DOI:10.32604/cmc.2021.016954

| Computers, Materials & Continua DOI:10.32604/cmc.2021.016954 |  |

| Article |

Blockchain-Based Flexible Double-Chain Architecture and Performance Optimization for Better Sustainability in Agriculture

1Beijing University of Posts and Telecommunications, Beijing, 100876, China

2Dublin City University (DCU), Dublin 9, Ireland

3University of Quebec at Montreal, Montreal, H2X 3X2, Canada

*Corresponding Author: Xiaojuan Wang. Email: wj2718@163.com

Received: 15 January 2021; Accepted: 16 February 2021

Abstract: Blockchain is an emerging decentralized distributed technology that can cross the boundaries and guarantee safe and trustworthy value transfers between participants. Combining the blockchain technology with the Internet of Things (IoT) technology to enhance the transparency and sustainability of agricultural supply chains, has attracted researchers from both academia and industry. This paper reviews the latest applications of the blockchain and IoT technologies in the sustainable agricultural supply chain management and explores the design and implementation of a blockchain-based sustainable solution. By placing the sustainable agricultural supply chain management at its core, a blockchain-based framework is designed. Considering the heterogeneity of the transaction data and the IoT data, the openness of sustainability information and the sensitivity of participants’ data, a double-chain structure is proposed including the consensus method, the transaction mechanisms, the sustainability assessment method and the performance optimization strategy. The sustainable management practices of all participants are introduced into the blockchain network, especially those allowing the government to play a more significant role in agriculture supply management. Meanwhile, to meet the scenario requirements, a data reduction method is designed to improve performance and reduce block size. Simulations are performed to evaluate the latency, throughput, costs and efficiency of the proposed structure. This paper can be a useful reference for further research on the application of blockchain and IoT technologies in sustainable agricultural management.

Keywords: Blockchain; IoT; sustainability management; information system

With the massive implementation of technology, sustainability in agriculture is now facing major challenges. The sustainable development goals (SDGs), in the form of established mitigation targets and industrial strategies, are top priorities for many countries. According to a meta-analysis published in Science [1], the food sector accounts for approximately 26% of global greenhouse gas emissions. The United Nations forecasts that the population to be fed will rise to nearly 10 billion by 2050. Many countries have established goals for climate neutrality (e.g., Denmark, France), productivity (e.g., Australia, Germany), the elimination of hunger (e.g., Canada, the United States) and land management (e.g., Israel, New Zealand, the Netherlands). Achieving the sustainability goals in the agricultural sector involves technical and non-technical elements.

The first challenge is the data shortage in the sustainability assessment process although big data is generated in the agriculture supply chains (ASCs). Different partners, such as farmers, process enterprises, logistics, and retailers, play different roles in an ASC. To improve agricultural sustainability, supply chain partners must take responsibility for their specific environmental impacts and monitor them. One practical approach is to build an ASC only with partners who are determined to meet sustainability targets and then communicate this success to consumers and related parties, such as government regulators. However, limited participation of farmers has led to the lack of critical details in sustainability assessment during the agri-food life cycle. The development of the Internet of Things (IoT) has provided a practical way to capture data generated during agricultural production, but farmers lack incentives to invest in IoT systems. Low-profit margins make any agricultural transformations (e.g., agriculture 4.0, rural revitalization, digital agriculture) more prudent, and using technology just for the sake of using technology can mar sustainability in both the short and long term [2]. Therefore, to improve transparency in ASCs, it is important to consider IT acceptance, cost and performance, as well as value creation mechanisms.

The performance and cost of technology deployment have become the second challenge in developing sustainable ASCs. In recent years, blockchain technology is found to be an ideal tool to prevent tampering and guarantee the traceability of agricultural data and provide a truthful record, based on which regulators can supervise and third parties can provide services. Due to its specific heterogeneity, the agricultural industry requires critical considerations of data heterogeneity, multipartite interactions, and technical indicators such as the usability and scalability of the system when adopting blockchain-based solutions. In sustainable ASCs, data generated during transactions and sustainability data collected by IoT devices are different in their security requirements, generation rates and scales; thus, the integration of data flows, the selection of blockchain networks, appropriate technology combinations, and the operation of sustainable ASCs deserve further attention from scholars and practitioners.

At present, many studies introduce blockchain-and IoT-based solutions into agricultural scenarios that include sustainability concerns to varying degrees (e.g., [3]). The majority of efforts have been invested in discovering technological possibilities (e.g., [4,5]) and evidence of improvement (e.g., [6]), summarizing use cases (e.g., [7]) and proposing frameworks and systems (e.g., [8]). Nevertheless, extensive research is required to enable blockchain systems to interact significantly with other technologies in a sustainability-driven ASC. Significant research is required to enable blockchain solutions that truly consider the demands and principles of other methodologies in a sustainable agricultural system, including monitoring and managing agricultural sustainability. This paper addresses the deployment of blockchain and IoT technologies in ASCs with a specific focus on sustainability. The main contributions of this paper include:

1. This paper summarizes the data requirements of a value creation mechanism for sustainability assessment designs to enhance interactions between related parties and improve sustainability in ASCs, and propose a sustainability framework for agricultural supply chains based on blockchain technology;

2. This paper also develops a blockchain-based flexible double-chain structure to fulfil the multifunctional sustainability management needs of agricultural systems, design corresponding incentive mechanisms, improve the consensus algorithm, and indicate the applicability and effectiveness of the proposed structure using throughput, latency, and cost indicators;

3. This paper proposes a data reduction method to improve the efficiency of data collection and further lower the storage pressure on blockchain-based databases and considers performance optimization of the vast scale and limited value of IoT data in ACSs scenarios.

The rest of the paper is organized as follows: Section 2 reviews the concept of sustainability in ASC and recent works of blockchain- and IoT-based solutions. Section 3 introduces the design of blockchain-based double-chain architecture in ASCs, the data reduction method, and performance optimization strategy. Section 4 presents the simulation and discussion. Section 5 concludes the paper.

Sustainability assessments of products have become an increasingly important field with increased public attention toward sustainable development, and there are many well-defined tools for such assessments. However, owing to information latency and a lack of transparency, data collection remains an enduring challenge in life-cycle assessments [9]. Meanwhile, improved transparency also brings challenges related to energy consumption in IT implementation. Thus, the performance and cost of technical solutions become a problem that cannot be ignored by any industry, especially agriculture, that considers the blockchain to be an enabler. A recent paper has proposed a data-driven framework including three-dimensional (economic, environmental, and social) sustainable performance indicators but remained vague as to how these objectives may be attained through improved data analytics capabilities, and the relevance of their objectives is unclear [2]. Another paper has reviewed the role of machine learning in sustainable agricultural supply chains and proposed an ASC performance framework that lists similar objectives [10]. Current frameworks lack measurements and ignore technological sustainability, making them less appropriate for blockchain-based systems.

IoT systems are widely used for data collection in current blockchain solutions for agricultural applications. Using the IoT instead of manual data collection not only avoids human error but also solves the problem of data tampering before upload. For current sensor deployment, many studies focus on production processes without data processing before upload and neglect the security of the sensor networks [10,11] and trust issues [12,13]. For instance, Lin et al. [14] proposed a trusted, self-organized, open and ecological system for food traceability based on blockchain and IoT. Sensors are used to record a variety of environmental data, which are stored in every node of the blockchain system through an IoT gateway. In [15], the blockchain nodes are divided into nine types to store data from different sensors. Accordingly, blockchain technology is also considered an ideal solution to tackle the challenges of security problems in IoT systems [16].

Regarding the deployment of the IoT in the supply chain, different approaches focus on different processes. Some studies consider all participants in the agricultural supply chain (e.g., [17,18]), while others involve only business users. In [14], a reliable food traceability system records information from processing companies, seeding companies, logistics companies and food retailers. Awan et al. [19] put forward a model for upgrading traditional agriculture to smart agriculture in which blockchain records the product name and origin and other information that is accessible to all stakeholders. While IoT information collection and sharing have penetrated many links in the supply chain, the depth and impact of this sharing are still relatively limited. Blockchain users have access only to product information. However, information on the sustainability assessment of products, which is closely related to stakeholders, is not collected, processed or shared effectively.

Regarding data processing, very few studies have considered the problem of information overload in the blockchain, which edge computing is a possible solution [20]. In [21], edge computing is used to reduce computing and storage costs and thus save network resources, while many other studies ignore this problem and suppose real-time updates and access to data (e.g., [17]). However, this previous work only mentions that edge computing can analyze data from the IoT layer, without providing details about deployment and processing. In [15], the transaction throughput and latency in agricultural blockchain are simulated, but resource efficiency and block scales are not considered. In [19,22], only the transaction throughput is simulated, without considering transaction latency, the number of users, or other issues.

3 Design of the Blockchain-Based Double-chain Architecture

The sustainability of agriculture involves economic, environmental, social and technological factors. Therefore, the designed system must adopt a reasonable consensus algorithm and system architecture to ensure safe and efficient sustainable agricultural development. The sustainability performance metrics of an ASC consists of economic sustainability (ES), potential environmental impacts (EI) and the social sustainability (SS) of the product i, as well as technological sustainability (TS). Sustainability assessments can be expressed as follows:

where in the above ES metric Eq. (1), Fm represents farmer m, PF represents farmer’s profitability and LP represents land productivity. In the EI metric Eq. (2), PTi represents product type or crop type i, and LCj represents life cycle phase j of product i, such as production, processing and transportation processes. WI, SI and AP represent water impact, soil impact and air pollution respectively.

wherein SS metric Eq. (3), HR, WE and PSR represent human rights, working environment, and product social responsibility respectively. The TS metric Eq. (4) focuses on the technology investment and return of agricultural supply chain participants and determines whether supply chain participants’ levels of informatization meet their current development needs. In the TS metric equation, IL represent technological level, FL stands for financial level, ML refers to management level and KL stands for knowledge and experience level.

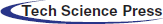

The combination of blockchain, IoT and other new technologies can result in a high degree of resource integration, enhance the transparency of ASCs, and quantify the sustainability of the performances of participants. For upstream farmers in ASCs, technologies can detect various indicators, such as crop growth, and help farmers increase production and income, thus realizing green agriculture. For the processing enterprises in ASCs, supporting farmers in deploying IoT equipment with extra computing power can help enterprises obtain additional tokens. Similarly, the sustainability of the enterprise is quantified by the results of analyses of the IoT data and the disclosure data. Green production can bring smart contracts into effect. To realize the above vision and functions in ASC scenarios, we construct a double-chain structure (as shown in Fig. 1) composed of a main-chain (Mainchain) and a sub-chain (Subchain).

Figure 1: Blockchain-based double-chain framework for sustainable ASCs

The arrangement accounts for function differentiation and security levels. The Mainchain connects enterprises, farmers, government regulators, and financial service providers and stores information on enterprises and farmers, such as their account information and their transaction and social sustainability assessment information. The Subchain mostly stores data collected by IoT devices in ASCs, including agriproduct information, product transportation information and data on the corresponding environmental impacts during the life cycle of agricultural products. Farmers and enterprises are the main uploaders of the information. As stakeholders, the government, consumers and financial institutions have the right to know and supervise part of the information.

3.1 Design of the Mainchain and Sustainability Assessment

The Mainchain stores information on a variety of transactions that occur in ASCs and is supervised by government regulators. It is necessary to design and manage the block data structure, consensus method, and transaction mechanisms.

3.1.1 Block Data Structure and Consensus Method

The key nodes in the Mainchain of the double-chain structure are government regulators, and the non-key nodes are enterprises, farmers and financial institutions. The initialization of the Mainchain for agricultural resources is shown in Eq. (5). In the Mainchain, the key nodes are responsible for the generation of new blocks.

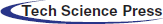

where BN is the Mainchain after initialization, E refers to enterprises, F refers to farmers, G refers to government regulators, FI refers to third parties such as financial institutions, BNeo refers to the information uploaded from environmental sustainability assessments (EI) in the Subchain, and IOt refers to transaction information in ASCs. SC represents smart contracts and CA is the consensus method. Our Mainchain and Subchain reference Proof-of-Authority (POA) to design consensus mechanism, and support users to deploy more appropriate mechanism. In the Mainchain, according to their functions, we define key nodes and non-key nodes. The key nodes mainly refer to government nodes and non-key nodes refer to the farmers, enterprises and third parties. The task of the key nodes is to audit the data submitted from the non-key nodes. The non-key nodes are responsible for providing information (transaction information of two sides and sustainability-related data) to the key nodes and are responsible for verifying the auditing results of the government nodes. Firstly, a non-key node generates a request about the transaction information that needs to be updated and the transaction information with sustainability-related data is sent to one of the key nodes. Secondly, the key nodes audit the transaction information in turn according to the audit procedures (the auditing order can be set by setting different reputation values). The last key node in the auditing procedures is the accounting node and it calculates the value of the data and sends the result to non-key nodes for verification. Thirdly, each non-key node verifies the result audited by the accounting node and sends a confirmation message to all other nodes after verification. Fourthly, the key nodes collect the verification result. Fifthly, the accounting key node then generates a new block. Finally, the content of the new block is broadcasted to all non-key nodes. Fig. 2 shows a logical diagram of the block-building procedure in the Mainchain.

Figure 2: Logical diagram of the block-building procedure in the Mainchain

The data block of the Mainchain contains the block header (Header) and the block body (Body). The block header encapsulates the hash value of the previous block, the version number, the Merkle root hash and the timestamp. The block body encapsulates the audit results, verification results, and a digital signature. Digital signatures come from all Mainchain participants, which can be used to prevent repudiation.

3.1.2 Transactions and Incentive Mechanisms

In the Mainchain, a variety of transactions will occur between different participants in ASCs. The broadcasted transaction information contains the product type, quantity, location, and volume, and the hash values and sustainability scores of both parties. To ensure the uniqueness and security of the transaction, enterprises and farmers will generate a unique hash code according to their identity information and time stamp. The hash code is calculated using Eq. (6) below.

where I is the hash code that identifies both parties, t is the timestamp, and IOa is the information from both parties. Taking the transactions between farmers and enterprises and the transactions between different enterprises as examples, we construct two transaction scenarios. When transactions occur between an enterprise and a farmer (MEF) or between enterprises (MEE), the broadcasted information is expressed as follows:

where PTi refers to product type, n is the quantity, l is the location of the transaction, TA is the total amount of the transaction, sreEi and sreFi are the sustainability scores of the enterprise and the farmer, and Ii is a hash code to identify each party.

The incentive mechanism usually refers to an incentive measure (such as awarding tokens) to stimulate the smooth operation and development of blockchain networks. In the Mainchain, there are several ways to obtain tokens, such as green production; enterprises buy agricultural products with high sustainability scores, and farmers sell agricultural products to enterprises with high sustainability scores. For instance, transactions between sustainable farmers and enterprises are rewarded by an incentive mechanism. Before each transaction, we calculate the sustainability score for each of the two parties (farmers or enterprises) based on their EI and SS values to get the combined sustainability score of the transaction. In trading, we set a basic reward unit (in terms of the number of tokens) and classify the sustainable scores into different scales, which correspond to different sustainability reward weights. The final reward for both parties in a transaction is obtained by multiplying the basic reward unit with the reward weight corresponding to the scale that the combined sustainability score of the transaction falls in.

3.2 Data Compression Method and Design of the Subchain

The Subchain collects data from several enterprises and farmers separately, involving a large volume of data and diverse data types, such as information on products, transportation and environmental impacts. Therefore, it is necessary to use IoT sensors to collect these data. Due to the explosive growth of real-time updating data, the data must be simplified before they are uploaded to the blockchain. Under the premise of ensuring the accuracy of the information, the compressed data is recorded in the Subchain and thus minimize the storage. Hence, we compress the massive data by designing a data reduction algorithm for the edge nodes and then use smart contracts to audit and verify the data so that participants can access the required data safely and easily. Because environmental data, such as those on water impacts and air pollution, may change slightly with time or temperature, data collected at adjacent times may be more similar. Given this fact, ASC members can set a baseline according to the type of the sensor, the type of the crop, or the data recorded at a certain time.

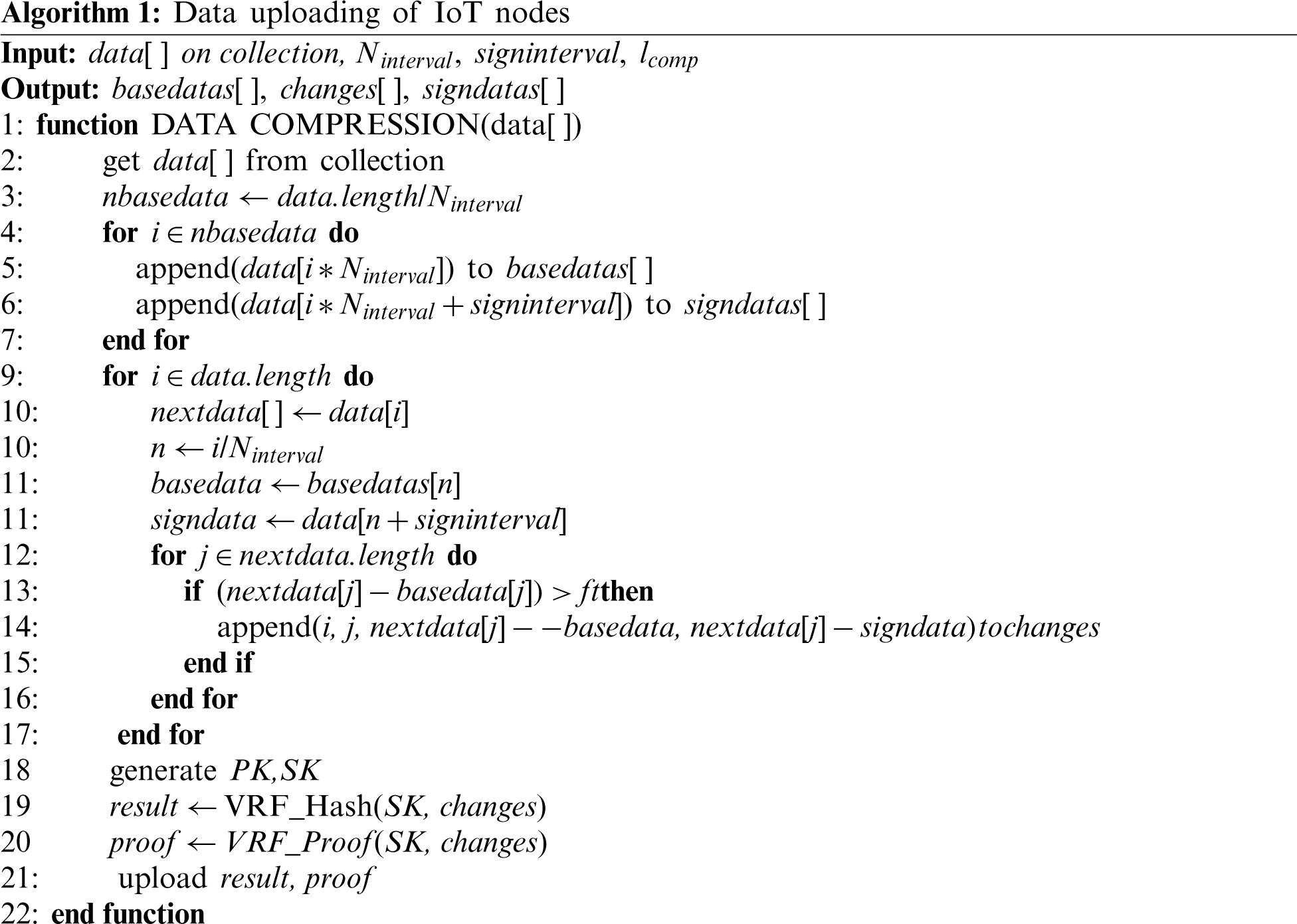

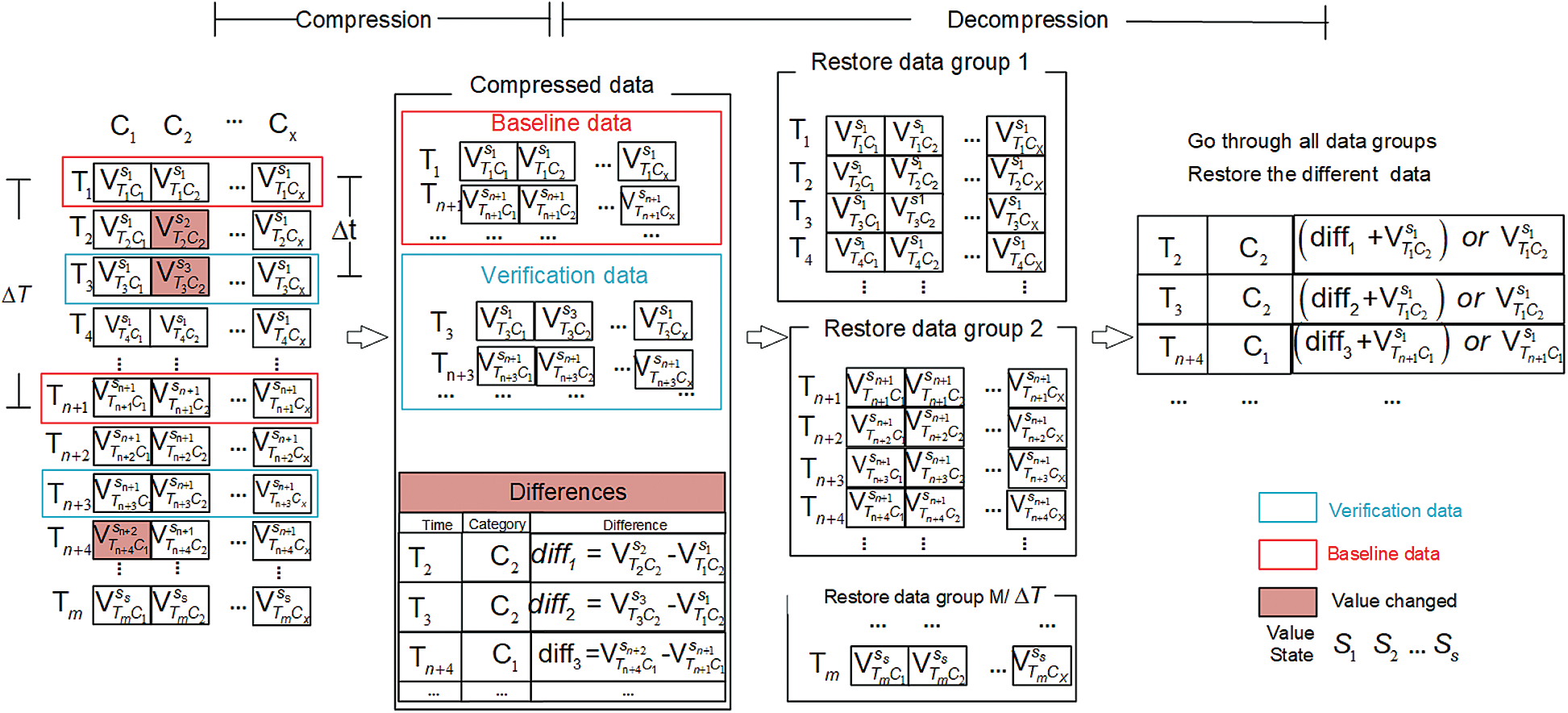

The input to the data-reduction algorithm is the data collected by each sensor at different time points. These data are temporarily stored in a large-scale two-dimensional matrix. The outputs of the algorithm are three much smaller two-dimensional matrices. The original input data can be recovered from these three small matrices within a controllable error range. The data reduction process is shown in Algorithm 1.

:

In Algorithm 1, data[ ] represents the collected raw data, Ninterval represents the number of collected raw data in the time interval between two adjacent baseline data time points (

Fig. 3 shows the data compression and decompression processes. We use data matrix

Figure 3: The data compression and decompression processes

As Fig. 3 shows, the values whose background are red denotes the changed ones compared with the baseline data in a time interval. To compress data, the ith difference is recorded as:

At the same time, the index of the difference also needs to be recorded. As described in Fig. 3, the time Tm and the category Cn are necessary. It is noted that the compression loss is bounded by the loss threshold value Lcomp, which ranges from 0 to lcomp. When the difference between any other collected raw data value and its corresponding baseline data value exceeds Lcomp, the collected raw data will be regarded as changed data and will be recorded as diffi. The lcomp controls the maximum loss of accuracy in the compression. Larger lcomp results in a higher loss of accuracy and achieve a higher compression rate, while smaller lcomp results in lower data accuracy loss and lower compression rate, and there is no compression when lcomp = 0. Besides, the baseline data and verification data are required. So, the compressed data consists of three parts: the baseline data list, the verification data list and the difference list. The final data reduction rate (DRR) can be defined as:

where

We can conclude that when m is large enough and the difference num

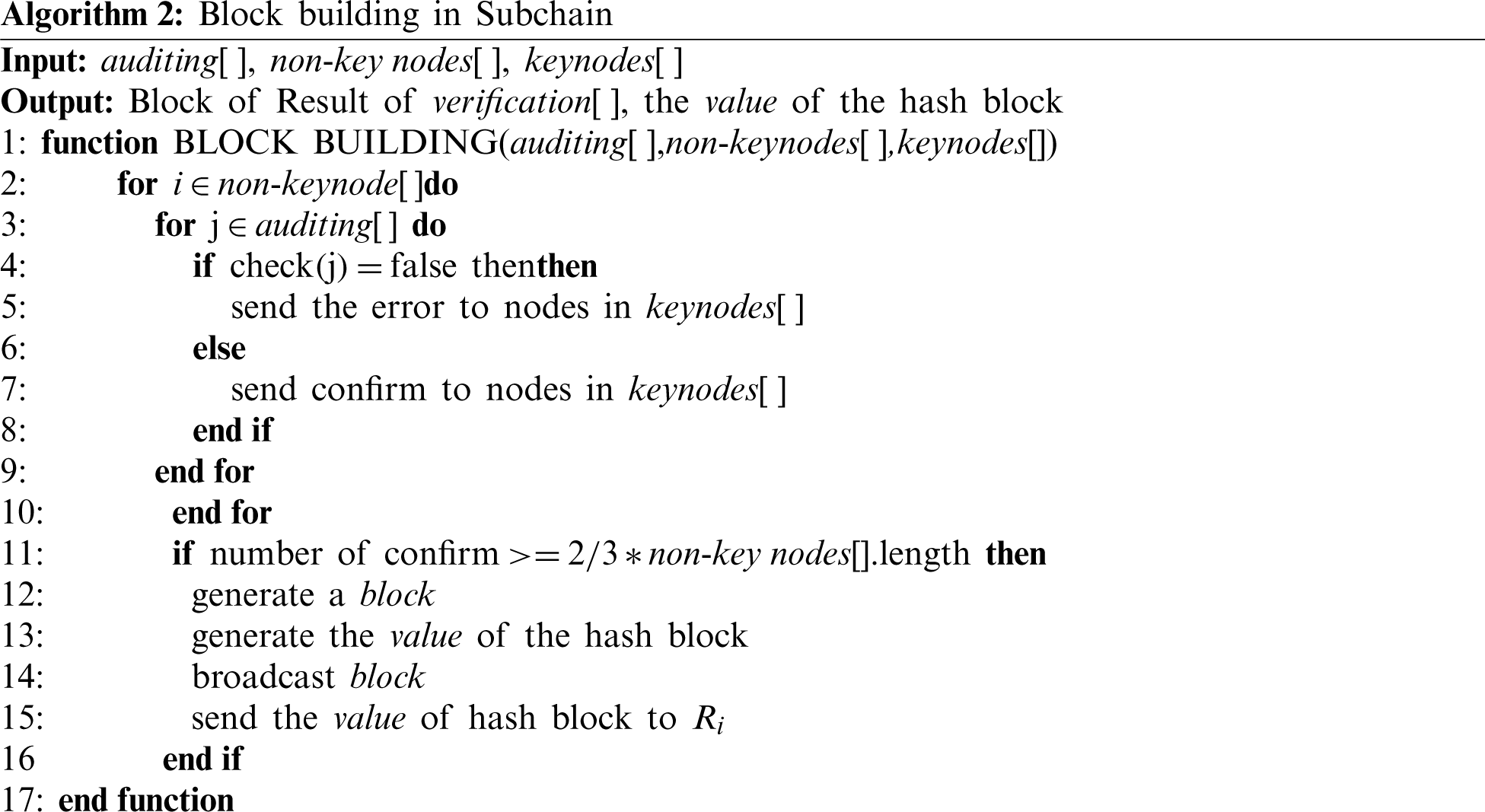

The compressed data then is uploaded to the Subchain. To guarantee security, we introduce Verifiable Random Function (VRF) to encrypt the compressed data. VRF is equivalent to random oracle adding non-interactive zero-knowledge proof functionally. When sending data locally, nodes can add random information through VRF, and other nodes can verify the selected results according to the public information including random number, proof and public key. The consensus process of the Subchain is as follows. Firstly, the IoT nodes generate data requests. The original raw data should be compressed first, and the compressed data should be combined with VRF generated random information to ensure the security of data. Secondly, the information will be broadcasted to all key nodes. Thirdly, calculating the reputation of all key nodes through the rules defined in advance, to select the accounting node. Fourthly, the accounting node calculates the hash value of the block and sends the result to other nodes for verification. In the last step, the other nodes will send correct messages to each other after verification. When each node receives confirm messages from more than

:

The input of Algorithm 2 includes three arrays, which are a set of data to be verified, a set of key nodes and a set of non-key nodes. The non-key nodes verify the data audited by the key nodes. If it is correct, every non-key node will return a positive signal to the key nodes. Otherwise, the non-key nodes will return negative signals. When a transaction occurs, the required data are sent to the key nodes of the government regulatory departments firstly. Similar to the Mainchain, the block of data in the Subchain includes the Header and the Body. However, The Body in the Subchain block contains all verified information records about the product, transportation and the environmental impacts.

To monitor and encourage farmers and enterprises in the Subchain, tokens can be issued as incentives. For farmers, conducting environmentally friendly practices has several benefits. First, land productivity and profitability can be recorded by technology. Second, tokens gained from sustainable production can be used to apply for agricultural insurance and tax benefits. Third, farmers can enhance their bargaining power. Through controllable IT implementation, enterprises can ensure the transparency of data along supply chains. The way to obtain tokens in the Subchain is to record and analyze the data from IoT devices.

In sustainable ASCs scenarios, there are three indicators to be focused on: the throughput R of the model, the latency TL of tasks and the cost P of tasks. The throughput is influenced by the number and size of the transactions initiated by clients, and the scale of the block. If the block can accommodate all the transactions, the throughput equals to the number of transactions. If not, the actual throughput is the biggest quantity that the block can accommodate. Here, we use ri to represent the number of the transactions that the client i initiates and use

And the latency TL contains two parts: the block interval TI and the consumed time TC. Thus, the latency can be calculated as:

where TI is a variable value defined by the model. TC is determined by the compression time TComp, the algorithm calculation time TA and the size sB. And we can conclude that

where

In the experiment, we expect to make the throughput R greater and reduce TL and P. Thus, the objective function can be defined as:

And if we use the original variable, it can be calculated as:

where

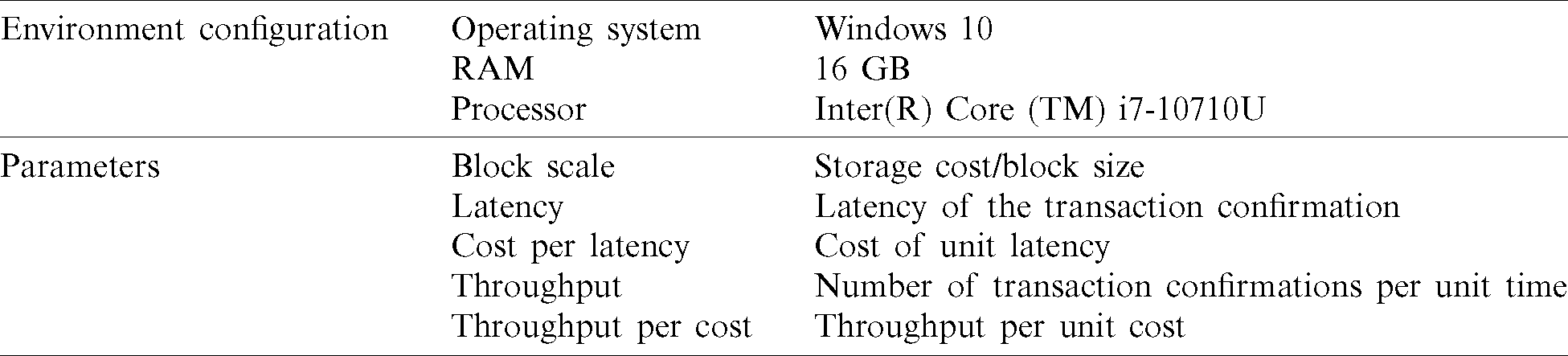

To verify the applicability and superiority of the double-chain structure in ASCs to improve sustainability, several experimental schemes are designed and simulated by OMNeT++ (an open-source software). The performance and cost of the double-chain and the single-chain structures are evaluated and compared in term of latency of transaction confirmations, cost of unit latencies, throughput, and throughput per unit cost.

Based on the main data flows in sustainable ASCs, the experiment divides the practical agricultural application into three business scenarios: an IoT scenario that contains only IoT data flows, an ASC scenario that contains only ASC transaction flows, and a hybrid scenario that contains both IoT and ASC data flows. In different application scenarios, there are some differences in performance and cost between a single chain and double chain structures. To study these differences, three blockchain structures have been designed, including two single chains and one double chain. One single chain (single-I) is set for IoT scenarios, and the other single chain (single-E) is for ASC scenarios. Double-chain has two chains that can accommodate both IoT and ASC scenarios. The performance and cost of the three chains were recorded under the three scenarios. The performance metrics include transaction latency and throughput, and cost metrics include cost per latency and throughput per unit cost. Moreover, we conduct a throughput comparison of the system under different data reduction rate (DRR) and different adaptive settings (flexibility of block size and block interval).

In different application scenarios, there will be differences in performance and costs between the single chains and the double chain, as well as between the different single chains. OMNeT++ is used to simulate the communication of an IoT device in the process from transaction generation in the actual environment to the final confirmation and encapsulation in the block by a consensus algorithm. The transaction confirmation latency, throughput, and cost are recorded for different scenarios. Finally, through the Matplotlib library, the recorded data are visualized for analysis. The simulation setup parameters are shown in Tab. 1.

Table 1: Simulation setup parameters

Performance affects the usability of the system, while cost consumption affects the scalability of the system. Assessing the sustainability of a system requires consideration of both performance and cost. An evaluation of these indicators can help achieve the lowest cost under a given performance demand to realize the sustainable development of agriculture.

4.2 Analysis and Discussion of the Experimental Results

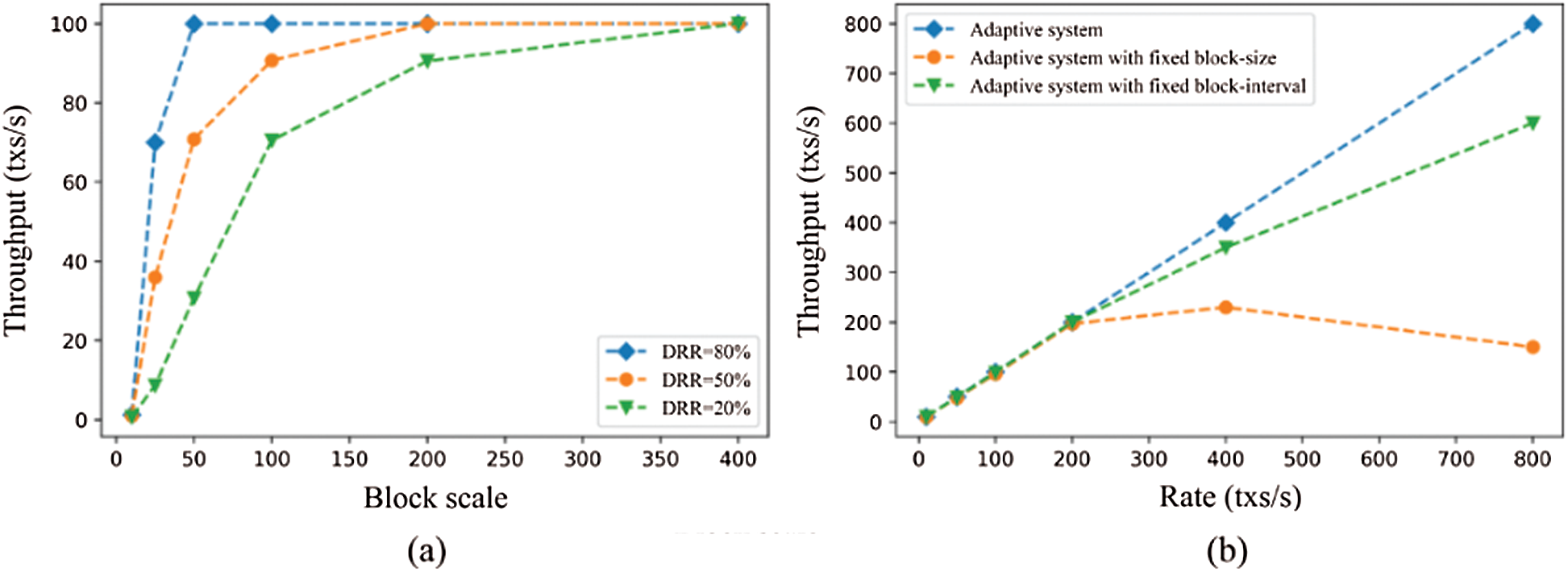

Fig. 4 shows the throughput comparison of the system under different DRR and different adaptive settings. The adaptive system includes three kinds of adaptive settings: 1) adjustable block size and interval; 2) fixed block size; 3) fixed block interval. In Fig. 4a,

Figure 4: Comparison of the system under different DRR and adaptive settings (a) Throughput of different data reduction rates (b) Throughput of different adaptive settings

In Fig. 4b, the adaptive system in which both block size and block interval are adjustable can always meet throughput requirements. When the transaction rate is high, the system with fixed block-size will experience congestion and throughput decline after the block interval reaches the regulated limit. The system with fixed block-interval can adjust the block size to meet the throughput requirements, but too large the block size will increase the cost and delay, so the throughput performance is not as good as that of the system with adjustable size and interval. The higher the DRR, the more data the block can contain at the same storage cost. Regarding when to do data reduction, data reduction is needed when the system needs to get rid of congestion quickly, or when the same block scale needs more throughput. In this case, the larger the DRR is, the faster it gets rid of congestion, and the larger the throughput is under the same block scale. As for the time cost of data reduction, under the same block scale, the higher the DRR, the greater the throughput. But the higher the DRR, the more time it takes to compress and decompress. This will lead to the increase of system delay. Therefore, it is necessary to select the appropriate DRR to meet the throughput requirements while maintaining the delay in an acceptable range.

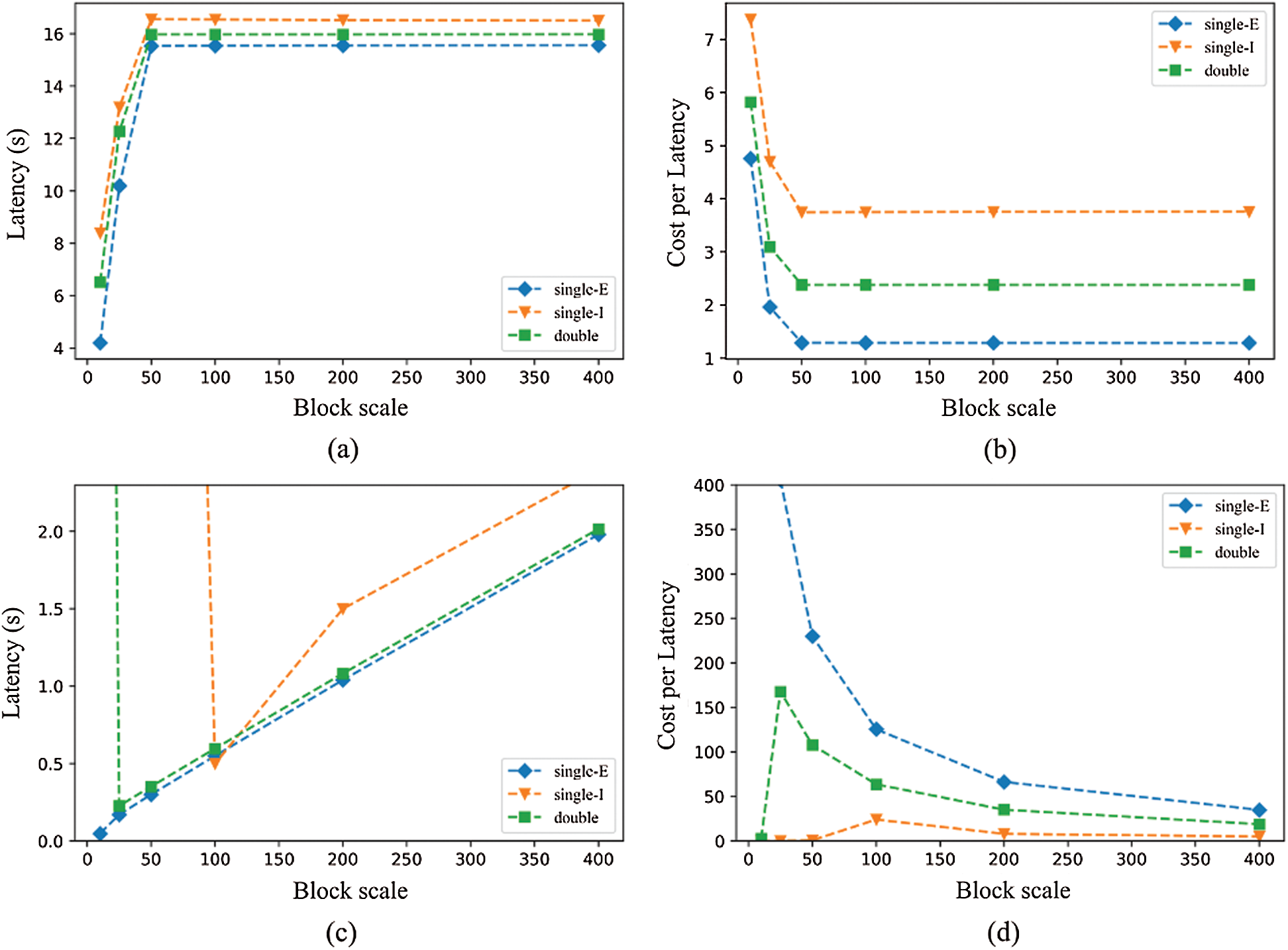

Fig. 5 shows a comparison of different chain structures in the ASC and IoT scenarios. The ASC scenario only contains transactions among ASC participants and the IoT scenario only contains IoT data flows. To achieve optimal performance and minimize cost, performance optimization is used to obtain optimal results. Figs. 5a and 5b correspond to the ASC scenario, and Figs. 5c and 5d correspond to the IoT scenario. In Fig. 5a, there is no congestion in the three chains, and the enterprise single-chain (single-E) latency is the smallest. The IoT single-chain (single-I) consensus algorithm has the longest execution time and the largest latency, while the latency of the double chain lies in the middle. In Fig. 5b, since the enterprise single-chain is designed for the ASC scenario, it has the lowest cost. The IoT single-chain costs more in the IoT scenarios than in the ASC scenarios. The cost of the double chain is moderate. Fig. 5c indicates that in the case of low block resource cost, the single-chain for enterprises does not suffer from congestion, while the single-chain for IoT does suffer from congestion. The total latency in the double-chain lies between those of the two single chains. In Fig. 5d, the cost of the IoT single-chain is the lowest, the cost of the enterprise single-chain is the highest, and the cost of the double-chain is moderate. For every single type of transaction only scenario, the corresponding single-chain performs better in terms of latency and cost, while the double-chain is in the middle.

Figure 5: Comparison of different chain structures in the ASC and IoT scenarios (a) Latency in different chains (b) Cost of different chains (c) Latency in different chains (d) Cost of different chains

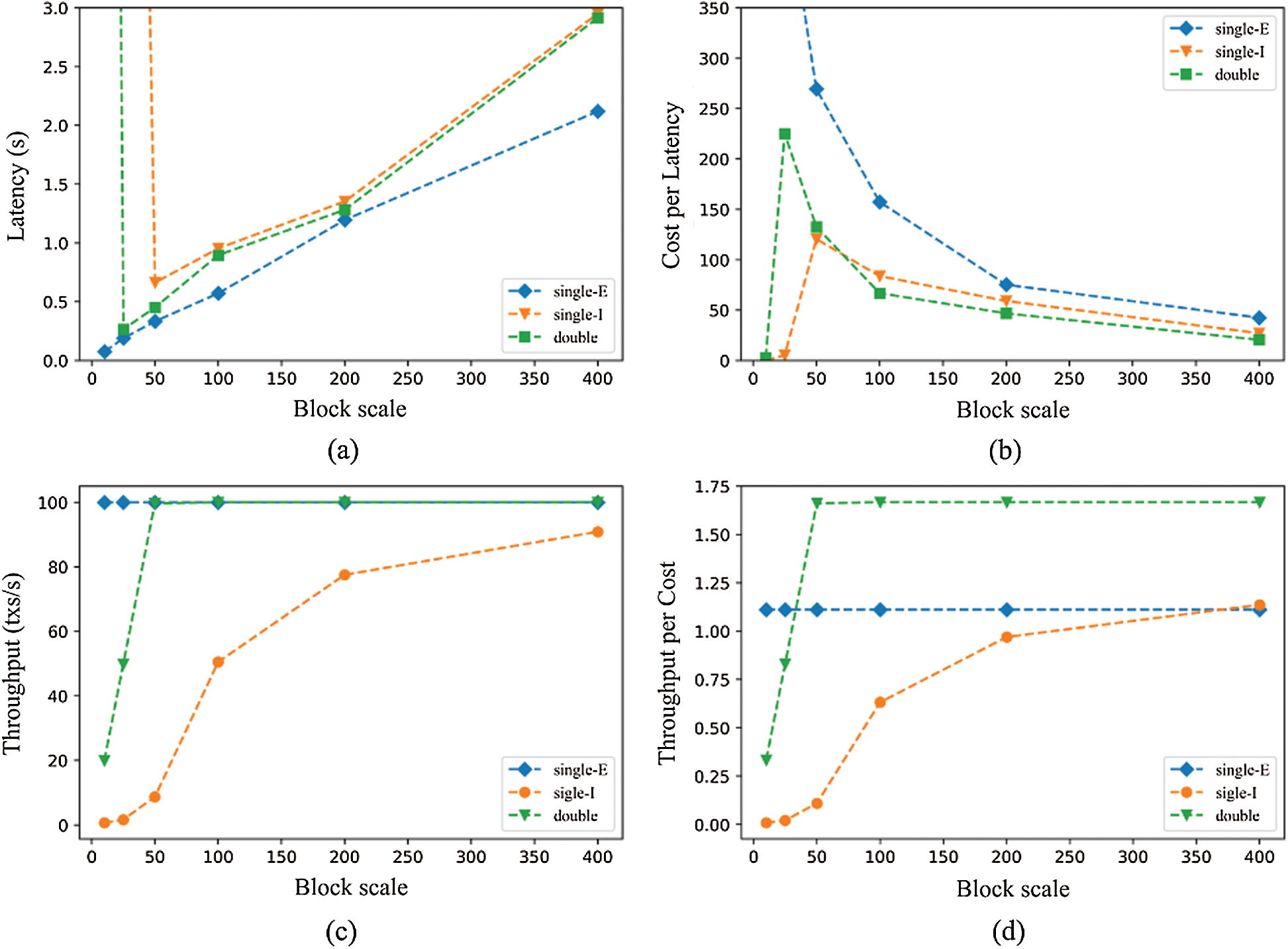

Fig. 6 shows a performance and latency comparison of different chains under the sustainable ASC scenario (a mixed scenario combining transactions with IoT data). The goal is to maximize throughput and minimize latency and cost through performance optimization. In this hybrid scenario, both ASC and IoT transactions occur.

Figure 6: Comparison of different chains in the sustainable ASC scenario (a) Latency in different chains (b) Cost of different chains (c) Throughput of different chains (d) Throughput per unit cost of different chains

In Fig. 6a, the enterprise has low single-chain latency and no congestion. The IoT single-chain has significant latencies in processing IoT transactions, causing congestion in the system. Therefore, the total latency of the double chain lies between the two single chains. In Fig. 6b, IoT single-chain transactions have the lowest costs when processing IoT transactions but the highest costs when processing ASC transactions as well as enterprise single-chain transactions. The double chain uses two mechanisms at the same time, and its cost is relatively moderate when processing both transactions, so the unit latency cost is the lowest when the system eliminates congestion. In Fig. 6c, the enterprise single-chain can always maintain high throughput. The IoT single-chain throughput starts small and then increases due to the long execution time of the consensus algorithm. The Subchain in the double chain has large latencies that cause congestion at the beginning, affecting performance. However, after eliminating the congestion, the two parts of the double chain adapt to the two scenarios, so the throughput of the double chain gradually increases. In Fig. 6d, the cost of the double chain is relatively moderate for both transactions, so the throughput of the unit cost is the highest once the system eliminates congestion.

For performance optimization, the double chain in the sustainable ASC scenario meets the performance requirements, and its implementation cost is the lowest. In the ASC transaction only or IoT transaction only scenarios, the performance and cost of a double-chain are in between the two corresponding single-chains. However, in a sustainable ASC scenario, although the performance of the double chain is moderate, its cost is the lowest, allowing it to achieve comprehensively optimal performance and cost. Therefore, in the sustainable ASC scenario, the double-chain scheme can meet the performance requirements, making the cost minimum.

The combination of blockchain and Internet of Things technologies not only provides transparent solutions for the traditional agricultural supply chain but also provides opportunities to support progress and innovation through sustainable management tools and methods. Concerning the challenges related to transparency, data collection and data sharing in sustainable development, this paper explores sustainable management in ASCs. Addressing the current situation of low-level farmer informatizationand inadequate government supervision about sustainable goals, a double-chain structure with low energy consumption is designed to achieve the sustainability management of the entire supply chain and promote value creation in the life cycle of agricultural products. Finally, the proposed technical scheme is evaluated through simulation and the performances of different implementation scales are analysed. The future work is to develop more accurate technical solutions for the double-chain application in different scenarios.

Acknowledgement: Thanks for the environment provided by laboratory ICN&CAD of School of Electronic Engineering.

Funding Statement: This study was funded by the project of the National Natural Science Foundation of China [Grant Numbers 62071056].

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. J. Poore and T. Nemecek. (2018). “Reducing food’s environmental impacts through producers and consumers,” Science, vol. 360, no. 6392, pp. 987–992. [Google Scholar]

2. S. S. Kamble, A. Gunasekaran and S. A. Gawankar. (2020). “Achieving sustainable performance in a data–driven agriculture supply chain: A review for research and applications,” International Journal of Production Economics, vol. 219, no. 1, pp. 179–194. [Google Scholar]

3. V. G. Venkatesh, K. Kang, B. Wang, R. Y. Zhong and A. Zhang. (2020). “System architecture for blockchain based transparency of supply chain social sustainability,” Robotics and Computer-Integrated Manufacturing, vol. 63, no. 101896, pp. 1–9. [Google Scholar]

4. M. Lezoche, J. E. Hernandez, M. M. E. A. Díaz, H. Panetto and J. Kacprzyk. (2020). “Agri-food 4.0: A survey of the supply chains and technologies for the future agriculture,” Computers in Industry, vol. 117, no. 103187, pp. 1–15. [Google Scholar]

5. J. Liu, X. Sun and K. Song. (2020). “A food traceability framework based on permissioned blockchain,” Journal of Cyber Security, vol. 2, no. 2, pp. 107–113. [Google Scholar]

6. S. Hayrutdinov, M. S. R. Saeed and A. Rajapov. (2020). “Coordination of supply chain under blockchain system-based product lifecycle information sharing effort,” Journal of Advanced Transportation, vol. 2020, no. 1, pp. 1–10. [Google Scholar]

7. L. Hughes, Y. K. Dwivedi, S. K. Misra, N. P. Rana, V. Raghavan et al. (2019). , “Blockchain research, practice and policy: Applications, benefits, limitations, emerging research themes and research agenda,” International Journal of Information Management, vol. 49, no. 1, pp. 114–129. [Google Scholar]

8. A. Zhang, R. Y. Zhong, M. Farooque, K. Kang and V. G. Venkatesh. (2020). “Blockchain-based life cycle assessment: An implementation framework and system architecture,” Resources Conservation and Recycling, vol. 152, no. 104512, pp. 1–11. [Google Scholar]

9. M. Jouini, J. Burte, Y. Biard, N. Benaissa, H. Amara et al. (2019). , “A framework for coupling a participatory approach and life cycle assessment for public decision-making in rural territory management,” Science of the Total Environment, vol. 655, no. 1, pp. 1017–1027. [Google Scholar]

10. R. Sharma, S. S. Kamble, A. Gunasekaran, V. Kumar and A. Kumar. (2020). “A systematic literature review on machine learning applications for sustainable agriculture supply chain performance,” Computers and Operations Research, vol. 1, no. 104926, pp. 1–47. [Google Scholar]

11. B. L. Nguyen, E. L. Lydia, M. Elhoseny, I. V. Pustokhina, D. A. Pustokhin et al. (2020). , “Privacy preserving blockchain technique to achieve secure and reliable sharing of IoT data,” Computers, Materials & Continua, vol. 65, no. 1, pp. 87–107. [Google Scholar]

12. J. Wang, W. Chen, L. Wang, R. Simon Sherratt, O. Alfarraj et al. (2020). , “Data secure storage mechanism of sensor networks based on blockchain,” Computers, Materials and Continua, vol. 65, no. 3, pp. 2365–2384. [Google Scholar]

13. B. Bordel, R. Alcarria, D. Martin and A. Sanchez-Picot. (2019). “Trust provision in the internet of things using transversal blockchain networks,” Intelligent Automation & Soft Computing, vol. 25, no. 1, pp. 155–170. [Google Scholar]

14. J. Lin, Z. Shen, A. Zhang and Y. Chai. (2018). “Blockchain and IoT based food traceability for smart agriculture,” in Proc. ICCSE, Singapore, pp. 1–6. [Google Scholar]

15. M. S. Devi, R. Suguna, A. S. Joshi and R. A. Bagate. (2019). “Design of IoT blockchain based smart agriculture for enlightening safety and security,” Proc. ICETCE, vol. 985, no. 1, pp. 7–19. [Google Scholar]

16. C. Li, G. Xu, Y. Chen, H. Ahmad and J. Li. (2019). “A new anti-quantum proxy blind signature for blockchain-enabled internet of things,” Computers, Materials & Continua, vol. 61, no. 2, pp. 711–726. [Google Scholar]

17. Z. Liu and Z. Li. (2020). “A blockchain-based framework of cross-border e-commerce supply chain,” International Journal of Information Management, vol. 52, no. 102059, pp. 1–18. [Google Scholar]

18. D. Bumblauskas, A. Mann, B. Dugan and J. Rittmer. (2020). “A blockchain use case in food distribution: Do you know where your food has been?,” International Journal of Information Management, vol. 52, no. 102008, pp. 1–10. [Google Scholar]

19. S. H. Awan, S. Ahmed, N. Safwan, Z. Najam, M. Z. Hashim et al. (2019). , “Role of internet of things (IoT) with blockchain technology for the development of smart farming,” Journal of Mechanics of Continua and Mathematical Sciences, vol. 14, no. 5, pp. 170–188. [Google Scholar]

20. Y. Wei, F. R. Yu, M. Song and Z. Han. (2019). “Joint optimization of caching, computing, and radio resources for fog-enabled IoT using natural actor-critic deep reinforcement learning,” IEEE Internet of Things Journal, vol. 6, no. 2, pp. 2061–2073. [Google Scholar]

21. R. S. Alonso, I. Sittón-Candanedo, Ó. García, J. Prieto and S. Rodríguez-González. (2020). “An intelligent Edge-IoT platform for monitoring livestock and crops in a dairy farming scenario,” Ad Hoc Networks, vol. 98, no. 102047, pp. 1–23. [Google Scholar]

22. A. Arena, A. Bianchini, P. Perazzo, C. Vallati and G. Dini. (2019). “BRUSCHETTA: An IoT blockchain-based framework for certifying extra virgin olive oil supply chain,” in Proc. SMARTCOMP, Washington, DC, USA, pp. 173–179. [Google Scholar]

23. K. A. Dowsland, J. M. Thompson and S. Annealing. (2012). Handbook of Natural Computing, Heidelberg, Berlin, Germany: Springer. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |