Open Access

Open Access

ARTICLE

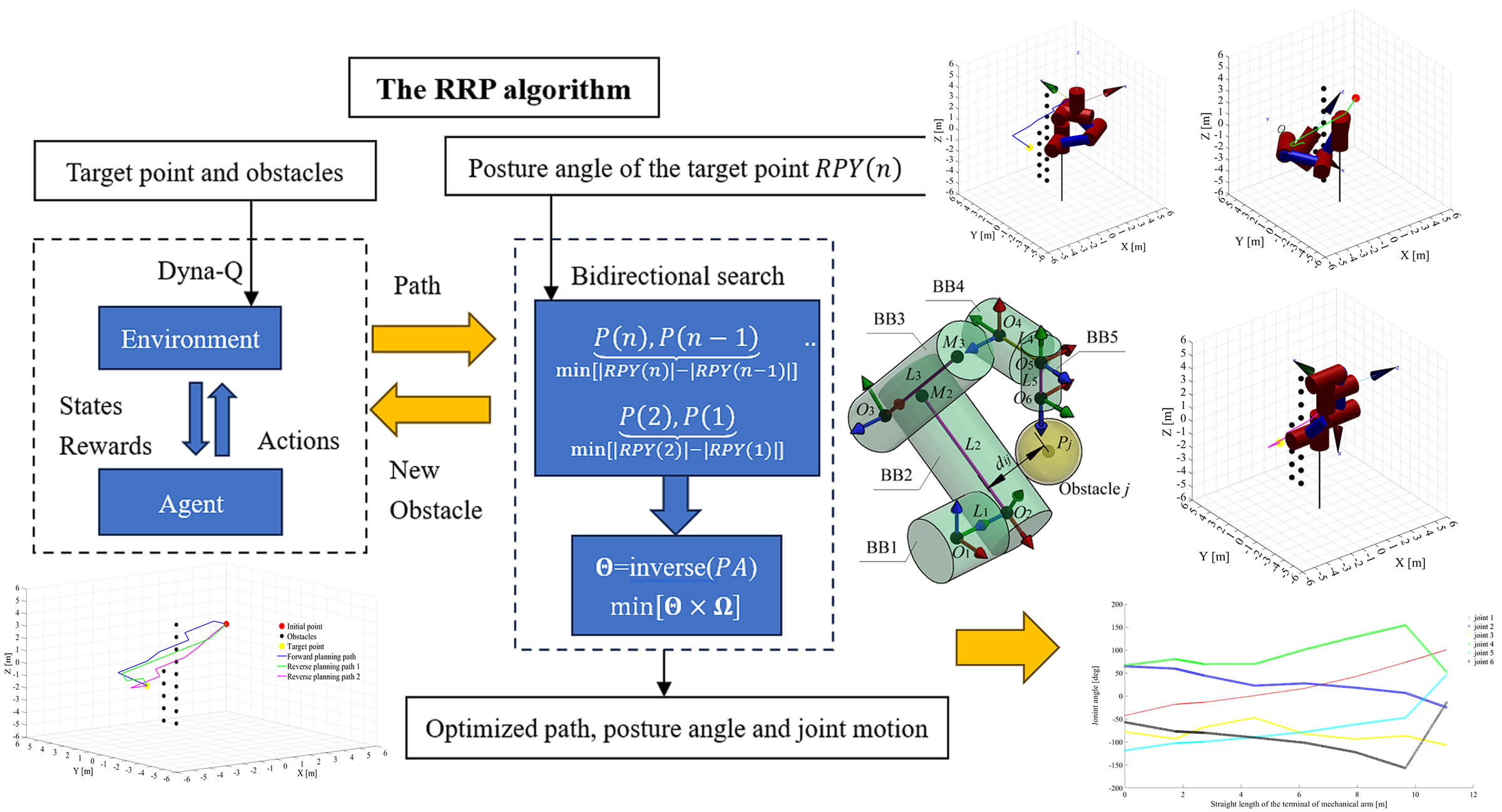

A Reverse Path Planning Approach for Enhanced Performance of Multi-Degree-of-Freedom Industrial Manipulators

1 Key Laboratory of Light Field Manipulation and System Integration Applications in Fujian Province, School of Physics and Information Engineering, Minnan Normal University, Zhangzhou, 363000, China

2 Department of Electrical and Computer Engineering, University of Nevada, Las Vegas, 89154, USA

3 College of Material Engineering, Fujian Agriculture and Forestry University, Fuzhou, 350000, China

* Corresponding Author: Hui Wang. Email:

Computer Modeling in Engineering & Sciences 2024, 139(2), 1357-1379. https://doi.org/10.32604/cmes.2023.045990

Received 14 September 2023; Accepted 17 November 2023; Issue published 29 January 2024

Abstract

In the domain of autonomous industrial manipulators, precise positioning and appropriate posture selection in path planning are pivotal for tasks involving obstacle avoidance, such as handling, heat sealing, and stacking. While Multi-Degree-of-Freedom (MDOF) manipulators offer kinematic redundancy, aiding in the derivation of optimal inverse kinematic solutions to meet position and posture requisites, their path planning entails intricate multi-objective optimization, encompassing path, posture, and joint motion optimization. Achieving satisfactory results in practical scenarios remains challenging. In response, this study introduces a novel Reverse Path Planning (RPP) methodology tailored for industrial manipulators. The approach commences by conceptualizing the manipulator’s end-effector as an agent within a reinforcement learning (RL) framework, wherein the state space, action set, and reward function are precisely defined to expedite the search for an initial collision-free path. To enhance convergence speed, the Q-learning algorithm in RL is augmented with Dyna-Q. Additionally, we formulate the cylindrical bounding box of the manipulator based on its Denavit-Hartenberg (DH) parameters and propose a swift collision detection technique. Furthermore, the motion performance of the end-effector is refined through a bidirectional search, and joint weighting coefficients are introduced to mitigate motion in high-power joints. The efficacy of the proposed RPP methodology is rigorously examined through extensive simulations conducted on a six-degree-of-freedom (6-DOF) manipulator encountering two distinct obstacle configurations and target positions. Experimental results substantiate that the RPP method adeptly orchestrates the computation of the shortest collision-free path while adhering to specific posture constraints at the target point. Moreover, it minimizes both posture angle deviations and joint motion, showcasing its prowess in enhancing the operational performance of MDOF industrial manipulators.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools