DOI:10.32604/cmc.2022.026845

| Computers, Materials & Continua DOI:10.32604/cmc.2022.026845 |  |

| Article |

Motion-Planning Algorithm for a Hyper-Redundant Manipulator in Narrow Spaces

1Faculty of Mechanical Engineering & Automation, Zhejiang Sci-Tech University, Hangzhou, 310018, China

2Key Laboratory of Transplanting Equipment and Technology of Zhejiang Province, Hangzhou, 310018, China

3Aeronautical Key Laboratory for Digital Manufacturing Technology, AVIC Manufacturing Technology Institute, Beijing, 100024, China

4Ingram School of Engineering, Texas State University, San Marcos, Texas, USA

*Corresponding Author: Lei Zhang. Email: lzhang@zstu.edu.cn

Received: 05 January 2022; Accepted: 01 March 2022

Abstract: In this study, a hyper-redundant manipulator was designed for detection and searching in narrow spaces for aerospace and earthquake rescue applications. A forward kinematics equation for the hyper-redundant manipulator was derived using the homogeneous coordinate transformation method. Based on the modal function backbone curve method and the known path, an improved modal method for the backbone curves was proposed. First, the configuration of the backbone curve for the hyper-redundant manipulator was divided into two parts: a mode function curve segment of the mode function and a known path segment. By changing the discrete points along the known path, the backbone curve for the manipulator when it reached a specified path point was dynamically obtained, and then the joint positions of the manipulator were fitted to the main curve by dichotomy. Combined with engineering examples, simulation experiments were performed using the new algorithm to extract mathematical models for external narrow space environments. The experimental results showed that when using the new algorithm, the hyper-redundant manipulator could complete the tasks of passing through curved pipes and moving into narrow workspaces. The effectiveness of the algorithm was also proven by these experiments.

Keywords: Hyper-redundant manipulator; backbone curve; narrow workspace; motion-planning

Hyper-redundant manipulators have tremendous application potential for complex working environments and narrow spaces, and currently play important roles in aerospace engineering [1,2], nuclear power engineering [3–5], and clinical medicine [6–9]. To maintain high flexibility and portability, hyper-redundant manipulators often adopt rope drives [10]. Owing to the many degrees of freedom in hyper-redundant manipulators, solving their inverse kinematics equations is usually more complicated. There are three primary method types commonly used for solving inverse kinematics [11]. One method is to solve the differential kinematics equations numerically using a pseudo-inverse solution of the Jacobian matrix [12,13]. This method involves a large number of calculations and has a slow calculation speed. Another method is to solve the inverse kinematics of a manipulator using an artificial neural network [14,15]; however, the training set for the neural network must be very large, and it is difficult to achieve instantaneous kinematics planning for the manipulator. The geometric method, based on the backbone curve proposed by Chirikjian et al. [16,17], is also useful for solving manipulator inverse kinematics. This method requires a small number of calculations and can be used for instantaneous control and online path planning.

Path-following motion [18] refers to motion where the end of a hyper-redundant manipulator follows a specified path, reproducing the path curve as closely as possible during the motion. During motion planning for a hyper-redundant manipulator with a mobile base platform, path-following motion is more aligned with its motion characteristics and can achieve the necessary flexibility and freedom. Fuzzy control methods can be used to achieve this kind of motion planning [19,20]. Additionally, for complex three-dimensional models, principal component analysis (PCA) can be used to reduce the dimensionality of the model, project the data into a low-dimensional subspace, and reduce the data processing complexity [21].

In this study, a hyper-redundant manipulator was designed, and its positive kinematics equation was derived by a homogeneous matrix coordinate transformation. Focusing on the problems that path-following motion is only suitable for a hyper-redundant manipulator with a moving base and that the mode function backbone curve is not suitable for moving along the tangent direction of a known path, a cost-effective method is proposed to achieve motion planning for a hyper-redundant manipulator based on a combination of the backbone curve and the path-following concept. The algorithm caused the position of the end effector to move along the tangent direction of a known path, and the joint position of the entering path was always close to the known path. This algorithm allows hyper-redundant manipulators to complete the motion in pipelines or other narrow workspaces.

2 Positive Kinematics of a Hyper-Redundant Manipulator

A hyper-redundant manipulator is shown in Fig. 1. This manipulator was composed of 12 links and an end effector. The links were connected by 12 universal joints, the hyper-redundant manipulator was driven by ropes, and driving motors were located in the manipulator box.

Figure 1: Coordinate system and structure of a hyper-redundant manipulator

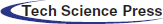

The structural and joint angle parameters of the hyper-redundant manipulator are shown in Tab. 1. The joints in the manipulator are characterized by θi and αi, where

Figure 2: Universal joint coordinate systems and conversion rules between adjacent coordinate systems

The homogeneous transformation matrix used during this study is presented as

where c and s represent

The coordinate transformation process from the basic

Figure 3: Coordinate transformation for the coordinate system of the first joint

The homogeneous transformation matrix from the basic

The transformation matrix of the ith joint is expressed by

The kinematics equation for the hyper-redundant manipulator can then be expressed by

When the joint angles are inserted into Eqs. (1)–(4), the position of the manipulator's end effector can be obtained.

3 Motion-Planning Algorithm Based on the Backbone Curve and Path-Following

The geometric method, based on the backbone curve, was used to solve the inverse kinematics of the hyper-redundant manipulator in this study. The backbone curve of the hyper-redundant manipulator had to be determined first. Then the positions of the hyper-redundant manipulator joints must be fitted to the backbone curve. Finally, the geometric method was used to solve for the joint angles.

3.1 Backbone Curve Based on the Mode Function

The modal method uses differential geometry to solve the inverse kinematics of hyper-redundant manipulators. The backbone curve of the mode function is shown in Fig. 4.

Figure 4: Mode function backbone curve

The mode function of the backbone curve [23] is expressed by

where s represents the normalized length parameter of the backbone curve and l represents the length of the backbone curve. The coordinates of each point in the backbone curve in the

In Eq. (6),

In Eq. (7),

When solving for the direction vector,

In Eq. (8),

where

The motion-planning algorithm for the hyper-redundant manipulator based on path-following and the backbone curve is primarily useful for passing the end effector through curved pipes and narrow spaces.

As shown in Fig. 5, the backbone curve was divided into a mode function curve segment and a known path curve segment. Point O represents the center of the first universal joint and the

Figure 5: The motion process of the backbone curve when the new algorithm was used

In Eq. (10), the integral's upper limit is

Five primary steps were used to solve for the set of backbone curves in the motion process.

Step 1: The total length of the initial mode function curve,

Step 2: At the ith step, the backbone curve was composed of the new mode function curve segment,

In Eq. (11),

Step 3: If the end-actuator position,

Step 4:

Step 5: When

3.3 Fitting of the Hyper-Redundant Manipulator and the Backbone Curve

As shown in Fig. 6, a dichotomy was used to fit the end point of the manipulator and the center of each universal joint to the backbone curve in turn, in the direction from the end point to the origin. The fitting process followed four primary steps.

Figure 6: The relationship between the manipulator and the backbone curve during motion

Step 1: The initial mode function curve from the base coordinate origin of the manipulator to the starting point of the known path was composed of

Step 2:

Figure 7: Selection of the center position of a universal joint

Step 3: Similarly, Steps 1 and 2 were repeated to fit all but the first two universal joints to the backbone curve in turn.

Step 4: When determining the position of the second universal joint, the middle vertical plane of vector

Figure 8: Selection of the center position of the second universal joint

When a hyper-redundant manipulator is fitted, the length of the backbone curve must be appropriately greater than the length of the manipulator if the backbone curvature is large.

3.4 Solving for the Joint Angles

The universal joint angles for the hyper-redundant manipulator were solved using the closed vector method. In Fig. 9,

Figure 9: Closed vector model for the hyper-redundant manipulator

The process of solving for the manipulator's joint angles was divided into three primary steps [23].

Step 1: For the first universal joint, the known vector, X2, could be expressed by

In Eq. (13),

Step 2: For the second universal joint,

Step 3: Similarly,

4.1 Motion Through a Bent Pipe

As shown in Fig. 10, during the exploration of a certain piece of aviation equipment, the base of a hyper-redundant manipulator was at

Figure 10: Bent pipe model and path selection

The origin of the mode function curve was at

Figure 11: Orientation of the backbone curve during the motion through the bent pipe

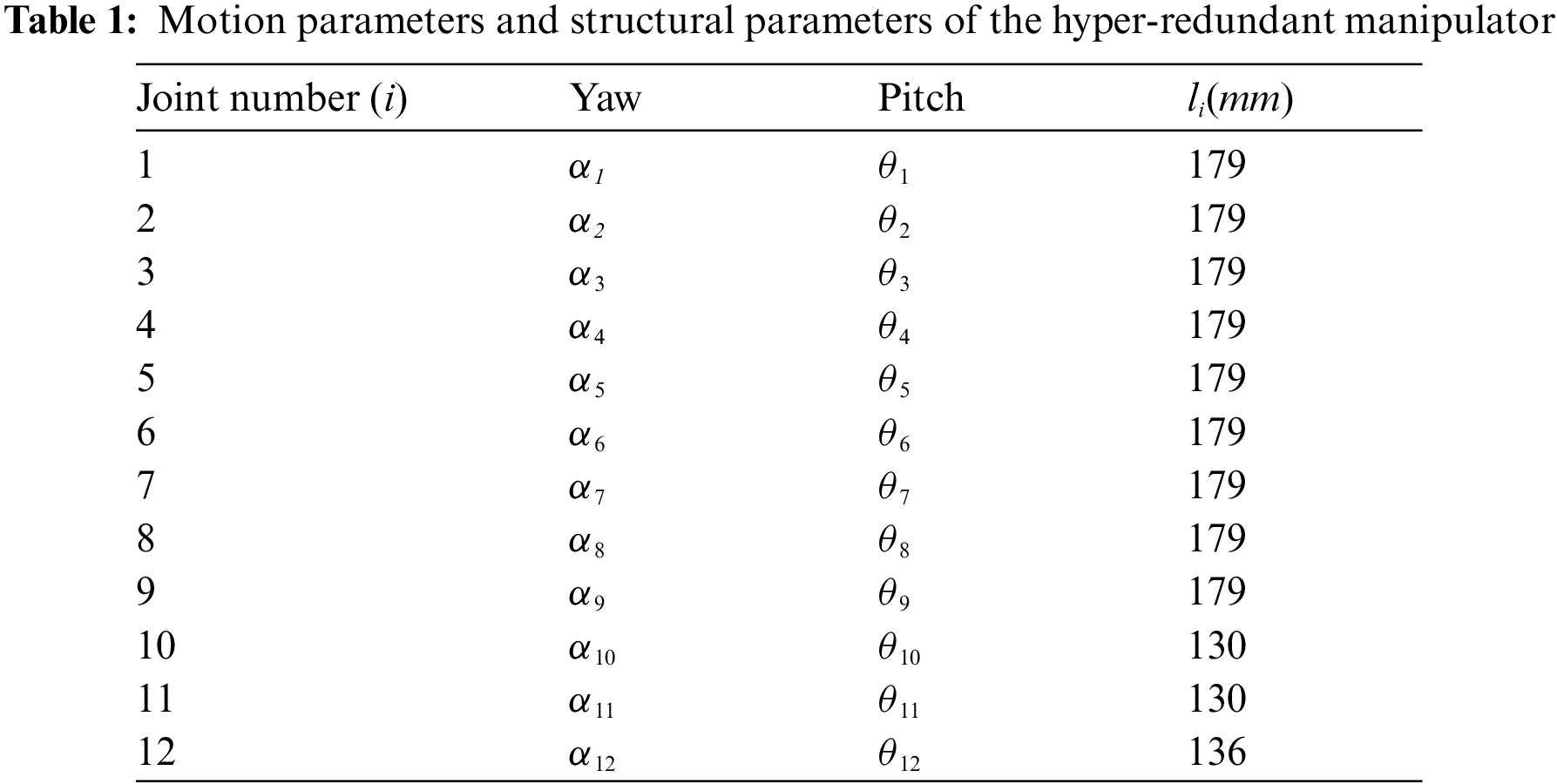

When solving for the backbone curve at each step, the hyper-redundant manipulator and the backbone curve were fitted by the algorithm described in Section 3.3, and the results are shown in Fig. 12. The three hyper-redundant manipulator orientations in Fig. 12 correspond to the three backbone curves in Fig. 11, and the manipulator orientations were consistent with the backbone curves. In Fig. 12a, the manipulator was in the initial motion state. In Fig. 12b, the end effector and the 11th and 12th universal joints were located on the known path and moved along the direction tangent to the path. Fig. 12c shows that the end effector coincided with the end point B, and that the 9th–12th universal joints were close to the known path to achieve the expected motion. The inverse solutions are shown in Fig. 13.

Figure 12: Orientations of the hyper-redundant manipulator during motion

Figure 13: Inverse solutions of the hyper-redundant manipulator as it traveled through the bent pipe

The red and blue curves in Fig. 13 represent the changes in

4.2 Motion When Entering Narrow Cabins

As shown in Fig. 14, during the process of exploring a piece of an aviation equipment, the center of the first universal joint in the hyper-redundant manipulator was at

Figure 14: Path selection and location of key points

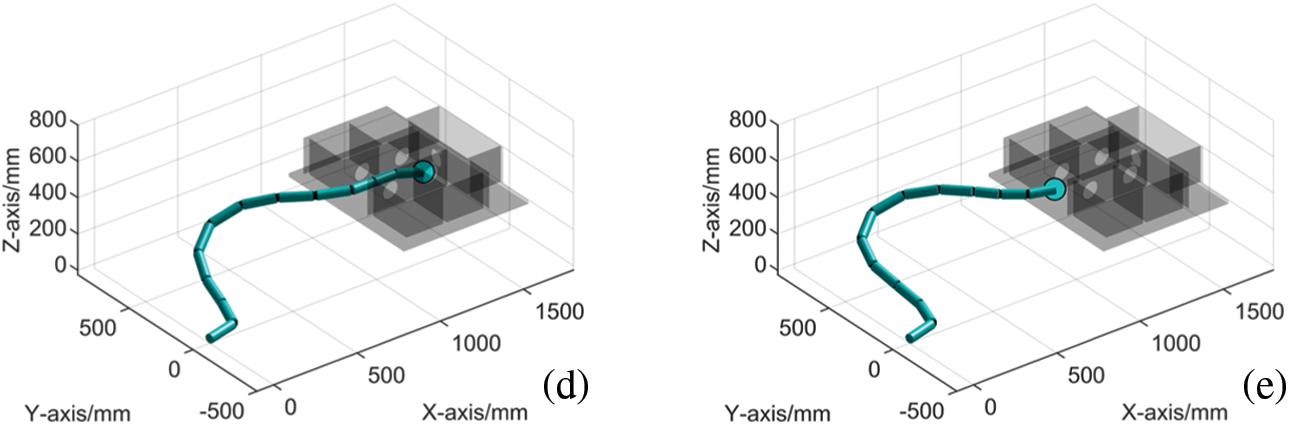

Using the new method proposed in this study, a series of results were generated. A backbone curve was obtained and is shown in Fig. 15a. The orientation of the backbone curve at the 60th step is shown in Fig. 15b. The length of the mode function curve segment was 1,707 mm. The modal participation factors of the mode function curve were regenerated using Equation (9), and the other parameters remained unchanged. In Fig. 15c, the manipulator had reached the target point. Fig. 15d and Fig. 15e represents the backbone curve during the return motion and the backbone curve when the manipulator had returned to the starting point, respectively. The hyper-redundant manipulator and the backbone curve were fitted by the algorithm from Section 3.3, and the results are shown in Fig. 16. The five orientations of the hyper-redundant manipulator in Fig. 16 correspond to the five backbone curves in Fig. 15, and the manipulator orientations were consistent with the backbone curves. The orientations at the initial position and when the manipulator had entered the cabin along the known path are shown in Fig. 16a and Fig. 16b, respectively. At this time, the end effector and the 11th and 12th universal joints had entered the cabin.

Figure 15: Backbone curve orientations when entering the narrow cabins

Figure 16: Manipulator orientations when entering the narrow cabins

Fig. 16c shows the orientation when the end effector had reached the end point, C. The end effector and the 11th and 12th universal joints were located in one cabin, and the 9th and 10th universal joints were located in another cabin. Fig. 16d shows that the end effector returned along the known path. Fig. 16e shows the end effector and the universal joints when the hyper-redundant manipulator had completely exited the cabins. These inverse solutions are shown in Fig. 17. Simulation experiments based on these inverse solutions verified the correctness and effectiveness of the new algorithm.

Figure 17: The angles of the universal joints and the manipulator motion when entering the narrow cabins

Using the homogeneous coordinate transformation method to derive the positive kinematics equation for a hyper-redundant manipulator can reduce the number of coordinate systems, simplify the derivation process for the transformation matrix, and save calculation time. An improved modal backbone curve method was proposed in this study. First, with changes in the discrete points along the known path, the backbone curves that the hyper-redundant manipulator used to reach these points were dynamically obtained. Then, the joints of the hyper-redundant manipulator were fitted to the modal backbone curves. Finally, the inverse kinematics of the hyper-redundant manipulator were solved based on the spatial geometry method. This method solved the motion-planning problem of an industrial hyper-redundant manipulator entering a known narrow environment.

Engineering application experiments verified the hyper-redundant manipulator's ability to move through curved pipes and narrow workspace areas. The effectiveness of the new algorithm was also proven by these experiments.

Funding Statement: The authors gratefully acknowledge the financial support provided by the National Key Research & Development Project of China (Grant No. 2019YFB1311203).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. F. Feng, L. N. Tang and J. F. Xu, “A review of the end-effector of large space manipulator with capabilities of misalignment tolerance and soft capture,” Science China Technological Sciences, vol. 59, no. 11, pp. 1621–1638, 2016. [Google Scholar]

2. T. Rybus, “Obstacle avoidance in space robotics: Review of major challenges and proposed solutions,” Progress in Aerospace Sciences, vol. 101, pp. 31–48, 2018. [Google Scholar]

3. T. Zhang, Y. Cheng and H. P. Wu, “Dynamic accuracy ant colony optimization of inverse kinematic (DAACOIK) analysis of multi-purpose deployer (MPD) for CFETR remote handling,” Fusion Engineering and Design, vol. 156, pp. 111522, 2020. [Google Scholar]

4. C. Choi, A. Tesini and R. Subramanian, “Multi-purpose deployer for ITER in-vessel maintenance,” Fusion Engineering and Design, vol. 98–99, pp. 1448–1452, 2015. [Google Scholar]

5. Q. Zhang, “Motion control system design of multi-joint snake-like manipulator for nuclear environment,” Journal of Shandong University (Engineering Science), vol. 48, no. 6, pp. 122–131, 2018. [Google Scholar]

6. L. Dupourqué, F. Masaki and Y. L. Colson, “Transbronchial biopsy catheter enhanced by a multisection continuum robot with follow-the-leader motion,” International Journal of Computer Assisted Radiology and Surgery, vol. 14, pp. 2021–2029, 2019. [Google Scholar]

7. Y. Gao, K. Takagi and T. Kato, “Continuum robot with follow-the-leader motion for endoscopic third ventriculostomy and tumor biopsy,” IEEE Transactions on Biomedical Engineering, vol. 67, no. 2, pp. 379–390, 2020. [Google Scholar]

8. P. J. Swaney, A. W. Mahoney and A. A. Remirez, “Tendons, concentric tubes, and a bevel tip: Three steerable robots in one transoral lung access system,” in IEEE Int. Conf. on Robotics and Automation (ICRA), Seattle, WA, USA, pp. 5378–5383, 2015. [Google Scholar]

9. X. R. Zhang, X. Sun, X. M. Sun, W. Sun and S. K. Jha, “Robust reversible audio watermarking scheme for telemedicine and privacy protection,” Computers, Materials & Continua, vol. 71, no. 2, pp. 3035–3050, 2022. [Google Scholar]

10. J. Q. Peng, W. F. Xu and T. W. Yang, “Dynamic modeling and trajectory tracking control method of segmented linkage cable-driven hyper-redundant robot,” Nonlinear Dynamics, vol. 101, pp. 233–253, 2020. [Google Scholar]

11. S. Yahya and M. Moghavvemi, “Redundant manipulators kinematics inversion,” Academic Journals, vol. 6, no. 26, pp. 5462–5470, 2011. [Google Scholar]

12. J. A. Tenreiro Machado and A. M. Lopes, “A fractional perspective on the trajectory control of redundant and hyper-redundant robot manipulators,” Applied Mathematical Modelling, vol. 46, pp. 716–726, 2017. [Google Scholar]

13. I. Gravagne and I. D. Walker, “Properties of minimum infinity-norm optimization applied to kinematically redundant robots,” in Proc. 1998 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, Victoria, BC, Canada, Innovations in Theory, Practice and Applications, vol. 1, pp. 152–160, 1998. [Google Scholar]

14. F. Yin, Y. N. Wang and Y. M. Yang, “Inverse kinematics solution for robot manipulator based on neural network under joint subspace,” International Journal of Computers Communications & Control, vol. 7, no. 3, pp. 459–472, 2012. [Google Scholar]

15. P. Y. Zhang, S. Lu and B. Song, “RBF networks-based inverse kinematics of 6R manipulator,” International Journal of Advanced Manufacturing Technology, vol. 26, no. 1–2, pp. 144–147, 2005. [Google Scholar]

16. G. S. Chirikjian and J. W. Burdick, “The kinematics of hyper-redundant robot locomotion,” IEEE Transactions on Robotics and Automation, vol. 11, no. 6, pp. 781–793, 1995. [Google Scholar]

17. G. S. Chirikjian and J. W. Burdick, “A modal approach to hyper-redundant manipulator kinematics,” IEEE Transactions on Robotics and Automation, vol. 10, no. 3, pp. 343–354, 1994. [Google Scholar]

18. J. G. Wang, L. Tang and G. Y. Gu, “Tip-following path planning and Its performance analysis for hyper-redundant manipulators,” Journal of Mechanical Engineering, vol. 54, no. 3, pp. 18–25, 2018. [Google Scholar]

19. X. R. Zhang, W. F. Zhang, W. Sun, X. M. Sun and S. K. Jha, “A robust 3-D medical watermarking based on wavelet transform for data protection,” Computer Systems Science & Engineering, vol. 41, no. 3, pp. 1043–1056, 2022. [Google Scholar]

20. Y. Han, H. Zhang, Z. Shi and S. Liang, “An adaptive fuzzy control model for multi-joint manipulators,” Computer Systems Science and Engineering, vol. 40, no. 3, pp. 1043–1057, 2022. [Google Scholar]

21. I. Al-Darraji, A. A. Kakei, A. G. Ismaeel, G. Tsaramirsis and F. Q. Khan et al., “Takagi–sugeno fuzzy modeling and control for effective robotic manipulator motion,” Computers, Materials & Continua, vol. 71, no. 1, pp. 1011–1024, 2022. [Google Scholar]

22. S. B. Andersson, “Discretization of a continuous curve,” IEEE Transactions on Robotics, vol. 24, no. 2, pp. 456–461, 2008. [Google Scholar]

23. F. Fahimi, H. Ashrafiuon and C. Nataraj, “An improved inverse kinematic and velocity solution for spatial hyper-redundant robots,” IEEE Transactions on Robotics and Automation, vol. 18, no. 1, pp. 103–107, 2002. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |