Open Access

Open Access

ARTICLE

Application of Deep Learning to Production Forecasting in Intelligent Agricultural Product Supply Chain

1 Department of Logistics Management and Engineering, Nanning Normal University, Nanning, 530023, China

2 Guangxi Key Lab of Human-Machine Interaction and Intelligent Decision, Nanning Normal University, Nanning, 530023, China

3 School of Management and Marketing, Faculty of Business and Law, Taylor’s University, Kuala Lumpur, 47500, Malaysia

4 Graduate Department,Yunnan Normal University, Kunming, 650500, China

* Corresponding Author: Xiao Ya Ma. Email:

Computers, Materials & Continua 2023, 74(3), 6145-6159. https://doi.org/10.32604/cmc.2023.034833

Received 28 July 2022; Accepted 24 October 2022; Issue published 28 December 2022

Abstract

Production prediction is an important factor influencing the realization of an intelligent agricultural supply chain. In an Internet of Things (IoT) environment, accurate yield prediction is one of the prerequisites for achieving an efficient response in an intelligent agricultural supply chain. As an example, this study applied a conventional prediction method and deep learning prediction model to predict the yield of a characteristic regional fruit (the Shatian pomelo) in a comparative study. The root means square error (RMSE) values of regression analysis, exponential smoothing, grey prediction, grey neural network, support vector regression (SVR), and long short-term memory (LSTM) neural network methods were 53.715, 6.707, 18.440, 1.580, and 1.436, respectively. Among these, the mean square error (MSE) values of the grey neural network, SVR, and LSTM neural network methods were 2.4979, 31.652, and 2.0618, respectively; and their R values were 0.99905, 0.94, and 0.94501, respectively. The results demonstrated that the RMSE of the deep learning model is generally lower than that of a traditional prediction model, and the prediction results are more accurate. The prediction performance of the grey neural network was shown to be superior to that of SVR, and LSTM neural network, based on the comparison of parameters.Keywords

The supply chain is an important pillar supporting the development of national economies, and the Internet of Things (IoT) is a key component of the information technology (IT) infrastructure that plays a major role in the development of an intelligent supply chain [1]. In recent years, the application of modern information and developments in science and technology have gained importance in supply chain development strategies. In addition, research on the IoT has yielded many practical applications, including an industrial IoT, intelligent cities, intelligent homes, intelligent supply chains, and intelligent retail [2].

For an overall lower level of informatisation, digitisation, and intelligence [3], the current developments of an agricultural product supply chain in the field of IoT, blockchain, machine learning, and deep learning based on new technologies, such as an agricultural supply chain, are the results of the application of science and technology through a traditional agricultural supply chain transformation. Each of these approaches can realise informatisation, digitisation, and progress in intelligent development. To address various concerns, such as the complexity of supply chain node enterprises, reliability of the supply chain, and optimisation objectives, some scholars have innovatively constructed a system model and proposed an optimisation strategy and supply solutions based on the agricultural characteristics and requirements of the agricultural supply chain [4]. Technologies, such as blockchain, have increased the transparency in various supply chains, and forecasting has increased their accountability. Prediction forms the basis of decision-making. By considering the supply chain of agricultural products as an example, optimisation schemes can be proposed from the perspective of prediction. With a quantitative prediction at the upper reaches of the supply chain, the follow-up nodes and links will have reference standards of action. In terms of agricultural output prediction, which is a conventional linear prediction, the outputs of agricultural products are affected by various factors and therefore, do not exhibit a simple linear relationship [5]. In theory, deep learning contains a data prediction algorithm that addresses the nonlinear relationship with a strong fitting ability, increasing the accuracy of the resulting agricultural output prediction [6]. Based on the accuracy of the prediction results, the agricultural supply chain can become more effective at reducing costs and increasing the efficiency.

Deep learning is a new research direction in the field of machine learning. As an emerging technology, to date, there have been few applied research achievements in the supply chain field. The demand forecasting of supply chain logistics is a major deep learning application in the supply chain field, covering production and sales forecasting [7,8].

Although science and technology have endowed the agricultural supply chain with better development, the agricultural supply chain has new risks in this IoT era, including perceived, network, and application-layer risks [9]. Among these, demand prediction is one of the main supply chain problems, and for the agricultural supply chain in particular, the perception, prediction, and response of the production demand are of great significance. Agricultural product yield forecasting and agricultural product demand forecasting influence each other. An accurate production forecast and a target demand forecast can reduce the waste caused by a blind production process and serious imbalance between supply and demand, reducing logistics costs and meeting the product demand of market consumers to a greater extent [10]. The research field of demand prediction based on deep learning is extensive. However, there have only been a few research achievements in terms of agricultural product yield prediction in the agricultural supply chain field [11].

Our study focused on the production of an agricultural product supply chain in the field of agricultural output prediction. To explore the application of deep learning to the yield prediction problem and achieve results that would enrich the research on agricultural output prediction, we attempted to use deep learning for prediction by considering the local characteristics of the Shatian pomelo fruit yield. A comparison between this method and traditional prediction methods showed contradictory results.

The research results verified the superiority of deep learning in terms of the model generalisation ability and accuracy of the prediction results in comparison to traditional prediction methods applied to agricultural yield prediction. Three deep learning methods, namely, a grey neural network, support vector regression (SVR), and long short-term memory (LSTM) neural network, were used to predict the annual output of Shatian pomelo, which enriched the research achievements of deep learning in the field of agricultural product supply chain production.

The remainder of this paper is organised as follows. Section 2 provides a detailed literature review. Section 3 introduces the research methods. Section 4 includes the data analysis results and discussion. Section 5 describes the future scope of this research and provides some concluding remarks.

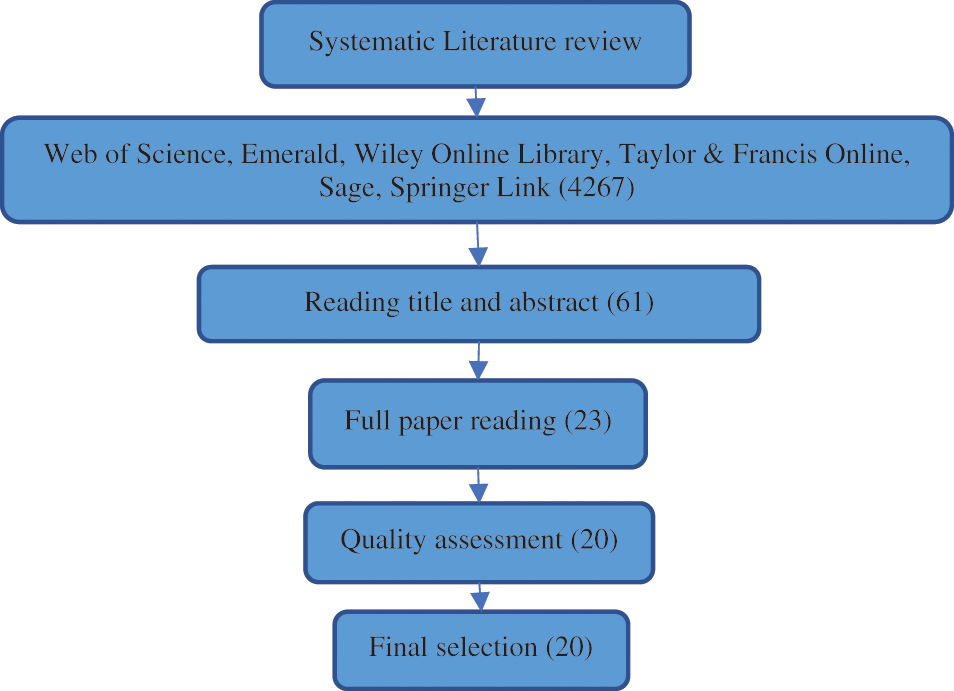

Fig. 1 shows the framework of the literature screening conducted, which reflects the procedure adopted in this study. The figure depicts the number of selected academic journals retrieved during each stage.

Figure 1: Flow chart of literature screening

We conducted separate searches using subject keywords, including professional terms such as ‘Internet of things’, ‘deep learning’, ‘intelligent supply chain’, ‘agriculture supply chain’, and ‘supply chain’ in databases that included the Web of Science, Emerald, the Wiley Online Library, Taylor & Francis Online, Sage, and Springer Link. When no documents containing all the subject words or keywords were retrieved, the relevance ranking of the subjects or keywords was set for the document results retrieved from each database. We reviewed the paper titles and abstracts presented in the search results and selected manuscripts related to this study. We read the full text of each article selected by title and abstract. We then evaluated the quality of the articles, and finally determined the relevant studies.

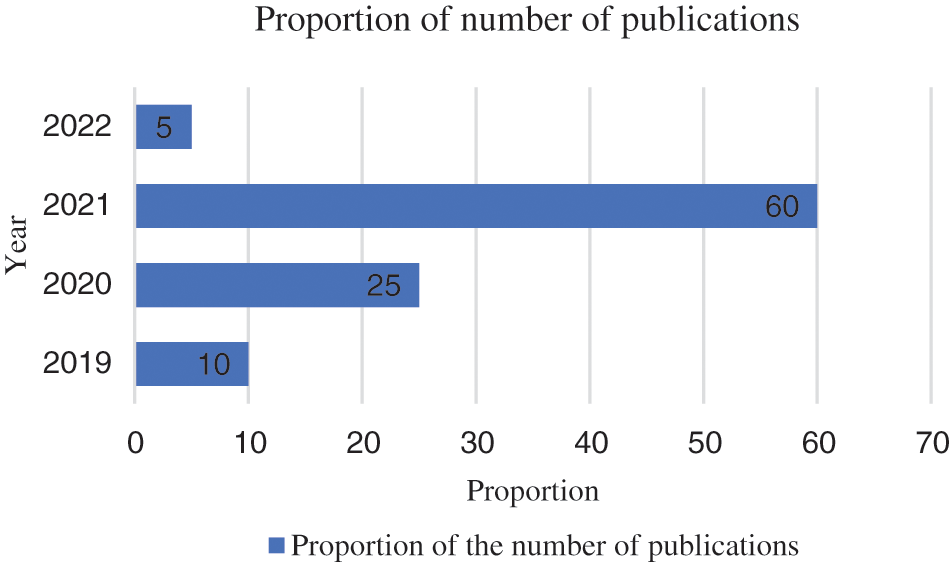

As depicted in Fig. 2, since 2019, the number of publications related to the research topic of deep learning applied to intelligent agricultural product supply chains in an IoT environment has exhibited an overall upward trend. As of the date of the literature search (March 10, 2022), publications from 2021 have a higher circulation. From the figure, it is clear that in an IoT environment, deep learning research on the supply chain of smart agricultural products is still in its infancy; however, the research shows good continuity. As the overall trend in the proportion of published papers indicates, relevant research results are increasing annually.

Figure 2: Proportion of number of publications annually

2.2 Agricultural Production Forecasts

Agricultural production is an important indicator for assessing the level of crop cultivation. The existing research on agricultural production forecasting can be generally divided into two categories: traditional forecasting methods based on linear fitting, and machine learning prediction methods that utilise nonlinear fitting. Among these two types of forecasting models, the grey forecasting model is the most commonly applied approach in agricultural production forecasting and demand forecasting. Cao [12] used the grey system theory to predict grain yield. Li et al. [13] predicted the demand for cold chain logistics of agricultural products in Hunan Province based on a sliding unbiased grey model. The application of such research has been extended from single to combined models. Ma et al. [14] conducted a study on agricultural production prediction based on the grey-Markov model.

The comparison of multiple individual prediction models is a common research method in agricultural production prediction studies [15], where a model with higher prediction accuracy can be obtained through a parameter comparison. However, the pursuit of accuracy does not end there. From the perspective of optimisation research, scholars have considered incorporating more influencing factors to improve the prediction accuracy and have further proposed different prediction models that combine non-deep learning with deep learning methods [16], as well as combinations of multiple deep learning prediction models [17].

In general, the development trend for the research on agricultural production forecasting is similar to that of price forecasting [18,19]. Both are closely integrated with the field of intelligent algorithms, such as machine learning, and have been extended to emphasise different factors, i.e., a strong robustness and fault tolerance based on deep learning neural networks. With its strong calculation and learning ability, such an approach has gradually received increasing attention in the prediction of agricultural production. Jia et al. [15] compared the performances of auto regression integrated moving average models, generalised regression neural network models, and LSTM artificial neural network models in grain yield prediction based on machine learning.

2.3 Deep Learning Production Forecasting in Intelligent Agricultural Supply Chains

In an intelligent agricultural product supply chain, the target output forecast for an agricultural product is an important basis for estimating the cost budget and decision-making regarding the packaging, logistics, and transportation of that agricultural product. In addition, a forecast of the agricultural product output is applied in the production field at the beginning of the supply chain, which has a domino effect on all the links in the middle and lower reaches of the supply chain.

Based on the results of a systematic literature review, there have been few applied research results in the supply chain field. In addition to a monitoring function based on image recognition and image processing, another significant deep learning application in the supply chain field is supply chain demand prediction [7,20]. Demand forecasting is one of the main issues in the supply chain, and includes production forecasting and sales volume forecasting. An IoT can have a profound impact on the realisation of an intelligent supply chain [21]. Tang et al. [22] used an IoT combined with blockchain to build an intelligent supply chain for the first time, which utilised optimised and improved intelligent supply chain indicators such as a tool application, automation, component interconnection, integrated innovation, and learning. Various improvements have been achieved in the development of an intelligent agricultural product supply chain, with the informatisation management of a food supply chain based on IoT technology achieving the initial results [23]. During the production and circulation of agricultural products, various quality factors must be considered. Data fusion technology based on an IoT has significantly improved the optimisation of factors such as agricultural products with an unknown source, health factors, cost, supply chain efficiency, and the saving of agricultural products [24]. In the IoT context, intelligent agricultural supply chain yield prediction based on deep learning plays an important role in reducing the risk of fracturing the agricultural supply chain, further alleviating the vulnerability of the agricultural supply chain and enhancing its resilience. For example, deep reinforcement learning is used to achieve scalable multi-product inventory control with lead time constraints [25].

With further research, more emerging technologies and algorithms are gradually being integrated into the development of intelligent agricultural product supply chains [26]. Among these, the research on the utilisation of deep learning for a supply chain is still in its infancy, with the earliest related studies focusing on the use of convolutional neural network-based deep learning for image recognition in the packaging link of a supply chain [27]. A monitoring function based on image recognition and image processing is a prominent application of deep learning in the supply chain [28–30].

At present, the research on the incorporation of deep learning to produce an intelligent agricultural product supply chains mainly focuses on three fields. (1) In the production and circulation fields of an intelligent agricultural product supply chain, image detection and image classification based on deep learning can assist in decision-making for the supply chain [31]. (2) In intelligent agricultural supply chain sales, a deep-learning-based automatic commodity pricing model [32] can use a consumer selection model to predict the product market share and establish constrained nonlinear programming to determine the optimal price, thereby making the pricing more scientific and reducing the price setting. (3) In the cold chain logistics of agricultural products, the intelligent prediction of cold chain product demand is an important means for cold chain enterprises to reduce storage and transportation costs and improve market competitiveness [33]. The transportation of fresh agricultural products is inseparable from cold chain logistics. Therefore, product demand prediction and output prediction are also pivotal functions in the supply chain of fresh agricultural products.

Previous studies have mostly focused on the selection of a certain type of prediction model. With the deepening of research, the focus on model selection for prediction has gradually shifted from traditional prediction models to econometric models, and thereafter to deep learning prediction models. Although previous scholars have compared different forecasting models, their applications were mostly concentrated in the field of price forecasting, and generally only two or three models were compared. In addition, few scholars have applied multiple types of yield forecasting models to a specific agricultural product as a joint comparative study. Thus, this study compared the yield prediction results of multiple prediction models for the Shatian pomelos yield. The models used in this comparison were representative models selected based on previous research.

3.1 Neural Network Model and Calculation Process

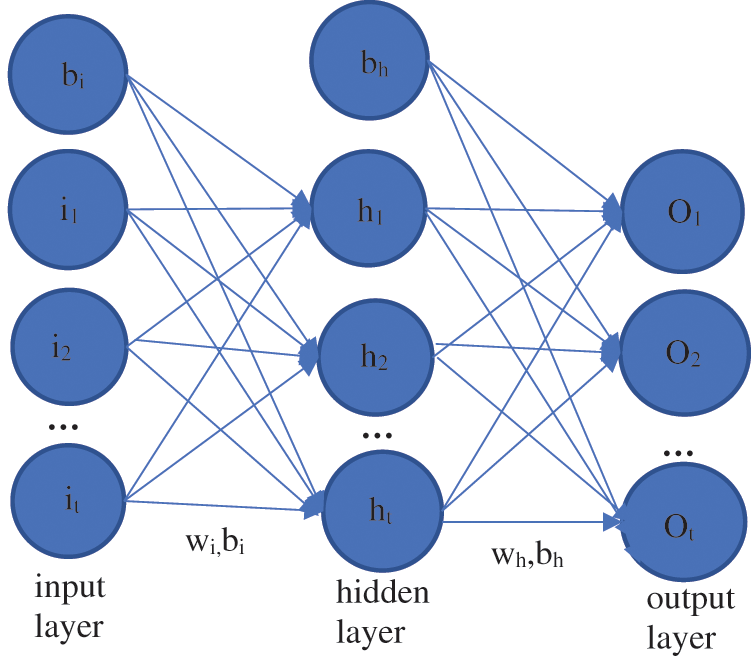

The learning process of the back propagation (BP) neural network algorithm combines forward and back propagation. The structure of neural network model is shown in Fig. 3. In the forward propagation process, the information is first propagated from the input layer to the hidden layer. Then, after being processed by the hidden layer, it is transmitted to the output layer. If the output layer does not indicate the expected output, the resulting error signal is reversed from the output layer to the input layer. During the back-propagation process, the error is gradually reduced by adjusting the weights between layers.

Figure 3: Structural diagram of neural network model

The input layer, hidden layer, and output layer are the components of a basic neural network. The layers are connected by weights, and the output is calculated using the activation function, which mainly includes the following steps [34].

Step 1: Network initialisation

The number of network input layer nodes (

Step 2: Calculation of the hidden layer

where f is the activation function, such as the sigmoid function

Step 3: Output layer calculation

Step 4: Error calculation

Step 5: Updating of weights and biases using gradient descent to reduce errors

During each iteration of the gradient descent, parameters

3.2 Support Vector Regression (SVR)

Given a set of data,

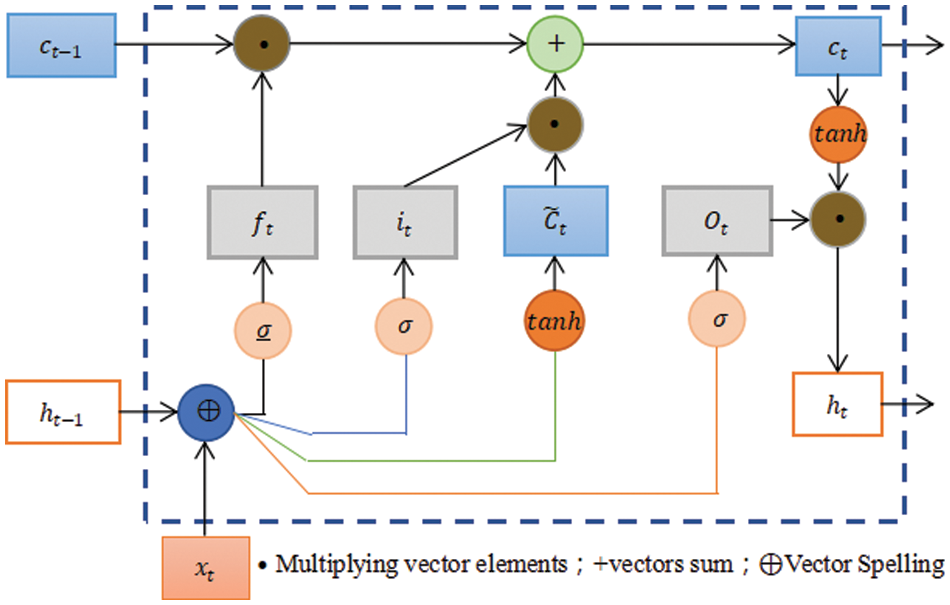

Figure 4: Structure of LSTM neural network (source: neural networks and deep learning [34])

The SVR model is formulated as follows [34]:

3.3 Core Principles and Computational Steps of LSTM

LSTM is a variant of a recurrent neural network (RNN), where the difference between the two indicates the structure of the cells and operations. LSTM solves the phenomenon of a gradient disappearance or gradient explosion by introducing a ‘gate’ mechanism [35]. A cell in the LSTM consists of an input gate, oblivion gate, and output gate.

The LSTM network introduces a new internal state,

Here,

The weight matrix,

The input gate

The input gate weight matrix

The influence of the

At this point, the forward propagation process of the LSTM neural network is complete.

The yield and trend prediction results for agricultural products are evaluated using various indicators. The mean square error (MSE) and root mean square error (RMSE) are used to evaluate the prediction error, where a smaller value indicates a higher prediction accuracy. The RMSE can be used to compare the advantages and disadvantages of different prediction models. The R value, which is a correlation coefficient, is an indirect measure of the goodness of fit between the actual and predicted values. For a prediction model, an R value that is closer to one is better.

The data used in this study were obtained from the 2021 Annual Statistical Yearbook of the local statistics website of the National Bureau of Statistics. The thirteenth agricultural part of the yearbook includes the main local values and product output of the main crop.

The fruit industry occupies an important position in China’s agricultural industry. A scientific and accurate prediction of fruit production is of great significance to the development of the fruit industry. Shatian pomelo is one of the local characteristic fruits of China and is an important representative of the developing regional economy. Forecasting the future Shatian pomelo output and regulating its planting based on the forecast data would assist in ensuring the market supply, reducing the supply chain costs, meeting consumer demand, and reducing waste. Moreover, this would provide positive guidance in maximising the beneficial transformation of characteristic fruits. Forecasting Shatian pomelo production would be extremely beneficial. Therefore, the annual regional Shatian pomelo yield was selected as the experimental data.

4.1.2 Experimental Environment

In the experimental study, deep learning prediction was conducted using Tubes-Bitki0LC, running on a 1.60-GHz Intel(R) Core(TM) I5-8265U CPU processor @1.80 GHz, with 8.00 GB (7.82 GB available) of installed memory, and a 64-bit Windows 10 operating system under a MATLAB 2021b environment with its own neural network toolbox.

4.1.3 Prediction Results and Analysis

In this study, regression analysis, quadratic exponential smoothing, grey prediction model, grey neural network, SVR, and LSTM methods were used to predict the production of Shatian pomelo. Among these, the regression analysis, quadratic exponential smoothing method, and grey prediction model are traditional prediction approaches, while the grey neural network model, SVM, and LSTM are deep learning prediction models. This group of prediction methods was selected based on a systematic literature review to determine methods that could be used for agricultural product output prediction. These included a traditional prediction method, single neural network prediction model, and neural network combined prediction model (grey neural network). Moreover, among the various methods, more classical specific prediction approaches were selected. After determining the traditional prediction method, we considered the influences of contrast and diversity on the selection of a deep learning prediction approach. Instead of selecting a combined prediction model with multiple deep learning prediction algorithms, we selected a single deep learning prediction model. This method was selected based on its representativeness, which was one of the key elements used to make the research more representative.

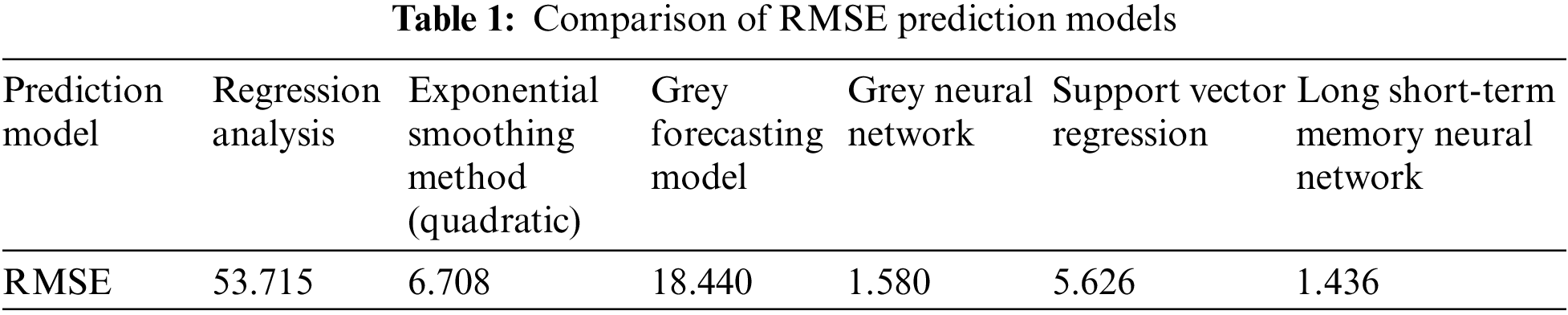

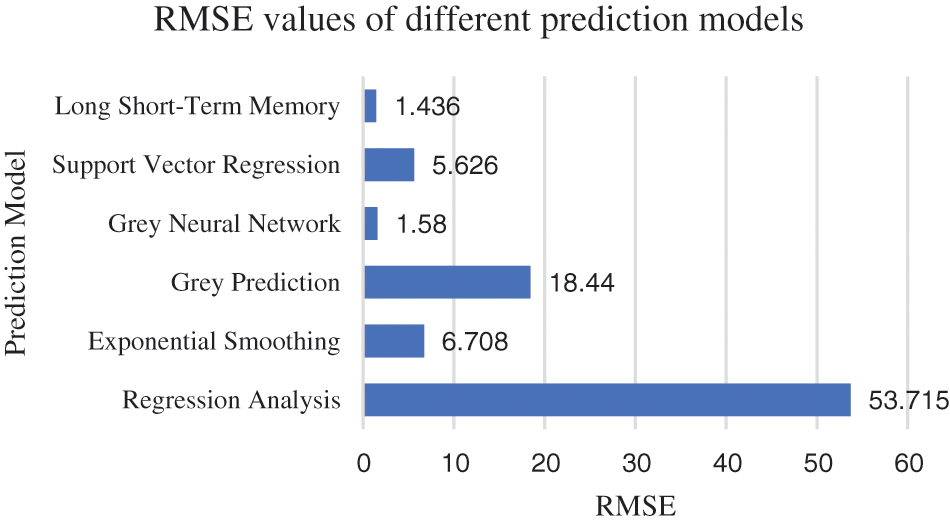

As listed in Table 1 and Fig. 5, the RMSE value of a deep learning prediction model is generally lower than that of a traditional prediction model, which indicates that the prediction results of the deep learning prediction model are more accurate.

Figure 5: Comparison of RMSE values of different prediction models

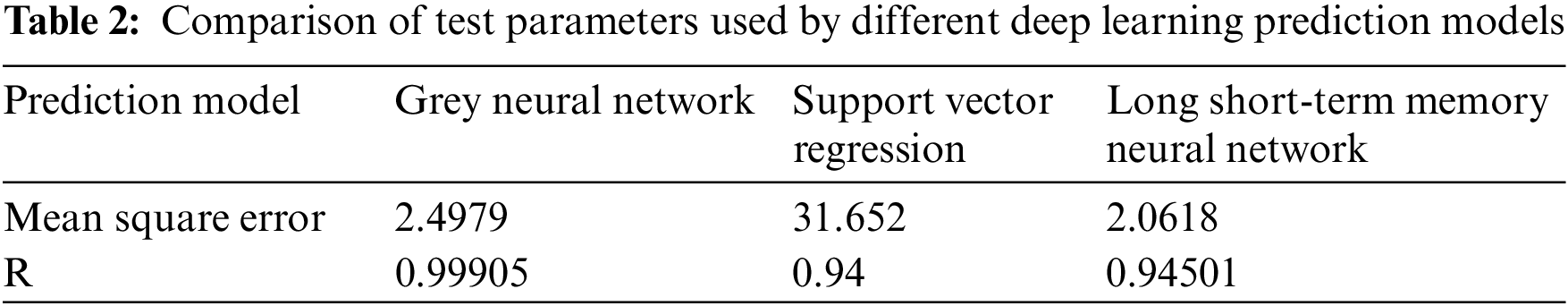

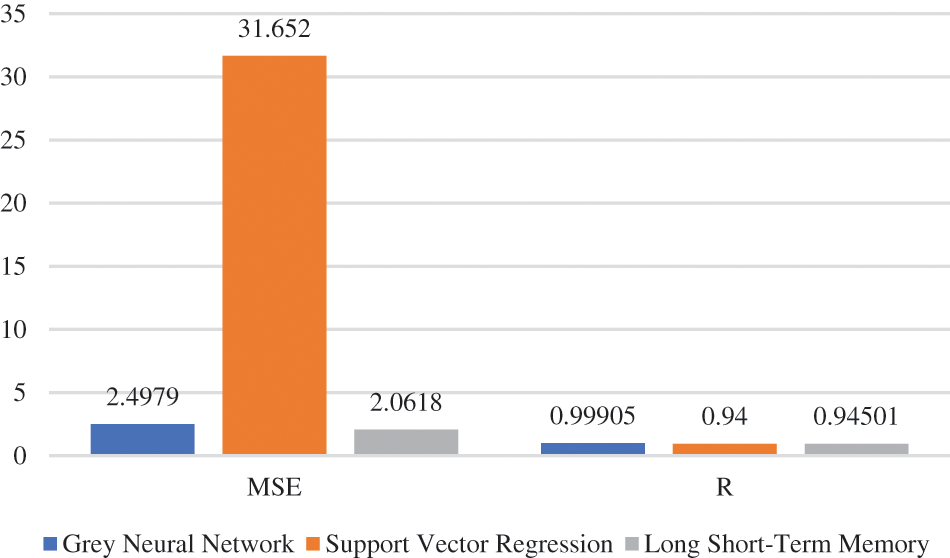

Table 2 and Fig. 6 show the MSE values of the production forecasting results of the different deep learning models. In this study, the MSE obtained when using the grey neural network for prediction was the smallest, further indicating its superiority compared to the other three deep learning methods applied. The deviation reflected the generalisation ability of the deep learning model, and the MSE reflected its accuracy. Therefore, from the perspective of the MSE measurement, a grey neural network is recommended for the prediction of the Shatian pomelo experimental data.

Figure 6: Comparison of test parameters of different deep learning prediction models

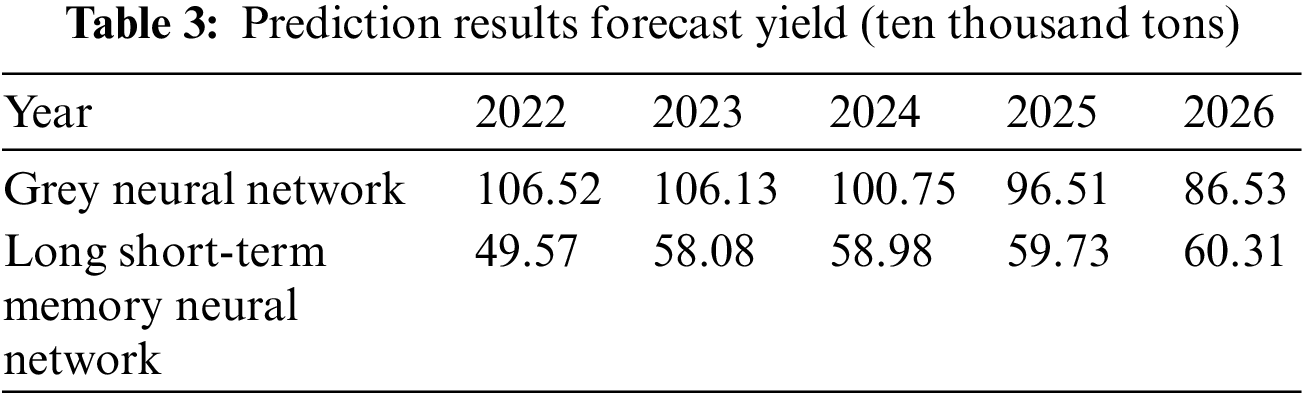

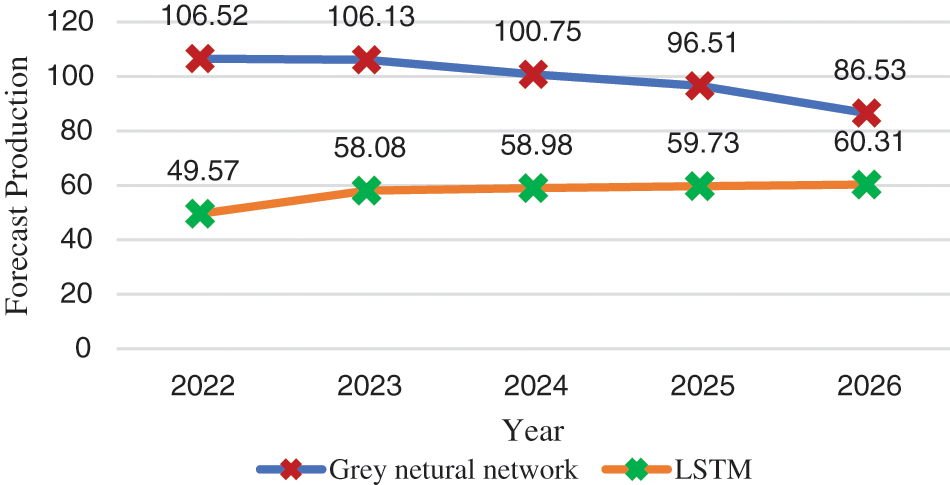

The prediction results based on grey neural network and LSTM neural network are shown in Table 3.

4.2.1 Comparison and Evaluation of Prediction Models

With ongoing research, newer prediction algorithms have been introduced, while the traditional prediction methods face various challenges. Based on the Shatian pomelo yield data, this study compared the prediction performances of different deep learning prediction models with those of several traditional prediction methods, and the universal superiority of a deep learning algorithm in agricultural production forecasting was verified according to the test parameters.

Data-driven agricultural supply chains pose challenges for data collection and visualisation. The similarity between the properties of the model and sample form of the dataset must be considered when using a single model for data prediction. The hyper-parameter settings of the deep learning neural network model applied also require heavy debugging. The hyper-parameter settings of the algorithm used in the neural network model can considerably influence the prediction results. To achieve the optimal prediction results, it is necessary to repeatedly adjust the relevant parameters to reduce loss value, reduce error, and improve accuracy.

In addition, although the accuracy of a deep learning prediction model is higher than that of a traditional prediction method, different deep learning prediction models produce different prediction results for the same event, as depicted in Fig. 7.

Figure 7: Comparison of prediction results

The research on the use of a deep learning method for an intelligent agricultural supply chain under an IoT environment has indicated that some studies applied deep learning to the prediction of demand in an agricultural supply chain, including quantity prediction, indicating that deep learning is suitable for the yield prediction of agricultural products.

This study focused on the prediction of an agricultural product yield, using the annual yield of Shatian pomelo as the experimental data. We attempted to explore the influence and performances of various methods for predicting the agricultural product output, including a traditional prediction method dominated by linear fitting and a deep learning prediction algorithm dominated by nonlinear fitting. The experimental results demonstrated the following. (1) The RMSE values of regression analysis, quadratic exponential smoothing, grey prediction model, grey neural network, SVR, and LSTM network methods were 53.715, 6.708, 18.440, 1.580, 5.626, and 1.436, respectively. (2) The MSE test parameters of the grey neural network, SVR, and LSTM methods were 2.4979, 31.652, and 2.0618, respectively; and their R values were 0.99905, 0.94, and 0.94501, respectively.

The results also demonstrated the following. (1) The RMSE of a deep learning model was generally smaller than that of a traditional prediction model, which indicated the higher accuracy of the prediction results of the former model. (2) After comparing the test parameters (i.e., the MSE and R values) of the grey neural network prediction model, SVR, and LSTM network, it could be concluded that the prediction performance of the grey neural network was the best, whereas the performance of the LSTM method was the second best. (3) Based on the annual Shatian pomelo output data, the grey neural network prediction model and LSTM neural network prediction model, which achieved high accuracies, were considered for predicting the Shatian pomelo output for the next five years (i.e., 2022–2026). Between them, the Shatian pomelo output data predicted by the grey neural network were generally more accurate than the data predicted by the LSTM method.

Based on the results obtained, the R value indicated that the model had moderate accuracy. A higher R value indicates a greater similarity between the model and data. Under a condition where the MSE values of the two models were not significantly different, the prediction results of the grey neural network prediction model could be considered to be more accurate. Therefore, we believe that the Shatian pomelo supply chain can be planned and that decision-making can be achieved based on the data predicted using a grey neural network. In other words, to reduce costs and improve the efficiency, the cost input can be derived from the predicted output in reverse or from the work input required for the subsequent supply chain node operation under the forward planning forecast output. By considering the influence of the two parameters comprehensively, it would be possible to sum the prediction results of the two models after experts make proportional assignments.

Forecasting the target output of an agricultural product is helpful in reducing logistics costs and improving the operation efficiency of the supply chain during production, as well as the circulation and sale of the agricultural product within the supply chain. An accurate prediction for an agricultural output is of great significance to agriculture, agricultural product logistics, and the supply chain. Therefore, in this study, three traditional prediction methods and three deep learning prediction models were used to predict the yield of Shatian pomelo. Through research and an experimental comparison, it could be concluded that the accuracy of the yield prediction results when using deep learning were generally superior to those of other traditional prediction methods. In addition, the prediction results of the grey neural network and LSTM neural network prediction model were superior to those of SVR in this experiment.

The theoretical contribution of this study lies in the comparison of the performances of a traditional prediction model and deep learning prediction model in predicting the yield of a characteristic fruit based on examples. A grey neural network was found to be superior to a single neural network model in the yield prediction of the characteristic fruit. In terms of research methods, different prediction models were compared with specific yield data, and more effective and persuasive prediction results were provided.

By considering Shatian pomelo as an example, this research focused on the production forecasting of intelligent agricultural product supply chains under the background of an IoT, and expanded the application research field of deep learning. The output forecast results provide reference information for other nodes in the supply chain, making it possible to avoid the waste caused by the blind operation of the back-end links of the supply chain, predicted the demand for cold chain logistics of agricultural products in Hunan Province based on a sliding unbiased grey model.

However, this study had certain limitations. Although a deep learning method was introduced to predict the yield of Shatian pomelo and used the prediction model architectures of three algorithms, the combined prediction performance of different neural network prediction architectures under deep learning was not considered. Individual deep learning prediction models have their own advantages and disadvantages. There is still room for further improvement in the prediction accuracy using a combined prediction model with the advantages of independent models. At present, in the field of prediction research based on deep learning, producing the optimal combination model by integrating multiple deep learning algorithms has become a research trend. The combination and optimisation of different models for improving the accuracy of agricultural product forecasting can be a direction for future production forecasting prediction research into an intelligent agricultural supply chain.

Acknowledgement: We are grateful to all of those who provided useful suggestions for this study.

Funding Statement: This work was supported by the 2021 ‘Cultivation plan for thousands of young and middle-aged backbone teachers in Guangxi Colleges and universities’ by the Project of Humanities and Social Sciences in ‘Research on Collaborative Integration of Logistics Service Supply Chain under High-Quality Development Goals’ (2021QGRW044). In addition, the study was supported by the 2019 National Social Science Project in ‘Research on the Integration of Transnational Supply Chains under the Belt and Road Initiative (19BJY184)’. This paper was also supported by Guangxi Philosophy and Social Science Planning Office Project: Research on the Dynamic Mechanism and Model Innovation of the Cross-border Integration Growth of Guangxi Logistics Enterprises (18BGL010).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. H. Nozari, M. Fallah, S. E. Najafi, P. H. Uyen and P. T. Bao, “Big data analysis of IoT-based supply chain management considering FMCG industries,” Bizn Inform, vol. 15, no. 1, pp. 78–96, 2021. [Google Scholar]

2. A. R. Mahlous, “Internet of things (IoTArchitecture, evolution, threats and defense,” International Journal of Computer Science and Network Security, vol. 19, no. 1, pp. 56–67, 2019. [Google Scholar]

3. L. Song, Y. Luo, Z. Chang, C. Jin and M. Nicolas, “Blockchain adoption in agricultural supply chain for better sustainability: A game theory perspective,” Sustainability, vol. 14, no. 3, pp. 1450–1470, 2022. [Google Scholar]

4. H. Cui, “Research on agricultural supply chain architecture based on edge computing and efficiency optimization,” IEEE Access, vol. 10, pp. 4896–4906, 2022. [Google Scholar]

5. S. Khaki and L. Wang, “Crop yield prediction using deep neural networks,” Frontiers in Plant Science, vol. 10, pp. 611–621, 2019. [Google Scholar]

6. T. V. Klompenburg, A. Kassahun and C. Catal, “Crop yield prediction using machine learning: A systematic literature review,” Computers and Electronics in Agriculture, vol. 117, pp. 1–18, 2020. [Google Scholar]

7. R. Wen and W. J. Yan, “Supply-demand prediction for agile manufacturing with deep neural network,” Smart and Sustainable Manufacturing Systems, vol. 3, no. 2, pp. 95–105, 2019. [Google Scholar]

8. Z. H. Kilimci, A. O. Akyuz, M. Uysal, S. Akyokus, M. O. Uysal et al., “An improved demand forecasting model using deep learning approach and proposed decision integration strategy for supply chain,” Complexity, vol. 2019, pp. 1–15, 2019. [Google Scholar]

9. B. Yan, X. N. Wang and P. Shi, “Risk assessment and control of agricultural supply chains under internet of things,” Agrekon, vol. 56, no. 1, pp. 1–12, 2017. [Google Scholar]

10. P. Magdalena, N. Gniewko, P. Tomasz, L. Tomasz, P. Krzysztof et al., “The application of multiple linear regression and artificial neural network models for yield prediction of very early potato cultivars before harvest,” Agronomy, vol. 11, no. 5, pp. 769–885, 2021. [Google Scholar]

11. M. Rashid, B. S. Bari, Y. Yusup, M. A. Kamaruddin and N. Khan, “A comprehensive review of crop yield prediction using machine learning approaches with special emphasis on palm oil yield prediction,” IEEE Access, vol. 9, pp. 63406–63439, 2021. [Google Scholar]

12. F. F. Cao, “Grey system theory in grain yield forecasting,” Practice and Understanding of Mathematics, vol. 47, no. 13, pp. 310–312, 2017. [Google Scholar]

13. Y. H. Li, C. Wang, Z. Wen, K. Du, Y. L. Sun et al., “Prediction of agricultural products cold chain logistics demand in Hunan Province based on sliding unbiased grey model,” Journal of Central South University of Forestry & Technology, vol. 41, no. 8, pp. 161–168, 2021. [Google Scholar]

14. C. Ma, Y. Yuan and H. S. You, “Forecasting method of agricultural product yield based on Gray-Markov model,” Computer Science, vol. 47, no. 6, pp. 535–539, 2020. [Google Scholar]

15. M. Q. Jia, Z. J. Cai, J. Hu, H. S. Chen, N. Wang et al., “Research on grain yield prediction model based on machine learning,” Journal of Agricultural University of Hebei, vol. 43, no. 3, pp. 103–108, 2022. [Google Scholar]

16. Y. Z. Feng, Y. R. Hu, H. J. Liu. “Study on lasso-grey prediction model of walnut yield in Lin’an,” Forest Resources Management, vol. 2021, no. 1, pp. 94–102, 2021. [Google Scholar]

17. H. C. Sun, B. Hu and Y. X. Zou, “BP-LSTM model for exponential trend prediction,” Journal of Sichuan University (Natural Science Edition), vol. 57, no. 1, pp. 27–31, 2020. [Google Scholar]

18. X. Q. Fang, C. Y. Wu, S. H. Yu, D. B. Zhang and Q. Ouyang, “Research on short-term forecasting model of agricultural product price based on EEMD-LSTM,” Chinese Journal of Management Science, vol. 29, no. 11, pp. 68–77, 2021. [Google Scholar]

19. M. A. Mohamed, I. M. El-Henawy and A. Salah, “Price prediction of seasonal items using machine learning and statistical methods,” Computers, Materials & Continua, vol. 70, no. 2, pp. 3473–3487, 2022. [Google Scholar]

20. Z. H. Kilimci, A. O. Akyuz, M. Uysal, M. O. Uysal, B. A. Bulbul et al., “An improved demand forecasting model using deep learning approach and proposed decision integration strategy for supply chain,” Complexity, vol. 2019, no. 2019, pp. 1–15, 2019. [Google Scholar]

21. A. B. Mohamed, M. Gunasekaran and M. Mai, “Internet of things (IoT) and its impact on supply chain: A framework for building smart, secure and efficient systems,” Future Generation Computer Systems, vol. 86, no. 9, pp. 614–628, 2018. [Google Scholar]

22. Y. M. Tang, K. Y. Chau, D. Xu and X. Liu, “Consumer perceptions to support IoT based smart parcel locker logistics in China,” Journal of Retailing and Consumer Services, vol. 62, pp. 102659, 2021. [Google Scholar]

23. N. Azizi, H. Malekzadeh, P. Akhavan, O. Haass, S. Saremi et al., “IoT-Blockchain: Harnessing the power of internet of things and blockchain for smart supply chain,” Sensors, vol. 21, no. 18, pp. 6024–6048, 2021. [Google Scholar]

24. Y. Hong, “New model of food supply chain finance based on the internet of things and blockchain,” Mobile Information Systems, vol. 2021, no. 2021, pp. 1–8, 2021. [Google Scholar]

25. M. Mohaimenuzzaman, C. Bergmeir and B. Meyer, “Pruning vs. XNOR-net: A comprehensive study of deep learning for audio classification on edge-devices,” IEEE Access, vol. 10, pp. 6696–6707, 2022. [Google Scholar]

26. O. Friha, M. A. Ferrag, L. Shu and X. Wang, “Internet of things for the future of smart agriculture: A comprehensive survey of emerging technologies,” IEEE CAA Journal of Automatica Sinica, vol. 8, no. 4, pp. 718–752, 2021. [Google Scholar]

27. L. Song, X. Wang, P. Wei, Z. Liu, X. Wang et al., “Blockchain-based flexible double-chain architecture and performance optimization for better sustainability in agriculture,” Computers Materials & Continua, vol. 68, no. 1, pp. 1429–1446, 2021. [Google Scholar]

28. D. P. Cavallo, M. Cefola, B. Pace, A. F. Logrieco and G. Attolico, “Non-destructive automatic quality evaluation of fresh-cut iceberg lettuce through packaging material,” Journal of Food Engineering, vol. 223, no. 2018, pp. 46–52, 2018. [Google Scholar]

29. K. Wang, V. Kumar, X. Zeng, L. Koehl, X. Tao et al., “Development of a textile coding tag for the traceability in textile supply chain by using pattern recognition and robust deep learning,” International Journal of Computational Intelligence Systems, vol. 12, no. 2, pp. 713–722, 2019. [Google Scholar]

30. S. Jagtap, C. Bhatt, J. Thik and S. Rahimifard, “Monitoring potato waste in food manufacturing using image processing and internet of things approach,” Sustainability, vol. 11, no. 11, pp. 3162–3173, 2019. [Google Scholar]

31. V. K. Chouhan, S. H. Khan and M. H. Keshteli, “Sustainable planning and decision-making model for sugarcane mills considering environmental issues,” Journal of Environmental Management, vol. 303, pp. 114240–114252, 2022. [Google Scholar]

32. J. Fernandes, M. Simsek, B. Kantarci and S. Khan, “Table Det: An end-to-end deep learning approach for table detection and table image classification in data sheet images,” Neurocomputing, vol. 468, pp. 317–334, 2022. [Google Scholar]

33. L. Guo, “Cross-border e-commerce platform for commodity automatic pricing model based on deep learning,” Electronic Commerce Research, vol. 22, no. 1, pp. 1–20, 2022. [Google Scholar]

34. X. P. Qiu, “Neural Networks and Deep Learning,” Beijing, China: Machinery Industry Press, 2021. [Online]. Available: https://nndl.github.io/. [Google Scholar]

35. Y. Yu, X. Si, C. Hu and J. Zhang, “A review of recurrent neural networks: LSTM cells and network architectures,” Neural Computation, vol. 31, pp. 1235–1270, 2019. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools