DOI:10.32604/cmc.2021.014438

| Computers, Materials & Continua DOI:10.32604/cmc.2021.014438 |  |

| Article |

Soil Properties for Earthen Building Construction in Najran City, Saudi Arabia

1Department of Architectural Engineering, Najran University, Najran, Saudi Arabia

2Department of Civil Engineering, Najran University, Najran, Saudi Arabia

*Corresponding Author: Gamil M. S. Abdullah. E-mail: gmabdullah@nu.edu.sa

Received: 20 September 2020; Accepted: 23 October 2020

Abstract: Earth is the most common and important building material used in the construction industry, since it is found in almost every country in the world. Modern earthen construction is alive and well, and is spread over an enormous geographical area. This technique utilizes various earthen materials and numerous methods, and features many benefits for both construction in general and buildings in particular. Najran, a city located in the south of Saudi Arabia, is distinguished by its heritage of earthen architecture, which displays many advantages and a marvelous variety of types and exterior designs. Many weaknesses of the material, however, along with a lack of knowledge and rapid development have caused the uplifting and destruction of many of Najran’s mud and heritage buildings during the last few generations. Not all soil types are suitable for every building need. Soil specification is thus very important in order to ensure that the materials used in construction meet all requirements. The main goal of this study was to invistegate the suitability of local soils for the earthen building construction. Thus, available local materials of common quality were taken from local sites in Najran. Laboratory experimentation and testing was then performed to determine the properties of those materials. The results showed that local soil properties are suitable for using in the earthen block construction since they satisified the specifications. The results were then recorded for use in further studies, as well as to explore heritage building and rehabilitation, and to improve modern earthen building materials and techniques.

Keywords: Najran; earthen building; local earthen material; soil suitability; standards; soil properties

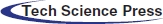

Earthen buildings are found throughout the world, as shown in Fig. 1. Traditional construction uses available local materials for wall-bearing earthen construction. The characteristics of earthen materials provide many important benefits, such as very low cost, environment conservation, and energy savings [1–4]. Recently, the Saudi government has increased its attention on tourist and historic culture and buildings. Many conservation and restoration projects have been completed, and research projects have also been performed in this area. Traditional buildings in the city of Najran are distinguished by their earthen architecture heritage, and feature many benefits as well as a splendid variety of types and exterior designs, as illustrated by the photo in Fig. 2. Earthen buildings have drawbacks, however, due to the economic situation and modern construction. It has been demonstrated that classical earthen building materials and techniques cannot fulfill the needs of modern housing. Usually, soils are mixed with additives or imported materials in order to achieve suitable soil combinations for modern construction [5,6]. Determining the most important properties of soil is crucial when developing new mixtures and earthen blocks, in the attempt to save historic earthen buildings and continue utilizing earthen materials.

Figure 1: Earthen building distribution and use around the world [7]

Figure 2: Traditional earthen building in Najran

The earthen building architecture of Najran is unique. Houses four to five stories high have been made out of mud using traditional “cob” techniques. Mud cob construction in the Najran Valley has been an active regional industry for centuries, providing durable and attractive buildings, as shown in Fig. 3. This industry has recently been impacted by numerous public, economic, and private changes.

Figure 3: Durable and attractive mud cob building in the Najran Valley

Using local materials and cob technology, earthen construction in the Najran Valley has an impressive heritage of sustainable buildings. The tradition of mud cob architecture in the Najran Valley, as illustrated in Fig. 4, offers a unique source of cultural and technical knowledge. Identifying the characteristics of the soil and its appropriateness is very important for use in building construction in order to improve structural quality [3,8,9]. Prior to application, the materials should be prepared, which usually consists of sieving, pulverizing, and drying [5]. It is important to ensure that the materials used in construction meet all specifications in every respect. This means that all relevant properties must be checked properly before construction [10]. We can promote the use of earth as a building material by understanding the characteristics of soil [11].

Figure 4: Traditional mud cob architecture in the Najran Valley

This study is an attempt to summarize information on the basic characteristics of the selected soil. This investigation supports the use of modern techniques for earth as a building material in Najran and focuses on soil properties for building materials and wall building knowledge. It is worth mentioning that this study is considered to be the first of its kind in Najran Province.

In spite of all the advantages of earthen materials and construction, soil is still unsuitable for use in many countries, mainly due to the disadvantages of this material and lack of information regarding its properties. Lack of knowledge concerning building material properties hinders the understanding of earthen building demands and the development of improvements, which involves reference to the local masons and associated professionals. Many researchers in this area have primarily focused on the use of these materials for roadbeds, roads, and construction foundations [3]. There is still poor understanding of the soil selection necessary for scientific engineers and architectural demands. Soil is not receiving the required research and attention as a material for earthen block and wall construction [12].

Traditional knowledge, however, is generally no longer sufficient or lasting [13].

This study was conducted to gain better knowledge and understanding of the characteristics of the local earthen materials of Najran. The local materials used in earthen building construction were classified for use in further research and the development of building materials.

2 Properties and Characteristics of the Soil Used in Earthen Production

Previous studies have revealed that the physical properties of soil must be checked before starting any important project [11]. It is commonly accepted that the soil to be used in earthen building walls should have a high sand content, with just enough clay to act as a binder. Too much clay can result in cracking problems due to shrinkage effects [13]. Particle size distribution and soil texture are important characteristics. Highly plastic clay, clean gravels, sand, and organic soils are unsuitable and not recommended [3,14–16].

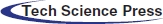

Swell capacity and soil shrinkage are related to clay content. The basic soil formula consists of 30% clay, with balance loam and a small amount of aggregate [17]. The silt percentage should be less than one-third. California’s Uniform Building Code Specification recommends 55%–75% sand and 25–45% clay and silt [18]. Tab. 1 lists these percentages.

Table 1: Suggested good mixture for most blocks [18]

Proposals have suggested balances between clay/silt and sand ranging from 30% to 70% [19]. Studies have summarized that the upper clay silt limit is 45% [20]. According to Burroughs [16], the satisfactory fraction of clay/silt is 36%–45%, while sand should vary from 66% to 75%. Similarly, the minimum percentage of sand has been determined to be 50%–55%, while the maximum is 70%–75%.

2.1 Soil Types and Classification

Clay deposits consist of several similar clay minerals. Clay deposits have different working characteristics due to their plasticity and their ability to bind non-plastic additives [21,22]. In many soil classification systems, soils are divided into three main groups: coarse, fine, and organic [23]. The mechanical properties of soil, such as strength and permeability, are dependent on the soil stress and grains, unit weight, and water content [24,25]. When using soil for construction and engineering purposes, the British soil classification system is recommended [26]. This classification is based on the range of particle sizes. The British Standard BS1377:1990 [27] classifies soil with particle sizes ranging from boulders, with a controlling dimension of over 200 mm, down to clay particles < 0.002 mm. Some clay contains particles < 0.001 mm in size [24], as shown in Fig. 5.

Figure 5: Range of particle sizes in soil

Clays and sands exhibit vastly different engineering behaviors [24,28]. The principal characteristic differences are particle size distribution, shape, and plasticity, while shape texture and color are secondary characteristics [29,30]. Chemical properties depend on the chemical composition of the soil components and the quantity of either magnesium or calcium, carbonate oxides of iron, and sulfates. In terms of pH level, soils do not usually stray very far from neutral [31].

2.2.1 Physical Index Properties

Porosity or void ratio: Voids between the particles in the soil itself can vary enormously depending on particle size and distribution. Both the apparent bulk density and specific bulk density of a soil sample are needed to calculate its porosity [29,32].

Specific bulk density: The specific bulk density of soil is calculated from the mass of the sample and the displaced volume of water, similar to the apparent bulk density.

Specific gravity: Specific gravity (Gs) is the property of minerals or rock material that indicates the formation of soil grains [24].

The range of specific gravity for soils is small, with the exception of organic soils. Most soils (sand and clay) have a typical specific gravity of 2.65 [33]. The range of Gs for common soils is 2.64–2.72 [24].

Volume-weight properties: The volume-weight properties of soil define its state and measure the amount of void space, amount of water, and weight of a unit volume of soil [24].

Shrinkage: In most clay textures, the moisture content changes the soil volume depending on the type and amount of clay found in the soil. At the soil surface, shrinkage and swelling are seen as cracks and develop when the soil dries [16]. Shrinkage of soil is a very common problem and must be addressed carefully [34]. A measure of the soil shrinkage is determined by measuring a specimen in wet and dry conditions. The change in dimensional variation should be only approximately  2 mm based on B.I.S. code IS 1377, 1990 part 2 [35], and generally varies from near zero to 0.12 for soils [36]. Other standards have determined 3% linear shrinkage as the maximum permissible value [20].

2 mm based on B.I.S. code IS 1377, 1990 part 2 [35], and generally varies from near zero to 0.12 for soils [36]. Other standards have determined 3% linear shrinkage as the maximum permissible value [20].

Dry density: Dry density is the degree of soil compaction, which is important when calculating loads on structural elements (measured in terms of dry density), and is referred to as either the “zero air voids” dry density or saturation dry density [37].

Soil compaction: Compaction decreases permeability and reduces the settling of foundations. Compaction process effectiveness depends on several factors [23]. Soil dry density depends on the amount of moisture during compaction. There is one moisture content value for each given soil, known as the “optimum moisture content,” that occurs with maximum dry density [26].

Optimum moisture content and bulk density: A standard compaction test was conducted following BS 1377:1990 part 4 [38] to determine the relationship between dry density and moisture content. Density is defined as the measure of the number of particles of an element or material that are packed within a given space.

2.2.2 Relationships Between Basic Properties

The property of soil that describes deformation without elastic failure, i.e., cracking or breaking [39], is indicated by the plasticity index [20].

The liquid limit (wL) is the change of consistency from plastic to liquid.

The plastic limit (wP) is the change of consistency from brittle/crumbly to plastic.

The plasticity index (IP or PI) is calculated by the formula

, i.e., wL–wP [24].

, i.e., wL–wP [24].

The Atterberg limits are utilized in specifications to control the properties, compaction, and behavior, and to describe the transitions of soil material from semi-solid to plastic to fluid. Sandy soils and silts have low plasticity index values, while most clays have higher values.

The liquid limit for earthen soils should be between 25% and 50%, with 30%–35% preferred, while the plastic limit should range from 10% to 25%, with 12%–22% preferred [31].

Organic content: Samples of cohesive soil were tested, and amount of organic content was recorded following BS 1377:1990 part 3 [40].

3 Field and Laboratory Testing

Two local soils were selected from the Najran Valley. Both samples were from earthen building construction sites. Visual testing was first conducted in order to select the best and most pure building soil. The first location was in the Najran Valley near historic clay buildings. Visual testing and a pilot laboratory experiment revealed that the soil from the second site soil (Zur Wadea, a) was mixed with organic materials. Thus, the first site in the central Najran Valley, as shown in Fig. 6, was recommended and trusted for the laboratory experiments used to determine its properties.

Figure 6: Soil site selection in the central Najran Valley

Based on a review of the literature, the most important tests were selected and conducted in order to define the soil sample properties of earthen construction and buildings. Using the selected soil, the samples were prepared and experiments performed in the civil engineering laboratories of the College of Engineering at Najran University. British standard tests were recommended and used. The testing was completed in three phases:

Visual and simple tests were performed to define the types of soil that seemed suitable.

Sieve analysis was utilized to determine the particle sizes and percentage of clay in the soil.

Laboratory tests were conducted to determine the engineering properties of the cohesive soil.

Sieve tests were carried out. For the wash-sieving standard method, BS 1377:1990 [41] was used to determine the particle sizes of the samples. The devices used included B.S. test sieves (10, 5, 2, 1.18, 0.63, 0.30, 0.15, and 0.063 mm), a mechanical sieve shaker, a sieve brush, trays or containers, a balance, an oven, and sodium hexametaphosphate, as shown in Fig. 7.

Figure 7: British standard sieve set and mechanical sieve shaker

Approximately 500 g of air-dried soil was placed in a bucket and covered with tap water. Next,  2 mg of sodium hexametaphosphate was added to it, and the mixture was stirred thoroughly. Following that, the soil was washed through a 63

2 mg of sodium hexametaphosphate was added to it, and the mixture was stirred thoroughly. Following that, the soil was washed through a 63  m B.S. test sieve, and the fine material passing through it was discarded. All of the retained material was collected in a proper dish and placed in an oven at 110

m B.S. test sieve, and the fine material passing through it was discarded. All of the retained material was collected in a proper dish and placed in an oven at 110 C for 24 h to dry. The dried material was then removed from the oven and allowed to cool. After cooling, the dried material was sieved through an appropriate set of sieves, using a mechanical sieve shaker for about 10 min. The soil retained in each sieve was weighed. The cumulative percentages by mass of the samples passing through each of the sieves were calculated, and the results were recorded.

C for 24 h to dry. The dried material was then removed from the oven and allowed to cool. After cooling, the dried material was sieved through an appropriate set of sieves, using a mechanical sieve shaker for about 10 min. The soil retained in each sieve was weighed. The cumulative percentages by mass of the samples passing through each of the sieves were calculated, and the results were recorded.

3.4 Characteristic Properties of Cohesive Soil

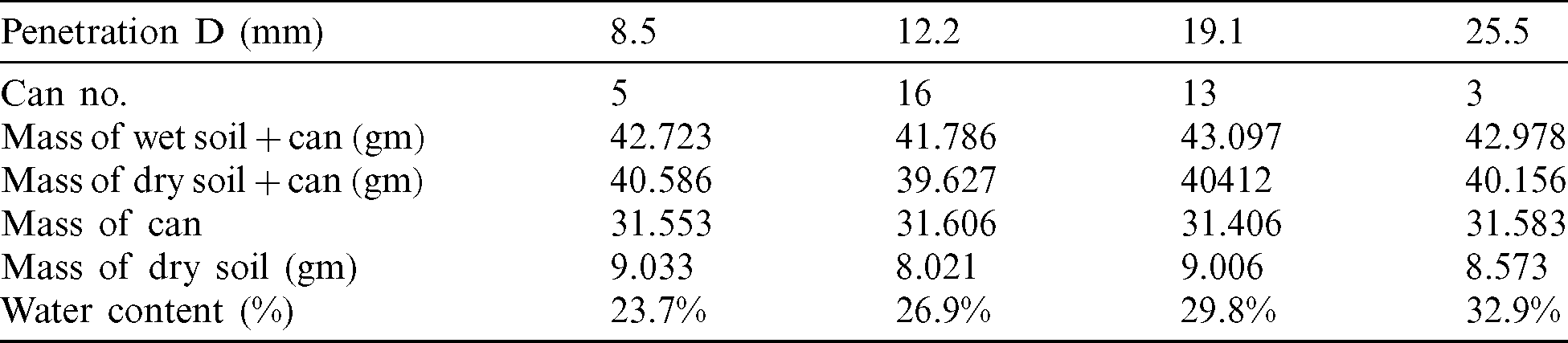

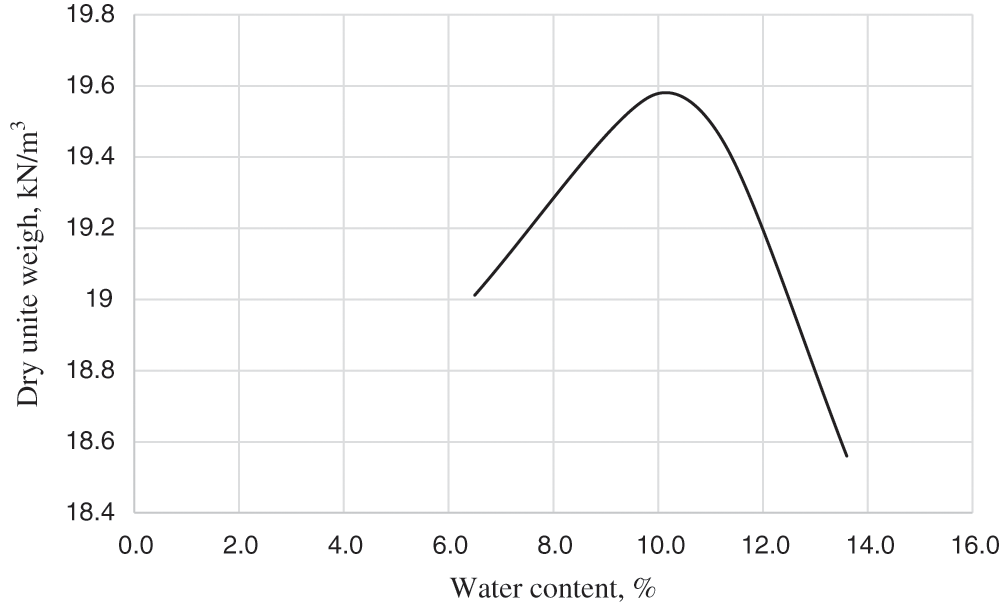

a) Optimum moisture content and bulk density: A standard compaction test was conducted following BS 1377:1990 part 4 [37] to determine the relationship between dry density and moisture content.

b) Grain specific gravity (Gs): A standard method was used according to BS 1377:1990 part 4 [42], where Gs = mass of soil/ mass of water displaced by soil.

c) Organic content: The amount of organic content was also recorded following BS 1377:1990 part 3 [40].

d) Linear shrinkage: A standard method (BS 1377:1990 part 2) [35] was applied to determine the linear shrinkage of the soil. The linear shrinkage was calculated using the equation:

The results were reported to the nearest whole number.

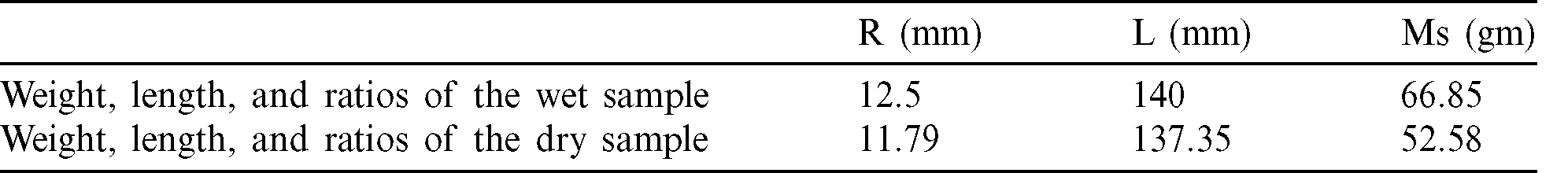

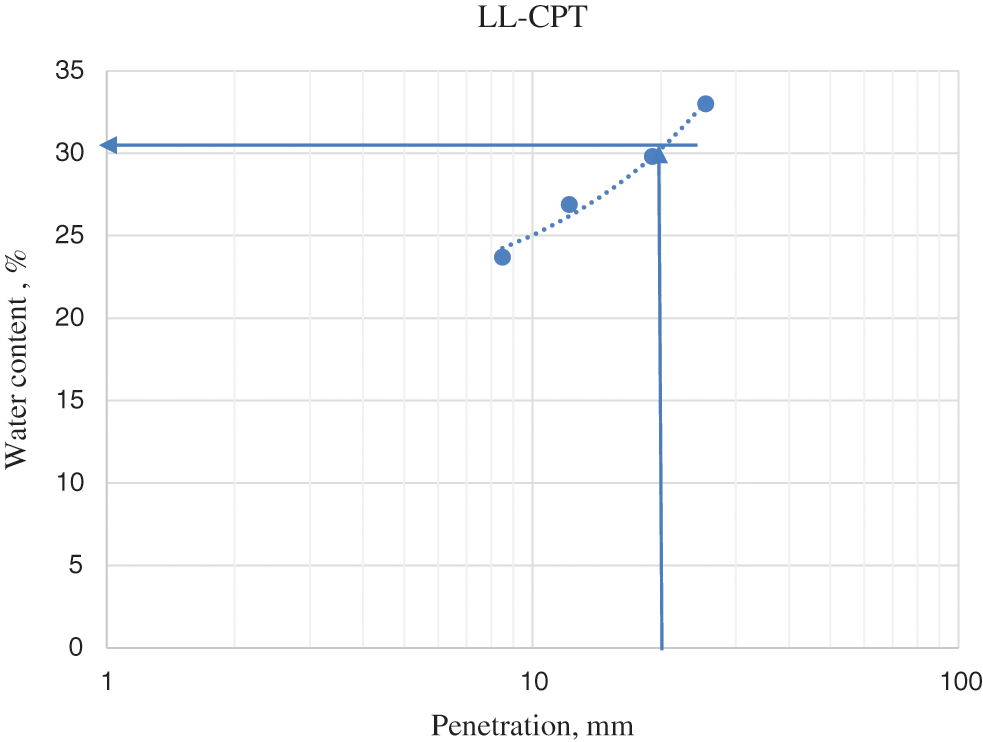

e) Liquid limit and plasticity: To determine the liquid limit (LL) of the air-dried soil, the cone penetration method (BS 1377:1990 part 2) [43] was utilized, and the moisture content was obtained. The natural moisture content, liquid limit, and plastic limit were determined, and the results were then recorded.

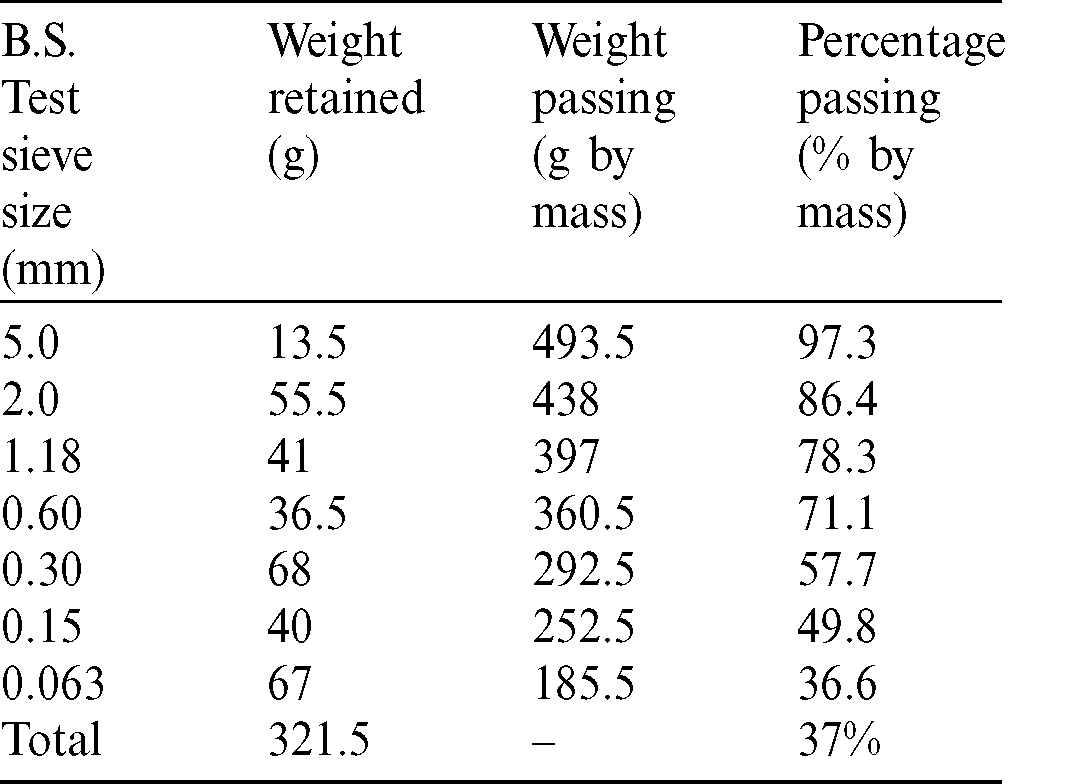

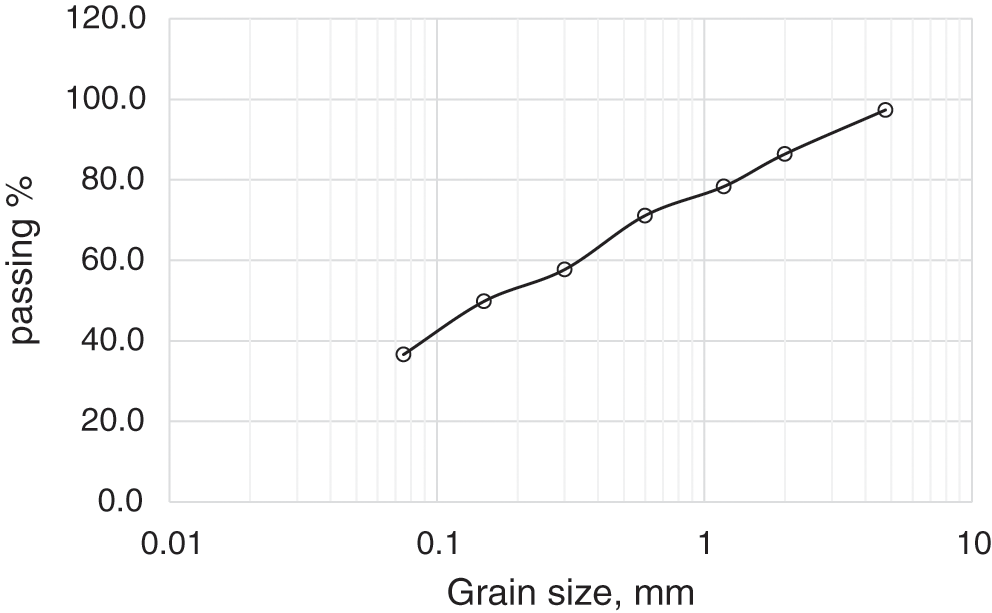

The results of the wash-sieving test according to sieve analysis standard (BS 1377:1990) [41] are listed in Tab. 2, along with the grading analysis and grading curve in Fig. 8.

Table 2: Determination of particle size distribution of soil samples

Figure 8: Grading curve of soil samples

A range of particle sizes is recommended for earthen construction, given the wide variety of this material. Thus, the selected soil was in the recommended zones. The grading curve of the particle size clearly shows that this soil consisted of approximately 36.6% clay silt particles and 60.7% sand, which fell within the average of the standards and contained a balanced amount of particle sizes between coarse and fine. California’s Uniform Building Code Specification, which is one of the few soil block standards, recommends 55%–75% sand and 25%–45% clay and silt [18]. The results in the preceding table and figure satisfied this specification, thus indicating the suitability of this soil for making blocks. The classification of soil according to British Classification Standard is CL (clay with low plasticity).

The shrinkage results revealed a level of 1.9%, which is within the acceptable range stated in the literature review. These results are listed in Tab. 3.

4.3 Determination of Liquid and Plastic Limits

Tab. 4 and Fig. 9 present the liquid limit (LL) test results. From Fig. 9, it can be seen that the LL was  31%. The plastic limit (PL) was determined to be 27.4%. Houben and Guillaud [44] reported that the liquid limit for earthen soils should range from 25% to 50% (30%–35% preferred), while the plastic limit should fall between 10% and 25%, with 12%–22% preferred. Danso [45] has concluded that the upper limits of the liquid limit and plasticity index are 50% and 30%, respectively. In comparison with these criteria, the LL and PL results of the tested soil were within the accepted range of soils suitable for earthen block construction.

31%. The plastic limit (PL) was determined to be 27.4%. Houben and Guillaud [44] reported that the liquid limit for earthen soils should range from 25% to 50% (30%–35% preferred), while the plastic limit should fall between 10% and 25%, with 12%–22% preferred. Danso [45] has concluded that the upper limits of the liquid limit and plasticity index are 50% and 30%, respectively. In comparison with these criteria, the LL and PL results of the tested soil were within the accepted range of soils suitable for earthen block construction.

Figure 9: Penetration versus water content for liquid limit determination

Specific gravity is an important property that is used to relate the weight of the soil to its volume, and is thus very beneficial in phase-shape relationship calculations. The results of our study revealed that the specific gravity of the soil samples was approximately 2.74. Danso [45] adopted 2 and 2.8 as respective lower and upper limits for the specific gravity of the soil suitability for earthen construction. Based on this, the tested soil fell within the acceptable and preferred range of soils suitable for earthen block construction.

The compaction process is simply the expelling of air from the voids of the soil. Soil with optimum moisture content features a low number of voids and maximum dry density. Approximately 10% of the moisture content was recorded as optimum. This result clearly indicates the capability of this material for use in earthen buildings and their construction. These results are presented in Fig. 10. From this figure, it can be seen that the optimum water content and the maximum dry unit weight of the tested soil were approximately 10% and 19.56 kN/m3, respectively. When the soil is compacted at the optimum water content, the maximum dry density is achieved; hence, compaction has a direct impact on the improvement of soil bearing and durability. These features are very important in earthen block construction. Although there are no known criteria for acceptable optimum moisture content and maximum dry density, some researchers have attempted to determine ranges for the desired values. Houben and Guillaud [44] indicated a range of values for the optimum moisture content of 3.5%–14% and a maximum dry density between 1750 and 2000 kg/m3. Considering the results obtained for our soil samples, we can conclude that the optimum water content and the maximum dry density fell within the preferred ranges.

Figure 10: Relationship between water content and dry unit weight of soil

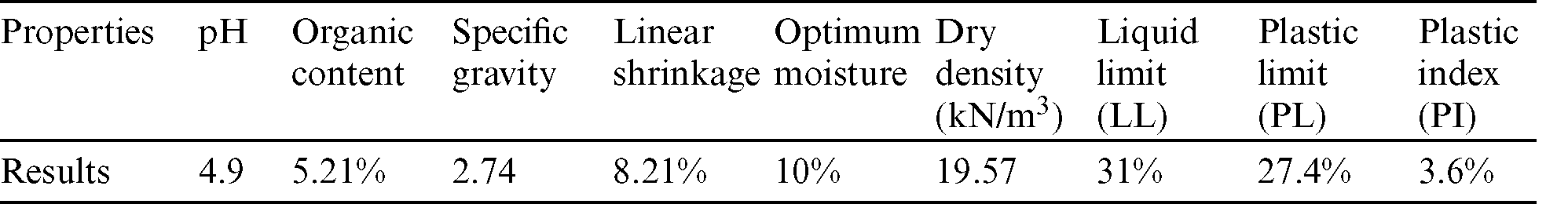

In order for soil to be safely and successfully utilized as a building material in earthen block construction, various geotechnical properties should be assessed and analyzed. These properties primarily consist of grain size distribution, plasticity indices, specific gravity, optimum moisture content, and maximum dry density. A summary of the results of these engineering properties for the selected and tested soil sample is presented in Tab. 5.

Based on these results, it was concluded that the determined values of the geotechnical properties of the soil samples satisfied the criteria reported in the literature and discussed previously in this manuscript. The organic content ratio and pH value were both found to be low. It is worth noting that the mechanical and engineering properties of the soils varied between sites.

This study compiled soil samples and compared them with soil suitability criteria used to recommend soil appropriate for earthen construction purposes and techniques (adobe, rammed earth, and compressed earthen blocks). Local soil taken from the city of Najran was found to be suitable for use in building construction as wall units. The results revealed that this soil featured properties suitable for earthen construction, and its clay content was within the proper range.

Author Contributions: All authors contributed to this work. All authors read and approved the final manuscript.

Funding Statement: This research was funded by the deanship of scientific research, Najran University, Kingdom of Saudi Arabia, under code number NU/ESCI/16/090 (https://www.nu.edu.sa/ar/web//deanship-of-scientific-research). The funding was received by Yaser Khaled Al-Sakkaf. The authors would like to express their gratitude to the Ministry of Education and the deanship of scientific research, Najran University, Kingdom of Saudi Arabia, for their financial and technical support.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. M. A. A. Al-Jadeed. (2004). “Mud architecture in Arab and Western Countries,” Journal of Al-Madinah Al-Munawwarah Research and Studies Center, vol. 8, no. 2, pp. 105–138.

2. J. Middendorf. (2001). “Properties and methodology of earth structures,” Harvard Graduate School of Design, . (GDS 6400: Energy and Environment Michelle Addington).

3. A. Fabbri, J. Morel and D. Gallipoli. (2018). “Assessing the performance of earth building materials: A review of recent developments,” RILEM Technical Letters, vol. 3, pp. 46–58.

4. J. C. Morel, A. Mesbah, M. Oggero and P. Walker. (2011). “Building houses with local materials: Means to drastically reduce the environmental impact of construction,” Building and Environment, vol. 36, no. 10, pp. 1119–1126.

5. D. Easton and T. Easton. (2012). “Modern rammed earth construction techniques,” Modern Earth Buildings, pp. 364–384.

6. J. Vyncke, L. Kupers and N. Denies. (2018). “Earth as building material–-An overview of RILEM activities and recent innovations in geotechnics,” Matec Web of Conferences, vol. 149, no. 4, pp. 2001.

7. Auroville Earth Institute, “Unesco Chair Earthen Architecture Building with Earth,” Earth-auroville.com, [Online] Available: http://www.earth.

8. R. Stulz and K. Mukerji. (1988). Appropriate Building Materials. A Catalogue of Potential Solutions, 2nd ed.Switzerland:Gallen Swiss Canter for Appropriate Technology (SKAT Switzerland).

9. A. G. Kerali. (2001). “Durability of compressed and cement-stabilised building blocks,” in Unpublished Doctor of Philosophy in Engineering. Warwick: University of Warwick.

10. R. Tuffin. (2007). “Reading–-pressure vessels–-construction and testing,” Tasmanian Historical Research Association, vol. 54, no. 2, pp. 69–83. [Google Scholar]

11. E. A. Adam and A. Agib. (2001). Compressed Stabilised Earth Block Manufacture in Sudan, Paris: United Nations Educational, Scientific and Cultural Organization. [Google Scholar]

12. I. Maria, D. Teresa and F. Paulina. (2014). “Unstabilized rammed earth: Characterization of material collected from old constructions in South Portugal and comparison to normative requirements,” International Journal of Architectural Heritage: Conservation, Analysis, and Restoration, Taylor and Francis, vol. 8, no. 2, pp. 185–212. [Google Scholar]

13. B. Milt. (2014). “Compressed earth block (CEB) construction: A viable building alternative for Olancho, Honduras,” in Department of Construction Management in Partial Fulfillment of the Requirements for the Degree of Master of Science. Fort Collins, Colorado: Colorado State University. [Google Scholar]

14. L. A. Wolfskill. (1963). Handbook for Building Homes of Earth, vol. 2. Agricultural and Mechanical College of Texas: Transportation Institute: Bulletin. [Google Scholar]

15. UN. (1992). Earth Construction Technology. Nairobi: United Nations Centre for Human Settlements. [Google Scholar]

16. V. S. Burroughs. (2001). “Quantitative criteria for the selection and stabilization of soils for rammed earth wall construction,” in Unpublished Built Environment. Sydney: University of New South Wales. [Google Scholar]

17. B. Christensen. (2001). “Book earth guidelines,” in A Source Book for Green and Sustainable Building. Book Earth Guideline, . [Online]. Available: http://greenbuilder.com/sourcebook/EarthGuidlines.html. [Google Scholar]

18. B. Sidibe, “Understanding adobe. The Volunteers in Technology Assistant (VITATP 24 (3/851985,” Technical paper #24, 1985 retrieved 6/4, 2006. [Online]. Available: http://sleekfreak.ath.cx:81/3wdev/VITAHTML/SUBLEV/EN1/ADOBE.HTM. [Google Scholar]

19. Eaton. (1981). “Ruth mud: An examination of earth architecture,” Architectural Review, vol. 170, pp. 220– 230. [Google Scholar]

20. V. Maniatidis and P. Walker. (2003). A Review of Rammed Earth Construction for DTi Partners in Innovation Project Developing Rammed Earth for UK Housing, Bath: Natural Building Technology Group (Department of Architecture and Civil Engineering) University of Bath. [Google Scholar]

21. R. Velckenborg. (2001). NMR on Technological Porous Materials. Eindhoven: Eindhoven University of Technology. [Google Scholar]

22. N. Ural. (2018). “The importance of clay in geotechnical engineering, current topics in the utilization of clay in industrial and medical applications,” Mansoor Zoveidavianpoor, Intech Open, Chapter 5, pp. 83–102. [Google Scholar]

23. R. Whitilow. (1995). Basic Soil Mechanics, 3rd ed. Malaysia: Longman. [Google Scholar]

24. L. Davison and S. Springman. (2000). “Soil description and classification retrieved 23/6, 2007,” University of West England, . [Online]. Available: http://environment.uwe.ac.uk/geocal/SoilMech/classification/soilclas.htm. [Google Scholar]

25. S. Roy and S. K. Bhalla. (2017). “Role of geotechnical properties of soil on civil engineering structures,” Resources and Environment, Scientific and Academic Publishing, vol. 7, no. 4, pp. 103–109. [Google Scholar]

26. F. H. Chen. (1999). Soil Engineering, Testing, Design, and Remediation. Florida: CRC Press LLC. [Google Scholar]

27. BS. (1990). British Standard Methods of Test for Soils for Civil Engineering. England: British Standard Institution. [Google Scholar]

28. H. Mekkiyah and A. Al-Khazragie. (2015). “Behavior of clay soil mixed with fine sand during consolidation,” Applied Research Journal, vol. 1, pp. 437–443. [Google Scholar]

29. D. E. Montgomery. (1997). Design and Realisation of a Test Rig to Research the Production of Full Size Dynamically Compacted Soil-Cement Blocks. UK: University of Warwick. [Google Scholar]

30. L. Cely-Illera, C. V. Cely-Illera and K. Anteliz-Contreras. (2016). “Evaluation of the technological characteristics of clay when adding building materials to manufacture structural products without implementing a sintering process,” Ciencia e Ingenieria Neogranadina, vol. 26, no. 2, pp. 5–20. [Google Scholar]

31. H. Houben and H. Ggillaud. (1994). Earth Construction–-A Comprehensive Guide. London: CRATerre-EAG, Intermediate Technology Publications. [Google Scholar]

32. P. R. Chaudhari and V. D. Ahire. (2013). “Soil bulk density as related to soil texture, organic matter content and available total nutrients of coimbatore soil,” International Journal of Scientific and Research Publications, vol. 3, no. 2, pp. 1–8. [Google Scholar]

33. W. L. Schroeder, S. E. Dickenson and D. C. Warrington. (2004). Soils in Construction, 5th ed. New Jersey: Pearson Prentice Hall. [Google Scholar]

34. A. Guettala, A. Abibsi and H. Houari. (2006). “Durability study of stabilized earth concrete under both laboratory and climatic conditions exposure,” Construction and Building Materials, vol. 20, no. 3, pp. 119–127. [Google Scholar]

35. BS. (1990). “Determination of shrinkage characteristics, british standard methods of test for Soils for civil engineering purposes, BSI 1377:1990 part 2, England: British Standard Institution, pp. 14–20. [Google Scholar]

36. M. J. Singer and D. N. Munns. (1999). Soils an introduction. 4th ed., NewJersey:Macmillan Publishing Company. [Google Scholar]

37. R. F. Craig. (1993). Soil Mechanics. 5th ed. London:Chapman & Hall. [Google Scholar]

38. BS. (1990). “Determination of the dry density/moisture content relationship and determination of the optimum moisture content,” British Standard Methods of Test for Soils for Civil Engineering Purposes, vol. BSI 1377:1990 part 4, pp. 22–24. [Google Scholar]

39. N. C. Brady. (1974). The Nature and Properties of Soils. 8th ed. NewYork:MacMillan Publishing Co. Inc. [Google Scholar]

40. BS. (1990). “Determination of the organic matter content,” British Standard Methods of Test for Soils for Civil Engineering Purposes, BSI 1377:1990 part 3, pp. 2–5. [Google Scholar]

41. BS. (1990). “Determination of particle size distribution, wet method, ” in British Standard Methods of Test for Soils for Civil Engineering Purposes BSI, vol. 1377:1990 part 2, pp. 30–33. [Google Scholar]

42. BS. (1990). “Determination of specific gravity,” British Standard Methods of Test for Soils for Civil Engineering Purposes, BSI 1377:1990 part 4, pp. 5–22. [Google Scholar]

43. BS. (1990). “Determination of the plastic limit and plasticity index,” British Standard Methods of Test for Soils for Civil Engineering Purposes, BSI 1377:1990 part 2, pp. 13–14. [Google Scholar]

44. H. Houben and H. Guillaud. (2006). Earth Construction: A Comprehensive Guide, 1st ed. London: Intermediate Technology Publications. [Google Scholar]

45. H. Danso. (2018). “Suitability of soil for earth construction as building material,” Advancements in Civil Engineering and Technology, vol. 2, no. 3, pp. 199–211. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |