Open Access

Open Access

ARTICLE

An Optimized Method for Accounting Information in Logistic Systems

1 Administrative Sciences Department, Community College, King Saud University, Riyadh, Saudi Arabia

2 Computer Science Department, Community College, King Saud University, P.O. Box 28095, Riyadh, 11437, Saudi Arabia

* Corresponding Author: Ahmad Ali AlZubi. Email:

Computer Systems Science and Engineering 2023, 45(2), 1595-1609. https://doi.org/10.32604/csse.2023.027971

Received 30 January 2022; Accepted 06 March 2022; Issue published 03 November 2022

Abstract

In the era of rapid information development, with the popularity of computers, the advancement of science and technology, and the ongoing expansion of IT technology and business, the enterprise resource planning (ERP) system has evolved into a platform and a guarantee for the fulfilment of company management procedures after long-term operations. Because of developments in information technology, most manual accounting procedures are being replaced by computerized Accounting Information Systems (AIS), which are quicker and more accurate. The primary factors influencing the decisions of logistics firm trading parties are investigated in order to enhance the design of decision-supporting modules and to improve the performance of logistics enterprises through AIS. This paper proposed a novel approach to calculate the weights of each information element in order to establish their important degree. The main purpose of this research is to present a quantitative analytic approach for determining the important information of logistics business collaboration response. Furthermore, the idea of total orders and the significant degrees stated above are used to identify the optimal order of all information elements. Using the three ways of marginal revenue, marginal cost, and business matching degree, the information with cumulative weights is which is deployed to form the data from the intersection of the best order. It has the ability to drastically reduce the time and effort required to create a logistics business control/decision-making system.Keywords

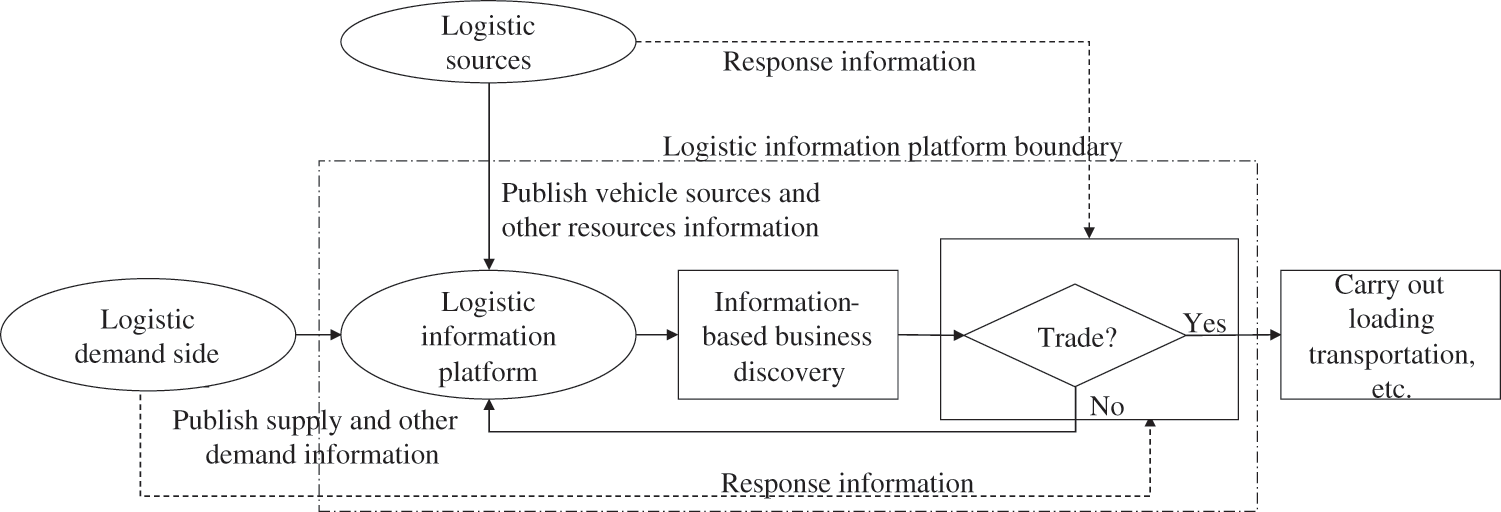

Logistics business is the object of logistics operation, including transportation, warehousing, packaging, etc. Among them, transportation is the core business. Carrying out logistics business operations through logistics information platforms and big data has become one of the main trends in future logistics operations [1–3]. In recent years, my country has successively established more than 200 different types of logistics information platforms or APPs, with different styles and different specifications and categories of business information provided. The logistics information platform realizes the aggregation and sharing of logistics business information, and improves the efficiency of logistics business discovery [4,5]. However, before the actual business operation starts, it generally involves three links: discovery, response, and transaction. As shown in Fig. 1, they affect each other and the result is uncertainty [6].

Figure 1: Transaction process based on logistics accounting information system

Due to the requirements of the logistics time effect, the timeliness of the response to the discovery of the logistics business determines whether the logistics business can be successfully executed, which in turn affects the operational efficiency and resource utilization of the corresponding business [7,8]. For example, for an empty vehicle that is going to return at a specific time, if the relevant source of goods that has learned the information does not respond before the departure time of the vehicle's return journey, it means that the vehicle cannot find the source of goods and must return with a low load or even no load [9–12]. Therefore, not controlling the response of the logistics business will greatly weaken the improvement efficiency of the logistics information platform on the operation of the logistics business [13–15]. The development of logistics information platform, especially after the active sharing economy, has attracted many scholars to carry out related research, but its research still focuses on the construction technology of logistics information platform [16], system structure [17,18] and application mode [19,20]. Although research on its operation has gradually emerged in recent years, such as the emergence of pricing [21] and auction mechanisms [22], especially business matching based on logistics information platforms, and discovery algorithms (such as matching) [23–25], but few people are involved in the research on response after logistics business discovery.

Since the logistics business involves both the supply and demand sides, the logistics business discovery method actually establishes the coupling relationship between multiple transaction parties of the logistics business through the logistics information platform organization. This means that the response to the logistics business actually requires a coordinated response in order to ensure that a specific business transaction is completed on schedule. Theoretically, the response process involves the following: the coupled transaction parties are related to the logistics information platform The interface checks the specific information of the discovered business (from recommendation or search), and then compares its own needs and analysis, and even conducts price games, income calculations, and decides whether to respond and trade. It can be seen that the response process to the logistics business is essentially a decision analysis process. The types and forms of specific information about a specific logistics business provided by the logistics information platform (interface) affect the coupling transaction. Through comparison and analysis of square processing, and then observe affects whether it can seize the opportunity to make decisions (i.e., decision-making speed [26]). For example, car owners usually consider revenue or transportation price when choosing to transport goods. If the logistics information platform directly provides the predicted revenue of the corresponding business, the car owner does not need to collect information, and can directly compare and eliminate concerns, reducing information collection in response to decision-making, machining action and time. Therefore, it is of great significance to optimize the corresponding design of the logistics information platform and provide reasonable decision support information about a specific business in a specific way. But there is a lot of information that affects everyone's decision-making, including the level of knowledge of traders, the benefits of business, and dozens of other types. If all are provided through the interface, it will greatly increase the design workload and difficulty of the decision support module corresponding to the logistics information platform. At the same time, if too much support information is provided, it will cause the prisoner's dilemma that the information is more abundant and the information is more insufficient [27]. Especially at present, many logistics information platform users obtain business information through mobile phones, that is, too much business support information will increase the decision-making analysis process of the transaction party and restrict the timeliness of the response. Therefore, it is necessary to determine the key information that affects the collaborative response of logistics business to drive the design of the corresponding information module, to ensure that the transaction decision makers of the logistics business response are provided with the most needed support information for their decision-making, and at the same time to avoid excessive information. At the same time, the existing research on decision support system rarely involves the information content and expression (including interface) of decision support.

In view of this, combined transportation is the core business of logistics business. Based on it, this paper determines the key information content of collaborative response control of logistics business by quantitatively calculating the weight of impact information to guide the logistics information platform (coordinated response control module). Optimize the design and provide key support information to the transaction parties, promote their rapid decision-making, and shorten the decision-making time. For the convenience of expression, the module dedicated to the coordinated response control of logistics business in the logistics information platform is called “coordinated response decision support system”.

2 Methods of Determining Key Impact Information

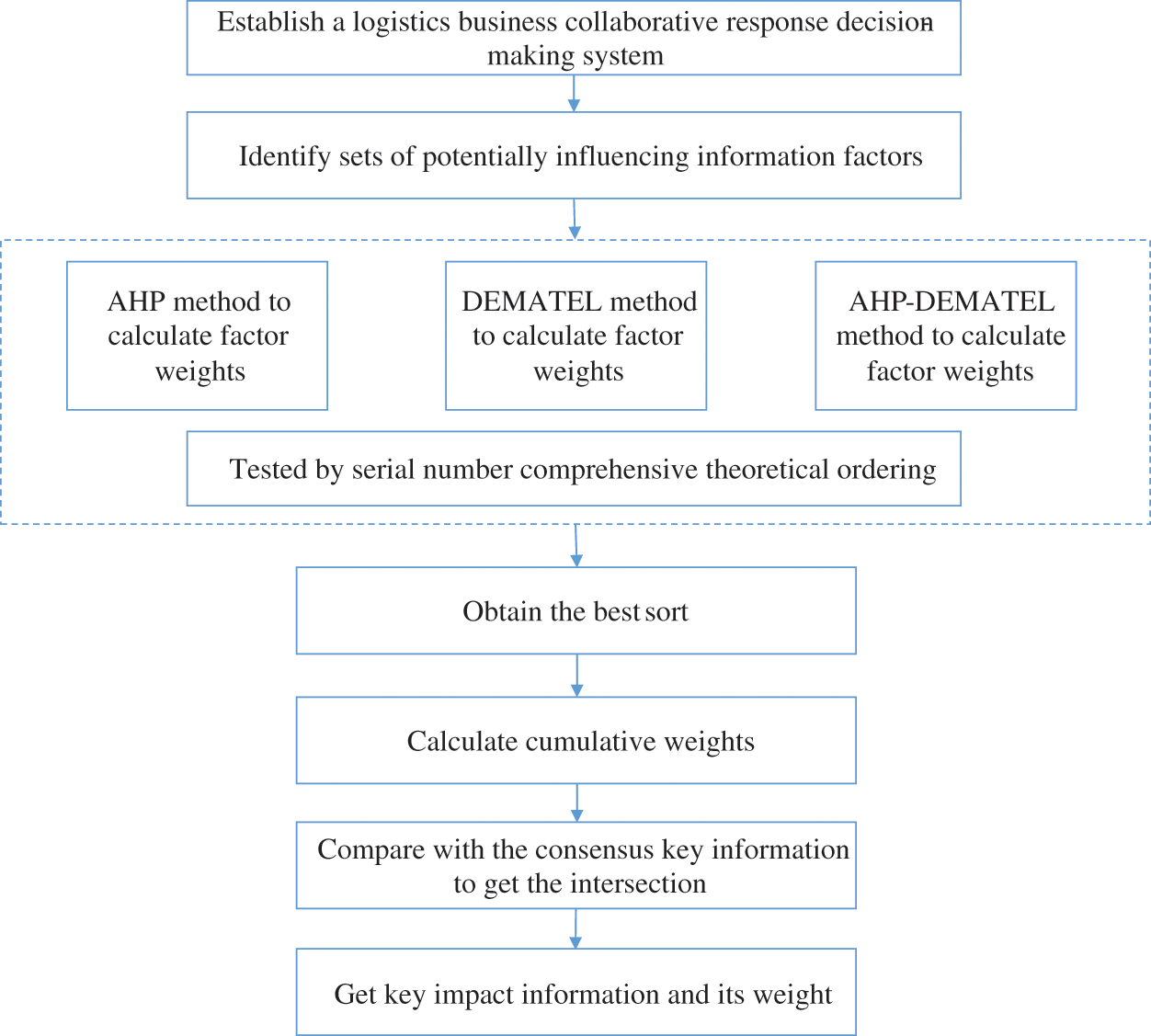

Based on the fact that the logistics business collaborative response process is the essence of the decision-making process, the decision-making system of the logistics business collaborative response is firstly constructed, and the factors affecting the decision-making in the system are determined as potential information. Then, for these information, the method of quantitative comparison and calculation of weights is adopted to reflect the importance of each information and sort it. Due to the lack of basic data on these factors, it is impossible to evaluate their importance through mathematical models and other methods. For this reason, the subjective weight evaluation method is selected. However, in order to avoid the subjective influence of each method and the randomness of the determined key information results and affect the design of the entire support system, the analytic hierarchy process (AHP), the decision-making trial and evaluation laboratory (DEMATEL) and the AHP-DEMATEL method were comprehensively selected. To calculate each information factor, reliability test is carried out by applying the summation theory of serial numbers to determine the optimal result. Then, the principal component idea is determined based on the principal component analysis method, and the information with a cumulative weight contribution rate greater than or equal to 85% is determined as the key impact information of the logistics business collaborative response. The intersection of key information is the consensus information, and the quantitative weight in the optimal method is used as its final weight. Its process is shown in Fig. 2.

Figure 2: Flow for determining the coordinated responses to control critical information

Let the weight of the i-th information be wi, and the calculation methods in the three methods are as follows.

(1) AHP selects the root value method to normalize the judgment matrix to obtain the weight.

In the formula,

(2) The formula for DEMATEL to calculate the weight is [28] expressed as follows:

In the formula,

(3) AHP-DEMATEL calculate the weight as follows:

In the formula,

3 Potential Impact Information Identification

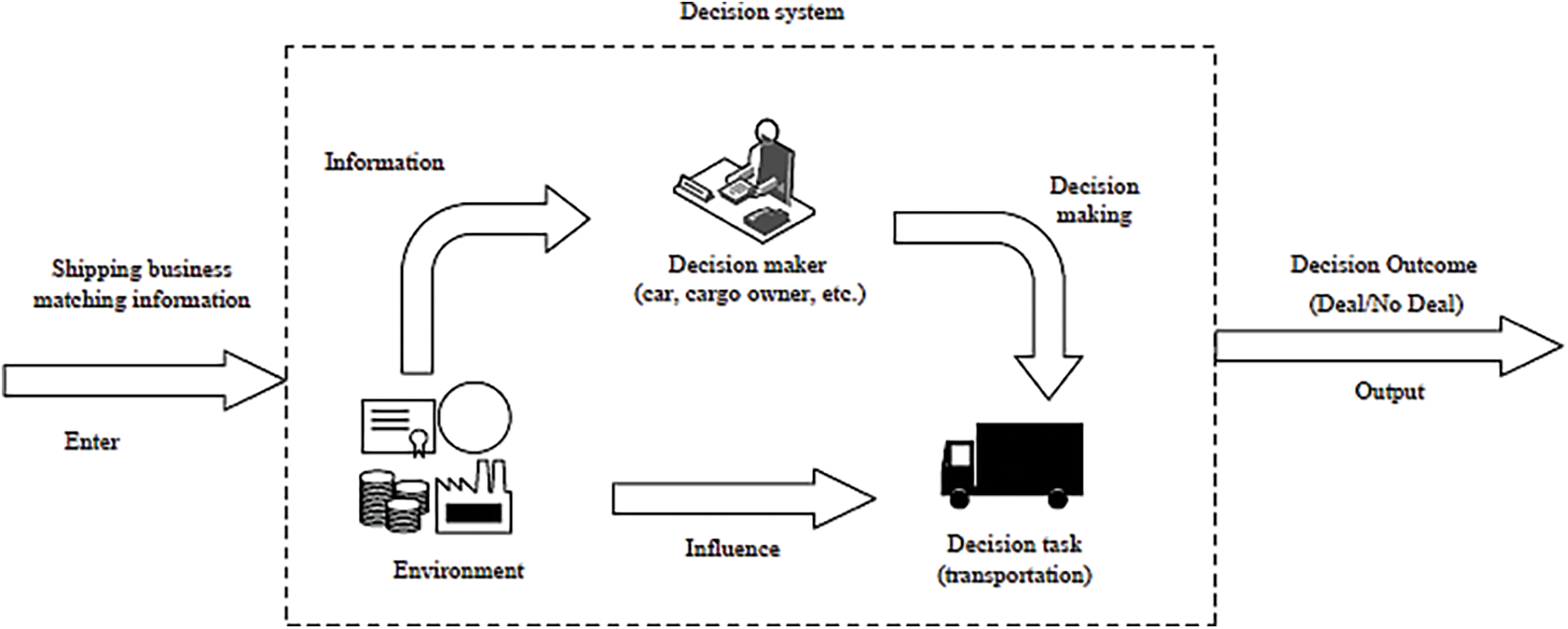

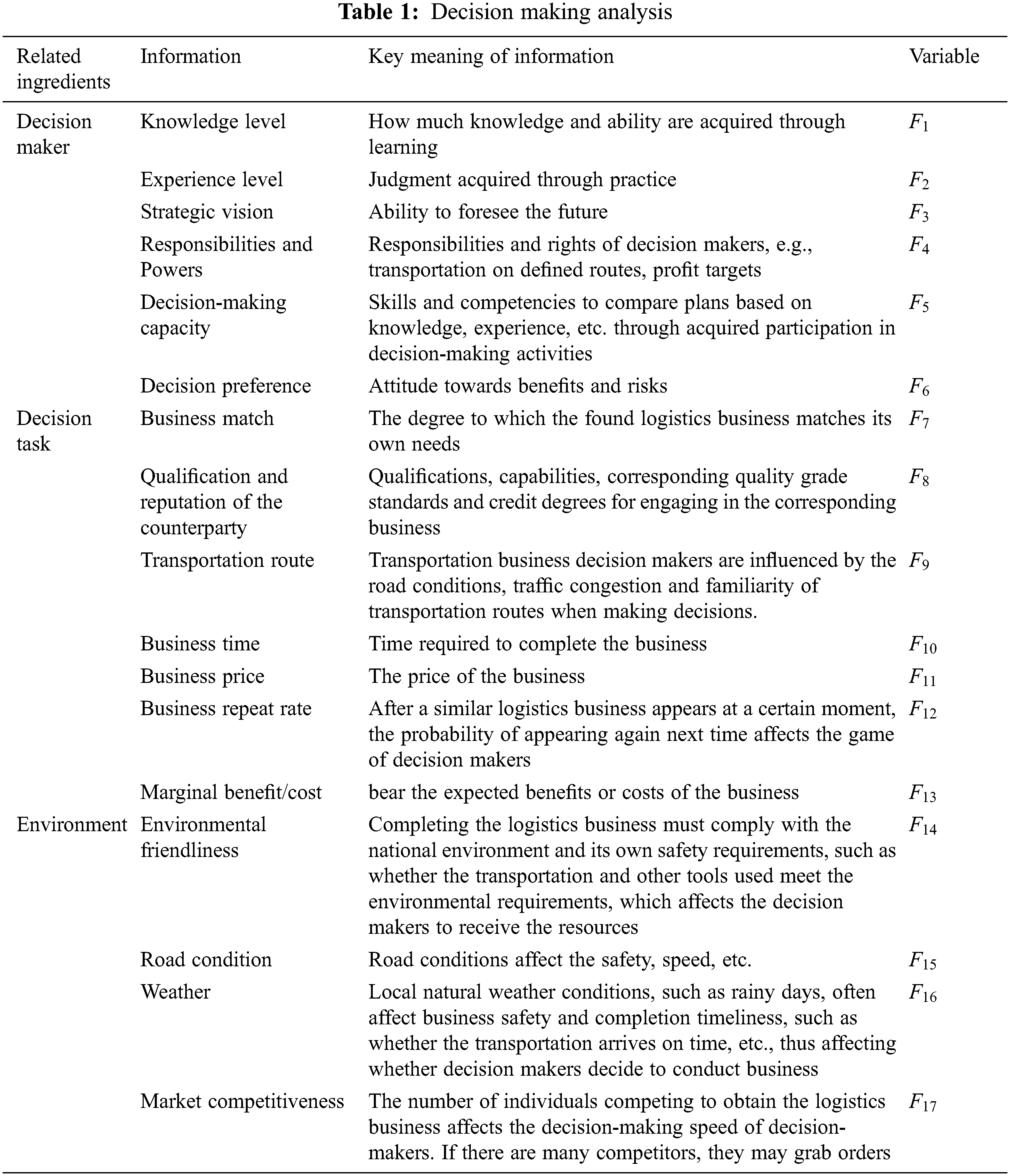

In the logistics business transaction environment based on the logistics information platform, the collaborative response process to the logistics business itself is a multi-party coupled decision-making process, but each transaction party makes an independent decision after obtaining business information from the logistics information platform, and the transaction decision makers make decisions. The information obtained in the process about the decision-making task affects the timeliness and results of completing the decision. Therefore, by incorporating the decision-related elements into the decision-making system, that is, the logistics business decision-making system, the initial impact information of the coordinated response of the logistics business can be obtained from the perspective of the influencing factors of the components of the logistics business decision-making system. Based on this, taking the transportation business as an example, the logical structure of the logistics business decision-making system is constructed, as shown in Fig. 3. From the three aspects of decision-maker, decision-making task and environment, 17 potential factors affecting the decision-making speed of logistics business were identified, as shown in Tab. 1.

Figure 3: AIS decision system

4 Determination of Key Information Content

4.1 Information Importance Calculation for Unit Methods

4.1.1 The Importance of AHP Calculation

Based on the principle of AHP, according to the relationship between the elements in Tab. 1, a hierarchical structure of factors influencing logistics business decision-making is constructed. Affects the information layer (information in Tab. 1). Based on the two-factor comparison method, consult customers and experts of logistics company and other units to construct a judgment matrix, set n = 17 in Eq. (1), use MATLAB software to calculate, after passing the consistency test, solve the weight of each influence information (due to space limitations, the obtained judgment matrix and solution process are not listed).

4.1.2 The Degree of Importance Calculated by the DEMATEL Method

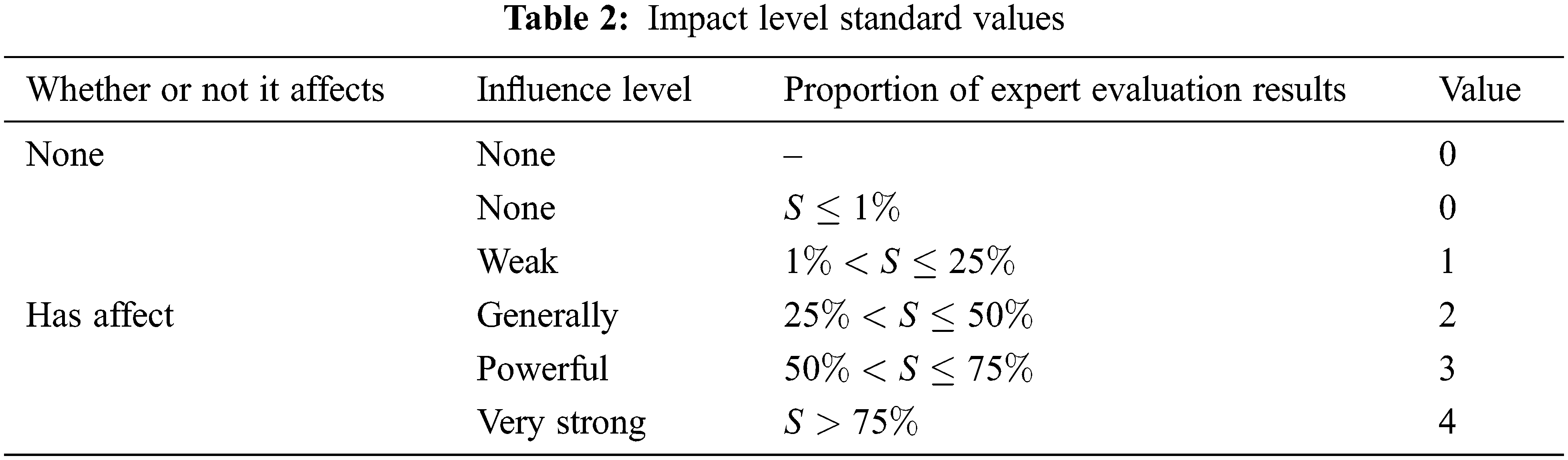

After consulting the experts of Guangxi AI Logistics Company and other enterprises, after the statistics of the relationship between the influencing factors given by the experts, the score of the statistical result S is calculated according to Tab. 2, and the direct influence matrix X is constructed with the score, which is denoted as:

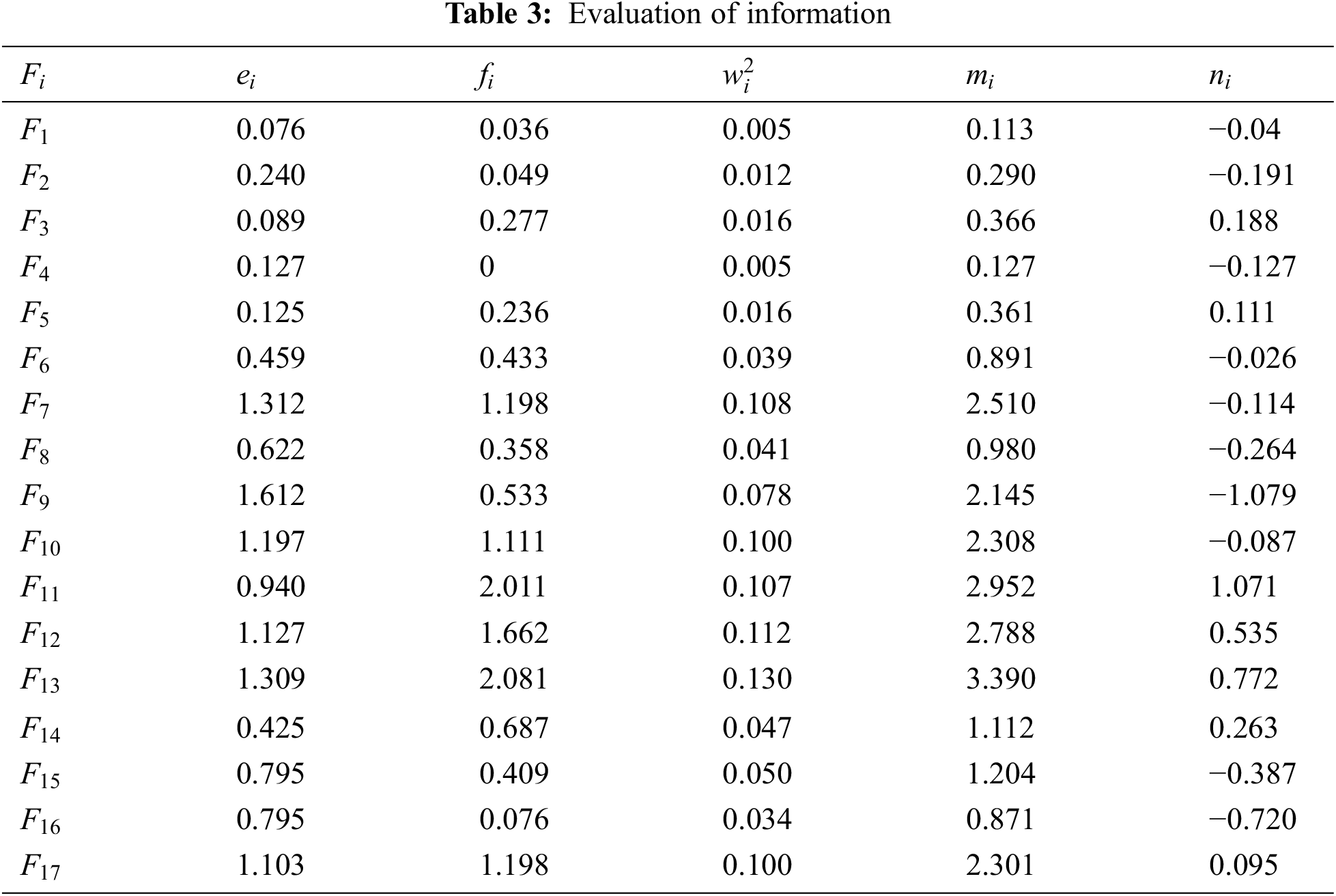

From Tab. 3, the importance ranking of each influencing information factor of logistics business collaborative response based on DEMATEL method is

4.1.3 The Importance of AHP-DEMATEL Method Calculation

It is calculated according to Eq. (4) from Tab. 3, and then comprehensive weight according to Eq. (3), and then through normalization, a new comprehensive weight vector is obtained as (0.001, 0.002, 0.011, 0.001, 0.008, 0.023, 0.234, 0.010, 0.018, 0.073, 0.119, 0.150, 0.271, 0.013, 0.007, 0.005, 0.054). Then the importance order under this weight is

4.2 Optimal Information Sequence

The key information determines the design of the collaborative response decision support system, and the method used is subject to a certain degree of subjectivity. The test is carried out by applying the summation theory of serial numbers. The summation of serial number theory considers the differences in the ranking of a research object by various methods, and adds the ranking numbers of different methods to obtain the sum of the serial numbers. The objective ranking is used as an ideal reference standard for testing the ranking results of each method. The consistency can be checked by calculating the Spearman rank correlation coefficient between the ranking of various methods and the reference ranking. The calculation formula is as follows:

In the formula,

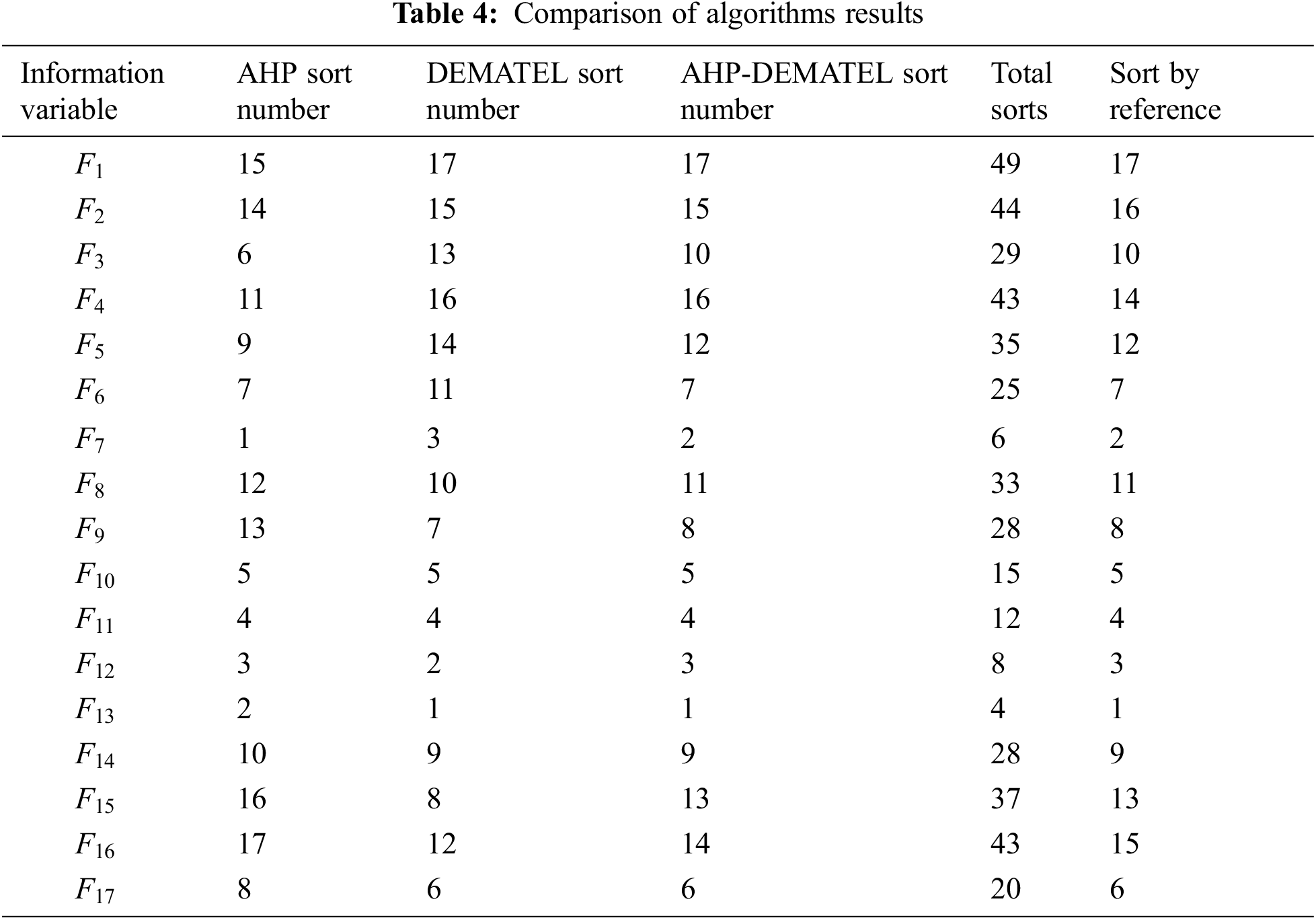

The Spearman rank coefficients of such methods relative to the sum of ordinal numbers were calculated to be 0.892, 0.912, 0.993, respectively. It can be seen that among the three methods, the difference between AHP and the total serial number ranking is the largest, because it is highly subjective and does not consider the influence of factors. The proposed method has the largest Spearman coefficient and is the best method. The result is the independent application method. The best ranking is close to the total serial number ranking, and only shows a small difference in F2, F4, and F16 factors, which has been relatively objective. Therefore, the proposed method can reduce the influence of subjective factors, which is consistent with other studies [29]. For simplicity, the proposed method can be directly applied to obtain the ranking and key factors [30].

4.3 Determination of Key Information Content

In theory, all 17 informational contents in Tab. 1 should be presented in the collaborative response control and support the trader in a suitable form. For example, according to the “decision preference F6” to provide the preferred matching business results, this will undoubtedly cause a huge workload of system design, and will also increase the complexity of the interface and the workload of user browsing, but it is known from the previous calculation that its impact on decision makers vary, and all offer value is not great. To this end, it is refined by accumulating weights [31−35].

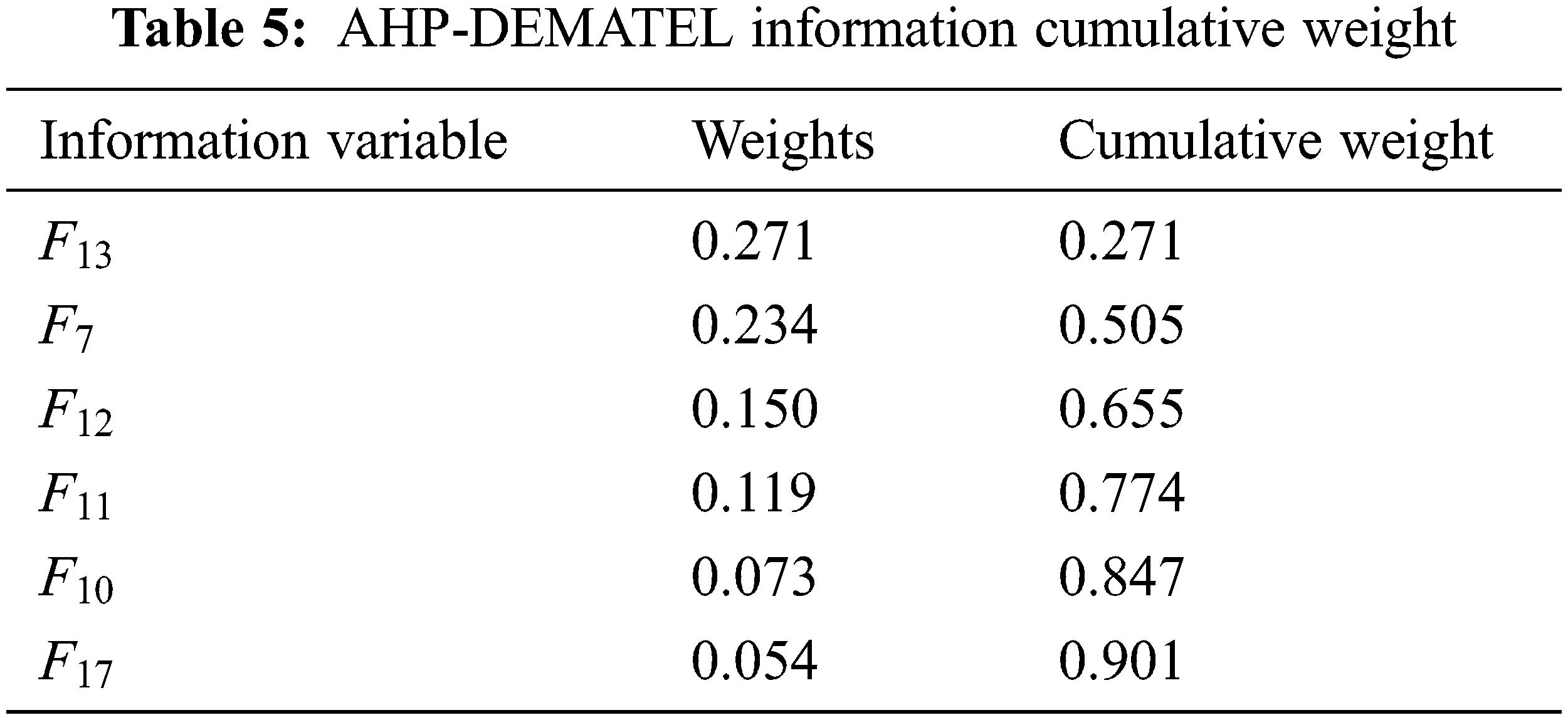

Since the ranking of the proposed method is the optimal ranking and the results are preferentially selected to calculate the cumulative weight, as shown in Tab. 5. Taking the cumulative weight of 0.85 as the boundary, the determined key information is “marginal benefit/cost (F13), business matching degree (F7), business reproduction probability (F12), business price (F11), business consumption time (F10), market competitiveness (F17)”, denoted as K1 = {F13, F7, F12, F11, F10, F17}.

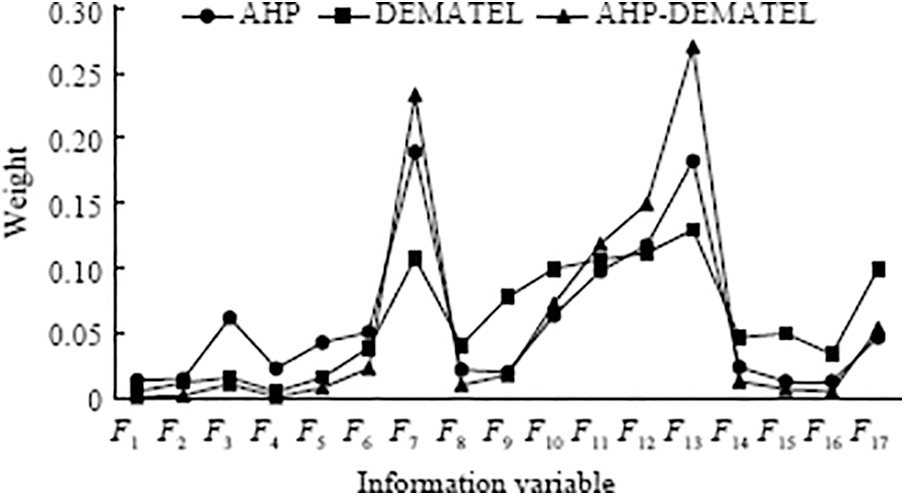

Comparing the number of key information determined by the three methods, it can be seen that the number of key information obtained by the proposed method is the least, and it has more key connotations, which also shows that this method has an obvious role in highlighting key effects. The weights of each factor under the three methods reflect this effect, as shown in Fig. 4. The maximum weight under AHP is 0.19, and the maximum and minimum weight ratio is 14.6. While DEMATEL is only 0.13, the maximum and minimum weight ratio is 26. However, under AHP-DEMATEL, the maximum weight reaches 0.27, which is almost 2 times that of DEMATEL, and the maximum and minimum weight ratio reaches 271, which widens the gap of importance, so that the cumulative weight value of the first 6 pieces of information has exceeded 0.9. This reflects that the proposed method has more convergent effect on the importance of factors [36,37].

Figure 4: Comparison of information weight of different algorithms

It can be seen that there are certain differences in the importance ranking of logistics business response support information based on those methods, but the overall results are roughly similar. The key information of the comprehensive logistics business collaborative response control is marginal benefit/cost, business matching degree, business reproduction probability, business price, business consumption time and market competitiveness. Tab. 5 shows the importance weight.

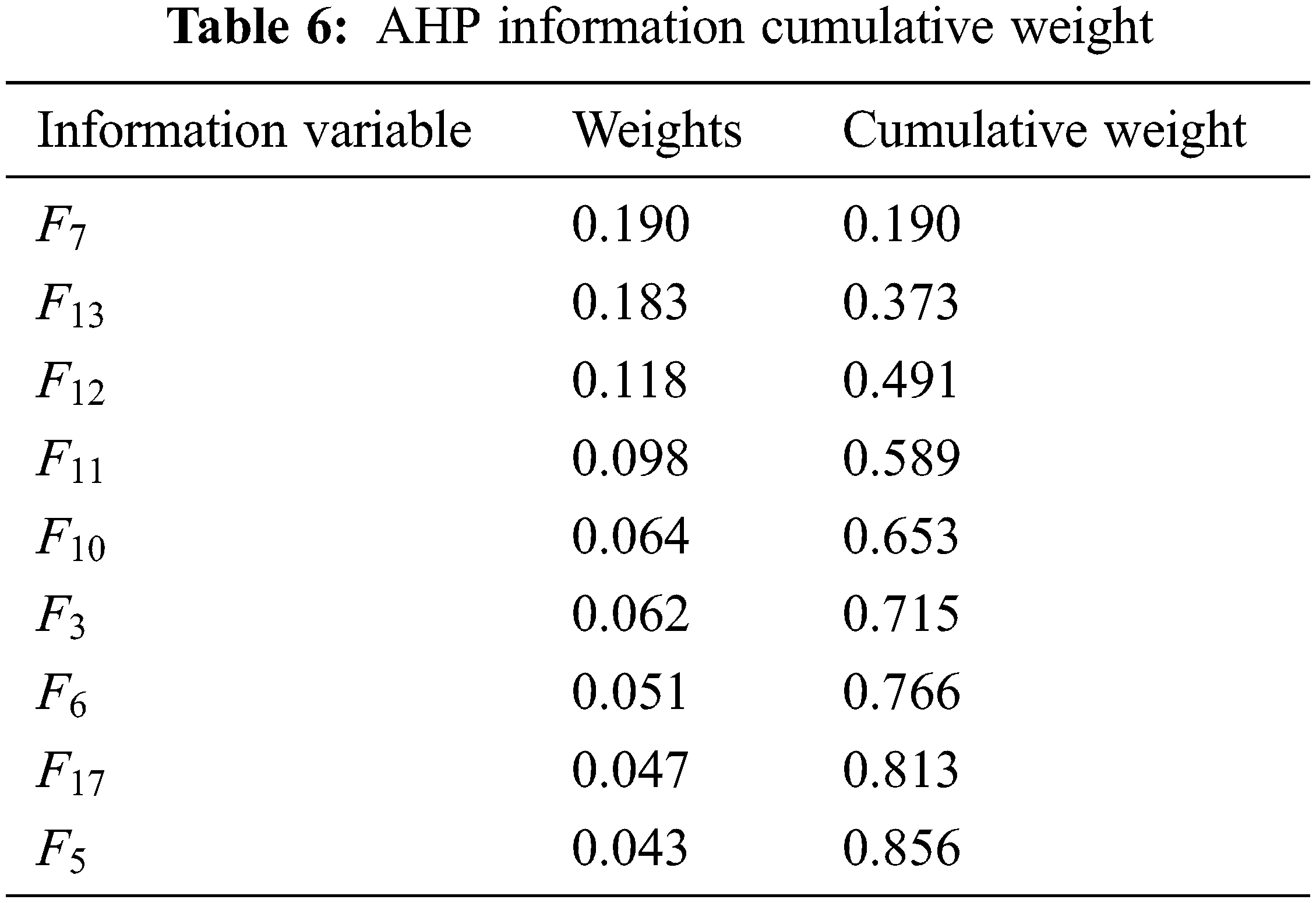

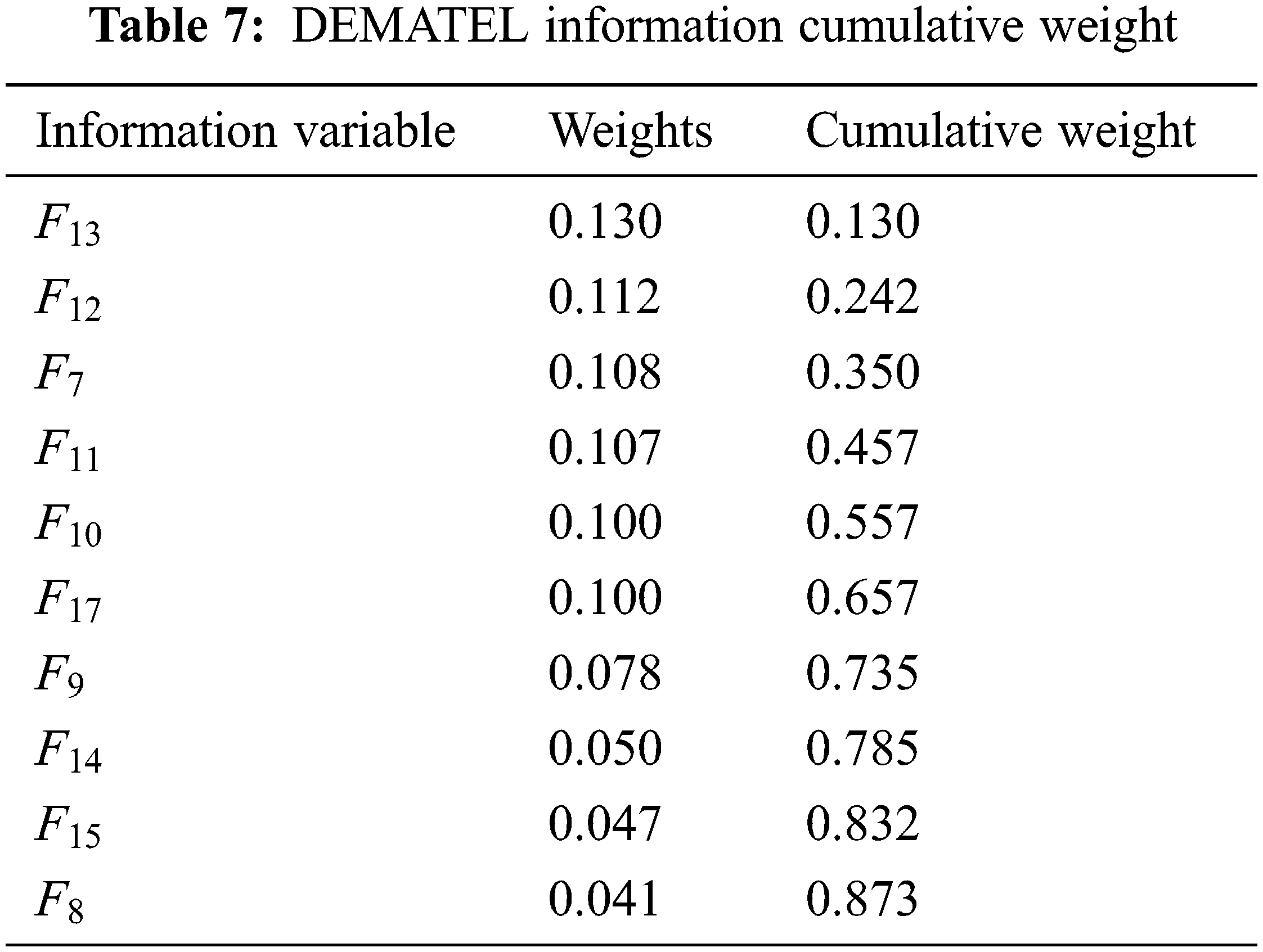

Then calculate the cumulative weights of the AHP and DEMATEL methods respectively, as shown in Tabs. 6 and 7. Taking the cumulative weight of 0.85 as the boundary, there are 9 key information under AHP, including business matching degree (F7), etc., which are denoted as K2 = {F7, F13, F12, F11, F10, F3, F6, F17, F5}. There are 10 key pieces of information in the DEMATEL method, denoted as K3 = {F13, F12, F7, F11, F10, F17, F9, F14, F15, F8}.

Thus, the intersection of the key factors under the three methods is KJ = {F13, F7, F12, F11, F10, F17} = K1. This also shows that the key informative factors can be obtained by directly applying the proposed method.

5 Applications Based on Critical Information

The collaborative response decision support system takes the matching result of the logistics information platform as input, presents the result and its relationship to the transaction parties of the business, and provides the interface of response control and the algorithm of coupling control. The determination of key information provides the basis for the design of the decision support system, which greatly simplifies the design and development workload of the decision support system, especially the design of the source method of information data and the design of information expression method (including interface) are reduced by about 2/3. Because this main information generally needs to be obtained by integrating a variety of information, such as the matching degree of the business, in the matching of vehicles and goods, various information such as the vehicle, the origin of the goods, time, flow direction, weight, etc. should be comprehensively considered, and the matching degree There are different calculation methods.

Based on the above information, their calculation methods and their expressions (including interfaces) are established to reduce the time for transaction parties to obtain information and make decisions. For example, Eq. (7) establishes the calculation method of business consumption time.

In the formula,

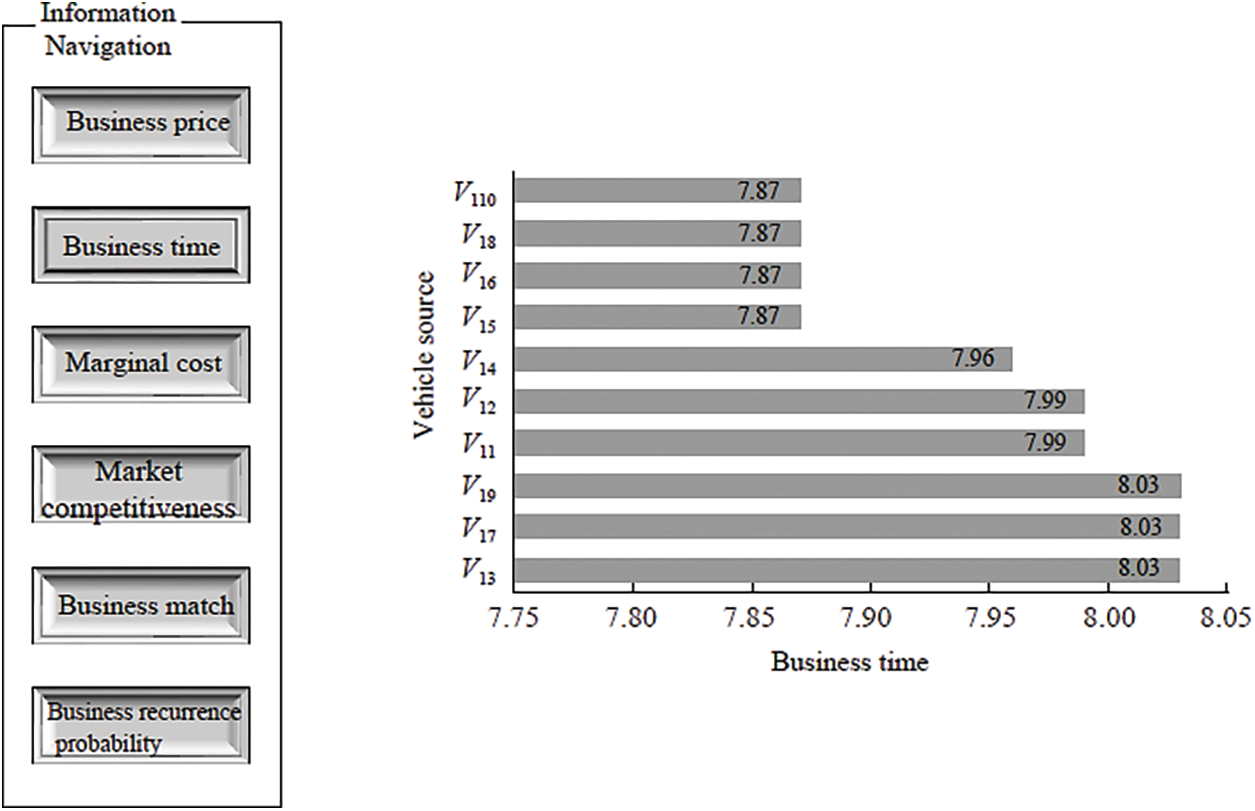

Fig. 5 is an example of the designed business consumption time expression. The whole expression framework is divided into two parts. On the left is the navigation bar of the key information determined earlier. We can switch to browse several kinds of information. The initial order is based on the weights in Tab. 5. The information with larger weights is located at the top, which can be adjusted according to the frequency of use to provide personalization. Interface. On the right is the specific expression content and method of each type of information. The relevant transaction parties can directly and quickly obtain the vehicle source with the least business time consumption matched by the current logistics information platform from this information, without the need for excessive information processing and improving the response efficiency.

Figure 5: AIS-logistics control model and evaluation

The collaborative response process of logistics business is essentially a coupled decision-making process. The timeliness of response and decision-making determines the benefit of decision-making, which in turn affects the development of logistics business and the optimal utilization of resources. Obtaining the key information that affects the response and decision-making of the transaction party plays an important role in realizing the decision-making benefit and optimizing the design of the corresponding support system of the logistics information platform. This paper proposes a quantitative analysis method to determine the key information of logistics business collaborative response.

From the perspective of decision-making, it can be seen that there are 17 types of information that affects the transaction party’s timely response and decision-making, or the information that the transaction party wants to obtain, business price, business time consumption, market competitiveness, and the weights are “0.271, 0.234, 0.150, 0.119, 0.073, 0.054” respectively. They are the basis for the design of the logistics business collaborative response control decision-making system, which greatly offload the logistics decision-making system. Providing these types of information by design not only provides the necessary support information for decision-making in the logistics business response, but also avoids excessive information, provides assurance for accelerated decision-making, and greatly reduces the design workload of the corresponding support system. This research can provide references for other decision support system designs, especially the impact of decision speed on benefits to research on impact.

In the future, we will address other important aspects of this study in the context of blockchain and ERP.

Acknowledgement: The authors extend their appreciation to King Saud University for funding this work.

Funding Statement: This work was supported by the Researchers Supporting Project (No. RSP-2021/395), King Saud University, Riyadh, Saudi Arabia.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. J. Wu, F. Xiong and C. Li, “Application of Internet of Things and blockchain technologies to improve accounting information quality,” IEEE Access, vol. 7, pp. 100090–100098, 2019. [Google Scholar]

2. A. Monteiro and C. Cepeda, “Accounting information systems: Scientific production and trends in research,” Systems Journal, vol. 9, no. 3, pp. 1–15, 2021. [Google Scholar]

3. H. Kareem, M. Dauwed, A. Meri, M. Jarrar, M. Bsheish et al., “The role of accounting information system and knowledge management to enhancing organizational performance in Iraqi SMEs,” Sustainability Journal, vol. 13, no. 22, pp. 1–28, 2021. [Google Scholar]

4. A. Faccia and P. Patratos, “Blockchain, enterprise resource allocation (ERP) and accounting information systems (AISResearch on e-procurement and system integration,” Applied Sciences, vol. 11, no. 15, pp. 1–29, 2021. [Google Scholar]

5. M. Li, W. Wei, J. Wang and X. Qi, “Approach to evaluating accounting informatization based on entropy in intutionistic fuzzy environment,” Entropy Journal, vol. 20, no. 6, pp. 1–24, 2018. [Google Scholar]

6. A. Monteiro, J. Vale and A. Silva, “Factors determining the success of decision making and performance of portuguese companies,” Administrative Sciences, vol. 11, no. 4, pp. 1–16, 2021. [Google Scholar]

7. A. Stroumpoulis, E. Kopanaki and G. Karaganis, “Examining the relationship between information systems, sustainable SCM, and competitive advantage,” Sustainability Journal, vol. 13, no. 21, pp. 1–18, 2021. [Google Scholar]

8. E. Walinska and J. Dobroszek, “The functional controller for sustainable and value chain management: Fashion or need? A sample of job advertisements in the COVID-10 period,” Sustainability Journal, vol. 13, no. 3, pp. 1–28, 2021. [Google Scholar]

9. E. Segura and M. Zamar, “Research analysis on emerging technologies in corporate accounting,” Mathematics Journal, vol. 8, no. 9, pp. 1–17, 2020. [Google Scholar]

10. M. Pomberg, H. Pourjalali, S. Daniel and M. Kimbro, “Management accounting information systems: A case of a developing country: Vietnam,” Asia-Pacific Journal of Accounting & Economics, vol. 19, no. 1, pp. 100–114, 2012. [Google Scholar]

11. E. Bonson, D. Lavorato, R. Lambogia and D. Mancini, “Artificial intelligence activities and ethical approaches in leading listed companies in the European Union,” International Journal of Accounting Information Systems, vol. 43, no. 8, pp. 1265–1281, 2021. [Google Scholar]

12. Q. Khalid, M. Arshad, S. Maqsood, M. Jahanzaib, A. R. Babar et al., “Hybrid particle swarm algorithm for products scheduling problem in cellular manufacturing,” Symmetry Journal, vol. 11, no. 6, pp. 1–21, 2019. [Google Scholar]

13. M. Farooq, Q. Salman, M. Arshad, I. Khan, R. Akhtar et al., “An artificial bee colony algorithm based on a multi-objective framework for supplier integration,” Applied Sciences, vol. 9, no. 3, pp. 1–15, 2019. [Google Scholar]

14. C. Lu, M. Zhao, I. Khan and P. Uthansakul, “Financing strategy of low-carbon supply chain with capital constraint under cap-and-trade regulation,” Computers, Materials & Continua, vol. 66, no. 1, pp. 437–455, 2020. [Google Scholar]

15. X. Tang, “Research on smart logistic model based on internet of things technology,” IEEE Access, vol. 8, pp. 151150–151159, 2020. [Google Scholar]

16. S. Bello, L. Oyedele, O. Akinade, M. Bilal, J. Manuel et al., “Cloud computing in construction industry: Use cases, benefits and challenges,” Automation in Construction, vol. 122, no. 8, pp. 2388–2411, 2021. [Google Scholar]

17. P. Helo, Y. Hao, R. Toshev and V. Boldosova, “Cloud manufacturing ecosystem analyssis and design,” Robotics and Computer-Integrated Manufacturing, vol. 67, no. 3, pp. 814–823, 2021. [Google Scholar]

18. E. Irannezhad, “The architectural design requirements of a blockchain-based port community system,” Logistics Journal, vol. 4, no. 4, pp. 1–14, 2020. [Google Scholar]

19. S. Chen, Y. Chen and C. Hsu, “A new approach to integrate Internet-of-Things and software-as-a-service model for logistic systems: A case study,” Sensors Journal, vol. 14, no. 4, pp. 1–15, 2014. [Google Scholar]

20. F. Kitsios, M. Kamariotou and E. Grigoroudis, “Digital entrepreneurship services evolution: Analysis of quadruple and quintuple helix innovation models for open data ecosystems,” Sustainability, vol. 13, no. 21, pp. 1–19, 2021. [Google Scholar]

21. S. Ji and Q. Feng, “Study on the casual feedback relationship of regional logistics information platform service innovation factors based on system dynamics,” in IEEE Int. Workshop on Advanced Research and Technology in Industry Applications (WARTIA), Ottawa, Canada, pp. 912–918, 2014. [Google Scholar]

22. H. Huang, L. Liu, G. Parker, Y. Tan and H. Xu, “Multi-attribute procurement auctions in the presence of satisfaction risk,” Production and Operations Management, vol. 28, no. 5, pp. 1206–1221, 2019. [Google Scholar]

23. A. Vargas, C. Fuster and D. Corne, “Towards sustainable collaborative logistics using specialist planning algorithms and a gain-sharing business model: A UK case study,” Sustainability, vol. 12, no. 16, pp. 1–26, 2020. [Google Scholar]

24. M. Feng and Y. Cheng, “Solving truck-cargo matching for drop-and-pull transport with genetic algorithm based on demand-capacity fitness,” Alexandria Engineering Journal, vol. 60, no. 1, pp. 61–72, 2021. [Google Scholar]

25. F. Noor, S. Padmanaban, L. Popa, M. Mollah and E. Hossain, “A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development,” Energies, vol. 10, no. 8, pp. 1–32, 2017. [Google Scholar]

26. Q. Wen, M. Qiang and P. Gloor, “Speeding up decision-making in project environment: The effects of decision makers’ collaboration network dynamics,” International Journal of Project Management, vol. 36, no. 3, pp. 819–831, 2018. [Google Scholar]

27. L. Xiao, Q. Lu and F. Guo, “Mobile personalized recommendation model based on privacy concerns and context analysis for the sustainable development of m-commerce,” Sustainability Journal, vol. 12, no. 7, pp. 1–28, 2020. [Google Scholar]

28. S. Altuntas and T. Dereli, “A novel approach based on DEMATEL method and patient citation analysis for prioritizing a portfolio of investment projects,” Expert Systems with Applications, vol. 42, no. 3, pp. 1003–1012, 2015. [Google Scholar]

29. S. Greco, A. Ishizaka, M. Tasiou and G. Torrisi, “On the methodological framework of composite indices: A review of the issue of weighting, aggregation, and robustness,” Social Indicators Research, vol. 141, no. 1, pp. 61–94, 2019. [Google Scholar]

30. K. Kijewska, W. Torbacki and S. Iwan, “Application of AHP and DEMATEL methods in choosing an analyzing the measures for the distribution of goods in Szczecin region,” Sustainability, vol. 10, no. 7, pp. 1–27, 2018. [Google Scholar]

31. W. Sun, G. Z. Dai, X. R. Zhang, X. Z. He and X. Chen, “TBE-Net: A three-branch embedding network with part-aware ability and feature complementary learning for vehicle re-identification,” IEEE Transactions on Intelligent Transportation Systems, vol. 23, no. 3, pp. 1–13, 2022. [Google Scholar]

32. W. Sun, L. Dai, X. R. Zhang, P. S. Chang and X. Z. He, “RSOD: Real-time small object detection algorithm in UAV-based traffic monitoring,” Applied Intelligence, vol. 3, pp. 1–16, 2021. [Google Scholar]

33. G. Koca and S. Yildirim, “Bibliometric analysis of DEMATEL method,” Decision Making: Applications in Management and Engineering, vol. 4, no. 1, pp. 85–103, 2021. [Google Scholar]

34. M. Bakir and O. Atalik, “Application of fuzzy AHP and fuzzy marcos approach for the evaluation of e-service quality in the airline industry,” Decision Making: Applications in Management and Engineering, vol. 4, no. 1, pp. 127–152, 2021. [Google Scholar]

35. A. Blagojevic, S. Veskovic, S. Kasalica and A. Gojic, “The application of the fuzzy AHP and DEA for measuring the efficiency of freight transport railway undertaking,” Journal of Operational Research in Engineering Sciences: Theory and Applications, vol. 3, no. 2, pp. 1–23, 2020. [Google Scholar]

36. A. Alossta, O. Elmansouri and I. Ibadi, “Resolving a location selection problem by means of an integrated AHP-RAFSI approach,” Reports in Mechanical Engineering, vol. 2, no. 1, pp. 135–142, 2021. [Google Scholar]

37. N. Osintev, A. Rakhmangulov and V. Baginova, “Evaluation of logistic flows in green supply chains based on combined DEMATEL-ANP method,” Facta Universitatis: Mechanical Engineering Journal, vol. 19, no. 3, pp. 473–498, 2021. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools