DOI:10.32604/cmc.2020.012587

| Computers, Materials & Continua DOI:10.32604/cmc.2020.012587 |  |

| Article |

Industry 4.0: Architecture and Equipment Revolution

1Department of Medical Instrumentation Techniques Engineering, Electrical Engineering Technical College, Middle Technical University, Baghdad, Iraq

2Department of Electrical Engineering, University of Engineering and Technology Peshawar, Peshawar, Pakistan

3School of Mathematics and Computer Science, University of Wolverhempton, Wulfruna Street, Wolverhempton, UK

4Center of Artificial Intelligence Research and Optimization, Torrens University, Brisbane, Australia

5Department of Computer Science, College of Computer & Information Systems, Umm Al-Qura University, Mecca, Saudi Arabia

6School of Computer Science and Engineering, Soongsil University, Seoul, South Korea

*Corresponding Author: Bong Jun Choi. Email: davidchoi@soongsil.ac.kr

Received: 05 July 2020; Accepted: 26 July 2020

Abstract: The development of science and technology has led to the era of Industry 4.0. The core concept is the combination of “material and informationization”. In the supply chain and manufacturing process, the “material” of the physical entity world is realized by data, identity, intelligence, and information. Industry 4.0 is a disruptive transformation and upgrade of intelligent industrialization based on the Internet-of-Things and Big Data in traditional industrialization. The goal is “maximizing production efficiency, minimizing production costs, and maximizing the individual needs of human beings for products and services.” Achieving this goal will surely bring about a major leap in the history of the industry, which will lead to the “Fourth Industrial Revolution.” This paper presents a detailed discussion of industrial big data, strategic roles, architectures, characteristics, and four types of innovative business models that can generate profits for enterprises. The key revolutionary aspect of Industry 4.0 is explained, which is the equipment revolution. Six important attributes of equipment are explained under the Industry 4.0 perspective.

Keywords: Industry 4.0; big data; smart manufacturing; business model; equipment revolution

We are now experiencing events that may indicate the arrival of a fourth industrial revolution, in which the objects in a factory begin to transform into intelligent objects capable of interacting with each other and communicating data about the state of production or about their own state. This fourth revolution has generated the concept of Industry 4.0, which began in Germany a few years ago and has increasingly spread throughout the world, especially in Europe [1–3]. Industry 4.0 will help improve efficiency in factories, achieve higher productivity, and optimize time, costs, materials, or energy. We are faced with an increasingly globalized world, a more changing market, and more stringent requirements from customers. Thus, another great advantage is that this system allows us to achieve the desired size of one lot; that is, to be able to manufacture different individual products for each client in the same series of production, depending on the needs, tastes, or general requirements of the client.

In Germany, Industry 4.0 refers to all products and services that need technology and communication by 2020 and has a market potential of 10.9 million Euros, with an annual added value of 1.7% [4–7]. The term Industry 4.0 was created by the German government [8]. This concept is part of the so-called Fourth Industrial Revolution, in which the physical real world and the virtual world unite in a system called a Cyber-Physical System (CPS), which is possible through the Internet of Things (IoT). IoT is defined as a new complementary concept of the evolution of communications and computing applied to objects, which allows better interaction between them [9–10]. It refers to a network of things that are interconnected daily through the Internet. CPS is defined as the integration of computing, networks, and physical processes, with embedded computing and monitoring in networks for the control of physical processes, as well as feedback loops where the physical processes affect the computational ones, and vice versa [11]. CPS integrates embedded systems into devices that allow interaction with the dynamics of physical processes, providing abstractions, models, designs, and analysis techniques for their integration.

Dregger et al. posed the characteristics of future industrial production in terms of the following aspects: greater individualization of the product (with a highly flexible mass production); greater and better integration of customers and suppliers in processes of business with high-quality products and services resulting from hybrid products; optimization for standardization and reference architectures in the control of complex systems, the internet infrastructure, and its coverage in terms of security for the industry; the organization and design of training of new jobs and the development of applications that meet the conditions of legal studies; the efficiencies of resources; vertical integration under added value to networks; the digitalization of the supply chain; and vertical integration with systems connected production [12]. As the core of intelligent manufacturing, industrial big data plays an important role in the integrated application in the whole process of enterprise R&D, manufacturing, operation management, sales service, and the whole industry chain. It also supports manufacturing innovation and promotes transformation and upgrading.

The rest of the paper is organized as follows. Section 2 presents related work. Section 3 provides the definition and characteristics of industrial big data. Section 4 discusses the industrial big data reference architecture. Section 5 elaborates on the governance of industrial big data. Section 6 explains the strategic role of industrial big data. Section 7 explains the big data and business model. Section 8 provides the proposed research analysis of different enterprises, and Section 9 concludes the paper.

In 2011, representatives from the business, political, and academic circles jointly proposed an Industry 4.0 initiative to enhance the competitiveness of German manufacturing. The German federal government incorporated the initiative into the “Germany 2020 High-Tech Strategy” [1–4]. The Industry 4.0 Working Group was formed, and the Industry 4.0 Roadmap [5–10] was released in 2013. Unlike the previous three industrial revolutions, Industry 4.0 is not a post-summer summary but a predictive industrial revolution, so companies involved can shape and influence future development models. Industry 4.0 will have a huge impact according to forecasts. By 2025, it will bring Germany a contribution of 78 billion euros in GDP [13]. As a joint initiative between government and business, it is no accident that Industry 4.0 appeared in Germany. It is based on the advanced level of equipment manufacturing in Germany. The Industry 4.0 Working Group describes Industry 4.0 as follows. In the future, business will be built to cover mechanical equipment, storage systems, and a network based on an information physical system, such as a production device. In the manufacturing sector, information physics systems will include intelligent machines, warehousing systems, and production facilities that automatically exchange information, trigger actions, and coordinate control. Thus, the production, design, material consumption, supply chain, and lifecycle management are qualitatively improved, among others.

Smart factories have been using new production methods, and smart products are uniquely labeled to trace their history throughout their life cycle while seeing the current status and future processing methods. The embedded production system will form a horizontal network with a vertical network and scattered value chain of the factory or enterprise business process. It will also form real-time management from the procurement of raw materials [14]. To achieve this vision, Industry 4.0 needs to include the following elements: a Cyber-Physical System (CPS), IoT, Cloud Storage, Big Data, Smart Factories, and so on. The realization of these elements depends on the application of advanced equipment, so Industry 4.0 will be a new format driven by advanced equipment. Based on this prospect, the basic equipment under Industry 4.0 needs new changes [15].

The industry is an activity of vital importance in a region since it can maintain both the labor market in that region and the added value or skills that employees can provide. A weak industry is even translated into modifications in the social estates of a region since it can affect the middle class and polarize the society more and more. Europe, among other powers, has plunged in recent years in terms of the percentage of the global industry share. According to one study [16–17], this has been due to two major industrial fractures that have occurred in recent years. The first of these came as a result of emerging countries such as BRIC or some countries in Eastern Europe. Between 1990 and 2011, the growth of added manufacturing value in these emerging countries was 10 times higher than in other countries with traditional industry.

The second major industrial fracture is occurring within Europe, where some countries have managed to maintain their industrial added value, while in others, it has declined considerably. But currently, there have been changes taking place to turn this situation around. For this, it is necessary to adapt to the current volatile markets. One study argues that the key to competitiveness is currently flexibility and that the current trend towards shorter terms, fluctuations in the quantities ordered, or increasingly personalized products require a much more flexible supply chain [18]. For this reason, the term Industry 4.0 was born.

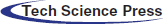

To arrive at Industry 4.0, we must first remember the industrial revolutions that have taken place throughout history. The first of them began in the eighteenth century and developed throughout the nineteenth century. It introduced mechanical elements that facilitate production tasks through the use of hydraulic energy, steam, or machine tools. The second industrial revolution took place in the late nineteenth century when electricity began to be used in production, mass production was introduced, and a system was started to organize the tasks and assigned times. The third revolution came more recently in approximately 1970 when electronics and information technologies began to be used with the aim of automating production tasks [19]. This revolution is also called the digital revolution, and its use has extended to this day. The fourth and last industrial revolution is currently taking place. Fig. 1 shows the development of these industrial revolutions along the time axis in addition to key features of each of them.

Figure 1: Industrial revolutions

This fourth industrial revolution is still taking place, and there are sectors that are changing more sharply and faster than others, which are evolving more constantly and slowly [20]. In all areas, physical objects, machines, processes, or production systems are being introduced within an information network connected to the Internet. Linked to this fourth industrial revolution the concept of “Industry 4.0” was born in 2011. The term was born as a result of the initiative “Industrie 4.0,” an association that emerged in Germany with the aim of improving the global competitiveness of Germany in the productive landscape, which was formed by great people from the worlds of business, politics, and education, among others. This initiative ended up leading to a project of great importance whose objective is to achieve leadership in technological innovation, with major objectives to be met from the moment of its creation until 2020 [20]. One of the principles of Industry 4.0 is to collect and share information in real-time [21]. According to the Ministry of Education and Research of Germany, the term Industry 4.0 includes cyber-physical systems that help improve the flexibility of networks, which translates into machines and plants that are capable of modifying their behavior before orders or different conditions. These systems are able to receive information, analyze it, and modify its way of acting depending on the information.

The factors that have influenced the birth of Industry 4.0 basically serve two different aspects [22]. First, there are factors more related to a social or economic perspective:

• Short development periods: Shortening the time it takes a product from the moment it is thought of until it reaches the customer starts to be an important competitive advantage for many companies.

• Individualization of the demand: There is a clear tendency towards a lot size of one since many customers look for a product that is differentiated from the rest or personalized.

• Flexibility: As previously mentioned, flexibility is the key to being competitive since the system must be able to adapt to changes effectively.

• Decentralization: For greater speed when making decisions, hierarchical scales should be reduced within the company.

• The efficiency of resources: Optimization of resources is required to achieve sustainability in the context of the industry.

Other factors are related to technology:

• Mechanization and automation: More and more technical aids are used to facilitate manufacturing tasks. In addition, there is a clear trend towards the automation of productive tasks through the use of automated workstations.

• Digitization: The growing installation of sensors in the field of manufacturing results in a large amount of digital data that must be controlled and analyzed. This trend also leads to the birth of other complementary technologies, such as digital protection or other technologies such as augmented reality.

• Miniaturization: The technological trend to achieve better performance in smaller spaces results in more complex products whose manufacture cannot be approached with only human labor.

One proposed model includes a series of steps with which to guide companies in their search for a strategy or objective related to Industry 4.0 [23]. This model is composed of three stages:

• Visualize: This stage consists of first familiarizing oneself with general concepts of Industry 4.0 to relate them to the specific objectives of the company. This stage consists of two phases. In the entry phase, a series of key concepts are explained, usually by external experts, and after that, the company’s shareholders expose the current state of the company. With this, shareholders can be advised on how to evolve the company, which can be done collaboratively given that key theoretical terms have been stated. In the exit phase, people try to form ideas with a clear drawing in mind at all times about how they want the company to be in the future.

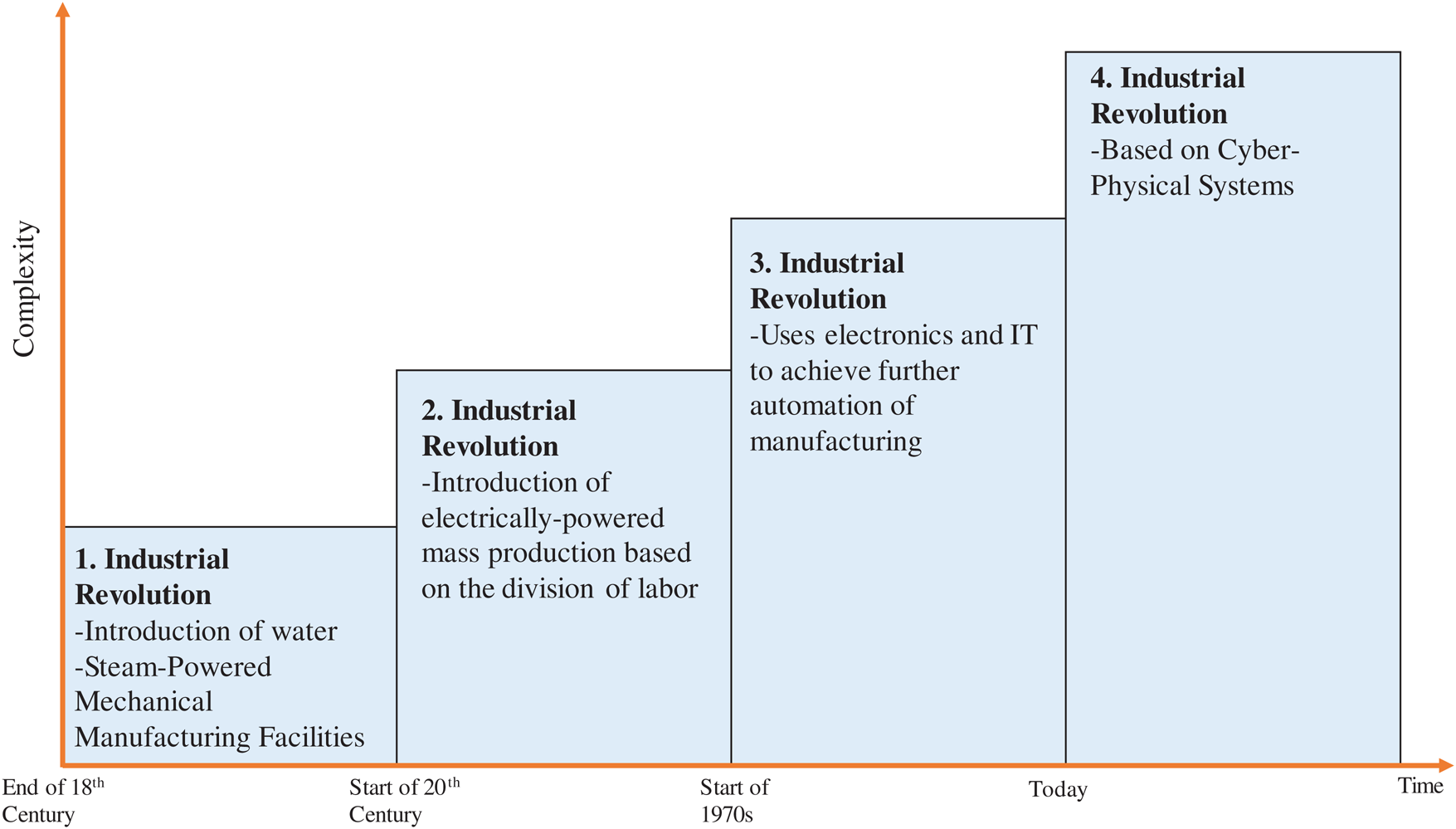

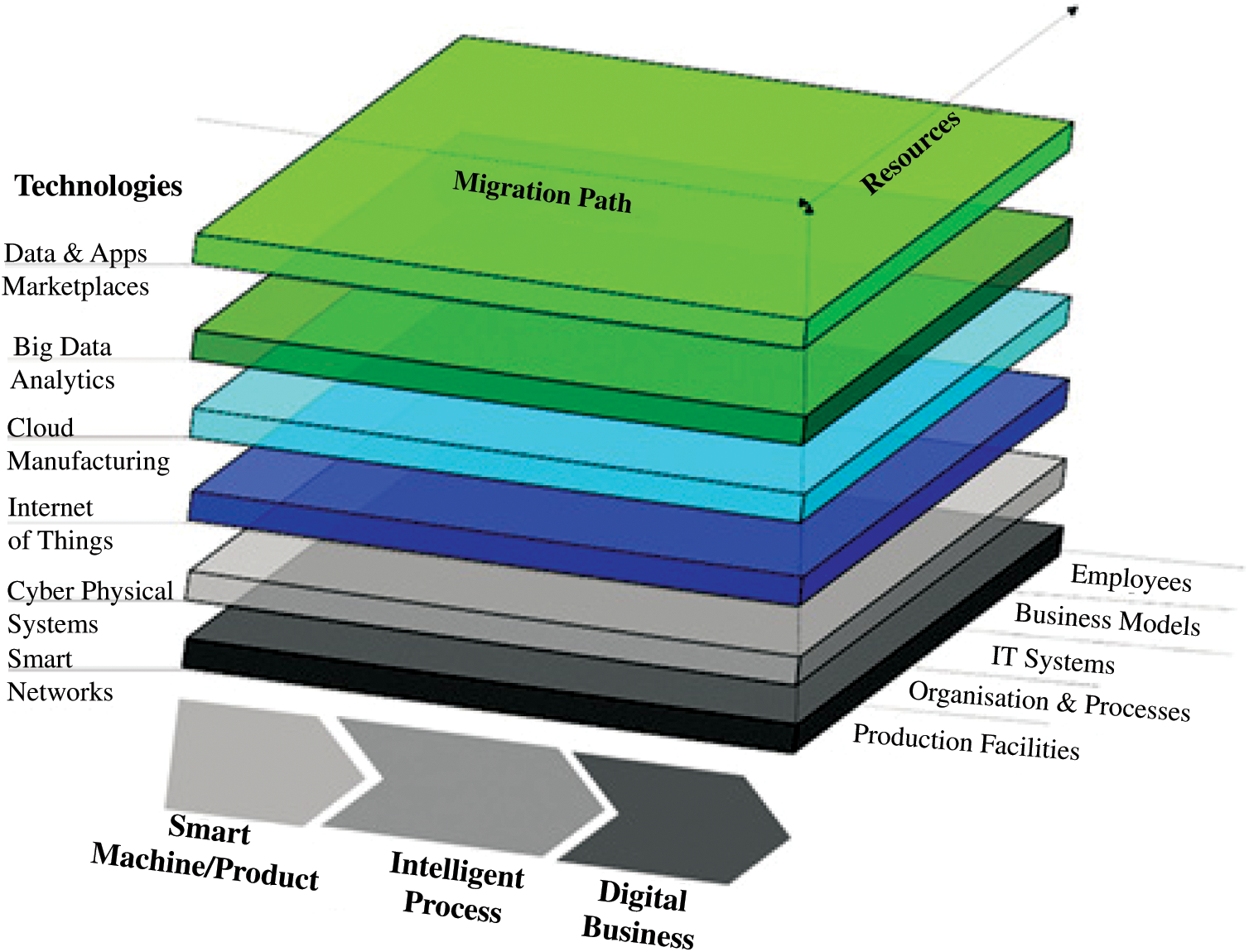

• Enable: At this stage, we reach a greater level of detail and make a roadmap in which to translate a series of strategies in a clear and orderly manner. In this roadmap, there is a horizontal axis of time, in which there is a difference between the short, medium, and long term, and a vertical axis with different perspectives such as market, product, process, and network perspectives. Fig. 2 shows an example of what this roadmap would look like.

Figure 2: Example of a roadmap for industry 4.0

Once this is done, objectives for each perspective and term begin to be defined, beginning with the market perspective, in which market segments are defined according to the evolution of future demand. From this market study, the products to be manufactured are obtained to satisfy that future demand. After this, the processes to manufacture the products are defined while considering the technology that will be needed in the production system. Finally, in the network perspective, a structure is defined with the necessary partners to be able to develop the final product. The objectives contained in the cells are related by arrows, which can be continuous or discontinuous. The continuous arrows represent the requirements of the initial (top) perspective for the final (bottom) perspective. The discontinuous ones show possible success factors for the final perspective. All of this gives a global perspective on the strategy that is pursued to achieve Industry 4.0.

• Represent: The objective of this point is to move from the strategies previously defined to projects. Therefore, objectives, work teams, deadlines, priorities, or risks must be defined. At this stage, there must also be collaboration since the departments affected by the adoption of a project should make suggestions to adapt it to the maximum. At the end of this stage, the results should be contrasted with what was stated in the two previous stages.

The creation of factories in the context of Industry 4.0 gives them a series of features and benefits. Some of these benefits or general characteristics are [24]:

• Mass customization: The new production lines must be able to vary the processes that must be followed for each production order. The advantage of this is that you can customize each product while getting a lot size one.

• Flexibility: An intelligent system must be able to adapt to changes, which are made by considering variables such as time or cost.

• Visibility and optimized decision making: Industry 4.0 provides transparency throughout the chain in real-time, so decisions can be made much more agile and accurate, thus achieving greater efficiency in the production process.

• New planning methods: Other variables that are not as common as the efficiency of resources or energy have a greater weight when optimizing manufacturing processes.

• Create a value from data: Big Data allows the collection of a large amount of data, and its analysis can generate many improvements at the plant or product level. This data comes from devices such as sensors.

• Create new services: Industry 4.0 will even create new services before and after the sale of a product. An example of this is the service offered by the beacons before the sale (some case studies will later be presented).

• Automation: Increasingly, the production lines will be increasingly automated, providing greater efficiency, effectiveness and fewer errors.

• Proactive maintenance: The collection of data from the system in real-time by means of sensors will allow people to know the status of the machines and perform maintenance on them when they begin to detect unusual data, which may mean that there is some type of failure, for example.

• Connected supply chain: In addition to internal factory transparency, the information will also be shared in real-time throughout the entire supply chain, thus improving the efficiency of the supply chain.

• Energy management: For there to be an improvement in terms of energy efficiency, smart meters can be used to provide real-time consumption and make decisions accordingly.

A large amount of data that is generated in the environment of an Industry 4.0 through devices such as sensors and the fact that part of this data is shared between companies to achieve greater efficiency in the supply chain make vital factor importance in this field is that of security. One general vision on this topic presents both the main actors and some aspects to consider [25]. The main actors are:

• People: Those who must manage security, define safety standards, and measure their effectiveness.

• Processes: To meet certain security requirements throughout the development of certain tasks in an Industry 4.0 environment.

• Object: One of the most important parts is the object itself, which is endowed with “intelligence” thanks to sensors. Since it is capable of issuing and receiving information, correct security must be ensured.

• Technological ecosystem: The environment created and the decision mode to ensure the security of the system.

Some aspects to consider to ensure security in the system is:

• Identification: This point considers the security that objects must have in order to defend themselves against people.

• Confidence: The level of security that the technological ecosystem can bring to the intelligent object.

• Privacy: This aspect relates people to the ecosystem. Privacy must be considered when collecting, sharing, and managing data.

• Responsibility: Responsibilities must be defined to avoid problems when an object regulates a process. Access rights must also be defined in processes that share resources between objects.

• Autoimmunity: This point refers to the objects themselves, which must detect failures or attacks in the system.

• Security: People must define processes that reduce the chances of failure in the system.

• Reliability: Reliability relates processes to the ecosystem. The availability of certain information must be ensured over time.

3 Definition and Characteristics of Industrial Big Data

Industrial big data refers to the typical intelligent manufacturing model in the industrial sector, from customer demand to aspects such as sales, orders, planning, research and development, design, processes, manufacturing, procurement, supply, inventory, delivery, after-sales service, operation and maintenance, and scrapping or recycling. Industrial big data is the general term for all kinds of data and related technologies and applications generated in all aspects of the whole life cycle. With product data at the core, it has greatly extended its biography. Industrial data has related technologies and applications with large data capacity, large variety, and fast speed, and in low-value density features, it also features high accuracy and closed loop. Industrial big data mainly comes from business data related to the production and operation of enterprises, industrial equipment, production activities, and product-related external Internet data.

Industrial big data technology is a series of technologies and methods that enable the value embedded in industrial big data to be mined and displayed, including data planning, acquisition, pre-processing, storage, analysis mining, visualization, and intelligent control. Industrial big data applications are popular for specific industries’ datasets, the process of integrating the application of industry big data series technologies, and methods to obtain valuable information. The essential goal of research and breakthroughs in industrial big data technology is to discover new patterns and knowledge from complex datasets and to mine valuable new information to promote manufacturing companies for industry product innovation, improving the business level, production operation efficiency, and expanding new business models.

4 Industrial Big Data Reference Architecture

4.1 Industrial 4.0 Reference Architecture

Industry 4.0 was proposed by the German Academy of Science and Technology (Acatech) in the agenda CPS research project, which is the application of CPS in manufacturing. Germany is a manufacturing country with a high level of technology in embedded systems and automation engineering. In order to consolidate its leading position in manufacturing, in 2015, the German Engineering Institute led the release of the “German Industry 4.0 Strategic Planning Report,” which clearly proposed the basic framework system based on RAMI4.0. The goal was to start from the manufacturing industry and rely on its excellent equipment manufacturing strength to use information technology and other means for the “bottom-up” transformation of manufacturing. The core content shows the Industry 4.0 architecture and the Industry 4.0 component model from the three dimensions of information technology, life cycle, and the value stream and enterprise vertical layer [26].

4.2 Industrial Internet Architecture

In 2011, the President of General Electric put forward the concept of “Industrial Internet.” In 2012, the United States launched the Industrial Internet Strategy. Unlike the manufacturing powerhouse of Germany, the United States is the leader in information technology. Therefore, the United States hopes to reshape the manufacturing industry from the top of the bottom, such as through CPUs, systems, software, the Internet, and tools such as big data analysis. In 2015, the US Industrial Internet Alliance IIC proposed the Industrial Internet Reference Architecture, whose core content is a reference architecture for the industrial Internet with cross-industry applicability [27].

4.3 Industrial Value Chain Reference Architecture (IVRA)

On December 8, 2016, the official release, of the Japan Industrial Value Chain Reference Architecture (IVRA) marked the formation of a basic model for the interconnection and interoperability of smart factories in Japan. In response to the global manufacturing upgrade strategy represented by German Industry 4.0, Japan has adopted three series of implementation actions to promote the upgrading of manufacturing. First, they promote the development of IVI in the industrial value chain and establish a consortium kingdom made in Japan. Second, through the robot revolution plan agreement, they use industrial machinery and small and medium-sized enterprises to explore ways of field coordination and enterprise cooperation. Third, they use IoT to promote the laboratory, which has intensified innovations in new business cooperation with other fields [28].

4.4 Intelligent Manufacturing System Architecture

“Made in China 2025” is the action plan of the Chinese government to implement the first decade of a strategy to become a strong manufacturing country. Through the in-depth integration of informationization and industrialization, the development of the entire manufacturing industry will be driven to achieve the goal of “Made in China 2025” and realize the integration of technology, products, services, and industry derivatives. This is being done through the construction of smart factories to achieve intelligent production and intelligent manufacturing, to achieve the transformation from centralized production to networked off-site collaborative production, the transformation of traditional manufacturing companies that want cross-border integration enterprises and the transformation from large-scale mass production to mass customization. In 2015, the China National Standardization Administration Committee built the intelligent manufacturing system architecture in three dimensions: life cycle, system-level, and intelligent function.

4.5 Industrial Big Data Architecture

The core of the term “architecture” is carrying the pressure of the upper layer through a series of component combinations in a system. The system architecture is “the basic components of a system and the design principles to follow, as well as systems, components, and external environments.” In order to better understand the connotation of industrial big data, there is a communication tool used by industrial big data related practitioners. Based on the German Industry 4.0 Reference Architecture, the US Industrial Internet Architecture, and the China Manufacturing 2025 Standard System, the industrial data architecture diagram presents an industrial big data reference architecture that provides versatility and consistency for cross-industry big data applications.

The architecture consists of three dimensions: the life cycle and value stream, the enterprise vertical layer, and the IT value chain. The life cycle and value stream dimensions are divided into three phases: R&D and design; production and supply chain management; and operation, maintenance, and services. According to the type, application, and value innovation, the enterprise vertical layer includes a CPS, management information system (MIS), and interconnection platform from bottom to top. System Internet+ discusses the work required by all layers of the enterprise to achieve industrial big data applications and industrial transformation IT value chain refers to leading the business architecture, information system architecture, and technical architecture of industrial big data. In the technical framework, targeting industrial big data and industrial enterprise characteristics, the technical components required to implement industrial big data applications are discussed. The industrial big data architecture is shown in Fig. 3 [29].

Figure 3: Reference architecture for industrial big data [29]

5 Governance of Industrial Big Data

Industrial big data governance is an institutional framework for assessing, guiding, and monitoring an organization’s industrial big data management and utilization. It passes a strategic policy, the establishment of organizational structure, a clear division of responsibilities, etc., to achieve risk control, safety compliance, performance improvement, and value creation of industrial big data, as well as provide innovative big data services [30]. Industrial big data governance is critical to ensuring the optimization, sharing, and security of industrial big data. An effective industrial big data governance program can return value to the business by improving decision making, reducing costs, reducing risk, and improving security compliance, ultimately reflecting increased revenue and profit. The role of industrial big data governance can be summarized as four points:

1. Effective industrial big data governance can promote industrial big data service innovation and value manufacturing

2. The scientific industrial big data governance framework helps to improve the organization’s industrial big data management and decision-making levels

3. Effective industrial big data governance can produce high-quality data, enhance data credibility and reduce costs

4. Effective industrial big data governance helps improve compliance and security controls and reduce risk

Industrial big data governance should adhere to the principles of strategic consistency, risk control, operational compliance, and performance improvement. Its governance areas include Strategy, organization, industrial big data quality, industrial big data security, industrial big data innovation applications, industrial big data lifecycle, and industrial big data architecture.

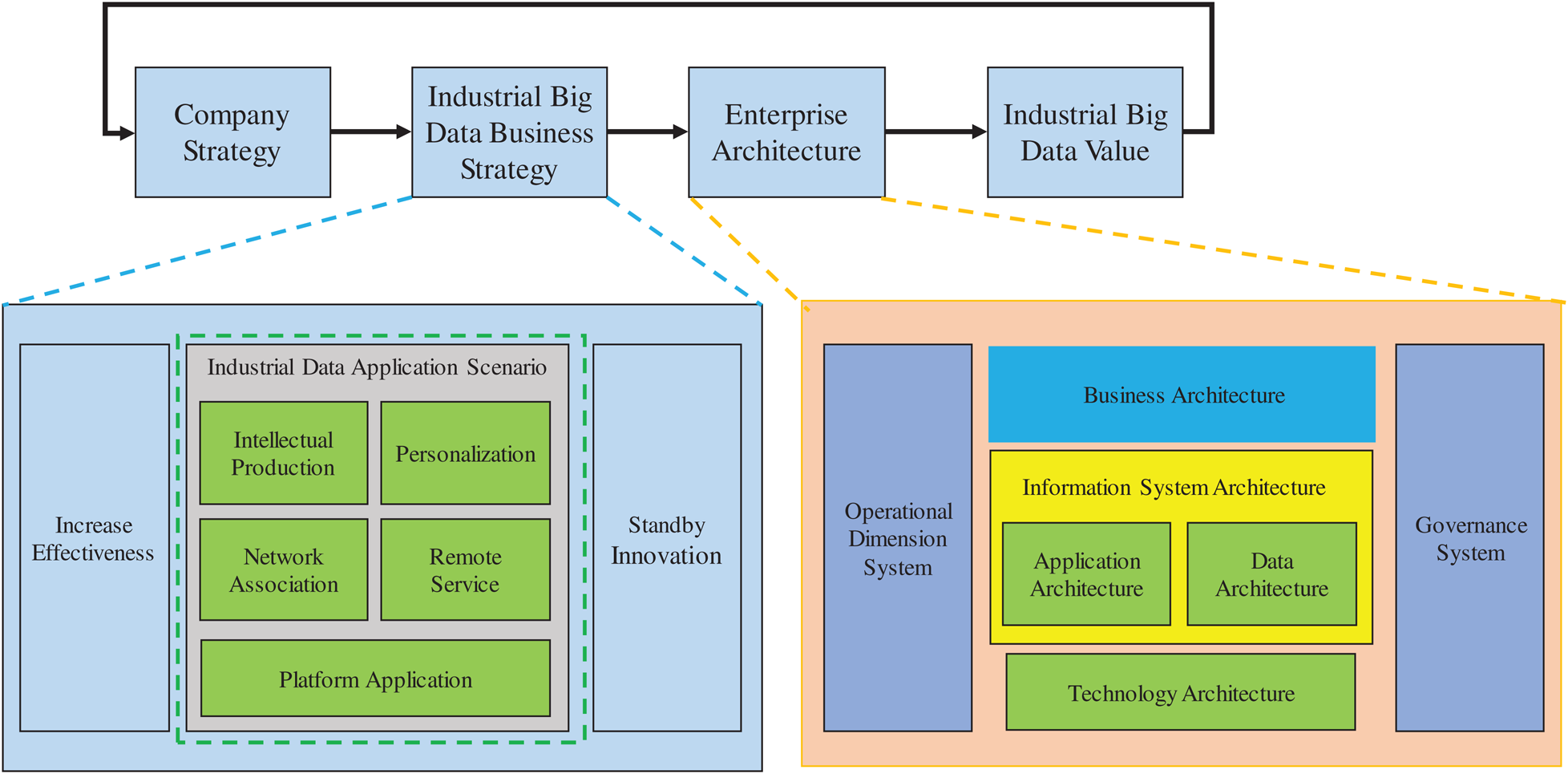

As an important strategy for manufacturing enterprises, industrial big data can be used not only to improve the operational efficiency of enterprises, but also to support business process and business model innovation, which is embodied in intelligent production, network collaboration, personalized customization, remote services, platforms, and many application scenarios. By planning and building an enterprise architecture for an industrial big data business, the value of industrial big data is obtained. The value obtained is compared with the expectations and prospects of the business strategy to form a closed loop of sustainable improvement, as shown in Fig. 4.

Figure 4: Proposed industrial big data business strategies and enterprise architecture

Manufacturing companies need to collect, organize, analyze, and summarize aspects of their business, such as the organizational structure and products provided according to their own competitive advantages. They establish a clear relationship with services, markets, customers, resources, business potential, stakeholders, the relationships between these functions, and entities in the industrial big data business architecture and its informationization strategy.

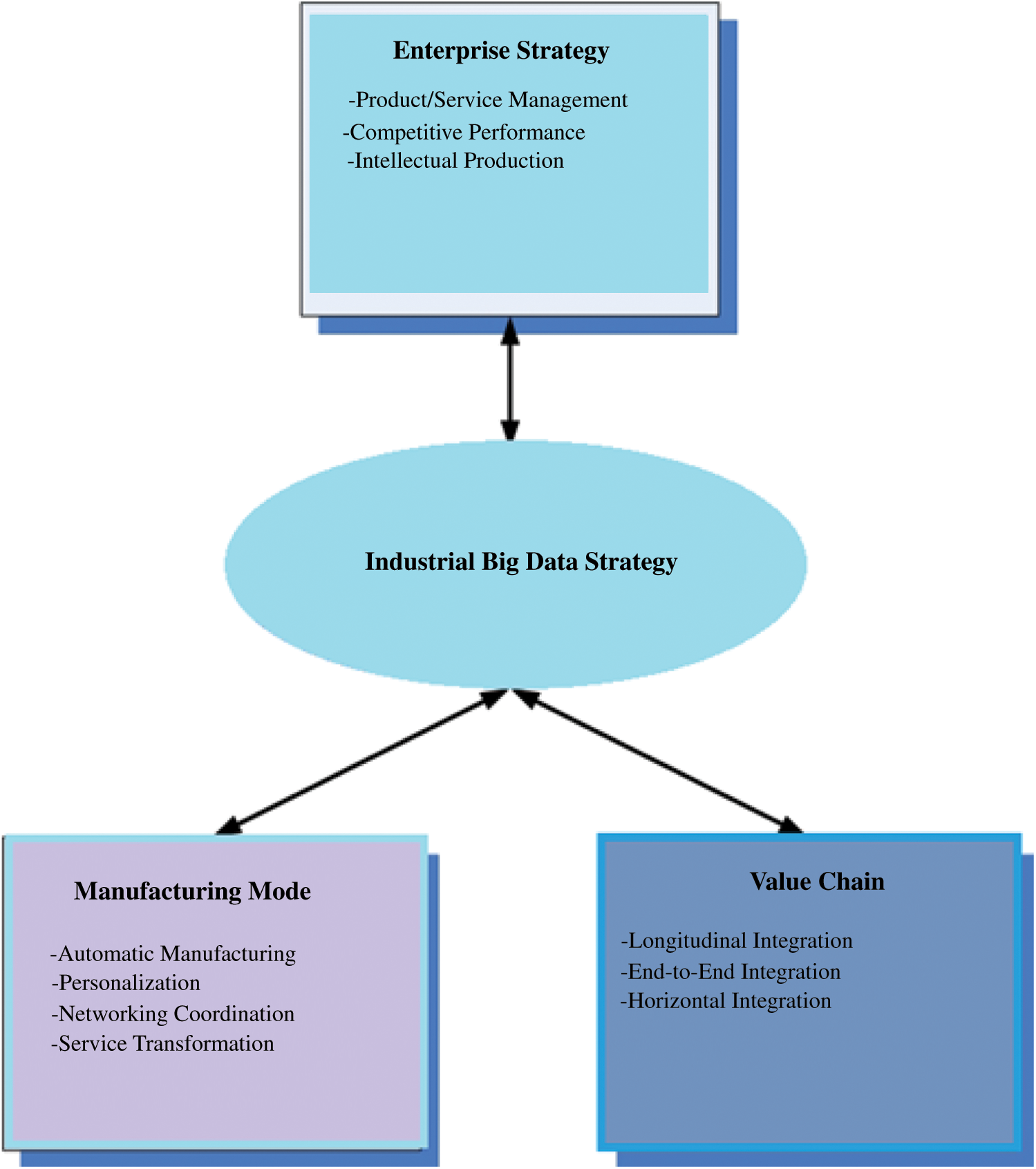

6 The Strategic Role of Industrial Big Data

For a manufacturing enterprise, big data cannot only be used to improve the operational efficiency of enterprises but more importantly, it can show how to change business processes and business models through the capabilities provided by next-generation information technologies such as big data. From the perspective of enterprise strategic management, we analyze the three main relationships between big data and related technologies and corporate strategies, as shown in Fig. 5.

Figure 5: Industrial big data strategic role

• Big data and core competencies: Big data can be used to improve the operational efficiency of an enterprise and enhance its core competencies.

• Big data and value chains: Big data and related technologies can help companies run-flat and accelerate the flow of information in the manufacturing process.

• Big data and manufacturing models: Big data can help change manufacturing patterns and form new business models. Among them, the typical intelligent manufacturing modes include automated production, personalized manufacturing, network coordination, and service transformation.

The core competency of an enterprise refers to a combination of complementary skills and knowledge within an enterprise. It has the ability to bring one or more businesses to the best level in a competitive field. Core competencies consist of insightful predictive capabilities and frontline execution capabilities. Insights are mainly based on scientific and technical knowledge, unique data, product creativity, superior analysis, and reasoning skills. Frontline execution capabilities arise from situations where the quality of the final product or service will change due to the quality of the frontline staff’s work. The core competency of an enterprise is the overall resources of the enterprise. It involves all aspects of the company’s technology, talents, management, culture, and cohesiveness. It is the common behavior of all departments and all employees. Only one enterprise has the ability to operate on the requirements of success. An enterprise’s strategic capabilities and corresponding organizational resources can survive, and big data can play a role in improving the insights of senior executives and the ability to work and serve at the enterprise executive level.

Big data can be used not only to improve the operational efficiency of enterprises but also to support business processes and business model changes [31]. There are four modes: “personalization,” “intelligent manufacturing,” “cooperative production,” and “service extension.”

As an important symbol of the transition from traditional industry to the intelligent manufacturing stage, personalized customization utilizes an Internet platform and smart factory construction to directly translate user needs into production orders, as well as carry out user-centered personalized customization and on-demand production to effectively meet market diversity demand, solve the long-standing inventory and capacity problems in the manufacturing industry, and achieve a dynamic balance between production and sales. Personalization is the automation of data flow. The application of industrial big data technology can automate data flow. With the accumulation of data accumulated by various design tools, simulation models, management software, and production equipment, information physics systems can be developed in enterprises. Testing, production, logistics, management, services, etc., in the horizontal, vertical, and product lifecycle data integration process of the enterprise, data exchange, interoperability, interoperability, or invisible automation, for human intervention.

The development trend of intelligent production is to integrate a series of manufacturing resources such as materials, energy, equipment, capital, technology, information, and manpower and to produce high quality and high efficiency through advanced manufacturing technology, advanced management techniques, and advanced manufacturing processes. Highly flexible, low cost, low labor, low consumption, multi-variety, full-size products. Intelligent equipment and modern production techniques are becoming more and more popular in key industries, and the informationization of production processes is developing in-depth.

Industrial big data technology can be used to perform various analyses on various state parameters collected on industrial manufacturing production lines, such as equipment diagnosis, power consumption analysis, energy consumption analysis, and quality accident analysis (including violation of production regulations and component failure). First, using big data, one can analyze the entire production process and understand how each link is executed. Once a process deviates from the standard process, an alarm signal is generated to detect errors or bottlenecks more quickly. It will also be easier to solve the problem. Second, using big data technology, one can also create virtual models of the production process, simulate and optimize the production process, and help manufacturers improve their production processes. For example, in energy consumption analysis, sensors are used to monitor all production processes in the production process of the equipment, and it is possible to find abnormal or peak energy consumption and optimize the energy consumption in the production process through big data analysis techniques.

For multi-variety and small-batch production modes, refined real-time data collection methods (such as MES, DCS, and other systems) and variability will lead to a sharp increase in data, plus more than a decade of information historical data. For APS, which needs a quick response, this is a huge opportunity. Big data can give enterprises more detailed data information, find historical predictions and actual deviation probabilities, combine various constraints, develop pre-planned scheduling through intelligent optimization algorithms, monitor actual deviations between plans and sites, and dynamically adjust plans. In order to help enterprises, avoid the defects of “portraits,” they directly assign group characteristics to individuals (work center data is directly changed to specific equipment, personnel, molds, etc.), and through data correlation analysis and monitoring, enterprises can plan for the future.

The core of networked collaborative manufacturing is the synergy between R&D and supply chain management among enterprises. The horizontal integration of two-in-one integration is an important indicator for enterprises to enter the stage of comprehensive integration. Networked collaborative manufacturing is not a new concept. The aviation and automobile industries have been engaged in networked collaborative manufacturing for decades. For example, the C919 large passenger aircraft developed by China Commercial Aircraft Corporation has realized the cross-domain and multi-agent globalization of suppliers through a networked collaborative manufacturing platform. Synergistic innovation has shortened the development cycle, reduced the development cost, and improved the development quality and development efficiency.

The development of a new generation of information and communication technology has given new meaning to networked collaborative manufacturing. With the help of the Internet or an industrial cloud platform, enterprises can develop new modes such as collaborative R&D, crowdsourcing design, and supply chain coordination among enterprises, which can effectively reduce the cost of resource acquisition, greatly extend the scope of resource utilization, break the closed boundary, accelerate the coordination from single to industrial cooperation, and transform promote the overall competitiveness of the industry.

Manufacturing service is the transformation of manufacturing companies from a manufacturing-centric to a service-oriented in order to gain a competitive advantage. Manufacturing service has two meanings. First, the efficiency of internal services is increasingly important for the competitiveness of manufacturing companies. Second, external products related to products are becoming more complex and important to customers. Industrial big data can promote the efficiency of internal and external services and enhance the value of services through intelligent services. The essence of intelligent services in the industrial field is intelligent products plus perceptual control capabilities and big data analysis. Online health detection and faults can be provided by collecting and analyzing data such as self-work conditions, the surrounding environment, and user operation behaviors during product use. Services such as diagnosis and warning, as well as support new service models such as online rental and pay-per-use, create new value for products and realize the service transformation of manufacturing enterprises.

8.1 Equipment Characteristics under Industry 4.0

In order to meet the requirements of various factors of Industry 4.0, the basic equipment of Industry 4.0 should have six characteristics: interoperability, virtualization, distribution, real-time, service orientation, and modularization.

• Interoperability

Interoperability means that all devices in a plant can communicate with each other through open networks and compatible technical standards. Device interoperability is at the heart of plant intelligence and automation. In the intelligent factory, between different equipment, between equipment and people, between people and other people through the Internet of Things and the service network, so as to realize the interconnection and intelligent interaction of all links, which requires mutual equipment. Compatible, accurate communication, consistent communication standards, and even design, production, quality standards, so this will be a major change in the entire equipment industry.

• Virtualization

Virtualization refers to the ability of a device to monitor physical processes, monitor data, and connect to a virtual plant model to create a virtual version of the real world. At the same time, each device has its own virtualization features that can be virtualized as part of the plant model. The virtual model can simulate various virtual scenarios based on monitoring data to identify risks, reduce errors, and reduce improvement costs.

• Distributed layout

A distributed layout refers to embedded computers that enable individual control and independent decision making of devices. With the development of customer customization and product diversification, flexible production lines will be more and more widely used, and the way to control the entire production line neatly is no longer desirable. The embedded control system can make every device or device unit have the ability to make independent decisions and identify which work steps or actions should be taken under which instructions. Therefore, in the future, centralization will be more suitable for the setting of production targets, and a distributed layout will be applied more to the production process.

• Real-Time Capability

Real-time capability is the immediacy of data collection and analysis. Of course, this also includes the real-time nature of the data sent by devices. The state of the smart factory requires real-time, uninterrupted monitoring and analysis, and externally entered information requires real-time feedback to detect anomalies and meet new demands.

• Service Orientation

Service-oriented means that a device meets the needs of users through service networking, and the service can be either internal or open-facing. Every industrial revolution in history is ultimately aimed at meeting human needs, and Industry 4.0 is no exception. Products will extend from a single item to a product and service. The equipment must consider human factors from the beginning of the design, including user-friendliness, convenience of maintenance, etc. Through the network of services, the equipment is integrated into an organism, so that the internal production demand and external customer needs can be reacted to immediately. Industry 4.0 is more able to meet these requirements.

• Modular

Modular means that equipment or equipment components are manufactured to standards and can be assembled, replaced, and expanded as needed, including standardized hardware and software. New modules can be automatically identified for added versatility and flexibility. In view of the Industry 4.0 requirements for advanced equipment, the overall replacement of smart devices’ cost is quite high. Modular and flexible manufacturing solutions that can be rapidly expanded will become research priorities and trends.

8.2 Equipment Application Case under Industry 4.0

According to the description of the Industry 4.0 Working Group, objectively, there is currently no smart factory that can fully meet the standards of Industry 4.0, but some equipment or certain parts of the factory have met the requirements.

• Tesla Battery

Tesla is currently the leader in the electric vehicle industry, and its core is the battery power system. Tesla’s power system is actually a system of more than 7,000 small cylindrical lithium “18650” batteries (18 mm in diameter. 65 mm long) provided by Panasonic. The voltages of these batteries remain exactly the same, providing strong power, stable safety, and low levels of wear. A large number of sensors are used in the battery system, and the sensors transmit data to the battery management system for battery state calculation, energy management, thermal management, safety management, equalization control, and communication functions.

Tesla batteries are a typical example of modular equipment. They consist of thousands of modular micro-batteries, consisting of micro-battery integrated battery packs, that are integrated into a Tesla battery. The integrated battery is a module of the electric vehicle. Each micro battery has its own running feedback system to prevent damage to the battery pack caused by single battery failure and realize the distribution of battery pack control. The Tesla battery replaces the fuel/gas engine of an ordinary car and forms a perfect intercommunication system with other linkage units of the car. The battery management system performs simulation calculation and analysis through real-time feedback from sensor data and issues instructions to keep the battery running smoothly. At the same time, the battery management system controls the output of the battery current to accurately provide the necessary power for the car to travel according to the requirements of the power system.

• German Brau Brewing Company Logistics Management Solution

Brau is a famous beer brand in Germany, and the Brau Brewing Company combines sensors and virtual software to form a logistics management system. This combination effectively reduces the probability of empty running of the forklift, increases storage space utilization, and reduces gas consumption and CO2 emissions. By simulating the entities involved in the warehousing activities in the real world in the software system, the production process can be automatically scanned into the warehouse. The functions are warehousing space planning, transportation instruction presentation, disordered storage of goods, misoperation correction, truck filling, and other functions.

8.3 Analysis with Respect to China’s Equipment Manufacturing Industry

Given that Industry 4.0 is still in its infancy and its requirements are very high-end, the realization of mature smart factories may still have a long way to go, and the mechanical equipment that is the basis of smart factories has been widely used in some factories and products. Since the concept of Industry 4.0 was put forward, the focus of the industry has focused on the ambiguity of the vision of Industry 4.0, and there are few specific discussions on its implementation. This paper summarizes the six characteristics of basic equipment, gives the basic and specific standards for equipment that meets the requirements of Industry 4.0, and provides a reference for the development of equipment manufacturing in the future.

From the two application cases listed in this article, it can be seen that the difference between Industry 4.0 and the previous three industrial revolutions is that it is not an energy revolution, nor a technological subversion, but a comprehensive innovation of technology combinations (admittedly, technology in this process is also evolving, so creativity will dominate the development of Industry 4.0 in the future). China’s equipment manufacturing industry started late, but it has accumulated rich experience and a considerable technical level in the decades of development. It is necessary to make full use of the opportunities of Industry 4.0 to narrow down and even catch up with the equipment manufacturing level in developed countries.

Equipment manufacturers must lay a solid foundation and make excellent products. They should not be in the midst of the tide of Industry 4.0, “scarring flowers and fascinating eyes,” blindly speculating concepts, and pursuing high-tech. The level of intelligence that Industry 4.0 expects to achieve is realized by the organic combination of basic functions and components of basic equipment. These basic functions and components have been mastered by equipment manufacturers in China to a certain extent. Equipment manufacturing enterprises should base their own products on the requirements of Industry 4.0. Product quality, optimize product features and create upgraded intelligent devices. Second, the equipment manufacturing industry should strengthen the integration of other elements of Industry 4.0, such as IoT, cloud storage, and big data. Third, the state should promptly introduce relevant policies, guide the support of equipment manufacturing enterprises to transform and upgrade them, and proactively promote the development of equipment manufacturing in general and compatibility standards.

8.4 Industry 4.0 Case Analysis under Big Data

Luo Xiang designed a personalized customized intelligent platform using the four business models of industrial big data: personalized customization, intelligent manufacturing, collaborative production, and service extension, which realize enterprise cost reduction and enterprise efficiency improvement. This is an example of creating value. Suzhou Luoxiang Software Co., Ltd. (Roman) is an IT company that provides information management solutions for manufacturing companies. Based on parametric design, the customized intelligent platform can realize the manufacturing and service management of the whole life cycle based on product parameters, such as sales, design, manufacturing, supply chain, delivery, and service, as well as create customized products for the equipment manufacturing industry. Luo Xiang developed a personalized customized intelligent platform for Yingwo through informationization planning using the network to transmit the needs and data of elevator terminal customers to the platform center database, as well as cloud computing and IoT technologies to realize quotations, design, manufacture, and services. The intelligent, automated, data-based, and network-based processing of the entire process completes the customized production and service for elevator terminal customers.

The platform internally uses product parametric graphical modeling and networked supply chain coordination and establishes personalized customer requirements to automatically connect and interact with factory manufacturing resources end-to-end, as well as externally through crowdsourcing models and platforms for better market integration and service resources. Therefore, it can better help enterprises to build a modern business model of C2M and realize rapid product and service response, professional manufacturing capability, and high-cost performance to meet the needs of large-scale customized production.

The C2M elevator personalized customized intelligent platform is leading Yingwo Elevator from a traditional elevator production process to an intelligent production process to realize the whole lifecycle management of elevator products. It provides a typical demonstration role for elevator enterprises so that it can be promoted and applied throughout the industry. For example, in the manufacturing process, the product drawings, structure, process information, production procurement plan, and workshop scheduling plan are automatically generated by collecting the product parameters and user requirements to realize the integration of the supply chain. Information such as the quantity, progress, and quality of the product, and the status of a device is grasped by collecting data such as equipment data. Real-time dynamic reflection of production processes, adjustment of production plans, control of processing quality, recording of processing costs, and other functions

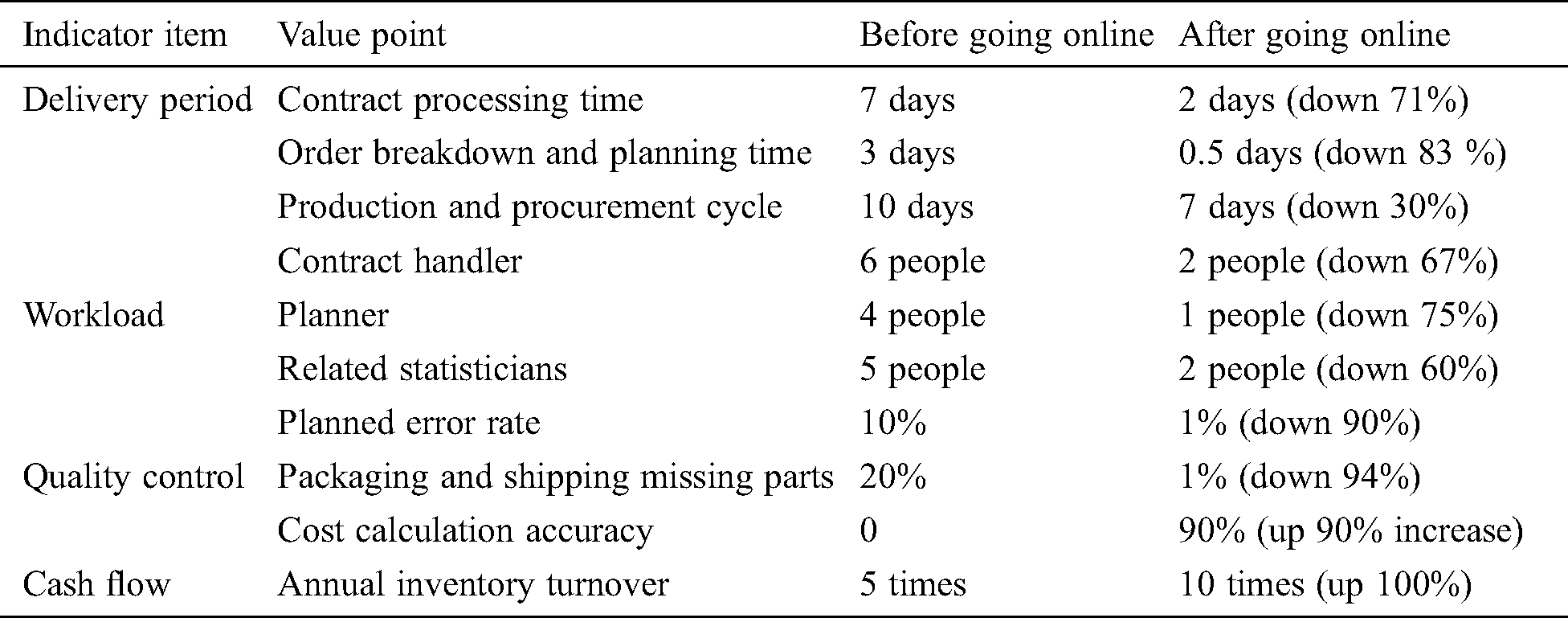

In addition, in the after-sales maintenance process, focus on elevator after-sales and maintenance processing and recording, record the corresponding operating parameters, parts or packaging parts are prone to use problems and problems, to determine whether there are design-related problems and parameters, so that optimize the design and reduce operational failures. The system integrates with the IoT system to collect the product operating status and operating parameter data, monitor the product operation status, generate preventive maintenance plans, prepare spare parts for repair and maintenance according to the plan, record maintenance execution, and master customer service. Complaint handling, maintenance information traceability, maintenance service processing time, cost, quality, and other information. The C2M elevator personalized customized intelligent platform can achieve the user-centered intelligent analysis of the elevator industry through continuous data accumulation, research and development, production, quality, service, operation big data, and building an elevator industry data center. Tab. 1 shows the application value achieved by Yingwo Elevator by implementing the C2M elevator personalized customized intelligent platform.

Table 1: Application value of the personalized customized intelligent platform

This paper highlighted the role of Industry 4.0 in the future manufacturing and production process. The key performance indicators and remarkable features were discussed in detail. Manufacturing enterprises are facing the challenge of transformation and upgrading. The core issue that enterprises should pay attention to is how to use the advanced technology represented by industrial big data to realize enterprise value. This paper clarified the value and realization of industrial big data to enterprises and demonstrated that innovation through big data business models can help enterprises achieve value. We hope that these results can provide a reference for readers who are concerned about industrial big data and its value.

The value of big data is still a relatively new concept. It is worthwhile for experts and enterprises in the field of big data to communicate and work together to realize the transformation and upgrading of the manufacturing industry. With the surge of Industry 4.0 under the influence of multiple factors such as policy, capital, and human resources, it is more prudent to meet the requirements of Industry 4.0. The popularity of the equipment will become an irreversible trend while Industry 4.0 is still in its infancy, and the equipment manufacturing industry is meeting the requirements of Industry 4.0.

There is a lack of clear understanding, so through the literature summary, this article described the six characteristics of equipment that meet the requirements of Industry 4.0, namely interoperability, virtualization, distribution, real-time processes, service-orientation, and modularity. We hope to have some inspiration for equipment manufacturing. To achieve these characteristics, equipment manufacturing enterprises need to focus on their own optimization and upgrading, as well as learning to transcend. They also need the guidance and support of relevant national policies to promote great changes in the equipment industry and thus realize the rapid development of the equipment manufacturing industry. This work can further be extended by focusing on the impact of the dual-channel supply chain under Industry 4.0 and considering offline and online retailers’ trade-offs in this context.

Acknowledgement: The authors (Basem Alkazemi, bykazemi@uqu.edu.sa; Ali Safaa Sadiq, ali.sadiq@wlv.ac.uk) would like to thank deanship of scientific research (DSR) at umm Al-Qura University for their partial funding the work (Grant# 17-COM-1-01-0007).

Funding Statement: This research was supported under the National Research Foundation (NRF), Korea (2019R1C1C1007277) funded by the Ministry of Science and ICT (MSIT), Korea.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. B. Chen, J. Wan, L. Shu, P. Li, M. Mukherjee et al. (2017). , “Smart factory of industry 4.0: key technologies, application case, and challenges,” IEEE Access, vol. 6, pp. 6505–6519. [Google Scholar]

2. D. Das, A. S. Sadiq, N. B. Ahmad and J. Lloret. (2017). “Stock market prediction with big data through hybridization of data mining and optimized neural network techniques,” Journal of Multiple-Valued Logic & Soft Computing, vol. 29, no. 1, pp. 157–181. [Google Scholar]

3. Z. Rezaee. (2018). “Supply chain management and business sustainability synergy: A theoretical and integrated perspective,” Sustainability, vol. 10, no. 1, pp. 1–17. [Google Scholar]

4. J. Lee, B. Bagheri and H. Kao. (2015). “A cyber-physical systems architecture for industry 4.0-based manufacturing systems,” Manufacturing Letters, vol. 3, pp. 18–23. [Google Scholar]

5. J. Wan, S. Tang, D. Li, S. Wang, C. Liu et al. (2017). , “A manufacturing big data solution for active preventive maintenance,” IEEE Transactions on Industrial Informatics, vol. 13, no. 4, pp. 2039–2047. [Google Scholar]

6. M. D. Nardo, M. Clericuzio, T. Murino and C. Sepe. (2020). “An economic order quantity stochastic dynamic optimization model in a logistic 4.0 environment,” Sustainability, vol. 12, no. 10, pp. 1–25. [Google Scholar]

7. F. Tao, Y. Cheng, L. D. Xu, L. Zhang and B. H. Li. (2014). “CCIoT-CMfg: cloud computing and internet of things-based cloud manufacturing service system,” IEEE Transactions on Industrial Informatics, vol. 10, no. 2, pp. 1435–1442. [Google Scholar]

8. J. H. Ang, C. Goh, A. A. F. Saldivar and Y. Li. (2017). “Energy-efficient through-life smart design, manufacturing and operation of ships in an industry 4.0 environment,” Energies, vol. 10, no. 5, pp. 1–13. [Google Scholar]

9. B. Mrugalska and M. K. Wyrwicka. (2017). “Towards clean production in industry 4. 0,” Procedia Engineering, vol. 182, no. 17, pp. 466–473. [Google Scholar]

10. B. Micieta, V. Binasova, R. Lieskovsky, M. Krajcovic and L. Dulina. (2019). “Product segmentation and sustainability in customized assembly with respect to the basic elements of industry 4.0,” Sustainability, vol. 11, no. 21, pp. 1–20. [Google Scholar]

11. N. H. Tran, H. S. Park, Q. V. Nguyen and T. D. Hoang. (2019). “Development of a smart cyber-physical manufacturing system in the industry 4.0 context,” Applied Sciences, vol. 9, no. 16, pp. 1–24. [Google Scholar]

12. J. Dregger, J. Niehaus, P. Ittermann, H. H. Kreinsen and M. T. Hompel. (2016). “The digitization of manufacturing and its societal challenges: a framework for the future of industrial labor,” in IEEE Int. Sym. on Ethics in Engineering, Science and Technology, Vancouver, BC, Canada, pp. 1–3. [Google Scholar]

13. T. Skrinjaric. (2020). “R&D in europe: Sector decomposition of sources of (in)efficiency,” Sustainability, vol. 12, no. 4, pp. 1–21. [Google Scholar]

14. M. Gotz and B. Jankowska. (2017). “Clusters and industry 4.0- Do they fit together?,” European Planning Studies, vol. 25, no. 9, pp. 1633–1653. [Google Scholar]

15. L. Barreto, A. Amaral and T. Pereira. (2017). “Industry 4.0 implications in logistics: An overview,” Procedia Manufacturing, vol. 13, no. 17, pp. 1245–1252. [Google Scholar]

16. J. M. Muller, D. Keil and K. Voigt. (2018). “What drives the implementation of industry 4.0? the role of opportunities and challenges in the context of sustainability,” Sustainability, vol. 10, no. 1, pp. 1–24. [Google Scholar]

17. D. O. Madsen. (2019). “The emergence and rise of industry 4.0 viewed through the lens of management fashion theory,” Administrative Sciences, vol. 9, no. 3, pp. 1–25. [Google Scholar]

18. W. Bauer, M. Hammerle, S. Schlund and C. Vocke. (2015). “Transforming to a hyper-connected society and economy- toward an Industry 4. 0,” Procedia Manufacturing, vol. 3, pp. 417–424. [Google Scholar]

19. O. Ungerman and J. Dedkova. (2019). “Marketing innovations in industry 4.0 and their impacts on current enterprises,” Applied Sciences, vol. 9, no. 18, pp. 1–21. [Google Scholar]

20. M. Hermann, T. Pentek and B. Otto. (2016). “Design principles for industry 4.0 scenarios,” in 49th Hawaii Int. Conf. on System Sciences, Koloa, HI, USA, pp. 3928–3937. [Google Scholar]

21. F. Shroud, J. Ordieres and G. Miragliotta. (2015). “Smart factories in industry 4.0: A review of the concept and of energy management approached in production based on the internet of things paradigm,” in IEEE Int. Conf. on Industrial Engineering and Engineering Management, Bandar Sunway, Malaysia, pp. 697–701. [Google Scholar]

22. H. Lesi, P. Fettke, H. Kemper, T. Field and M. Hoffmann. (2014). “Industry 4.0,” Business & Information Systems Engineering, vol. 6, no. 4, pp. 239–242. [Google Scholar]

23. S. Erol, A. Schumacher and W. Sihn. (2016). “Strategic guidance towards industry 4.0- A three-stage process model,” in Int. Conf. on Competitive Manufacturing, Stellenbosch, pp. 495–500. [Google Scholar]

24. Y. J. Choi, H. J. Kang and G. Lee. (2019). “Scalable and secure internet of things connectivity,” Electronics, vol. 8, no. 7, pp. 1–15. [Google Scholar]

25. F. Perez, E. Irisarri, D. Orive, M. Marcos and E. Estevez. (2015). “A CPPS architecture approach for industry 4.0,” in IEEE 20th Int. Conf. on Emerging Technologies & Factory Automation, Luxembourg, pp. 1–4. [Google Scholar]

26. K. Wang, Y. Wang, Y. Sun, S. Guo and J. Wu. (2016). “Green industrial internet of things architecture: an energy-efficient perspective,” IEEE Communication Magazine, vol. 54, no. 12, pp. 48–54. [Google Scholar]

27. C. M. Olvera and J. M. Vargas. (2019). “A comprehensive framework for the analysis of industry 4.0 value domains,” Sustainability, vol. 11, no. 10, pp. 1–21. [Google Scholar]

28. S. We, J. Hu, Y. Cheng, Y. Ma and Y. Yu. (2018). “The essential elements of intelligent manufacturing system architecture,” in IEEE 13th Conf. on Automation Science and Engineering, Xi’an, China, pp. 1006–1011. [Google Scholar]

29. V. Pilloni. (2018). “How data will transform industrial processes: Crowdsensing, crowdsourcing and big data as pillars of industry 4.0,” Future Internet, vol. 10, no. 3, pp. 1–14. [Google Scholar]

30. M. Flyverbom, R. Deibert and D. Matten. (2019). “The governance of digital technology, big data, and the internet: New roles and responsibilities for business,” Business & Society, vol. 58, no. 1, pp. 3–19. [Google Scholar]

31. R. Chaudhary, J. R. Pandey and P. Pandey. (2015). “Business model innovation through big data,” in IEEE Int. Conf. on Green Computing and Internet of Things, Noida, India, pp. 259–263. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |