Open Access

Open Access

ARTICLE

Natural Convection and Irreversibility of Nanofluid Due to Inclined Magnetohydrodynamics (MHD) Filled in a Cavity with Y-Shape Heated Fin: FEM Computational Configuration

1 School of Energy and Power Engineering, Jiangsu University, Zhenjiang, 212013, China

2 Department of Mathematics, Air University, Islamabad, 44000, Pakistan

3 Center of Research, Faculty of Engineering, Future University in Egypt, New Cairo, 11835, Egypt

4 Department of Mathematics, University of Management and Technology, Lahore, 54770, Pakistan

5 Department of Mathematics, University of Sargodha, Sargodha, 40100, Pakistan

6 Department of Mathematics, College of Science, King Khalid University, Abha, 61413, Saudi Arabia

7 Faculty of Sciences, The Superior University, Lahore, 54000, Pakistan

* Corresponding Author: Imran Saddique. Email:

(This article belongs to the Special Issue: Numerical Modeling and Simulations on Non-Newtonian Flow Problems)

Computer Modeling in Engineering & Sciences 2024, 139(2), 1505-1519. https://doi.org/10.32604/cmes.2023.030255

Received 28 March 2023; Accepted 25 July 2023; Issue published 29 January 2024

Abstract

This study explains the entropy process of natural convective heating in the nanofluid-saturated cavity in a heated fin and magnetic field. The temperature is constant on the Y-shaped fin, insulating the top wall while the remaining walls remain cold. All walls are subject to impermeability and non-slip conditions. The mathematical modeling of the problem is demonstrated by the continuity, momentum, and energy equations incorporating the inclined magnetic field. For elucidating the flow characteristics Finite Element Method (FEM) is implemented using stable FE pair. A hybrid fine mesh is used for discretizing the domain. Velocity and thermal plots concerning parameters are drawn. In addition, a detailed discussion regarding generation energy by monitoring changes in magnetic, viscous, total, and thermal irreversibility is provided. In addition, line graphs are created for the u and v components of the velocity profile to predict the flow behavior. Current simulations assume the dimensionless representative of magnetic field Hartmann number Ha between 0 and 100 and a magnetic field inclination between 0 and 90 degrees. A constant 4% volume proportion of nanoparticles is employed throughout all scenarios.Keywords

Entropy is a fundamental property of any dynamic thermal system, serving as a quantitative representation of the disorder introduced by the irreversibility process at work during heat exchange. The second rule of thermodynamics asserts that total entropy uniformly predominates in reversible processes and rises with time in non-reversible techniques, leading to entropy measurement in thermalized systems. Bejan [1] was one of the pioneers in entropy development by inventing an approach to thermodynamic optimization. The purpose of optimizing the structure of entropy thermal hydraulic systems is to enhance their performance in several fields. Moreover, entropy analysis can improve the performance of heating equipment such as heat engines, heat pumps, coolers, cooling electronic chips, and micro-thermal channels. Parvin et al. [2] investigated the entropy irreversibility of metal nanoparticles in a water-saturated chamber. Rayleigh and Bejan numbers correlate, affecting their impact on entropy variation. Kefayati [3] employed the Lattice Boltzmann method to explore the effects of natural convection and an external magnetic source on a ferrofluid in a cavity. Nanoscale ferromagnetic cobalt particles were suspended in kerosene. There is a negative correlation between the percentage of nanoscale ferromagnetic particles in the volume and the heat transmission for a range of Ra. Rabbi et al. [4] utilized pure mixed convection magnetized investigation directed toward the cavity to investigate the impacts of two different geometric heater configurations. A single-phase model of ferrofluid was employed as a working fluid. Heaters on the bottom wall were always kept on, while those on the vertical side walls were preserved at a steady, low temperature. The top wall permanently moved at the same rate and temperature in geometric layouts. The Galerkin weighted residuals approach of finite element analysis was employed to solve the flow equations. Merji et al. [5] and Mahmoudi et al. [6] investigated the process of entropy and how it is carried out in a square cage filled with water and features the fusing of hybrid nanoparticles. They described the volume of nanoparticle fraction on the accumulative entropy procedure. Including alumina nanoparticles, Armaghani et al. [7] evaluated the entropy generation characteristics in the baffle of an L-shaped water-saturated duct, which are flow-differentiated by buoyant thermal convection. Zamily [8] assessed the various thermal features of water along with Ti

Flow analysis is not only exciting but also thought-provoking. Further numerical and experimental research is needed across various topics, although several technology applications and scientific challenges exist. This study explores the effects of friction and heat transfer in viscous fluid flows across solid surfaces and in ducts and channels. These consequences must be factored into evaluating the fluid’s qualities. The issue can be solved in either an experimental or theoretical setting. Numerical approaches, such as finite differences, finite elements, and finite volumes, are developed for solving incompressible Newtonian flow problems. The most well-known approach is the traditional PARDISO algorithm, which first presents the idea of a stalled grid in conjunction with the pressure adjustment equation. It indicates a dearth of information in the literature on non-Newtonian fluid flows, particularly polymer melts in the molding process, evaluated in [17–20]. Khan et al. [21] examined a comprehensive study of hydromagnetic thermal flow effects over a cavity cylinder. They implemented a finite element scheme for solving the nonlinear coupled equations. Soomro et al. [22] considered a constructional design-based study to analyze the features of thermal flows in a semi-circular cavity. They concluded that as Richardson’s number increases, heat transport slows down. In addition, as the Hartmann number grows, the heat transmission rate improves. Chelia et al. [23] investigated the characteristics of natural convection with nanofluid in a cavity utilizing the famous numerical approach, the Lattice Boltzmann Method (LBM). In addition, they indicated that the heat transmission rate from a bottom-heated cavity is greater than that of a sidewall-heated cavity.

This study explains an entropy-generating process, including an angled magnetic field induction and a natural convection component. It discusses various types of irreversibility against different effective parameters that have not yet been revealed. The research’s result can be a reference for future studies.

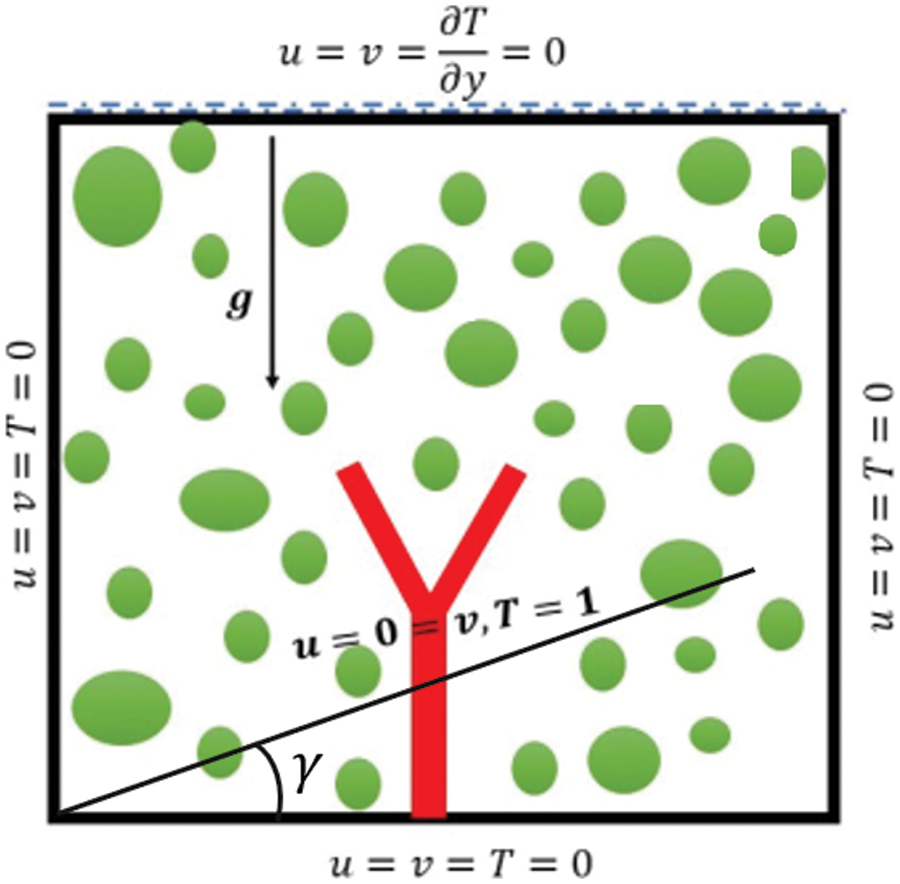

This study considered the unit dimensions of the cavity are saturated by water and copper nanoparticles were induced. Flow domain density variations include the addition of Boussinesq approximation to the buoyancy term, containing the role of natural convection in the flow domain. The constant

Figure 1: Physical structuring of problem

The continuity, flow velocity, and heat equation [24–26] for a copper fluid are described in a non-dimensional mathematical form as follows:

The boundary conditions are given below:

•

•

•

•

2.1 Properties of Copper Fluid

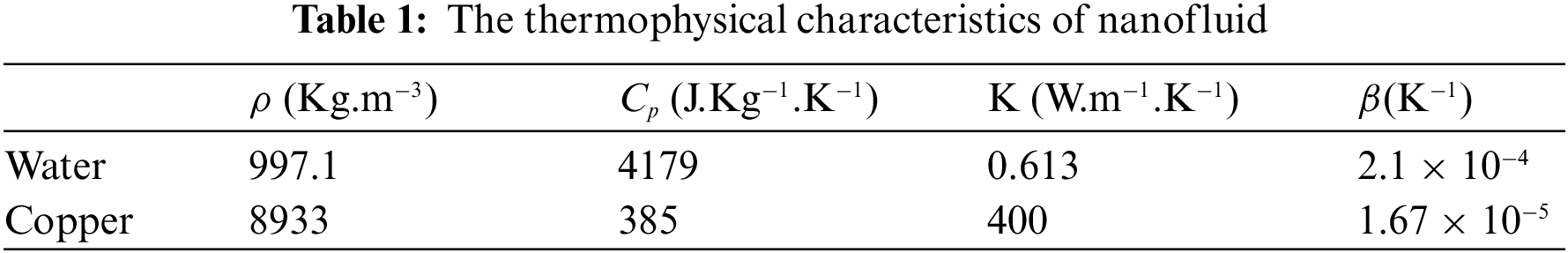

These equations are appropriate for the thermo-physical properties of the nanofluid in this study [13–15]. The physical characteristics of copper fluid are listed in Table 1.

• Density:

• Thermal diffusivity:

• Electrical conductivity:

• Specific heat:

• Thermal conductivity:

• Thermal expansion coefficient:

• Dynamic viscosity:

• Average Nusselt number

The term “irreversibility analysis” refers to quantifying the local entropy production resulting from the sum of the conjugated fluxes and the forces that are generated. A convective process subject to a magnetic field yields the following expression for the non-dimensional local entropy production:

On the right-hand side of Eq. (5) initially stands the energy entropy, then viscous entropy, and finally, magnetic entropy located at the top right side. The irreversibility ratio (

where

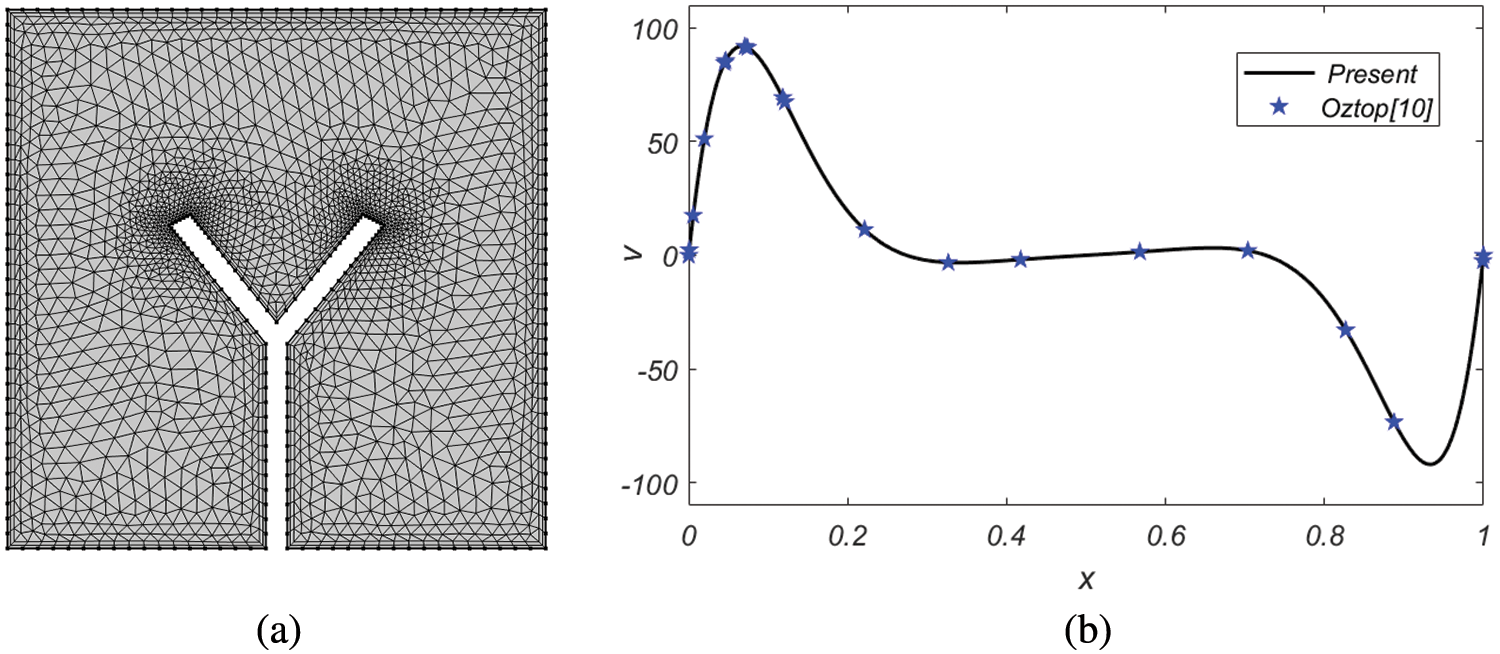

The velocity field and temperature at every location in the analyzed physical model must be known to numerically calculate the production of local entropy using Eq. (5). A numerical approach called the finite element method (FEM) is applied to compute an estimation of the solution to the model problem because analytical solutions to the coupled equations are not possible due to the nonlinearity of the governing equations. This was conducted to better understand how the model problem will be solved. In order to solve the underlying discrete nonlinear system of equations, Newton’s method was employed to linearize the system, and then the direct solver PARDISO was applied to address the linearized inner systems. The PARDISO solver has numerous benefits. LU matrix factorization is employed to achieve the needed level of convergence with a minimum number of iterations. This reduces the total number of necessary iterations. Fig. 2a depicts the computing grid.

Figure 2: (a): Discretization of the computational domain (b): Comparison of the present study with Oztop [10]

Domain coarse-resolution meshing is conducted using a pressure-velocity finite element pair. Fig. 2a indicates that coarser-grained rectangular and triangular elements represent the entire computational domain. A nonlinear system is iterated until the convergence requirement is satisfied, typically defined as a residual of less than 10−6.

Fig. 2b shows vertical velocity profiles along the center of the cavity, as measured with different nanofluids. The results demonstrate good agreement with the Oztop study [10].

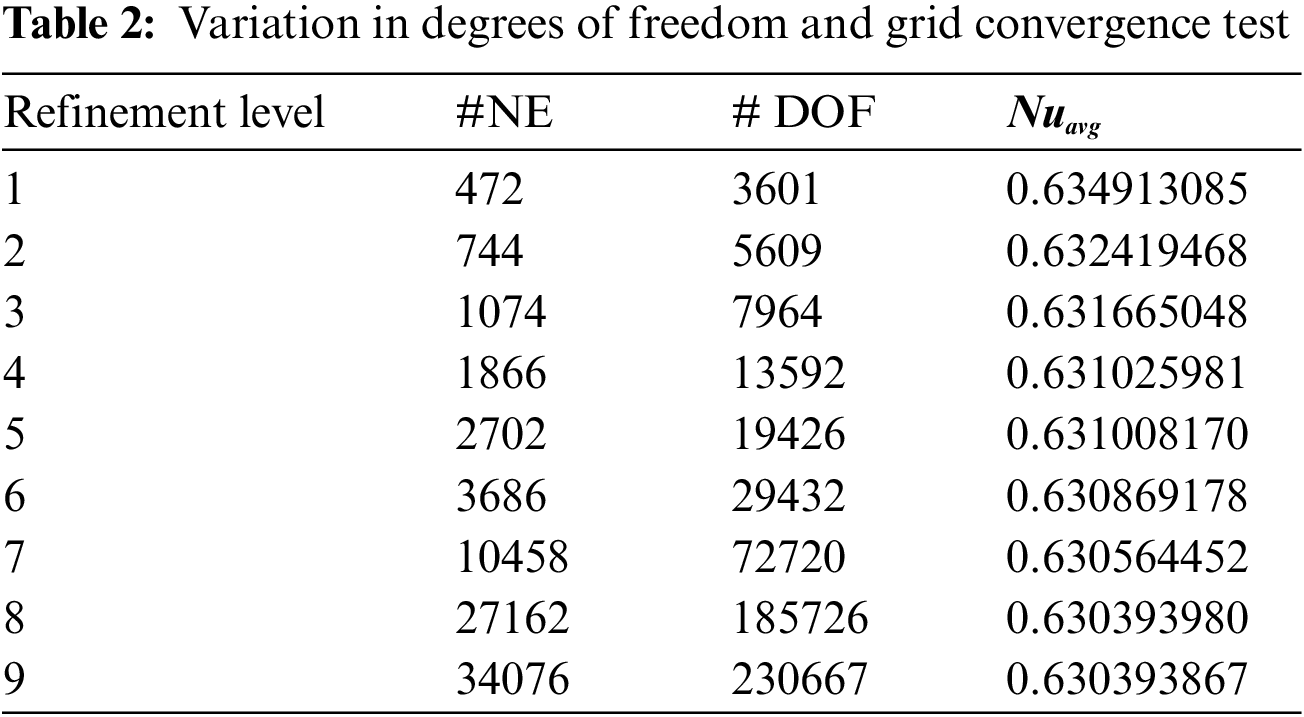

This section demonstrates how entropy quantities change in response to modifications in flow-controlling parameters. Galerkin finite element method and hybridized meshing are applied to achieve highly accurate results. Elements with triangular and rectangular shapes are employed to represent domain discretization. Table 2 lists data about the number of elements and degrees of freedom at nine levels. It shows the results of a grid independence analysis for

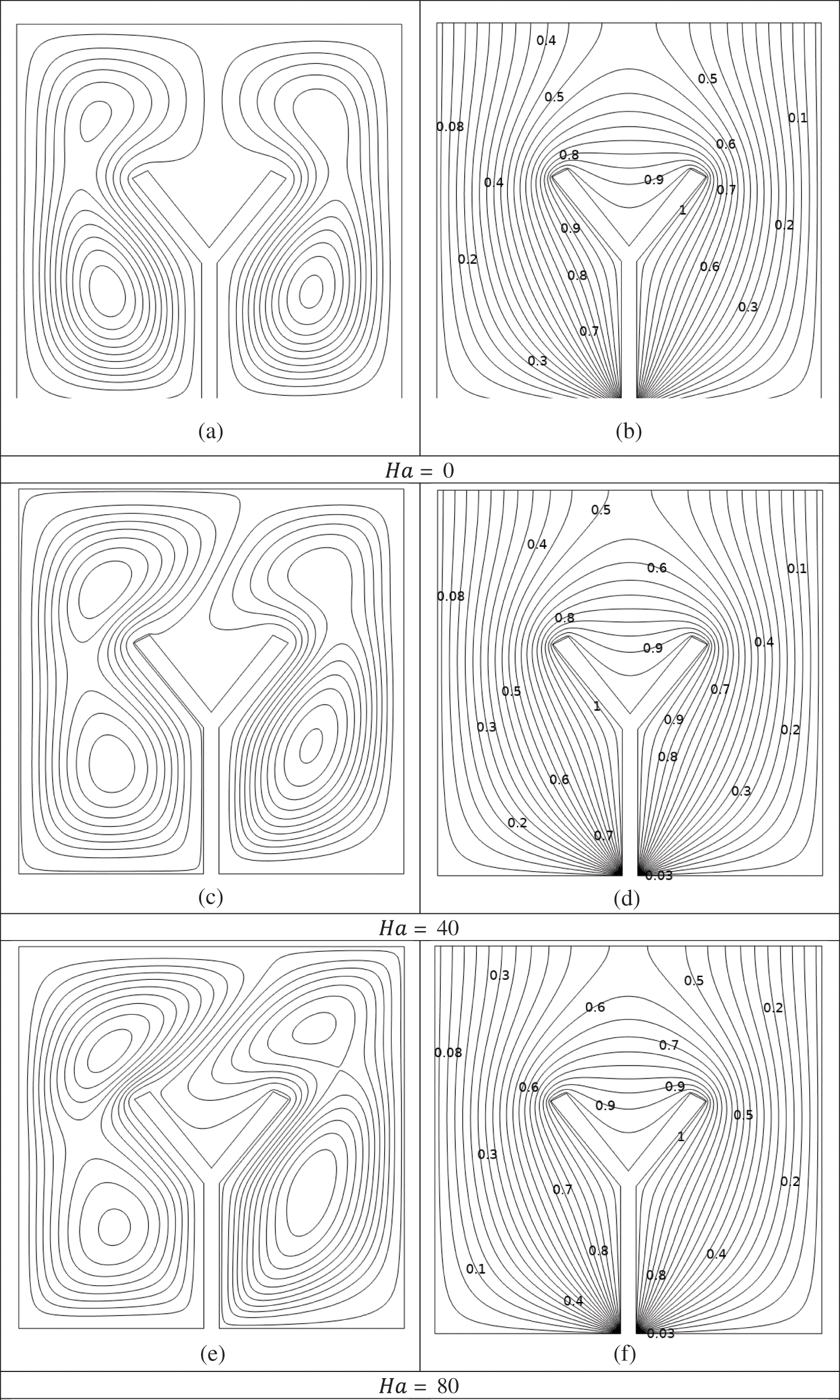

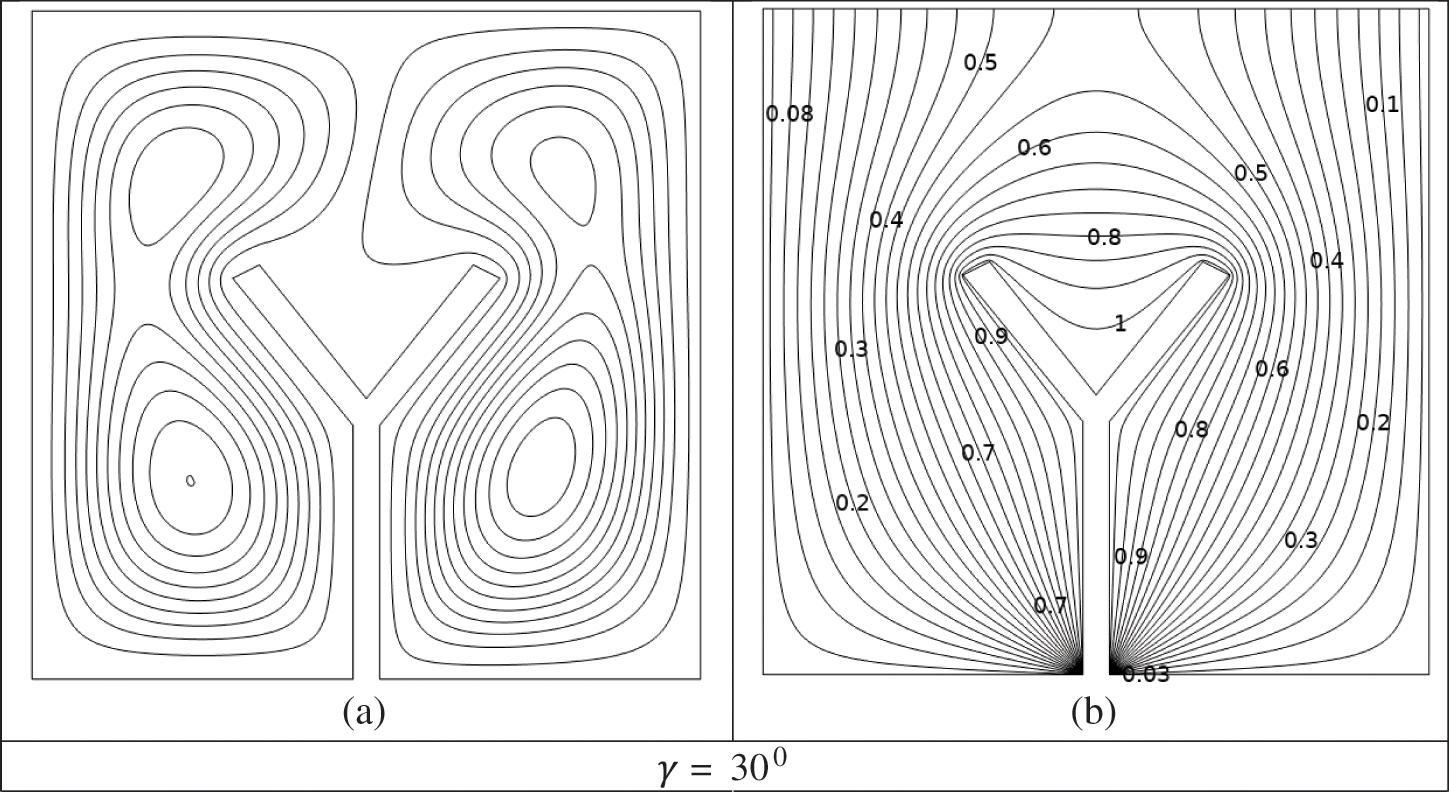

Figs. 3a–3h display streamline and isotherm patterns with varying

Figure 3: (a–h) Impacts of

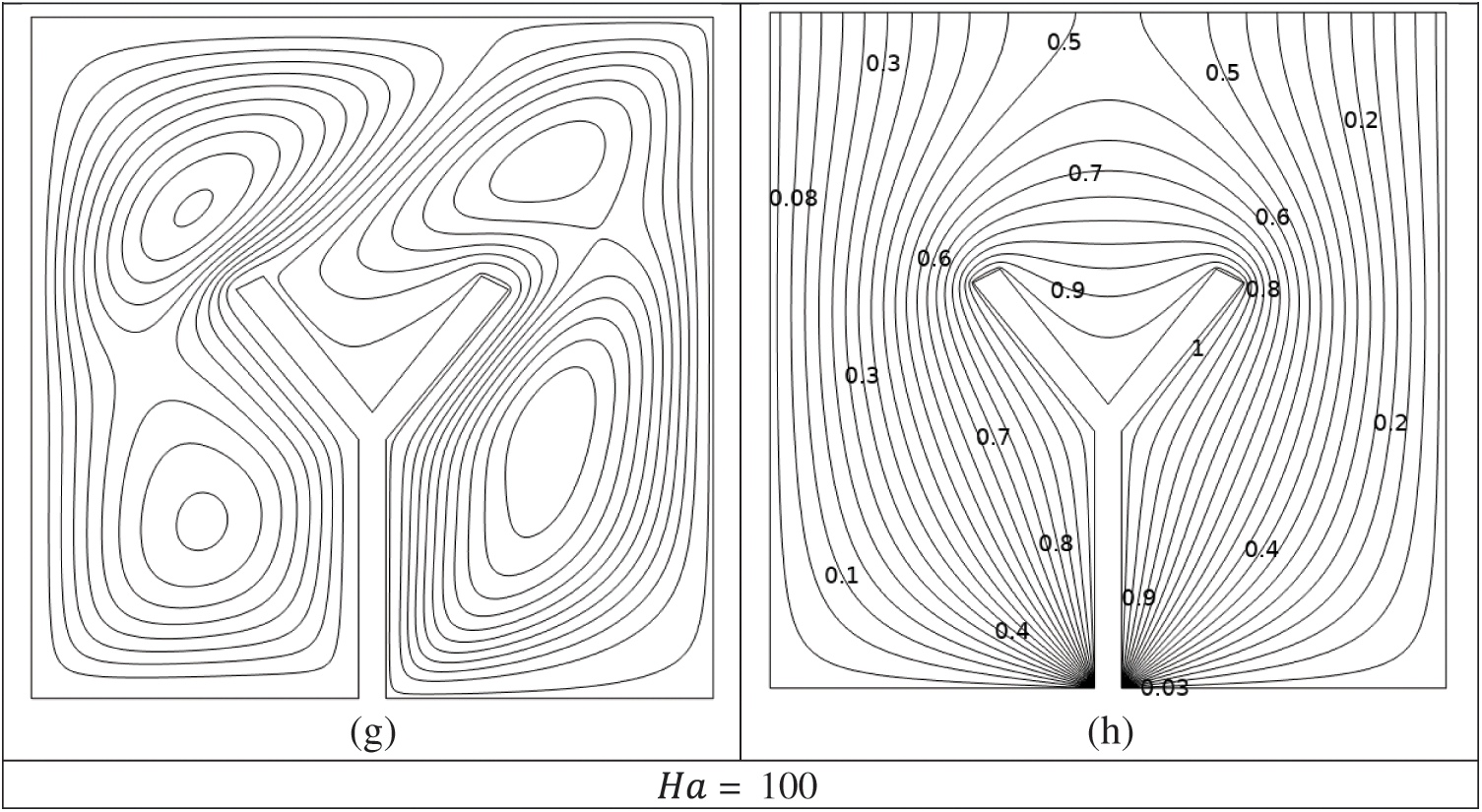

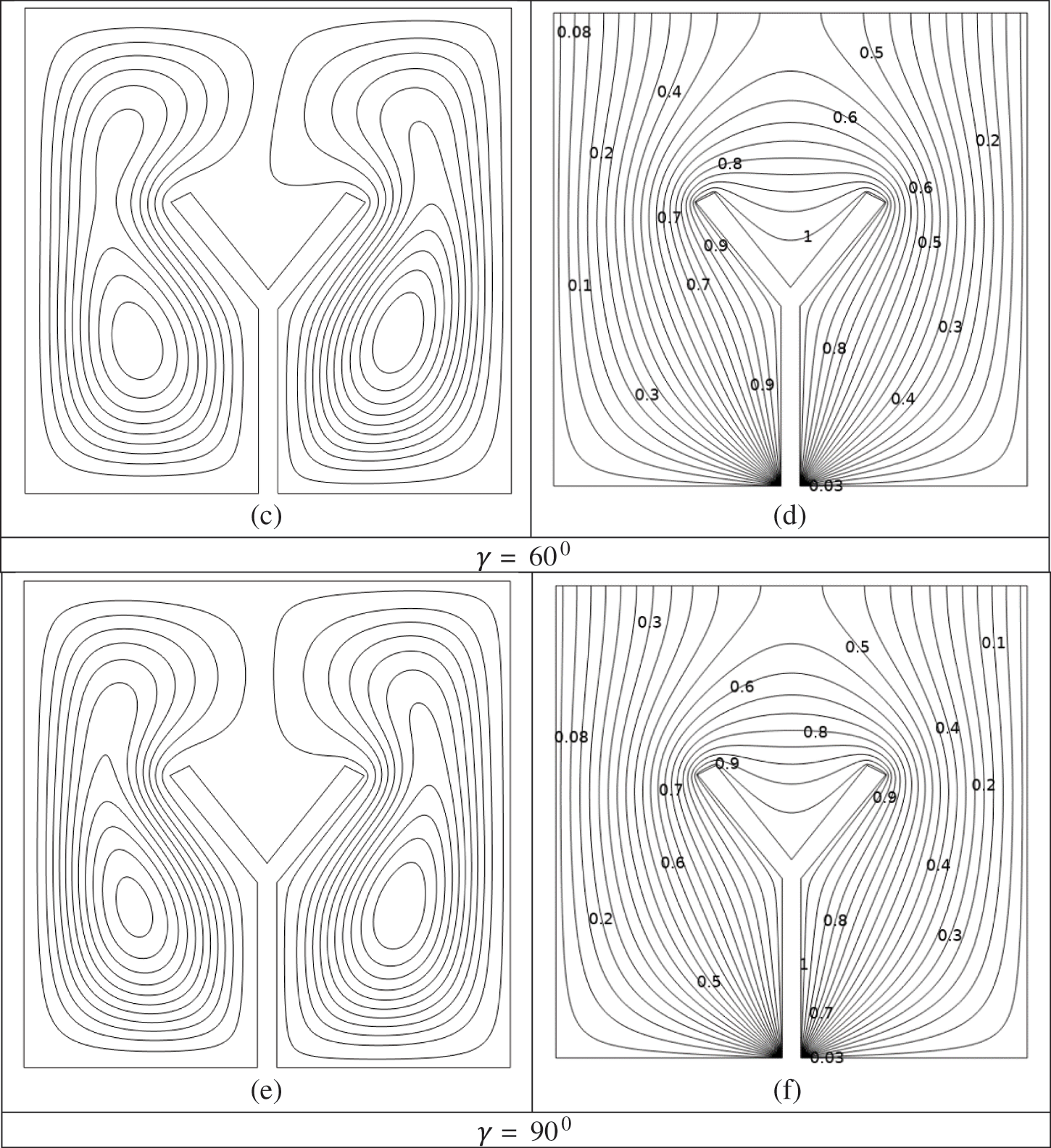

In Figs. 4a–4f, the

Figure 4: (a–f) Impacts of

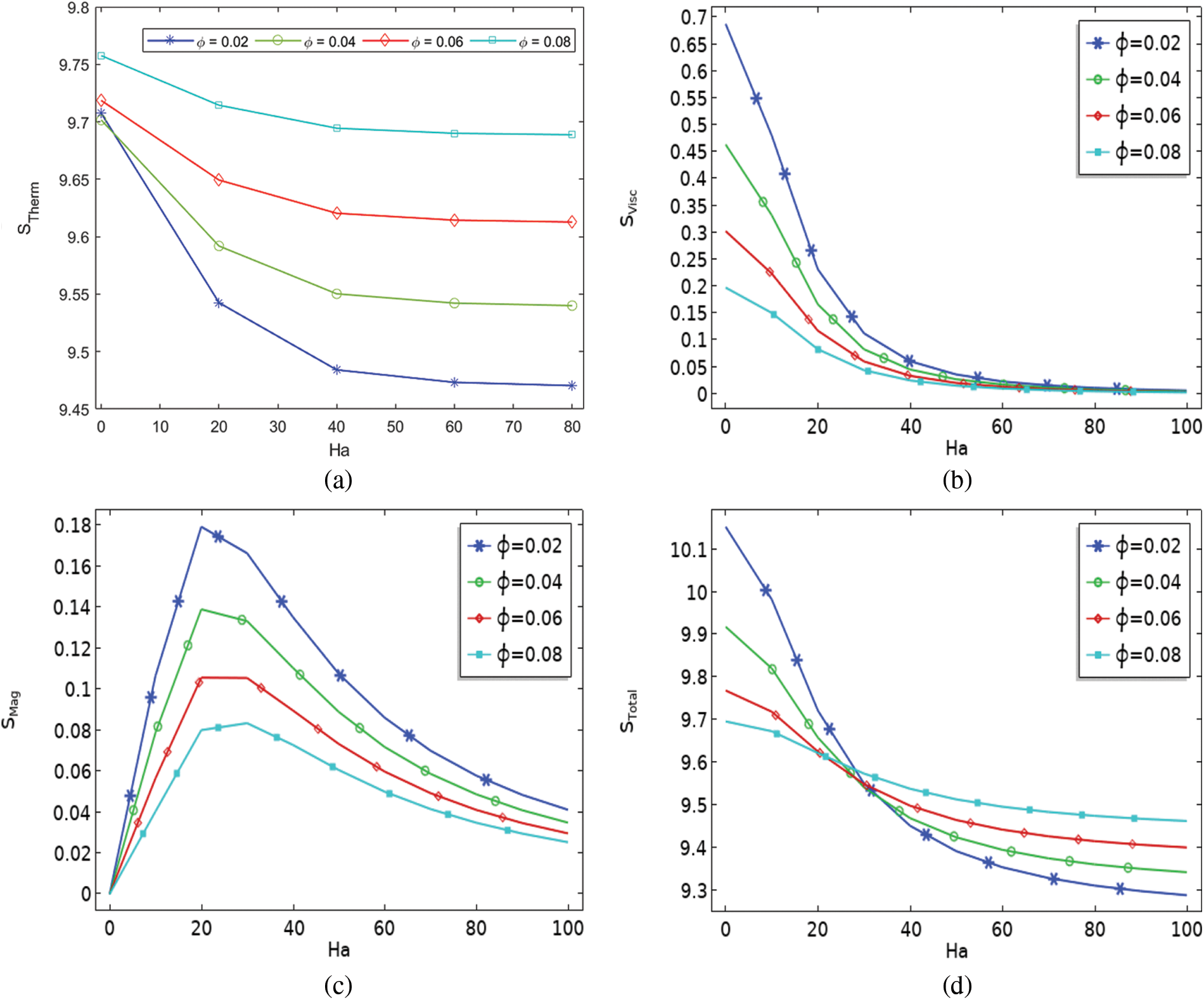

It was reported that nanoparticle volume fraction significantly impacts

Figure 5: (a–d) Impacts of

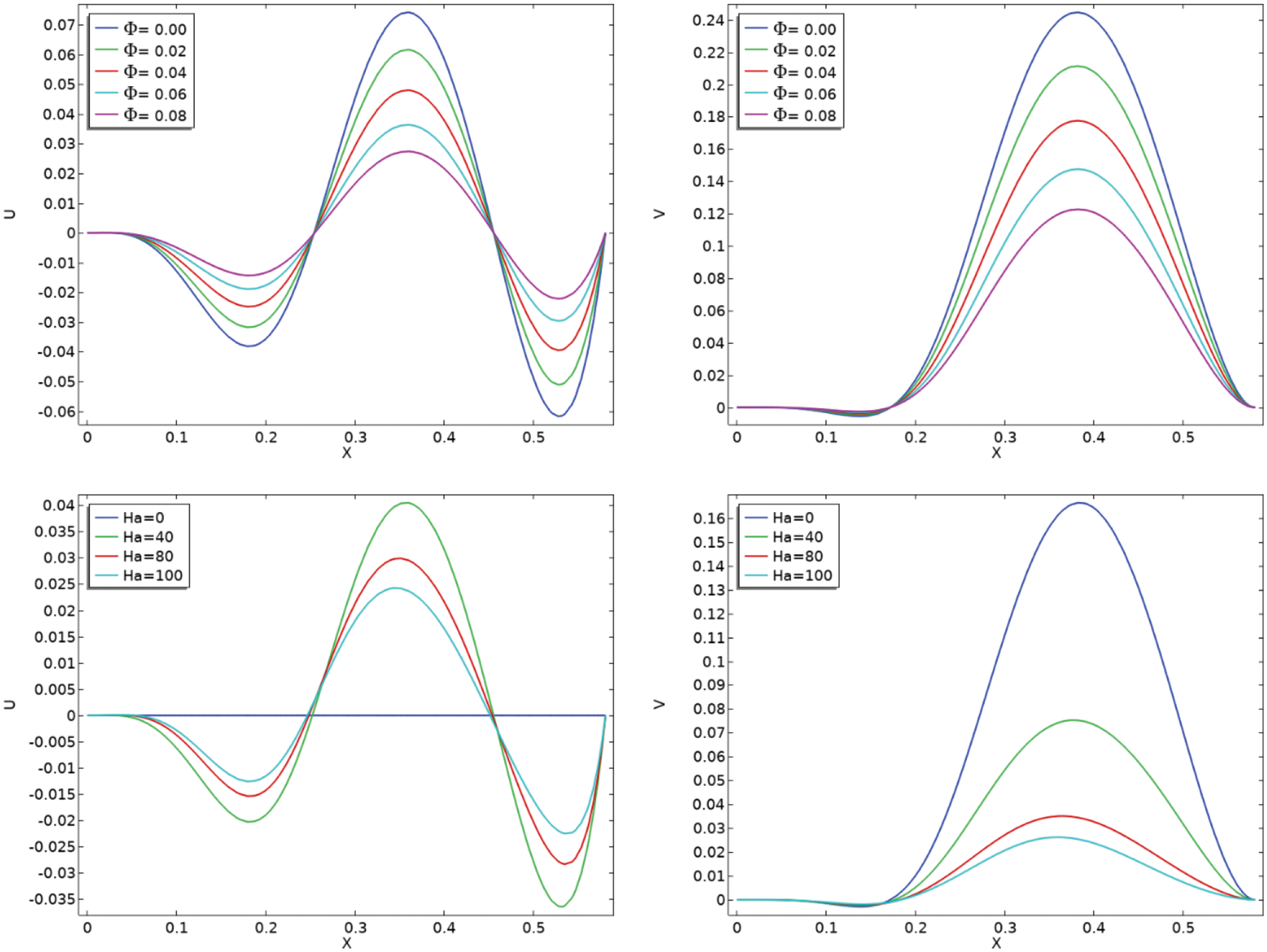

For different

Figure 6: Velocity line graphs for different

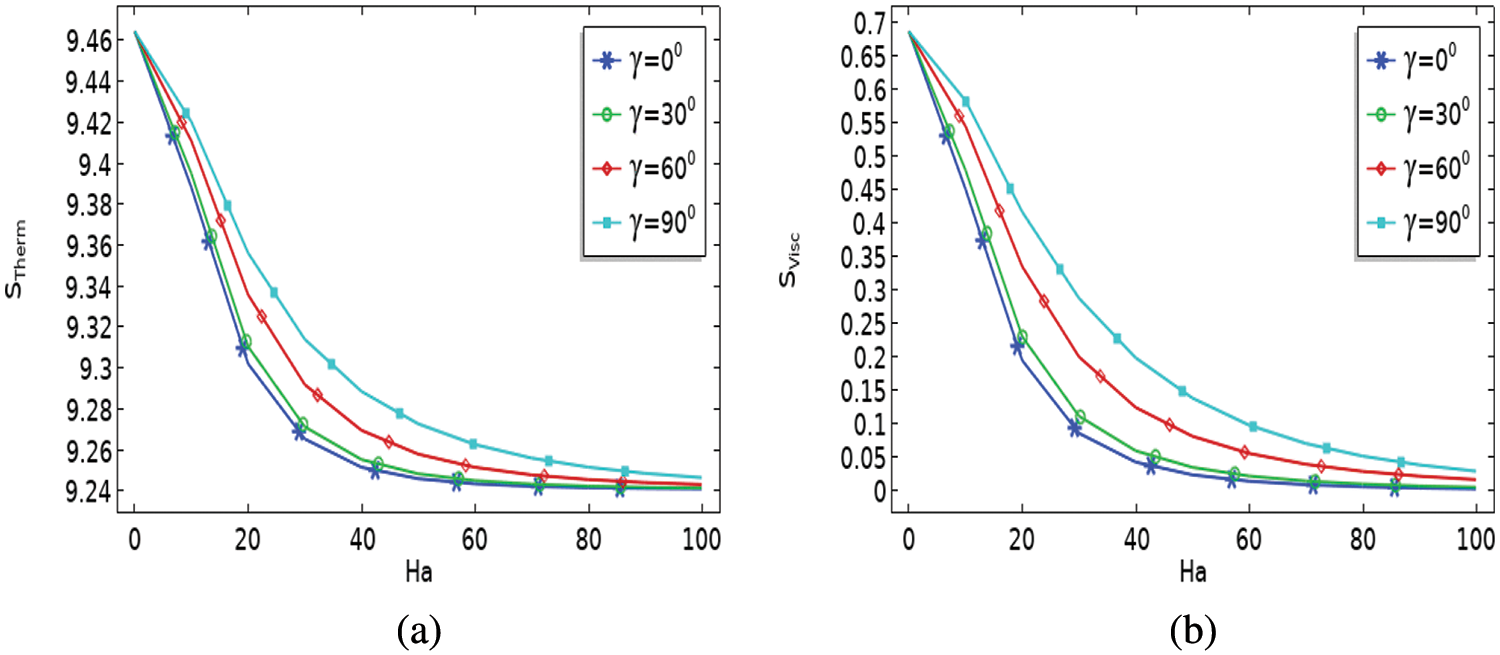

Figs. 7a and 7b depict the effect of the magnetic fields

Figure 7: (a–b) Entropy variation against (

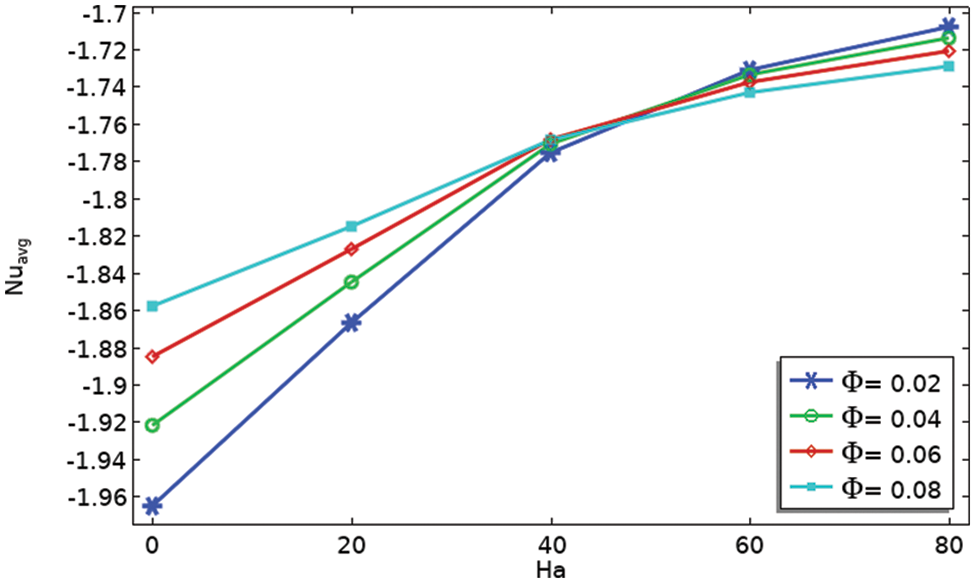

Fig. 8 reveals the dependence of the heat flux coefficient on the Ha and the

Figure 8: Impacts on

This study discusses the issue of irreversibility during the natural convective thermal flow of a Cu-

• Because of the created temperature disparity, heat is transferred in the shape of parabolic curves and starts at the top of the enclosure.

• For

• For Ha > 0, a diminishing trend of (

• It can be observed that as

• It is widely accepted that the variation in magnetic entropy becomes zero at

Acknowledgement: The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through a small group Research Project under Grant Number RGP1/154/44.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm their contribution to the paper as follows: study conception and design: Afraz Hussain Majeed, Sayed M Eldin; methodology: Imran Siddique, Rashid Mahmood; data collection: S. Saleem, Muhammad Jawad; analysis and interpretation of results: Rashid Mahmood Sayed M Eldin; draft manuscript preparation: Muhammad Jawad, Afraz Hussain Majeed; writing—review and editing: Imran Siddique; funding acquisition: Sayed M Eldin: supervisor: Rashid Mahmood. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Bejan, A. (1980). Second law analysis in heat transfer. Energy, 5, 720–732. https://doi.org/10.1016/0360-5442(80)90091-2 [Google Scholar] [CrossRef]

2. Parvin, S., Chamkha, A. J. (2014). An analysis on free convection flow, heat transfer and entropy generation in an odd-shaped cavity filled with nanofluid. International Communications in Heat and Mass Transfer, 54, 8–17. https://doi.org/10.1016/j.icheatmasstransfer.2014.02.031 [Google Scholar] [CrossRef]

3. Kefayati, G. H. R. (2014). Natural convection of ferrofluid in a linearly heated cavity utilizing LBM. Journal of Molecular Liquids, 191, 1–9. https://doi.org/10.1016/j.molliq.2013.11.021 [Google Scholar] [CrossRef]

4. Rabbi, K. M., Saha, S., Mojumder, S., Rahman, M. M., Saidur, R. et al. (2016). Numerical investigation of pure mixed convection in a ferrofluid-filled lid-driven cavity for different heater configurations. Alexandria Engineering Journal, 55, 127–139. https://doi.org/10.1016/j.aej.2015.12.021 [Google Scholar] [CrossRef]

5. Mejri, I., Mahmoudi, A., Abbassi, M. A., Omri, A. (2014). Magnetic field effect on entropy generation in a nanofluid-filled enclosure with sinusoidal heating on both side walls. Powder Technology, 266, 340–353. https://doi.org/10.1016/j.powtec.2014.06.054 [Google Scholar] [CrossRef]

6. Mahmoudi, A., Mejri, I., Abbassi, M. A., Omri, A. (2014). Analysis of the entropy generation in a nanofluid-filled cavity in the presence of magnetic field and uniform heat generation/absorption. Journal of Molecular Liquids, 198, 63–77. https://doi.org/10.1016/j.molliq.2014.07.010 [Google Scholar] [CrossRef]

7. Armaghani, T., Kasaeipoor, A., Alavi, N., Rashidi, M. M. (2016). Numerical investigation of water-alumina nanofluid natural convection heat transfer and entropy generation in a baffled L-shaped cavity. Journal of Molecular Liquids, 223, 243–251. https://doi.org/10.1016/j.molliq.2016.07.103 [Google Scholar] [CrossRef]

8. Al-Zamily, A. M. J. (2017). Analysis of natural convection and entropy generation in a cavity filled with multi-layers of porous medium and nanofluid with a heat generation. International Journal of Heat and Mass Transfer, 106, 1218–1231. https://doi.org/10.1016/j.ijheatmasstransfer.2016.10.102 [Google Scholar] [CrossRef]

9. Bouchoucha, A. E. M., Bessaïh, R., Oztop, H. F., Al-Salem, K., Bayrak, F. (2017). Natural convection and entropy generation in a nanofluid filled cavity with thick bottom wall: Effects of non-isothermal heating. International Journal of Mechanical Sciences, 126, 95–105. https://doi.org/10.1016/j.ijmecsci.2017.03.025 [Google Scholar] [CrossRef]

10. Oztop, H. F., Abu-Nada, E. (2008). Numerical study of natural convection in partially heated rectangular enclosures filled with nanofluids. International Journal of Heat and Fluid Flow, 29, 1326–1336. https://doi.org/10.1016/j.ijheatfluidflow.2008.04.009 [Google Scholar] [CrossRef]

11. Sheremet, M. A., Grosan, T., Pop, I. (2017). Natural convection and entropy generation in a square cavity with variable temperature side walls filled with a nanofluid: Buongiorno’s mathematical model. Entropy, 19, 337. https://doi.org/10.3390/e19070337 [Google Scholar] [CrossRef]

12. Siavashi, M., Yousofvand, R., Rezanejad, S. (2018). Nanofluid and porous fins effect on natural convection and entropy generation of flow inside a cavity. Advanced Powder Technology, 29, 142–156. https://doi.org/10.1016/j.apt.2017.10.021 [Google Scholar] [CrossRef]

13. Kashyap, D., Dass, A. K. (2018). Two-phase lattice Boltzmann simulation of natural convection in a Cu-water nanofluid-filled porous cavity: Effects of thermal boundary conditions on heat transfer and entropy generation. Advanced Powder Technology, 29, 2707–2724. https://doi.org/10.1016/j.apt.2018.07.020 [Google Scholar] [CrossRef]

14. Gibanov, N. S., Sheremet, M. A., Oztop, H. F., Abu-Hamdeh, N. (2018). Mixed convection with entropy generation of nanofluid in a lid-driven cavity under the effects of a heat-conducting solid wall and vertical temperature gradient. European Journal of Mechanics–B/Fluids, 70, 148–159. https://doi.org/10.1016/j.euromechflu.2018.03.002 [Google Scholar] [CrossRef]

15. Mansour, M. A., Siddiqa, S., Gorla, R. S. R., Rashad, A. M. (2018). Effects of heat source and sink on entropy generation and MHD natural convection of Al2O3-Cu/water hybrid nanofluid filled with square porous cavity. Thermal Science and Engineering Progress, 6, 57–71. https://doi.org/10.1016/j.tsep.2017.10.014 [Google Scholar] [CrossRef]

16. Rahimi, A., Sepehr, M., Lariche, M. J., Kasaeipoor, A., Malekshah, E. H. et al. (2018). Entropy generation analysis and heatline visualization of free convection in nanofluid (KKL model-based)-filled cavity including internal active fins using lattice Boltzmann method. Computers & Mathematics with Applications, 75, 1814–1830. https://doi.org/10.1016/j.camwa.2017.12.008 [Google Scholar] [CrossRef]

17. Bilal, S., Majeed, A. H., Mahmood, R., Khan, I., Seikh, A. H. (2020). Heat and mass transfer in hydromagnetic second-grade fluid past a porous inclined cylinder under the effects of thermal dissipation, diffusion and radiative heat flux. Energies, 13, 278. https://doi.org/10.3390/en13010278 [Google Scholar] [CrossRef]

18. Majeed, A. H., Bilal, S., Mahmood, R., Malik, M. Y. (2020). Heat transfer analysis of viscous fluid flow between two coaxially rotated disks embedded in permeable media by capitalizing non-Fourier heat flux model. Physica A: Statistical Mechanics and its Applications, 540, 123182. https://doi.org/10.1016/j.physa.2019.123182 [Google Scholar] [CrossRef]

19. Mahmood, R., Bilal, S., Majeed, A. H., Khan, I., Sherif, E. S. M. (2020). A comparative analysis of flow features of Newtonian and power law material: A new configuration. Journal of Materials Research and Technology, 9, 1978–1987. https://doi.org/10.1016/j.jmrt.2019.12.030 [Google Scholar] [CrossRef]

20. Bilal, S., Mahmood, R., Majeed, A. H., Khan, I., Nisar, K. S. (2020). Finite element method visualization about heat transfer analysis of Newtonian material in triangular cavity with square cylinder. Journal of Materials Research and Technology, 9, 4904–4918. https://doi.org/10.1016/j.jmrt.2020.03.010 [Google Scholar] [CrossRef]

21. Khan, Z. A., Usman, M., Khan, W. A., Hamid, M., Haq, R. U. (2022). Thermal treatment inside a partially heated triangular cavity filled with casson fluid with an inner cylindrical obstacle via FEM approach. The European Physical Journal Special Topics, 231, 2683–2694. https://doi.org/10.1140/epjs/s11734-022-00587-6 [Google Scholar] [CrossRef]

22. Soomro, F. A., Hamid, M., Hussain, S. T., Haq, R. U. (2022). Constructional design and mixed convection heat transfer inside lid-driven semicircular cavity. The European Physical Journal Plus, 137, 781. https://doi.org/10.1140/epjp/s13360-022-03009-7 [Google Scholar] [CrossRef]

23. Chelia, W., Laouer, A., Mezaache, E. H., Teggar, M., Arici, M. et al. (2023). Investigation of nanofluid natural convection inside a square cavity for two orientations using lattice boltzmann method. Journal of Nanofluids, 12, 889–903. https://doi.org/10.1166/jon.2023.1964 [Google Scholar] [CrossRef]

24. Mahmood, R., Khan, Y., Rehman, N., Majeed, A. H., Alameer, A. et al. (2022). Numerical computations of entropy generation and MHD ferrofluid filled in a closed wavy configuration: Finite element based study. Frontiers of Physics, 10, 916394. https://doi.org/10.3389/fphy.2022.916394 [Google Scholar] [CrossRef]

25. Mahmood, R., Rehman, N., Majeed, A. H., Rehman, K. U., Shatanawi, W. (2023). Numerical solution for heat transfer in a staggered enclosure with wavy insulated baffles. AIMS Mathematics, 8(4), 8332–8348. https://doi.org/10.3934/math.2023420 [Google Scholar] [CrossRef]

26. Rehman, N., Mahmood, R., Majeed, A. H., Rehman, K. U., Shatanawi, W. (2023). Finite element analysis on entropy generation in MHD Iron (III) Oxide-Water NanoFluid equipped in partially heated fillet cavity. Journal of Magnetism and Magnetic Materials, 565, 170269. https://doi.org/10.1016/j.jmmm.2022.170269 [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools