| Computers, Materials & Continua DOI:10.32604/cmc.2022.029433 |  |

| Article |

Flexible Strain Sensor Based on 3D Electrospun Carbonized Sponge

1College of Information Technology, Jilin Agricultural University, Changchun, 130118, China

2State Key Laboratory of Integrated Optoelectronics, College of Electronic Science and Engineering, Jilin University, Changchun, 130012, China

3Jilin Province Intelligent Environmental Engineering Research Center, Changchun, 130118, China

4College of Resources and Environment, Jilin Agricultural University, Changchun, 130000, China

5Department of Agricultural Economics and Animal Production, University of Limpopo, 0727, Polokwane, South Africa

*Corresponding Author: Tianli Hu. Email: hutianli@jlau.edu.cn

Received: 03 March 2022; Accepted: 06 April 2022

Abstract: Flexible strain sensor has attracted much attention because of its potential application in human motion detection. In this work, the prepared strain sensor was obtained by encapsulating electrospun carbonized sponge (CS) with room temperature vulcanized silicone rubber (RTVS). In this paper, the formation mechanism of conductive sponge was studied. Based on the combination of carbonized sponge and RTVS, the strain sensing mechanism and piezoresistive properties are discussed. After research and testing, the CS/RTVS flexible strain sensor has excellent fast response speed and stability, and the maximum strain coefficient of the sensor is 136.27. In this study, the self-developed CS/RTVS sensor was used to monitor the movements of the wrist joint, arm elbow joint and fingers in real time. Research experiments show that CS/RTVS flexible strain sensor has good application prospects in the field of human motion monitoring.

Keywords: Flexible strain sensor; electrostatic spinning technology; human motion detection; carbonized sponge

With the continuous development of sensor technology [1], flexible strain sensors have been used in many fields, especially in human body application detection, intelligent electronic skin [2], behavior monitoring and so on. From the current research status, the conduction mechanisms of strain sensors are mainly divided into four types: piezo-capacitance, piezoelectric, piezoresistive and triboelectric [3]. The flexible strain sensor studied in this paper is based on the piezoresistive effect [4]. The piezoresistive sensor can generate a changing resistance signal according to the mechanical deformation generated by the external pressure [5]. The piezoresistive sensor requires simple materials, low cost and easy advantages of production, wide detection range and fast response speed are widely used in various fields [6].

Electrospinning is a practical [7], cheap and versatile technology for the preparation of ultrafine fibers with diameters ranging from nano to micron. Electrospinning often produces planar two-dimensional non-woven fiber pads [8]. When these mats are used as pressure sensing materials, they will lead to relatively low pressure sensitivity, which is attributed to the tightly packed nanofibers, resulting in low porosity and limiting the resistance change of the mats [9]. This phenomenon has limited the application of electrospun 3D porous materials in pressure sensors [10].

RTVS is a silicon-based elastomerr. RTVS is a silicone based elastomer. RTVS has excellent flexibility due to its good biocompatibility, and its excellent thermal stability ensures that the sensor can be used in various fields in practical applications. Its high elasticity and fast response speed are more in line with this study. The requirements of the resistive matrix are more suitable for the detection of human use.

In this study, we report a flexible strain sensor composed of an RTVS elastic matrix and a conductive carbonized sponge (CS). The 3D conductive carbonized sponge was prepared by electrospinning technology and carbonization technology [11], and fully fused with elastic matrix to prepare CS/RTVS flexible strain sensor. Its practical application in the field of human motion detection is tested and discussed [12].

Polyacrylonitrile (Pan, Mw = 150000), N, N-dimethylformamide (DMF, 99.8%), anhydrous aluminum chloride (AlCl3%, 99.8%) were purchased from Aladdin Chemical Co., Ltd. (China), and anhydrous ferric chloride (FeCl3%, 99.8%) were purchased from Aladdin Chemical Co., Ltd. (China). RTVS605 silica gel compound (American hasuncast brand product). All chemicals are used as is without further treatment.

2.2 Preparation of Electrospun Carbonized Sponge (CS)

Firstly, polyacrylonitrile powder and dimethylformamide were magnetically stirred in a 60 °C water bath for 6 h to obtain a uniform polyacrylonitrile solution (13 wt%). Then, 0.5 g of aluminum trichloride and 0.5 g of iron trichloride were added to 13 wt% polyacrylonitrile solution, and then magnetically stirred in a 50 °C water bath for 6 h. The precursor solution is then filled into a syringe with a metal spinneret. During electrospinning, the applied voltage, the feed speed of precursor solution and the distance of nozzle collector are controlled at 15 kV, 0.5 ml/h and 15 cm respectively. The grounded steel roller (length 5 cm; diameter 7 cm) is used as a collector, and the rotation speed of the steel roller is limited to 120 rad/min. After electrospinning, a non-woven porous sponge was obtained. The obtained sponge was dried in an air circulation oven at 60 °C for 3 h, and then oxidized and stabilized under the same conditions, but the temperature and time changed to 210 °C and 2 h respectively. Subsequently, the sponge was carbonized in a tubular furnace at 800 °C for 4 h in a nitrogen atmosphere to convert the sponge into carbon sponge (CS), and the temperature was increased at a rate of 5 °C/min. Finally, after cooling the tubular furnace to room temperature, the carbonized sponge is obtained.

2.3 Assembly of the Flexible Strain Sensor

CS strain sensors were made by simply encapsulating CS with RTVS. First, the obtained CS was cut into slices (20 mm × 10 mm × 2 mm). Then, two copper foil electrodes with conductive silver paste were glued on both sides of the CS sheet. Finally, the RTVS base monomer and the curing agent were uniformly mixed at a mass ratio of 10:1 and poured onto the surface of the CS with electrodes inside the mold, followed by degassing in a vacuum chamber for 1 h and then heating at 60 °C for 6 h.

Characterization The morphologies of CS were performed by scanning electron microscopy (SEM, SHIMADZUX-550). The tensile tests of the CS/RTVS strain sensor were measured by STD100 microcomputer-controlled electronic universal testing machine (RicKs Measurement and Control Co., Ltd.), while the electrical signals were measured by Keysight B2902A Precision Source/Measure Unit (KEYSIGHT B2902A).

In this work, 3D aluminum-iron sponge was prepared by electrospinning technology. In the experiment, a well-mixed precursor solution of AlCl3 and FeCl3 was used for electrospinning [13]. The iron ions and aluminum ions in the precursor solution could increase the viscosity of the precursor solution, and during the electrospinning process, the precursor solution was in a strong state. Under the action of an electric field, iron ions and aluminum ions are easily polarized [14]. The mutual repulsive force between the spinning fibers increases, thereby increasing the gap between each fiber layer, which is not only conducive to the curing of the fibers, but also conducive to the support of the coagulated fiber layers to the subsequent fiber layers. During the uninterrupted electrospinning process, the thickness of the nanofiber layer was increased through the continuous superposition of the fiber layers and the repeated sedimentation process, and a 3D aluminum-iron sponge with porous multilayers was successfully prepared [15]. Then, the 3D aluminum-iron sponge was encapsulated with the RTVS elastic matrix solution to prepare the CS/RTVS flexible strain sensor, and then the performance of the flexible strain sensor was experimentally tested and studied.

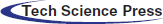

(GF) is defined as δ( Δ R/R0)/δε, where ε represents strain, which measures the sensitivity of strain sensors. At the same time, as shown in Fig. 1. The test results show that according to the variation range of the sensitivity test of the CS/RTVS flexible strain sensor, it is divided into three stages: 0%–30%, 30%–50%, and 50%–60%. The sensitivity test results of the three stages are: 15.14, 46.28 and 136.27. The GF of the sensor in the high tensile strain range is nine times that of the low tensile strain range and three times that of the medium tensile strain range. The CS/RTVS flexible strain sensor has a GF of 15.14 in the low tensile strain range, which is several times higher than that of the traditional metal strain sensor, which has a GF of 2. This experiment demonstrates the wide tensile strain range and excellent sensitivity of the CS/RTVS flexible strain sensor.

Figure 1: RCR response tensile strain function graph of CS/RTVS sensor

In this study, the sensing mechanism of the fabricated flexible strain sensor is discussed. In different tensile strain ranges, the resistance change of the flexible strain sensor is related to the change between CS fiber layers [16]. With the increase of tensile force, the flexible strain sensor is divided into three parts: Fracture stage, sliding stage and disconnection stage [17]. The CS carbon fibers encapsulated by RTVS are tightly continuous. In the application of the flexible strain sensor, with the strengthening of the tensile force, the inside of the flexible strain sensor enters the fracture stage, and the fracture between the carbon fiber layers inside the CS causes its internal resistance to increase rapidly, thus showing excellent sensitivity [18]. With the continuous increase of the tensile force, the CS carbon fiber enters the sliding stage, and the carbon fiber changes from long fibers to short fibers. The mutual sliding between the short fibers reduces the contact area between the carbon fibers, resulting in the continuous resistance of the overall sensor. increase [19]. When the tensile force exceeds the sliding limit of the carbon fiber, it enters the breaking stage, and the resistance of the flexible strain sensor increases continuously due to the discontinuity of the carbon fiber. The flexible strain sensor is packaged by RTVS to increase its flexibility and continuous use capability [20].

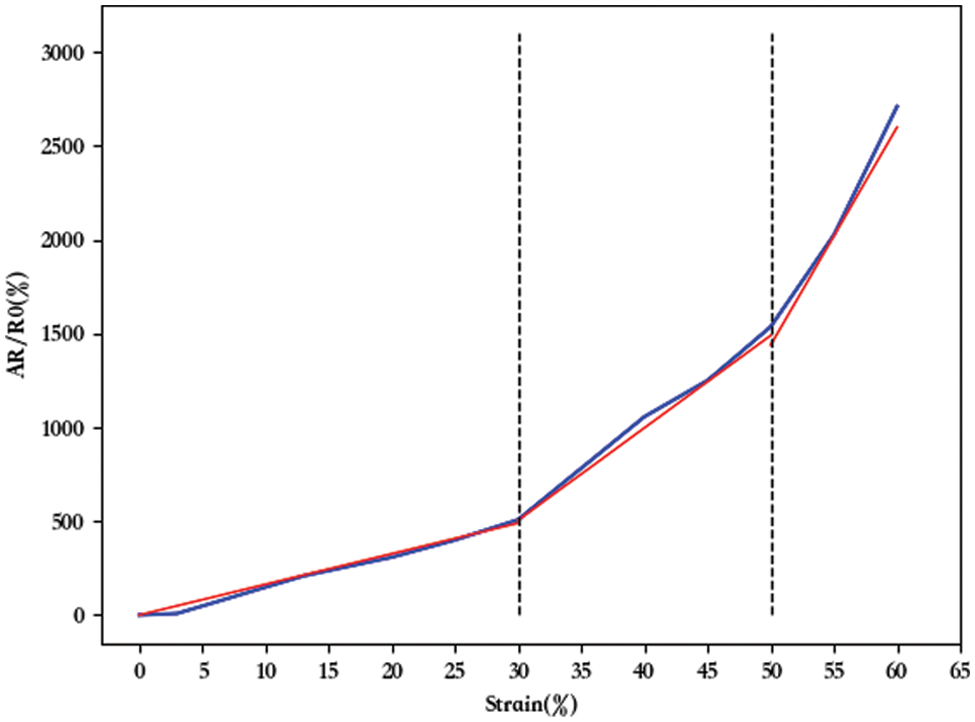

Fig. 2 shows the RCR response under different tensile strain cycles. In this experimental test, the CS/RTVS flexible strain sensor was tested for its stability, and the RCR response signal exhibited by the sensor was detected under the condition of cyclic tensile strain. The experimental test results show that from the beginning to the end of the cyclic tensile strain, the response signal displayed by the sensor tends to be stable, showing the excellent stability of the CS/RTVS flexible strain sensor in the face of cyclic tensile strain. It lays a theoretical and experimental basis for practical application.

Figure 2: The RCR response of CS/RTVS strain sensor to cyclic tension under various tensile strain cycles

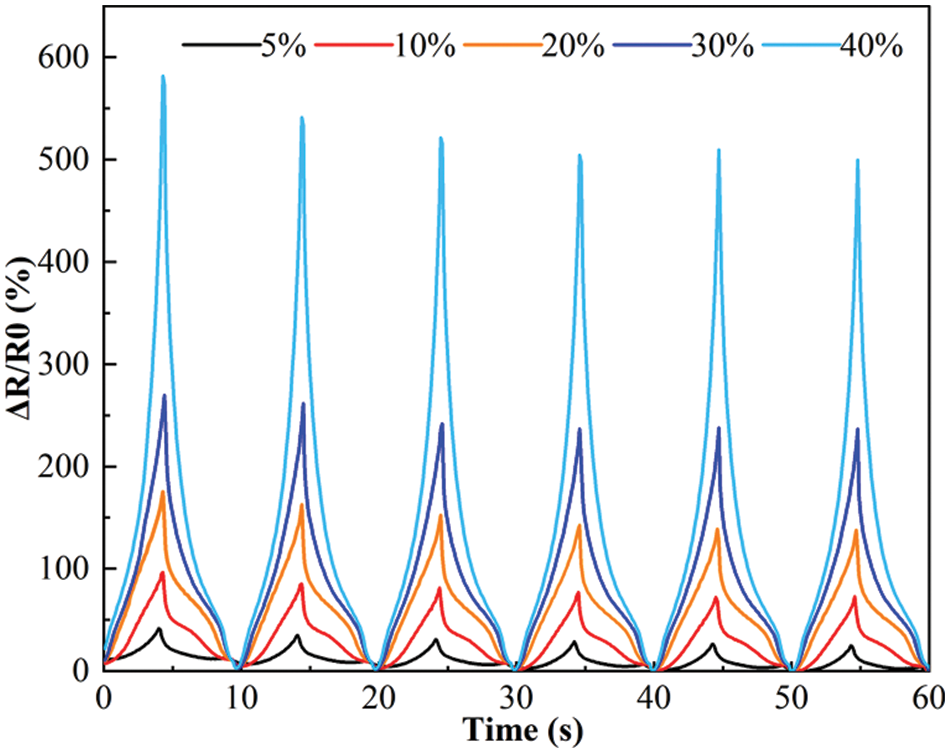

Considering that the durability of the CS/RTVS strain sensor is a key feature of its practical application, as shown in Fig. 3, the flexible strain sensor is subjected to 1,000 cycles of tensile release experiments. The RCR of the CS/RTVS strain sensor is almost unchanged in 1000 tensile release cycles, showing excellent stability and durability.

Figure 3: Durability test of CS/RTVS strain sensor

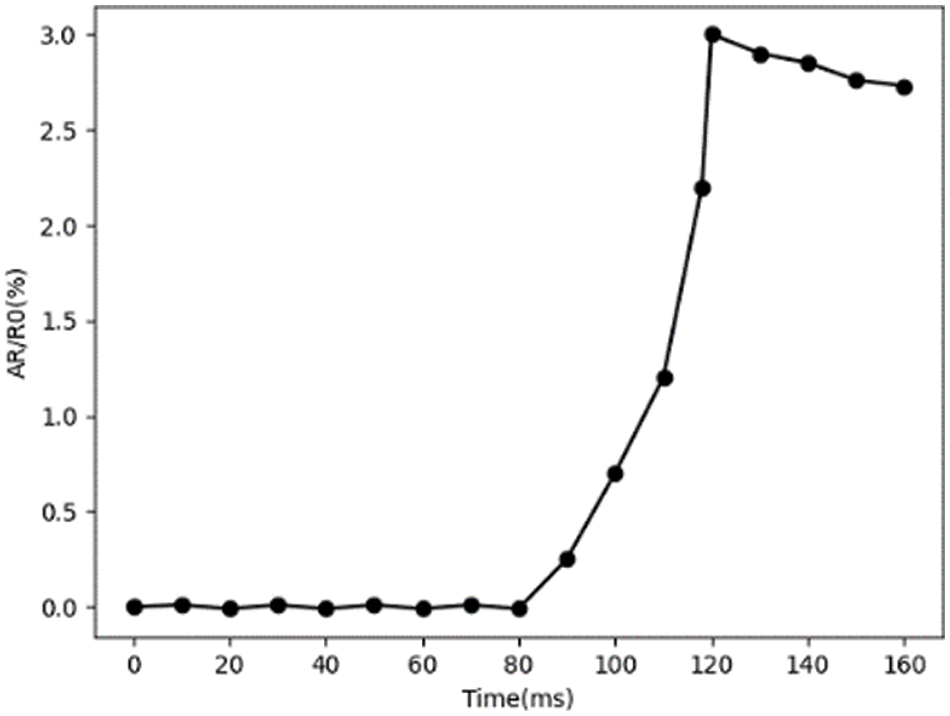

In the process of studying the response time of the CS/RTVS strain sensor, as shown in Fig. 4, the experimental results show that the response time of the CS/RTVS flexible strain sensor is only 40 ms under the test conditions of a tensile rate of 500 mm/min and a tensile strain of 0.5%. The experimental results confirm that the CS/RTVS flexible strain sensor has excellent fast response ability to external stretching stimuli under the condition of high stretching rate, and has potential in the field of human stretching motion detection.

Figure 4: Response time of CS/RTVS strain sensor

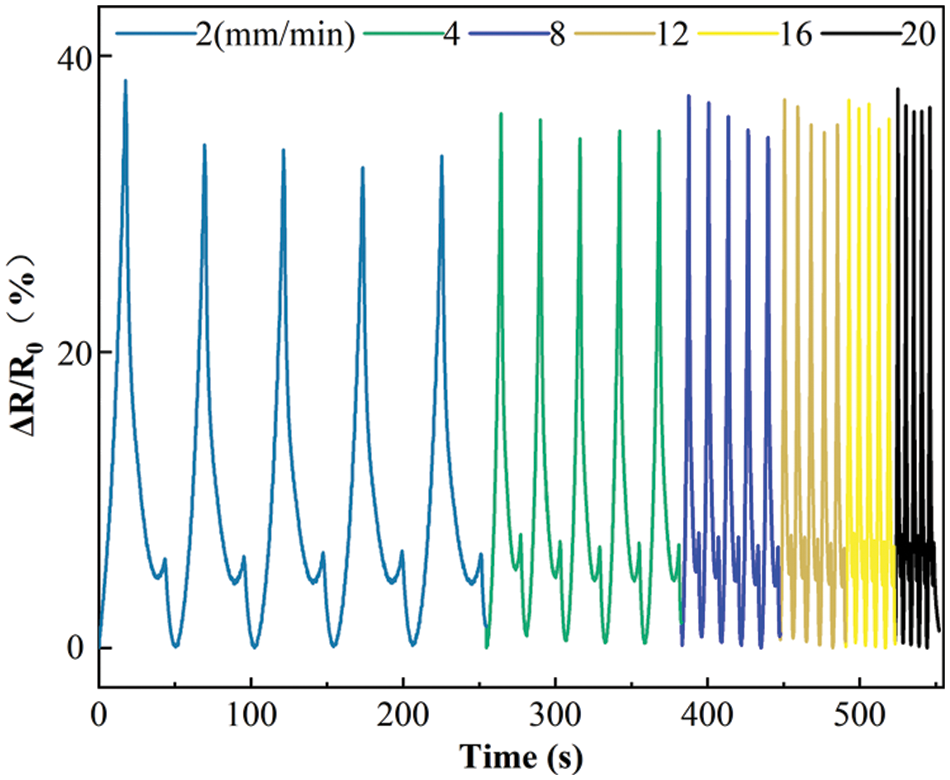

The strain rate dependence of flexible strain sensors is one of the important properties reflecting the sensor performance. In this study, the strain rate performance of CS/RTVS flexible strain sensor is experimentally and discussed, and the flexible strain sensor is tested in the range of tensile speed range of 2–20 mm/min. as shown in Fig. 5. With the change of the strain range, the response signal exhibited by the sensor also changes. The sensor has almost no frequency dependence, and the sensor responds quickly within a certain frequency range, showing the excellent sensitivity of CS/RTVS flexible strain sensor. At the same time, it can be observed that when tension is applied, RCR generally increases. This typical behavior can be defined as the normal strain effect. The results show that the CS/RTVS strain sensor has superior performance and good stability.

Figure 5: RCR response of CS/RTVS strain sensor at different stretching speeds

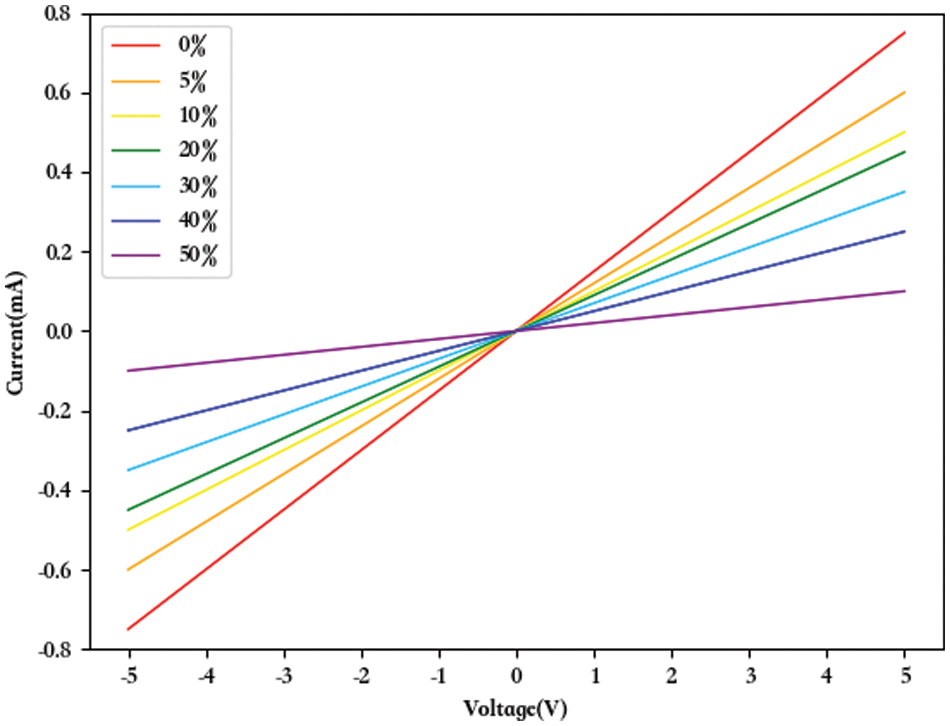

Fig. 6 shows the current-voltage (I-V) curves of CS/RTVS sensors with different tensile strains. The test results show that, under a certain voltage, changing the tensile strain of the sensor can clearly see the change of the resistance of the sensor. The experimentally obtained volt-ampere characteristic curves show the excellent ohmic behavior of the CS/RTVS flexible strain sensor. And in the wide tensile strain range of 0% to 50%, the excellent electrical conductivity of the CS/RTVS flexible strain sensor is exhibited, confirming that the sensor’s excellent ohmic behavior and excellent electrical conductivity are suitable for human motion detection.

Figure 6: I-V curve of CS/RTVS strain sensor under different tensile strains

In order to prove the potential application of the flexible strain sensor in detecting human movement, it was installed at the joints of the fingers, wrist, and elbow of a 25-year-old healthy male with a height of 180 cm to determine the flexibility of the flexible strain sensor in detecting human movement. ability.

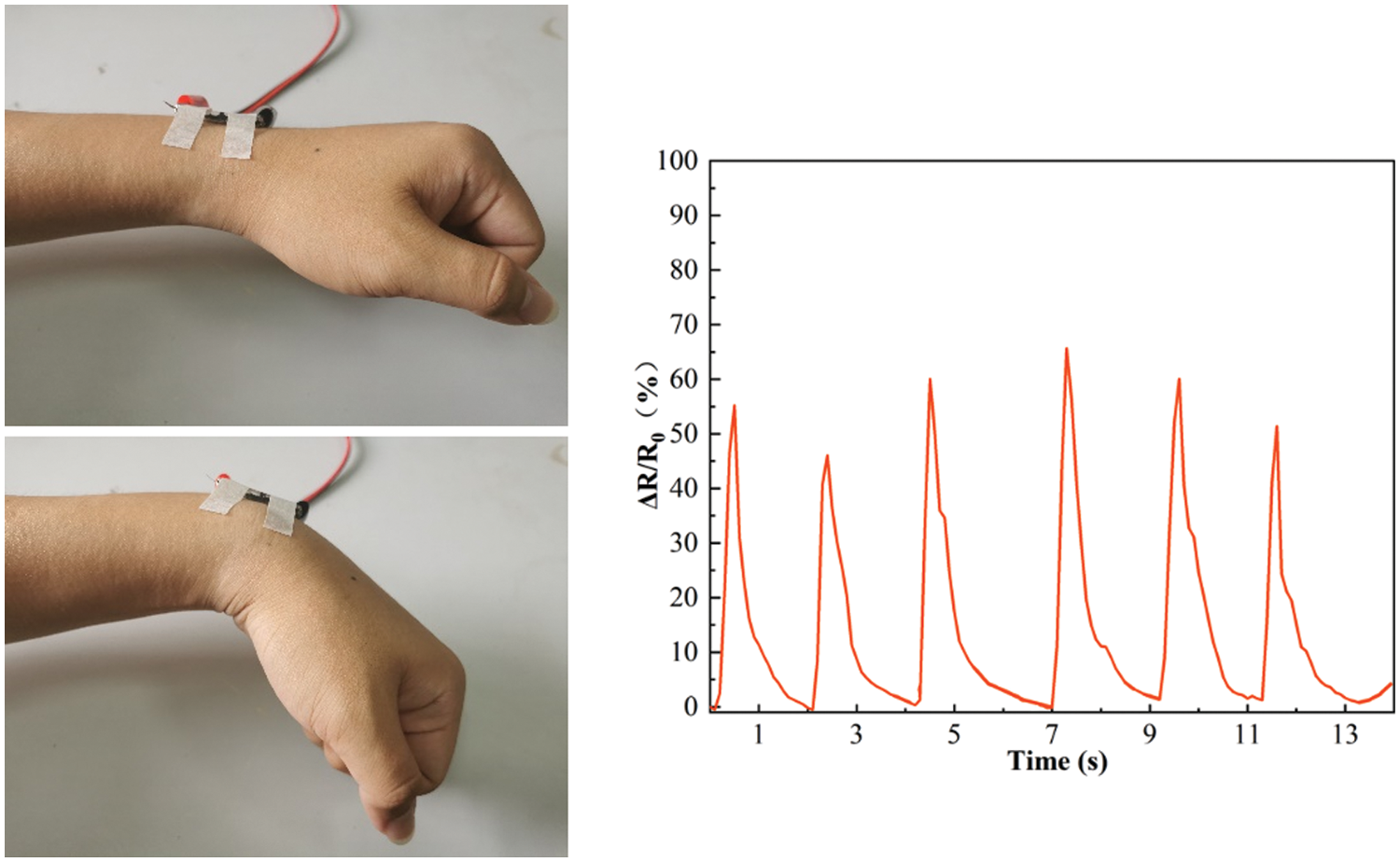

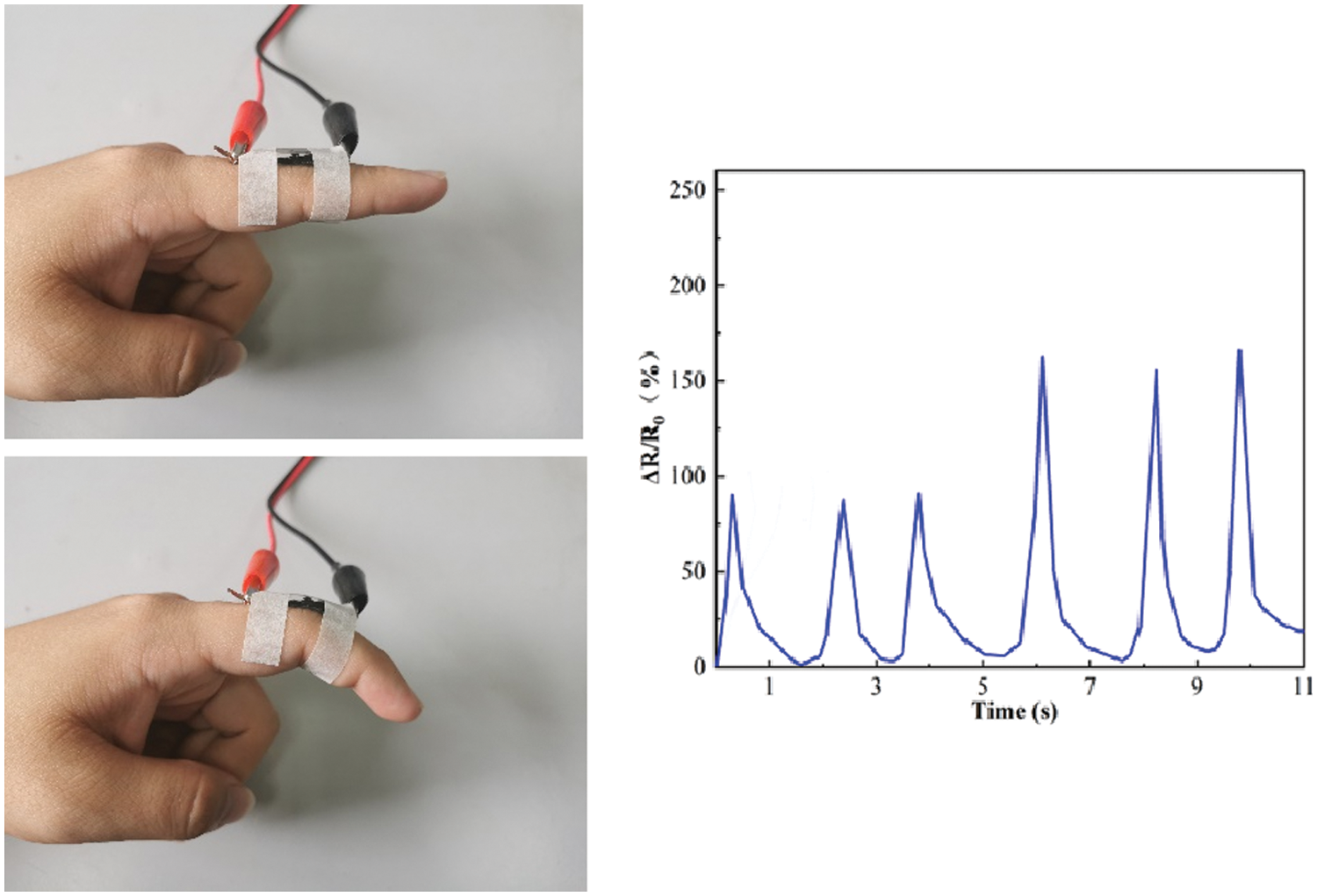

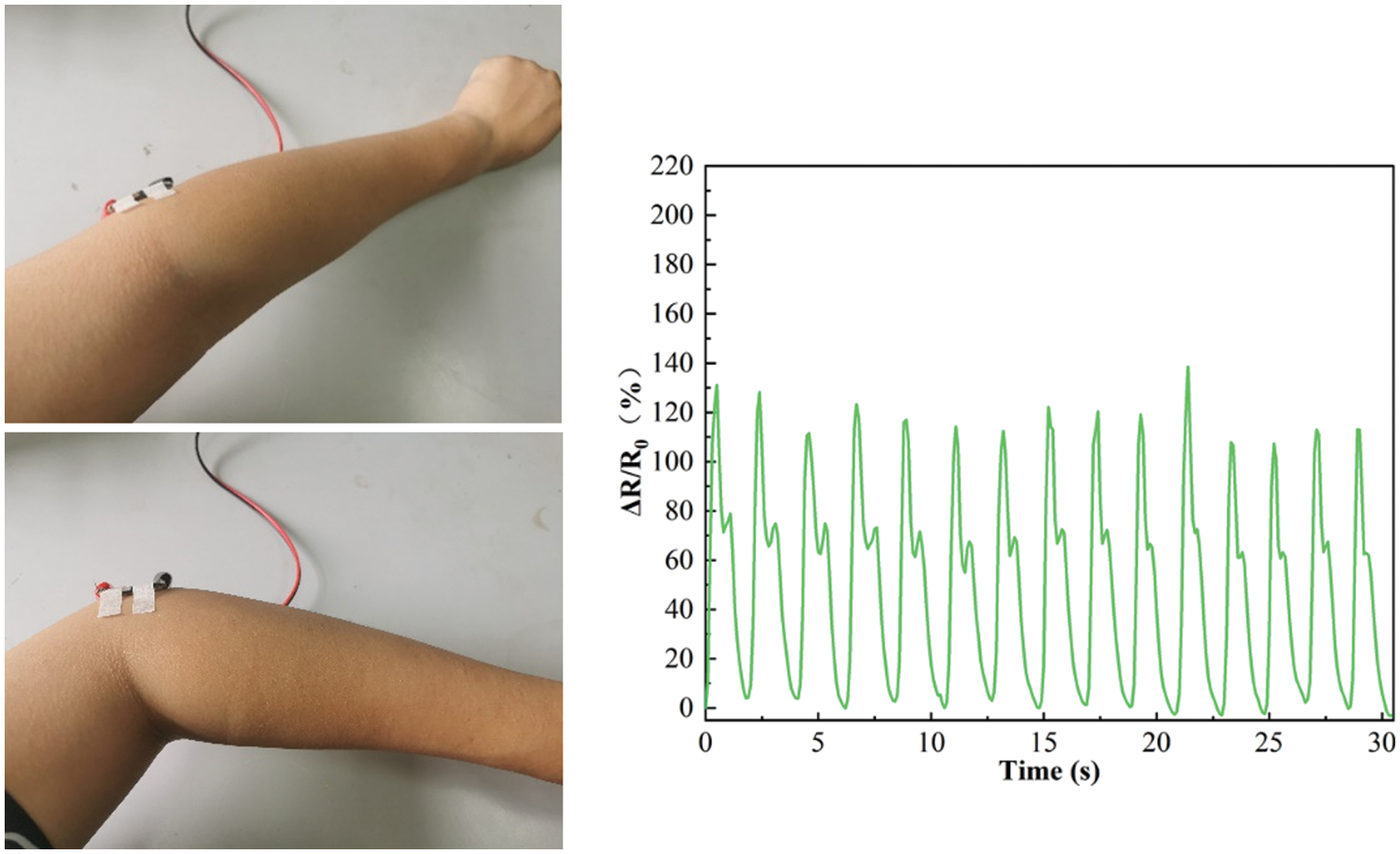

As shown in the Fig. 7, in the experiment, both ends of the CS/RTVS flexible strain sensor are fixed on the human wrist, the wrist joint moves from the horizontal state to the bending state, and the two ends of the sensor are connected externally, so as to monitor the wrist bending state signal in real time. The test results show that the CS/RTVS flexible Strain sensors can well detect changes in wrist bending, which will have profound significance in the field of human motion monitoring in the future. As shown in the Fig. 8, the two ends of the sensor are connected to the human knuckles, and the human body moves by continuously extending the finger to the bending, which causes the change of the response signal of the CS/RTVS flexible strain sensor. The test results show that the response signal displayed by the sensor changes with the bending of the finger. The degree of increase increases, showing high sensitivity and excellent repeatability, with a good detection function of finger bending motion [21]. As shown in the Fig. 9, the CS/RTVS flexible strain sensor is not only for the detection of small-amplitude bending motion of the human body, but also can detect the large-scale motion of the human body. The sensor is connected to the elbow joint of the human arm. From the experimental results, it can be clearly seen that the CS/RTVS flexible strain sensor has obvious effect on the detection of the periodic motion of the human elbow joint, and the RCR response increases with the increase of the elbow bending degree showing excellent reactivity. In summary, the actual test results show that the CS/RTVS flexible strain sensor has good responsiveness and sensitivity in the monitoring of human motion, can be used for human motion detection, and has a good application prospect in the field of human motion detection.

Figure 7: Wrist bending movement monitoring

Figure 8: Finger bending movement monitoring

Figure 9: Monitoring of elbow bending motion

In conclusion, a flexible strain sensor was prepared based on RTVS encapsulated electrospinning technology. The formation mechanism of self-assembled sponges with three-dimensional nanostructures constructed by aluminum trichloride and iron trichloride as ion sources was explored. The structure of RTVS porous three-dimensional carbon sponge as a key sensing element is introduced. The mechanism of resistance change is related to three stages of tensile strain: Fracture stage, sliding stage and disconnection stage. In this work, CS/RTVS strain sensor can obtain high GF of 15.14, 46.28 and 136.27 in the tensile strain range of 0%–30%, 30%–50% and 50%–60%, respectively. In addition, the CS/RTVS strain sensor has fast response (40 ms), high stability (1000 cycles) and a wide tensile speed range of 2–18 mm/min. Therefore, CS/RTVS flexible strain sensor can accurately detect all kinds of human motion, such as finger motion, wrist motion, arm and elbow motion, which shows its practical application prospect in flexible strain sensor equipment, and these equipment will have broad application prospects in human motion detection.

Acknowledgement: Availability of data and material are available.

Funding Statement: This research is supported by the Science and Technology Department of Jilin Province [20210202128NC]; The People’s Republic of China Ministry of Science and Technology [2018YFF0213606–03]; Jilin Province Development and Reform Commission [2019C021].

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. N. R. Sivakumar and A. Z. Ibrahim, “Deep neural artificial intelligence for IOT based tele health data analytics,” Computers, Materials & Continua, vol. 70, no. 3, pp. 4467–4483, 2022. [Google Scholar]

2. A. Arif, Y. Y. Ghadi, M. Alarfaj, A. Jalal, S. Kamal et al., “Human pose estimation and object interaction for sports behaviour,” Computers, Materials & Continua, vol. 72, no. 1, pp. 1–18, 2022. [Google Scholar]

3. A. Leal-Junior, L. Avellar and A. Frizera, “Smart textiles for multimodal wearable sensing using highly stretchable multiplexed optical fiber system,”Scientific Reports, vol. 10, no. 1, pp. 1–12, 2020. [Google Scholar]

4. X. Wang, S. Meng and M. Tebyetekerwa, “Highly sensitive and stretchable piezoresistive strain sensor based on conductive poly (styrene-butadiene-styrene)/few layer graphene composite fiber,” Composites Part A: Applied Science and Manufacturing, vol. 105, pp. 291–299, 2018. [Google Scholar]

5. H. Zheng and D. Shi, “A Multi-agent system for environmental monitoring using boolean networks and reinforcement learning,” Journal of Cybersecurity, vol. 2, no. 2, pp. 85, 2020. [Google Scholar]

6. Y. Jiang, Z. Liu and N. Matsuhisa, “Auxetic mechanical metamaterials to enhance sensitivity of stretchable strain sensors,” Advanced Materials, vol. 30, no. 12, pp. 1706589, 2018. [Google Scholar]

7. X. R. Zhang, X. Chen, W. Sun and X. Z. He, “Vehicle re-identification model based on optimized DenseNet121 with joint loss,” Computers, Materials & Continua, vol. 67, no. 3, pp. 3933–3948, 2021. [Google Scholar]

8. J. Lee, S. Shin and S. Lee, “Highly sensitive multifilament fiber strain sensors with ultrabroad sensing range for textile electronics,” ACS Nano, vol. 12, no. 5, pp. 4259–4268, 2018. [Google Scholar]

9. Q. Liu, J. Chen and Y. Li, “High-performance strain sensors with fish-scale-like graphene-sensing layers for full-range detection of human motions,” ACS Nano, vol. 10, no. 8, pp. 7901–7906, 2016. [Google Scholar]

10. G. Cai, J. Wang and K. Qian, “Extremely stretchable strain sensors based on conductive self-healing dynamic cross-links hydrogels for human-motion detection,” Advanced Science, vol. 4, no. 2, pp. 1600190, 2017. [Google Scholar]

11. Z. Liu, D. Qi and G. Hu, “Surface strain redistribution on structured microfibers to enhance sensitivity of fiber-shaped stretchable strain sensors,” Advanced Materials, vol. 30, no. 5, pp. 1704229, 2018. [Google Scholar]

12. S. Liu, R. Zheng and S. Chen, “A compliant, self-adhesive and self-healing wearable hydrogel as epidermal strain sensor,” Journal of Materials Chemistry C, vol. 6, no. 15, pp. 4183–4190, 2018. [Google Scholar]

13. N. Chen, N. Xialihaer, W. Kong and J. Ren, “Research on prediction methods of energy consumption data,” Journal of New Media, vol. 2, no. 3, pp. 99–109, 2020. [Google Scholar]

14. H. Liu, Q. Li and S. Zhang, “Electrically conductive polymer composites for smart flexible strain sensors: A critical review,” Journal of Materials Chemistry C, vol. 6, no. 45, pp. 12121–12141, 2018. [Google Scholar]

15. M. D. Ho, Y. Ling and L. W. Yap, “Percolating network of ultrathin gold nanowires and silver nanowires toward “invisible” wearable sensors for detecting emotional expression and apexcardiogram,” Advanced Functional Materials, vol. 27, no. 25, pp. 1700845, 2017. [Google Scholar]

16. M. Ren, Y. Zhou and Y. Wang, “Highly stretchable and durable strain sensor based on carbon nanotubes decorated thermoplastic polyurethane fibrous network with aligned wave-like structure,” Chemical Engineering Journal, vol. 360, pp. 762–777, 2019. [Google Scholar]

17. J. Kwon, Y. D. Suh and J. Lee, “Recent progress in silver nanowire based flexible/wearable optoelectronics,” Journal of Materials Chemistry C, vol. 6, no. 28, pp. 7445–7461, 2018. [Google Scholar]

18. D. P. Dubal, N. R. Chodankar and D. H. Kim, “Towards flexible solid-state supercapacitors for smart and wearable electronics,” Chemical Society Reviews, vol. 47, no. 6, pp. 2065–2129, 2018. [Google Scholar]

19. D. Wang, Y. Zhang and X. Lu, “Chemical formation of soft metal electrodes for flexible and wearable electronics,” Chemical Society Reviews, vol. 47, no. 12, pp. 4611–4641, 2018. [Google Scholar]

20. Y. Yang and W. Gao, “Wearable and flexible electronics for continuous molecular monitoring,” Chemical Society Reviews, vol. 48, no. 6, pp. 1465–1491, 2019. [Google Scholar]

21. M. M. Ali, D. Maddipatla and B. B. Narakathu, “Printed strain sensor based on silver nanowire/silver flake composite on flexible and stretchable TPU substrate,” Sensors and Actuators A: Physical, vol. 274, pp. 109–115, 2018. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |