Open Access

Open Access

ARTICLE

Impact of Pollutant Concentration and Particle Deposition on the Radiative Flow of Casson-Micropolar Fluid between Parallel Plates

1 Department of Mathematics and Statistics, College of Science, Imam Mohammad Ibn Saud Islamic University (IMSIU), Riyadh, 11564, Saudi Arabia

2 Department of Mathematics, College of Science, King Saud University, Riyadh, 11989, Saudi Arabia

3 Department of Mathematics, Amity School of Applied Sciences, Amity University Rajasthan, Jaipur, 302002, Rajasthan, India

4 Department of Studies in Mathematics, Davangere University, Davangere, 577002, India

5 Department of Electronics and Communication Engineering, Amrita School of Engineering, Amrita Vishwa Vidyapeetham, Bengaluru, 560035, India

* Corresponding Author: Badr Saad T. Alkahtani. Email:

(This article belongs to the Special Issue: Scientific Computing and Its Application to Engineering Problems)

Computer Modeling in Engineering & Sciences 2025, 142(1), 665-690. https://doi.org/10.32604/cmes.2024.055500

Received 28 June 2024; Accepted 16 October 2024; Issue published 17 December 2024

Abstract

Assessing the behaviour and concentration of waste pollutants deposited between two parallel plates is essential for effective environmental management. Determining the effectiveness of treatment methods in reducing pollution scales is made easier by analysing waste discharge concentrations. The waste discharge concentration analysis is useful for assessing how effectively wastewater treatment techniques reduce pollution levels. This study aims to explore the Casson micropolar fluid flow through two parallel plates with the influence of pollutant concentration and thermophoretic particle deposition. To explore the mass and heat transport features, thermophoretic particle deposition and thermal radiation are considered. The governing equations are transformed into ordinary differential equations with the help of suitable similarity transformations. The Runge-Kutta-Fehlberg’s fourth-fifth order technique and shooting procedure are used to solve the reduced set of equations and boundary conditions. The integration of a neural network model based on the Levenberg-Marquardt algorithm serves to improve the accuracy of predictions and optimize the analysis of parameters. Graphical outcomes are displayed to analyze the characteristics of the relevant dimensionless parameters in the current problem. Results reveal that concentration upsurges as the micropolar parameter increases. The concentration reduces with an upsurge in the thermophoretic parameter. An upsurge in the external pollutant source variation and the local pollutant external source parameters enhances mass transport. The surface drag force declines for improved values of porosity and micropolar parameters.Keywords

Nomenclature

| Symbols | |

| Distance between two plates | |

| Length | |

| Time | |

| Velocity components | |

| Coordinates | |

| Pressure | |

| Vertex viscosity | |

| The permeability of the porous medium | |

| Micro rotation component | |

| Temperature | |

| Thermal conductivity | |

| Specific heat capacity | |

| Micro-inertia density | |

| Mean absorption coefficient | |

| The reference temperature | |

| Local Reynolds number | |

| Nusselt number | |

| Sherwood number | |

| Fluid concentration | |

| Mass diffusivity | |

| Thermophoretic velocity | |

| External pollutant concentration | |

| Pollutant source external variation parameter | |

| Microrotation parameter | |

| Mass transfer velocity | |

| The temperature of the wall | |

| The thermophoretic coefficient | |

| The temperature of the plate | |

| The concentration of the plate | |

| Micropolar parameter | |

| Squeeze number | |

| Prandtl number | |

| Schmidt number | |

| Radiation parameter | |

| Skin friction | |

| Greek Symbols | |

| Spin radiation viscosity | |

| Dynamic viscosity | |

| Solid volume fraction | |

| Thermophoretic parameter | |

| Stefan-Boltzmann coefficient | |

| Casson parameter | |

| Squeeze rate | |

| Thermal diffusivity | |

| Kinematic viscosity | |

| The density of the fluid` | |

| Local pollutant external source parameter | |

| External pollutant source variation parameter | |

| Porous parameter | |

| Abbreviations | |

| RKF-45 | Runge-Kutta-Fehlberg’s fourth-fifth order |

| TPD | Thermophoretic particle deposition |

| BCs | Boundary conditions |

| T-R | Thermal radiation |

| ODEs | Ordinary differential equations |

A fluid that exhibits microscopic phenomena like spin inertia and micro-rotational motions is called a micropolar fluid. Micropolar liquid is a type of non-Newtonian liquid. Initially, Eringen developed the concept of micropolar fluid. Micropolar fluids have applications in numerous industrial and biological processes, including the synthesis of polymers, the drawing of wire, the manufacturing of glass fiber, and the cooling process of metallic sheets. Ismael et al. [1] examined the impacts of chemical reaction, viscosity loss, thermal radiation (T-R), and ohmic dissipation on magnetohydrodynamic movement of a micropolar non-Newtonian nanofluid by peristalsis circulating across a permeable medium within two horizontal co-axial tubes. Yasir et al. [2] investigated the motion of the thermodynamic substance of a micropolar fluid over a curved stretching/shrinking sheet, and the thermal irregular creation and absorption of nanoscale energy. Siddiqui et al. [3] investigated the flow effects of two fluids (Newtonian and micropolar fluids) via a rectangular channel with porous, orthogonally dynamic walls. Ram et al. [4] examined the flow of magnetized micropolar fluid towards the stagnation point in mixed convective heat and mass transmission on a porous stretched sheet with heat source/sink and changeable species reactivity. Siddiqui et al. [5] investigated the thin-film motion of a micropolar fluid across an angled surface with the influence of gravitational force and viscous dissipation. Li et al. [6] examined the movement of micropolar fluid across a hybrid nanomaterial sheet that is exponentially stretched. Shamshuddin et al. [7] examined the magneto-micropolar nanofluid flow between parallel plates that are filled with chemically reactive Casson fluid with electrical and Hall current impact. Shamshuddin et al. [8] examined the influence of vortex viscosity on the stream of micropolar liquid via a channel.

In physics and engineering, the impacts of T-R on heat transmission and flow are important for developing dependable machinery, nuclear reactors, gas engines, airplanes, missiles, satellite navigation, and rocket vehicle propulsion technologies. Yasir et al. [9] examined the gyrotactic microorganisms with the convective energy transportation characteristics, activation energy, heat radiation, Ohmic, and viscous dissipation effects of the stagnation point region in the magnetized micropolar fluid flow towards a porous shrinking surface. Muntazir et al. [10] studied the influence of T-R on the magnetohydrodynamic nanofluids flow around a permeable linearly extending sheet. Salawu et al. [11] examined the heat radiative and convective hybrid magneto-nanofluids motion through a cylinder with the influence of elastic deformation. Famakinwa et al. [12] assessed the effects of T-R and viscosity changes on the motion of an electrically conducting nanoliquid through a surface that is convectively heated. Mohamed et al. [13] examined how a chemical reaction and T-R affect a non-Newtonian nanofluid circulation between two parallel plates using the Cattaneo-Christov double diffusion method. Fatunmbi et al. [14] scrutinized the influence of T-R on the flow of micropolar fluid across a stretching sheet.

A solid matrix with pores that are usually filled with fluid or gas is called porous media. In solid, open-cell, and saturated porous media, every pore is connected, filled with fluid, and designed to let the fluid flow via the gaps. Among the many uses for porous media in the fields of mechanical and construction engineering are fibrous insulating materials, food preparation, and storage, developing thermal insulation, geophysical systems, electrical chemistry, metalworking, non-nuclear waste disposal, solar energy collectors, and geothermal power applications. Zhang et al. [15] examined the temperature properties and flow behavior of a radiating, homogeneous hybrid nanofluidic mixture moving in a constant mixed convective movement across a fixed wedge surface. Zheng et al. [16] examined the numerical simulation of heat transmission from melting across a permeable shrinking surface nearing the stagnation point region. Hiremath et al. [17] evaluated magnetohydrodynamics nanofluid movement in a combination permeable square enclosure with a corrugated wall by employing the Response surface methodology and central composite design. Rahman et al. [18] examined the Darcy-Brinkman permeable medium for the transmission of dusty fluid through a stretching sheet with the influence of the slip effect. Shamshuddin et al. [19] scrutinized the consequences of radiation on the nanofluid flow across a permeable vertical surface. Ram et al. [20] inspected the effects of cross-diffusion on heat and mass transport of micropolar fluid flow over a porous stretched surface that is magnetically radiated. Rahman et al. [21] examined the effects of slip and porous dispersion on the unstable flow of fluid in a Darcy-Brinkman porous medium.

A phenomenon known as thermophoresis occurs when separated vapor particles move from the hot to the cold region of the gas due to a temperature gradient. A temperature gradient acts on suspended particles to produce the thermophoretic force. Thermophoretic particle deposition (TPD) in liquid circulation is important in many engineering processes, including powdered coal burners, heat exchangers, building ventilation, air cleaners, nuclear power station security, thermal precipitation design, and physical vapor confession. Abbas et al. [22] inspected the role of TPD and heat generation in Marangoni convective-induced boundary layer movement of cross nanofluid in the existence of activation energy. Yasir et al. [23] examined the Soret-Dufour effects and TPD in the time-dependent axisymmetric transmission of heat energy via a stretchy cylinder. Rauf et al. [24] studied the micropolar ferrofluid movement and the transmission of heat resulting from a non-linearly stretched sheet in the existence of the magnetic field. Srilatha et al. [25] studied how the solid-liquid interface layer and nanoparticle diameter affected the time-varying Maxwell nanofluid circulation with TPD. Jyothi et al. [26] studied Casson hybrid nanofluid squeezing motion between parallel plates with a heat sink or source and TPD.

Pollutant concentration states to the amount of contaminants found in soil, water, or the air. Humans, animals, and other living things are more severely affected by pollutants in terms of health. It may be difficult to conduct experimental capacities of the dispersion of air and pollutant concentrations in a restricted region due to the limitations of multi-sampling. Preliminary findings from certain experiments have provided first insights into the effects of external sources of pollution on the concentration of contaminants. Xin et al. [27] examined the concentration of pollutants discharged during non-Newtonian nanofluid movement through a Riga sheet with the impact of T-R and porous medium. Albalawi et al. [28] investigated how Stefan blowing and the distribution of pollution concentrations affected the fluid flow across the co-axial cylinder. Jagadeesh et al. [29] studied the transient distribution of a pollutant in a Jeffrey nano liquid with the impacts of an irregular heat source/sink and magnetic effects across a stretched sheet. Kalleshachar et al. [30] studied the consequence of pollutant concentration and irregular heat source/sink on ternary nanofluid circulation via a divergent and convergent channel. Chinyoka et al. [31] studied the impact of irregular distribution of a pollutant into a channel movement ejected from an external source. Ouyang et al. [32] studied the flow of hybrid nanofluid across a porous media with the consequence of pollutant concentration.

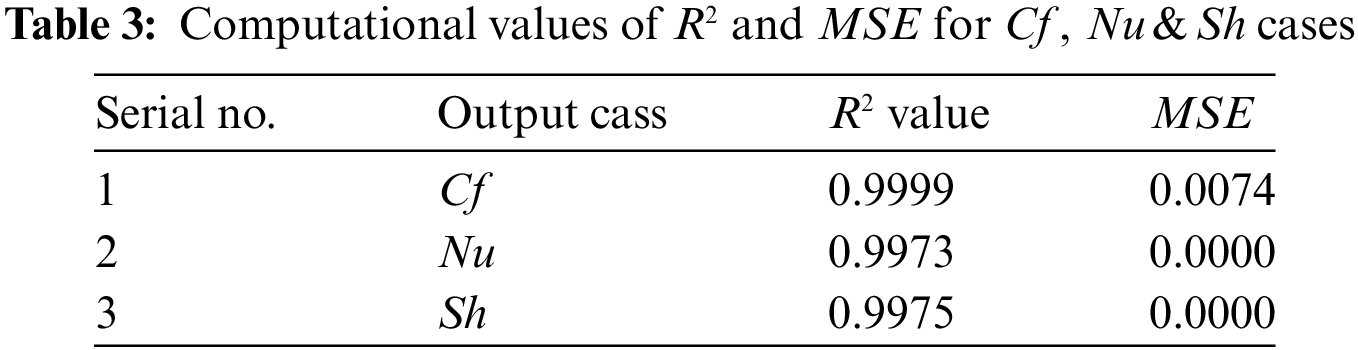

Ongoing through the literature survey, no work has been conducted to examine the mass and heat transmission analysis of Casson-micropolar liquid flow between a parallel plate in the presence of porous medium, T-R, TPD, and waste discharge concentration (see Table 1). The originality of our study is in the comprehensive examination of Casson micropolar fluid flow between parallel plates, incorporating crucial aspects such as waste discharge concentration, thermophoretic particle deposition, porous media, and thermal radiation-parameters that were not taken into account in prior research. In the present work, we utilize the RKF-45 scheme in combination with the shooting technique to efficiently handle the intricacies of highly nonlinear equations, resulting in accurate and dependable outcomes. This paper also presents the use of Artificial Neural Network methodology to enhance the precision of forecasts and optimize the analysis of parameters. New perspectives arising from the incorporation of environmental and thermal impacts greatly enrich the current body of knowledge. By acquiring knowledge of patterns in the parameter changes, the neural network facilitates the optimization of the solution process. The numerical outcomes are visualized concerning various parameters’ impact over different profiles, and important engineering factors are discussed in detail. Furthermore, our investigations provide practical applications in environmental management, namely in enhancing wastewater treatment and minimizing pollutants. Through a comprehensive analysis of thermophoretic effects and pollutant dynamics.

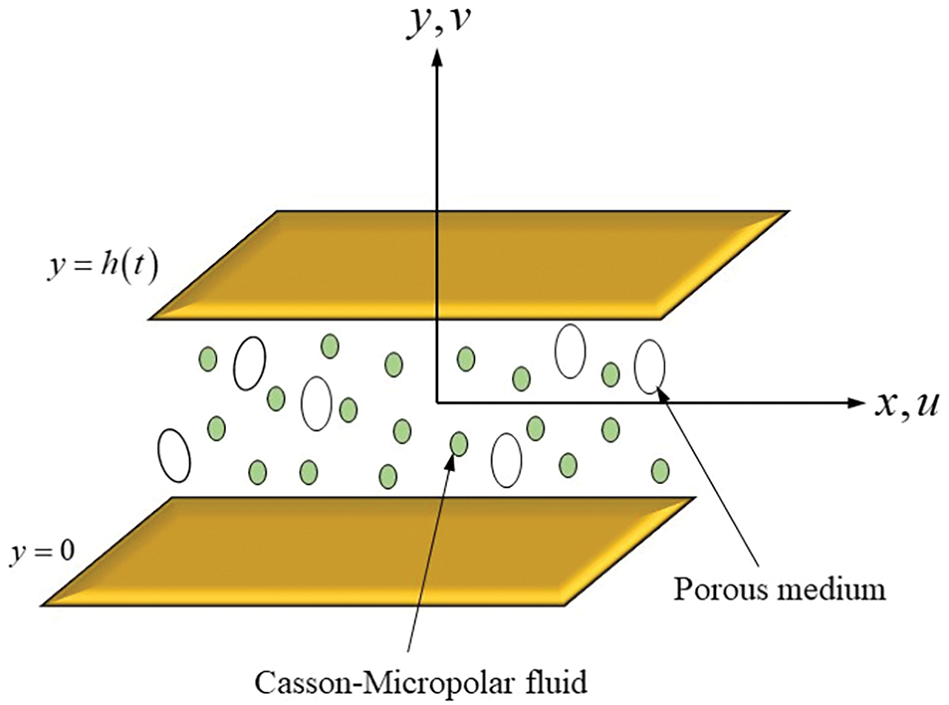

Consider the unsteady two-dimensional Casson micropolar fluid flow across two parallel plates in the existence of a permeable medium. The parallel plates are positioned at

Figure 1: Flow diagram

The work of [34], specifically details the rheology of the Casson fluid model, providing the fundamental basis for the non-Newtonian behavior described. The non-newtonian model of Casson fluid is defined as (see [34])

where,

In developing the governing equations for the present study, previous literature provided a strong foundation. For instance, the research in [31], the paper examines the concentration of pollutants, while [35] investigates the dynamics of micropolar fluids between parallel surfaces. The Casson-Micropolar model is explored in [36], offering valuable insights, and [37,38] enhances our knowledge of the flow between parallel plates. Additionally, References [37] and [38] provide evidence for the representation of unstable or time-varying flows. Collectively, these sources provide a thorough basis for the development of the governing equations, and their combined perspectives were essential in generating the innovative elements of the present work.

The governing equations of the assumed flow are represented as follows (see for Eq. (7) [31], Eqs. (1)–(5) [35–38], Eq. (6) [39]):

The corresponding boundary circumstances are (see [33,39])

where,

In Eq. (5), the spin radiation viscosity is defined as (see [35])

Here,

And in Eq. (7), the thermophoretic velocity is (see [40])

The Eq. (10),

Similarity variables are (see [39–41])

Using Eq. (11), the Eq. (2) is identically satisfied. The pressure term is eliminated from the governing Eqs. (3) and (4) and takes the form of Eq. (12). Further, the Eqs. (5)–(7) will be reduced to Eqs. (13)–(15), respectively.

Boundary conditions (BCs) are reduced to the following form:

From the Eqs. (12) to (16), non-dimensional parameters are

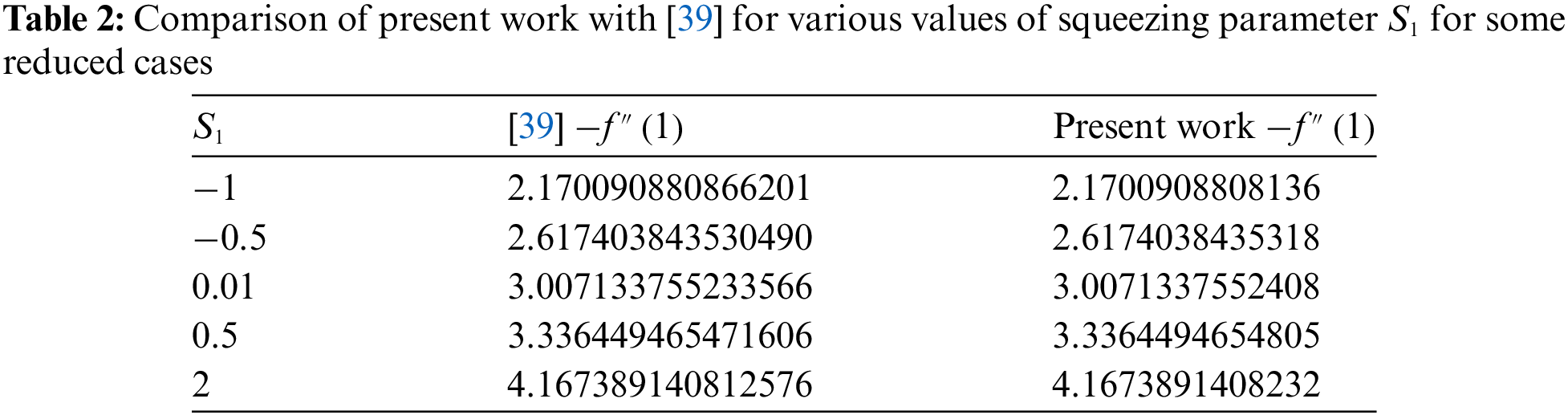

Special Cases:

a) If

b) If

Some important Engineering coefficients are (see [13,42])

Skin friction:

The reduced form of Eq. (18) is

where,

Nusselt number:

The reduced form of Eq. (20) is

Sherwood number:

Eq. (22) is reduced to the following form:

The reduced Eqs. (12)–(15) and BCs (16) are solved numerically utilizing the RKF-45 and a shooting approach due to the presence of higher order and two-point boundary. Obtaining the analytical solution is too difficult for these kinds of problems. Hence, to obtain the solutions, the first step is to make them in a first-order equation form. For this process, the following substitutions are used.

Boundary conditions become

The converted equations are now solved by using the RKF-45 and the shooting scheme is used to find the values of unknown boundary conditions present in the equation number (29) such as

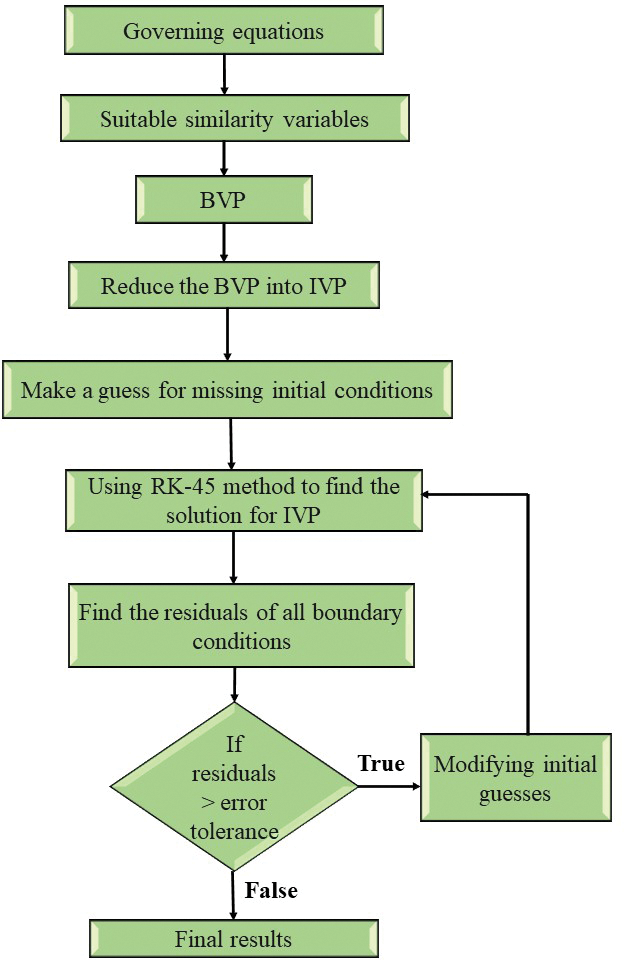

The numerical flowchart of the current scheme is shown in Fig. 2. The solution algorithm to solve the given system of reduced equations and boundary conditions is given below.

Figure 2: Numerical flow chart

Initialization:

• Define the initial and BCs (29) for the variables

• Set the range of independent variable

Substitution:

• Substitute the following variables:

• Transform the fourth-order and second-order ODEs into first-order ODEs by employing these substitutions.

System of first-order ordinary differential equations:

• Compute the first-order system of equations and give the values for all the parameters.

• Apply the BCs to the first-order ODEs.

Numerical solver:

• The shooting scheme is used to find the unknown values of the boundary conditions. The values obtained during the shooting procedure are used to solve the system of equations. The solution of these equations is compared with the boundary conditions. The initial guesses are chosen in such a way that they should meet the error tolerance criteria and boundary conditions at the endpoint. The unknown boundary conditions present in the resultant equations such as

• Using MATLAB and RKF-45, the following transformed system of equations and BCs can be implemented, with the step size set to 0.01 and the error tolerance set to roughly 10−6.

The process described above outlines the step-by-step computing approach to solve the system of equations and BCs numerically. When an approach is incorporated into the research, understanding of the sequence in which the equations are solved will be improved, ensuring that the method can be repeated and understood.

This section explores the impact of various dimensionless parameters (porous parameter, micropolar parameter, radiation parameter, thermophoretic parameter, local pollutant external source parameter, and external pollutant source variation). The effects of these elements are examined using graphical evaluation, which offers a deeper understanding of how they influence the velocity, temperature, and concentration profiles in the liquid. In addition, the discussion emphasizes the importance of these parameters in engineering applications by examining key factors such as skin friction, Nusselt number, and Sherwood number. Such coefficients are crucial for assessing the properties of both mass and heat transmission. This thorough analysis provides a more profound comprehension of the motion of fluids and dispersion of pollutants in the system, which assists in the creation of more efficient solutions for environmental management. The considered parameter ranges are:

Fig. 3 represents the impact of

Figure 3: Effect of porous parameter on velocity profile

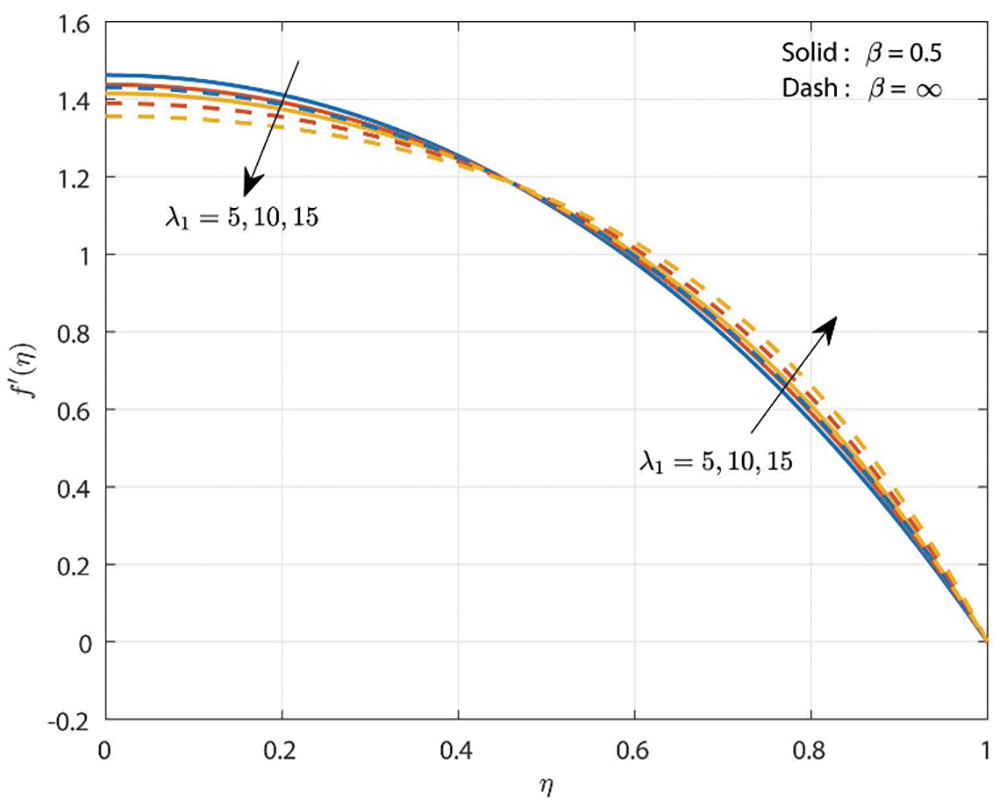

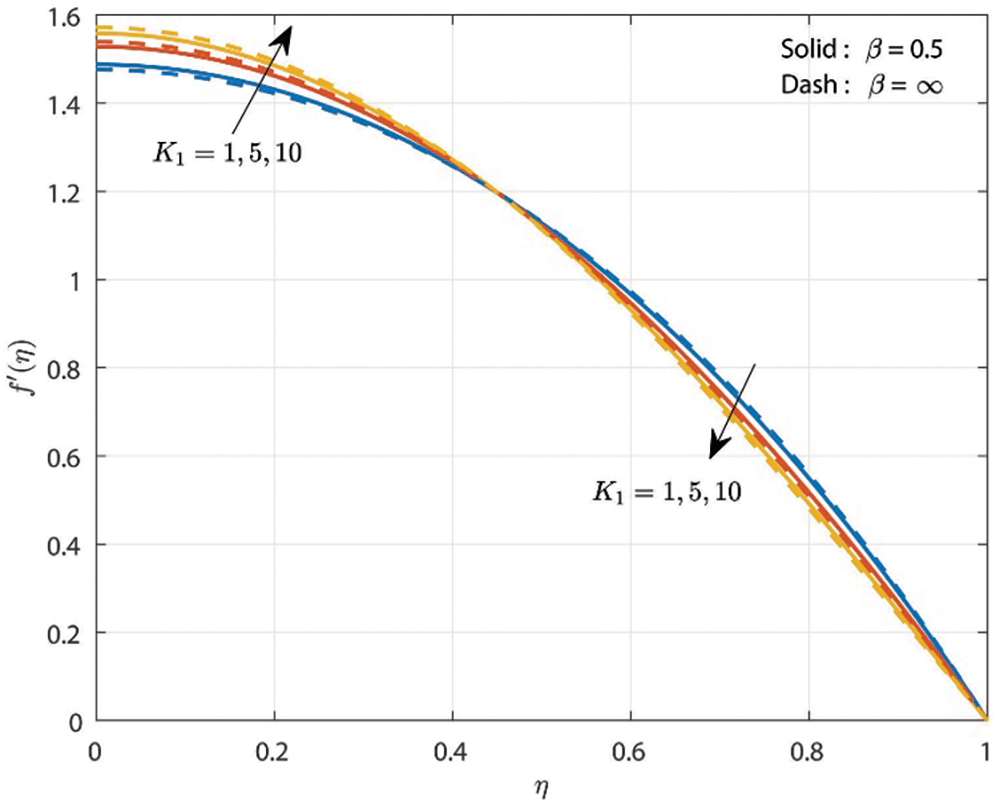

Fig. 4 exemplifies the effect of

Figure 4: Effect of micropolar parameter on velocity profile

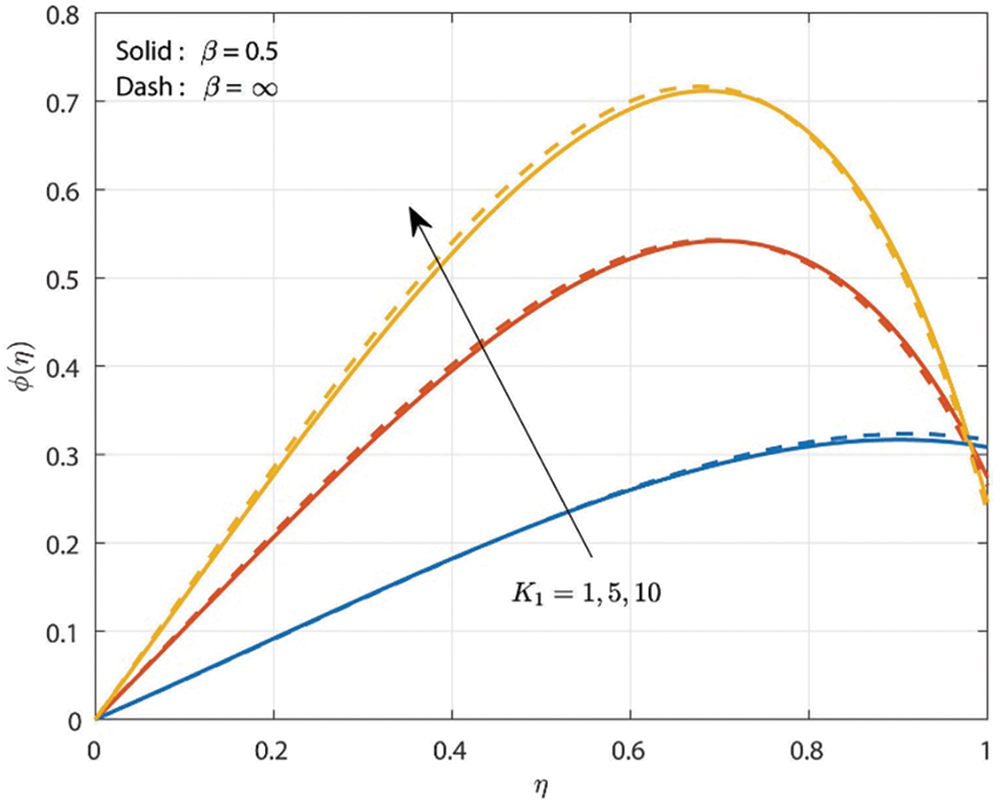

The effect of

Figure 5: Effect of micropolar parameter on the micro rotation velocity profile

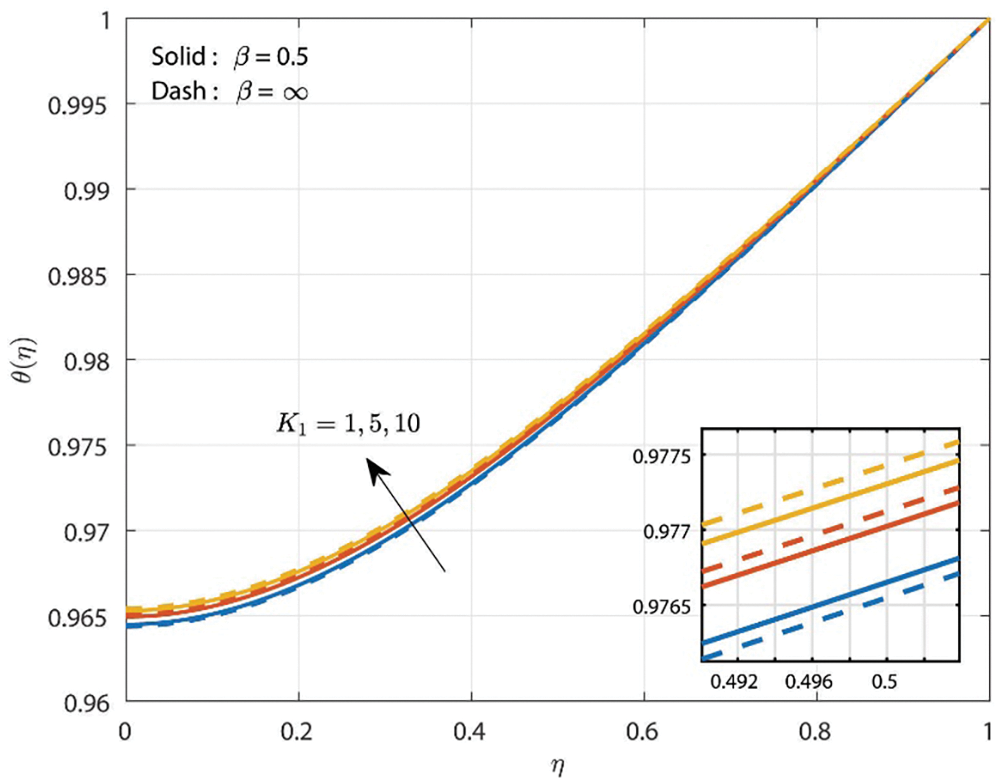

Fig. 6 shows the consequence of

Figure 6: Effect of micropolar parameter on temperature profile

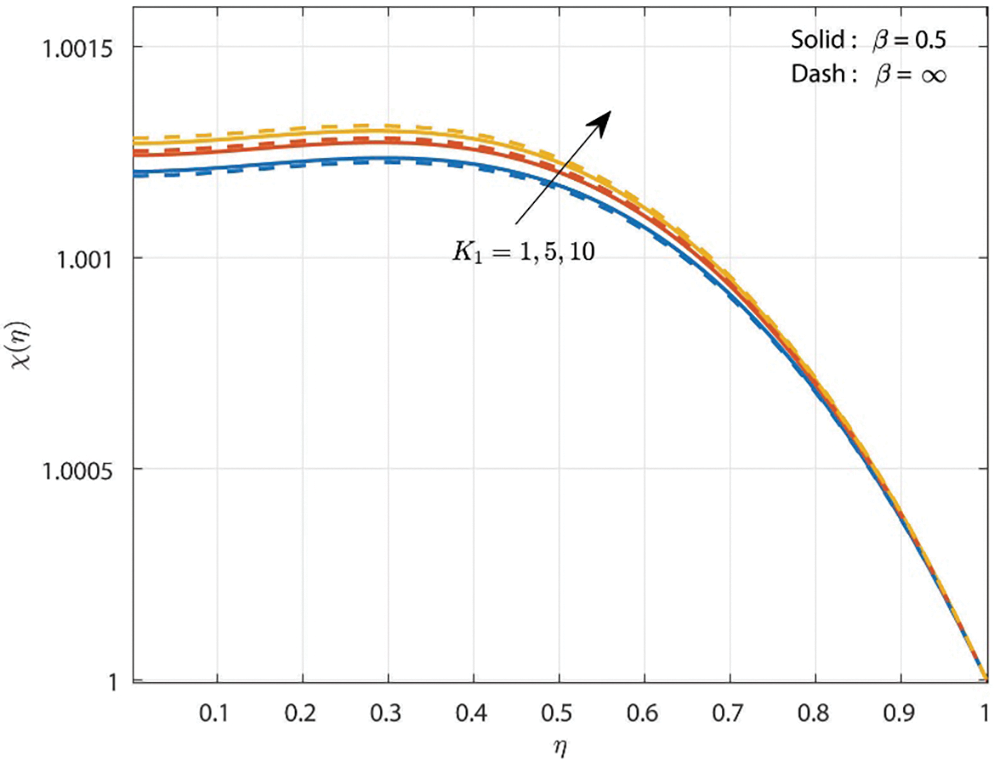

The nature of

Figure 7: Effect of micropolar parameter on concentration profile

In Fig. 8, the influence of

Figure 8: Effect of microrotation parameter on the micro rotation velocity profile

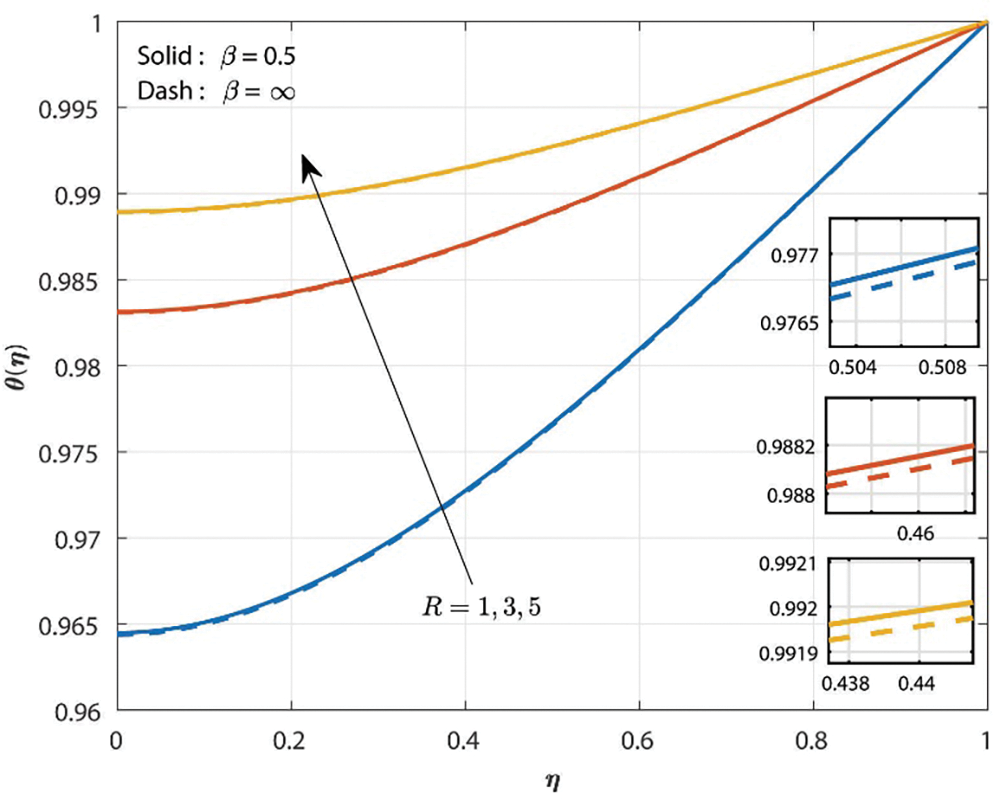

The outcome of

Figure 9: Effect of radiation parameter on temperature profile

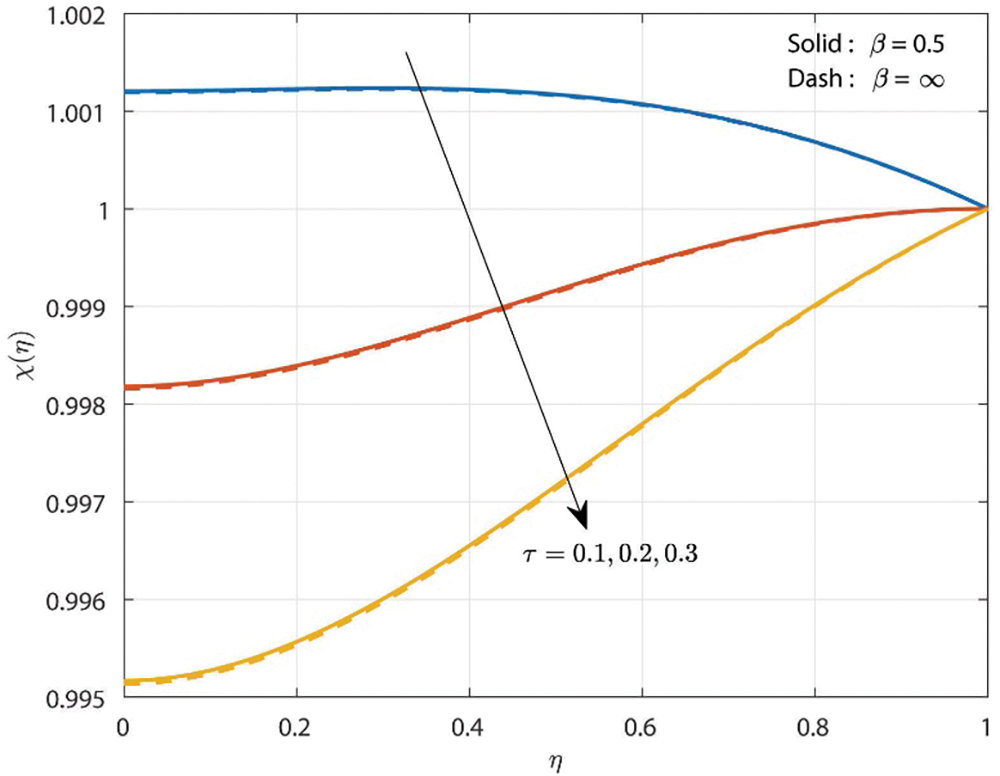

Fig. 10 describes how

Figure 10: Effect of thermophoretic parameter on concentration profile

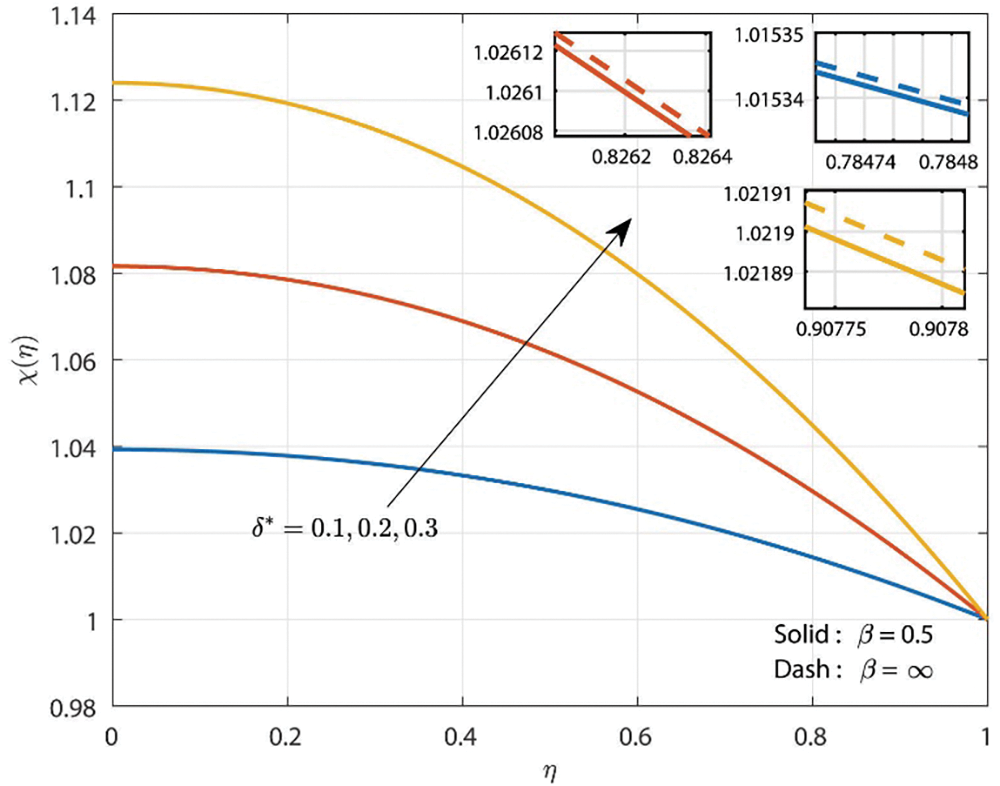

Fig. 11 illustrates the effect of

Figure 11: Effect of local pollutant external source parameter on concentration profile

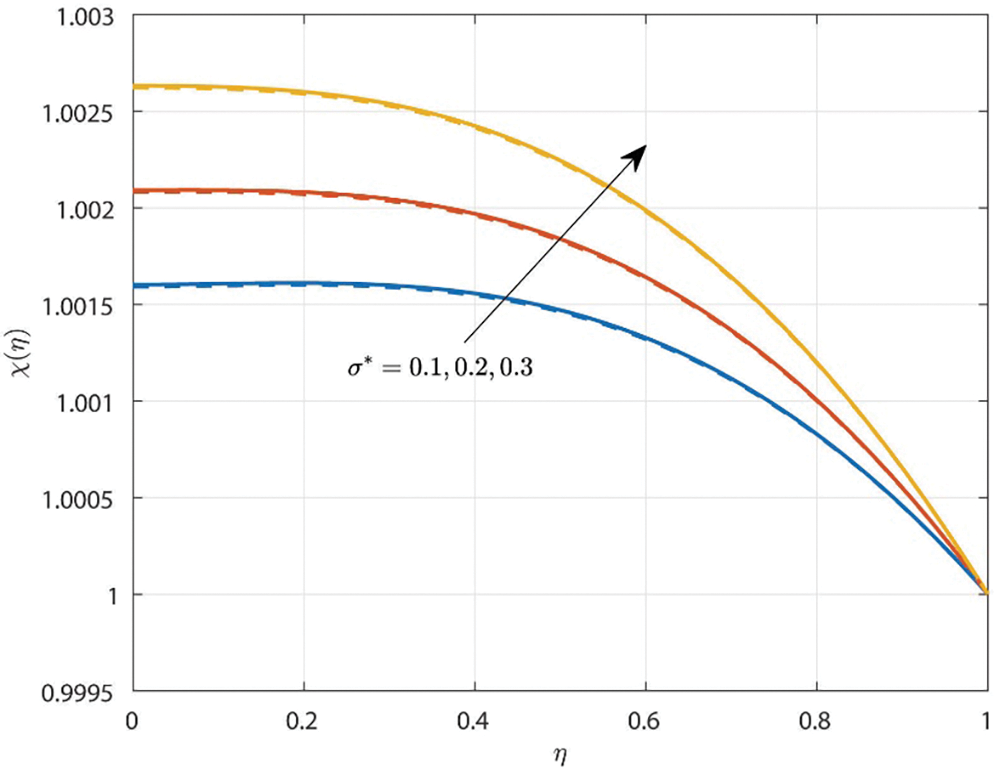

Fig. 12 illustrates how the

Figure 12: Effect of external pollutant source variation parameter on concentration profile

Fig. 13 shows the influence of

Figure 13: Effect of micropolar parameter on skin friction vs. porous parameter

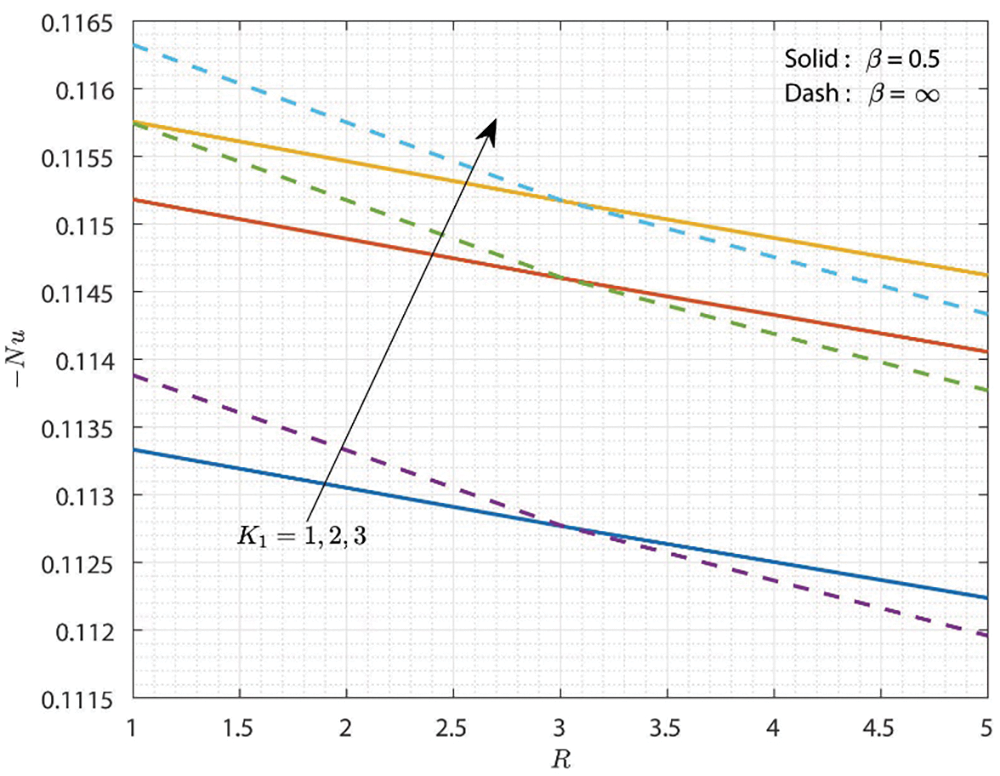

Fig. 14 shows the influence of

Figure 14: Effect of micropolar parameter on Nusselt number vs. radiation parameter

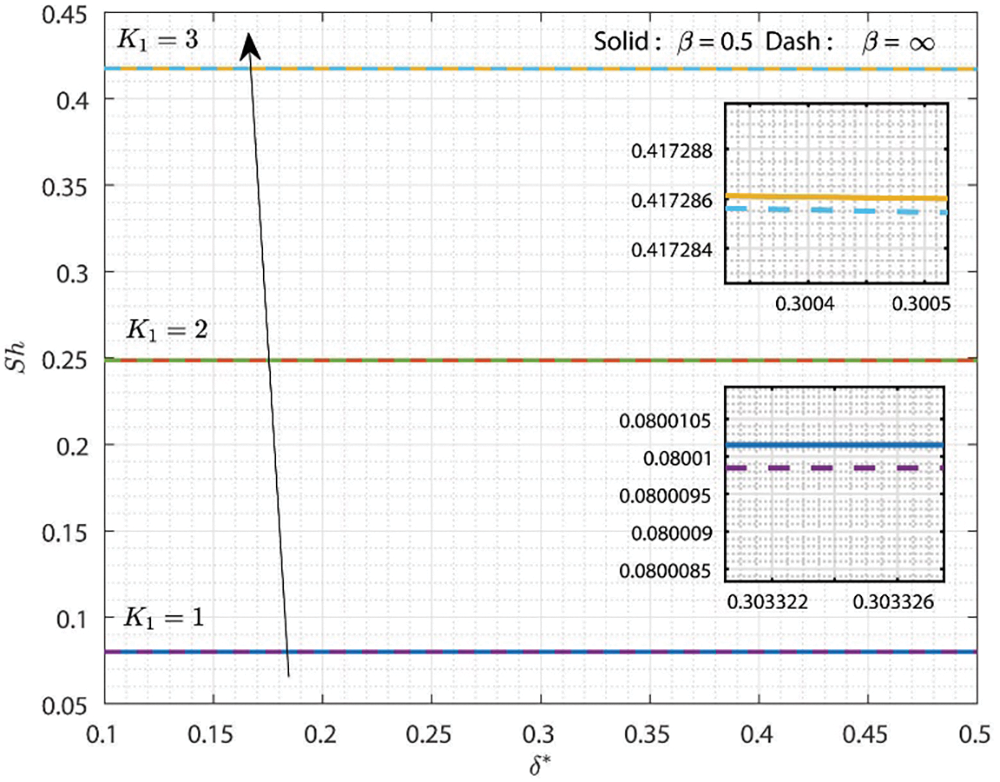

Fig. 15 shows the influence of

Figure 15: Effect of micropolar parameter on Sherwood number vs. local pollutant external source parameter

5 Application of Artificial Neural Network (ANN): Levenberg-Marquardt (LM) Backpropagation Technique

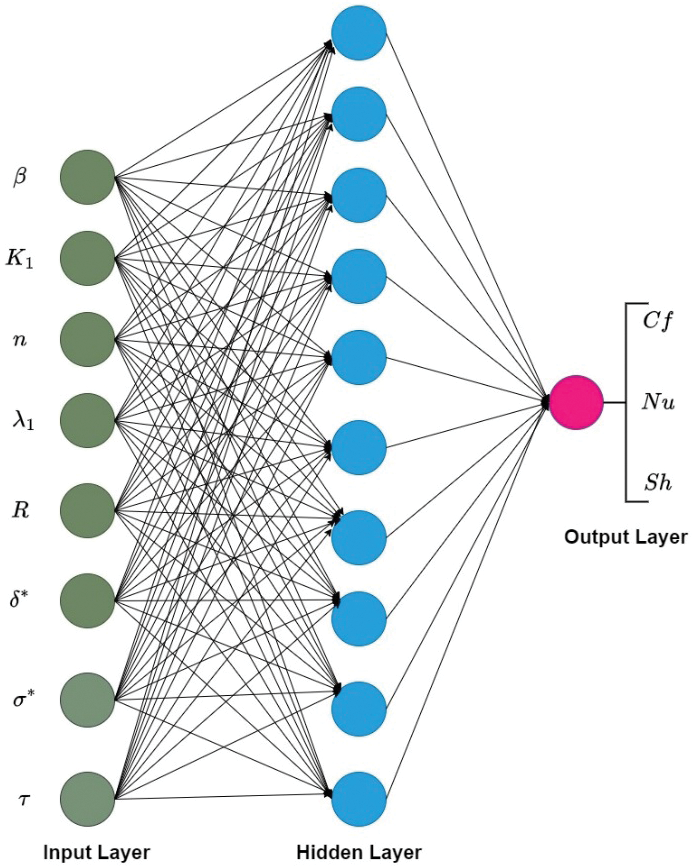

Neural networks are highly effective for simulating mathematical models and excel at predicting their outcomes. One such network is a Multi-Layer Perceptron (MLP) with Levenberg-Marquardt (LM) backpropagation. LM backpropagation technique is one of the powerful optimization methods used for solving non-linear problems. This scheme was first introduced by the mathematician Kenneth Levenberg in the year 1944. His work is mainly carried out to improve the efficiency of least-squares minimization techniques, particularly for nonlinear systems. Later it was rediscovered by the scientist Donald Marquardt in the year 1963. Marquardt first built upon Levenberg’s work in refining the algorithm to produce more efficient and stable performance. With his enhancements, the method could find a way to adaptively toggle between two optimization strategies (Gauss-Newton and gradient descent) depending on problem characteristics at every iteration. The LM backpropagation algorithm quickly gained extensive attention as it showed fast convergence and reliable results so it is widely applied to many areas of science and engineering. The architecture of MLP proposed in this work is shown in Fig. 16.

Figure 16: Geometry of the MLP-proposed model

The proposed model contains mainly three components namely, input layer, hidden layer, and output layer. The input layer is called the first layer of the ANN model, such that it acts as an entry point to the data into the neural network model. This layer forwards the data to the next layer called the hidden layer without any processing. In the input layer, the number of neurons is equivalent to the number of input (

An activation function (LeakyReLU) is applied to this weighted sum to generate the output using Eq. (31).

Then based on the difference between the generated and desired output the LM algorithm adjusts the weights and biases. This process continues till the error between the neural network-generated outputs and the desired outputs for the entire training dataset is minimal. During testing, the trained model predicts the output by using Eq. (31). The

where,

where,

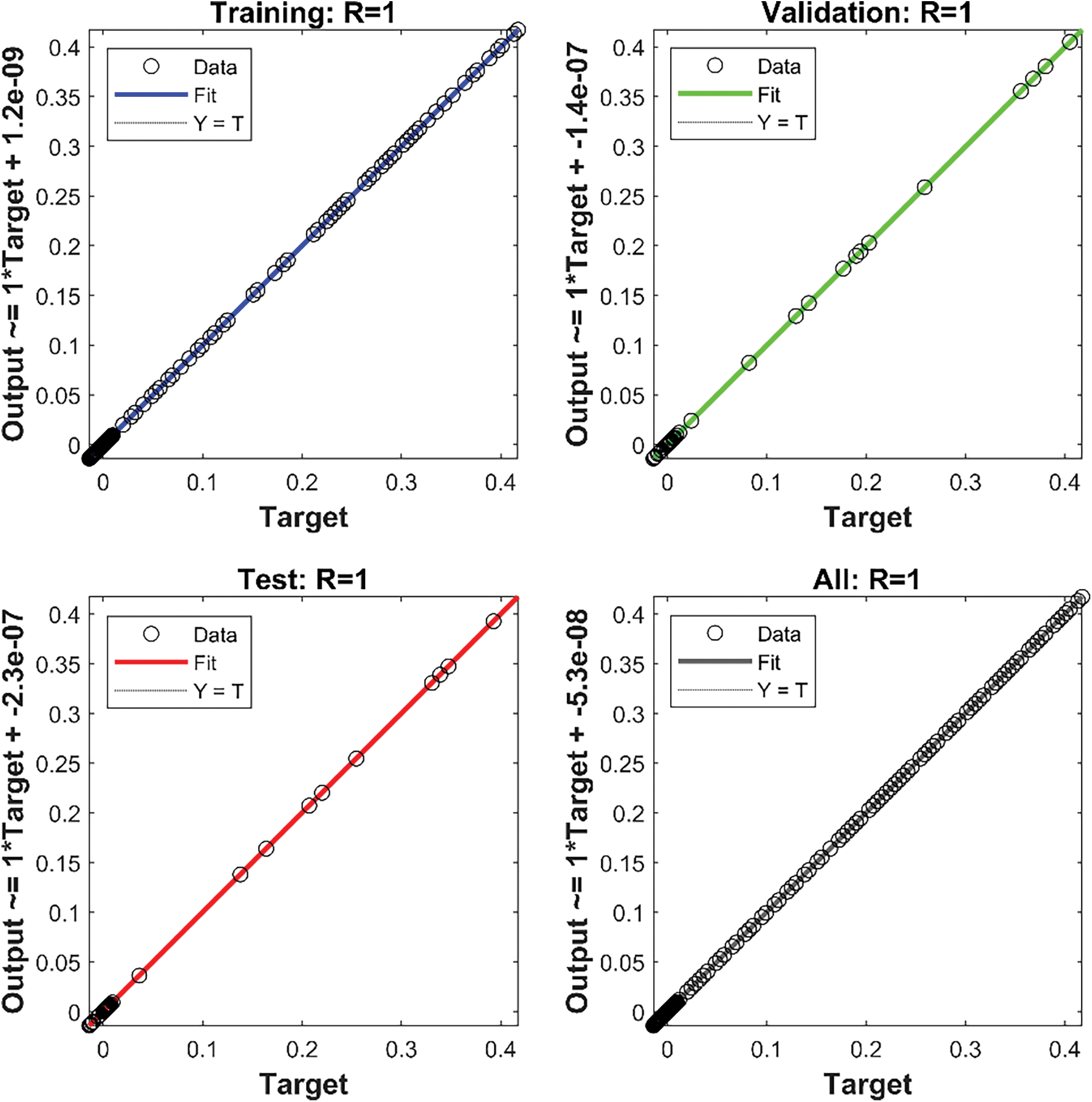

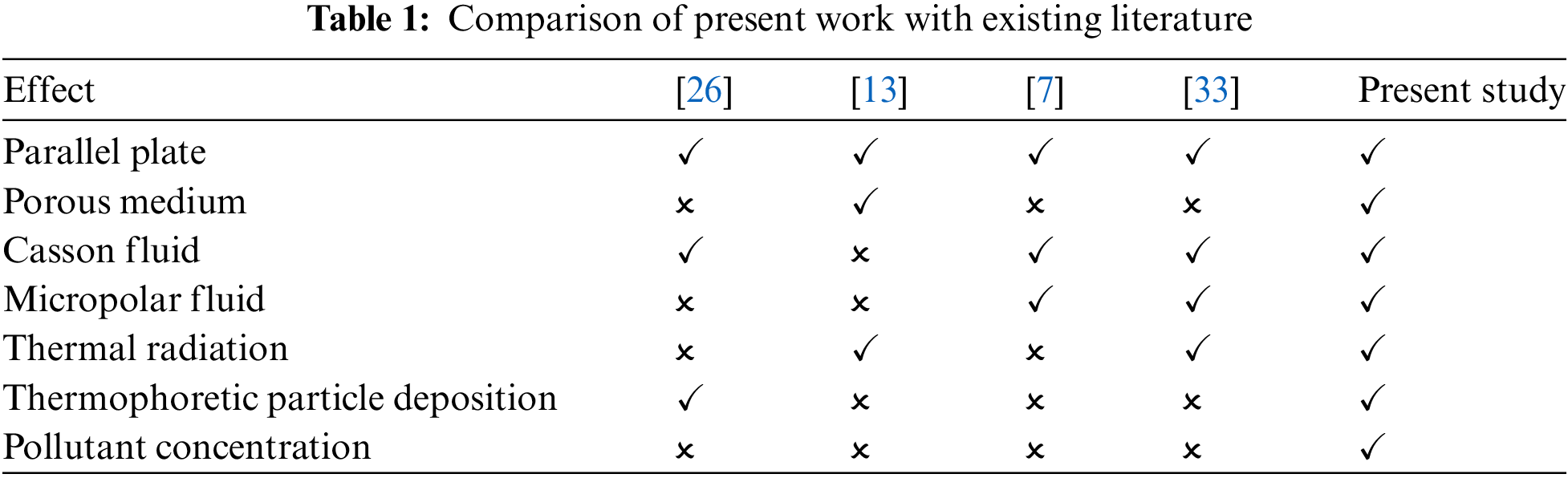

Fig. 17a shows the validation performance for the output variables

Figure 17: (a) Performance plot of ANN, (b) Error histogram

An essential tool for assessing the effectiveness of a neural network model trained with the Levenberg-Marquardt (LM) backpropagation approach is a regression chart. This metric graphically illustrates the degree of agreement between the projected outcomes of the model and the real data for training, testing, validation, and overall efficacy. A regression plot of the current analysis of the data is shown in Fig. 18. From the figure it is seen that there are four regression subplots such as training, testing, validation, and overall. In the training plot, it is seen that there is a linear relationship between the data. The training plot claims that the present model is well-fitted for the training phase. Furthermore, the validation regression plot indicates that the model has acquired specific patterns from the training data rather than generalized patterns. The testing regression plot shows an excellent correspondence between the observed and projected values in this case validates the model’s resilience and ability to generalize. Lastly, the overall regression plot facilitates the comparison of outcomes throughout the several phases of the modeling approach and guarantees uniformity.

Figure 18: Pictorial representation of regression plot for output and predicted values

The individual computational values of

The current study explores the time-dependent two-dimensional stream of Casson micropolar fluid through parallel surfaces under the effect of porous media, T-R, TPD, and waste discharge concentration. The governing equations are reduced to ODEs with the help of suitable similarity transformations. The RKF-45 and shooting procedure are utilized to solve the reduced set of equations and boundary conditions numerically. The major findings of the study are given below:

➢ The velocity declines at the lower plate and enhances at the upper plate due to an increase in the values of porous constraint while reverse behavior is seen in the case of micropolar parameter.

➢ The increase in the values of micropolar parameters will enhance microrotation, temperature, and concentration profiles.

➢ The upsurge in the values of the thermal radiation parameter will increase the temperature profile.

➢ Augmented values of thermophoretic constraint will decline the concentration while local and external pollutant sources will enhance the concentration.

➢ The improvement in micropolar and porous parameters will reduce the surface drag force.

➢ In major cases, micropolar fluid outperforms Casson-micropolar liquid.

➢ The ANN models achieve the best performance of

➢ The training, testing, validation, and overall performance are obtained by regression plots and the best fit of data is observed in all these phases.

The present study is limited to examining the stream of Casson micropolar fluid through parallel surfaces under the effect of porous media, T-R, TPD, and waste discharge concentration. The present work can be extended to examine the various kinds of non-Newtonian fluids, different kinds of nanofluid models, various types of physical constraints, and different boundary conditions.

Acknowledgement: This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU).

Funding Statement: We would like to thank the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) for paying the open access fees.

Author Contributions: The authors confirm their contribution to the paper as follows: study conception and design: Ghaliah Alhamzi, Vinutha Kalleshachar, Badr Saad T. Alkahtani; data collection: Vinutha Kalleshachar, Badr Saad T. Alkahtani; analysis and interpretation of results: Vinutha Kalleshachar, Ravi Shanker Dubey, Badr Saad T. Alkahtani; draft manuscript preparation: Vinutha Kalleshachar, Neelima Nizampatnam, Ghaliah Alhamzi. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data are available from the corresponding author on reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Ismael AM, Eldabe NT, Zeid MYA, Shabouri SME. Thermal micropolar and couple stresses effects on peristaltic flow of biviscosity nanofluid through a porous medium. Sci Rep. 2022;12(1):16180. doi:10.1038/s41598-022-20320-6. [Google Scholar] [PubMed] [CrossRef]

2. Yasir M, Bilal S, Ahammad NA, Elseesy IE. Thermal irregular generation and absorption of nanoscale energy transportation of thermodynamic material of a micropolar fluid. Ain Shams Eng J. 2024;15(9):102948. doi:10.1016/j.asej.2024.102948. [Google Scholar] [CrossRef]

3. Siddiqui AA, Turkyilmazoglu M. Slit flow and thermal analysis of micropolar fluids in a symmetric channel with dynamic and permeable. Int Commun Heat Mass Transf. 2022;132:105844. doi:10.1016/j.icheatmasstransfer.2021.105844. [Google Scholar] [CrossRef]

4. Ram MS, Spandana K, Shamshuddin MD, Salawu SO. Mixed convective heat and mass transfer in magnetized micropolar fluid flow toward stagnation point on a porous stretching sheet with heat source/sink and variable species reaction. Int J Model Simul. 2022;43(5):670–82. doi:10.1080/02286203.2022.2112008. [Google Scholar] [CrossRef]

5. Siddiqui AA, Turkyilmazoglu M. Film flow of nano-micropolar fluid with dissipation effect. Comput Model Eng Sci. 2024;140(3):2488–9. doi:10.32604/cmes.2024.050525. [Google Scholar] [CrossRef]

6. Li P, Duraihem FZ, Awan AU, Al-Zubaidi A, Abbas N, Ahmad D. Heat transfer of hybrid nanomaterials base maxwell micropolar fluid flow over an exponentially stretching surface. Nanomaterials. 2022;12(7):1207. doi:10.3390/nano12071207. [Google Scholar] [PubMed] [CrossRef]

7. Shamshuddin MD, Ibrahim W. Finite element numerical technique for magneto-micropolar nanofluid flow filled with chemically reactive casson fluid between parallel plates subjected to rotatory system with electrical and Hall currents. Int J Model Simul. 2022;42(6):985–1004. doi:10.1080/02286203.2021.2012634. [Google Scholar] [CrossRef]

8. Shamshuddin MD, Mabood F, Khan WA, Rajput GR. Exploration of thermal Péclet number, vortex viscosity, and Reynolds number on two-dimensional flow of micropolar fluid through a channel due to mixed convection. Heat Transfer. 2022;52(1):854–73. doi:10.1002/htj.22719. [Google Scholar] [CrossRef]

9. Yasir M, Khan M, Al-Zubaidi A, Saleem S. Arrhenius activation energy effect in thermally viscous dissipative flow of micropolar material with gyrotactic microorganisms. Alex Eng J. 2023;84:204–14. doi:10.1016/j.aej.2023.11.003. [Google Scholar] [CrossRef]

10. Muntazir RM, Mushtaq M, Shahzadi S, Jabeen K. MHD nanofluid flow around a permeable stretching sheet with thermal radiation and viscous dissipation. Proc Inst Mech Eng C J Mech Eng Sci. 2021;236(1):137–52. doi:10.1177/09544062211023094. [Google Scholar] [CrossRef]

11. Salawu SO, Obalalu AM, Fatunmbi EO, Shamshuddin M. Elastic deformation of thermal radiative and convective hybrid SWCNT-Ag and MWCNT-MoS4 magneto-nanofluids flow in a cylinder. Results Mater. 2023;17:100380. doi:10.1016/j.rinma.2023.100380. [Google Scholar] [CrossRef]

12. Famakinwa OA, Koriko OK, Adegbie KS, Omowaye AJ. Effects of viscous variation, thermal radiation, and Arrhenius reaction: the case of MHD nanofluid flow containing gyrotactic microorganisms over a convectively heated surface. Partial Differ Equ Appl Math. 2021;5:100232. doi:10.26565/2312-4334-2023-4-10. [Google Scholar] [CrossRef]

13. Mohamed Y, Eldabe N, Abouzeid M, Mostapha D, Ouaf M. Chemical reaction and thermal radiation via Cattaneo-Christov double diffusion (CCDD) effects on squeezing non-Newtonian nanofluid flow between two-parallel vertical plates. Egypt J Chem. 2022;26(3):209–31. doi:10.21608/ejchem.2022.145286.6332. [Google Scholar] [CrossRef]

14. Fatunmbi EO, Okoya SS. Nonlinear radiative thermal analysis of magneto-micropolar fluid over a bidirectionally extending sheet with varied thermal conditions. Case Stud Therm Eng. 2024:104712. doi:10.1016/j.csite.2024.104712. [Google Scholar] [CrossRef]

15. Zhang K, Shah NA, Alshehri M, Alkarni S, Wakif A, Eldin SM. Water thermal enhancement in a porous medium via a suspension of hybrid nanoparticles: MHD mixed convective Falkner’s-Skan flow case study. Case Stud Therm Eng. 2023;47:103062. doi:10.1016/j.csite.2023.103062. [Google Scholar] [CrossRef]

16. Zheng K, Shah SI, Khan MN, Tag-Eldin E, Yasir M, Galal AM. Numerical simulation of melting heat transfer towards stagnation point region over a permeable shrinking surface. Sci Iran. 2022. doi:10.24200/sci.2022.59956.6518. [Google Scholar] [CrossRef]

17. Hiremath P, Hanumagowda BN, Subray PVA, Sharma N, Varma SVK, Muhammad T, et al. Sensitivity analysis of MHD nanofluid flow in a composite permeable square enclosure with the corrugated wall using response surface methodology-central composite design. Numer Heat Transf A Appl. 2024:1–18. doi:10.1080/10407782.2024.2350029. [Google Scholar] [CrossRef]

18. Rahman M, Waheed H, Turkyilmazoglu M, Siddiqui MS. Darcy-Brinkman porous medium for dusty fluid flow with steady boundary layer flow in the presence of slip effect. Int J Mod Phys B. 2023;38(11). doi:10.1142/S0217979224501522. [Google Scholar] [CrossRef]

19. Shamshuddin MD, Ram MS, Ashok N, Salawu SO. Exploring thermal and solutal features in stagnation point flow of Casson fluid over an exponentially radiative and reactive vertical sheet. Numer Heat Transf B Fundam. 2024:1–16. doi:10.1080/10407790.2024.2355561. [Google Scholar] [CrossRef]

20. Ram MS, Shamshuddin MD, Srinitha B, Salawu SO. Numerical treatment of cross-diffusion impact on heat and mass transfer with magnetic radiation of micropolar fluid flow over a porous stretching surface. Mod Phys Lett B. 2024;38(31):2450289. doi:10.1142/S0217984924502890. [Google Scholar] [CrossRef]

21. Rahman M, Waheed H, Turkyilmazoglu M, Siddiqui MS. Unsteady fluid flow in a Darcy-Brinkman Porous medium with slip effect and porous dissipation. Int J Mod Phys B. 2023;38(9). doi:10.1142/S0217979224501236. [Google Scholar] [CrossRef]

22. Abbas. Significance of heat generation and thermophoretic particle deposition in marangoni convective driven boundary layer flow of cross nanofluid with activation energy. Case Stud Therm Eng. 2024:104427. doi:10.1016/j.csite.2024.104427. [Google Scholar] [CrossRef]

23. Yasir M, Khan M, Malik ZU. Analysis of thermophoretic particle deposition with Soret-Dufour in a flow of fluid exhibit relaxation/retardation times effect. Int Commun Heat Mass Transf. 2022;141:106577. doi:10.1016/j.icheatmasstransfer.2022.106577. [Google Scholar] [CrossRef]

24. Rauf A, Shah NA, Mushtaq A, Botmart T. Heat transport and magnetohydrodynamic hybrid micropolar ferrofluid flow over a non-linearly stretching sheet. AIMS Math. 2022;8(1):164–93. doi:10.3934/math.2023008. [Google Scholar] [CrossRef]

25. Srilatha P, Abu-Zinadah H, Kumar RSV, Alsulami MD, Kumar RN, Abdulrahman A, et al. Effect of nanoparticle diameter in maxwell nanofluid flow with thermophoretic particle deposition. Mathematics. 2023;11(16):3501. doi:10.3390/math11163501. [Google Scholar] [CrossRef]

26. Jyothi AM, Kumar RSV, Madhukesh JK, Prasannakumara BC, Ramesh GK. Squeezing flow of Casson hybrid nanofluid between parallel plates with a heat source or sink and thermophoretic particle deposition. Heat Transfer. 2021;50(7):7139–56. doi:10.1002/htj.22221. [Google Scholar] [CrossRef]

27. Xin X, Ganie AH, Alwuthaynani M, Bonyah E, Khalifa HAEW, Fathima D, et al. Parametric analysis of pollutant discharge concentration in non-Newtonian nanofluid flow across a permeable Riga sheet with thermal radiation. AIP Adv. 2024;14(4). doi:10.1063/5.0200401. [Google Scholar] [CrossRef]

28. Albalawi KS, Karthik K, Bin-Asfour M, Alkahtani BST, Madhu J, Alazman I, et al. Impact of waste discharge concentration on fluid flow in inner stretched and outer stationary co-axial cylinders. Appl Therm Eng. 2024;244:122757. doi:10.1016/j.applthermaleng.2024.122757. [Google Scholar] [CrossRef]

29. Jagadeesh M, Kalachar K, Shashikala VKR, Jayadevamurthy PGR, Rangaswamy NK, Ballajja CP. Dynamics of pollutant dispersion and solid-fluid interfacial layer in Jeffrey nanofluid flow subjected to waste discharge concentration: implementation of probabilists’ Hermite polynomial collocation method. Numer Heat Transf Part Appl. 2024:1–19. doi:10.1080/10407782.2024.2319349. [Google Scholar] [CrossRef]

30. Kalleshachar V, Sunitha M, Madhukesh JK, Khan U, Zaib A, Sherif ESM, et al. Computational examination of heat and mass transfer induced by ternary nanofluid flow across convergent/divergent channels with pollutant concentration. Water. 2023;15(16):2955. doi:10.3390/w15162955. [Google Scholar] [CrossRef]

31. Chinyoka T, Makinde OD. Analysis of nonlinear dispersion of a pollutant ejected by an external source into a channel flow. Math Probl Eng. 2010;2010(1):446. doi:10.1155/2010/827363. [Google Scholar] [CrossRef]

32. Ouyang Y, Basir MFM, Naganthran K, Pop I. Effects of discharge concentration and convective boundary conditions on unsteady hybrid nanofluid flow in a porous medium. Case Stud Therm Eng. 2024;58:104374. doi:10.1016/j.csite.2024.104374. [Google Scholar] [CrossRef]

33. Shah Z, Islam S, Ayaz H, Khan S. Radiative heat and mass transfer analysis of micropolar nanofluid flow of casson fluid between two rotating parallel plates with effects of hall current. J Heat Transf. 2018;141(2):205. doi:10.1115/1.4040415. [Google Scholar] [CrossRef]

34. El-Aziz MA, Afify AA. Influences of slip velocity and induced magnetic field on MHD stagnation-point flow and heat transfer of casson fluid over a stretching sheet. Math Probl Eng. 2018;2018:1–11. doi:10.1155/2018/9402836. [Google Scholar] [CrossRef]

35. Hussain T, Xu H. Time-dependent squeezing bio-thermal MHD convection flow of a micropolar nanofluid between two parallel disks with multiple slip effects. Case Stud Therm Eng. 2022;31:101850. doi:10.1016/j.csite.2022.101850. [Google Scholar] [CrossRef]

36. Jusoh R, Nazar R. Effect of heat generation on mixed convection of micropolar Casson fluid over a stretching/shrinking sheet with suction. J Phys Conf Ser. 2019;1212:012024. doi:10.1088/1742-6596/1212/1/012024/meta. [Google Scholar] [CrossRef]

37. Turkyilmazoglu M. Unsteady flow over a decelerating rotating sphere. Phys Fluids. 2018;30(3):1308. doi:10.1063/1.5021485. [Google Scholar] [CrossRef]

38. Turkyilmazoglu M. Evidence of stretching/moving sheet-triggered nonlinear similarity flows: atomization and electrospinning with/without air resistance. Int J Numer Methods Heat Amp Fluid Flow. 2024;34:3598–614. doi:10.1108/HFF-04-2024-0254/full/html. [Google Scholar] [CrossRef]

39. Naduvinamani NB, Shankar U. Radiative squeezing flow of unsteady magneto-hydrodynamic Casson fluid between two parallel plates. J Central South Univ. 2019;26(5):1184–204. doi:10.1007/s11771-019-4080-0. [Google Scholar] [CrossRef]

40. Khan U, Zaib A, Ishak A, Waini I, Raizah Z, Boonsatit N, et al. Significance of thermophoretic particle deposition, arrhenius activation energy and chemical reaction on the dynamics of wall jet nanofluid flow subject to Lorentz forces. Lubricants. 2022;10(10):228. doi:10.3390/lubricants10100228. [Google Scholar] [CrossRef]

41. Kumar MS, Sandeep N, Kumar BR. Effect of nonlinear thermal radiation on unsteady MHD flow between parallel plates. Glob J Pure Appl Math. 2016;12:60–5. [Google Scholar]

42. Guedri K, Mahmood Z, Fadhl BM, Makhdoum BM, Eldin SM, Khan U. Mathematical analysis of nonlinear thermal radiation and nanoparticle aggregation on unsteady MHD flow of micropolar nanofluid over shrinking sheet. Heliyon. 2023;9(3):e14248. doi:10.1016/j.heliyon.2023.e14248. [Google Scholar] [PubMed] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools