Open Access

Open Access

ARTICLE

Analysis on Operational Safety and Efficiency of FAO System in Urban Rail Transit

Department of Traffic Engineering, College of Urban Rail Transit and Logistics, Beijing Union University, Beijing, China

* Corresponding Authors: Jin Zhou. Email: ; Di Sun. Email:

Computers, Materials & Continua 2023, 77(3), 3677-3696. https://doi.org/10.32604/cmc.2023.038660

Received 23 December 2022; Accepted 20 April 2023; Issue published 26 December 2023

Abstract

This paper discusses two urgent problems that need to be solved in fully automatic operation (FAO) for urban rail transit. The first is the analysis of safety in FAO, while another is the analysis of efficiency in FAO. Firstly, this paper establishes an operational safety evaluation index system from the perspective of operation for the unique or typical risk sources of the FAO system, and uses the analytic hierarchy process (AHP) to evaluate the indicators, analyzes various factors that affect the safe operation of FAO, and provides safety management recommendations for FAO lines operation to maintain the FAO system specifically. Secondly, taking the Yanfang Line as an example, this paper uses OpenTrack software to analyze the efficiency of FAO operation, and conducts simulation calculations for key links such as the mainline tracking interval, train entry and exit, and return limit interval. The fault impact surface of the FAO trains is simulated and discussed to verify whether FAO can meet the long-term operation requirements of Yanfang Line. Finally, this paper compares the simulation data of FAO on the Yanfang Line with manual operation (MO) to verify the advantages of FAO and guide the engineering construction of subsequent fully automated driving lines.Keywords

With the acceleration of urbanization, rail transit has become an indispensable means of transportation for people life and travel. By the end of 2021, a total of 50 cities have opened urban rail transit, with 283 operating lines and a total operating line length of 9,206.8 kilometers. Among them, the subway operating lines are 1997.1 kilometers, accounting for 78.3% of the whole urban rail transit system [1,2]. To maintain this late-mover advantage in the future and realize “curve overtaking” in the application of science and technology, the application of new technologies represented by FAO is essential. Now 14 cities in the mainland of China, namely, Beijing, Shanghai, Tianjin, Chongqing, Guangzhou, Shenzhen, Wuhan, Chengdu, Suzhou, Ningbo, Nanjing, Jinan, Taiyuan and Wuhu, opened their FAO system lines. The current existing 23 lines cover a distance of 554 kilometers [3]. The “Outline for the Development of Intelligent Urban Rail in China’s Urban Rail Transit” proposes that the goals in 2025 is the continuous improvement and optimization of the FAO of urban rail, the application scope further expanded, requirements communicated and interconnected, and make it possible for China’s FAO technology to compete in the international market, and the goal in 2035 is the technology is mature, the market share of the FAO system in the international market gradually increased, and the technology taking a leading role in the world [4].

According to the statistics of the Union Internationale des Transports Publics (UITP), by 2030 the total number of kilometers of FAO line in the word will increase more than three times compared with that of the number in the end of 2018, most of which are contributed by China. Therefore, the next 10 years will be a golden period for China’s FAO system of urban rail transit [5]. To ensure the orderly development of the FAO technology in China’s urban rail transit, explore the potential of China’s urban rail transit and improve the service and competitiveness of China’s urban rail transit, it is necessary to study the safety and efficiency of FAO in China’s urban rail transit.

Compared with MO systems, FAO has the characteristics of high efficiency, safety and low cost. At the same time, it also puts forward higher requirements for operation and maintenance technicians. The FAO system mainly uses an automatic operation control system to replace the driver to control train operation [6]. This results in the management and technical solutions for MO system not being applicable to the FAO system. The FAO system has highly centralized characteristics, so it is crucial to establish sound operational safety management and efficiency technical solutions for the FAO system.

Therefore, this paper focuses on the analysis of safety and efficiency of FAO systems. The contributions of this paper are summarized as follows:

(1) Based on the collection of statistics on FAO system failure events and combined with the experience of railway industry experts, this paper identifies the unique or typical risk sources of FAO systems and establishes an operational safety evaluation index system for risk sources from the perspective of operation. The AHP is used to evaluate each index and analyze the various factors that affect the safe operation of FAO systems. The ranking of weights for various factors that affect the safe operation of FAO systems is obtained to provide safety management recommendations for the operation of FAO lines, in order to facilitate targeted maintenance of FAO systems.

(2) The Beijing Metro Yanfang Line is the first fully autonomous and FAO system line in China, while is a demonstration project for China’s FAO line [7–9]. Therefore, this paper uses the Yanfang Line as an example to analyze the efficiency of FAO systems using OpenTrack software. The paper conducts simulated calculations of train operation for key operational links to verify whether FAO can meet the long-term operational requirements of the Yanfang Line. The paper also compares the simulated data of FAO on the Yanfang Line with MO to verify the advantages of FAO, providing a theoretical basis for guiding the engineering construction of subsequent fully automated driving lines.

The paper is organized as follows: Section 2 is a literature review. Section 3 is an introduction to FAO. Section 4 is an analysis of the safety of FAO. Section 5 is an analysis of the efficiency of FAO. Section 6 discusses the advantages of FAO during the epidemic period. The conclusion can be found at the end of this paper.

The FAO technology has become a hot topic of concern across various sectors of society at present. This paper focuses on analyzing the safety and efficiency of FAO, and summarizes the academic discussions related to these topics. The purpose is to prepare in advance for the research and technological reserve of FAO technology, as there are relatively few studies on safety and efficiency analysis of FAO systems currently.

Reference [10] solved the problem of the lack of accurate operation management emergency plans for FAO systems, which leads to the emergency efficiency of trains not meeting the expected level during emergencies. It analyzes and models the emergency process of FAO fault events based on time Petri networks and uses MATLAB to simulate and calculate different emergency plans, providing methods and ideas for finding and establishing emergency plans that are more suitable for FAO system operation.

Reference [11] focused on the emergency handling capabilities of FAO systems. Starting from the safety of the emergency unlocking control scheme of the train door and the continuity of the line operation, it discusses and proposes the control scheme and emergency unlocking device scheme for train door emergency unlocking, in order to improve the safety and efficiency of FAO operations.

Reference [12] mainly focused on the safety control functions and circuit design of FAO trains. It identifies vehicle risks through preliminary hazard analysis (PHA) and subsystem hazard analysis (SSHA) methods, determines the safety integrity level (SIL) level by using semi-quantitative analysis methods, and conducts related control function design based on the determined SIL level. It verifies whether the design scheme meets the expected requirements of the SIL level through fault tree analysis (FTA) methods and provides safety control function design recommendations for FAO trains.

Reference [13] introduced the scenario division of FAO trains from the depot to mainline operation, and analyzes typical fault state scenarios to construct a structural system for train fault diagnosis, while provides a theoretical basis for the development of on-board fault diagnosis systems for FAO trains.

Reference [14] solved the problem of integration testing mismatch between FAO and traditional CBTC systems and proposes a new safety analysis method that applies the STPA method to FAO to capture causal scenarios, helps extract abnormal operation scenarios of FAO metro, and improves emergency response capability through system design.

At present, scholars mainly focus on the subsystem design, functions, and emergency management requirements of FAO, lacking a comprehensive analysis of the safety and efficiency of FAO operation lines. Therefore, this paper aims to improve this aspect of research by conducting a comprehensive analysis of the safety of FAO operations lines using the AHP and simulating and analyzing FAO operational efficiency using OpenTrack software. The purpose is to guide the subsequent engineering construction of FAO lines and provide a reference for the improvement and promotion of rail transit FAO technology worldwide.

3 Introduction to Fully Automatic Operation

The core of the FAO system is to replace the work of the train drivers with automated and intelligent systems and control center dispatchers. The automation of urban rail transit is divided into five levels: Grade of automation 0 (GOA0), GOA1, GOA2, GOA3, and GOA4 [15–17]. Among them, the urban rail transit system corresponding to the GOA3 and GOA4 automation levels can be called FAO systems.

In 1998, the Paris Metro Line 14 was put into operation. In June 2003, the Singapore Northeast Line was opened. The Dubai Metro system was completed and put into operation in September 2009 and March 2010. The maglev line at Incheon International Airport in South Korea opened on February 03, 2016.

Compared with foreign countries, the development of China’s FAO technology is relatively late, but through continuous innovation and development, it has also achieved certain achievements. The Beijing Metro Capital Airport Line (named Airport Line before September 26, 2019) is the first urban rail transit line with automatic driving function in China. The Shanghai Metro Line 10 is the second FAO line in China and the first FAO line in Shanghai. The Guangzhou Metro APM Line was put into operation on November 8, 2010, which is the first automatic guidance track system line built and operated in Guangzhou. The Beijing Subway Yanfang Line was completed and put into operation on December 30, 2017, which is the first FAO line in China with completely independent intellectual property rights.

Compared with MO, there are different risk sources in the operation process of FAO. The importance of FAO drivers has been seriously weakened and the importance of managers has been increased. In order to improve ability of the FAO lines of urban rail transit to resist major accidents and natural disasters, this paper evaluates the safety operation of the FAO systems, analyzes various factors affecting the safe operation of FAO, and provides some safety management proposals for the operation of FAO lines to ensure the safe operation of FAO [18].

4.1 Construction of Operation Safety Evaluation Index System

In order to comprehensively construct a safety evaluation index system for FAO operations and to avoid the interference of non-conventional operation data during the epidemic period. This paper statistically analyzes the types of operational failure events of the MO Beijing metro Line 1, Line 2, and Line 6, as well as the FAO Beijing Airport Line during the period of 2015–2019, as shown in Fig. 1.

Figure 1: Fault comparison of each line

Beijing Airport Line is the first metro line in China to introduce FAO conditions. From the Fig. 1, it can be seen that the Beijing subway lines using FAO technology have significant advantages in reducing vehicle and signal failures, with a significant reduction in operational failures and a more reliable system.

There are many factors that affect the safety of FAO operations, which not only involves human, vehicle, and track system factors, but also social environment and related equipment factors for train operations [19]. The main advantage of the AHP is that it can decompose complex multi-factor problems into different levels of sub-factor weight calculations and comparison problems, thereby achieving qualitative and quantitative decision-making, which ensures the systematic and rationality of the model, and is a simple and practical multi-criteria decision-making method. It is especially useful for complex target factor structures that lack necessary data and require the decision-maker's experiential judgment and quantification [20,21]. The greatest difficulty in evaluating the safety of FAO system operations is the multiple indicators that need to be considered comprehensively. Moreover, the indicators include qualitative and quantitative indicators, and it is difficult to compare different types of indicators directly, which coincides with the concept of AHP. Therefore, this paper selects the most mature AHP method for evaluation. This method can objectively reflect the importance of each indicator systems of the FAO system in safe operation [22].

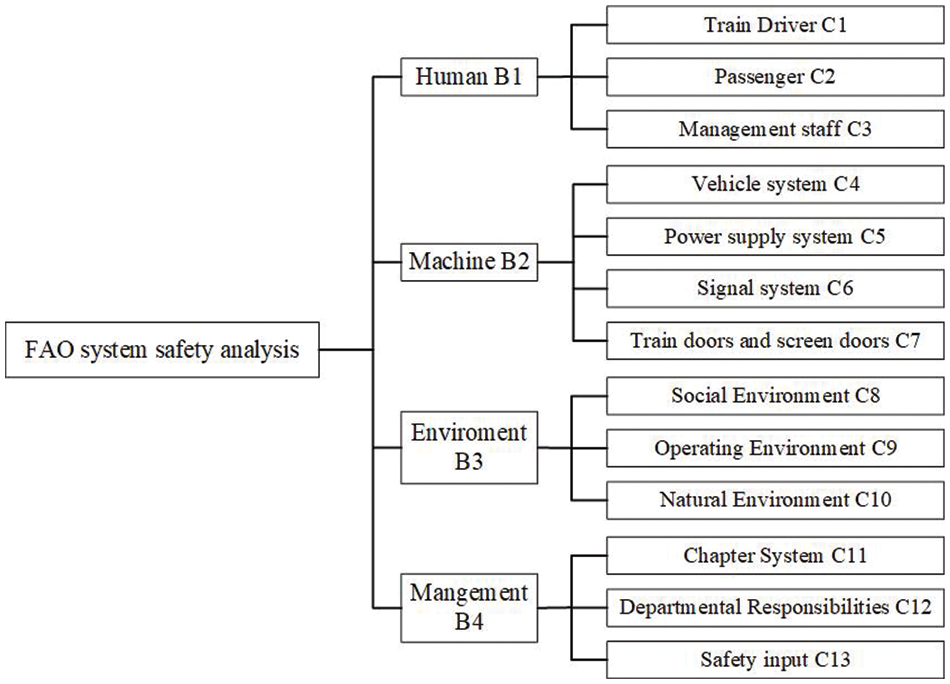

According to the statistical analysis of fault events in FAO operation, combined with the statistics and experience summary of railway industry accidents, the risk sources are classified into four aspects: human, machine, environment and management, as shown in Fig. 2. Based on the identified risk sources, the evaluation indicators are selected from the perspective of operation, the evaluation system is constructed. According to the influence of different risk sources on various operation indicators, the importance of indicators is determined. The comprehensive evaluation of the safety operation of the FAO system is a composite action of the weight of each factor and the single factor evaluation, and the determination of the weights is very important [23,24]. This paper uses the AHP to evaluate the safety of FAO operations. The calculation process of the AHP is shown in Fig. 3.

Figure 2: Classification of risk sources

Figure 3: The flow chart of analytic hierarchy process

The AHP structure model is constructed from four aspects: human, machine, environment and management. The safety index of urban rail transit operation is divided into three layers. The target layer is the safety analysis of the urban rail transit operation system; the criterion layer includes the relevant safety levels covered human factors, equipment factors, environmental factors and management factors; the sub-criteria layer is the specific evaluation indexes [25]. According to the hierarchical relationship of the safety analysis of FAO of urban rail transit, the expert scoring table is constructed. The hierarchical structure model is shown in Fig. 4.

Figure 4: FAO system safety hierarchy model

4.2 Evaluation of Factors for the Safe Operation of FAO

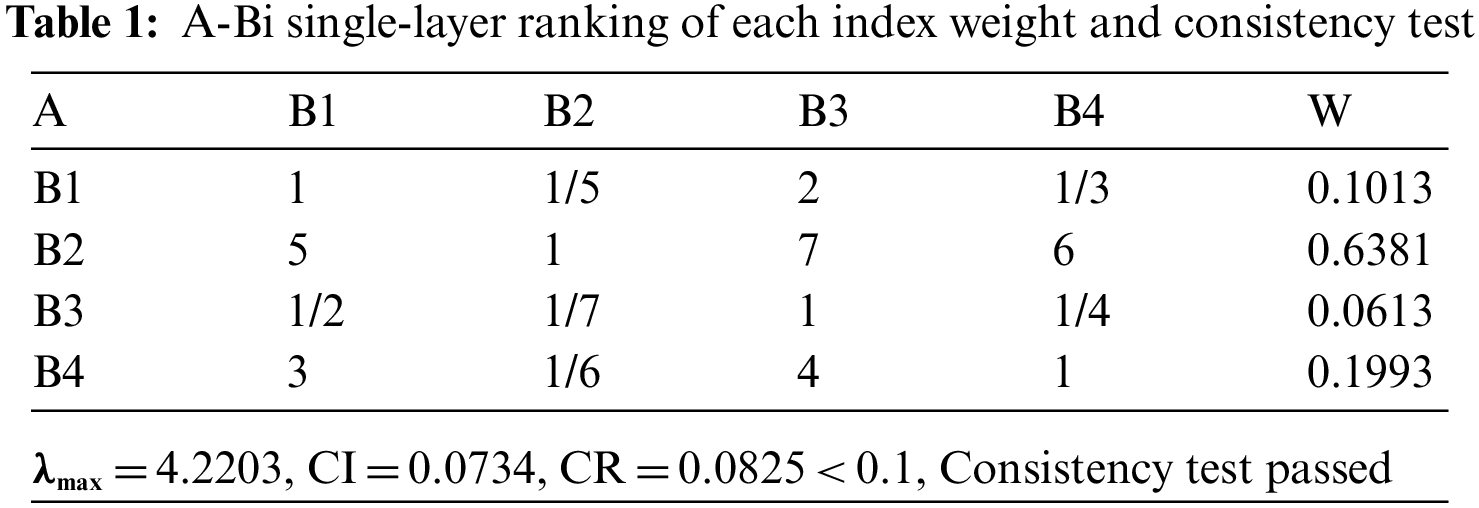

According to the statistics of faults of the FAO line research in China and combined with the operation experience, the expert scoring table of FAO safety hierarchy analysis is assigned, while the root method is used to solve the matrix. In the FAO criterion layer, the importance scoring of the four factors, namely, human, machine, environmental and management, alternatively named A-Bi single-layer scoring, the weight of each factor and consistency test are shown in Table 1. Other elements layers are scored in the same way, with all the single layer ranking and consistency test results CR < 0.1, which implies that all the consistency tests meet the conditions. The weight of each element is obtained by scoring each layer of FAO by experts. In order to facilitate the analysis, the values in the FAO safety analysis conclusion table are sorted according to the global weight value, and the results are shown in Table 2.

It is worth noting that B1, B2, B3 and B4 below refer to humanB1, machineB2, environmentB3 and managementB4.

4.3 Evaluation of FAO Safety Analysis and Recommendations

For the convenience of comparison, the data in the FAO safety analysis conclusion table is transformed into a pie chart, as shown in Fig. 5.

Figure 5: FAO safety analysis underlying element weights

It can be seen from the analysis in Fig. 5 that the train drivers, passengers, power supply system, social environment, natural environment, department responsibilities, operating environment, and safety input factors account for a relatively low proportion of the factors affecting FAO safety, the above-mentioned factors have less interference with safe operation in the FAO environment. Vehicle systems, signal systems, rules and regulations, train doors and platform screen doors and management staff account for a relatively high proportion. In the FAO environment, the above-mentioned factors would produce severe interference to safe operation. This is mainly determined by the highly centralized characteristics of the FAO system. For example, the process of passenger pick-up and drop-off at a regular station is mainly observed by the train driver on the platform yellow line to see if there are any people or objects stuck between the train doors and the platform screen doors [17]. In contrast, the FAO system mainly uses an automatic operation control system to replace the driver to control train operation, although to improve the efficiency of the train, but at the same time also aggravate the door and the screen door of the danger factor.

Therefore, if the line adopts the FAO mode, it is necessary to focus on the vehicle system, signal system, rules and regulations, train doors and platform screen doors and management staff. Among them, the vehicle system, signal system, train doors and platform screen doors are machine and equipment factors of the FAO system, management staff are human factors of the FAO system, rules and regulations are management factors of the FAO system. This paper proposes management suggestions from the perspectives of machine and equipment, staff, and management to improve the safety of FAO operations.

(1) Regarding machine and equipment: Increase intelligent monitoring system to prevent equipments fault related to vehicle systems, signal systems and train doors and platform screen doors [26]. Real-time monitoring and inspection will be conducted through intelligent technology and the cooperation of operation and maintenance staff to ensure safety and stability at every stage. Additionally, by summarizing and digging deep into the maintenance staff inspection and fault diagnosis experience, a fault library will be created and matched with maintenance methods to develop reasonable emergency response plans.

(2) Regarding staff: First, strengthen the training and assessment of management staff, improve the responsibilities of each department, enhance communication and collaboration among departments, and increase safety investment. Secondly, increase the number of dispatcher positions [27]. Due to the highly centralized characteristics of the FAO system, the professional division of labor for the dispatcher of the FAO system is more detailed, which places higher requirements on the professional skills and operational management experience of staff. Therefore, compared with the MO system, it is necessary to further increase the number of dispatcher positions, including passenger dispatchers, maintenance dispatchers, and comprehensive monitoring dispatchers, to ensure the safe and stable operation of trains. Finally, establish a team of multi-intelligent inspectors [28], with a focus on vehicle equipment, signal equipment, and power supply equipment, maintenance efforts should be increased, and reasonable emergency response plans should be developed, while maintaining communication with equipment providers to prevent equipment failures from affecting operation safety.

(3) Regarding management: Improve relevant rules and regulations. Due to the higher requirements of the FAO system compared to MO technology, the train system is more complicated. Therefore, it is necessary to revise the rules and regulations related to staff, train equipment management and maintenance in order to enhance the safety assurance capability of FAO operation.

5 Operational Efficiency Analysis

As the most automated system in urban rail transit trains, the FAO system integrates communication, signaling, control, and computer technologies, enabling the train to operate automatically throughout the entire process [29]. Compared with the MO system, the FAO system not only ensures the safety of the train, but also improves its operational efficiency. The safety and efficiency of the FAO system are closely related, it would be pointless to pursue only safety or efficiency, it is crucial to ensure that the safety and efficiency of FAO systems go hand in hand. Therefore, this paper analyzes the safety and efficiency of the FAO system, Only on the premise of ensuring safety, it is meaningful to improve the efficiency of FAO.

Therefore, this paper not only analyzes the safety of the FAO system, but also analyzes its the efficiency. The Beijing Subway Yanfang Line, as a national independent innovation demonstration project, it is the first fully autonomous line with FAO system. This paper takes Yanfang Line as an example and applies OpenTrack to simulate the train operation to verify the efficiency of the FAO line [30].

The Yanfang Line starts from Yancun East Station in Fangshan District. It crosses the West Sixth Ring Road to the west, passes Yancun and Fangshan Chengguan, and ends in Yanshan area and Zhoukoudian. The main line is 20.5 kilometers long, all of which are elevated lines. There are 9 stations and 1 vehicle base (Yancun North Depot). Through several field investigations into the Yanfang Line, the mileage data between the stations of the Yanfang Line, the length of the station buildings and the actual operating speed of the FAO are determined, so as to prepare the preliminary data for the subsequent simulation.

(1) basic information of vehicle depot

The main line of the Yanfang Line has a vehicle deposit in Yancun, which is located on the ground. This paper uses Google Earth software to measure. The parking garages of the Yanfang Line and the Fangshan Line are separated by a wall. The southern side of the wall is used by the Fangshan Line, and the northern side is used for the Yanfang Line. There are 9 parking lines on one side of the Yanfang line, each of which can be used for two sets of trains. Currently, a maximum of 18 groups of trains can be parked at the same time.

(2) vehicle Information of Yanfang Line trains

Based on the data provided by the company responsible for the installation, construction and commissioning of the Yanfang Line, the vehicle data required for OpenTrack simulation is extracted, as follows:

Train formation: 4 B-type carriages: Tc+M+M+Tc.

Train length: 79.32 m.

Train empty mass (unit: ton): Tc: 33.7; M: 35.

Maximum speed allowed for vehicles: 80 km/h.

Power source: third rail power supply.

Braking deceleration (unit: m/s2): 0.8 in general and 1.2 in emergency.

The whole line would be equipped with 16 groups of vehicles in the near future (YF001-YF016), and two groups of vehicles (YF017, YF018) would be added in the far future.

(3) Model construction of Yanfang Line simulation

According to the rail line, train parameters and parking lot data of Yanfang Line, the simulation model is built with OpenTrack to set the station, train, trip and schedule parameters [31]. The infrastructure modeling (including lines, signals, etc.) is shown in Fig. 6.

Figure 6: OpenTrack infrastructure model of Yanfang Line

5.2 Full-Line Simulation Analysis of Yanfang Line

(1) Analysis of the mainline tracking interval for trains on the Yanfang Line

In this paper, OpenTrack is utilized to implement the simulation to generate the FAO upward tracking operation diagram and the FAO downward tracking operation diagram, as shown in Figs. 7 and 8. The vertical axis in the figure designates the distance, and the horizontal axis designates the time.

Figure 7: FAO upward tracking operation

Figure 8: FAO downward tracking operation

After an OpenTrack simulation, the minimum tracking interval of the main line can be shortened to 60 s when the trains of Yanfang Line are in FAO mode, which was within the two-minute departure interval constraint.

(2) Analysis of tracking interval in Yancun vehicle depot

The train operation line is set in the depot model, so that all the 18 groups of trains in the long-term depot can automatically exit or enter the depot at an interval of 90 s. According to the field observation and theoretical calculation in the Fangshan Suzhuang depot, the average time of the train from the parking line to the contact line with the main line is set as 3 min and 4 s as a standard to calculate the delay time [7].

After testing, the trains enter and exit the depot continuously at an interval of 90 s, which is ± 4 s different from the planned time. If the operation chart continues to be optimized, the entry and exit time can be controlled within 3 min and 43 ± 2 s. The trains on the Yanfang Line can basically run at an interval of 90 s to meet the needs of the far future operation.

(3) Analysis of the limit interval of turn-back at Yanshan Station

With the help of OpenTrack to test the turn-back interval of Yanshan Station FAO second by second, the final turn-back limit interval of Yanshan Station in FAO mode is determined to be 98 s, and the results are shown in Table 3.

The Yanfang Line operates in FAO mode. If the current turn-back method is continued, the turn-back line supports trains running at intervals of 98 s, which basically meets the operational requirements of the far future.

(4) 98 s tracking interval test for all trains on the main line

After the test of the train tracking interval, the limit interval of entry and exit, and the limit interval of turn-back, the limiting factor of the train running interval is found to be the turn-back of the terminal platform, and the turn-back line supports the train to run at an interval of 98 s. The OpenTrack is used to test the tracking interval of all trains on the whole line with 98 s (1 min 38 s) as a benchmark. The running results are shown in Fig. 9.

Figure 9: Results of 98 s-limit interval operation of all trains on the FAO main line

5.3 Analysis of Failure Impact Surface

During the operation of the FAO trains on the Yanfang Line, the fault types of the train on the line are divided into two types: slow movement and traction system failure. The failure of the traction system is to be solved by arranging the subsequent train to drag the failed train off the main line [32].

(1) The principal influencing factors of the rescue process

The principal influencing factors of the train rescue process include the following three parts: fault disposal time, rescue preparation time and coupling time. Based on the accident disposal standards of the subway industry and the lessons accumulated, the fault disposal time is generally 3 min, the rescue preparation time takes 6.5 min, and the coupling time takes 5.5 min, so the train fault disposal rescue time is 15 min [33]. In the FAO mode, the train can quickly find the fault through self-check and send it back to the command center at the first time. The dispatchers can immediately take effective measures to implement the rescue work, thus saving the time (3 min) of the faulty car driver [33]. Therefore, the fault simulation time is set as 12 min in the FAO mode.

The rescue train is pushed in RM mode with a maximum speed of 25 km/h. The fault train without tractor and braking force runs at a speed of 45 km/h [34].

(2) Test of failure impact surface

In order to obtain more accurate fault simulation results, this part tests the fault impact surface of FAO and MO of the urban rails, respectively. The test adopts the single-variable principle of the control-variable method. To prevent the interference of other factors, it is assumed that the following faults occur in the FAO and MO vehicles under the same conditions. Through systematic analysis and comparison, the simulation conclusions of FAO fault of urban rail are obtained.

(a) When the train can move slowly

In the failure simulation of FAO and MO trains, the faulty train fails at the down platform of Xingcheng Station between 12:00 and 13:00, The train travels slowly to the destination at a speed of 45 km/h. The fault impact surfaces are shown in Figs. 10 and 11 respectively when the FAO and MO trains can move slowly. After the analysis, it is concluded that the punctuality rate of MO decreases by 1.1029% and the punctuality rate of FAO decreases by 0.7299% when the train fails.

(b) When the train is immovable

Figure 10: Fault impact surface of FAO trains when cars can slowly move

Figure 11: Fault impact surface of MO trains when cars can slowly move

In the FAO and MO train traction fault simulation, the fault train failed on the upward platform of Xingcheng Station at 12:15, The rescue train pushed the fault train away from the main line in the upward direction without stopping at any station on the way, and running at a speed of 25 km/h. The impact surfaces of the immovable fault of the FAO and MO trains are shown in Figs. 12 and 13, respectively. After the analysis, it is concluded that if the train is immovable, except for the rescue train, the punctuality rate of MO decreases by 1.8382%, while the punctuality rate of FAO decreases by 1.0948%.

Figure 12: Impact surface of immovable fault: FAO train

Figure 13: Impact surface of immovable fault: MO train

5.4 Summary of Efficiency Analysis

In order to verify the efficiency of FAO, this paper simulates the MO mode of Yanfang Line on the basis of the existing ones. The comparison and summary of the MO and FAO simulation results of Yanfang Line are shown in Table 4.

According to Table 4, it can be seen from the simulation results of the FAO system and MO systems on the Yanfang Line that when the line is operated with the FAO system, the running speed in both the upstream and downstream directions is faster than that of the MO system. At the same time, the test results of the FAO system mainline tracking interval, entry and exit vehicle section and turn-back limit interval reach 60, 90, and 98 s respectively, which is much better than the MO system. In particular, for the turn-back limit interval of the train, the MO system requires 5 min and 30 s, while the FAO system only needs 98 s, which is the unique advantage of the FAO system. From the analysis of the failures of the FAO and MO systems, it can be seen that regardless of the type of failure, the FAO system is more reliable than the MO system, and the impact of failure on the punctuality of the FAO system is less.

6 The Advantages of FAO during the Epidemic

Since 2020, the new coronavirus epidemic has been raging. China’s urban rail transit operators have taken corresponding measures to deal with it. The Beijing Subway Company has taken extraordinary measures to shorten the interval time of the lines. Among them, the intervals of Line 1, Line 5, Line 9 and other lines are shortened to 105 s, but the interval of 1 min 45 s is not the interval of each big interchange train, but the result of adding interval small interchange midway, which has obviously reached the limit interval of the existing line signal system.

During the epidemic, the FAO trains can reduce the gathering of people by shortening the departure interval of the trains, improving the safety and effectiveness of the train operation. Through the safety and efficiency analysis of the FAO system, this study finds that the FAO has greater adjustment space compared with the MO system, which can further shorten the departure interval of the trains and greatly improve the service level and efficiency of the FAO trains. This is mainly because the FAO trains use automatic control systems to control train operation, which avoids human interference and can adjust the operation plan more conveniently at any time. The highly automated features of the fully automatic driving system ensure that the train can be automatically awakened and entry and exit vehicle section automatically, which not only improves the operation efficiency and turn-back efficiency of the train vehicle section, but also reduces the tracking interval of the train and increases the departure frequency of the train, making it more efficient than the MO system. Therefore, when the Yanfang Line adopts the FAO system, the mainline tracking interval of the FAO system is determined by the turn-back interval, and it can be shortened by 1 min and 38 s, greatly improving the operational efficiency of the train.

Based on the simulation results of the fully automatic and manual driving systems on the Yanfang Line, if these lines use the same FAO-supporting system as the Yanfang Line, the running interval of the long running rout trains can be steadily reduced to 1 min and 38 s, and the operating capacity can be increased by 6%, which is a unique advantage of the FAO technology.

This study effectively verified the safety of the FAO by using the AHP, obtained and analyzed various factors affecting the safety of the FAO operation, and provided management suggestions to ensure the safe and stable operation of the FAO system. At the same time, this study effectively verified the efficiency of the FAO system through simulation and data analysis using OpenTrack software, and the specific innovative features are described as follows:

(1) This paper uses the AHP to evaluate the operation safety of FAO in the urban rail transit, and analyzes the factors affecting the safety of FAO. The global weight value and ranking of FAO are obtained, and suggestions for the safety management of FAO lines are provided. Management staff, vehicle system, signal system, train door and platform screen door, rules and regulations have a great impact on the safety of FAO, these factors should be paid more attention to, in order to improve the safety and stability of rail transit operation.

(2) This paper uses OpenTrack to analyze the efficiency of FAO.

After the simulation and analysis of the whole Yanfang Line, it is concluded that the Yanfang Line could be operated with 98 s as the tracking interval of the whole line when adopting the FAO mode, which implies that the requirements of the long-term operation of the Yanfang Line would be basically met.

Through the comparison of the impact of MO and FAO faults on Yanfang Line, it was found that no matter what kind of train fault occurred, the rescue efficiency of FAO was significantly improved compared with MO, and the influence on the subsequent trains was reduced, which could improve the full-day punctuality rate.

(3) In order to prevent people from gathering during the epidemic, the minimum intervals of MO trains could only be shortened to 105 s, while the minimum interval of FAO trains could be shortened to 98 s. In the future if the MO lines apply the same FAO-support system as that of Yanfang Line, the operating capacity would be significantly improved, which is also the direction of future research.

Acknowledgement: Thanks to our tutors and researchers for their assistance and guidance.

Funding Statement: Self-funded; The authors received no specific funding for this study.

Author Contributions: Study conception and design: Kaige Guo, Jin Zhou, Di Sun and Lixian Zhao; data collection: Xiaoming Zhang and Zishuo Wang; analysis and interpretation of results: Kaige Guo, Jin Zhou and Di Sun; draft manuscript preparation: Kaige Guo. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that support the findings of this study are available from the corresponding author, Jin Zhou, upon reasonable request.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. S. S. Pei, “Research on the formation mechanism and improvement strategy of metro operation resilience,” M.S. Dissertation, China University of Mining and Technology, Jiangsu, China, 2022. [Google Scholar]

2. China Association of Metros, “Statistics and analysis of urban rail transit in 2021,” Modern Urban Rail Transit, vol. 19, no. 5, pp. 117, 2022. [Google Scholar]

3. China Association of Metros, “Statistics and analysis report of urban rail transit in 2021,” Urban Rail Transit, vol. 10, no. 7, pp. 116, 2022. [Google Scholar]

4. W. J. Tan, “Research on the design of operation scenarios and intelligent operation and maintenance under fully automatic operation conditions of rail transportation,” M.S. Dissertation, Beijing Jiaotong University, Beijing, China, 2020. [Google Scholar]

5. J. Jin, “The first fully automated rail transit line operation mode discussion,” Tunnel and Rail Transit, vol. 35, no. S1, pp. 140–143, 2021. [Google Scholar]

6. L. M. Song and Q. Zhou, “Safety analysis of fully automatic unmanned driving in urban rail transit,” Information and Communication, vol. 34, no. 3, pp. 148–149, 2020. [Google Scholar]

7. China Urban Rail Transit Association, “China urban rail transit association investigates the national independent innovation demonstration project of the fully automatic operation system of Beijing Yanfang line,” Urban Express Rail Transit, vol. 30, no. 3, pp. 2, 2017. [Google Scholar]

8. M. Y. Zhang, “Research and simulation of fully automated vehicle section ATS system,” M.S. Dissertation, Southwest Jiaotong University, Sichuan, China, 2019. [Google Scholar]

9. H. W. Yan, “Research on safety analysis of fully automated rail transit operation system based on STAMP,” M.S. Dissertation, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

10. Z. Guo and F. Yan, “Study on emergency disposal processes of urban rail transit with fully automatic operation system based on time petri net,” in 2022 34th Chinese Control and Decision Conf., Hefei, China, pp. 5452–5457, 2022. [Google Scholar]

11. Q. Gao and Y. Zhang, “Analysis of emergency door unlocking scheme for fully automated trains,” Rolling Stock Technology, vol. 59, no. 5, pp. 11–13 + 20, 2022. [Google Scholar]

12. C. G. Bai, “Safety function design of fully automated subway trains based on safety integrity level analysis,” Railway Technology Supervision, vol. 49, no. 4, pp. 53–57, 2021. [Google Scholar]

13. K. Lu, D. Q. He, H. S. Xiao and R. Guo, “Research on fault scenario analysis and diagnosis architecture of fully automated trains,” Control and Information Technology, no. 2, pp. 59–63 + 81, 2019. [Google Scholar]

14. S. Lu, R. Niu and T. Tang, “Scenarios oriented safety analysis of fully automatic operation metro,” in 2018 Int. Conf. on Intelligent Rail Transportation (ICIRT), Singapore, pp. 1–5, 2018. [Google Scholar]

15. B. Ning, C. H. Gao, K. C. Li and Q. Zhang, “Technology and application of fully automatic operation system for urban rail transit in China,” Journal of Beijing Jiaotong University, vol. 43, no. 1, pp. 1–6, 2019. [Google Scholar]

16. Q. Gao, C. Su and R. J. Liang, “New system functions of fully automatic running trains for urban rail transit and its design points,” Urban Rail Transit Research, vol. 22, no. S2, pp. 35–38, 2019. [Google Scholar]

17. J. Zhang, “Exploration and reflection on engineering construction of fully automatic operation FAO system for urban rail transit,” Modern Urban Rail Transportation, vol. 19, no. 2, pp. 18–22, 2022. [Google Scholar]

18. I. B. Shubinsky, H. Schäbe and E. N. Rozenberg, “On the safety assessment of an automatic train operation system,” Dependability, vol. 21, no. 4, pp. 31–37, 2021. [Google Scholar]

19. H. D. Wang, K. Pan and F. D. Jiang, “AHP-based analysis of hazards affecting the safety of urban metro operation and preventive measures,” Journal of Railway, vol. 30, no. 2, pp. 27–31, 2007. [Google Scholar]

20. J. H. Ding, G. J. Li and J. Jiang, “Research on the evaluation of subway passenger interior design based on hierarchical analysis,” Computer Application Research, vol. 37, no. S1, pp. 19–20 + 8, 2020. [Google Scholar]

21. S. k. Jia, X. H. Wen, D. J. Lin and Z. G. Jiang, “Research on safety evaluation technology of subway operation system based on hierarchical analysis method,” Chinese Journal of Safety Science, vol. 18, no. 5, pp. 137–141, 2008. [Google Scholar]

22. H. Jasim Mohammed and H. Ati Daham, “Analytic hierarchy process for evaluating flipped classroom learning,” Computers, Materials & Continua, vol. 66, no. 3, pp. 2229–2239, 2021. [Google Scholar]

23. Y. H. Guo, “Research on the evaluation of safety risks of fully automatic driving operation of urban rail transit in China,” M.S. Dissertation, Southwest Jiaotong University, Sichuan, China, 2020. [Google Scholar]

24. K. Liu, J. T. Zhu and M. Wang, “An event-based probabilistic model of disruption risk to urban metro networks,” Transportation Research Part A: Policy and Practice, vol. 147, pp. 93–105, 2021. [Google Scholar]

25. P. G. Liu, “Safety analysis and train operation simulation of fully automatic operation for urban rail transit,” M.S. Dissertation, Beijing Jiaotong University, Beijing, China, 2017. [Google Scholar]

26. H. Y. Liu, “Study on the training practice of Nanjing metro operation management talents in the context of fully automated driving,” Logistics Science and Technology, vol. 45, no. 14, pp. 94–96 + 100, 2022. [Google Scholar]

27. W. Li, “Analysis of fully automated driving operation and management mode of Shanghai metro line 10,” Economic and Trade Practice, vol. 18, no. 12, pp. 254–255, 2018. [Google Scholar]

28. H. Y. Liu, “Research on the impact of fully automated driving on Nanjing metro operation management and countermeasures,” Science and Technology Information, vol. 20, no. 3, pp. 132–135, 2022. [Google Scholar]

29. J. Deng, R. Li, Z. Chen and Y. Bai, “Design and application of metro vehicle scheduling system based on big data architecture in fully automated driving mode,” Control and Information Technology, vol. 45, no. 6, pp. 104–108, 2022. [Google Scholar]

30. P. Nachtigall and E. Tischer, “Efficiency of increasing of the track speed using simulation in opentrack,” in Proc. of the 32nd European Modeling & Simulation Symp. (EMSS 2020), Athens, Greece, pp. 130–136, 2020. [Google Scholar]

31. F. Gao, H. Y. Zhu, S. H. Xie, J. J. Mei and L. Liu, “Design and development of simulation experiment of rail transit operation based on Opentrack,” University Education, vol. 3, no. 18, pp. 101–102, 2014. [Google Scholar]

32. H. X. Yin, K. Wang and Q. B. Jiang, “Reliability analysis of subway vehicles based on the data of operational failures,” EURASIP Journal on Wireless Communications and Networking, vol. 2017, no. 1, pp. 1–8, 2017. [Google Scholar]

33. S. Q. Liu, “Analysis of the necessity of adopting FAO system for Bitong of Chongqing suburban railway,” Railway Communication Signal Engineering Technology, vol. 18, no. 6, pp. 63–68, 2017. [Google Scholar]

34. J. F. Wang, “The history of train operation safety development,” in Safety Theory and Control Technology of High-Speed Train Operation, 1st ed., Salt Lake City UT, USA: Academic Press, pp. 1–32, 2018. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools