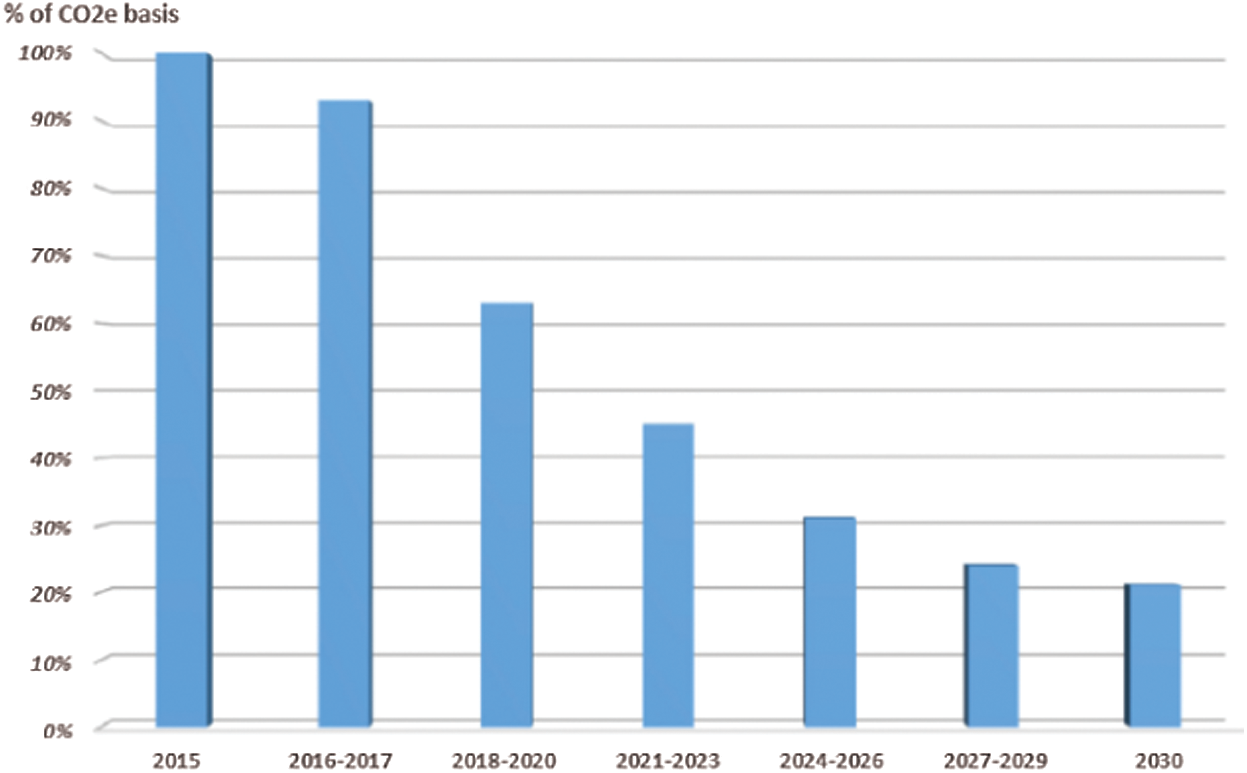

Thailand refrigerant trends have shown improvement of reduced GWP and increased energy efficiency, as shown in Fig. 3 [8,9], that concerned to the HFCs Discontinue timetable, as shown in Fig. 4 [10]. Starting generation refrigerants are mixed of eco refrigerants and HCs, both refrigerants do not affect the eco, have GWP close to zero, and have zero ODP [11–13]. R744 high operates pressure and is combustible and highly toxic [14–16]. Following the next generation refrigerants are mixed of CFCs [17–19] and HCFCs [20–22], can operate under low pressure that easy to use, and are innocuous. But, the GWP and ODP increased. Therefore, progressing of refrigerant developed to reduced ODP and GWP. Moreover, in present generation refrigerants (i.e., CFCs and HCFCs) were further developed as HFCs refrigerants that low GWP and zero ODP [23–25]. Future generation refrigerants are generally HFOs with low capacity and low GWP [26–28]. These refrigerants are generally a mixture of HFCs [29–31], HFOs [32–34], HCs [35–37] and eco refrigerants [38–40].

Figure 3: Evolution of refrigerants [8,9]

Figure 4: Hydrofluorocarbon (HFCs) phase-down schedule (Co2e %) [10]

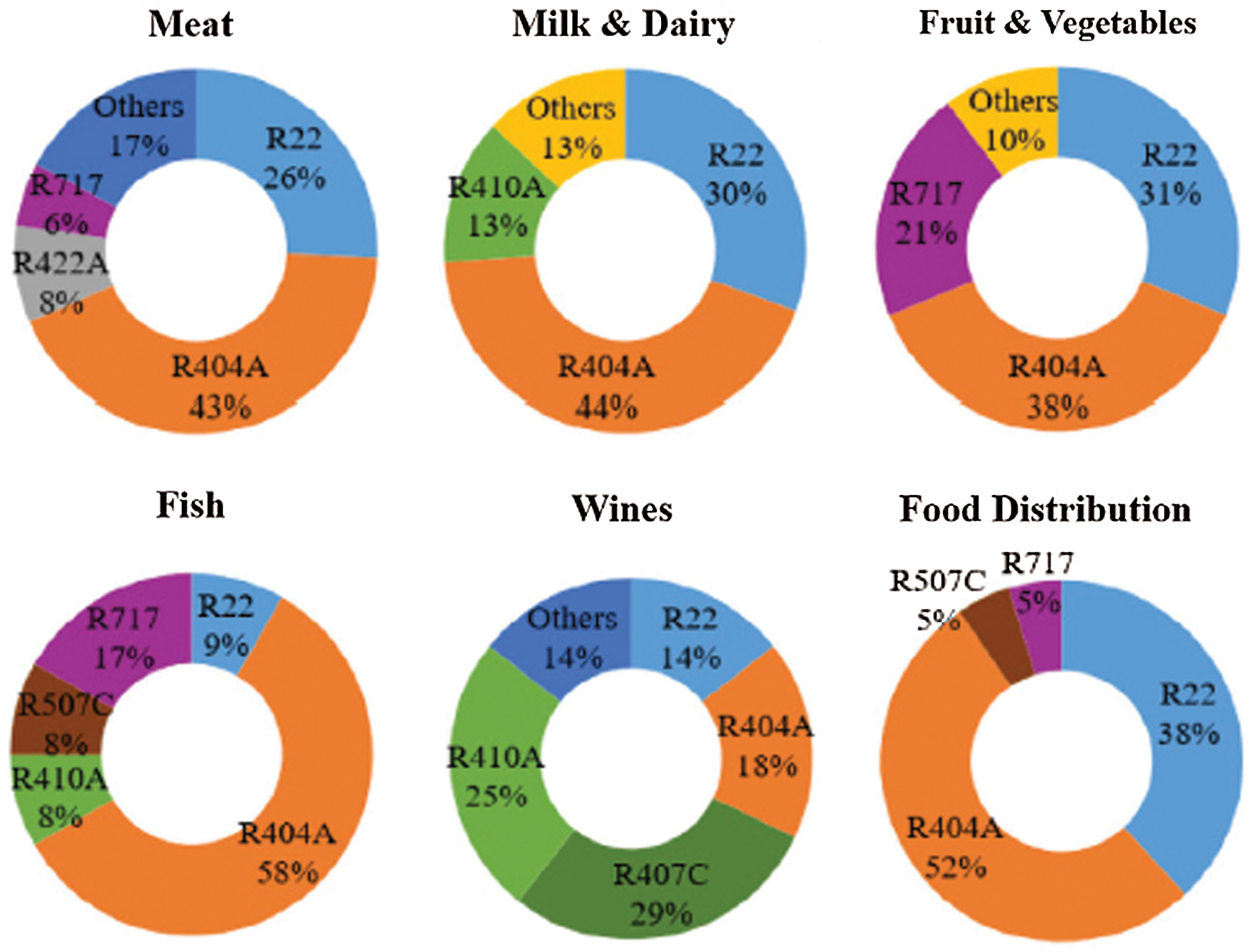

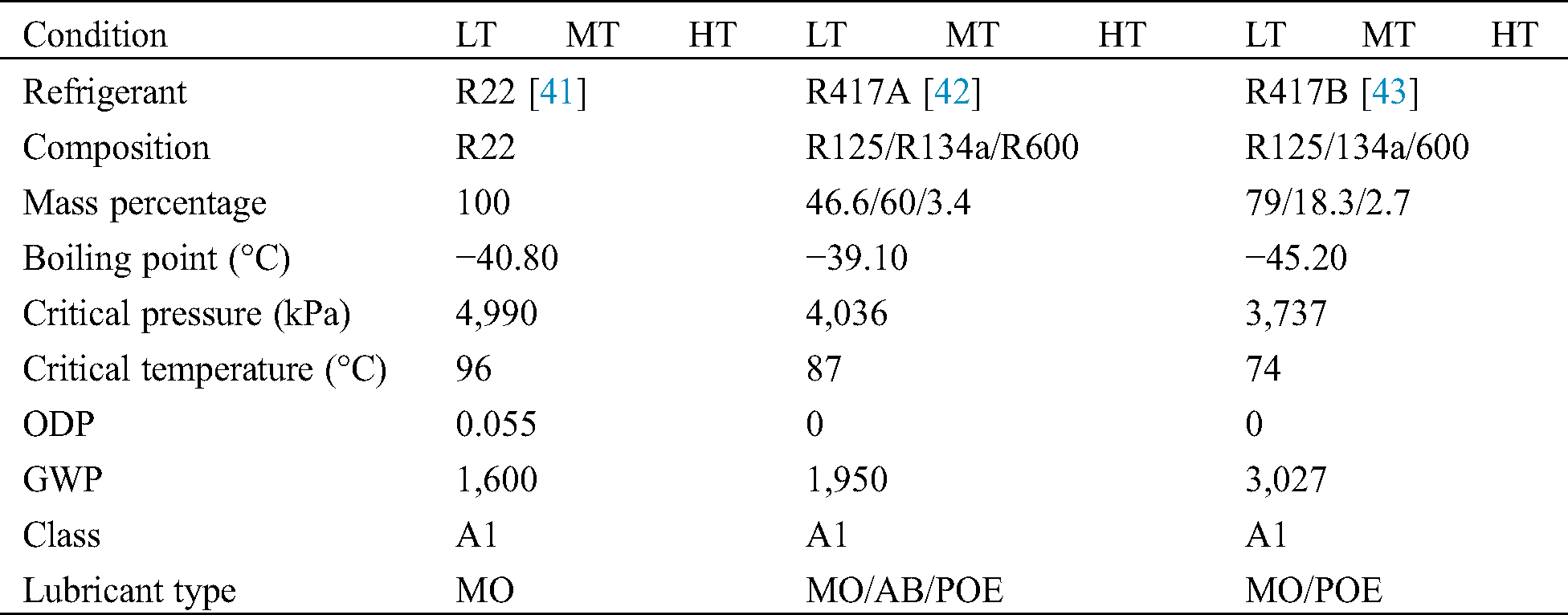

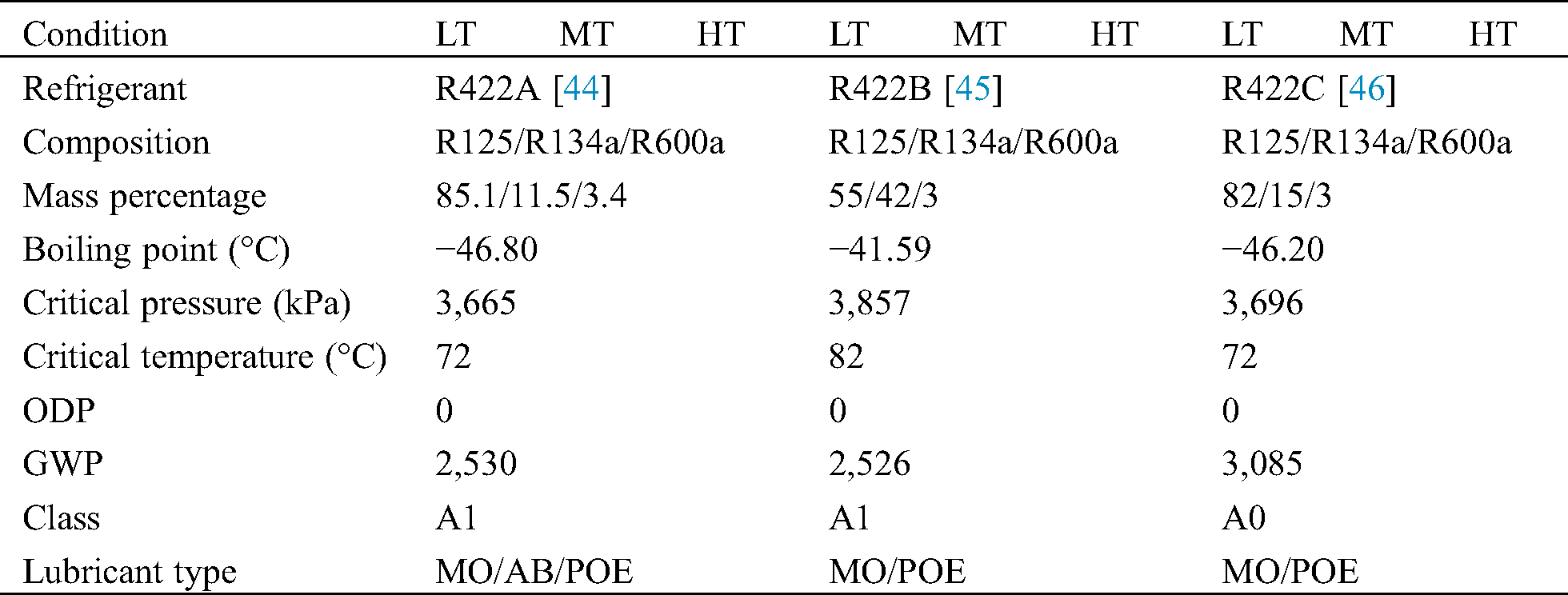

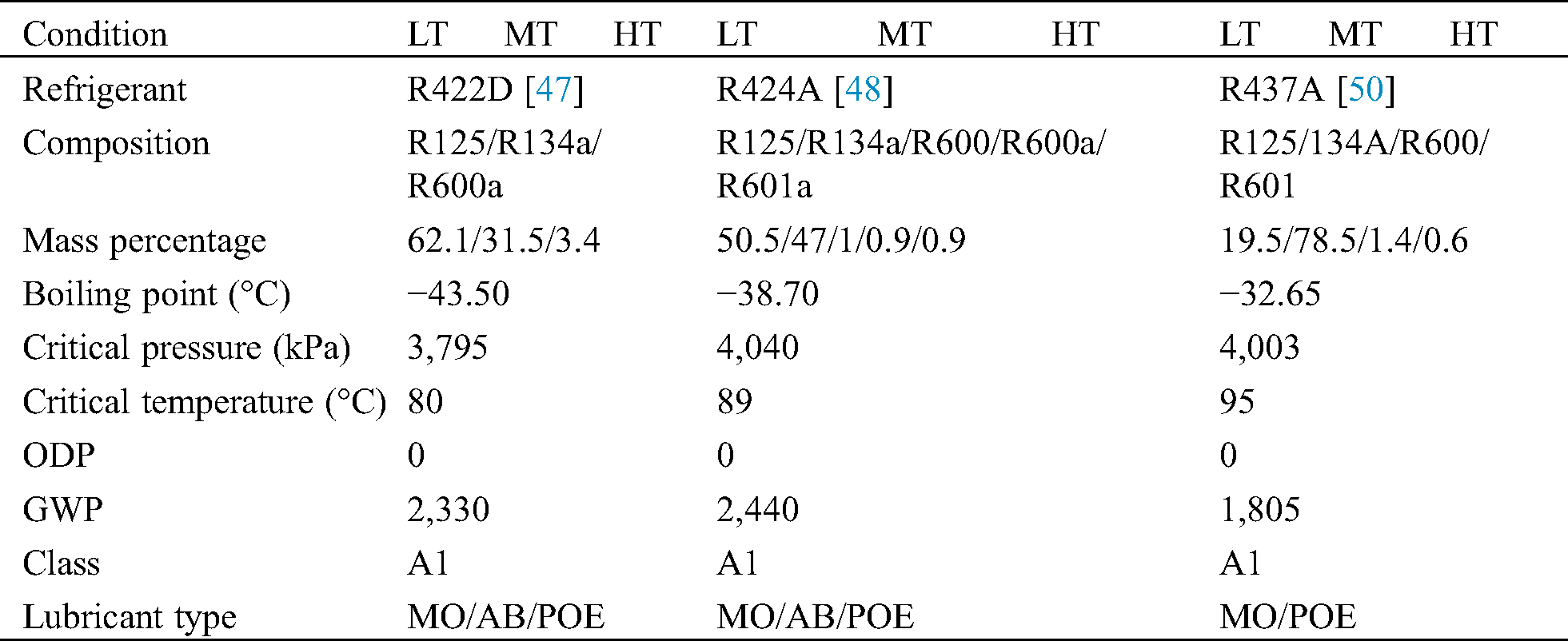

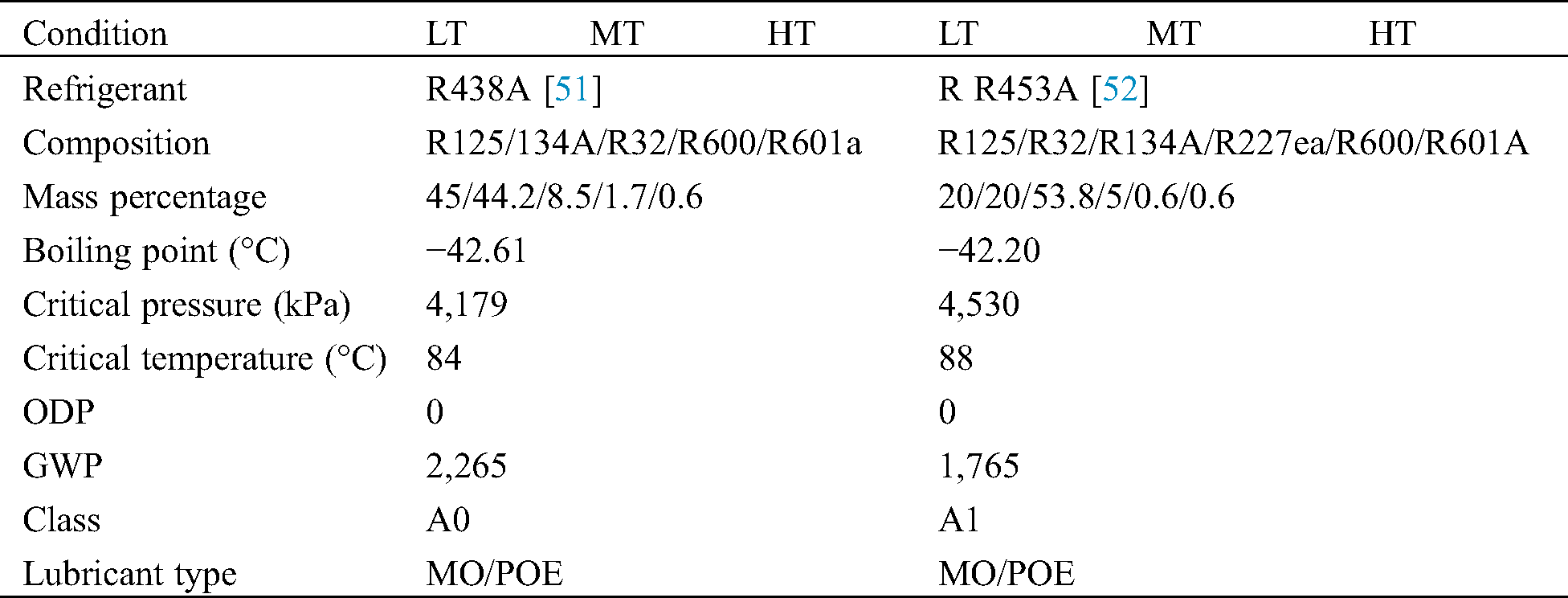

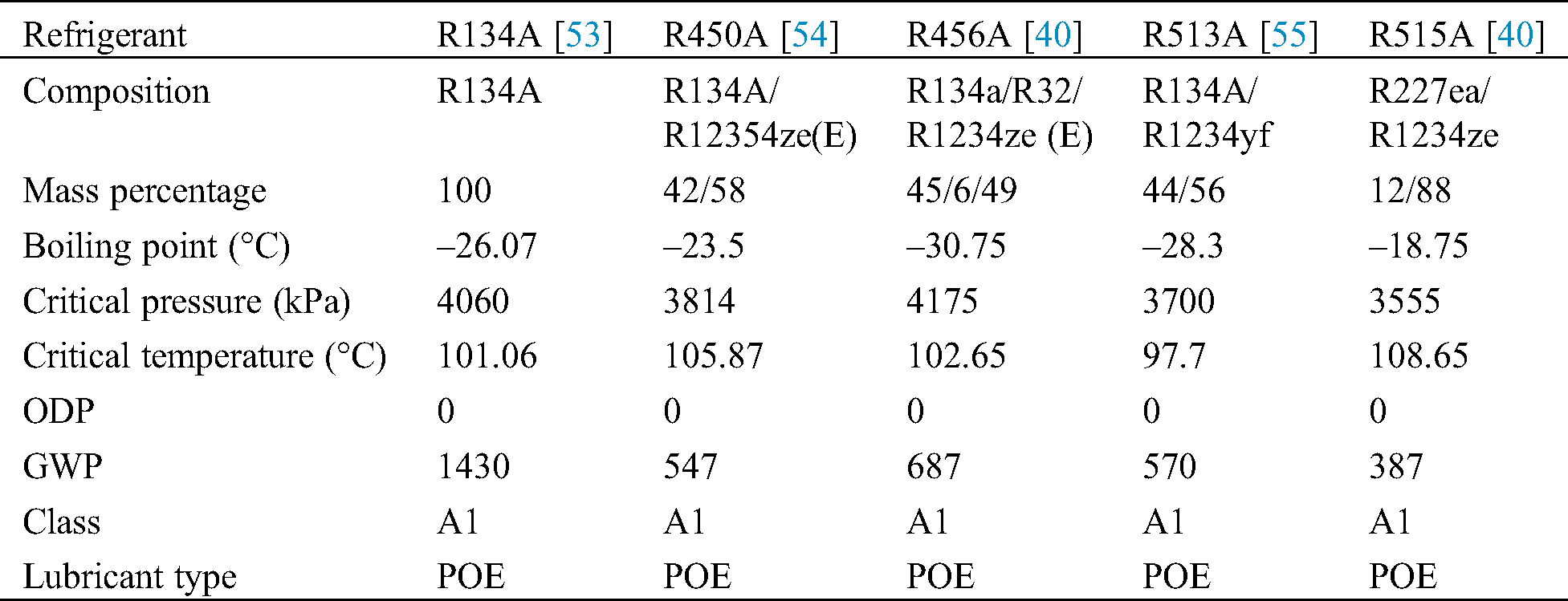

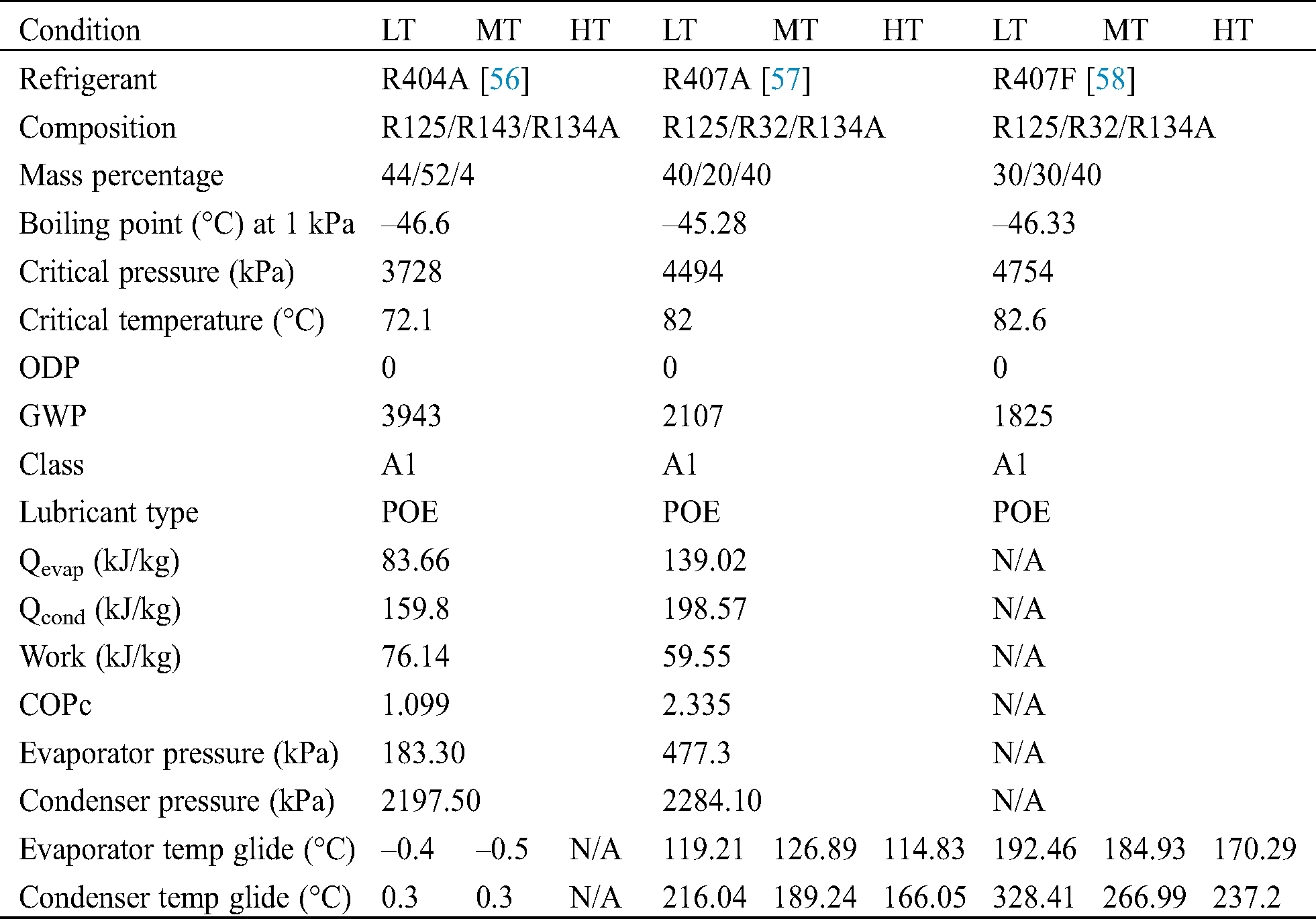

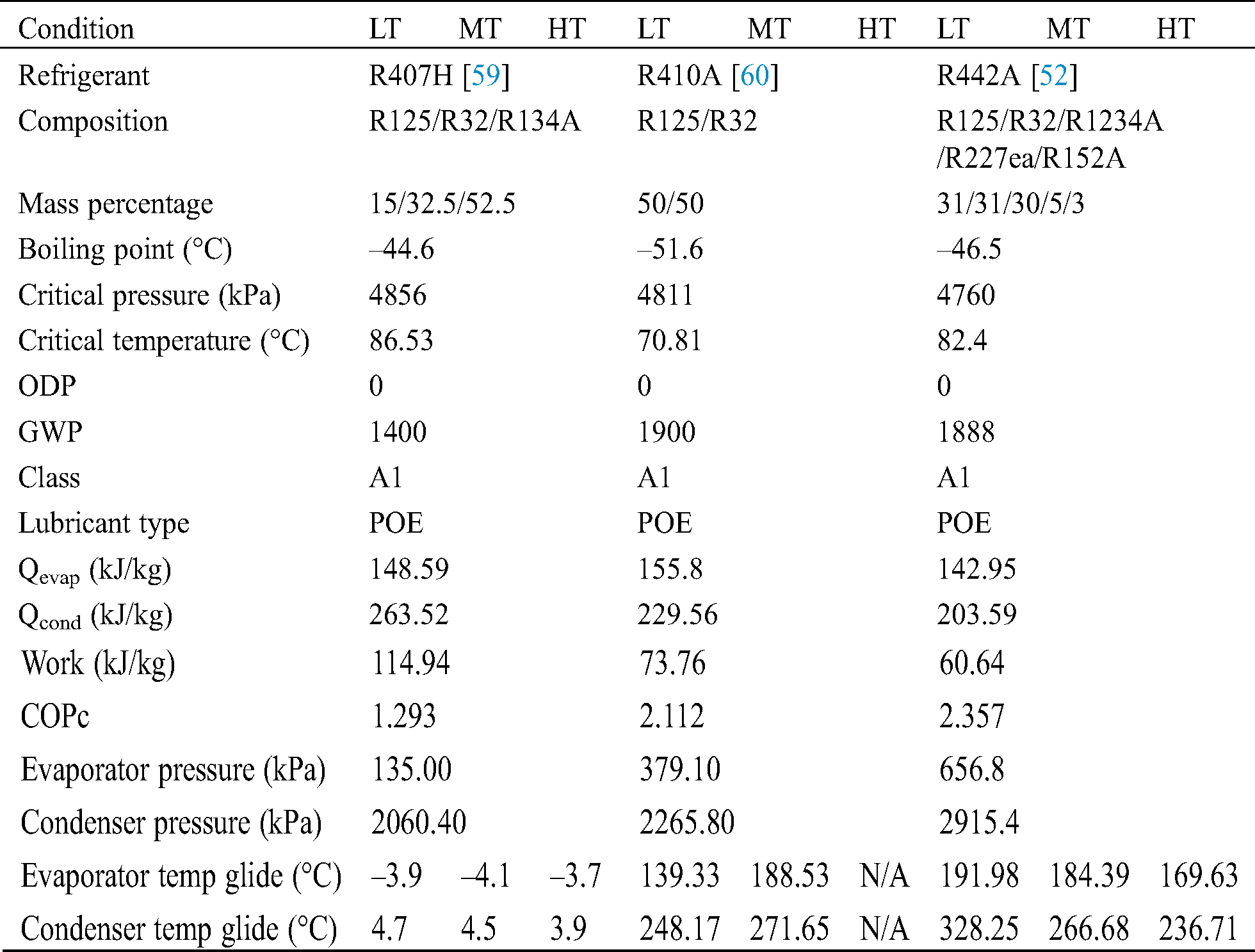

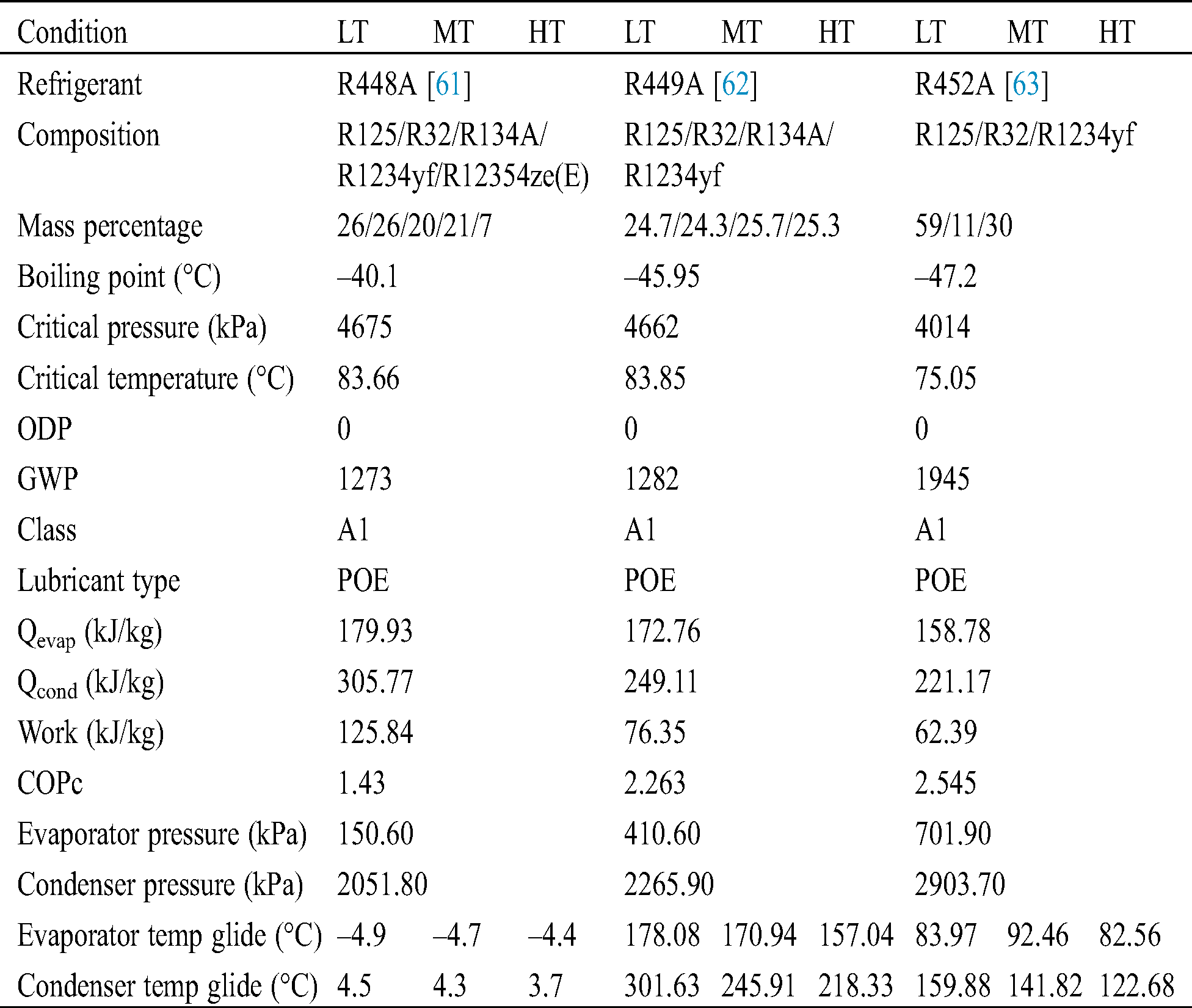

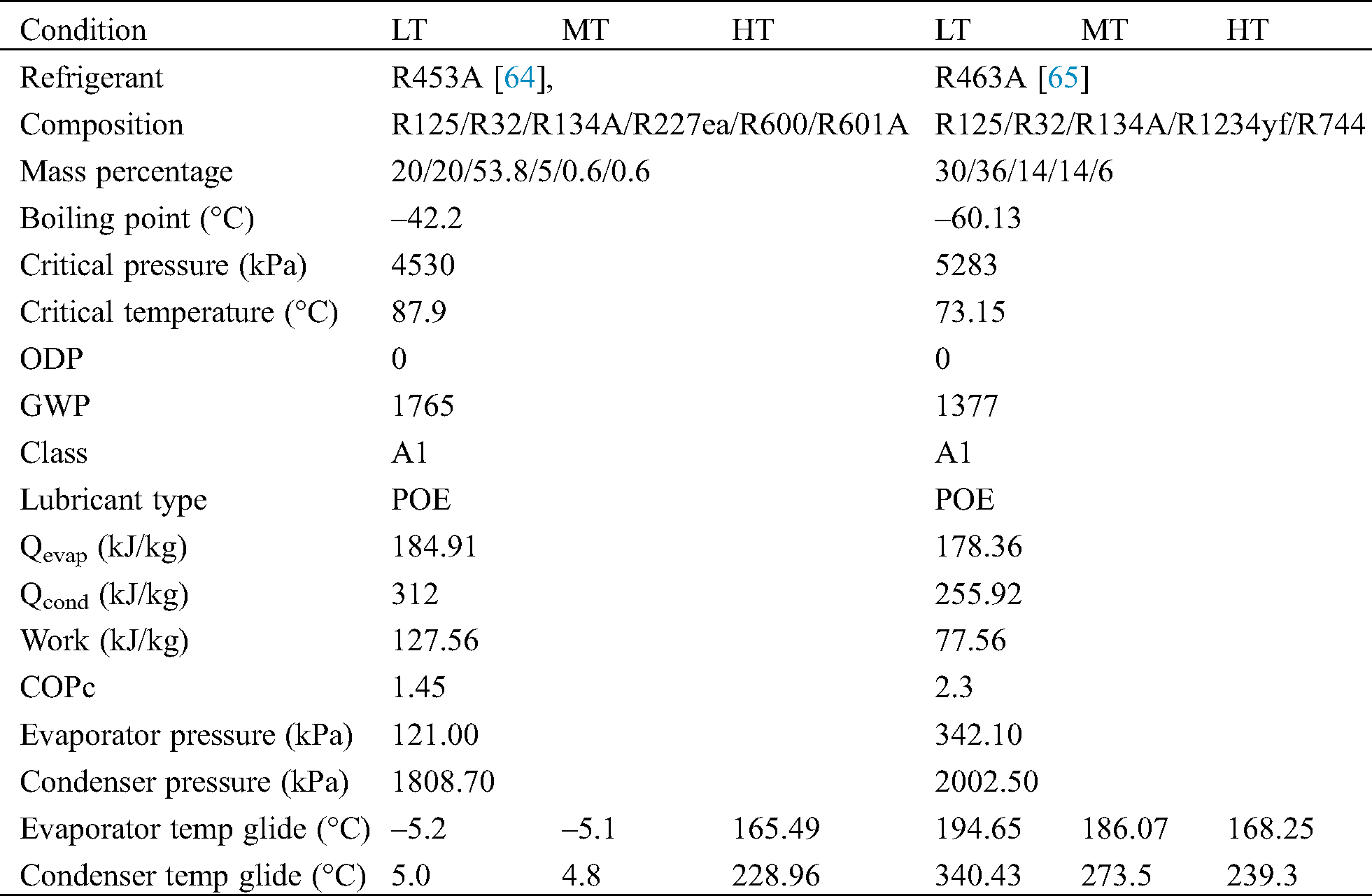

Refrigerants need to be low-GWP, zero-ODP, high-capacity, low-pressure, and non-toxic, and should, thus, be mixed with HCs and HFOs; however, current refrigerants are still highly flammable and have low capacity. An alternative is to incorporate other HFCs. R32 is low-GWP, zero ODP, high-capacity, and non-toxic, but operates under high pressure and is flammable; in contrast to R134A, which possesses highly similar properties but can operate under low pressure and has low capacity. Current refrigeration systems use R22 [41], as well as R417A [42], R417B [43], R422A [44], R422B [45], R422C [46], R422D [47], R424A [48], R433A [49], R437A [50], R438A [51], and R453A [52], all of which were developed as alternatives to R22 and which are mixed with HCs and HFCs, as shown in Tabs. 1–4. The lowest normal boiling points (of R422A and R422C) are −46.80°C and −46.20°C, respectively, lower than that of R22 by 12.82% and 11.69%. This is due to the presence of hydrofluorocarbon (HFCs) R125 in their composition (85.1% and 82.0%, respectively), consistent with those of R410A and R507, which have boiling points of −51.6°C and −46.74°C, respectively, and are considered attractive as alternative refrigerants to R134A and R404A, due to their HFCs R125 content of 50%. The boiling point of R125 is −48.1°C, with a high GWP value (3,450); leading to R422A and R422C having the high GWP values of 3,143 and 3,185, respectively. R422A and R422C also have hydrocarbon (HCs) R601a in their composition (3%). The boiling point and GWP of R601a are 0 and −11.73°C, respectively, the effect of which is reducing the GWP and increasing the boiling point of refrigerant mixtures it is contained in. The lower GWP, compared with R22 f R453A and R437A (1,765 and 1,805, respectively) is due to hydrofluorocarbon (HFCs) R134a (53.8% and 78.5%) in their composition and hydrofluorocarbon (HFCs) R32 (20%) in the composition of R453A; this is consistent with R407A, R407H, and R407F, which combine R134a and R32 with R744 in contents of 6% and 3%, respectively, in their compositions. The boiling point and GWP naturally change when adjusting the composition of the refrigerant. The refrigerant effect and heat rejection of R453A were found to be higher than those of R22, due to the presence of hydrofluorocarbon (HFCs) R32 (20%). R453A also has the hydrocarbon (HCs) R600 (0.6%) in its composition. The lowest refrigerant work was found for R422A, which possesses HCs R600a (3%) in its composition. The mixed-refrigerant design should be comparable to natural refrigerants, in terms of having a strong refrigerant effect and high heat rejection, but certain hydrocarbon refrigerant types (e.g., R290 and R1270) are commonly selected for their refrigerant effect and high heat rejection. However, the high refrigerant work and high operating pressure of such refrigerants affect the power consumption of the compressor. Considering systems that operate with R134A [53], R450A [54], R456A [40], R513A [55], and R515A [40] are all refrigerants that have been developed as an alternative to R134A, which are mixed with HCs, HFCs, and HFOs and operated under low pressure, achieving similar results to R453A operating under high pressure with 20% hydrofluorocarbon (HFCs) R32 content in its composition, as shown in Tab. 5. The fourth-generation refrigerant R404A was the basis for this research, which is currently the most-used refrigerant, as shown in Fig. 5. R404A is an azeotropic blend of 143a/125/134a with zero ODP, which is non-flammable, non-toxic, and operates under low pressure, with a GWP of 3922 [56]. R407A [57], R407F [58], R407H [59], R410A [60], R442A [52], R448A [61], R449A [62], R452A [63], R453A [64], and R463A [65] are all refrigerants developed to be retrofitted to replace R404A, as shown in Tabs. 6–9. The lowest normal boiling point of R463A is –60.13°C, which is lower than that of R404A by 23%. This is due to hydrofluorocarbon (HFCs) R32 (36%) and carbon dioxide (CO2) R744 (7%) being in its composition, consistent with R445A [64] and R455A [65]. R445A and R455A both have low boiling points (–49.15°C and –52.0°C, respectively) and are attractive as alternative refrigerants with lower GWP than R134A and R404A, due to the CO2 R744 content of 6% and 3%, respectively, in their compositions. R448A and R449A displayed the lowest GWP values of 1273 and 1282, respectively, due to the HFOs R1234yf and R1234ze in their compositions. The GWP of R463A has been found to be 1377, with a lower boiling point than that of R404A by 23%; even though the ratio of R1234yf in R463A is less than that in both R448A and R449A. However, the GWP of R463A has been found to be slightly higher than those of R448A and R449A. The cost of R463A is also lower than R448A and R449A. Hydrofluorocarbons can also be combined with carbon dioxide (CO2), which has a lower GWP and boiling point. The lower boiling point and GWP are consistent with the evolution of the fourth-generation refrigerants that contain a mixture of HFCs, HFOs, HCs, and natural refrigerants, which are required to produce a low-GWP, zero ODP, high-capacity, low-operating pressure, and non-toxic refrigerant. The refrigerant effect and heat rejection of R463A have been found to be higher than those of R404A, due to the presence of hydrofluorocarbon (HFCs) R32 (36%) and carbon dioxide (CO2) R744 (7%) in its composition, consistent with R424A and R453A, which are composed of hydrocarbons (HCs) at contents of 1.8% and 1.2%, respectively. The mixed-refrigerant design should be comparable to natural refrigerants, in terms of having a strong refrigerant effect and high heat rejection. Refrigerants operated under low pressure display low refrigerant work value; in this case, the lowest refrigerant work is observed in R452A. This refrigerant possesses HFOs R1234yf and R1234ze (E) in its composition. The highest refrigerant work value is observed for R463A, which contains hydrofluorocarbon (HFCs) R32 (36%) and carbon dioxide (CO2) R744 (7%), and operates at the highest evaporator pressure. This means that a refrigerant system which is operated at low pressure should use a mix of refrigerants that can operate under low pressure, such as R1234yf, R1234ze, and R134A. R450A [49], R456A [50], R513A [51], and R515A [50], which are mixed with hydrofluoroolefins (HFOs) and can operate under low pressure, have achieved similar results. R453A had the highest COPc, as R453A does not have the highest refrigerant effect and heat rejection, nor the lowest boiling point, but can be operated under low pressure, which has an impact on low refrigerant work. The COPc level of R463A was recorded at 1.34, which is 10% higher than that of R404A under low-temperature conditions only. The promising results for COPc obtained by R407F, R448A, and R449A are due to the refrigerants being operated under low pressure, which has an impact on low refrigerant work. The same effect has been observed for R453A; however, these four refrigerants do not have a low normal boiling point or high Cp liquid/vapor or liquid/vapor conductivity. This shows that a mixed-refrigerant design should consider all parameters, such as the GWP, boiling point, Cp liquid/vapor and liquid/vapor conductivity, refrigerant effect, heat rejection, refrigerant work, evaporator pressure, high pressure, and COPc.

Figure 5: Top refrigerants in the food industry [9]

Table 1: Properties of R22, R417A, and R417B

Table 2: Properties of R422A, R422B, and R422C

Table 3: Properties of R422D, R424A, and R437A

Table 4: Properties of R438A and R453A

Table 5: Properties of R134A, R450A, R456A, R513A, and R515A

Table 6: Properties of R404A, R407A, and R407F

Table 7: Properties of R407H, R410A, and R422A

Table 8: Properties of R448A, R449A, and R452A

Table 9: Properties of R453A and R463A

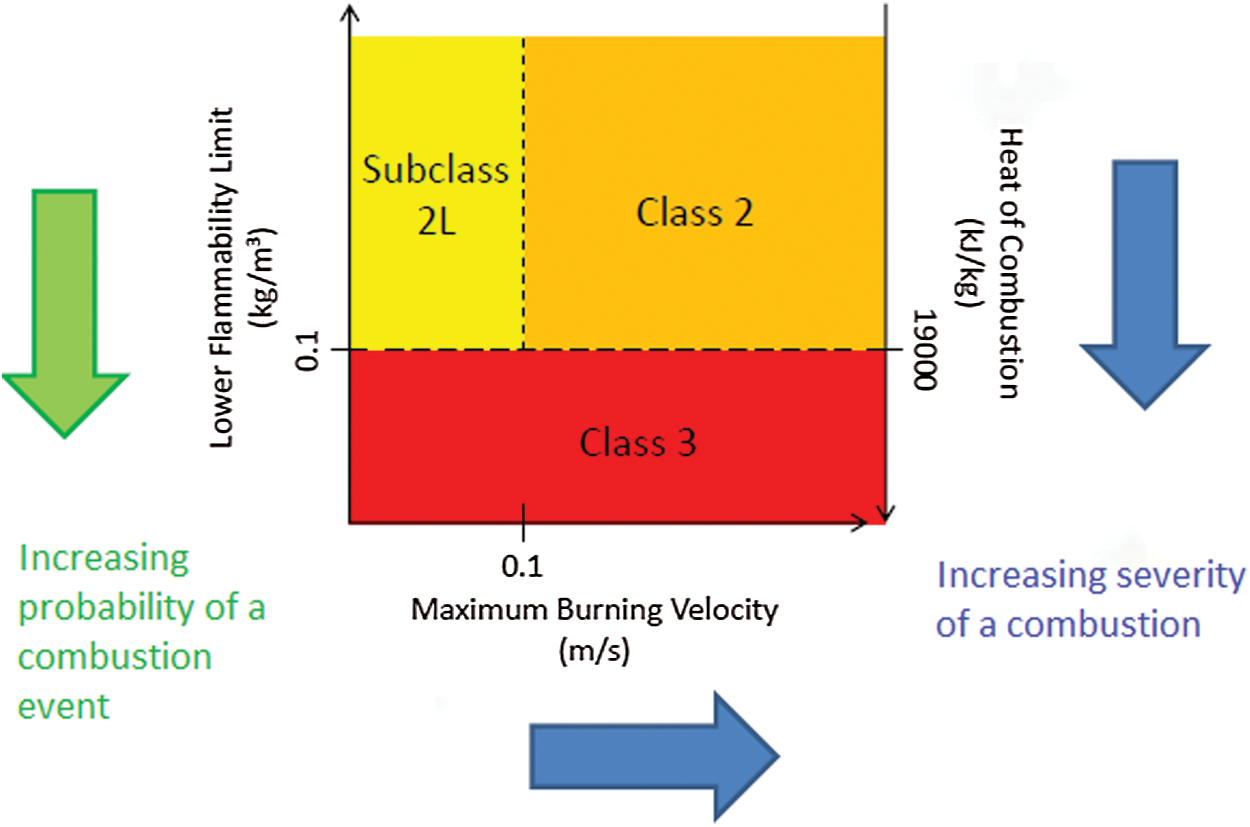

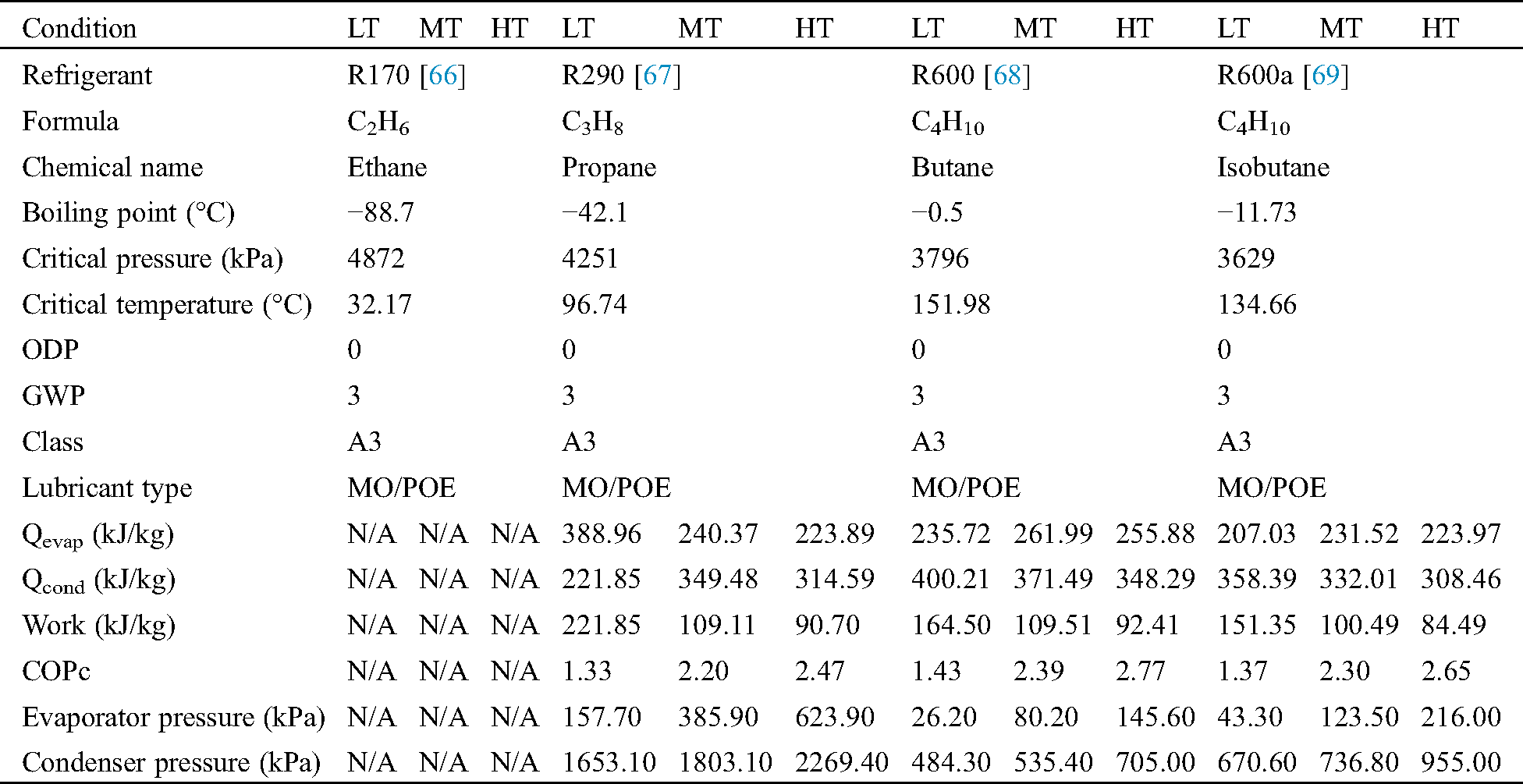

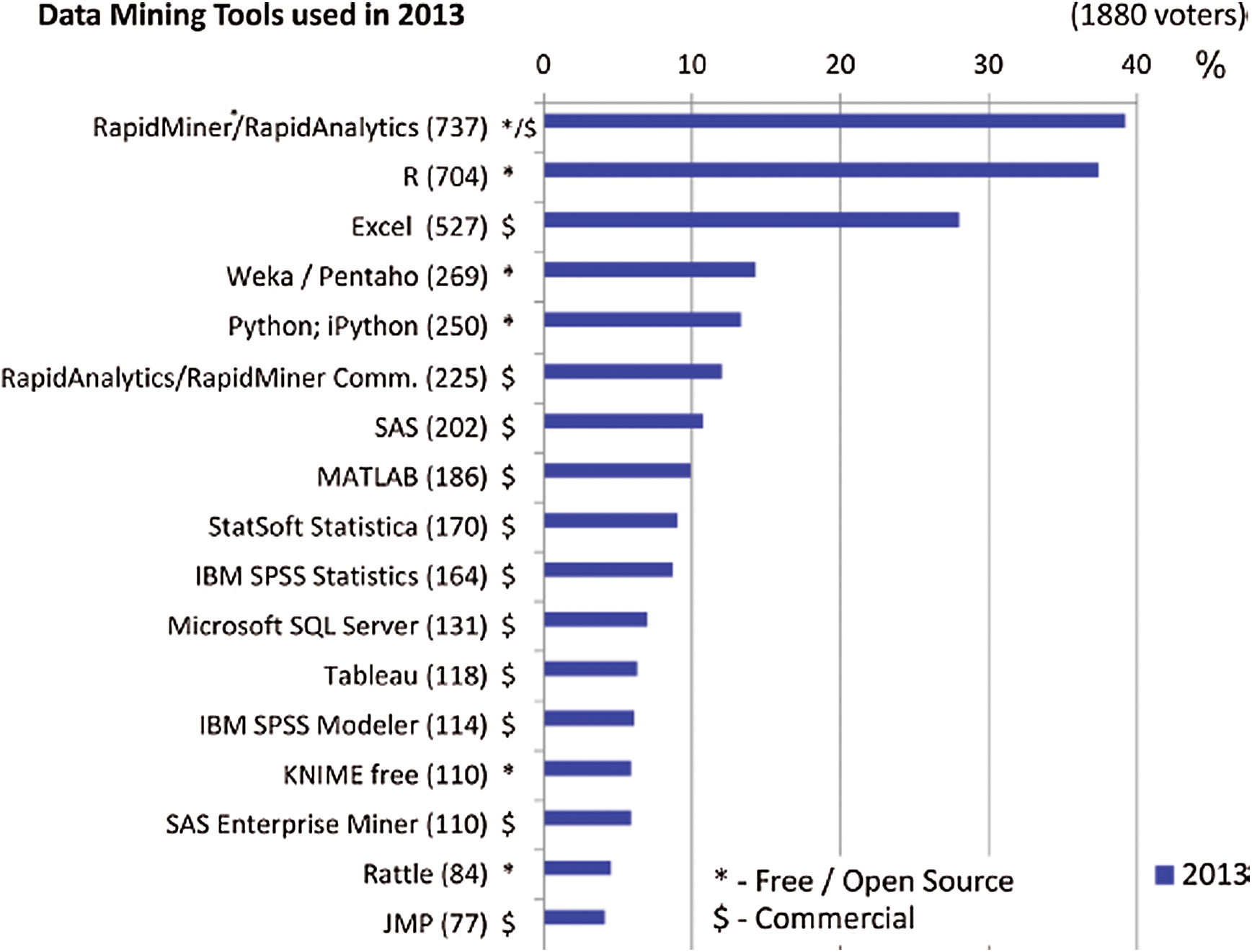

Due to the costs shown in Fig. 6 [43], refrigerants should be mixed with HFOs. The figure shows that the HFOs had the highest refrigerant cost, but does not include HCs refrigerant costs compared with HFO refrigerant costs, and is presented for comparative purposes in this research (as it is generally composed of HCs). The class properties of hydrocarbon refrigerants are shown in Fig. 7 below. Some zero ODP and near-zero GWP Class A3 refrigerants, as shown in Tab. 10, are R170 [66], R290 [67], R600 [68], R600a [69] and Tab. 11 for R601 [70], R601a [71], R1150 [72], and R1270 [73]. The lowest boiling points were found to be −88.70°C and −103.8°C, respectively, for R170 and R1270; however, their critical temperatures were found to be 32.17°C and 9.5°C. This means that these cannot be operated as refrigerants in accordance with the CAN/ANSI/AHRI540 Air-Conditioning, Heating, and Refrigeration Institute (AHRI) standards considered in this research [74–76]. R290 and R1270 were found to have boiling points near that of with R22 (−42.1°C and −47.7°C, respectively), but operate at high condenser pressures, which affect the evaporator pressure, condenser pressure, and cooling coefficient of performance. Therefore, in this research, we used R1270 for the base line for new refrigerant mixes, as R1270 has a low boiling point and high refrigerant effect.

Figure 6: Cost of refrigerants [43]

Figure 7: Refrigerant classification [2]

Table 10: Properties of R170, R290, R600, and R600a

Table 11: Properties of R601, R601a, R1150, and R1270

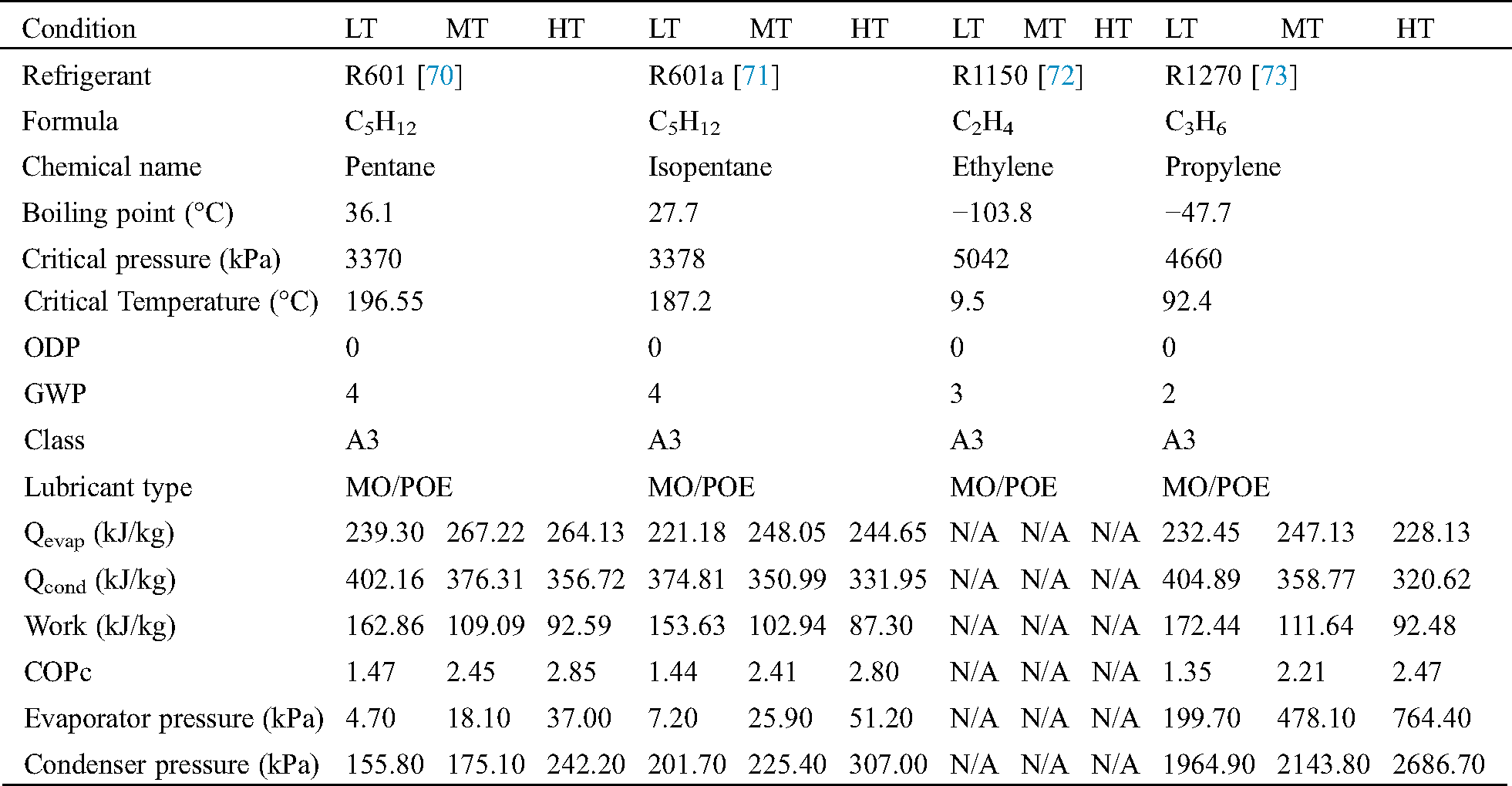

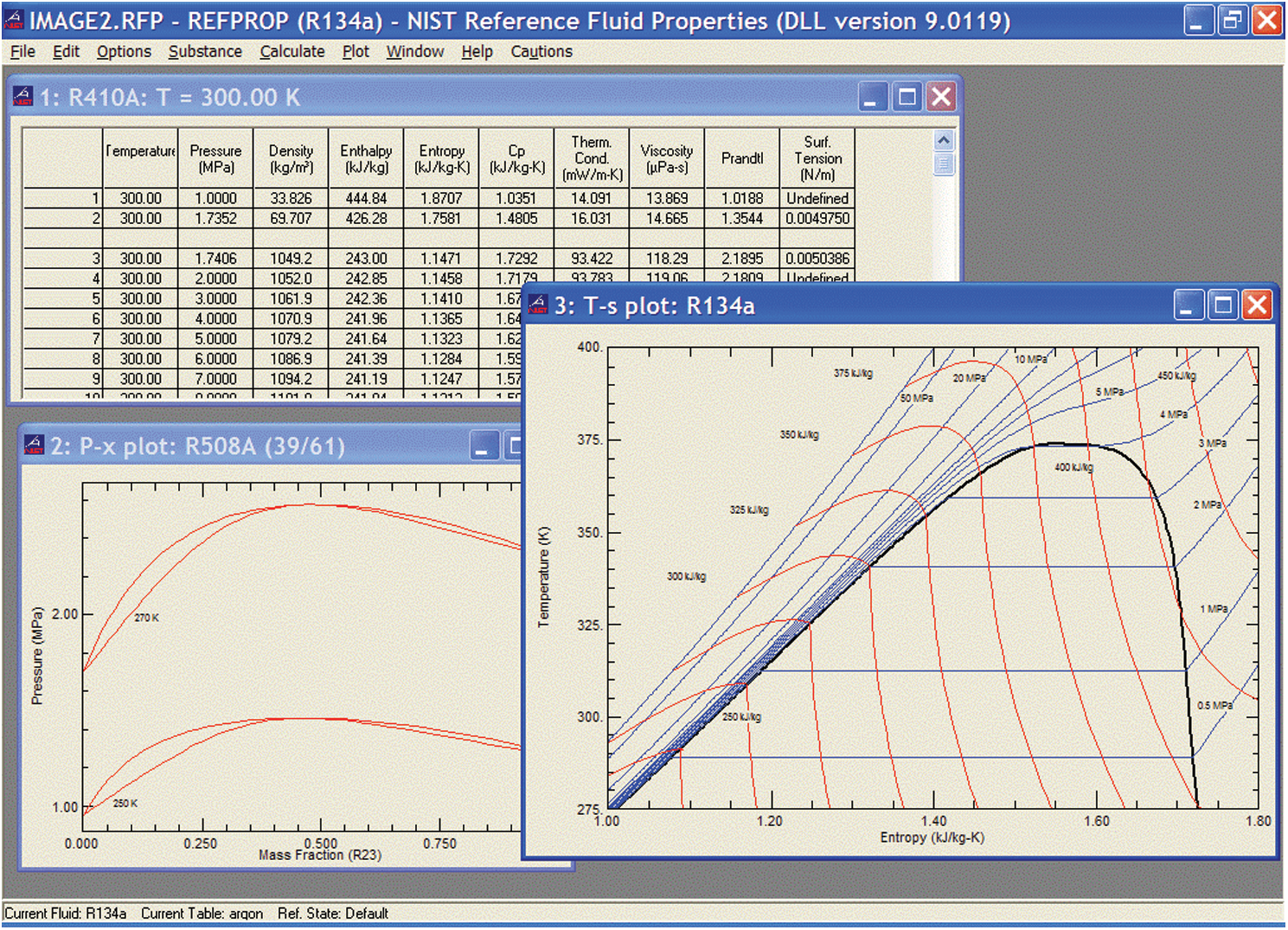

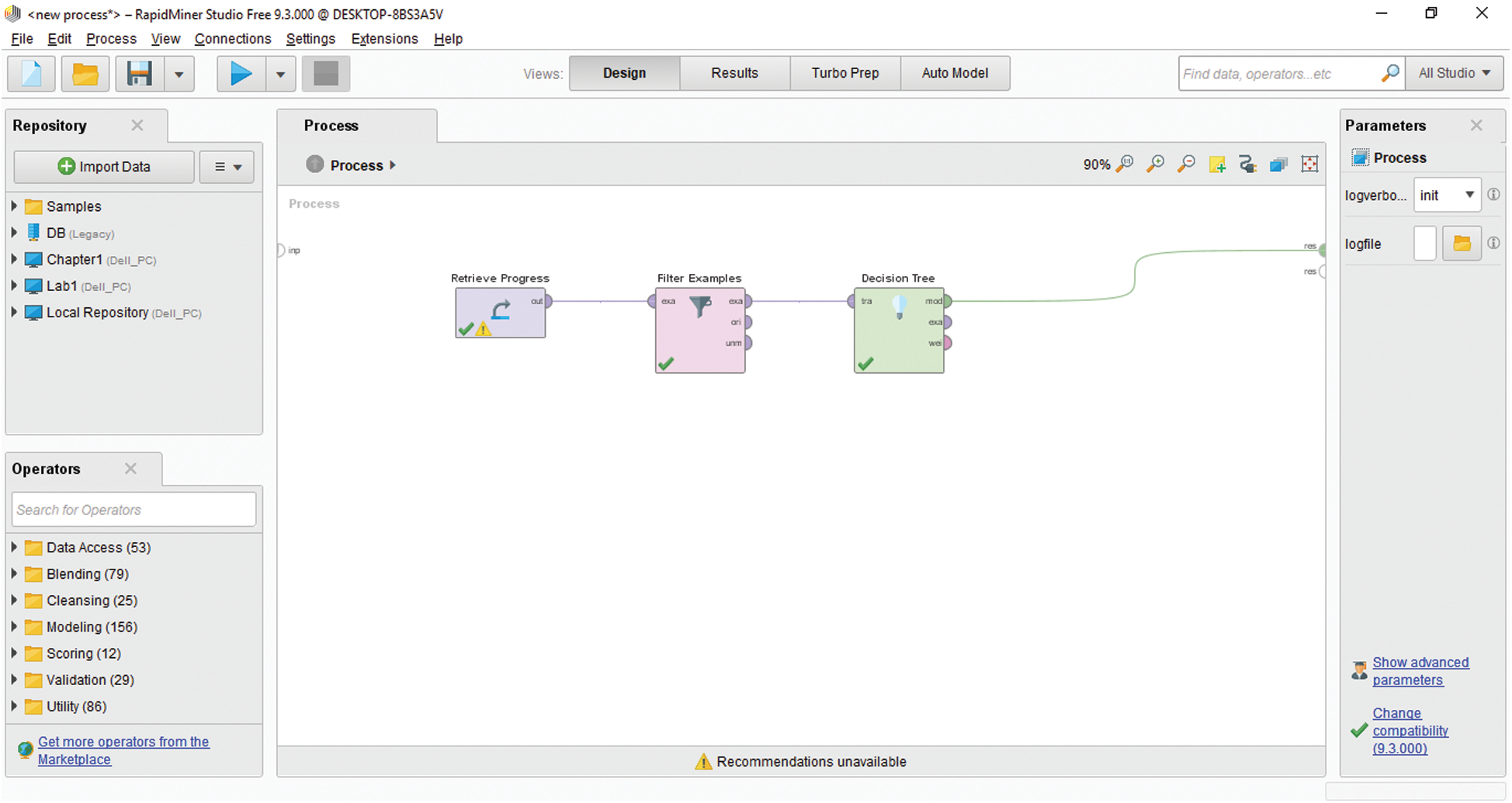

For the properties of refrigerants and the refrigeration simulation system, we used the REFPROP database and CYCLE_D-HX software from the National Institute of Standards and Technology [78–80], respectively, as shown in Fig. 9 below. The properties of all refrigerants, summarized in Tab. 14b, conformed to the use of REFPROP and the CYCLE_D-HX software, as stipulated by the National Institute of Standards and Technology (NIST) [78–80], in accordance with the CAN/ANSI/AHRI540 Air-Conditioning, Heating, and Refrigeration Institute (AHRI) standards, as shown in Tab. 12 [74–76]. Both software programs can pre-define mixtures and create new refrigerant mixtures. REFPROP can display results related to refrigerant properties under various conditions, and the CYCLE_D-HX software can also display results related to refrigerant cycles under various conditions. The results illustrated the relationships of all parameters, such as GWP, boiling point, refrigerant effect, heat rejection, refrigerant work, evaporator pressure, high pressure, and cooling coefficient of performance (COPc), as well as the result of the decision tree function through datamining using the RapidMiner software (which came first in the 2013 KDnuggets annual software poll [77]), as shown in Fig. 8 below. The baseline refrigerant, using R134, R32, R125, and R1270, was determined from the literature review.

Figure 8: Report of the KDnuggets annual software poll on the most-used data mining tools [77]

Figure 9: The REFPROP software used for refrigerant properties [78–80]

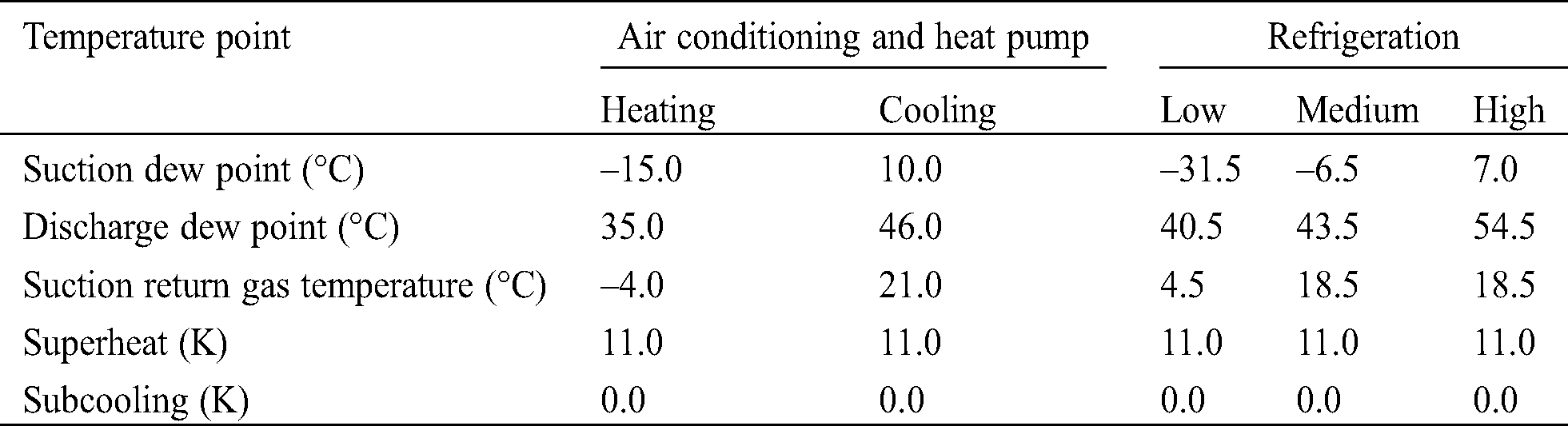

Table 12: Standard testing for refrigeration systems [74–76]

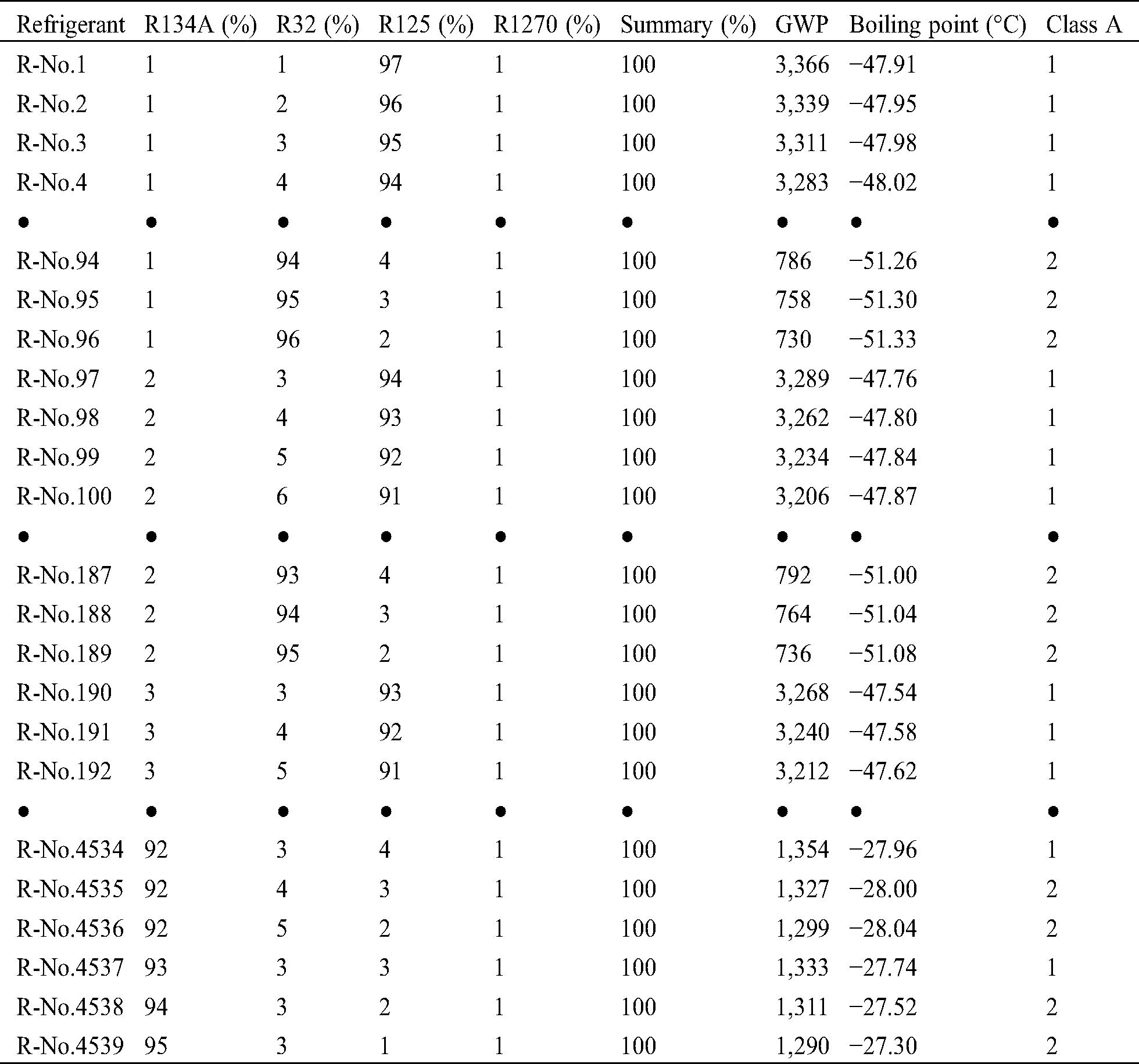

The mixture of refrigerants R134, R32, R125, and R1270 can be carried out in 4,539 different types, as reported in Tab. 13 below, which shows the refrigerant mixtures with R1270 fixed at 1% and various mass percentages of R134, R32, and R125. The refrigerant proportion mixed with R125 was, more or less, similar to that of the R32 mixture, and also possessed the Class A1 non-flammability property, similar to R410A (which is comprised of 50% R125 and 50% R32) [81–83]. The class A2 mixed refrigerants had a mass percentage of R32 higher than that of R125, similar to R452B (R32/125/1234yf [67/7/26]). The GWP, calculated by mass percentage of refrigerants, and boiling point, simulated using the National Institute of Standards and Technology (NIST) reference fluid thermodynamic and transport properties (REFPROP) database software and the NIST vapor compression cycle model accounting for refrigerant thermodynamic and transport properties (CYCLE_D-HX) software, were in accordance with the CAN/ANSI/AHRI540 standards of the Air-Conditioning, Heating, and Refrigeration Institute (AHRI).

Table 13: Refrigerant mixtures of R134, R32, R125, and R1270

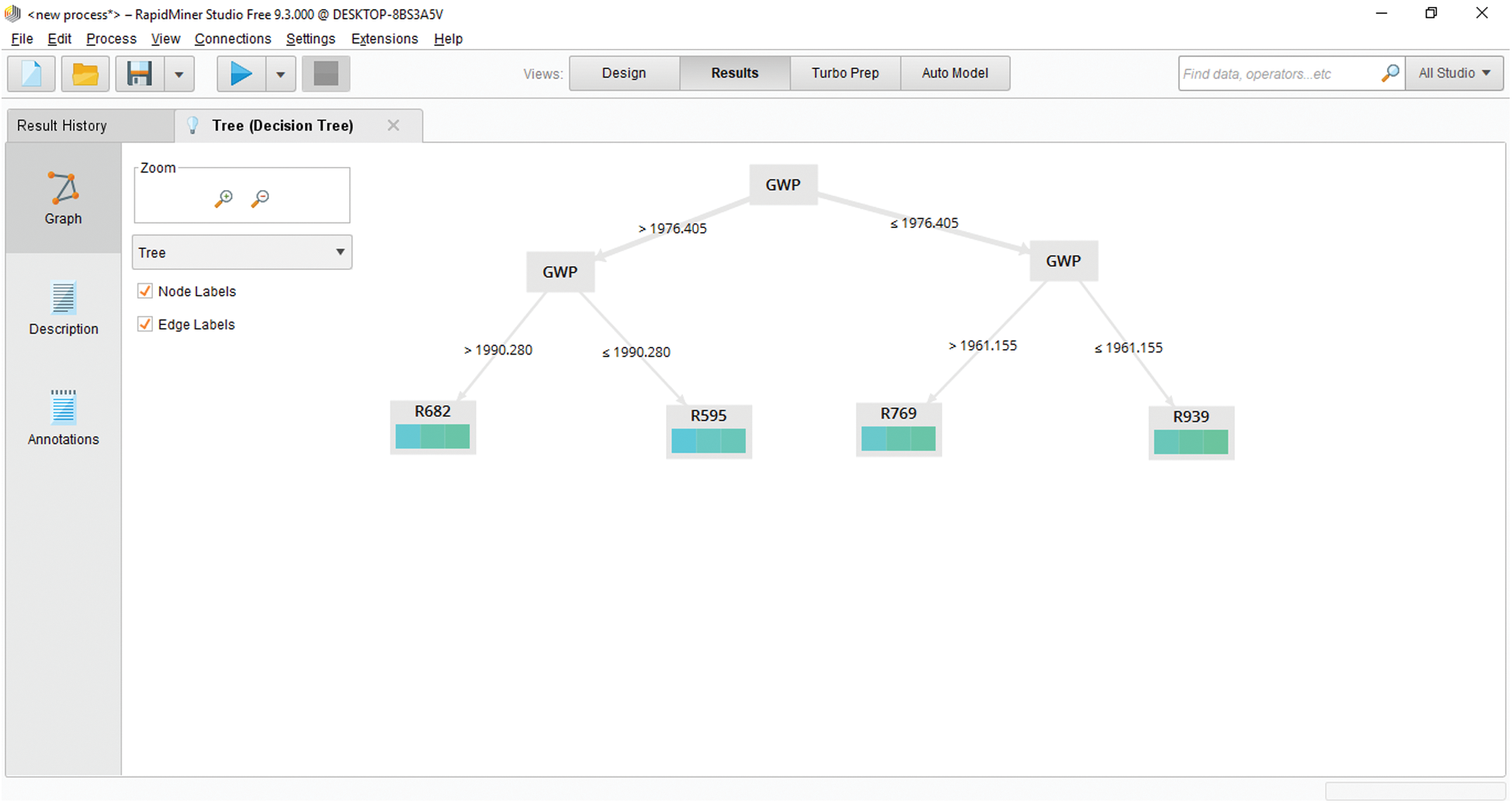

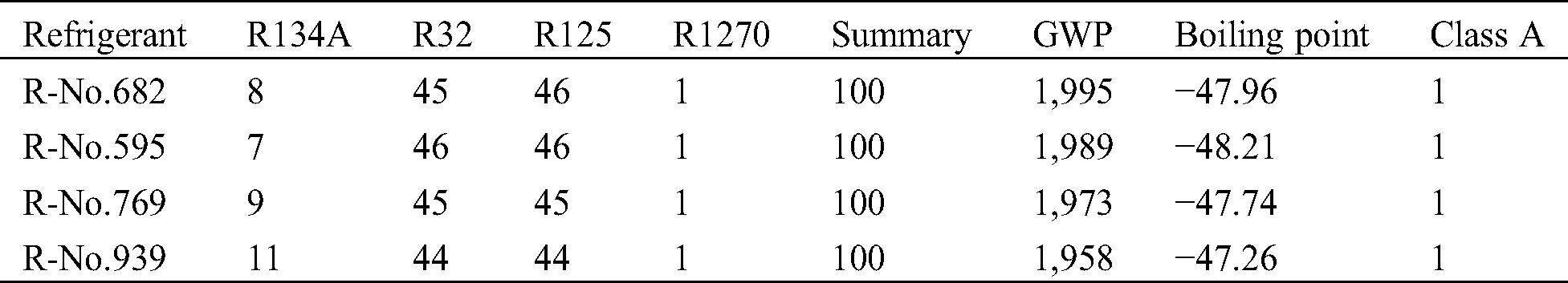

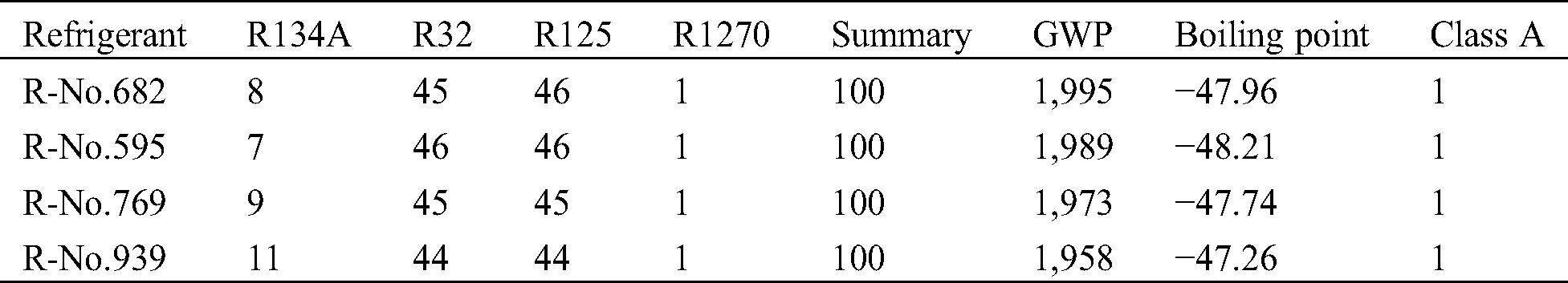

The refrigerant mixes were developed to have low GWP, zero ODP, high capacity, low pressure, and no toxicity [6], such that we could select the refrigerant requirements from refrigerant data 4,539 type using the RapidMiner software. The refrigerant requirements were: class A1, boiling point lower than that of R404 (−46.5°C), and GWP lower than 2000. The datamining function by decision tree in the RapidMiner software obtained four refrigerant results that followed the refrigerant requirement, as shown in Figs. 10 and 11, and listed in Tab. 14a below.

Figure 10: The datamining function by decision tree in RapidMiner

Figure 11: The four refrigerants following our refrigerant requirements

Table 14a: The four refrigerants found using the RapidMiner software

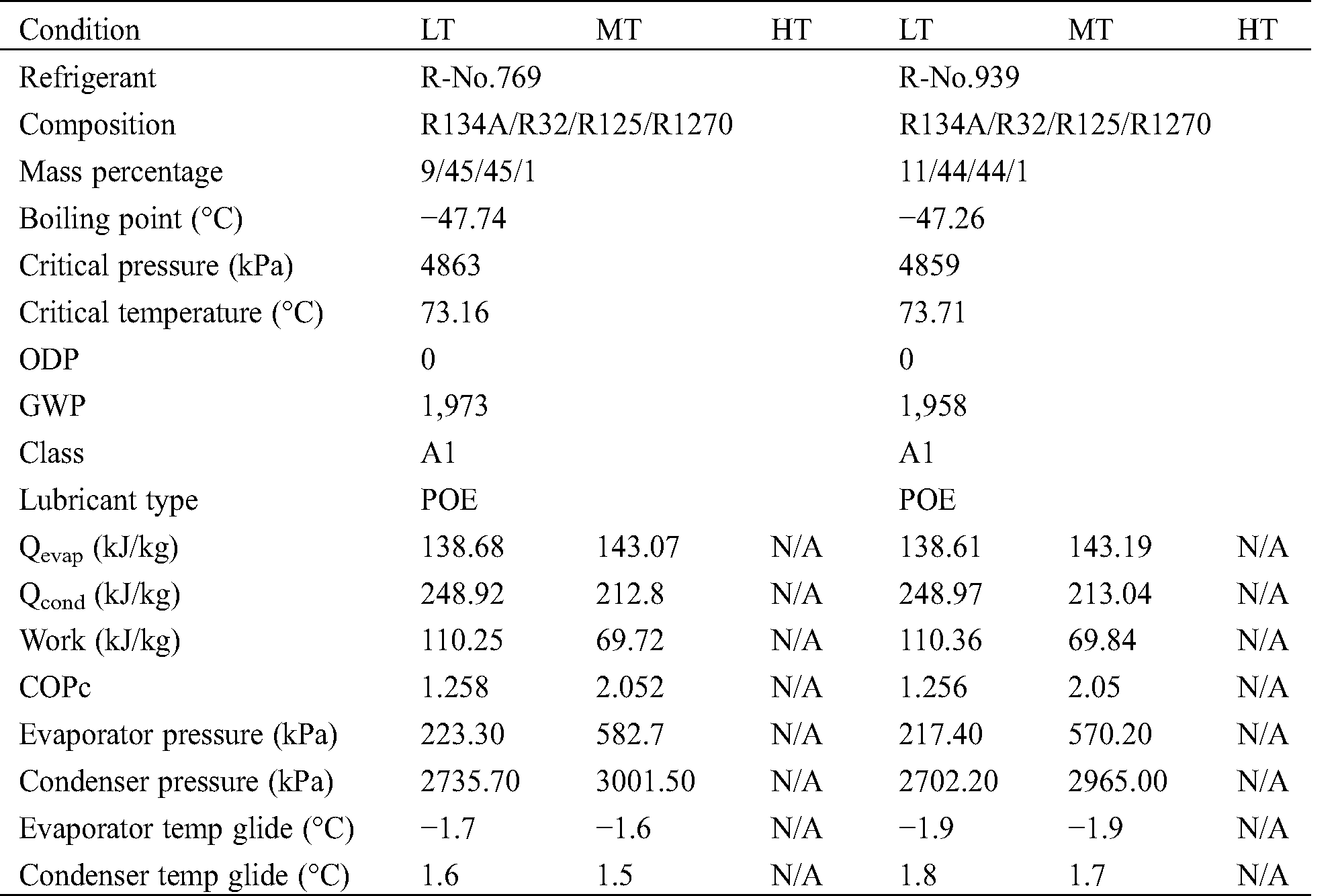

The simulation system then used the REFPROP and CYCLE_D-HX software of the National Institute of Standards and Technology [19] to define new mixtures from the results of the RapidMiner software, in order to verify that the properties and simulation system follow the CAN/ANSI/AHRI540 standard of the Air-conditioning, Heating, and Refrigeration Institute (AHRI), as shown in Tabs. 14b and 15. All refrigerant results were composed of polyol ester oil (POE), which is classified as a Class A1 incombustible and non-toxic refrigerant. R-No.595 had the lowest boiling point at −48.21°C; lower than that of R404A by 4.58%. This was due to the presence of hydrofluorocarbon (HFCs) R32 (36%) and hydrocarbon (HCs) R1270 (1%). The lowest GWP was 1,958, 50.34% lower than that of R404A, which was due to the presence of hydrofluorocarbon (HFCs) R134A (11%) and hydrocarbon (HCs) R1270 (1%). The critical pressures and temperatures of all refrigerants were found to be higher than those of R404A and, so, they can all be used in high ambient temperature environments. The highest refrigerant effect was attained by R-No.595, with 138.72 and 142.93 kJ/kg for low and medium conditions, respectively. The highest heat rejection was 248.83 and 212.52 kJ/kg for low and medium conditions, respectively, consistent with the normal boiling point. For all refrigerants, the cooling coefficient of performance (COPc) was lower than that of R404A (13.49%), only for low temperature conditions. This was due to the presence of hydrofluorocarbon (HFCs) R32 and hydrocarbon (HCs) R1270; however, R32 operates at high pressures, thus affecting the evaporator pressure, condenser pressure, and COPc under medium temperature conditions (as the work of compressor will be high). This shows that a mixed-refrigerant design should consider all parameters, such as the GWP, boiling point, Cp liquid/vapor and liquid/vapor conductivity, refrigerant effect, heat rejection, refrigerant work, evaporator pressure, high pressure, and COPc.

Table 15: Results of the simulation system using REFPROP and CYCLE_D-HX

Table 14b: Results of the simulation system using REFPROP and CYCLE_D-HX

In this paper, we determined new refrigerant mixtures comprised of R134, R32, R125, and R1270 by using refrigerant composition results of the decision tree function in the RapidMiner software, which came first in KDnuggets annual software poll. All resulting refrigerants were composed of polyol ester oil (POE), which has been classified as a Class A1, incombustible, and non-toxic refrigerant. The properties of the refrigerants were verified using the National Institute of Standards and Technology (NIST) reference fluid thermodynamic and transport properties database (REFPROP) software and the NIST vapor compression cycle model accounting for refrigerant thermodynamic and transport properties (CYCLE_D-HX) software, and were in accordance with the CAN/ANSI/AHRI540 standards of the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). It was indicated that the normal boiling point of R-No. 595 was higher than that of R404A by 4.58%, with a higher cooling capacity and a lower GWP than those of R404A by a margin of 50.34% due to the presence of hydrofluorocarbon (HFCs) R32 and hydrocarbon (HCs) R1270. The COP of R-No. 595 was found to be higher than that of R404A by 13.49% under low temperatures. It should be emphasized that a mixed-refrigerant design must consider all relevant parameters, such as the GWP, boiling point, Cp liquid/vapor and liquid/vapor conductivity, refrigerant effect, heat rejection, refrigerant work, evaporator pressure, high pressure, and COPc. The proposed refrigerant mixes provide alternate refrigerant options which are composed of 1% hydrocarbon (HCs) R1270, consistent with the evolution of the fourth-generation refrigerants; which contain a mixture of HFCs, HFOs, HCs, and natural refrigerants, in order to produce a low-GWP, zero ODP, high-capacity, low-operating pressure, and non-toxic refrigerants. In the future, researchers should incorporate the use of natural refrigerants that have low cost. The problems of high evaporator pressure and high condenser pressure, which lead to high refrigerant work, can be solved by adjusting the composition of the refrigerant or mix (i.e., by using a refrigerant that operates at low pressure), thereby improving the COP of the refrigerant.

Acknowledgement: This study was supported by Prince of Songkla University and SANYO S.M.I. (Thailand) Co., Ltd.

Funding Statement: This research was funded by Prince of Songkla University and SANYO S.M.I. (Thailand) Co., Ltd.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Jeffrey Kuo, C. F., Lin, C. H., Lee, M. H. (2018). Analyze the energy consumption characteristics and affecting factors of Taiwan’s convenience stores-using the big data mining approach. Energy and Buildings, 168, 120–136. DOI 10.1016/j.enbuild.2018.03.021. [Google Scholar] [CrossRef]

2. Saengsikhiao, P., Taweekun, J., Maliwan, K., Sae-Ung, S., Theppaya, T. (2020). Investigation and analysis of R463A as an alternative refrigerant to R404A with lower global warming potential. Energies, 13(6), 1514. DOI 10.3390/en13061514. [Google Scholar] [CrossRef]

3. Shen, H., Xu, K., Freihaut, J. (2019). A statistical study on energy performance of U.S. convenience stores: Investigation of factors and bench marking on store energy use. Energy and Buildings, 183, 792–802. DOI 10.1016/j.enbuild.2018.10.018. [Google Scholar] [CrossRef]

4. Tassou, S. A., Ge, Y., Hadawey, A., Marriott, D. (2011). Energy consumption and conservation in food retailing. Applied Thermal Engineering, 31(2), 147–156. DOI 10.1016/j.applthermaleng.2010.08.023. [Google Scholar] [CrossRef]

5. Wang, A. P., Hsu, P. L. (2008). The network-based energy management system for convenience stores. Energy and Buildings, 40(8), 1437–1445. DOI 10.1016/j.enbuild.2008.01.007. [Google Scholar] [CrossRef]

6. Chou, D.c, Chang, C. S., Hsu, Y. Z. (2016). Investigation and analysis of power consumption in convenience stores in Taiwan. Energy and Buildings, 133, 670–687. DOI 10.1016/j.enbuild.2016.10.010. [Google Scholar] [CrossRef]

7. Evans, J. A., Hammond, E. C., Gigiel, A. J., Fostera, A. M., Reinholdt, L. et al. (2014). Assessment of methods to reduce the energy consumption of food cold stores. Applied Thermal Engineering, 62(2), 697–705. DOI 10.1016/j.applthermaleng.2013.10.023. [Google Scholar] [CrossRef]

8. Mota-Babiloni, A., Navarro-Esbrí, J., Makhnatch, P., Molés, F. (2017). Refrigerant R32 as lower GWP working fluid in residential air conditioning systems in Europe and the USA. Renewable and Sustainable Energy Reviews, 80, 1031–1042. DOI 10.1016/j.rser.2017.05.216. [Google Scholar] [CrossRef]

9. Cardoso, B. J., Lamas, F. B., Gaspar, A. R., Ribeiro, J. B. (2017). Refrigerants used in the Portuguese food industry: Current status. International Journal of Refrigeration, 83, 60–74. DOI 10.1016/j.ijrefrig.2017.07.013. [Google Scholar] [CrossRef]

10. Sánchez, D., Cabello, R., Llopis, R., Catalán-Gil, J., Nebot-Andrés, L. (2019). Energy assessment and environmental impact analysis of an R134a/R744 cascade refrigeration plant upgraded with the low-GWP refrigerants R152a, R1234ze(Epropane (R290) and propylene (R1270). International Journal of Refrigeration, 104, 321–334. DOI 10.1016/j.ijrefrig.2019.05.028. [Google Scholar] [CrossRef]

11. Calleja-Anta, D., Nebot-Andrés, L., Catalán-Gil, J., Sánchez, D., Cabello, R. et al. (2020). Thermodynamic screening of alternative refrigerants for R290 and R600a. Results in Engineering, 5, 100081. DOI 10.1016/j.rineng.2019.100081. [Google Scholar] [CrossRef]

12. Massuchetto, L. H. P., Nascimento, R. B. C. d, Carvalho, S. M. R. d, Araújo, H. V. d, d’Angelo, J. V. H. (2019). Thermodynamic performance evaluation of a cascade refrigeration system with mixed refrigerants: R744/R1270, R744/R717 and R744/RE170. International Journal of Refrigeration, 106, 201–212. DOI 10.1016/j.ijrefrig.2019.07.005.

13. Zhang, L., Yang, C., Liu, H., Du, P., Gao, H. (2017). Theoretical investigation on the properties of R744/R290 mixtures. Procedia Engineering, 205, 1620–1626. DOI 10.1016/j.proeng.2017.10.304. [Google Scholar] [CrossRef]

14. Mečárik, K., Masaryk, M. (1991). Thermodynamic properties of refrigerants R11, R12, R13, R14, R22, R23, R113, R114, R500 and R502. Heat Recovery Systems and CHP, 11(2), 193–197. DOI 10.1016/0890-4332(91)90135-Q. [Google Scholar] [CrossRef]

15. Bao, Z. Y., Fletcher, D. F., Haynes, B. S. (2000). Flow boiling heat transfer of Freon R11 and HCFC123 in narrow passages. International Journal of Heat and Mass Transfer, 43(18), 3347–3358. DOI 10.1016/S0017-9310(99)00379-8.

16. Chen, S., Liu, J., Liu, X., Hou, Y. (2015). An experimental comparison of heat transfer characteristic between R134-a and R22 in spray cooling. Experimental Thermal and Fluid Science, 66, 206–212. DOI 10.1016/j.expthermflusci.2015.03.015. [Google Scholar] [CrossRef]

17. Fatouh, M., Ibrahim, T. A., Mostafa, A. (2010). Performance assessment of a direct expansion air conditioner working with R407C as an R22 alternative. Applied Thermal Engineering, 30(2), 127–133. DOI 10.1016/j.applthermaleng.2009.07.009. [Google Scholar] [CrossRef]

18. Kuczynski, W., Bohdal, T., Meyer, J. P., Denis, A. (2019). A regressive model for dynamic instabilities during the condensation of R404A and R507 refrigerants. International Journal of Heat and Mass Transfer, 141, 1025–1035. DOI 10.1016/j.ijheatmasstransfer.2019.06.095.

19. Kuczynski, W. (2019). Experimental research on condensation of R134a and R404A refrigerants in mini-channels during impulsive instabilities. Part I. International Journal of Heat and Mass Transfer, 128, 728–738. DOI 10.1016/j.ijheatmasstransfer.2018.09.045. [Google Scholar] [CrossRef]

20. Kondou, C., Umemoto, S., Koyama, S., Mitooka, Y. (2017). Improving the heat dissipation performance of a looped thermosyphon using low-GWP volatile fluids R1234ze(Z) and R1234ze(E) with a super-hydrophilic boiling surface. Applied Thermal Engineering, 118, 147–158. DOI 10.1016/j.applthermaleng.2017.02.073. [Google Scholar] [CrossRef]

21. Colombo, L. P. M., Lucchini, A., Molinaroli, L. (2020). Experimental analysis of the use of R1234yf and R1234ze(E) as drop-in alternatives of R134a in a water-to-water heat pump. International Journal of Refrigeration, 115, 18–27. DOI 10.1016/j.ijrefrig.2020.03.004.

22. Sun, Z., Cui, Q., Wang, Q., Ning, J., Guo, J. et al. (2019). Experimental study on CO2/R32 blends in a water-to-water heat pump system. Applied Thermal Engineering, 162, 114303. DOI 10.1016/j.applthermaleng.2019.114303. [Google Scholar] [CrossRef]

23. Hu, X., Yang, T., Meng, X., Wu, J. (2017). Isothermal vapor liquid equilibrium measurements for difluoromethane (R32) + fluoroethane (R161) + trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) ternary mixtures. International Journal of Refrigeration, 79, 49–56. DOI 10.1016/j.ijrefrig.2017.04.019. [Google Scholar] [CrossRef]

24. Ju, F., Fan, X., Chen, Y., Zhang, H., Wang, T. et al. (2017). Performance assessment of heat pump water heaters with R1233zd(E)/HCs binary mixtures. Applied Thermal Engineering, 123, 1345–1355. DOI 10.1016/j.applthermaleng.2017.05.137.

25. Longo, G. A., Mancin, S., Righetti, G., Zilio, C., Steven Brown, J. (2020). Assessment of the low-GWP refrigerants R600a, R1234ze(Z) and R1233zd(E) for heat pump and organic Rankine cycle applications. Applied Thermal Engineering, 167, 114804. DOI 10.1016/j.applthermaleng.2019.114804. [Google Scholar] [CrossRef]

26. Zhu, J., Elbel, S. (2020). Experimental investigation into the influence of vortex control on transcritical R744 ejector and cycle performance. Applied Thermal Engineering, 164, 114418. DOI 10.1016/j.applthermaleng.2019.114418. [Google Scholar] [CrossRef]

27. Zhang, Y., Wang, X., Yin, J. (2020). Viscosity of saturated mixtures of 1-hexyl-3-methyl-imidazolium bis(trifluoromethylsulfonyl)amide with R600a and R152a. Journal of Chemical Thermodynamics, 141, 105970. DOI 10.1016/j.jct.2019.105970.

28. Longo, G. A., Righetti, G., Zilio, C. (2019). Heat-transfer assessment of the low GWP substitutes for traditional HFC refrigerants. International Journal of Heat and Mass Transfer, 139, 31–38. DOI 10.1016/j.ijheatmasstransfer.2019.04.144. [Google Scholar] [CrossRef]

29. Shaik, S. V., Babu, T. P. A. (2017). Theoretical computation of performance of sustainable energy efficient R22 alternatives for residential air conditioners. Energy Procedia, 138, 710–716. DOI 10.1016/j.egypro.2017.10.205. [Google Scholar] [CrossRef]

30. La Rocca, V., Panno, G. (2011). Experimental performance evaluation of a vapour compression refrigerating plant when replacing R22 with alternative refrigerants. Applied Energy, 88(8), 2809–2815. DOI 10.1016/j.apenergy.2011.01.051.

31. Kasera, S., Bhaduri, S. C. (2017). Performance of R407C as an alternate to R22: A review. Energy Procedia, 109, 4–10. DOI 10.1016/j.egypro.2017.03.032. [Google Scholar] [CrossRef]

32. Elgendy, E., Melike, M., Fatouh, M. (2018). Experimental assessment of a split air conditioner working with R-417A under different indoor and outdoor conditions. International Journal of Refrigeration, 85, 268–281. DOI 10.1016/j.ijrefrig.2017.10.005. [Google Scholar] [CrossRef]

33. Fernández-Seara, J., Uhía, F. J., Diz, R., Dopazo, J. A. (2010). Vapour condensation of R22 retrofit substitutes R417A, R422A and R422D on CuNi turbo C tubes. International Journal of Refrigeration, 33(1), 148–157. DOI 10.1016/j.ijrefrig.2009.09.006.

34. Jacob, T. A., Matty, E. R., Fronk, B. M. (2019). Experimental investigation of in-tube condensation of low GWP refrigerant R450A using a fiber optic distributed temperature sensor. International Journal of Refrigeration-Revue Internationale Du Froid, 103, 274–286. DOI 10.1016/j.ijrefrig.2019.04.021. [Google Scholar] [CrossRef]

35. Oruç, V., Devecioğlu, A. G. (2015). Thermodynamic performance of air conditioners working with R417A and R424A as alternatives to R22. International Journal of Refrigeration, 55, 120–128. DOI 10.1016/j.ijrefrig.2015.03.021. [Google Scholar] [CrossRef]

36. Chen, X., Liu, C., Yang, J., Chen, J. (2018). Experimental study on R-22, R-427A, R-161 and R-290 in air-source heat pump for space heating at low ambient temperatures. International Journal of Refrigeration, 96, 147–154. DOI 10.1016/j.ijrefrig.2018.08.021.

37. Devecioğlu, A. G., Oruç, V. 2017b. The influence of plate-type heat exchanger on energy efficiency and environmental effects of the air-conditioners using R453A as a substitute for R22. Applied Thermal Engineering, 112, 1364–1372. DOI 10.1016/j.applthermaleng.2016.10.180. [Google Scholar] [CrossRef]

38. Yang, M., Zhang, H., Meng, Z., Qin, Y. (2019). Experimental study on R1234yf/R134a mixture (R513A) as R134a replacement in a domestic refrigerator. Applied Thermal Engineering, 146, 540–547. DOI 10.1016/j.applthermaleng.2018.09.122. [Google Scholar] [CrossRef]

39. Makhnatch, P., Mota-Babiloni, A., López-Belchí, A., Khodabandeh, R. (2019). R450A and R513A as lower GWP mixtures for high ambient temperature countries: Experimental comparison with R134a. Energy, 166, 223–235. DOI 10.1016/j.energy.2018.09.001.

40. Heredia-Aricapa, Y., Belman-Flores, J. M., Mota-Babiloni, A., Serrano-Arellano, J., García-Pabón, J. J. (2020). Overview of low GWP mixtures for the replacement of HFC refrigerants: R134a, R404A and R410A. International Journal of Refrigeration, 111, 113–123. DOI 10.1016/j.ijrefrig.2019.11.012. [Google Scholar] [CrossRef]

41. Yousif, Q. A., Mohd-Ghazali, N., Pamitran, A. S., Mohd-Yunos, Y. (2019). Optimized condition for pairing of different friction factor and viscosity equations for the frictional pressure drop of R22 and R290. International Journal of Air-Conditioning and Refrigeration, 27(4), 7. DOI 10.1142/S2010132519500378. [Google Scholar] [CrossRef]

42. Zhang, X. (2011). Heat transfer and enhancement analyses of flow boiling for R417A and R22. Experimental Thermal and Fluid Science, 35(7), 1334–1342. DOI 10.1016/j.expthermflusci.2011.04.020. [Google Scholar] [CrossRef]

43. Llopis, R., Torrella, E., Cabello, R., Sánchez, D. (2012). HCFC-22 replacement with drop-in and retrofit HFC refrigerants in a two-stage refrigeration plant for low temperature. International Journal of Refrigeration, 35(4), 810–816. DOI 10.1016/j.ijrefrig.2012.01.001. [Google Scholar] [CrossRef]

44. Oruç, V., Devecioğlu, A. G., Berk, U., Vural, İ. (2016). Experimental comparison of the energy parameters of HFCs used as alternatives to HCFC-22 in split type air conditioners. International Journal of Refrigeration, 63, 125–132. DOI 10.1016/j.ijrefrig.2015.11.004. [Google Scholar] [CrossRef]

45. Wang, F., Wang, F., Fan, X., Lian, Z. (2012). Experimental study on an inverter heat pump with HFC125 operating near the refrigerant critical point. Applied Thermal Engineering, 39, 1–7. DOI 10.1016/j.applthermaleng.2012.01.016. [Google Scholar] [CrossRef]

46. Arora, A., Sachdev, H. L. (2009). Thermodynamic analysis of R422 series refrigerants as alternative refrigerants to HCFC22 in a vapour compression refrigeration system. International Journal of Energy Research, 33(8), 753–765. DOI 10.1002/er.1508. [Google Scholar] [CrossRef]

47. Saeed, M. U., Qureshi, S. R., Hashmi, K. J., Khan, M. A., Danish, S. N. (2018). Performance assessment of alternate refrigerants for retrofitting R22 based air conditioning system. Thermal Science, 22(2), 931–941. DOI 10.2298/TSCI160811315S. [Google Scholar] [CrossRef]

48. Devecioǧlu, A. G., Oruç, V. (2016). The experimental comparison of environmental impacts of some hfc’s used instead of hcfc-22. Isi Bilimi Ve Teknigi Dergisi/Journal of Thermal Science and Technology, 36(1), 99–105. [Google Scholar]

49. Paradeshi, L., Srinivas, M., Jayaraj, S. (2020). Performance studies of R433A in a direct expansion solar-assisted heat pump. International Journal of Ambient Energy, 41(3), 262–273. DOI 10.1080/01430750.2018.1451369. [Google Scholar] [CrossRef]

50. Subiantoro, A., Ooi, K. T., Junaidi, A. Z. (2013). Performance and suitability comparisons of some R22 possible substitute refrigerants. In: Condensation of superheated R134a and R437A inside a vertical tube. Woodhead Publishing, 67–76. [Google Scholar]

51. Hari Sankar, R., Basnth, S., Ajay Ghosh, K. J., Sivan, M., Vyshak Dileep, K. (2019). Research on environment friendly alternatives for R22, R12 and R409A refrigerants. International Journal of Recent Technology and Engineering, 8(1 Special Issue 4), 265–271. [Google Scholar]

52. Oruç, V., Devecioğlu, A. G., Ender, S. (2018). Improvement of energy parameters using R442A and R453A in a refrigeration system operating with R404A. Applied Thermal Engineering, 129, 243–249. DOI 10.1016/j.applthermaleng.2017.10.035. [Google Scholar] [CrossRef]

53. Ma, Z. X., Liu, F. G., Tian, C. F., Jia, L. L., Wu, W. (2020). Experimental comparisons on a gas engine heat pump using R134a and low-GWP refrigerant R152a. International Journal of Refrigeration-Revue Internationale Du Froid, 115, 73–82. DOI 10.1016/j.ijrefrig.2020.03.007. [Google Scholar] [CrossRef]

54. Jacob, T. A., Matty, E. R., Fronk, B. M. (2019). Experimental investigation of in-tube condensation of low GWP refrigerant R450A using a fiber optic distributed temperature sensor. International Journal of Refrigeration-Revue Internationale Du Froid, 103, 274–286. DOI 10.1016/j.ijrefrig.2019.04.021. [Google Scholar] [CrossRef]

55. Sun, J., Li, W. H., Cui, B. R. (2020). Energy and exergy analyses of R513a as a R134a drop-in replacement in a vapor compression refrigeration system. International Journal of Refrigeration-Revue Internationale Du Froid, 112, 348–356. DOI 10.1016/j.ijrefrig.2019.12.014. [Google Scholar] [CrossRef]

56. Mota-Babiloni, A., Navarro-Esbrí, J., Peris, B., Molés, F., Verdú, G. (2015). Experimental evaluation of R448A as R404A lower-GWP alternative in refrigeration systems. Energy Conversion and Management, 105, 756–762. DOI 10.1016/j.enconman.2015.08.034. [Google Scholar] [CrossRef]

57. Hu, X., Zhang, Z., Yao, Y., Wang, Q. (2018). Non-azeotropic refrigerant charge optimization for cold storage unit based on year-round performance evaluation. Applied Thermal Engineering, 139, 395–401. DOI 10.1016/j.applthermaleng.2018.04.089. [Google Scholar] [CrossRef]

58. Bortolini, M., Gamberi, M., Gamberini, R., Graziani, A., Lolli, F. et al. (2015). Retrofitting of R404a commercial refrigeration systems using R410a and R407f refrigerants. International Journal of Refrigeration, 55, 142–152. DOI 10.1016/j.ijrefrig.2015.02.015. [Google Scholar] [CrossRef]

59. Mota-Babiloni, A., Makhnatch, P., Khodabandeh, R. (2017). Recent investigations in HFCs substitution with lower GWP synthetic alternatives: Focus on energetic performance and environmental impact. International Journal of Refrigeration, 82, 288–301. DOI 10.1016/j.ijrefrig.2017.06.026. [Google Scholar] [CrossRef]

60. Mancin, S., Del Col, D., Rossetto, L. (2012). Partial condensation of R407C and R410A refrigerants inside a plate heat exchanger. Experimental Thermal and Fluid Science, 36, 149–157. DOI 10.1016/j.expthermflusci.2011.09.007. [Google Scholar] [CrossRef]

61. Mendoza-Miranda, J. M., Mota-Babiloni, A., Navarro-Esbrí, J. (2016). Evaluation of R448A and R450A as low-GWP alternatives for R404A and R134a using a micro-fin tube evaporator model. Applied Thermal Engineering, 98, 330–339. DOI 10.1016/j.applthermaleng.2015.12.064. [Google Scholar] [CrossRef]

62. Makhnatch, P., Mota-Babiloni, A., Rogstam, J., Khodabandeh, R. (2017). Retrofit of lower GWP alternative R449A into an existing R404A indirect supermarket refrigeration system. International Journal of Refrigeration, 76, 184–192. DOI 10.1016/j.ijrefrig.2017.02.009. [Google Scholar] [CrossRef]

63. Górny, K., Stachowiak, A., Tyczewski, P., Zwierzycki, W. (2019). Lubricity of selected oils in mixtures with the refrigerants R452A, R404A, and R600a. Tribology International, 134, 50–59. DOI 10.1016/j.triboint.2018.12.033. [Google Scholar] [CrossRef]

64. Devecioğlu, A. G., Oruç, V. 2017a. An analysis on the comparison of low-GWP refrigerants to alternatively use in mobile air-conditioning systems. Thermal Science and Engineering Progress, 1, 1–5. DOI 10.1016/j.tsep.2017.02.002. [Google Scholar] [CrossRef]

65. Mota-Babiloni, A., Haro-Ortuño, J., Navarro-Esbrí, J., Barragán-Cervera, Á. (2018). Experimental drop-in replacement of R404A for warm countries using the low GWP mixtures R454C and R455A. International Journal of Refrigeration, 91, 136–145. DOI 10.1016/j.ijrefrig.2018.05.018. [Google Scholar] [CrossRef]

66. Wang, D., Liu, Y., Kou, Z., Yao, L., Lu, Y. et al. (2019). Energy and exergy analysis of an air-source heat pump water heater system using CO2/R170 mixture as an azeotropy refrigerant for sustainable development. International Journal of Refrigeration, 106, 628–638. DOI 10.1016/j.ijrefrig.2019.03.007. [Google Scholar] [CrossRef]

67. Berkah Fajar, T. K., Restu Bagas, P., Ukhi, S., Alhamid, M. I., Lubis, A. (2020). Energy and exergy analysis of an R410A small vapor compression system retrofitted with R290. Case Studies in Thermal Engineering, 21, 100671. DOI 10.1016/j.csite.2020.100671. [Google Scholar] [CrossRef]

68. Yang, L., Gong, M., Guo, H., Dong, X., Shen, J. et al. (2016). Isothermal (vapour+liquid) equilibrium measurements and correlation for the {n-butane (R600)+1,1,1,3,3-pentafluoropropane (R245fa)} system at temperatures from (303.150 to 373.150)K. Journal of Chemical Thermodynamics, 95, 49–53. DOI 10.1016/j.jct.2015.11.021. [Google Scholar] [CrossRef]

69. Qiu, J., Zhang, H. (2020). Experimental investigation on two-phase frictional pressure drop of R600a and R600a/3GS oil mixture in a smooth horizontal tube. International Journal of Refrigeration, 117, 307–315. DOI 10.1016/j.ijrefrig.2020.04.025. [Google Scholar] [CrossRef]

70. Pratama, F., Reyseliani, N., Syauqi, A., Daud, Y., Purwanto, W. W. et al. (2020). Thermoeconomic assessment and optimization of wells to flash-binary cycle using pure R601 and zeotropic mixtures in the Sibayak geothermal field. Geothermics, 85, 101778. DOI 10.1016/j.geothermics.2019.101778. [Google Scholar] [CrossRef]

71. Li, J., Liu, Q., Duan, Y., Yang, Z. (2017). Performance analysis of organic Rankine cycles using R600/R601a mixtures with liquid-separated condensation. Applied Energy, 190, 376–389. DOI 10.1016/j.apenergy.2016.12.131. [Google Scholar] [CrossRef]

72. Wu, X., Yang, Z., Wang, X., Lin, Y. (2013). Experimental and theoretical study on the influence of temperature and humidity on the flammability limits of ethylene (R1150). Energy, 52, 185–191. DOI 10.1016/j.energy.2013.01.042. [Google Scholar] [CrossRef]

73. Zhang, Y., He, Y., Wang, Y., Wu, X., Jia, M. et al. (2020). Experimental investigation of the performance of an R1270/CO2 cascade refrigerant system. International Journal of Refrigeration, 114, 175–180. DOI 10.1016/j.ijrefrig.2020.02.017. [Google Scholar] [CrossRef]

74. CAN/ANSI/AHRI540. (E) 2015. Performance rating of positive displacement refrigerant compressors and compressor units. Air-Conditioning, Heating, and Refrigeration Institute (AHRI5. [Google Scholar]

75. Aprea, C., Maiorino, A., Mastrullo, R. (2011). Change in energy performance as a result of a R422D retrofit: An experimental analysis for a vapor compression refrigeration plant for a walk-in cooler. Applied Energy, 88(12), 4742–4748. DOI 10.1016/j.apenergy.2011.06.049.

76. Lumpkin, D. R., Bahman, A. M., Groll, E. A. (2018). Two-phase injected and vapor-injected compression: Experimental results and mapping correlation for a R-407C scroll compressor. International Journal of Refrigeration, 86, 449–462. DOI 10.1016/j.ijrefrig.2017.11.009. [Google Scholar] [CrossRef]

77. Lausch, A., Schmidt, A., Tischendorf, L. (2015). Data mining and linked open data–New perspectives for data analysis in environmental research. Ecological Modelling, 295, 5–17. DOI 10.1016/j.ecolmodel.2014.09.018. [Google Scholar] [CrossRef]

78. Bell, I. H., Domanski, P. A., McLinden, M. O., Linteris, G. T. (2019). The hunt for nonflammable refrigerant blends to replace R-134a. International Journal of Refrigeration, 104, 484–495. DOI 10.1016/j.ijrefrig.2019.05.035. [Google Scholar] [CrossRef]

79. Domanski, P. A., Brignoli, R., Brown, J. S., Kazakov, A. F., McLinden, M. O. (2017). Low-GWP refrigerants for medium and high-pressure applications. International Journal of Refrigeration, 84, 198–209. DOI 10.1016/j.ijrefrig.2017.08.019.

80. Brignoli, R., Brown, J. S., Skye, H. M., Domanski, P. A. (2017). Refrigerant performance evaluation including effects of transport properties and optimized heat exchangers. International Journal of Refrigeration, 80, 52–65. DOI 10.1016/j.ijrefrig.2017.05.014. [Google Scholar] [CrossRef]

81. Saengsikhiao, P., Taweekun, J., Maliwan, K., Sae-ung, S., Theppaya, T. 2020a. The improvement of energy efficiency for refrigeration system in Thailand convenience store by digital scroll compressor. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 74(1), 144–150. DOI 10.37934/arfmts.74.1.144150. [Google Scholar] [CrossRef]

82. Saengsikhiao, P., Juntakan, T., Kittinan, M., Somchai, S., Thanansak, T. (2020). The replacement of the R404A refrigeration system with the environmentally friendly R448A, to improve convenience store energy efficiency in Thailand. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 75(1), 137–146. DOI 10.37934/arfmts.75.1.137146.

83. Saengsikhiao, P., Juntakan, T., Kittinan, M., Somchai, S., Thanansak, T. (2020). The performance simulation of the new R463A HFC/HFO/Carbon dioxide refrigerant with lower GWP, as an alternate option for the R404A refrigeration system. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 76(1), 113–123. DOI 10.37934/arfmts.76.1.113123. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |