DOI:10.32604/cmc.2021.016284

| Computers, Materials & Continua DOI:10.32604/cmc.2021.016284 |  |

| Article |

A Model for Selecting a Biomass Furnace Supplier Based on Qualitative and Quantitative Factors

1Department of Industrial Engineering and Management, National Kaohsiung University of Science and Technology, Kaohsiung, 80778, Taiwan

2Department of Marketing and Distribution Management, National Kaohsiung University of Science and Technology, Kaohsiung, 80778, Taiwan

3Department of Supply Chain Management, National Kaohsiung University of Science and Technology, Kaohsiung, 80778, Taiwan

4Faculty of Commerce, Van Lang University, Ho Chi Minh City, 70000, Vietnam

5Faculty Department of Statistics, Faculty of Mathematics and Natural Sciences, Universitas Negeri Makassar, Makassar, 90223, Indonesia

*Corresponding Author: Hsien-Pin Hsu. Email: hphsu@nkust.edu.tw

Received: 29 December 2020; Accepted: 24 April 2021

Abstract: In developing countries, solar energy is the largest source of energy, accounting for 35%–45% of the total energy supply. This energy resource plays a vital role in meeting the energy needs of the world, especially in Vietnam. Vietnam has favorable natural conditions for this energy production. Because it is hot and humid, and it has much rainfall and fertile soil, biomass develops very quickly. Therefore, byproducts from agriculture and forestry are abundant and continuously increasing. However, byproducts that are considered natural waste have become the cause of environmental pollution; these include burning forests, straw, and sawdust in the North; and rice husks dumped into rivers and canals in the Mekong Delta region. Biomass energy is provided in a short cycle, is environmentally safe to use and is encouraged by organizations that support sustainable development. Taking advantage of this energy source provides energy for economic development and ensures environmental protection. Due to the abovementioned favorable conditions, many biomass energy plants are being built in Vietnam. Like other renewable energy investment projects, the selection of the construction contractor, the selection of equipment for the installation of the power plant, and the choice of construction site are complex multi-criteria decisions. In this case, decision-makers must evaluate many qualitative and quantitative factors. These factors interact with each other and it is difficult to use personal experience to choose the optimal solution for such complex decision-making problems, especially in a fuzzy decision-making environment. Therefore, in this study, the authors use a Multi-Criteria Decision-Making (MCDM) model that uses a Fuzzy Analytic Hierarchy Process (FAHP) model and the Combined Compromise Solution (CoCoSo) algorithm to select biomass furnace suppliers utilizing both qualitative and quantitative factors. Furthermore, the results of this work will provide the first look at a hybrid CoCoSo/FAHP method that decision-makers in other fields can use to find the best supplier.

Keywords: Biomass energy; supplier selection; biomass furnace; MCDM; optimization; CoCoSo algorithm; fuzzy theory; FAHP model; industry 4.0

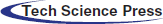

For the past decade, Vietnam has witnessed a positive trend of economic development, with its annual Gross Domestic Product (GDP) remaining at approximately 6% [1]. In order to achieve sustainable development, the demand for renewable energy has increased significantly, in the wake of fossil fuel resources having become limited. Beyond that, greenhouse effects as a result of CO2 emission from burning fossil fuel cannot be neglected. Therefore, according to the framework of energy power in Vietnam through 2030, the contribution of renewable alternatives will rise to 20% [2], including hydroelectricity, thermoelectricity, wind power, and solar power. By comparison, among renewable sources and thermoelectricity, biomass power in particular has been a dominant energy source from 1990 to 2018 in Vietnam (Fig. 1). With COVID-19’s impact on the global economy [3] and the volatility of energy prices in recent years [4], it is important for the Vietnamese government to explore sustainable energy options in the near future.

Figure 1: Total energy supply (TES) in Vietnam from 1990 to 2018 [5]

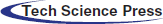

Common biological fuel sources such as wood, waste, and alcohol fuels composed of cellulosic or ligno-cellulosic forms are termed as biomass [6]. These biobased products can be converted into several kinds of energy: electricity, heat, biofuels, and gas by thermochemical, biochemical, and chemical technologies, as depicted in the study by Gavrilescu [6]. In the study, Gavrilescu also indicates the potential energy produced by 1000 tons of dried materials: up to 1 MkWh according to a case study in the U.S. (Fig. 2). The fact that discarded materials from urban and industrial use is one of the main sources of biomass leads not only to an effective solution to manage solid and manufacturing waste, but also to sustainability in terms of economic, ecological, and social impacts. The most popular method of conversion is combustion based on thermochemical reactions. Materials are burned after pre-treatment to heat the boiler or furnace, resulting in high-pressure steam. The turbine is then driven by the steam to generate electricity [7] (Fig. 3). According to a study in Austria, the cost of a heating system with a nominal capacity of 2,100 kW is around 1,885,000 €, with the boiler accounting for about half of that figure [8]. Accordingly, the selection of an efficient and effective heating unit should be regarded as a crucial part of a biomass power plant project. Since the system is considered a conventional technology, the suppliers in the market offer a variety of solutions. Therefore, a comprehensive evaluation of suppliers is proposed to support the decision-making process. Although there are many methods that can be employed in the decision-making process, Multiple Criteria Decision-Making (MCDM) is recognized as a useful technique for solving complex problems. The problem of deciding upon a biomass furnace supplier is a process that involves quantitative and qualitative criteria. While many models have been developed to solve supplier selection problems, only a few have focused on solving these problems in a fuzzy decision-making environment. Therefore, in this research, the authors suggest solving the problems based on an MCDM approach in a fuzzy environment, a solution that has not been considered before. First, a set of criteria will be identified by interviewing industry experts and consulting the related literature. Then, to determine the weight of criteria, the Fuzzy Analytic Hierarchy Process (FAHP) is applied. Finally, the objects will be ranked by the Combined Compromise Solution (CoCoSo) algorithm.

Figure 2: Bioenergy per biomass resources [6]

Figure 3: Basic diagram of a biomass power plant [7]

The main objective of the research is to introduce the Fuzzy MCDM (FMCDM) process as a solution for recommending biomass furnace suppliers based on qualitative and quantitative factors. Furthermore, this work will provide the first look at a hybrid CoCoSo-FAHP method that can guide decision-makers in any field to find the best supplier.

MCDM models have been used in supplier evaluation and selection processes in many industries in recent years [9]. Mamay et al. [10] identified the influencing factors on the investment decision and the company value in the agriculture sector. Yazdani et al. [11] proposed an integrated Quality Function Development and MCDM method framework for selecting a green supplier. Decision-Making Trial and Evaluation Laboratory (DEMATEL) and Complex Proportional Assessment (COPRAS) were employed to calculate the ranking of alternative suppliers based on a set of environmental performance criteria. Wang et al. [12] developed a hybrid Fuzzy ANP and preference ranking organization method for enrichment evaluation (Promethee) II to support the supplier evaluation and selection process in the garment industry. Hamdam et al. [13] proposed an MCDM model to support a supplier selection and order allocation process. The proposed method was built upon a combination of the analytic hierarchy processAnalytic Hierarchy Process (AHP) and fuzzy Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), based on a set of traditional and green performance criteria. Liu et al. [14] developed an integrated MCDM model for selection of sustainable suppliers, using a combination of best-worst method (BWM) and alternative queuing method (AQM) to better express the uncertainty of the decision-making process. Yazdani et al. [15] proposed a Grey Combined Compromise Solution (CoCoSo-G) MCDM model to assist in supplier evaluation and selection in the construction industry. Peng et al. [16] developed a Fuzzy MCDM method using CoCoSo and Criteria Importance Through Inter-criteria Correlation (CRITIC) to evaluate 5G technology suppliers based on a set of quantitative criteria.

Several MCDM models have been developed to assist in the decision-making process of energy plant development projects, where multiple quantitative and qualitative criteria must be considered in order to ensure the effectiveness and efficiency of the process. Chien et al. [17] introduced a hybrid MCDM model to assist with the selection process of hydroelectric plant locations. The authors utilized a Fuzzy Analytical Network Process (FANP) and TOPSIS to create the MCDM model. Wang et al. [18] proposed an integrated MCDM model using Data Envelopment Analysis (DEA) and an FANP to solve the site selection problem of a solar power plant development project in Vietnam’s Mekong Delta region. Lee et al. [19] applied multiple MCDM methods to rank potential renewable energy resources in Taiwan. Four MCDM methods—ELECTRE, WSM, TOPSIS, and VIKOR—were employed and the results show that hydropower is the most appropriate renewable energy source for Taiwan. Çolak et al. [20] created an integrated AHP-Fuzzy TOPSIS model for ranking potential renewable energy resources for Turkey. The research found that wind energy is the most suitable energy resource, followed by solar energy. Díaz-Cuevas et al. [21] proposed a Geographical Information Systems (GIS) integrated MCDM model to assess the individual and combined performance of biomass, solar, and wind energy in Malaga, Spain. The results suggested that single or combined use of wind and solar energy is the optimal solution.

Wang et al. [22] developed a Fuzzy MCDM model for the process of selecting a wind turbine supplier. The model used FANP and TOPSIS to ensure proper presentation of the vague nature of the process, which involves quantitative and qualitative criteria. Değirmenci et al. [23] proposed an integrated GIS-MCDM model for selecting suitable locations for wind energy farms in Turkey. The results suggested that 20.3% of Turkish territory is highly suitable for building wind energy farms. Madhu et al. [24] developed an MCDM model for the evaluation and selection of biomass material in biofuel production. Ali and Waewsak [25] proposed a GIS-MCDM model to support the location selection process of a biomass power plant in South Thailand. Kheybari et al. [26] introduced an AHP-based MCDM model to evaluate biomass energy production technologies, and used 22 criteria (from technical, environmental, economic, and social aspects) to evaluate the technologies. The results suggested that biogas is the most effective technology. Ghasempour et al. [27] reviewed MCDM models for the selection of solar energy technologies and solar farm locations. Results showed that the main criteria for location selection include environment, geography, risk factors, vision, ecology, economy, and climate, whereas the main criteria for technology selection included economic factors, feasibility, flexibility, carbon footprint, efficiency, reliability, and accuracy. Yuan et al. [28] proposed an MCDM approach for evaluating the performance of renewable energy projects. The results from the case study in Fujian suggested that a wind energy project was the most suitable for the area. Chen et al. [29] introduced a hybrid MCDM model to assist in the selection process of a GIS-based solar energy plant location. The author employed the DEMATEL-based Analytical Network Process (DANP) to integrate expert opinions into the existing geomorphological GIS-based method. Büyüközkan et al. [30] proposed a novel MCDM model for renewable energy selection for the United Nations’ sustainable development goals. Ervural et al. [31] developed an ANP integrated fuzzy TOPSIS-based SWOT analysis for evaluation of alternative energy strategies for Turkey. The results suggested that becoming an energy hub of the region is the highest priority strategy. The least favored strategy is developing nuclear power technologies.

3.1 Fuzzy Analytic Hierarchy Process (FAHP) Method

The Analytic Hierarchy Process (AHP) is a method for solving MCDM problems. The AHP works by analyzing a complex, multifocal problem according to a hierarchical structure. The hierarchical structure starts with the goal and it is analyzed through the major criteria and the component criteria, and then the final hierarchy usually includes options that can be selected. The evaluation process determines weights based on the eigenvectors corresponding to the maximum. This method is recognized and widely used Nevertheless, the AHP method has limitations, due to its inability to combine the uncertainty and inaccuracy inherent in the mapping between decision-makers’ perceptions and judgments into exact numbers [32].

Many aggregate methods can be used to overcome these problems, in which the integration between fuzzy theory and AHP can lead to improvements in the representation of the uncertain nature of human language. The fuzzy AHPFAHP is based on fuzzy interval arithmetic with triangular fuzzy numbers and a confidence index with an interval mean approach to determine the weights for evaluative elements [33].

First, the main criteria and sub-criteria for the performance evaluation of biomass furnace suppliers in this research are identified by reviewing related literature and interviewing industry experts. Then the fuzzy preference weights of the criteria are calculated using a combination of fuzzy numbers and AHP. The related methods of this process are described in the following sections.

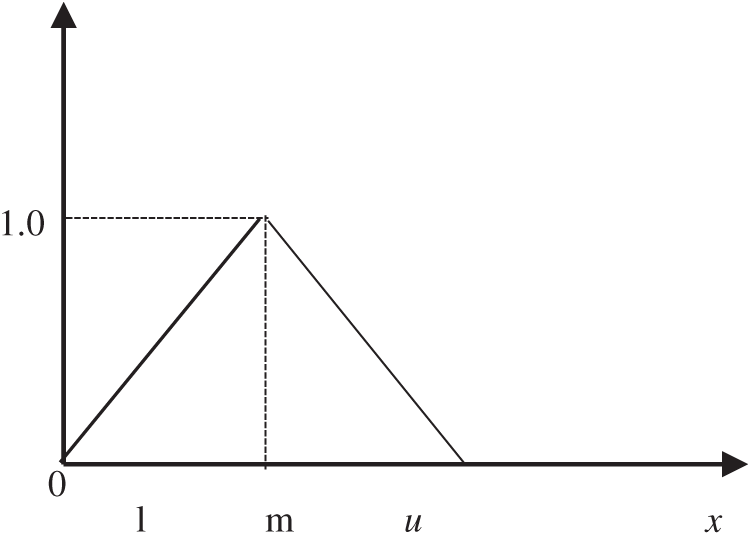

3.1.1 Establishing Fuzzy Number

Zadeh [34] has shown fuzzy sets to be an extension of the classical notion of set. Fuzzy sets were understood as a collection of elements that have degrees of membership. The membership of elements in a set is assessed in binary terms according to a bivalent condition—meaning that an element either belongs or does not belong to the set according to classical set theory [35,36]. The mathematical concept is borrowed from Hsieh, Tzeng et al. [37]. A fuzzy number Triangular Fuzzy Number (TFN) Ã has its membership function

From Eq. (1),

Figure 4: A triangular fuzzy number [34]

Addition of the fuzzy number

Multiplication of the fuzzy number

for

Subtraction of the fuzzy number Ꝋ

Division of a fuzzy number

for

Reciprocal of the fuzzy number

for

In this research, authors compare the evaluation dimension for biomass furnace suppliers through nine basic linguistic terms with respect to the fuzzy nine-level scale introduced by Gumus [38]. These linguistic variables are expressed in positive triangular fuzzy numbers.

The proposed fuzzy AHPFAHP implementation process can be represented by two steps.

Step 1: A pairwise comparison matrix is constructed for all criteria. Then, the linguistic terms are allocated to the pairwise comparisons as in matrix à below.:

Step 2: Calculate the fuzzy geometric mean and fuzzy weights of each criterion using geometric mean technique [38].:

where

3.2 Combined Compromise Solution (CoCoSo):

CoCoSo is an MCDM method based on an integrated simple additive weighting and exponentially weighted product model [39].

Step 1: Determining the initial decision-making matrix:

With

Step 2: Normalizing the criteria values:

Step 3: Calculate the total of the weighted comparability sequence (

This

Step 4: Calculating the related weights of each alternative.

Calculate the arithmetic mean of sums of WSM and WPM scores:

Calculate the the sum of relative scores of WSM and WPM compared to the best alternative:

Calculate the balanced compromise of WSM and WPM model scores:

Step 5: Defining the final ranking of the alternatives

The potential for creation of energy from biomass in Vietnam is assessed in terms of a diverse and large reserve of biofuel. According to calculations by the Vietnam Energy Institute, the country’s total biomass resources are about 118 million tons/year, which includes about 40 million tons of straw, 8 million tons of rice husks, 6 million tons of bagasse, and over 50 million tons of coffee grounds, and wood waste. Biomass sources mainly include wood and plant byproducts, such as natural and planted forests, scattered crops, industrial trees and fruit trees, and industrial wood residues. According to the Institute of Energy Ministry of Industry and Trade, the potential for energy wood biomass is up to nearly 25 million tons, equivalent to 8.8 million tons of crude oil. The biomass energy potential of the agricultural byproducts of Vietnam, including straw, rice-straw, rice husks, bagasse, and other agricultural products, is up to nearly 53.5 million tons. This is equivalent to 12.8 million tons of crude oil. Of particular importance is the fact that this energy source will continuously be regenerated and will steadily grow for 30 years.

Taking advantage of this energy source will also provide energy for economic development and ensure environmental protection. Due to the above favorable conditions, many biomass energy plants are being built in Vietnam. Like other renewable energy investment projects, the selection of the construction contractor, the selection of equipment for the installation of the power plant, and selection of the construction site are all multi-criteria decisions.

In this case, decision-makers must evaluate many qualitative and quantitative factors. Because these factors interact with each other, it is difficult to rely on personal experience to choose the optimal solution. Therefore, in this study, the authors use an MCDM model, including the FAHP model and CoCoSo algorithm, to select biomass furnace suppliers with regard to qualitative as well as quantitative factors.

The biomass furnace is an automated, independent heat supply system that uses biomass as fuel. Biomass furnace technology provides heat with highly technical solutions, safe use, no fire, and no risk of explosion. The use of biomass furnaces not only promotes the process of using renewable energy and reduces the use of fossil fuels to protect the environment, but also brings about significant economic benefits to the businesses that use them.

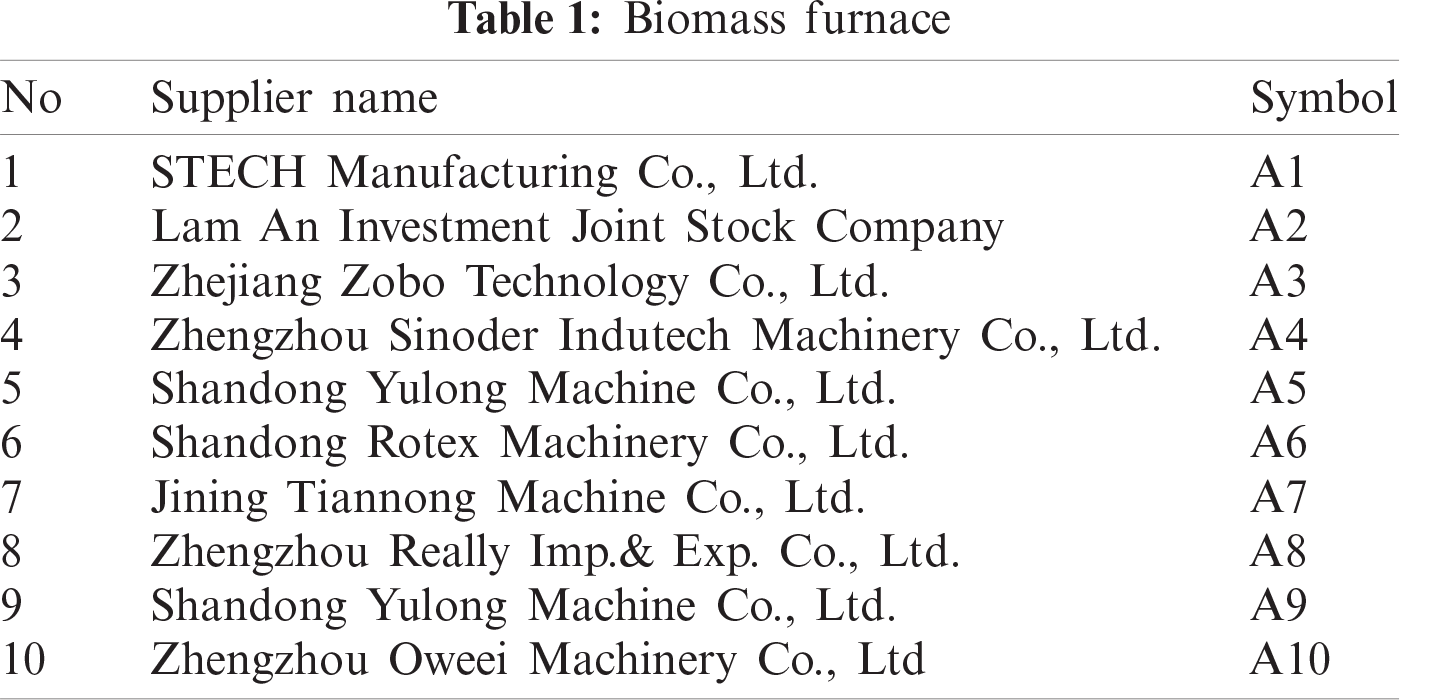

Currently, there are many biomass furnace suppliers. After checking out information such as the supply capacity, reputation, and reliability of each supplier, this paper considers 10 potential biomass furnace suppliers. The name and symbol of the supplier are shown in Tab. 1.

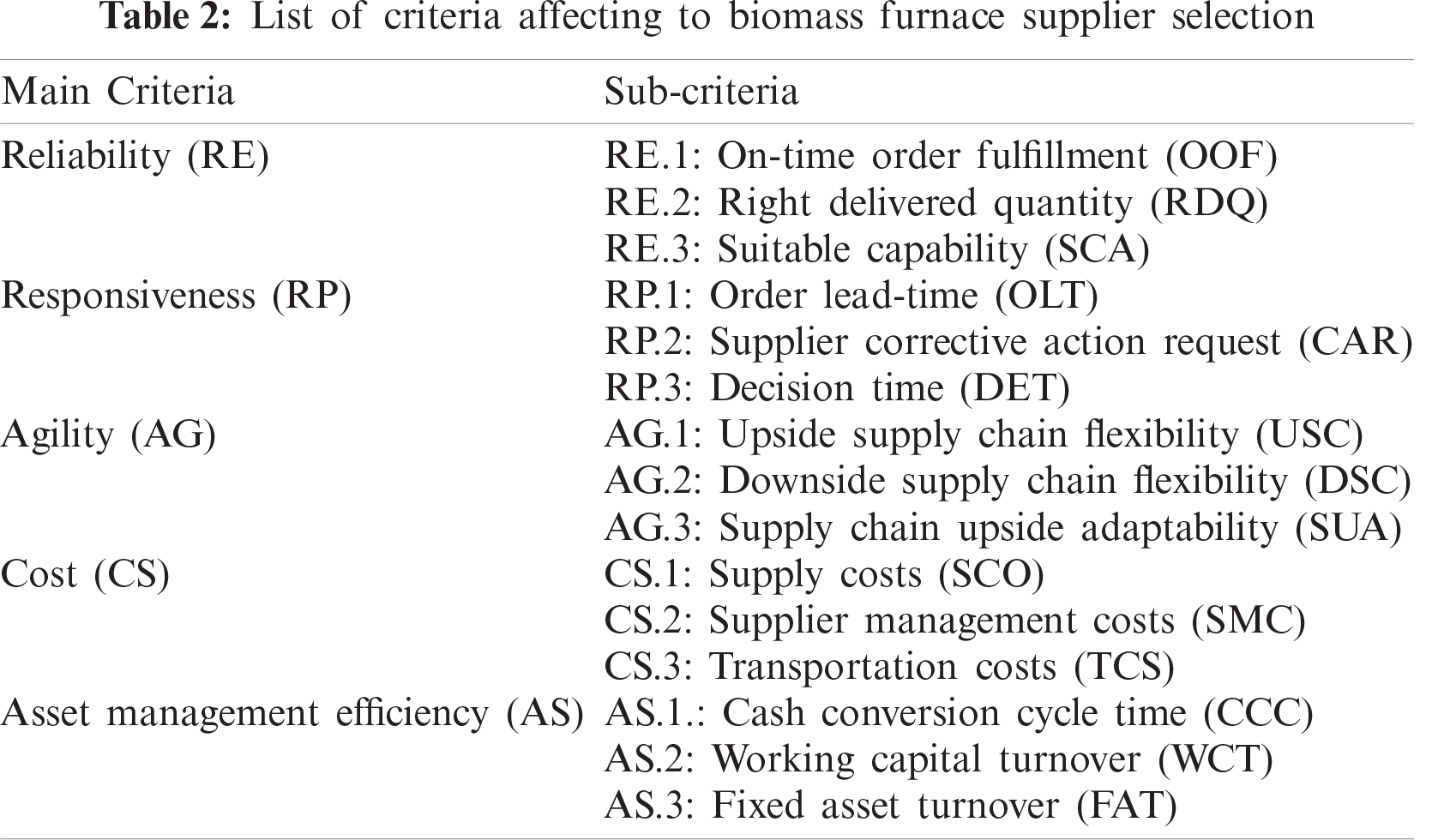

To evaluate and select the optimal biomass furnace supplier pertaining to an investment in biomass energy construction projects, the authors interviewed 12 industry experts, including project managers and procurement managers, and consulted related literature to identify the most useful evaluation criteria. The results have identified 15 criteria (both qualitative and quantitative) to be used in evaluating suppliers. These 15 criteria are shown in Tab. 2.

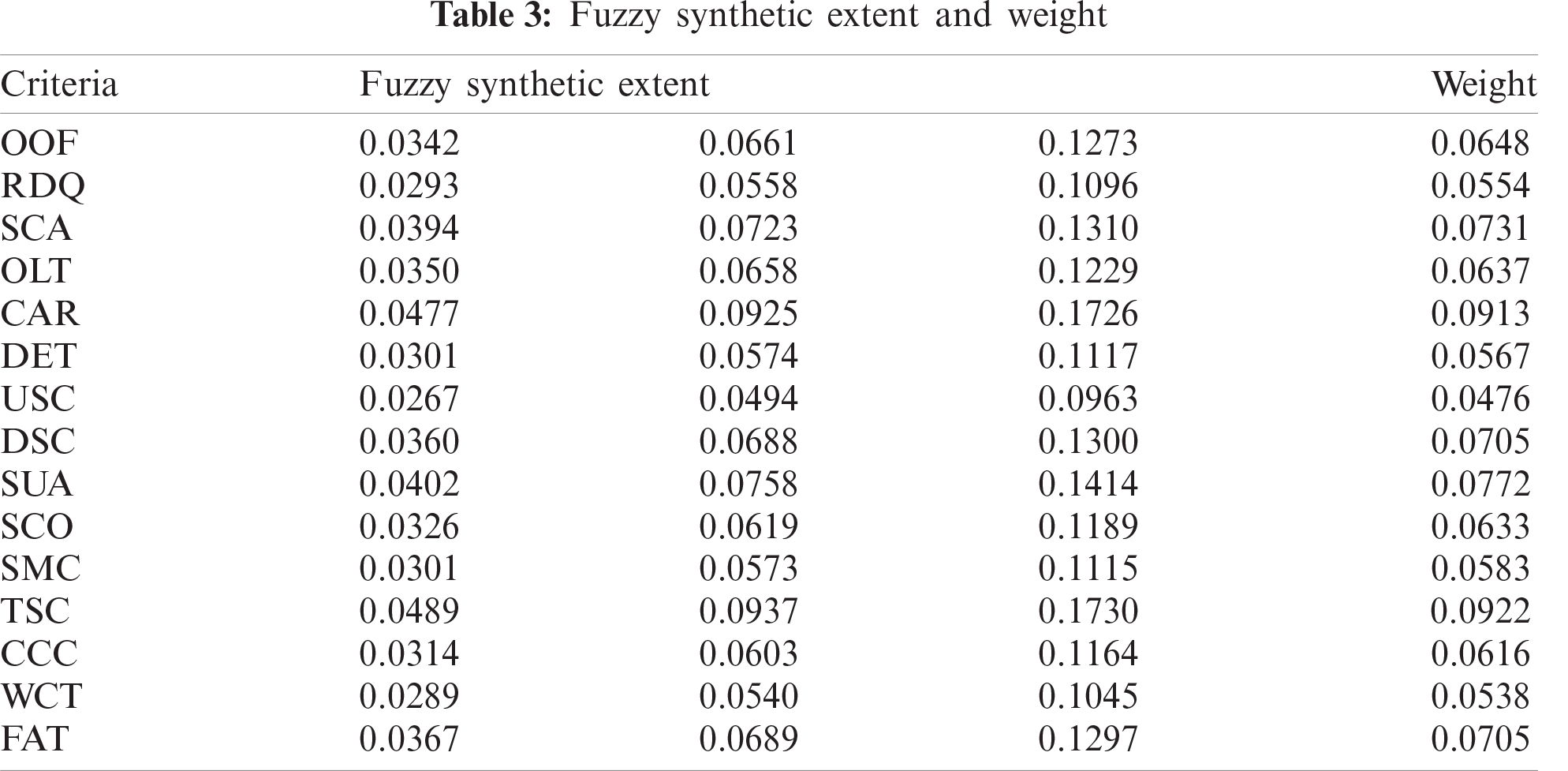

In the first phase of the study, the FAHP model was applied to determine the weights of each criteria. The 12 industry experts performed evaluations to determine the input data for the FAHP model. The fuzzy synthetic extent and the weight of all criteria are shown in Tab. 3.

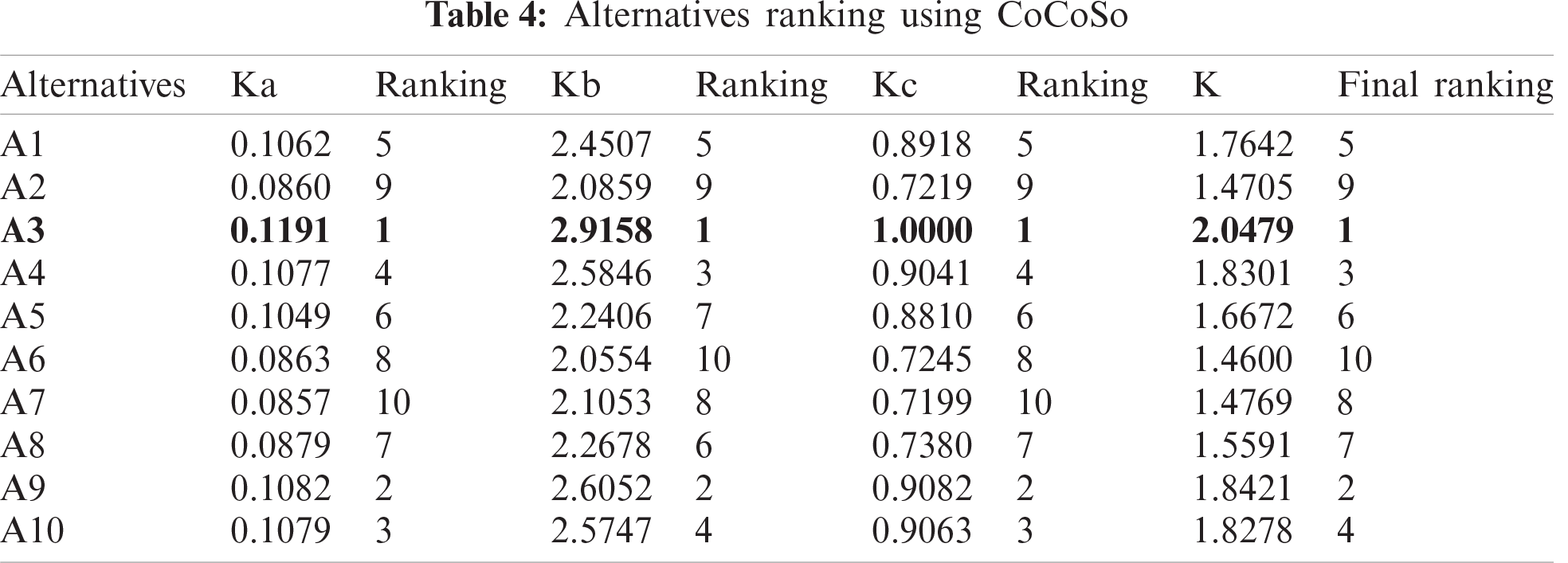

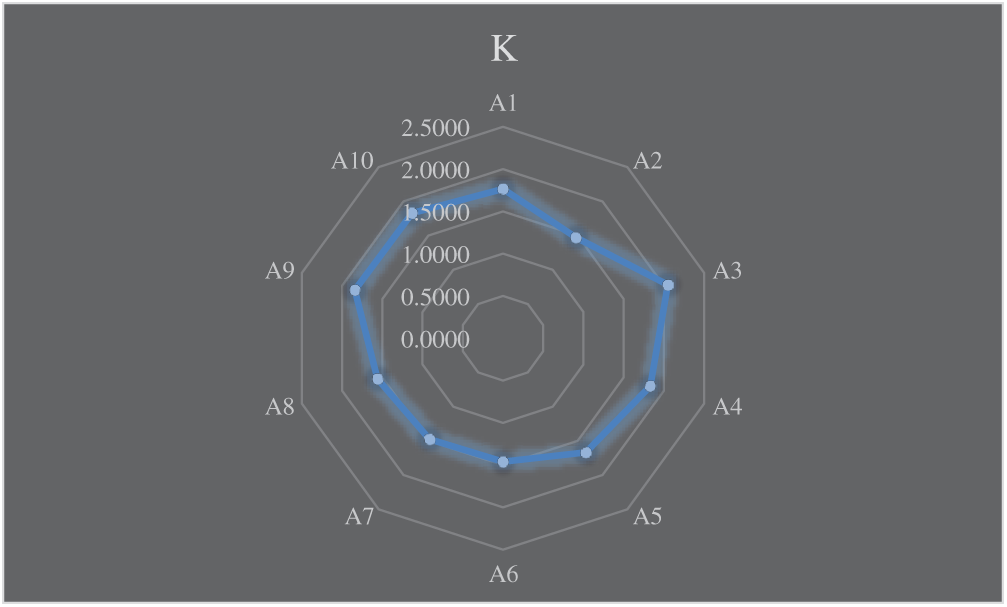

Finally, the objects were ranked by the CoCoSo algorithm. These results are shown in Tab. 4 and Fig. 5.

The problem of selecting a biomass furnace supplier is an MCDM process involving quantitative and qualitative criteria. The proposed MCDM model based on FAHP and CoCoSo has demonstrated the viability of this process through its application to this case study. First, 10 potential suppliers were identified. Next, 5 main supplier selection criteria and 15 sub-criteria were identified after interviewing 12 industry experts and consulting related literature. The inputs of the FAHP model were then based on the evaluation of the experts and were used to calculate the weight of the criteria. Finally, the weights of the criteria were used as the input to the CoCoSo model to calculate the rankings of the 10 suppliers.

As can be seen in Fig. 5, Supplier A3, Zhejiang Zobo Technology Co., Ltd., is ranked as the top biomass furnace provider, while Supplier A6, Shandong Rotex Machinery Co., Ltd., was at the bottom of the list. The results are reliable as the rankings produced by each piece of k are consistent with the final ranking. In this case study, the evaluation result of the selection of potential biomass furnace providers are A3 > A9 > A4 > A10 > A1 > A5 > A8 > A7 > A2 > A6.

Figure 5: Final ranking of alternatives

The model can be expanded so that it can be applied to similar supplier evaluation and selection processes in energy development projects. The model can also be modified and further developed to be applied to any industry where the supplier evaluation process takes place in uncertain decision-making environments that involve multiple quantitative and qualitative decision-making criteria.

Biomass energy is energy generated from excess materials such as rice husks, straw, bagasse, or waste from human activities (garbage and sludge/sewage). Biomass involves the conversion of these materials into electricity (biochemistry and chemistry) or heat (burning). As a predominantly agricultural country, Vietnam has the potential to use about 150 million tons of these types of biofuel per year. This not only helps reduce the amount of waste entering the environment, but also contributes to energy security and reduces dependence on fossil fuels.

Once a biomass energy plant has been built, it needs to be operated efficiently and carefully maintained. Although biomass power plants have lower maintenance requirements than other power generation technologies, proper maintenance of a biomass power plant is nevertheless essential to maximize the productivity and useful life of the plant. Optimal operations must strike a balance between maximizing power output and minimizing costs. Therefore, the selection of the supplier of the equipment used in the biomass energy project, in particular the biomass furnace, is an important and complex decision, requiring decision-makers to understand all of the criteria that directly influence the decision-making process.

In this research, the authors apply fuzzy MCDM methodology to the recommendation of biomass furnace suppliers in regard to qualitative and quantitative factors. Furthermore, the results of this work will provide the first look at a hybrid of FAHP and CoCoSo methods to enable decision-makers in other fields to select the best supplier.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. H. Fu, GDP Growth (Annual %). Vietnam: The World Bank, 2019. [Online]. Available: https://data.worldbank.org/indicator/NY.GDP.MKTP.KD.ZG?locations=VN. [Google Scholar]

2. P. Q. Tuan, Vì sao Việt Nam cần phát triển nhiệt điện than? (Bài 2). Vietnam: Vietnam Energy Online, 2017. [Online]. Available: http://nangluongvietnam.vn/news/vn/nhan-dinh-phan-bien-kien-nghi/phan-bien-kien-nghi/vi-sao-viet-nam-can-phat-trien-nhiet-dien-than-bai-2.html. [Google Scholar]

3. S. Atuahene, Y. Kong and G. Bentum-Micah, “COVID-19 pandemic, economic loses and education sector management,” Quantitative Economics and Management Studies, vol. 1, no. 2, pp. 103–109, 2020. [Google Scholar]

4. A. A. Ojugo and O. D. Otakore, “Investigating the unexpected price plummet pnd volatility rise in energy market: A comparative study of machine learning approaches,” Quantitative Economics and Management Studies, vol. 1, no. 3, pp. 219–222, 2020. [Google Scholar]

5. F. Birol, Vietnam Key Energy Statistics in 2018. Paris, France: International Energy Agency, 2018. [Online]. Available: https://www.iea.org/countries/viet-nam. [Google Scholar]

6. M. Gavrilescu, “Biomass power for energy and sustainable development,” Environmental Engineering and Management Journal, vol. 7, no. 5, pp. 617–640, 2008. [Google Scholar]

7. M. Henson, How a biomass power plant works: Technology & design, PNGbiomass, 2019. [Online]. Available: https://pngbiomass.com/how-a-biomass-power-plant-works/. [Google Scholar]

8. P. Poikonen, B. Asztemborski, O. Caba, M. Duca, J. Eronen et al., Promotion of regional bioenergy initiatives in Poland, Romania and Slovakia: Final report, PromoBio Project, 2014. [Google Scholar]

9. E. K. Zavadskas, K. Govindan, J. Antucheviciene and Z. Turskis, “Hybrid multiple criteria decision-making methods: A review of applications for sustainability issues,” Ekonomska Istraživanja, vol. 29, no. 1, pp. 857–887, 2016. [Google Scholar]

10. K. Mamay and A. Naufal, “The effects of technical and fundamental factors on the investment decision and the company value in the agricultural sector,” Quantitative Economics and Management Studies, vol. 1, no. 6, pp. 411–425, 2020. [Google Scholar]

11. M. Yazdani, P. Chatterjee and E. K. Zavadskas, “Integrated QFD-MCDM framework for green supplier selection,” Journal of Cleaner Production, vol. 142, no. 2, pp. 3728–3740, 2017. [Google Scholar]

12. C. N. Wang, V. T. H. Viet, T. P. Ho, V. T. Nguyen and V. T. Nguyen, “Multi-criteria decision model for the selection of suppliers in the textile industry,” Symmetry (Basel), vol. 12, no. 6, pp. 979, 2020. [Google Scholar]

13. S. Hamdan and A. Cheaitou, “Supplier selection and order allocation with green criteria: An MCDM and multi-objective optimization approach,” Computers & Operations Research, vol. 81, pp. 282–304, 2017. [Google Scholar]

14. H. C. Liu, M. Y. Quan, Z. W. Li and Z. L. Wang, “A new integrated MCDM model for sustainable supplier selection under interval-valued intuitionistic uncertain linguistic environment,” Information Sciences, vol. 486, pp. 254–270, 2019. [Google Scholar]

15. M. Yazdani, Z. Wen, H. Liao, A. Banaitis and Z. Turskis, “A grey combined compromise solution (CoCoSo-G) method for supplier selection in construction management,” Journal of Civil Engineering and Management, vol. 25, no. 8, pp. 858–874, 2019. [Google Scholar]

16. X. Peng, X. Zhang and Z. Luo, “Pythagorean fuzzy MCDM method based on CoCoSo and CRITIC with score function for 5G industry evaluation,” The Artificial Intelligence Review, vol. 53, no. 5, pp. 3813–3847, 2019. [Google Scholar]

17. F. Chien, C. N. Wang, V. T. Nguyen, V. T. Nguyen and K. Y. Chau, “An evaluation model of quantitative and qualitative fuzzy multi-criteria decision-making approach for hydroelectric plant location selection,” Energies (Basel), vol. 13, no. 11, pp. 2783, 2020. [Google Scholar]

18. C. N. Wang, V. T. H. Viet, T. P. Ho, V. T. Nguyen and S. T. Husain, “Optimal site selection for a solar power plant in the mekong delta region of Vietnam,” Energies (Basel), vol. 13, no. 16, pp. 4066, 2020. [Google Scholar]

19. H. C. Lee and C. T. Chang, “Comparative analysis of MCDM methods for ranking renewable energy sources in Taiwan,” Renewable & Sustainable Energy Reviews, vol. 92, no. 1, pp. 883–896, 2018. [Google Scholar]

20. M. Çolak and I. Kaya, “Prioritization of renewable energy alternatives by using an integrated fuzzy MCDM model: A real case application for Turkey,” Renewable & Sustainable Energy Reviews, vol. 80, no. 5, pp. 840–853, 2017. [Google Scholar]

21. P. Díaz-Cuevas, J. Domínguez-Bravo and A. Prieto-Campos, “Integrating MCDM and GIS for renewable energy spatial models: Assessing the individual and combined potential for wind, solar and biomass energy in southern Spain,” Clean Technologies and Environmental Policy, vol. 21, no. 9, pp. 1855–1869, 2019. [Google Scholar]

22. C. N. Wang, C. Y. Yang and H. C. Cheng, “Fuzzy multi-criteria decision-making model for supplier evaluation and selection in a wind power plant project,” Mathematics (Basel), vol. 7, no. 5, pp. 417, 2019. [Google Scholar]

23. S. Değirmenci, F. Bingöl, S. C. Sofuoglu, S. Charlesworth and K. Adeyeye, “MCDM analysis of wind energy in Turkey: Decision making based on environmental impact,” Environmental Science and Pollution Research International, vol. 25, no. 20, pp. 19753–19766, 2018. [Google Scholar]

24. P. Madhu, C. S. Dhanalakshmi and M. Mathew, “Multi-criteria decision-making in the selection of a suitable biomass material for maximum bio-oil yield during pyrolysis,” Fuel (Guildford), vol. 277, no. 2, pp. 118–109, 2020. [Google Scholar]

25. S. Ali and J. Waewsak, “GIS-MCDM approach to scrutinize the suitable sites for a biomass power plant in southernmost provinces of Thailand,” IOP Conf. Series. Earth and Environmental Science, vol. 265, pp. 12–21, 2019. [Google Scholar]

26. S. Kheybari, F. M. Rezaie, S. A. Naji and F. Najafi, “Evaluation of energy production technologies from biomass using analytical hierarchy process: The case of Iran,” Journal of Cleaner Production, vol. 232, no. 13, pp. 257–265, 2019. [Google Scholar]

27. R. Ghasempour, M. A. Nazar, M. Ebrahimi and M. H. Ahmadi, “Multi-criteria decision making (MCDM) approach for selecting solar plants site and technology: A review,” International Journal of Renewable Energy Development, vol. 8, no. 1, pp. 15–25, 2019. [Google Scholar]

28. J. Yuan, C. Li, W. Li, D. Liu and X. Li, “Linguistic hesitant fuzzy multi-criterion decision-making for renewable energy: A case study in Jilin,” Journal of Cleaner Production, vol. 172, pp. 3201–3214, 2018. [Google Scholar]

29. C. R. Chen, C. C. Huang and H. J. Tsuei, “A hybrid MCDM model for improving GIS-based solar farms site selection,” International Journal of Photoenergy, vol. 2014, pp. 1–9, 2014. [Google Scholar]

30. G. Büyüközkan, Y. Karabulut and E. Mukul, “A novel renewable energy selection model for United Nations’ sustainable development goals,” Energy (Oxford), vol. 165, no. 3, pp. 290–302, 2018. [Google Scholar]

31. B. C. Ervural, S. Zaim, O. F. Demirel, Z. Aydin and D. Delen, “An ANP and fuzzy TOPSIS-based SWOT analysis for Turkey’s energy planning,” Renewable & Sustainable Energy Reviews, vol. 82, no. 7, pp. 1538–1550, 2018. [Google Scholar]

32. C. C. Yang and B. S. Chen, “Key quality performance evaluation using fuzzy AHP,” Journal of The Chinese Institute of Industrial Engineers, vol. 21, no. 6, pp. 543–550, 2004. [Google Scholar]

33. J. J. Buckley, “Fuzzy hierarchical analysis,” Fuzzy Sets and Systems, vol. 17, no. 3, pp. 233–247, 1985. [Google Scholar]

34. L. A. Zadeh, “Fuzzy sets,” Information and Control, vol. 8, no. 3, pp. 338–353, 1965. [Google Scholar]

35. J. J. H. Liou, L. Yen and G. H. Tzeng, “Building an effective safety management system for airlines,” Journal of Air Transport Management, vol. 14, no. 1, pp. 20–26, 2008. [Google Scholar]

36. W. W. Wu and Y. T. Lee, “Developing global managers’ competencies using the fuzzy DEMATEL method,” Expert Systems with Applications, vol. 32, no. 2, pp. 499–507, 2007. [Google Scholar]

37. T. Y. Hsieh, S. T. Lu and G. H. Tzeng, “Fuzzy MCDM approach for planning and design tenders selection in public office buildings,” International Journal of Project Management, vol. 22, no. 7, pp. 573–584, 2004. [Google Scholar]

38. A. T. Gumus, “Evaluation of hazardous waste transportation firms by using a two-step Fuzzy-AHP and TOPSIS methodology,” Expert Systems with Applications, vol. 36, no. 2, pp. 4067–4074, 2009. [Google Scholar]

39. M. Yazdani, P. Zarate, E. K. Zavadskas and Z. Turskis, “A combined compromise solution (CoCoSo) method for multi-criteria decision-making problems,” Management Decision, vol. 57, no. 9, pp. 2501–2519, 2019. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |