Open Access

Open Access

ARTICLE

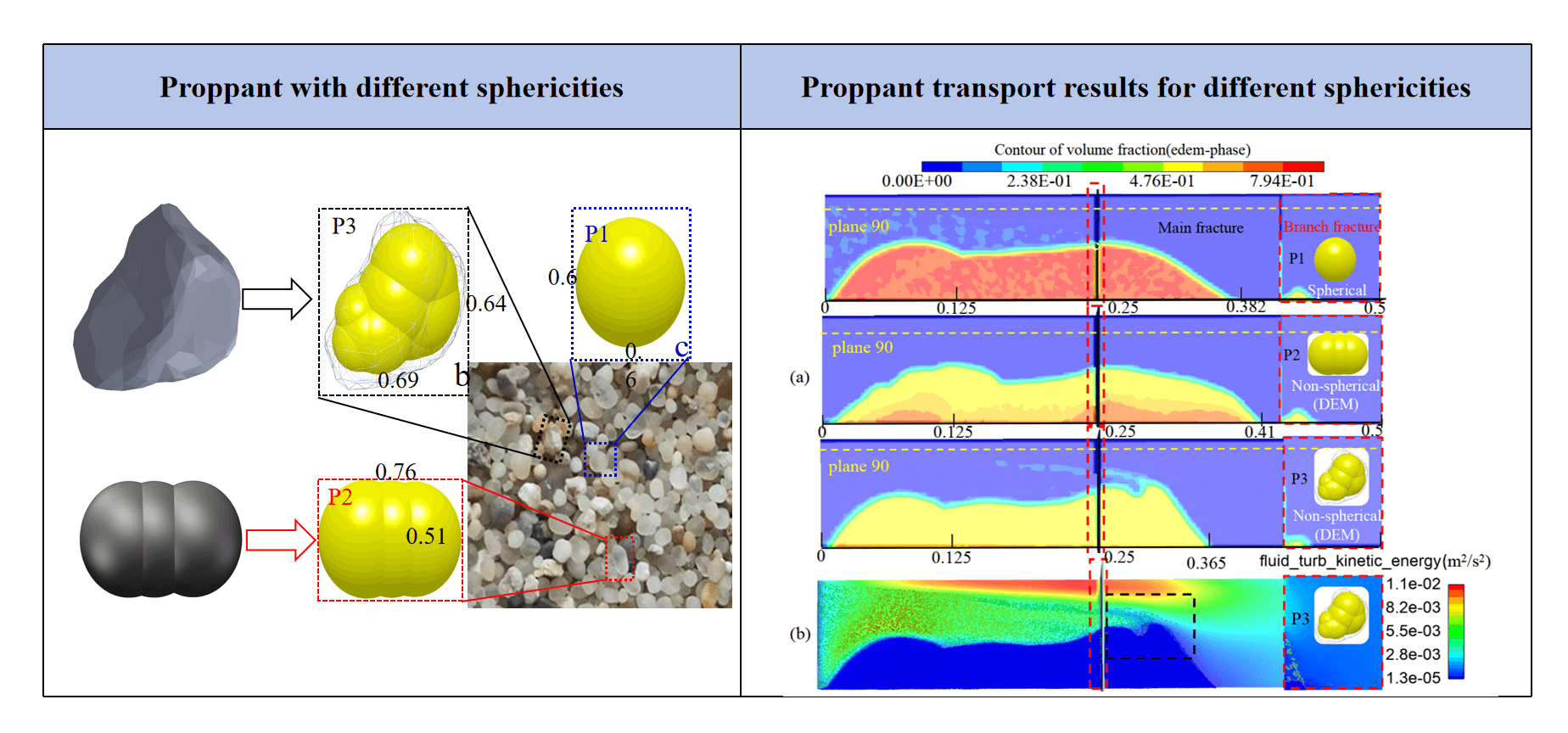

Study of the Transport Behavior of Multispherical Proppant in Intersecting Fracture Based on Discrete Element Method

1 CNOOC Research Institute Company Limited, Beijing, 100028, China

2 School of Petroleum Engineering, Yangtze University, Wuhan, 430100, China

3 Hubei Key Laboratory of Oil and Gas Drilling and Production Engineering (Yangtze University), Wuhan, 430100, China

* Corresponding Author: Biao Yin. Email:

(This article belongs to the Special Issue: Hydraulic Fracturing Theory and Application for Geo-energy Development)

Energy Engineering 2025, 122(1), 185-201. https://doi.org/10.32604/ee.2024.056062

Received 13 July 2024; Accepted 22 October 2024; Issue published 27 December 2024

Abstract

To analyze the differences in the transport and distribution of different types of proppants and to address issues such as the short effective support of proppant and poor placement in hydraulically intersecting fractures, this study considered the combined impact of geological-engineering factors on conductivity. Using reservoir production parameters and the discrete element method, multispherical proppants were constructed. Additionally, a 3D fracture model, based on the specified conditions of the L block, employed coupled (Computational Fluid Dynamics) CFD-DEM (Discrete Element Method) for joint simulations to quantitatively analyze the transport and placement patterns of multispherical proppants in intersecting fractures. Results indicate that turbulent kinetic energy is an intrinsic factor affecting proppant transport. Moreover, the efficiency of placement and migration distance of low-sphericity quartz sand constructed by the DEM in the main fracture are significantly reduced compared to spherical ceramic proppants, with a 27.7% decrease in the volume fraction of the fracture surface, subsequently affecting the placement concentration and damaging fracture conductivity. Compared to small-angle fractures, controlling artificial and natural fractures to expand at angles of 45° to 60° increases the effective support length by approximately 20.6%. During hydraulic fracturing of gas wells, ensuring the fracture support area and post-closure conductivity can be achieved by controlling the sphericity of proppants and adjusting the perforation direction to control the direction of artificial fractures.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools