DOI:10.32604/cmc.2022.017262

| Computers, Materials & Continua DOI:10.32604/cmc.2022.017262 |  |

| Article |

Convolutional Neural Network-Based Regression for Predicting the Chloride Ion Diffusion Coefficient of Concrete

1Architectural Engineering, Hanyang University ERICA, Ansan, 15588, Korea

2Graduate School of Information, Yonsei University, Seoul, 03722, Korea

3Division of Smart Convergence Engineering, Hanyang University ERICA, Ansan, 15588, Korea

*Corresponding Author: Sang Hyo Lee. Email: mir0903@hanyang.ac.kr

Received: 25 January 2021; Accepted: 30 July 2021

Abstract: The durability performance of reinforced concrete (RC) building structures is significantly affected by the corrosion of the steel reinforcement due to chloride penetration, thus, the chloride ion diffusion coefficient should be investigated through experiments or theoretical equations to assess the durability of an RC structure. This study aims to predict the chloride ion diffusion coefficient of concrete, a heterogeneous material. A convolutional neural network (CNN)-based regression model that learns the condition of the concrete surface through deep learning, is developed to efficiently obtain the chloride ion diffusion coefficient. For the model implementation to determine the chloride ion diffusion coefficient, concrete mixes with w/c ratios of 0.33, 0.40, 0.46, 0.50, 0.62, and 0.68, are cured for 28 days; subsequently, the surface image data of the specimens are collected. Finally, the proposed model predicts the chloride ion diffusion coefficient using the concrete surface image data and exhibits an error of approximately 1.5E−12

Keywords: Chloride ion diffusion coefficient; convolutional neural network; deep learning

In the construction industry, the demand for reinforced concrete (RC) structures with high durability, is increasing [1–3]. The service life of porous concrete materials that constitute RC structures, is adversely affected by chlorides that penetrate into the concrete from the outer surface [4,5]. Given that chloride ions have a direct impact on the durability performance of RC, they are used as an important indicator for durability analysis, design, and service life assessment [5,6]. Because chloride ion penetration is affected by various factors, such as the concrete characteristics and exposed environment, various studies have been conducted on the factors that affect chloride ion penetration [7]. It has been proved that aggregates affect chloride diffusivity [8]. It has also been confirmed that dilution, tortuosity, and interfacial transition zone (ITZ) affect chloride diffusivity [9]. To rephrase, because the composition of cement and material properties pertaining to the porosity significantly affect chloride ion penetration, it is important to observe the components of concrete and the conditions of the materials. Previous studies have shown that the geographical factors [10] and temporal factors [7,11] of the marine environment, where the structures are installed, affect chloride penetration; it is essentially affected by a combination of various factors; further, there are many theoretical equations that represent such mechanisms [12].

Chloride ions, through penetration, eventually reach the surface of steel reinforcement and corrode the steel reinforcement, thereby reducing its durability. Therefore, it is important to measure the time period within which chlorides can reach the surface of steel reinforcement. The chloride ion diffusion coefficient represents the chloride ion diffusion rate that implies the time elapsed between the penetration of chloride ions into concrete and corrosion of the steel reinforcement. It represents the resistance of an RC structure to chloride penetration and is used as the main parameter to determine the durability performance of an RC structure [13]. In general, two methods (the natural diffusion test and accelerated diffusion test methods) are used to measure the chloride ion diffusion coefficient [14]. Since the natural diffusion test is time-intensive, various accelerated diffusion test methods have been recently used to reduce the overall experimental time [6,8,12]. Methods for measuring the chloride ion diffusion coefficient have already been reported in previous studies [5,14], and studies have been continuously conducted to develop an efficient measurement method. A simple model has been proposed based on the concrete microstructure at different length scales to predict the chloride ion diffusion coefficient; this model is based on the fact that chloride penetration is affected by the pore characteristics inside the concrete [6]. An artificial neural network (ANN) has also been developed to predict the diffusion coefficient of chloride ions based on four parameters: W/B ratio, cement content, fly ash(FA) or ground-granulated blast furnace slag (GGBFS) content, and curing age [15]. It has been proved that the chloride ion diffusion coefficient can be predicted based on the various mixing factors of the concrete by setting the concrete mixing factors as input parameters and the chloride ion diffusion coefficient as the output value. Generally, chloride penetration occurs through the micropores and cracks on the concrete surface exposed to chlorides [15]. Therefore, the conditions and characteristics of the concrete surface play an important role in chloride penetration. In previous studies, the components and internal pore characteristics of the concrete were considered for predicting the chloride ion diffusion coefficient; however, the characteristics of the concrete surface, such as the distribution of cement particles, aggregate, and micropores, were not considered.

In concrete, various pores and microcracks are present owing to the air bubbles generated during hardening or material separation. Generally, chloride ions diffuse into the concrete through pores and microcracks. Therefore, chloride penetration occurs through the microcracks at the interface between the aggregate and cement, for example, penetration through the concrete defects, such as the relatively large cracks or the numerous pores in hardened cement. Therefore, the condition and characteristics of the concrete surface are important factors in determining the chloride ion diffusion coefficient.

This study aims to propose a feasibility model to predict the chloride diffusion coefficient based on the concrete surface images. This study proposes a method for estimating the chloride ion diffusion coefficient by analyzing the material properties appearing on the surface of a concrete specimen using the images of the surface. In this method, a neural network that utilizes a convolution filter was applied to predict the chloride ion diffusion coefficient. The performance of the proposed model was verified by comparison with the experimental results collected through the NT build 492 experiment.

Chlorides penetrate into concrete through micropores, aggregates, interfacial transition zones (ITZs), and cracks on the concrete surface [16]. Therefore, the chloride ion diffusion coefficient can be affected by the condition of the concrete surface exposed to the external environment. This study attempts to estimate the chloride ion diffusion coefficient by analyzing the characteristics of the concrete surface using an ANN algorithm. A convolutional neural network (CNN) was applied to thoroughly analyze the images that represent the condition of the concrete surface. CNN is an algorithm specialized in analyzing image data, and many studies have confirmed that it demonstrates an excellent performance for tasks such as, classification, detection, tracking, and prediction, by automatically extracting features in the images [17].

According to the literature, numerical data can be estimated by connecting the image data and numerical values. Regression is used to predict the target value (chloride diffusion coefficient) of this study by inputting the surface information of heterogeneous materials to the CNN of the proposed method. The concrete surface image data include features in the form of the height × width pixel matrix through image conversion. Each pixel includes features that appear on the concrete surface, and the convolution kernel extracts the features in the image by dividing the image into small blocks. Through the convolution operation (Eq. (1)), features are automatically extracted [18].

An image can be expressed using Eq. (2) below because it is a two-dimensional (2D) plane (height:

where

Over the last 10 years, CNNs have been intensively investigated and applied in a wide range of research fields [17]. Starting with AlexNet [20], CNN-based deep learning algorithms, such as VGGnet [21], ResNet [22], and InceptionV3 [23], have demonstrated excellent performances with respect to image recognition and detection. In this study, a CNN has been applied to estimate the chloride ion diffusion coefficient using the surface images acquired from concrete specimens. In addition, the linear regression function that estimates the numerical data, was combined with CNN to predict the chloride ion diffusion coefficient for the concrete specimen.

Cement, a major component of concrete, generates hydration products through a continuous hydration reaction; further, the hydration products reduce the pores. Such reduction in the pores and increase in the hydration products are essential factors for determining the chloride ion diffusion coefficient because such factors essentially act as defense mechanisms for effectively resisting the chlorides introduced from outside. Therefore, in this study, six different concrete mixes were subjected to water curing for 28 days, and a comparative test was conducted. Tab. 1 lists the concrete mixes. Specimens were fabricated using the concrete mixes with the design strengths of 18, 21, 24, 27, 30, and 40 MPa.

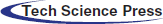

The chloride ion diffusion coefficient was obtained using the NT Build 492 test method [24] that is essentially an accelerated test method. In this test method, a concrete specimen with a 100 mm diameter is cut to attain a thickness of approximately 50 mm, and the thickness is accurately measured using a Vernier caliper. The specimen is thereafter saturated with an aqueous solution of calcium hydroxide (Ca(OH)2) and combined with a rubber container. Thereafter, an electrical potential difference is applied by filling the anode with a 0.3 M NaOH aqueous solution and a cathode with a 10% NaCl aqueous solution. In this instance, the first applied voltage is 30 V. The current value is immediately measured upon the application of the voltage to correct the applied voltage (U). After examining whether a valid initial current value (I0) is obtained, an accelerated test is conducted during the corresponding time (t). After the application of the potential difference, the specimen is disassembled and split in the axial direction. A 0.1 N silver nitrate (AgNO3) aqueous solution is sprayed onto the split surface to examine the chloride ion penetration depth. When the silver chloride precipitate is clearly visible after approximately 15 min, the chloride ion penetration depth is accurately measured up to a unit of 0.1 mm using a vernier caliper, and the average value is obtained. The chloride ion diffusion coefficient of the specimen can be estimated by substituting the test conditions and measurement results into Eq. (3). Tab. 2 and Fig. 1 shows the chloride ion diffusion coefficient test results.

where D is the chloride ion diffusion coefficient (m2/s), F is the Faraday constant (9.648 × 104 J/V·mol), R is the gas constant (8.314 J/K·mol), L is the thickness of the specimen (m), t is the test duration (s),

Figure 1: Chloride ion diffusion coefficient data distribution

In this study, image processing was utilized to estimate the chloride ion diffusion coefficient. The prediction of the chloride ion diffusion coefficient of concrete through image processing has been performed in the following order: feature extraction, feature selection, and post-processing. Among these steps, feature extraction is the most important and difficult step. As mentioned previously, concrete is a heterogeneous material, and the chloride ion diffusion coefficient is affected by the complex spatial distribution of aggregates, cement hydration products, and pores. Because the components are heterogeneous and have irregular shapes, there are limitations in the manual extraction of all the features that affect the compressive strength. To overcome these limitations, an attempt is made to utilize a deep convolution neural network (DCNN) that has exhibited an excellent prediction performance.

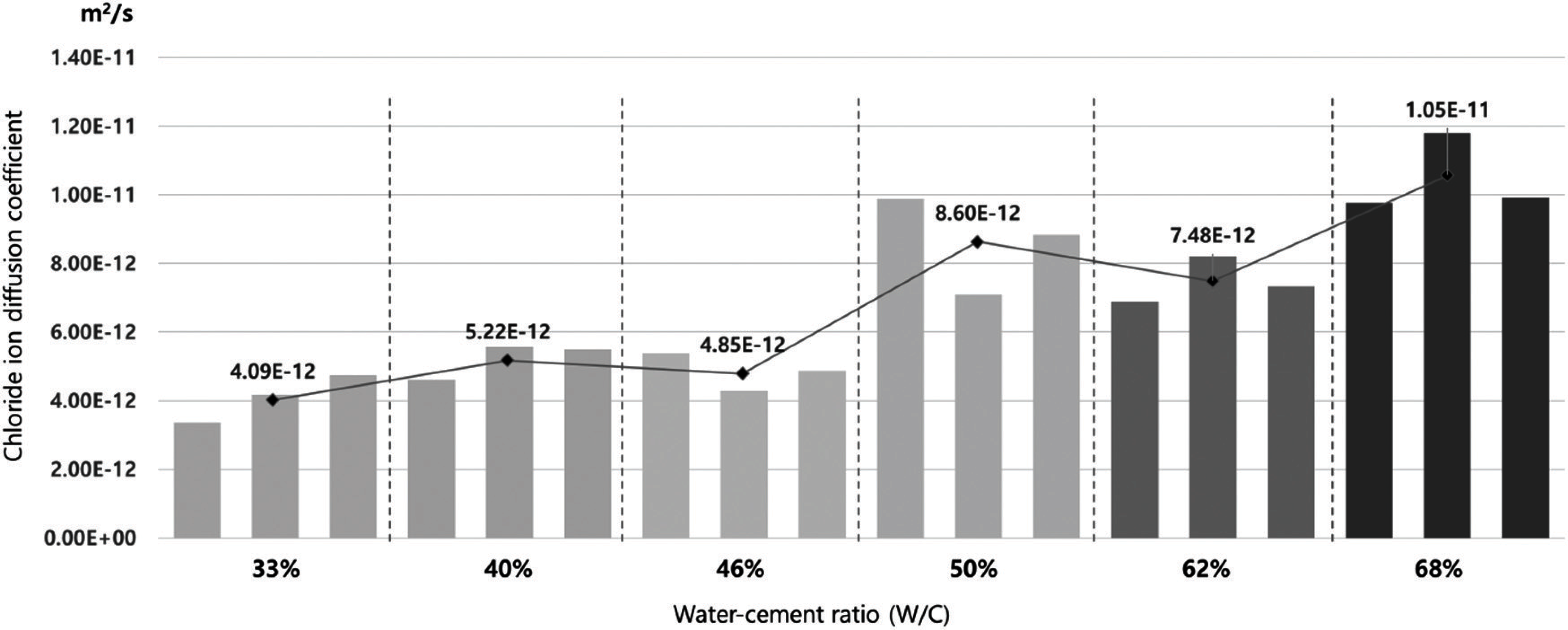

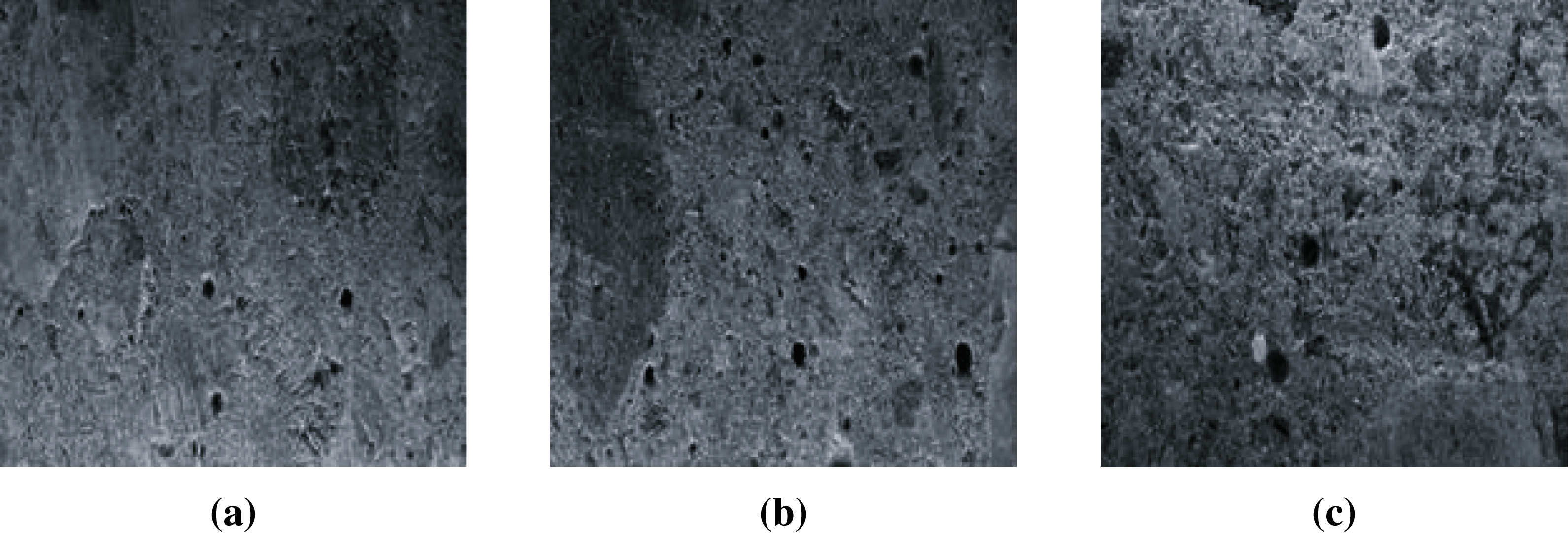

Therefore, it is necessary to capture the images and photographs of the concrete specimens fabricated in a laboratory environment, calculate the chloride ion diffusion coefficient through a test, and train the model by labeling the calculated chloride ion diffusion coefficient on the captured data. The dataset constructed as images was acquired using a DSLR camera sensor. The size of the image obtained using the DSLR camera was 6000 × 3376 pixel. Fig. 2 shows the surface images of the concrete specimens.

Figure 2: Examples of DSLR data: images (224 × 224) and chloride ion diffusion coefficient: (a)

For a large image size, a large amount of information is available; however, it may interfere with learning owing to the high dimensionality and overlapping pixels. If the image size is extremely small, the performance of the DCNN deteriorates owing to a significant reduction in the amount of information. Therefore, determining the optimal input image size is very important during the design of a DCNN algorithm for its performance and learning. Because the performance of an algorithm significantly depends on the image size, multiple studies have been conducted to determine the optimal image size for a new image dataset. Therefore, in this study, an experiment was performed using the following three image dimensions: 224 × 224, 112 × 112, and 84 × 84.

This study intends to perform an experiment on the chloride ion diffusion coefficient. Therefore, the images of the concrete specimens were obtained using the DSLR camera, and the chloride ion diffusion coefficient was used as the target value for each image. The chloride ion diffusion coefficient obtained through the NT Build 492 described above, was a real value ranging from 3.37E–12 to 1.18E–11. Therefore, for the proposed model, each chloride ion diffusion coefficient was replaced with values ranging from 1.18 to 11.8, to be used as the output value. Consequently, 9,726 images were used as the training (7,780) and validation (1,946) data, and 4,169 images were used as the test data.

In this study, a DCNN algorithm structure that can predict the chloride ion diffusion coefficient, is designed; the diffusion coefficient is an important index for the performance assessment of a concrete structure and is determined using the DSLR data obtained by capturing the images of concrete specimens. Determining the optimal structure for learning features that facilitate predicting the chloride ion diffusion coefficient, is extremely important for the performance and training of the algorithm. In addition, multiple studies have been conducted to determine the optimal structure from various types of data, and each structure exhibits a significant difference in the performance. In the field of deep learning, it has been experimentally proven that a deep neural network structure can demonstrate a high accuracy if sufficient data are available. However, given that the number of datasets is not sufficient in practical environments, the performance of DCNN models could be influenced not only on the architecture of networks but also by the image size of the dataset. Because the amount of information in data could affect to recognize the features extracted from the surface images of heterogeneous materials such as concrete. Thus, this study experimented with the various DCNN models with different image sizes.

The structure of a DCNN is determined by various factors, such as the number of layers, type of each layer, number of output neurons for each layer, activation function, and weight connection. The layer types include the fully connected layer, convolutional layer, normalization layer, and pooling layer. In addition, there are various parameters for each layer that cause a variation in the overall structure. Therefore, the structure of the DCNN is determined based on numerous combinations. Because there is still no established theoretical method to determine the optimal structure of a DCNN, the optimal structure must be determined based on the empirical trial-and-error method. In this study, three approved DCNN structures (VGGNet, Inception and ResNet) were used, and simpler CNN were experimented for confirming the most suitable architecture to solve the regression problem using the image data. The experiments were performed by changing the structures according to the experimental data to determine the optimal structure.

The VGGNet architectures used in this study are adopted 16 parameter layers from the reported study [21] and, the ResNet was used with 50 parameter layers from [22]. Moreover, the Inception model adopted the InceptionV3 from [23]. However, the original models are designed for image classification problems, hence, we refined the end layer to one neuron layer with linear regression function to address the one value of chloride ion diffusion coefficient. For instance, the end layer in VGGNet has fully connected layer of 1000 neuron with softmax activation function, it is for solving 1000 class classification problems, thus in this study, the end layer is modified to solve the one regression target. The above structures are pre-established models whose performance has been certified in the ImageNet Large-Scale Visual Recognition Challenge (ILSVRC) [25], an image recognition competition, and these models afford different advantages [21–23]. However, in order to confirm whether the proposed deeper model is a suitable model to solve the problem of this study, a performance comparison with the existing model is required. Therefore, in this study, the experimental performance was compared with additional model, a simpler CNN. Herein, the simpler CNN comprises two convolutional hidden layers with 3×3 filter size, including the maximum pooling, fully-connected layer with 512 neuron and linear regression on the end of network.

To verify the feasibility of the presented algorithms, the input and output of the DCNN model were defined, and the data of the DCNN model were preprocessed and amplified for matching the experimental data with the target value. The algorithms were modified according to the input size of the concrete data, and the algorithm structures were optimized for the concrete data such that the algorithms could efficiently track the performance target value. For the chloride ion diffusion coefficient, a single output characterization model was constructed by applying the above several algorithms, and the model was evaluated. To predict the chloride ion diffusion coefficient as a real number, the mean square error loss shown in Eq. (4) was used as the loss function for DCNN training. Here,

When the parameter of the deep learning-based model is

A representative method to minimize this loss function is the gradient descent that facilitates determining the optimal parameter

In this study, the initial learning rate was set to 0.00001. Further, Keras, a deep learning framework, was used to train the chloride ion diffusion coefficient prediction model in this study.

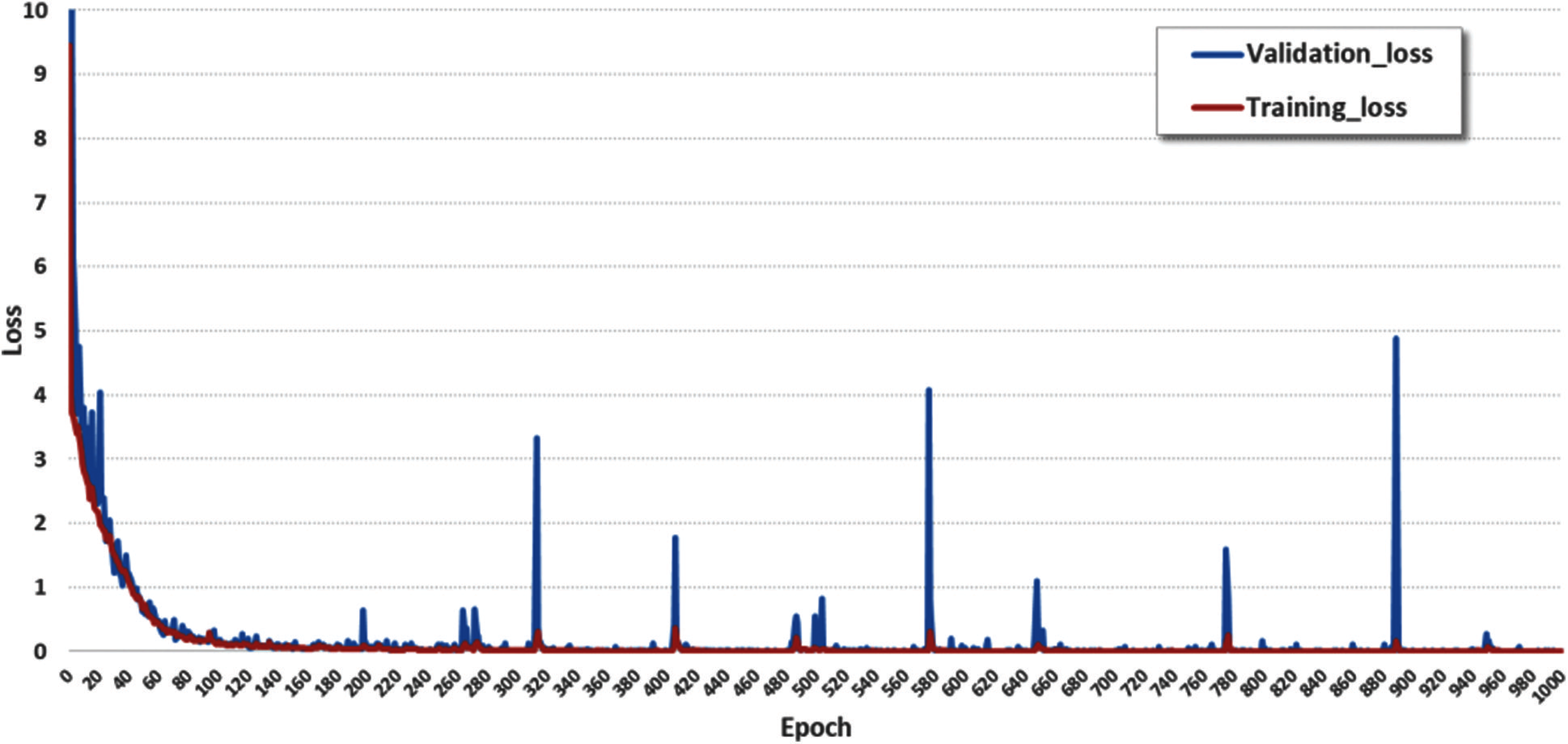

The conjecture of this study is that a DCNN that can learn data-based features by itself will be able to learn features in concrete images that may facilitate predicting the chloride ion diffusion coefficient. To verify this conjecture, an experiment was performed by constructing a single DCNN for the chloride ion diffusion coefficient, using the image data. Initially, the image dimension was fixed at 84 × 84, and Fig. 3 shows the results of performing approximately 1,000 epochs. In the experiment, one epoch involves 30 batch updating model with training about 256 images per mini batch. Thus, experimented models were trained on total 3 × 104 iterations to estimate the chloride ion diffusion coefficient of concrete. It was found that both the train loss and validation loss decreased as the number of iterations increased. This implied that the proposed model was well-trained without overfitting. Therefore, the experimental results confirmed that the DCNN could learn the patterns included in the image data for predicting the chloride ion diffusion coefficient.

Figure 3: Train and validation loss graph

In this study, the prediction of chloride ion diffusion coefficient of a concrete structure was attempted using the simply modified VGG16 [21], InceptionV3 [22], and ResNet50 [23] by connecting a linear regression layer for attaining the one target value. Additionally, the simpler CNN is also investigated for the comparison of performance between experimented models. The results are summarized in Tab. 3. It is confirmed that the InceptionV3 algorithm is the most optimal algorithm for the prediction.

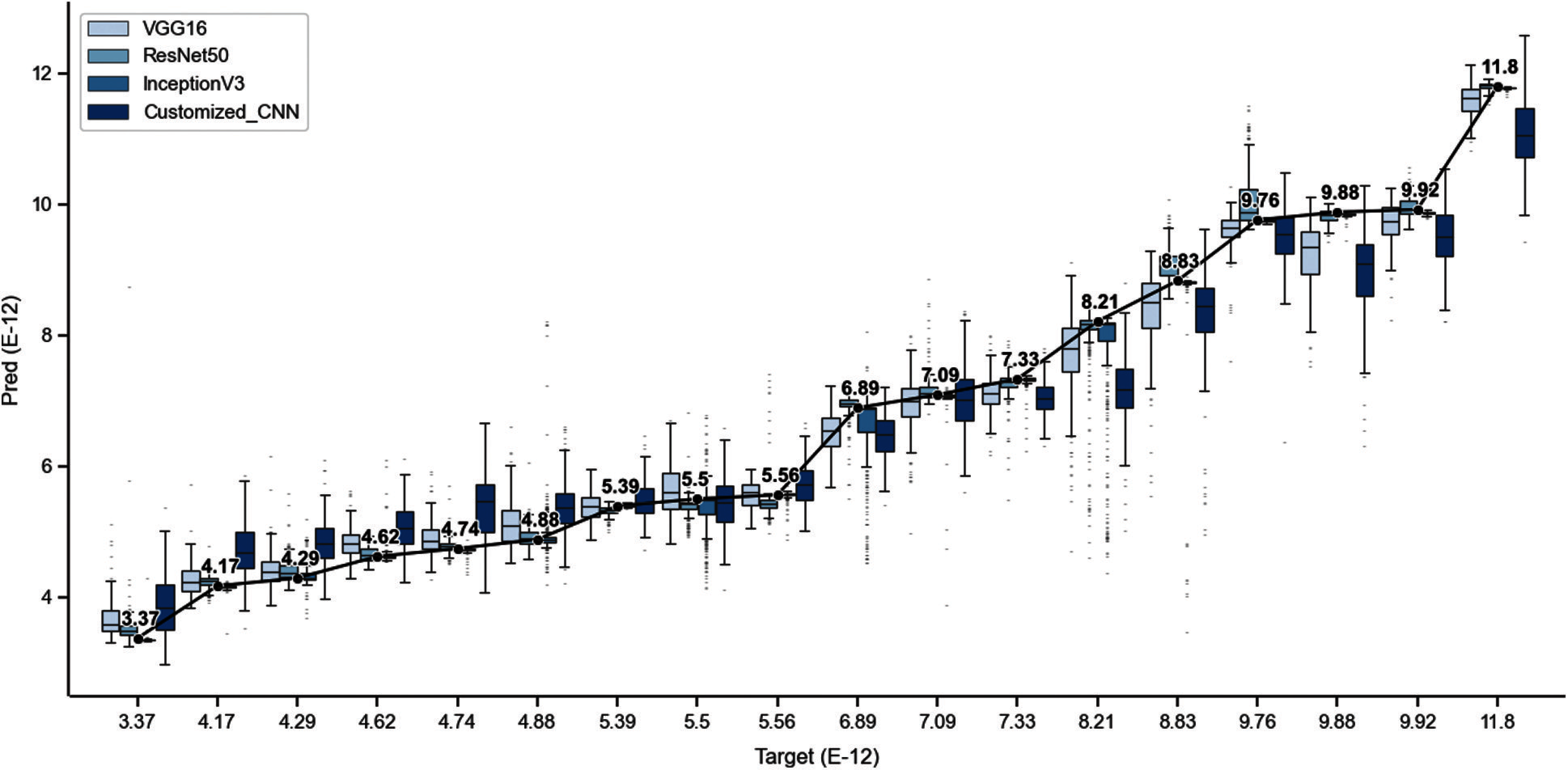

Figure 4: Chloride ion diffusion coefficient prediction results of three models (84 × 84)

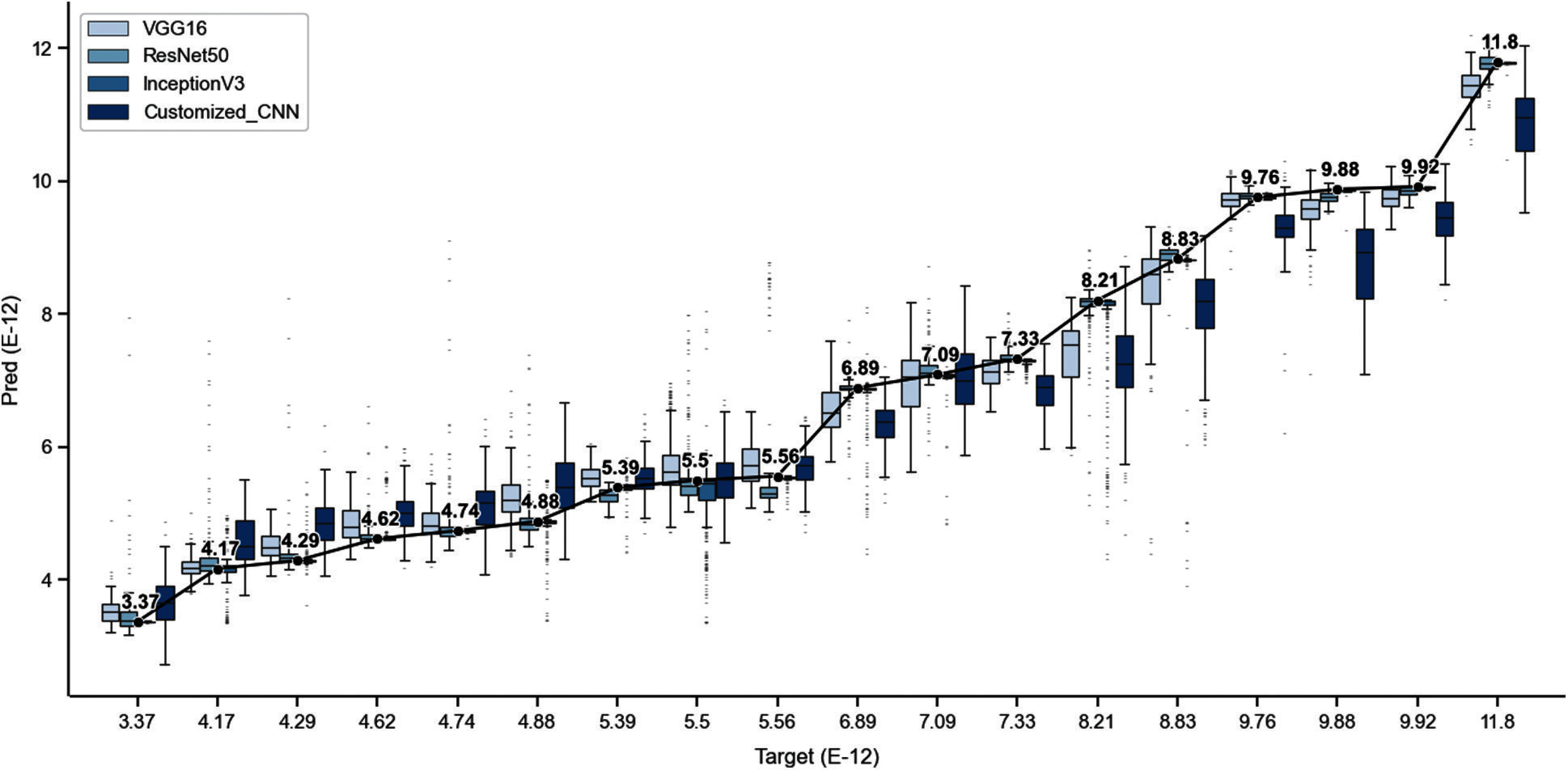

Figure 5: Chloride ion diffusion coefficient prediction results of three models (112 × 112)

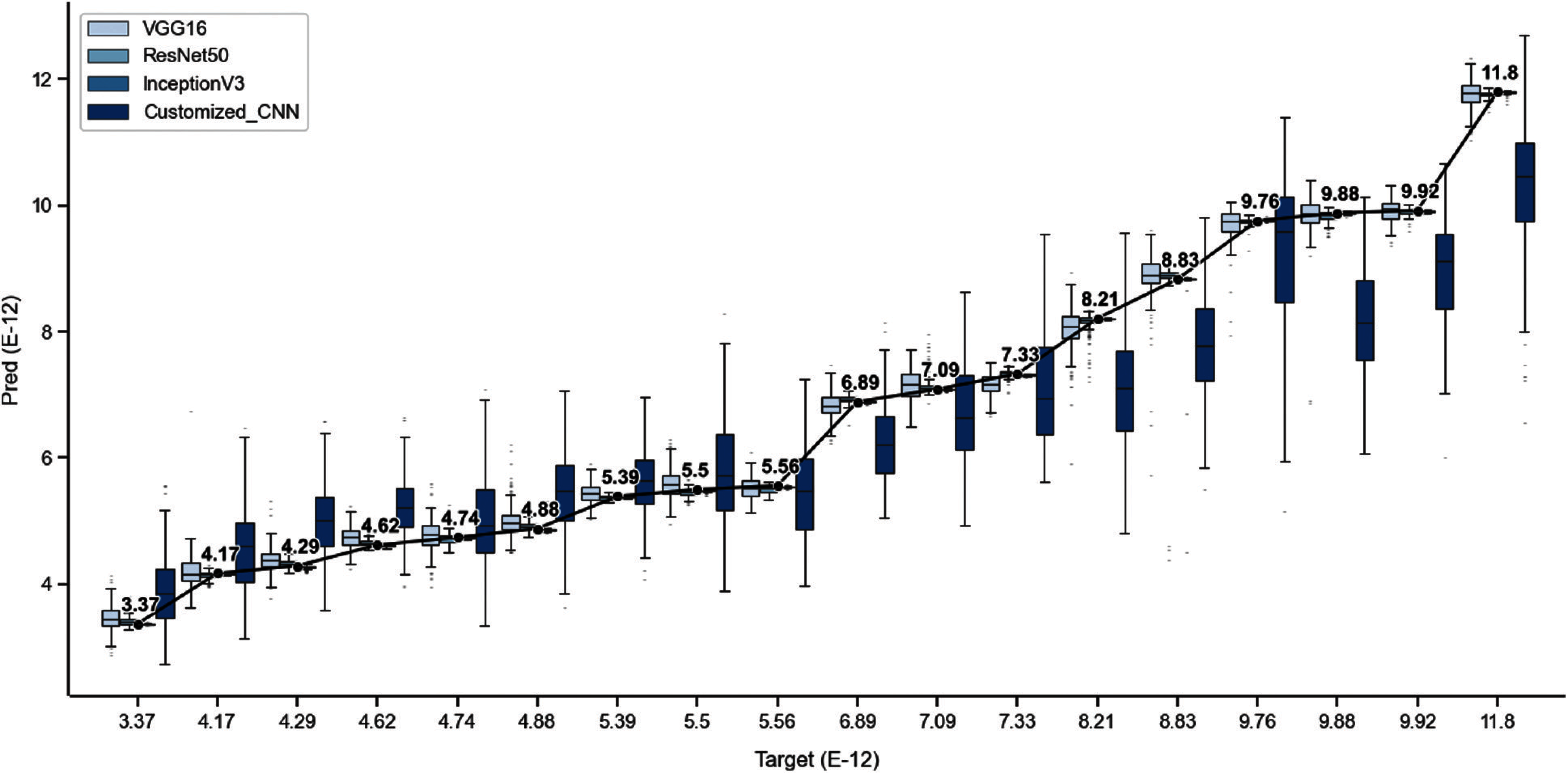

Figure 6: Chloride ion diffusion coefficient prediction results of three models (224 × 224)

When the several experimental metrics of the various models were compared through Tab. 3, it was observed that the InceptionV3 model demonstrated smaller values for the concrete surface images. It has already been proven through multiple experiments that the InceptionV3 model demonstrates the best performance, compared with the VGG16 and ResNet50 models; however, such experiments were performed on standardized datasets, such as ImageNet and CIFAR-100. In addition, the experimental results for the images of concrete structures confirm that InceptionV3 demonstrates a better performance, compared with VGG16 and ResNet50.

Figs. 4–6 show the predicted chloride ion diffusion coefficient based on the four different models using all the three size image data. Overall, the predicted values were not significantly different from the actual values, although there were some outliers. This indicates that the model can be used to estimate the performance of concrete structures. In Figs. 4–6, the target value is indicated by a black line, and the distribution of the predicted values relative to each target value is visualized using boxplots and scatter plots. Among the four models, the InceptionV3 model exhibits multiple predicted values closer to the target value. Therefore, it is confirmed that the chloride ion diffusion coefficient can be predicted using only the image information, although an error of approximately 1.5E–12 has been observed (summarized in Tab. 3).

In this study, an algorithm for predicting the chloride ion diffusion coefficient based on the concrete images was designed using deep learning, and it was verified for the actual application. With the aging of domestic concrete structures, the importance of assessing the durability of concrete also increases. Among the basic indices for assessing the durability of concrete, the chloride ion diffusion coefficient, an important parameter for assessing the durability of concrete, generally utilizes two methods (the natural diffusion test and accelerated diffusion test methods). Considering that the natural diffusion test is time-intensive, various accelerated diffusion test methods have recently been used to reduce the overall experimental time. Although recent studies have been conducted using image processing techniques, there are limitations in directly extracting features from the surface of concrete, a heterogeneous material. This study proposes a model that can automatically extract the unique features appearing on a concrete surface using a CNN and predict the chloride ion diffusion coefficient based on such features. In addition, the validity of the model was verified through the application of the concrete chloride ion diffusion coefficient dataset constructed in a laboratory environment.

The surface image data of the concrete specimens were input to the proposed model, and the architecture was implemented through a combination of CNN and regression. For the optimization of the model, the method of minimizing the loss (i.e., the difference between the chloride ion diffusion coefficient predicted through learning and the experimental value, output value) was used. The chloride ion diffusion coefficient was predicted by extracting the high-dimensional features of concrete using deep learning methods, while only concrete surface images were used as input values. In this study, image dimensions of 84 × 84, 112 × 112, and 224 × 224 were constructed, and an experiment was performed by combining VGG16, ResNet50, InceptionV3, simpler CNN and refining them. Based on the experimental results, 224 × 224 images were used as the input data. The Inception-based CNN-Regression model exhibited the best performance with an error of approximately 1.5E–12

This study suggests the applicability of deep learning to the field of facility maintenance by proposing a method for estimating the chloride ion diffusion coefficient of concrete using images. This study has the limitations of the inappropriate representation of the various concrete characteristics in a real environment because the data that were collected were those of the laboratory-refined concrete specimens. Therefore, in the future, it will be necessary to conduct research on the estimation of the chloride ion diffusion coefficient under various deterioration phenomena of the concrete surface, such as microcracks and spalling. Moreover, only image data were used in this study; if various other variables, such as concrete mix information, geographic environment information, and time information, are used for learning, it will be possible to construct a more accurate and sophisticated model.

Acknowledgement: The authors would like to thank the National Research Foundation of Korea for funding this research project.

Funding Statement: This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (NRF-2021R1A2C2007904).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Q. F. Liu, J. Yang, J. Xia, D. Easterbrook, L. Y. Li et al., “A numerical study on chloride migration in cracked concrete using multi-component ionic transport models,” Computational Materials Science, vol. 99, no. 12, pp. 396–416, 2015. [Google Scholar]

2. M. Alexander and H. Beushausen, “Durability, service life prediction, and modelling for reinforced concrete structures–review and critique,” Cement and Concrete Research, vol. 122, no. 1, pp. 17–29, 2019. [Google Scholar]

3. E. Zacchei and C. G. Nogueira, “Chloride diffusion assessment in RC structures considering the stress-strain state effects and crack width influences,” Construction and Building Materials, vol. 201, no. 20, pp. 100–109, 2019. [Google Scholar]

4. P. S. Mangat, J. M. Khatib and B. T. Molloy, “Microstructure, chloride diffusion and reinforcement corrosion in blended cement paste and concrete,” Cement and Concrete Composites, vol. 16, no. 2, pp. 73–81, 1994. [Google Scholar]

5. B. Yu, Q. Ma, H. C. Huang and Z. Chen, “Probabilistic prediction model for chloride diffusion coefficient of concrete in terms of material parameters,” Construction and Building Materials, vol. 215, no. 1, pp. 941–957, 2019. [Google Scholar]

6. G. Sun, Y. Zhang, W. Sun, Z. Liu and C. Wang, “Multi-scale prediction of the effective chloride diffusion coefficient of concrete,” Construction and Building Materials, vol. 25, no. 10, pp. 3820–3831, 2011. [Google Scholar]

7. G. R. Meira, C. Andrade, I. J. Padaratz, C. Alonso and J. C. Borba, “Chloride penetration into concrete structures in the marine atmosphere zone-relationship between deposition of chlorides on the wet candle and chlorides accumulated into concrete,” Cement and Concrete Composites, vol. 29, no. 9, pp. 667–676, 2007. [Google Scholar]

8. A. Delagrave, J. P. Bigas, J. P. Ollivier, J. Marchand and M. Pigeon, “Influence of the interfacial zone on the chloride diffusivity of mortars,” Advanced Cement Based Materials, vol. 5, no. 3–4, pp. 86–92, 1997. [Google Scholar]

9. C. C. Yang and J. K. Su, “Approximate migration coefficient of interfacial transition zone and the effect of aggregate content on the migration coefficient of mortar,” Cement and Concrete Research, vol. 32, no. 10, pp. 1559–1565, 2002. [Google Scholar]

10. A. Lindvall, “Chloride ingress data from field and laboratory exposure–influence of salinity and temperature,” Cement and Concrete Composites, vol. 29, no. 2, pp. 88–93, 2007. [Google Scholar]

11. M. H. F. Medeiros and P. Helene, “Surface treatment of reinforced concrete in marine environment: Influence on chloride diffusion coefficient and capillary water absorption,” Construction and Building Materials, vol. 23, no. 3, pp. 1476–1484, 2009. [Google Scholar]

12. Q. F. Liu, D. Easterbrook, L. Y. Li and D. Li, “Prediction of chloride diffusion coefficients using multi-phase models,” Magazine of Concrete Research, vol. 69, no. 3, pp. 134–144, 2017. [Google Scholar]

13. Q. F. Liu, Z. Hu, X. Y. Lu, J. Yang, I. Azim et al., “Prediction of chloride distribution for offshore concrete based on statistical analysis,” Materials, vol. 13, no. 1, pp. 174, 2020. [Google Scholar]

14. R. V. Noort, M. Hunger and P. Spiesz, “Long-term chloride migration coefficient in slag cement-based concrete and resistivity as an alternative test method,” Construction and Building Materials, vol. 115, no. 5, pp. 746–759, 2016. [Google Scholar]

15. O. A. Hodhod and H. I. Ahmed, “Developing an artificial neural network model to evaluate chloride diffusivity in high performance concrete,” HBRC Journal, vol. 9, no. 1, pp. 15–21, 2013. [Google Scholar]

16. Y. Wang, X. Gong and L. Wu, “Prediction model of chloride diffusion in concrete considering the coupling effects of coarse aggregate and steel reinforcement exposed to marine tidal environment,” Construction and Building Materials, vol. 216, no. 1, pp. 40–57, 2019. [Google Scholar]

17. T. Shimobaba, T. Kakue and T. Ito, “Convolutional neural network-based regression for depth prediction in digital holography,” in 2018 IEEE 27th Int. Symp. on Industrial Electronics, Cairns, QLD, Australia, pp. 1323–1326, 2018. [Google Scholar]

18. Y. Bengio, I. Goodfellow and A. Courville, “Convolutional networks,” in Deep Learning, 1st ed., Cambridge, MA, USA: MIT Press, pp. 297–298, 2016. [Google Scholar]

19. Y. Lecun, Y. Bengio and G. Hinton, “Deep learning,” Nature, vol. 521, no. 7553, pp. 436–444, 2015. [Google Scholar]

20. A. Krizhevsky, I. Sutskever and G. E. Hinton, “ImageNet classification with deep convolutional neural networks,” Communications of the ACM, vol. 60, no. 6, pp. 84–90, 2017. [Google Scholar]

21. K. Simonyan and A. Zisserman, “Very deep convolutional networks for large-scale image recognition,” arXiv preprint arXiv: 1409.1556, 2014. [Google Scholar]

22. K. He, X. Zhang, S. Ren and J. Sun, “Deep residual learning for image recognition,” in 2016 IEEE Conf. on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, pp. 770–778, 2016. [Google Scholar]

23. C. Szegedy, V. Vanhoucke, S. Ioffe, J. Shlens and Z. Wojna, “Rethinking the Inception architecture for computer vision,” in Proc. of the IEEE Conf. on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, pp. 2818–2826, 2016. [Google Scholar]

24. Nordtest, “NT build 492-99: Concrete, mortar and cement-based repair materials: Chloride migration coefficient from non-steady-state migration experiments,” in Finland: Nordtest Method. Espoo, Finland, 1999. [Google Scholar]

25. O. Russakovsky, J. Deng, H. Su, J. Krause, S. Satheesh et al., “ImageNet large scale visual recognition challenge,” International Journal of Computer Vision, vol. 115, no. 3, pp. 211–252, 2015. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |