Open Access

Open Access

ARTICLE

Rock Mass Quality Rating Based on the Multi-Criteria Grey Metric Space

1 Faculty of Mining and Geology, University of Belgrade, Belgrade, 11000, Serbia

2 Faculty of Technical Sciences, University of Priština, Kosovska Mitrovica, 38220, Serbia

3 Department of Operations Research and Statistics, Faculty of Organizational Sciences, University of Belgrade, Belgrade, 11000, Serbia

4 College of Engineering, Yuan Ze University, Taoyuan City, 320315, Taiwan

* Corresponding Author: Miloš Gligorić. Email:

(This article belongs to the Special Issue: Meta-heuristic Algorithms in Materials Science and Engineering)

Computer Modeling in Engineering & Sciences 2024, 140(3), 2635-2664. https://doi.org/10.32604/cmes.2024.050898

Received 21 February 2024; Accepted 16 April 2024; Issue published 08 July 2024

Abstract

Assessment of rock mass quality significantly impacts the design and construction of underground and open-pit mines from the point of stability and economy. This study develops the novel Gromov-Hausdorff distance for rock quality (GHDQR) methodology for rock mass quality rating based on multi-criteria grey metric space. It usually presents the quality of surrounding rock by classes (metric spaces) with specified properties and adequate interval-grey numbers. Measuring the distance between surrounding rock sample characteristics and existing classes represents the core of this study. The Gromov-Hausdorff distance is an especially useful discriminant function, i.e., a classifier to calculate these distances, and assess the quality of the surrounding rock. The efficiency of the developed methodology is analyzed using the Mean Absolute Percentage Error (MAPE) technique. Seven existing methods, such as the Gaussian cloud method, Discriminant method, Mutation series method, Artificial neural network (ANN), Support vector machine (SVM), Grey wolf optimizer and Support vector classification method (GWO-SVC) and Rock mass rating method (RMR) are used for comparison with the proposed GHDQR method. The share of the highly accurate category of 85.71% clearly indicates compliance with actual values obtained by the compared methods. The results of comparisons showed that the model enables objective, efficient, and reliable assessment of rock mass quality.Keywords

Nomenclature

| GHDQR | Gromov-Hausdorff Distance for Rock Quality |

| RQD | Rock Quality Index |

| GCM | Gaussian Cloud Model |

| ANN | Artificial Neural Network |

| SVM | Support Vector Machine |

| GWO–SVC | Grey Wolf Optimizer and Support Vector Classification method |

| RMR | Rock Mass Rating method |

| MAPE | Mean Absolute Percentage Error |

Underground and open-pit mines are complex undertakings, mainly underground mines, for stability and economy. In addition to mining, many engineering projects are closely related to rock stability, such as tunneling, hydropower engineering, traffic engineering, and others. For all these endeavors, the stability assessment of surrounding rock is vital in designing and constructing such engineering objects.

The significance of the assessment of rock mass quality is supported by the fact that there are different approaches to solving this problem. Many scholars implemented various methods and approaches for rock mass classification and rock mass analysis, such as fuzzy sets theory [1–4], fuzzy RMR method [5,6], RMR method [7], Gaussian cloud model [8], modified RMR method [9], fuzzy inference system [10,11], multi-criteria decision–making (MCDM) methods [12–15], Least squares support vector machine [16], Support vector machine [17], Deep learning approach [18,19], Artificial neural networks [20], Deep neural network [21], Support vector regression [22], Stacking ensemble learning [23], Convolutional neural networks [24,25], Machine learning [26], Cloud model [27], Discrete element method [28] and others. Also, several authors analyzed and investigated rock fracture and crack conditions that highly influenced rock mass classification [29–32].

A comprehensive literature review indicated that no studies have investigated the Hausdorff distance for rock mass classification. In addition, the integrated Gromov-Hausdorff distance was applied as a discriminant function (classifier) of rock mass quality. Accordingly, the GHDQR method seeks to fill a gap in the literature review by representing an authentic, innovative, and efficient mechanism for rock mass quality optimization.

The innovative aspects and significance of this study can be summarized as follows:

a) A new methodology for rock mass classification based on the Gromov-Hausdorf distance is presented.

b) The GHDQR method is developed under the MCDM and interval environment.

c) This method offers a relatively simple and easy procedure for calculating the rock mass quality.

d) A computational process is minimally time-consuming,

e) The GHDQR method is more stable and effective than other rock mass classification approaches.

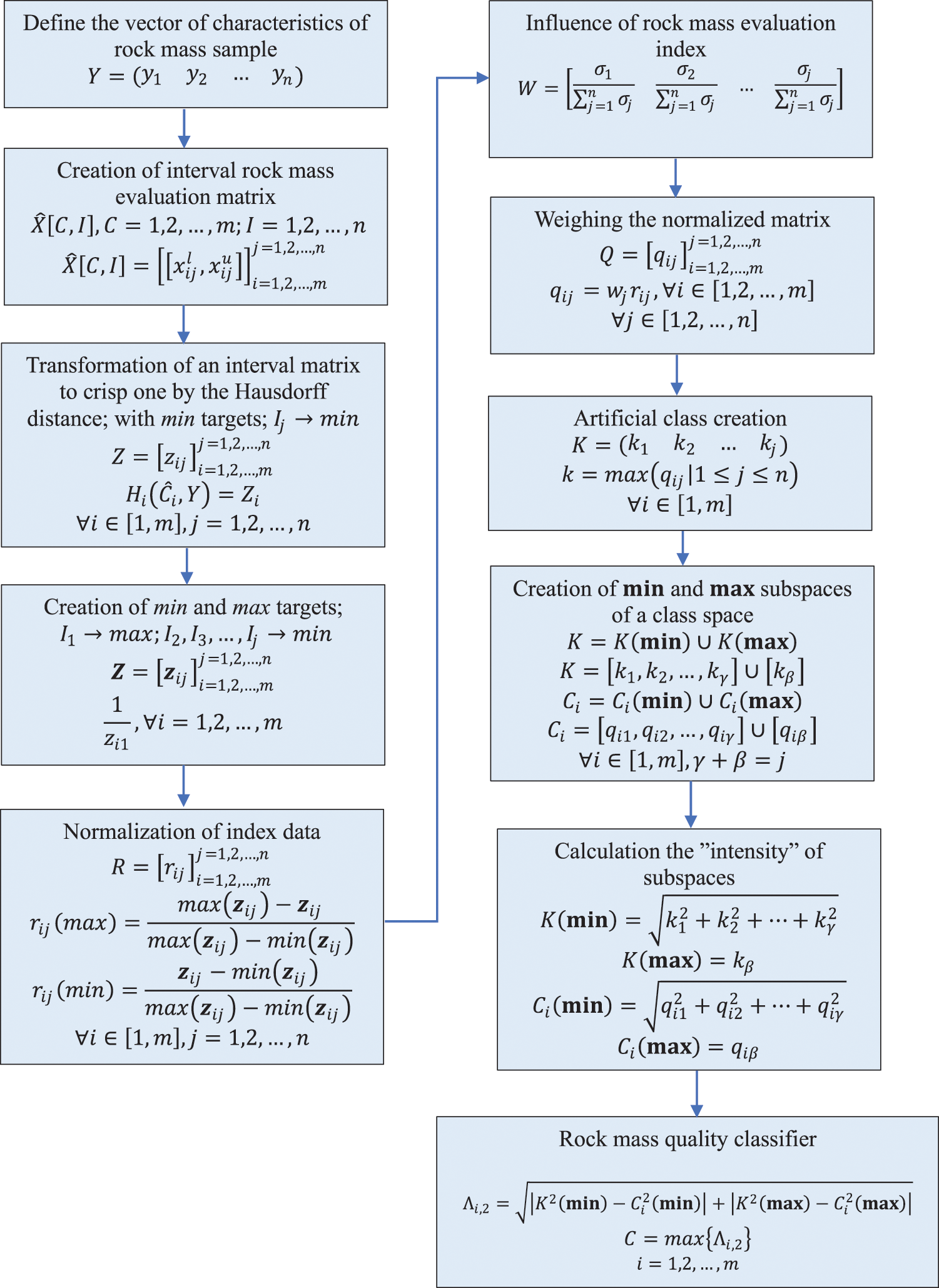

This study proposes a methodology based on the discriminant function with uncertainty. Firstly, the algorithm transforms interval values of selected evaluation indices into crisp values by calculating the Hausdorff distance between rock samples and indices. This indicates the capability of treating the data uncertainties, where the interval numbers quantify uncertainties. The normalization of data creates a nondimensional environment. The developed methodology includes the influence (weight) of each evaluation index. Weights are defined by the Standard deviation method. Weighted-normalized data are further processed. The algorithm creates an artificial class of rock mass and partitions each space of real and artificial class into min and max subspaces. For min and max subspaces separately, the Gromov-Hausdorff function on metric spaces defines the distance between each real and artificial class. Finally, the algorithm calculates the aggregated intensities of distances of min and max subspaces for each real class and sorts them in descending order. The maximum value of aggregated intensity defines the class of the rock mass sample. The method’s efficiency is validated by comparing it to seven existing methods. The results showed that the model enables objective, efficient, and reliable assessment of rock mass quality.

The structure of this study is as follows. Section 1 presents the background of the conducted research. Section 2 indicates the developed methodology in detail. Section 3 contains comparisons of the GHDQR method to seven existing methods, sensitivity analysis, and a discussion of the results for efficiency estimation of the developed model. Section 4 provides conclusions and further direction of research.

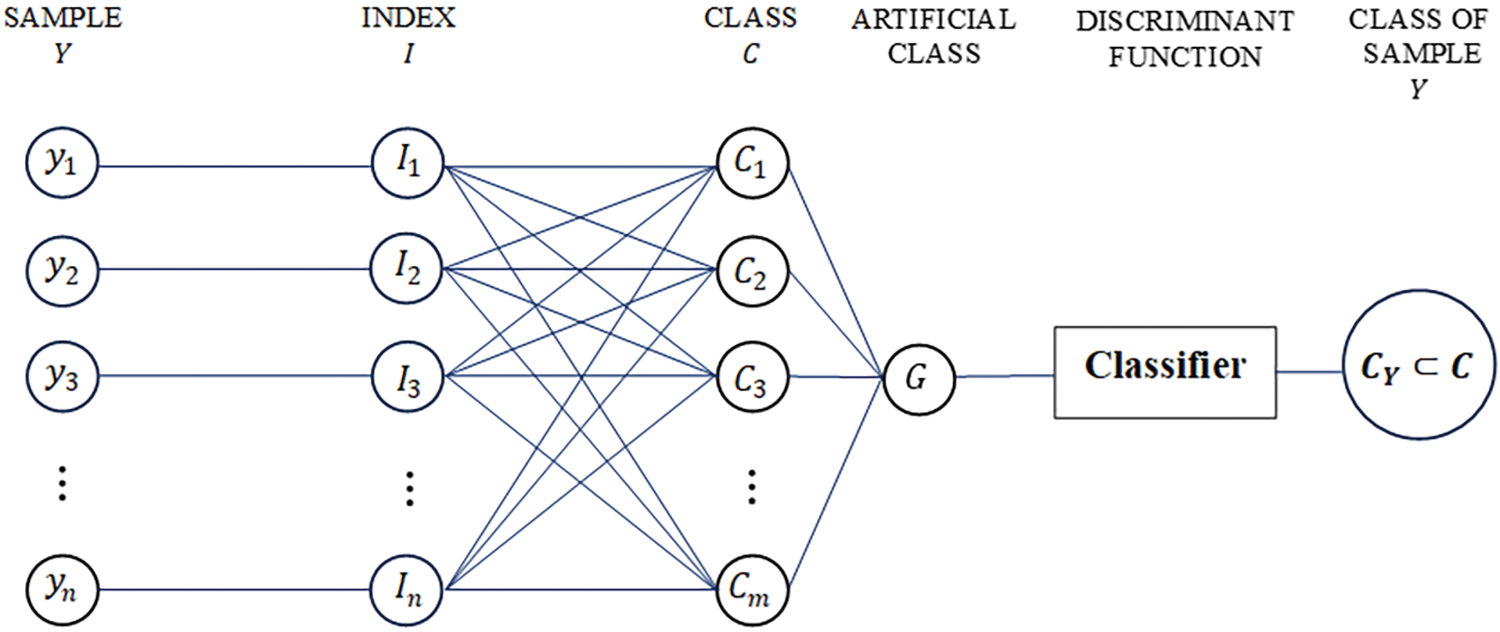

This study uses the Gromov-Hausdorff distance to match rock samples and a defined set of classes for a finite set of evaluation indexes. Samples and classes present the metric spaces, and the algorithm calculates the matching intensity between them. The calculated intensity between the rock sample and each class presents a discriminant value employed to determine the class to which the sample belongs. The developed classifier selects the maximum intensity value and assigns the class to the rock sample. Experts can define a finite set of evaluation indices based on available information about the rock sampled and form the evaluation matrix. In the following part, the mathematical formulation of the developed methodology is presented in twelve successive steps.

Step 1: Define the vector of characteristics of the rock mass sample.

The rock sample is obtained by core-drilling operations, and it is characterized by the following vector

where:

Each element of the vector

Step 2: Creation of interval rock mass evaluation matrix.

The interval rock mass evaluation matrix is created according to the information obtained from different tests that were conducted on the rock mass sample, and the characteristics are presented by the vector

The stability of the surrounding rock is defined by classes, where each class signifies a closed region that contains a description of the rock. Each class property is influenced by the finite set of rock mass evaluation indices, which form a closed region. Accordingly, it is more appropriate to consider indices as interval numbers when determining the class of surrounding rock. Hence, the index is treated as an interval number.

Definition 1: The number

The relationship between classes and rock mass evaluation indexes can be presented in the following interval matrix form:

where elements of the matrix are as follows:

Analyzing the matrix

Step 3: Transformation of an interval matrix to crisp one.

The crisp rock mass evaluation matrix is obtained by calculating the Hausdorff distance between each element of the i-th class vector and each vector

Definition 2: Let

where:

where:

The function

Let

The Hausdorff distance between each element of the i-th class vector and each element of the vector

where

The calculation’s outcome of the Hausdorf distance is the following matrix with crisp elements:

Step 4: Creation of min and max targets.

Since all desired values are uniformly distributed, i.e., all indices tend to get

Step 5: Normalization of index data.

Because the dimensions of the index values are not consistent, the data in the matrix

For

For

The output of normalization is a normalized matrix of the following form:

Step 6: Influence of rock mass evaluation index.

The standard deviation method is employed to determine the influence of the rock mass evaluation index on the classification process. This method belongs to the group of objective methods, and it excludes the subjectivity of the experts. The following equation is utilized to determine the influence of the index:

where

The influence of the index can be called the index’s weight by applying decision-making terminology.

Step 7: Weighing the normalized matrix.

Each element of a matrix

Element

Step 8: Artificial class creation.

In this step, an artificial class is created, composed of the max values of each class index. Elements of an artificial class are as follows:

where:

The artificial class creation process presents the creation of an optimal class space of Hausdorff distances based on extracting the best value from the existing distance values for each index’s desired target.

Step 9: Creation of

This step implies dividing an artificial class space into two subspaces. An artificial class space is the union of

Let

Step 10: Creation of

Each class in the original matrix

Step 11: Calculation the “intensity” of subspaces.

Intensities of min and max subspaces of an artificial class are calculated as follows:

The same approach is applied for the min and max subspaces of each class:

Step 12: Rock mass quality classifier.

A classifier was developed based on the Gromov-Hausdorff distance between two metric spaces to assess to which class a rock mass sample belongs. For basic properties of the Gromov-Hausdorff distance, see [35–37].

Let

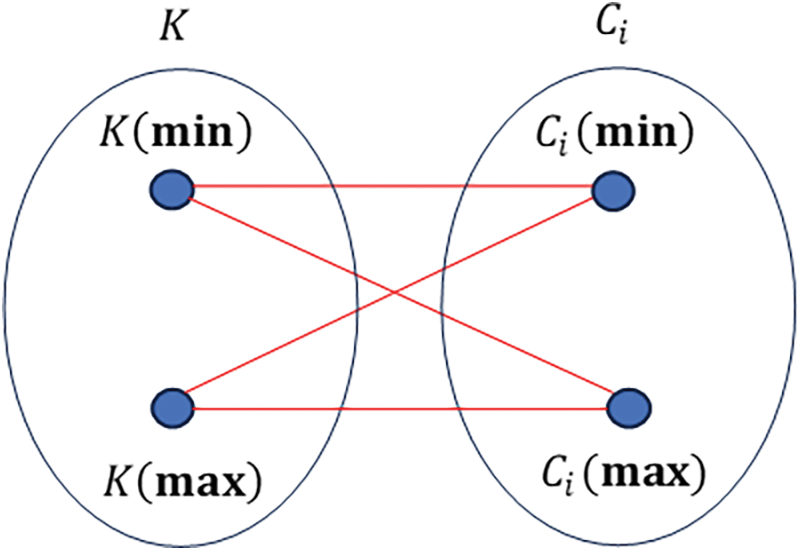

The main idea of the rock mass quality classifier is to use the Gromov-Hausdorff distance between an artificial class space and i-th class space to find out the class of the rock sample. Based on the decomposition process, there are two spaces,

Figure 1: Relations between an artificial class space and i-th class space

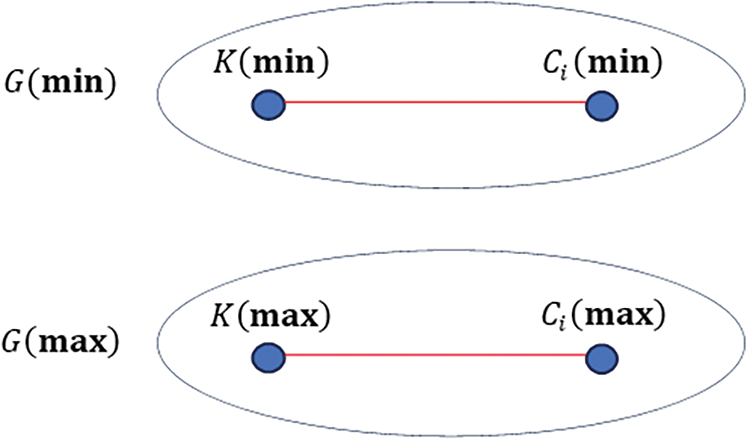

No crossing edges are allowed in the graph. It implies the existence of only one-to-one relationships between

Figure 2: Disjoint subgraphs of an original graph

Let

Analogically, this study defines absolute

For rock mass quality assessment, the value of

Finally, the discriminant function (classifier) is defined as follows:

A class with the highest value of

The methodology for determining the rock mass class of surrounding rock is shown in the following graphical way (Fig. 3).

Figure 3: Graphical presentation of the rock mass quality assessment

The developed algorithm for the same purpose is depicted in Fig. 4.

Figure 4: Flowchart for the rock mass quality assessment based on the Gromov-Hausdorff distance

This section uses three numerical examples from different studies to validate the developed method. Classes obtained by the GHDQR method are compared to classes obtained by other methods.

The underground engineering of the Guangzhou Pumped Storage Power Station is considered an engineering example to evaluate the efficiency of the developed methodology. The stability of the surrounding rock is affected by many parameters. In this comparison, the research applies the following parameters, i.e., rock mass evaluation indices [8]:

a) the rock quality index

b) uniaxial saturated compressive strength

c) integrity coefficient

d) structural plane strength coefficient

e) groundwater seepage quantity

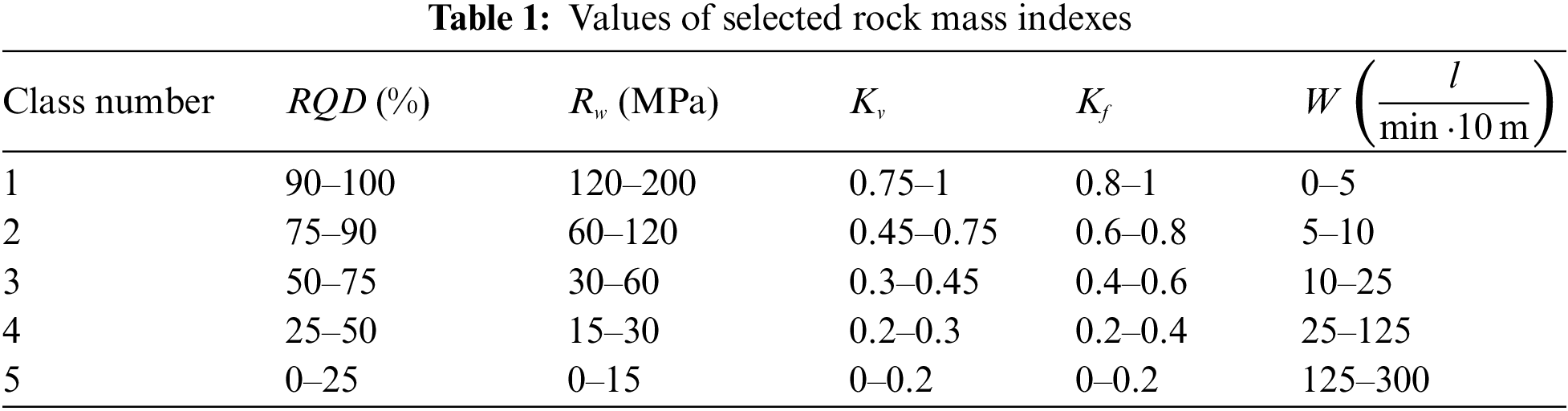

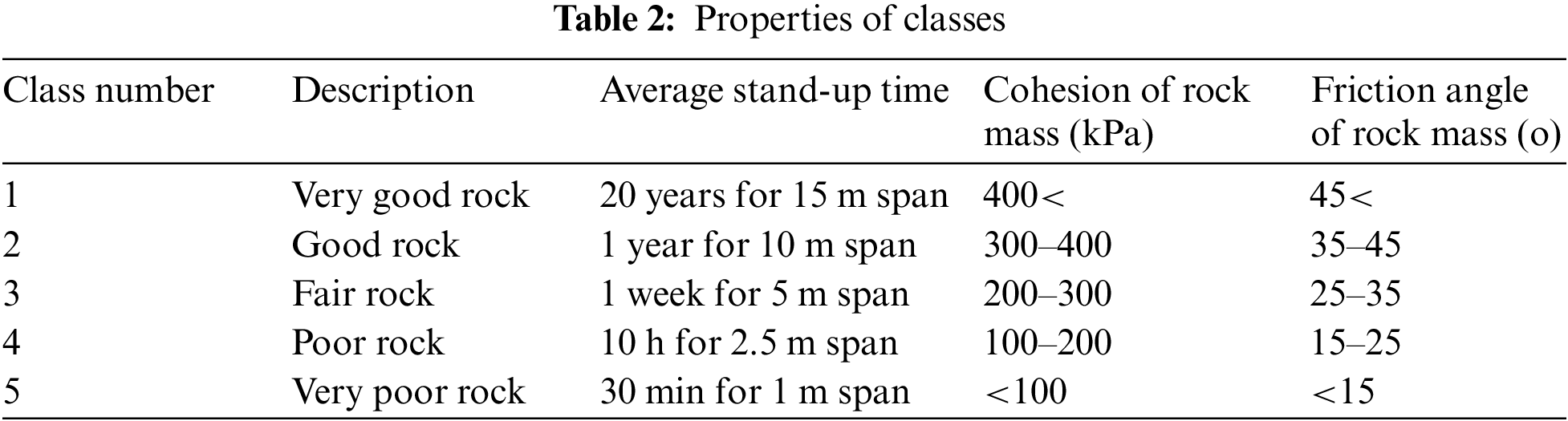

The stability of surrounding rock is divided into the following five classes based on the previously selected rock mass evaluation indices (Table 1) [8].

The properties of each class are presented in Table 2 [38].

Interval matrix

Sample vector, with values of

For the

Analogically, the following matrix

Since all indexes

Values of the elements

Values of the remaining indices for classes hold the same values as in the matrix

For

Accordingly, the normalized matrix

The influence (weight) of each index is calculated using the standard deviation method. The vector of the standard deviation is as follows:

Weights

Analogically, the weights of indices

Weighted normalized element

In the same way, the rest of the weighted normalized elements are calculated, and the outcome of the calculation is presented by matrix

The artificial value of index

The artificial class space is yielded by applying the same equation to the rest of the indices as follows:

It is necessary to define elements of these subspaces while respecting the prerequisite of existing min and max subspaces of each class space. Artificial class space

Class space

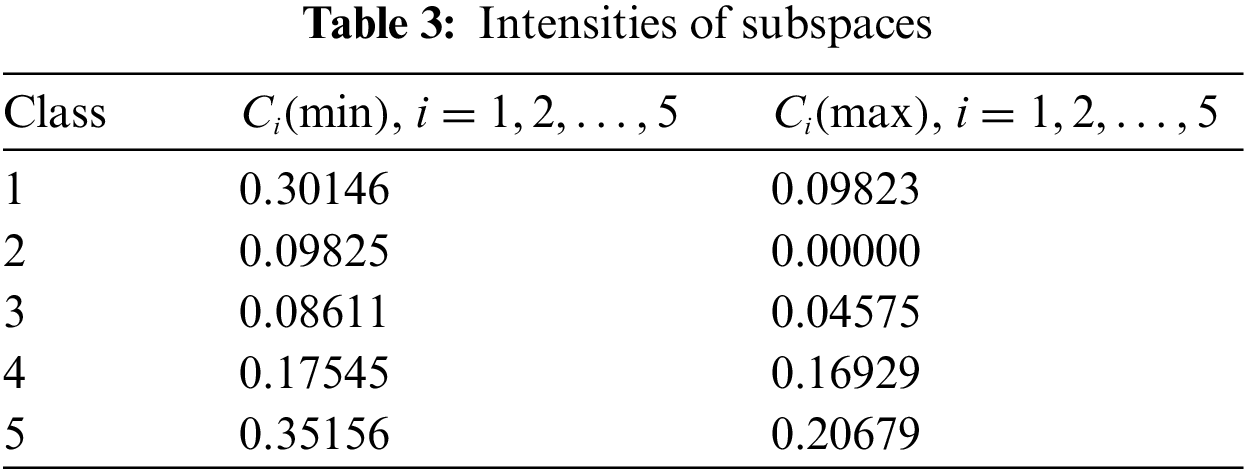

Following the calculation of the intensity of subspaces

Intensities of

The same way is applied to get subspaces of classes

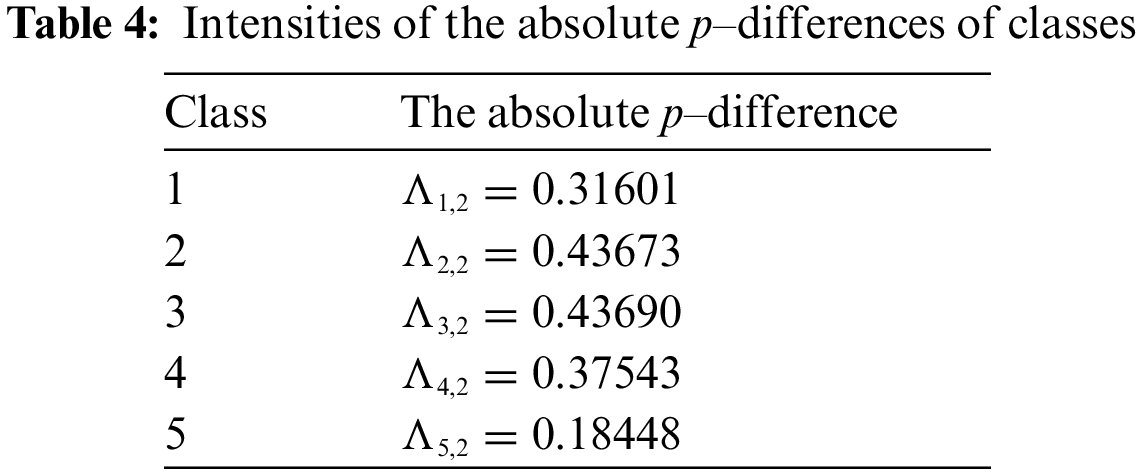

The absolute

The absolute

The intensity of the integrated absolute

Intensities of the absolute

The value of the discriminant function (classifier) of the rock sample is determined using Eq. (30) as follows:

Since

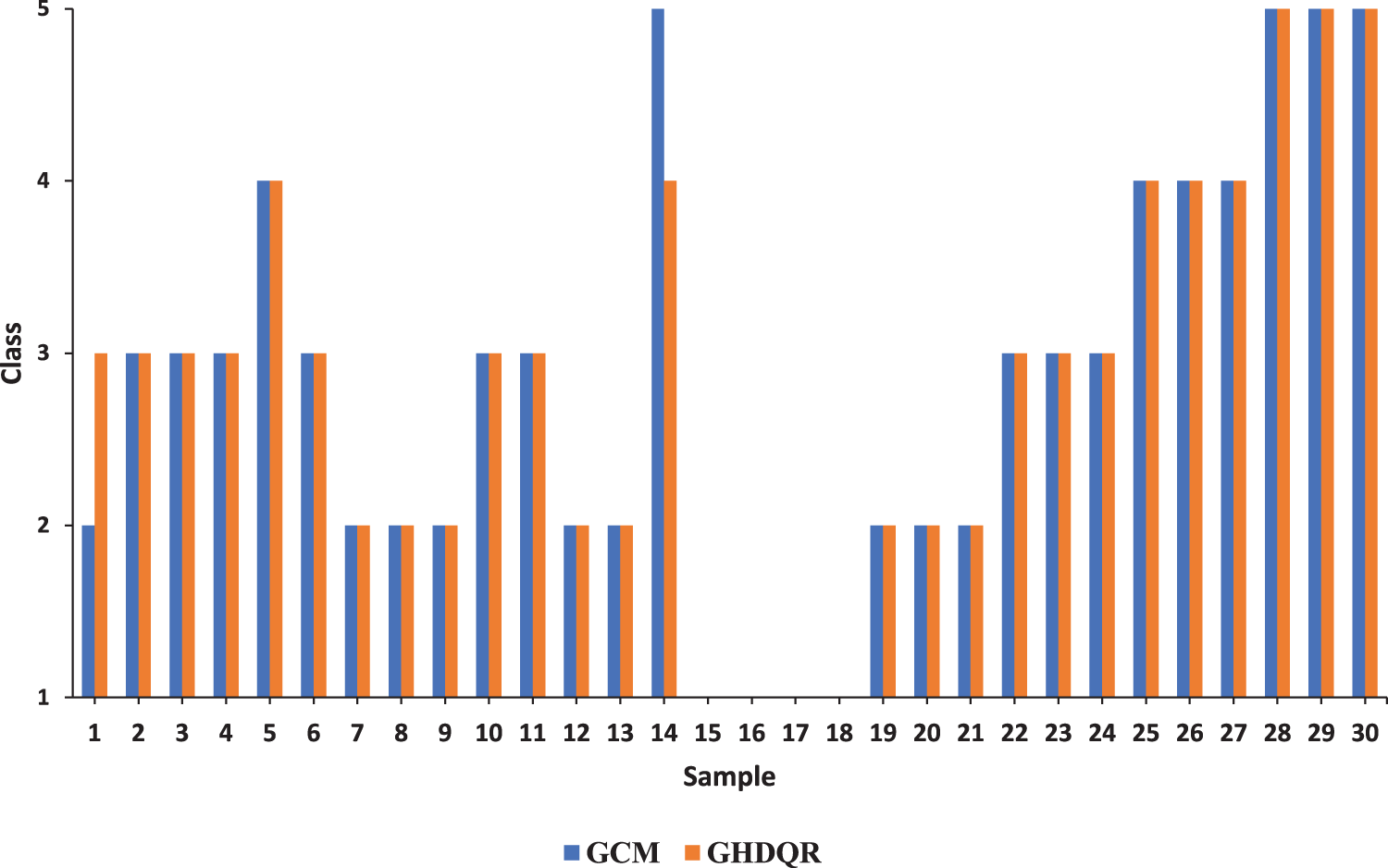

A developed rock mass classifier was applied to thirty rock samples, and the classification results are presented in Table 5 and Fig. 5.

Figure 5: Comparison results between the obtained and actual values

In two cases, the GHDQR model missed actual values. It happened in Samples 1 and 14. The model assigned one class lower on Sample 1 and one class higher on Sample 4. MAPE was employed to analyze the efficiency of the GHDQR method. The following equation defines it:

where:

In this comparison,

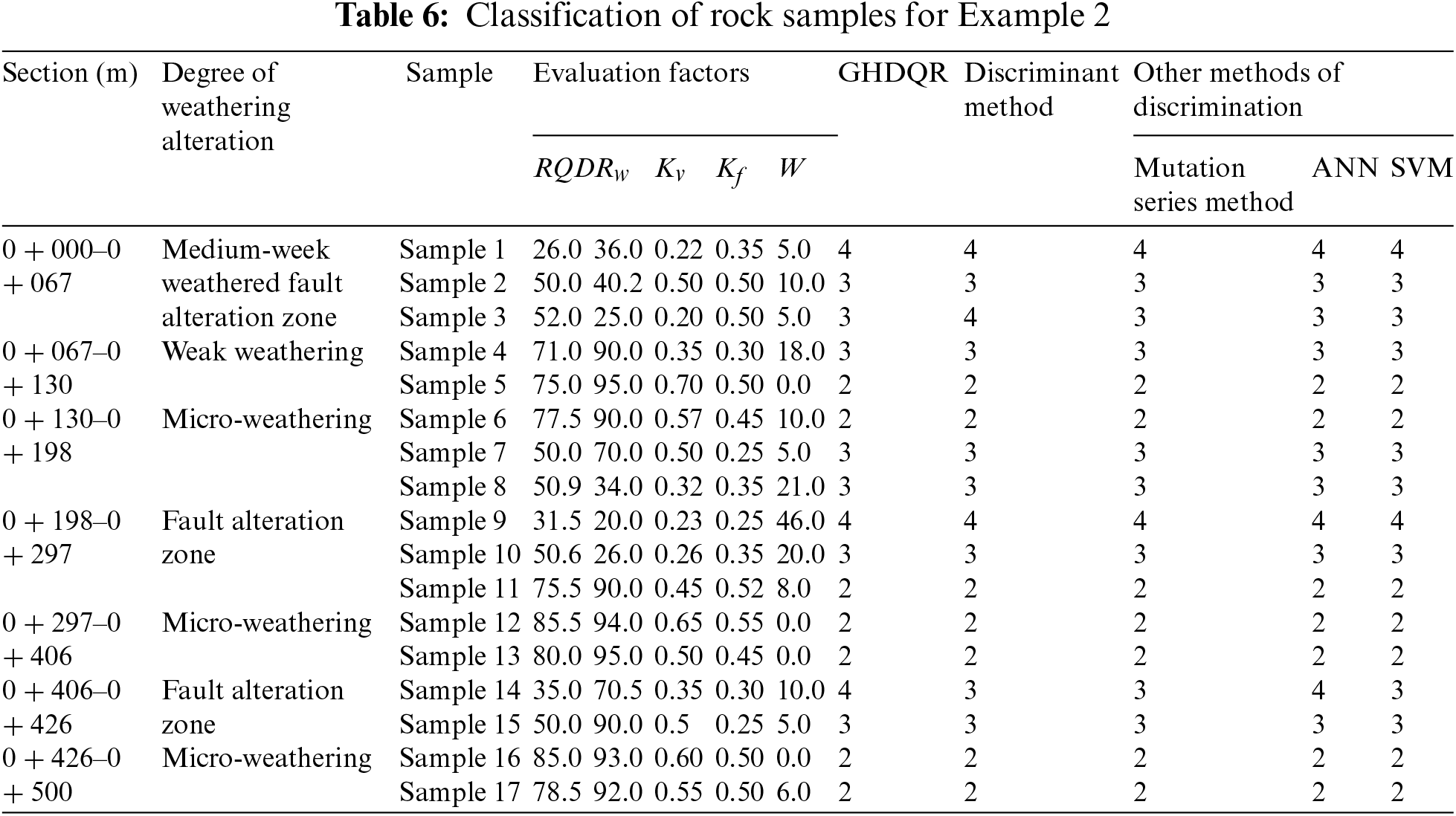

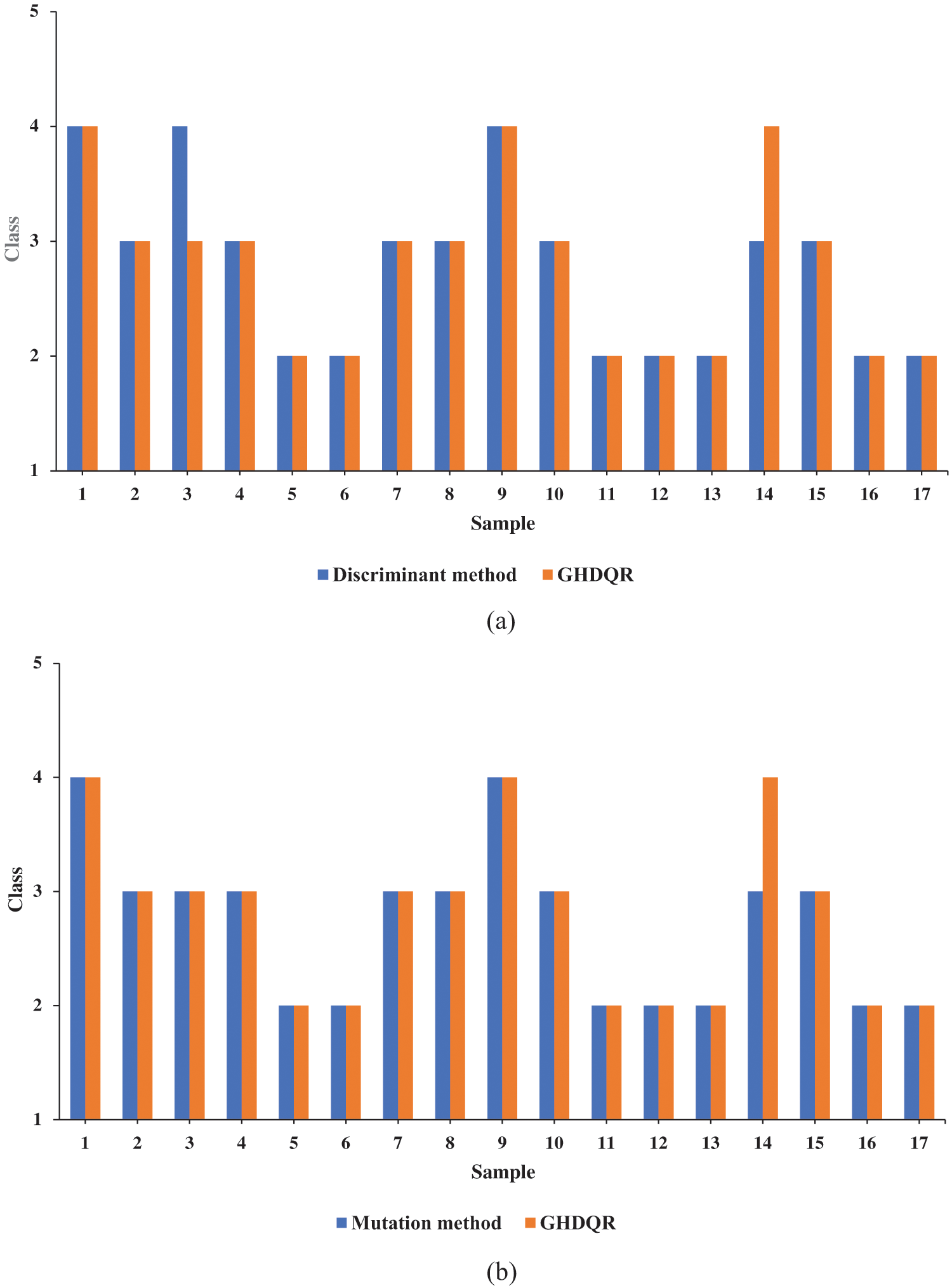

This subsection will not present detailed calculus, as in the previous one, but only the obtained results and comparison indicators. This comparison is conducted using data obtained from the literature [27]. Classification indices for rock mass quality grades are previously listed in Table 1. A developed rock mass classifier is applied to seventeen rock samples, and the classification results are depicted in Table 6 and Fig. 6. The literature [27] used the following four methods for classification: Discriminant, Mutation series, ANN, and SVM.

Figure 6: Comparison results between the obtained and actual values: (a) Discrimination method, (b) Mutation method, (c) ANN, (d) SVM

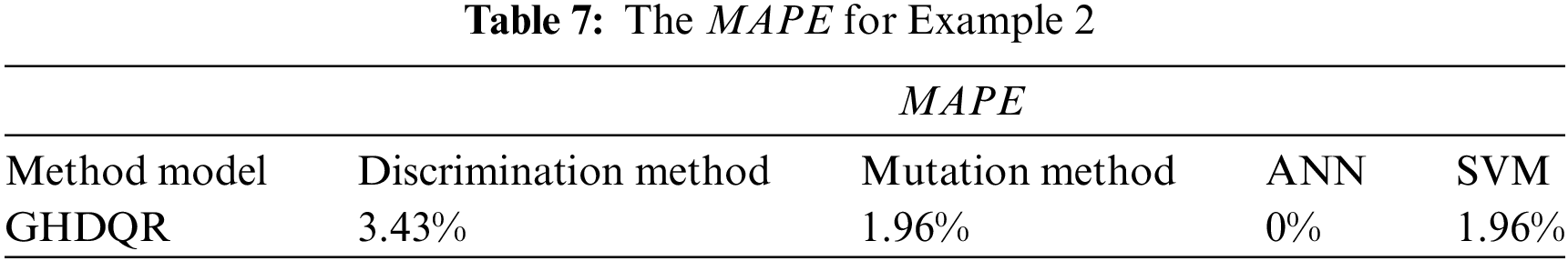

The efficiency of the GHDQR method for the Discrimination, Mutation, ANN, and SVM is listed in Table 7.

GHDRQ-Discrimination method: in two cases, the GHDQR model missed actual values. It occurred in Samples 3 and 14. The model assigned one class higher on Sample 3 and one lower on Sample 14. The

GHDRQ-Mutation method: in one case, the GHDQR model missed actual values. It occurred on Sample 14. The model assigned one class lower than the actual one. The

GHDRQ-ANN method: there are no missed values. The

GHDRQ-ANN method: The same result was obtained as the GHDQR-Mutation method.

The average value of the

Fig. 6 and Table 7 indicate that the GHDQR methodology is compared to four rock mass classification methods: Discrimination, Mutation, ANN, and SVM. The results clearly show that the relationship between the methods compared to the proposed method is very high. It is also proven by the average value of the

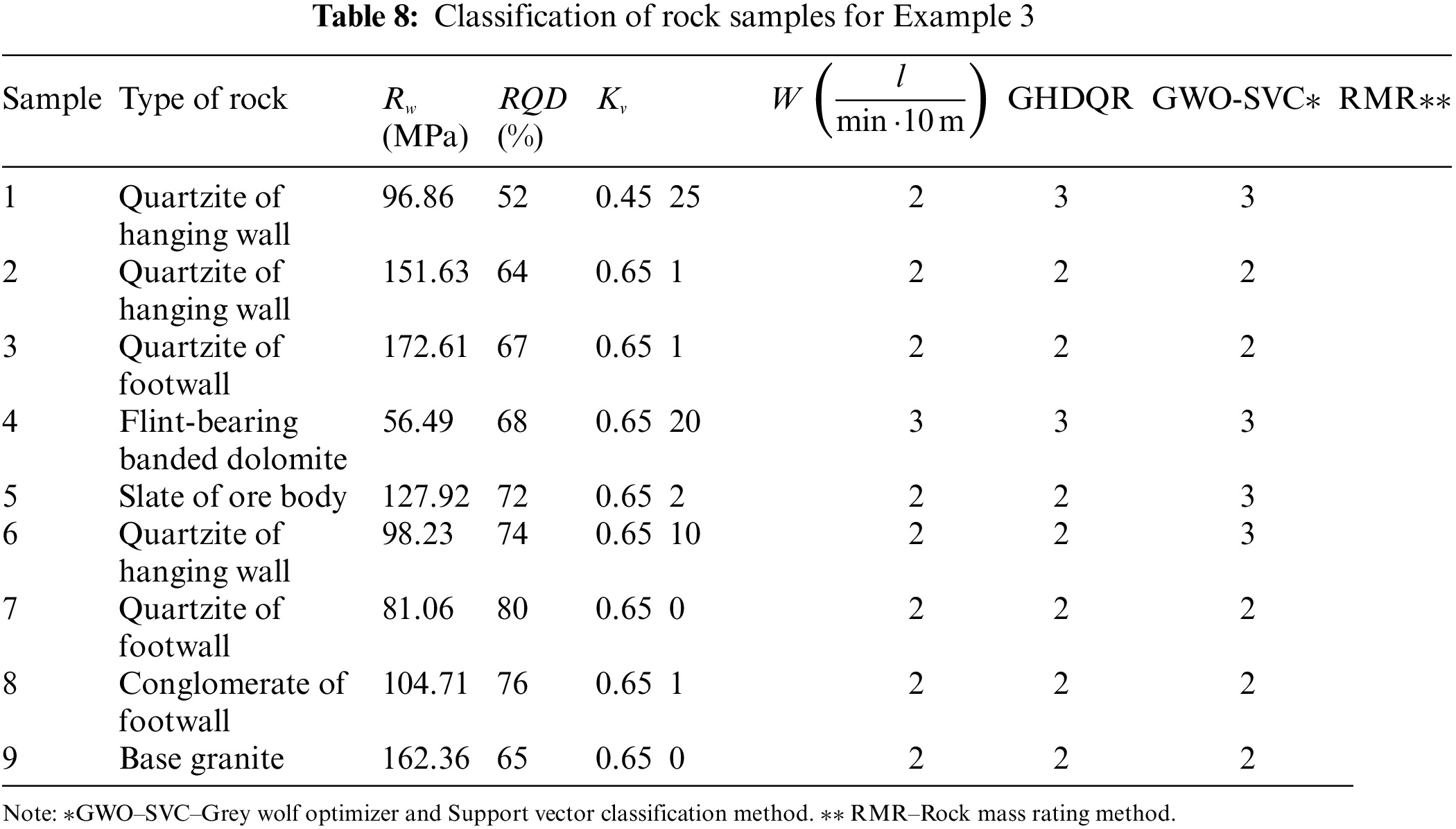

This comparison adopted data from the literature [17]. The selected rock mass indices are:

f) Uniaxial saturated compressive strength

g) Rock quality index

h) Integrity coefficient

i) Groundwater seepage quantity

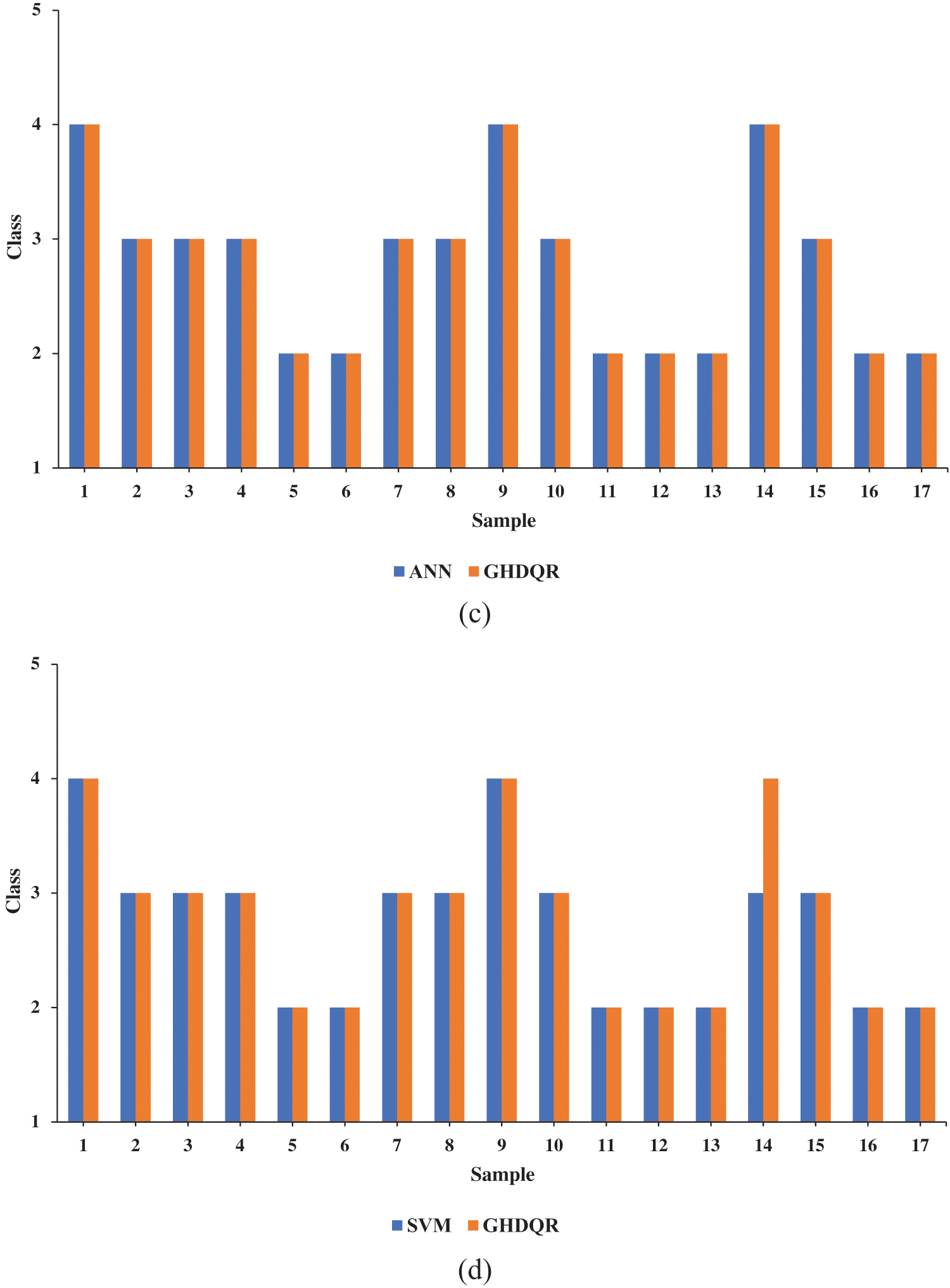

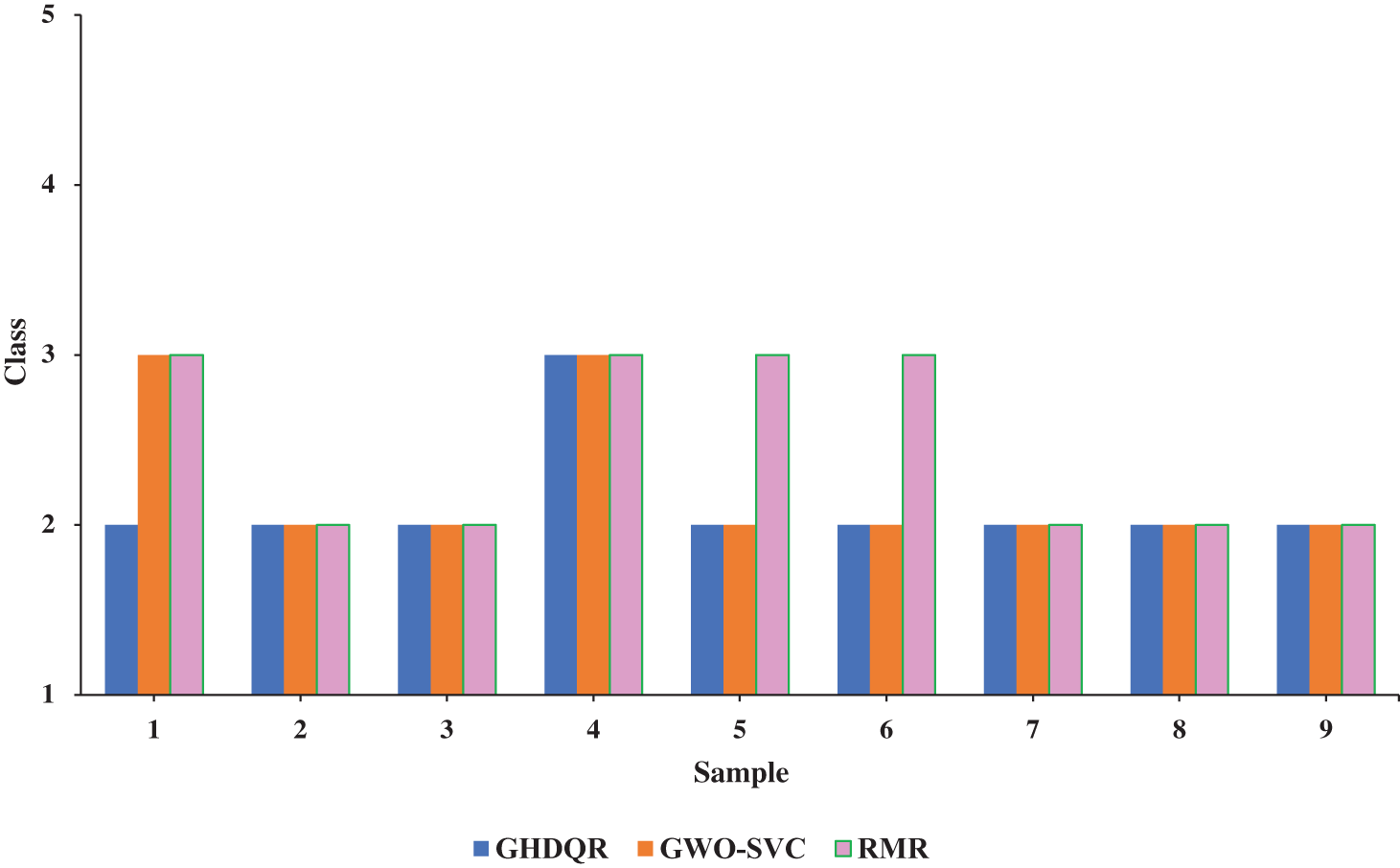

Table 1 shows the indices values. The developed GHDQR classifier was applied to nine rock samples, and the classification results are listed in Table 8 and Fig. 7.

Figure 7: Comparison results between the GHDQR, GWO-SVC and RMR methods

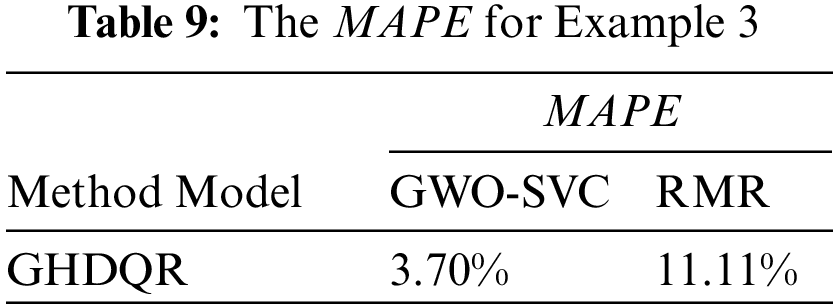

The

The average value of the

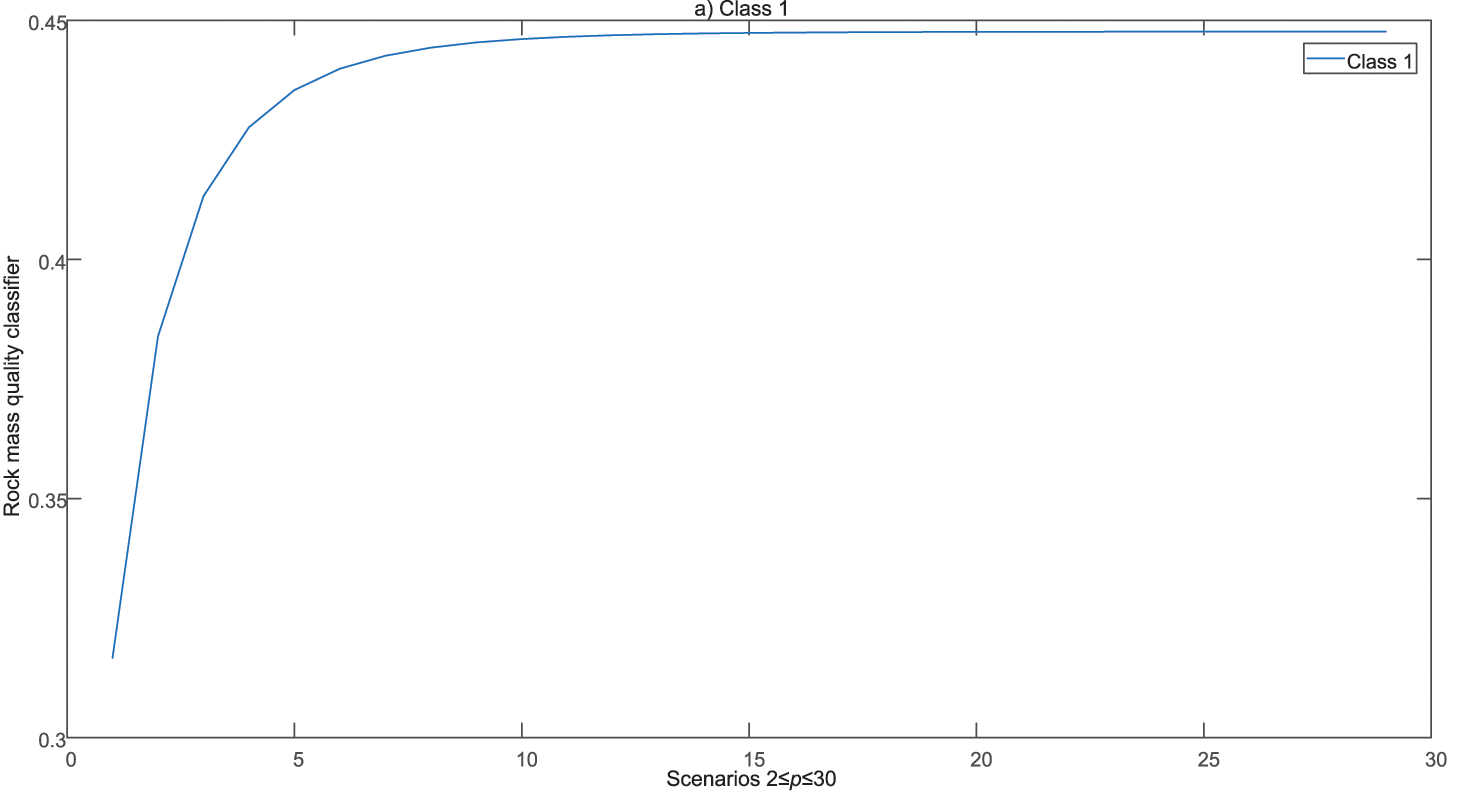

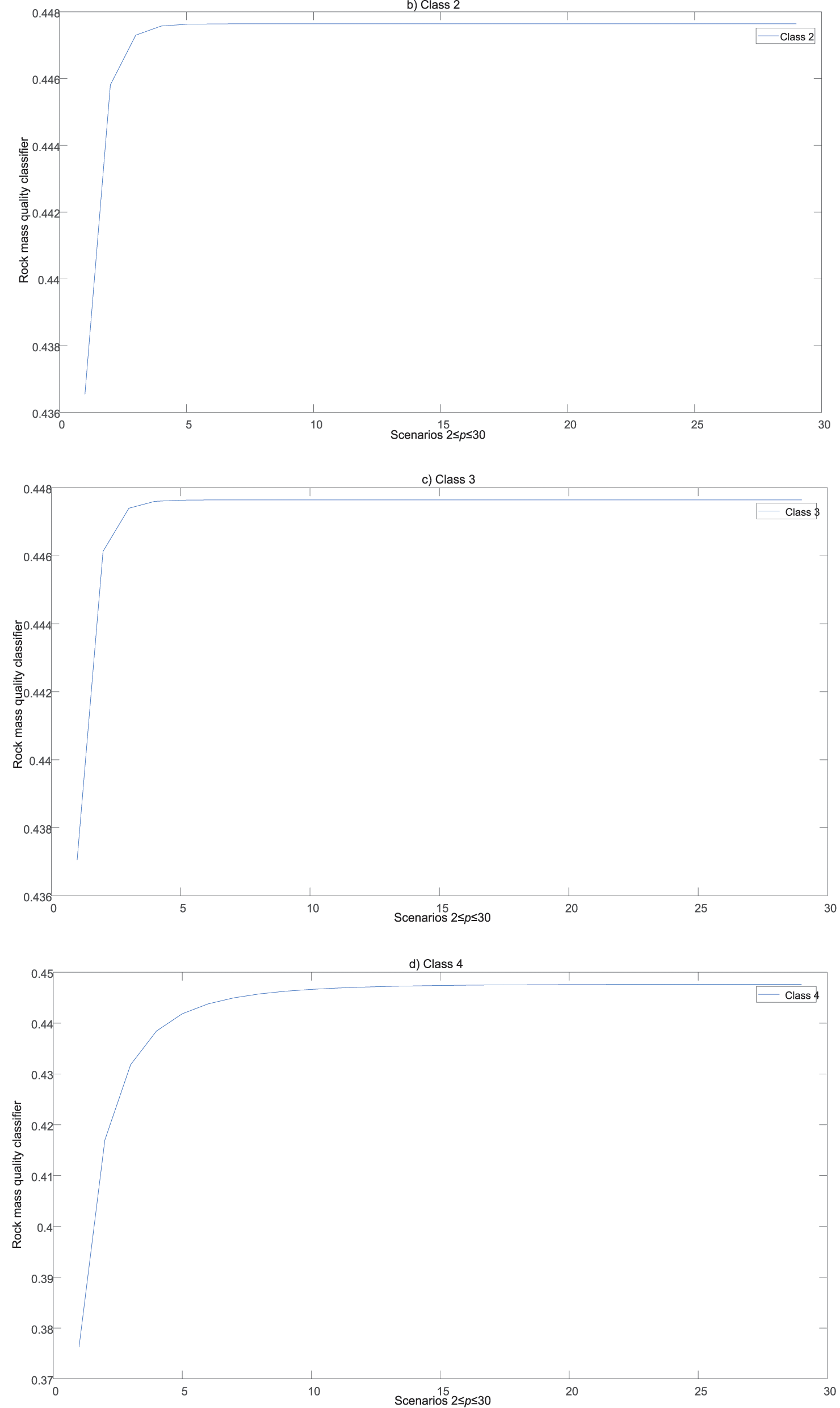

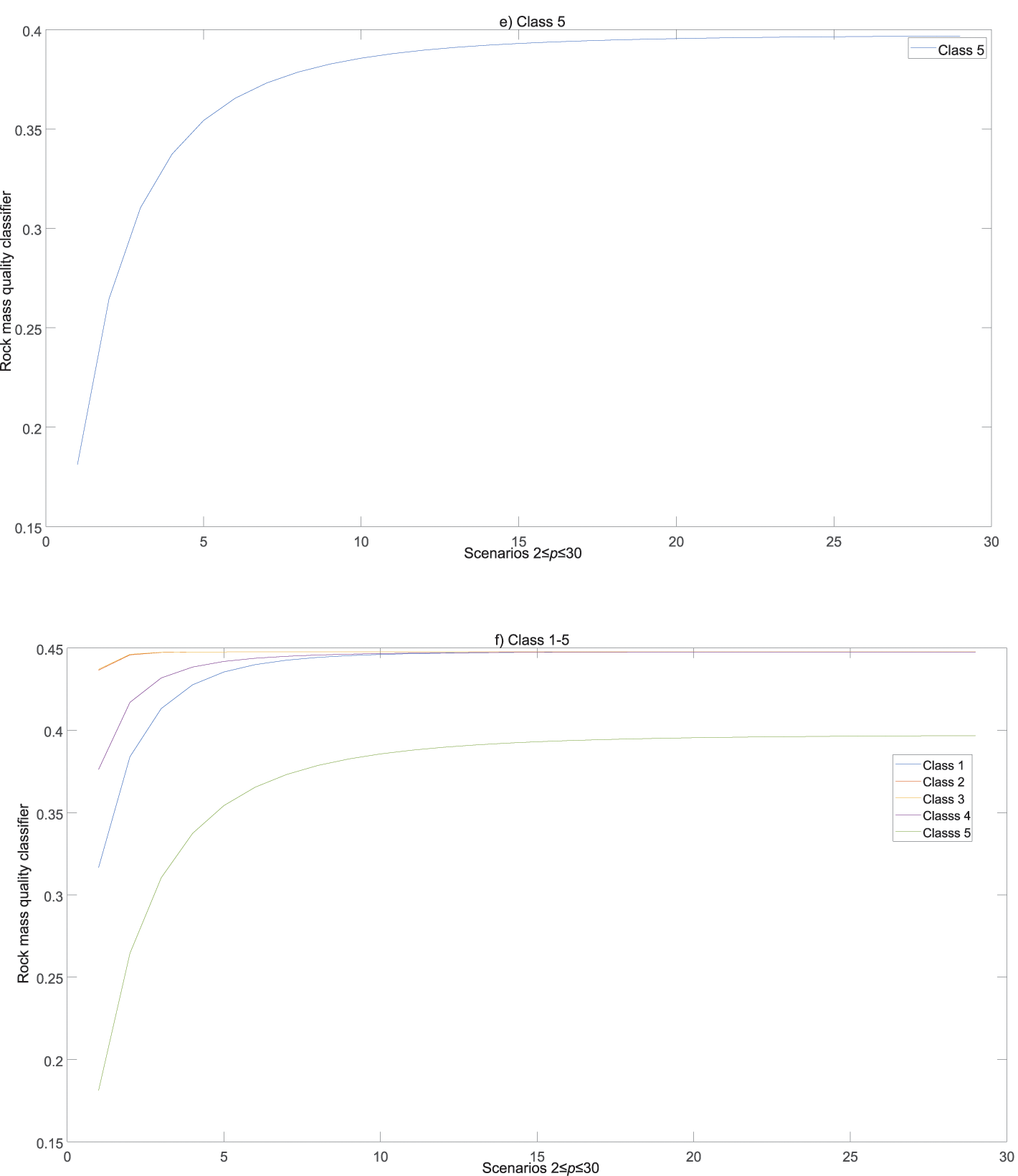

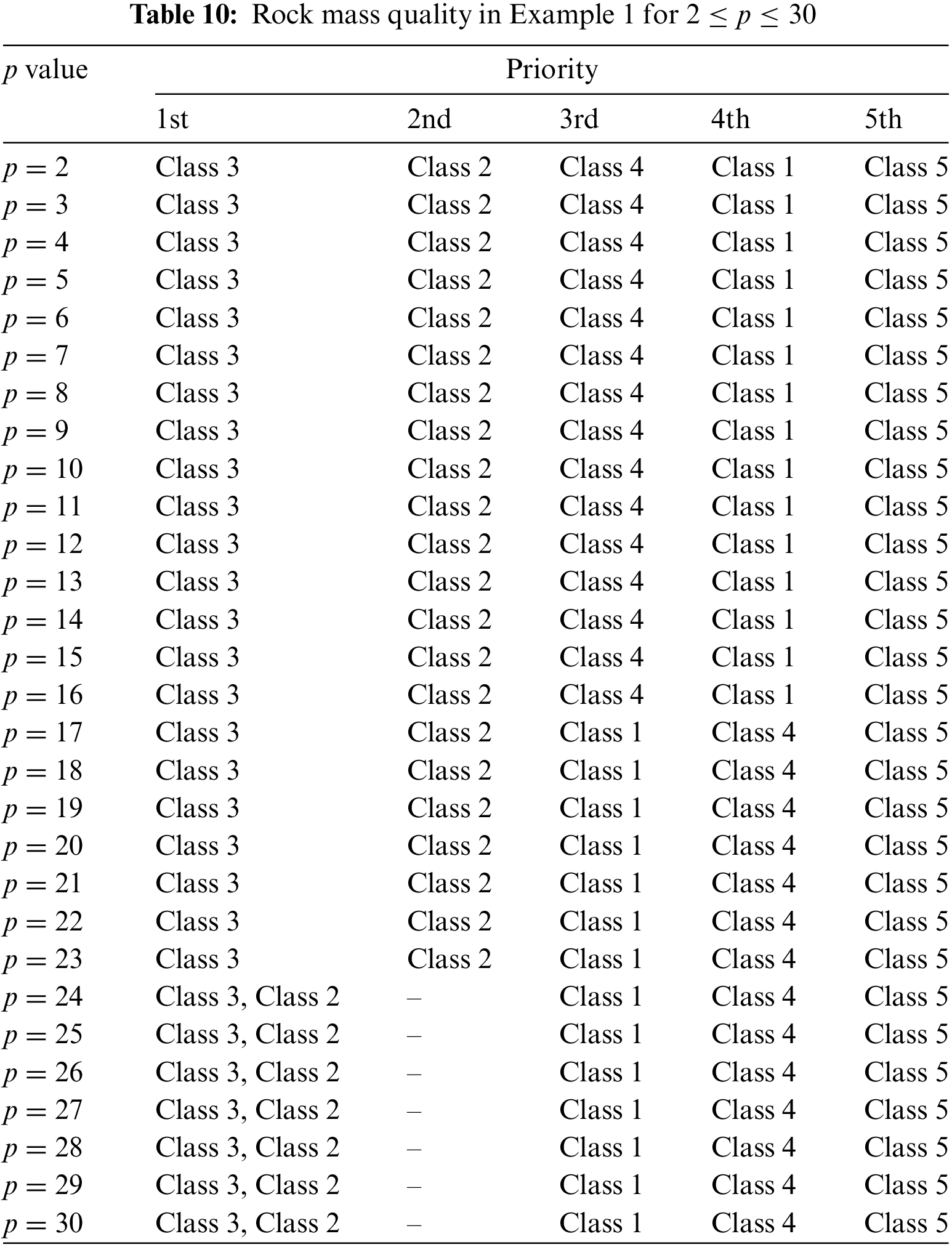

The following part presents the sensitivity analysis of the proposed methodology. As part of the sensitivity analysis, the variation of the parameter

Since the value of the parameter

Figure 8: Rock mass quality classifier values for

Fig. 8a through 8f indicate that the parameter

The graphical interpretation of the results of the change of the parameter

Table 10 shows that for all values of the parameter p, Class 3 illustrates the dominant solution from the considered set. Since the statistical correlation of the results across the scenarios is high, it can be concluded that the initial solution was confirmed. A similar analysis was performed for examples two and three, which is omitted in this paper.

3.5 Summary Discussion on Comparison and Model

In Section 3, the Gromov-Hausdorff distance for quality of rock method was compared to the following seven methods:

1. Gaussian cloud method,

2. Discriminant method,

3. Mutation series method,

4. ANN,

5. SVM,

6. GWO-SVC,

7. RMR.

Comparisons were conducted for the following five-rock mass evaluation indices:

j) Rock quality index

k) Uniaxial saturated compressive strength

l) Integrity coefficient

m) Structural plane strength coefficient

n) Groundwater seepage quantity

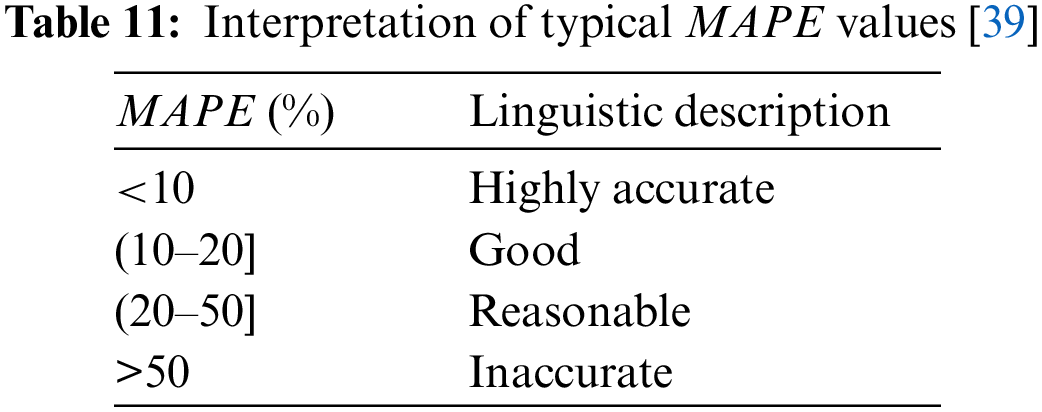

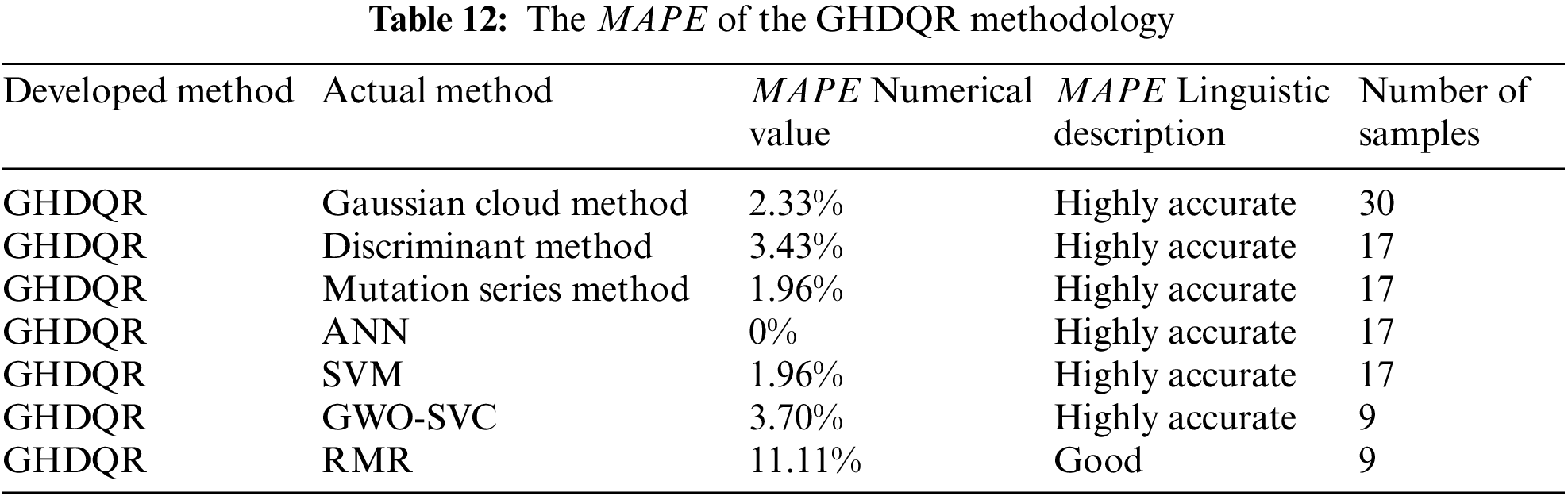

Table 11 details the interpretation of typical

The

The comparisons demonstrated that the classification results of the model are consistent with the actual classes obtained by the mentioned methods. The share of the highly accurate category is 85.71%, while the share of the good category is 14.29%. It indicates that the GHDQR methodology is feasible for surrounding rock quality classification.

Compared to other rock mass classification methods, the GHDQR method is a transparent tool for asses the quality of the rock sample. GHDQR methodology consists of a total of twelve steps. Each step is described in detail by the mathematical formulas and graphically illustrated through the flowchart of the model. Also, the exhaustive step-by-step presentation of numerical examples shows a high level of explainability and interpretability. The proposed methodology is simple and easy to understand. Although this methodology consists of twelve steps, it does not require high computational time. The algorithm is not limited to the input data size, which indicates the developed model’s great stability and reliability. Considering all these positive aspects, the proposed GHDQR methodology presents a powerful tool for analyzing the rock mass and rock sample classification.

The performances of the GHDQR method are listed as follows: data type is quantitative,

This study develops an innovative approach for rock mass quality rating in a multi-criteria grey environment named GHDQR. It proposes a new discriminant function (classifier) based on the Gromov-Hausdorff metric space distance for assessing rock mass quality. These metric spaces are the rock mass evaluation matrix and rock sample vector. The algorithm can deal with uncertainties of input data, as interval-grey numbers express the elements of the matrix. The performance of the proposed methodology is verified by comprehensive comparative analysis through the three numerical examples, showing its strength and stability. Several advantages can be observed from the obtained results:

o) A developed classifier objectively defines the class of rock samples, with no experts interfering in the classification process.

p) The GHDQR method is simple and easy to understand, minimal mathematical calculation is required, and transparency is good.

q) Compared to seven actual methods, the developed model produces high-accuracy results and aligns with all mentioned methods.

r) The GHDQR can be a valuable and reliable rock mass classification tool from all these positive aspects.

The study has several limitations that can be analyzed in the future. One of the limitations of the proposed methodology can be reflected in the fact that a case study with actual data is not presented but only through a comparative analysis. Mining engineers must understand this developed model and compare the results obtained with our original values. Another limitation can be observed in the number of parameters evaluating the rock mass. Only five-rock mass evaluation indices are considered in the proposed model, which should be improved for more parameters such as discontinuity and groundwater conditions.

Future research will focus on developing a model capable of processing more rock samples and hydraulic radius simultaneously to assess the conditions for bulk underground mining methods, such as block caving, sublevel caving, and longwall mining. Another direction of future research will include actual data, i.e., a case study where the results will verify the proposed methodology’s practical implication and efficiency. Also, the specific numerical example should be extended to include the number of parameters evaluating the rock mass in future research. From the point of view of mathematical calculation, future research can include other techniques for calculating the distance metrics such as Euclidean distance, Chebyshev distance, Manhattan distance, and others. By performing a detailed comparative analysis of these methods, the most suitable distance methodology can be selected as the best one. Also, by combining these approaches, hybrid methods for rock mass classification can be created.

Acknowledgement: The authors would like to thank the unknown reviewers for their valuable suggestions and greatly appreciate the time spent in reviewing.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm their contribution to the paper as follows: study conception and design: MG, ZG; data collection: SJ, SL; analysis and interpretation of results: DP, IJ; draft manuscript preparation: MG, ZG. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data utilized in this study is fully documented within the paper. Should there be any inquiries, please feel free to contact the authors.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Wu S, Du X, Yang S. Rock mass quality evaluation based on unascertained measure and intuitionistic fuzzy sets. Complexity. 2020;2020:1–14. doi:10.1155/2020/5614581. [Google Scholar] [CrossRef]

2. Mao X, Hu A, Zhao R, Wang F, Wu M. Evaluation and application of surrounding rock stability based on an improved fuzzy comprehensive evaluation method. Mathematics. 2023;11:3095. doi:10.3390/math11143095. [Google Scholar] [CrossRef]

3. Nikafshan Rad H, Jalali Z. Modification of rock mass rating system using soft computing techniques. Eng Comput. 2019;35(4):1333–57. doi:10.1007/s00366-018-0667-6. [Google Scholar] [CrossRef]

4. Shao JL, Gao L, Wu QH, Gu XB. The application of variable fuzzy sets theory on the quality assessment of surrounding rocks. Adv Mater Sci Eng. 2022;2022:5441829. doi:10.1155/2022/5441829. [Google Scholar] [CrossRef]

5. Ataei M, Besheli AD, Sereshki F, Jamshidi M. An application of fuzzy sets to the rock mass rating (RMR) system used in rock engineering; a case study in Iran. In: Proceedings of the 8th International Scientific Conference-SGEM2008; 2008 Jun 16–20; Albena, Bulgaria. p. 347–56. [Google Scholar]

6. Namin FS, Rinne M, Rafie M. Uncertainty determination in rock mass classification when using FRMR Software. J S Afr Inst Min Metall. 2015;115(11):1073–82. doi:10.17159/2411-9717/2015/v115n11a12. [Google Scholar] [CrossRef]

7. Zhang J, Shi K, Majiti H, Shan H, Fu T, Shi R, et al. Study on the classification and identification methods of surrounding rock excavatability based on the rock-breaking performance of tunnel boring machines. Appl Sci. 2023;13:7060. doi:10.3390/app13127060. [Google Scholar] [CrossRef]

8. Teng Y, Zhou K, Li Z. Classification of underground engineering surrounding rock based on Gaussian cloud model. J Phys Conf Seri. 2021;1983(1):012024. doi:10.1088/1742-6596/1983/1/012024. [Google Scholar] [CrossRef]

9. Mohammadi M, Hossaini MF. Modification of rock mass rating system: interbedding of strong and weak rock layers. J Rock Mech Geotech Eng. 2017;9(6):1165–70. doi:10.1016/j.jrmge.2017.06.002. [Google Scholar] [CrossRef]

10. Sebbeh-Newton S, Ismail S, Zabidi H. Prediction of rock mass rating using adaptive neuro-fuzzy inference system (ANFIS) for NATM-3 of Pahang-Selangor raw water transfer tunnel (PSRWT) project, Malaysia. AIP Conf Proc. 2020;2267(1):020021. doi:10.1063/5.0016415. [Google Scholar] [CrossRef]

11. Jalalifar H, Mojedifar S, Sahebi A. Prediction of rock mass rating using fuzzy logic and multi-variable RMR regression model. Int J Min Sci Technol. 2014;24:237–44. doi:10.1016/j.ijmst.2014.01.015. [Google Scholar] [CrossRef]

12. Liu YC, Chen CS. A new approach for application of rock mass classification on rock slope stability assessment. Eng Geol. 2007;89:129–43. doi:10.1016/j.enggeo.2006.09.017. [Google Scholar] [CrossRef]

13. Wu LZ, Li SH, Zhang M, Zhang LM. A new method for classifying rock mass quality based on MCS and TOPSIS. Environ Earth Sci. 2019;78:199. doi:10.1007/s12665-019-8171-x. [Google Scholar] [CrossRef]

14. Song S, Xu Q, Chen J, Zhang W, Cao C, Li Y. Engineering classification of jointed rock mass based on connectional expectation: a case study for Songta dam site, China. Adv Civ Eng. 2020;2020:1–15: 3581963. doi:10.1155/2020/3581963. [Google Scholar] [CrossRef]

15. Gu XB, Ma Y, Wu QH, Liu YB. The application of intuitionistic fuzzy set-TOPSIS model on the level assessment of the surrounding rocks. Shock Vib. 2022;2022:4263276. doi:10.1155/2022/4263276. [Google Scholar] [CrossRef]

16. Zheng S, Jiang A, Yang X, Luo G, Pham BT. A new reliability rock mass classification method based on least squares support vector machine optimized by bacterial foraging optimization algorithm. Adv Civ Eng. 2020;2020:3897215. doi:10.1155/2020/3897215. [Google Scholar] [CrossRef]

17. Hu J, Zhou T, Ma S, Yang D, Guo M, Huang P. Rock mass classification prediction model using heuristic algorithms and support vector machines: a case study of Chambishi copper mine. Sci Rep. 2022;12(1):928. doi:10.1038/s41598-022-05027-y. [Google Scholar] [PubMed] [CrossRef]

18. Sheng D, Yu J, Tan F, Tong D, Yan T, Lv J. Rock mass quality classification based on deep learning: a feasibility study for stacked autoencoders. J Rock Mech Geotech Eng. 2023;15(7):1749–58. doi:10.1016/j.jrmge.2022.08.006. [Google Scholar] [CrossRef]

19. Azarafza M, Hajialilue Bonab M, Derakhshani R. A deep learning method for the prediction of the index mechanical properties and strength parameters of marlstone. Materials. 2022;15:6899. doi:10.3390/ma15196899. [Google Scholar] [PubMed] [CrossRef]

20. Santos AEM, Lana MS, Pereira TM. Evaluation of machine learning methods for rock mass classification. Neural Comput Appl. 2022;34:4633–42. doi:10.1007/s00521-021-06618-y. [Google Scholar] [CrossRef]

21. Cheng X, Tang H, Wu Z, Liang D, Xie Y. BILSTM-based deep neural network for rock-mass classification prediction using depth-sequence MWD data: a case study of a tunnel in Yunnan, China. Appl Sci. 2023;13:6050. doi:10.3390/app13106050. [Google Scholar] [CrossRef]

22. Gholami R, Rasouli V, Alimoradi A. Improved RMR rock mass classification using artificial intelligence algorithms. Rock Mech Rock Eng. 2013;46:1199–209. doi:10.1007/s00603-012-0338-7. [Google Scholar] [CrossRef]

23. Hou S, Liu Y, Yang Q. Real-time prediction of rock mass classification based on TBM operation big data and stacking technique of ensemble learning. J Rock Mech Geotech Eng. 2021;14:123–43. doi:10.1016/j.jrmge.2021.05.004. [Google Scholar] [CrossRef]

24. Yang G, Li TB, Ma CC, Meng LB, Zhang HG, Ma JJ. Intelligent rating method of tunnel surrounding rock based on one-dimensional convolutional neural network. J Intell Fuzzy Syst. 2022;42(3):2451–69. doi:10.3233/JIFS-211718. [Google Scholar] [CrossRef]

25. Yalcin I, Can R, Kocaman S, Gokceoglu C. Rock mass discontinuity determination with transfer learning. Int Arch Photogramm Remote Sens Spatial Inf Sci. 2023;48:609–14. doi:10.5194/isprs-archives-XLVIII-M-1-2023-609-2023. [Google Scholar] [CrossRef]

26. Alzubaidi F, Mostaghimi P, Si G, Swietojanski P, Armstrong RT. Automated rock quality designation using convolutional neural networks. Rock Mech Rock Eng. 2022;55(6):3719–34. doi:10.1007/s00603-022-02805-y. [Google Scholar] [CrossRef]

27. Wang J, Guo J. Research on rock mass quality classification based on an improved rough set-cloud model. IEEE Access. 2019;7:123710–24. doi:10.1109/ACCESS.2019.2938567. [Google Scholar] [CrossRef]

28. Tan F, You M, Zuo C, Jiao YY, Tian H. Simulation of rock-breaking process by drilling machine and dynamic classification of surrounding rocks. Rock Mech Rock Eng. 2022;55(1):423–37. doi:10.1007/s00603-021-02659-w. [Google Scholar] [CrossRef]

29. Riazi E, Yazdani M, Afrazi M. Numerical study of slip distribution at pre-existing crack in rock mass using extended finite element method (XFEM). Iran J Sci Technol Trans Civil Eng. 2023;47(4):2349–63. [Google Scholar]

30. Majedi MR, Afrazi M, Fakhimi A. A micromechanical model for simulation of rock failure under high strain rate loading. Int J Civ Eng. 2021;19(5):501–15. [Google Scholar]

31. Zhang Y, Zhuang X. Cracking elements: a self-propagating strong discontinuity embedded approach for quasi-brittle fracture. Finite Elem Anal Des. 2018;144:84–100. [Google Scholar]

32. Zhang Y, Mang HA. Global cracking elements: a novel tool for Galerkin-based approaches simulating quasi-brittle fracture. Int J Numer Methods Eng. 2020;121(11):2462–80. [Google Scholar]

33. Liu S, Fang Z, Yang Y, Forrest J. General Grey numbers and their operations. Grey Syst Theory Appl. 2012;2(3):341–9. doi:10.1108/20439371211273230. [Google Scholar] [CrossRef]

34. Szmidt E, Kacprzyk J. Intuitionistic fuzzy sets—Two and three term representations in the context of a Hausdorff distance. Acta Univ Matth Belii Ser Math. 2011;19:53–62. [Google Scholar]

35. Mémoli F, Smith Z, Wan Z. The Gromov-Hausdorff distance between ultrametric spaces: its structure and computation. 2021. doi:10.48550/arXiv.2110.03136. [Google Scholar] [CrossRef]

36. Mémoli F, Wan Z. On p-metric spaces and the p-Gromov-Hausdorff distance. 2019. doi:10.48550/arXiv.1912.00564. [Google Scholar] [CrossRef]

37. Majhi S, Vitter J, Wenk C. Approximating gromov-hausdorff distance in euclidean space. Comput Geom. 2024;116(2024):102034. doi:10.1016/j.comgeo.2023.102034. [Google Scholar] [CrossRef]

38. Hamidi JK, Shahriar K, Rezai B, Bejari H. Application of fuzzy set theory to rock engineering classification systems: an illustration of the rock mass excavability index. Rock Mech Rock Eng. 2010;43:335–50. doi:10.1007/s00603-009-0029-1. [Google Scholar] [CrossRef]

39. Lewis CD. Industrial and business forecasting methods. London, UK: Butterworths Scientific; 1982. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools