Open Access

Open Access

ARTICLE

Modified DS np Chart Using Generalized Multiple Dependent State Sampling under Time Truncated Life Test

1 Division of Applied Statistics, Department of Mathematics and Computer Science, Faculty of Science and Technology, Rajamangala University of Technology Thanyaburi, Pathum Thani, 12110, Thailand

2 Division of Mathematics, Department of Mathematics and Computer Science, Faculty of Science and Technology, Rajamangala University of Technology Krungthep, Bangkok, 10120, Thailand

* Corresponding Author: Pramote Charongrattanasakul. Email:

Computer Modeling in Engineering & Sciences 2024, 138(3), 2471-2495. https://doi.org/10.32604/cmes.2023.031433

Received 15 June 2023; Accepted 11 September 2023; Issue published 15 December 2023

Abstract

This study presents the design of a modified attributed control chart based on a double sampling (DS) np chart applied in combination with generalized multiple dependent state (GMDS) sampling to monitor the mean life of the product based on the time truncated life test employing the Weibull distribution. The control chart developed supports the examination of the mean lifespan variation for a particular product in the process of manufacturing. Three control limit levels are used: the warning control limit, inner control limit, and outer control limit. Together, they enhance the capability for variation detection. A genetic algorithm can be used for optimization during the in-control process, whereby the optimal parameters can be established for the proposed control chart. The control chart performance is assessed using the average run length, while the influence of the model parameters upon the control chart solution is assessed via sensitivity analysis based on an orthogonal experimental design with multiple linear regression. A comparative study was conducted based on the out-of-control average run length, in which the developed control chart offered greater sensitivity in the detection of process shifts while making use of smaller samples on average than is the case for existing control charts. Finally, to exhibit the utility of the developed control chart, this paper presents its application using simulated data with parameters drawn from the real set of data.Keywords

A control chart is a statistical analysis tool used to monitor processes through time. It can also identify changes or trends that could indicate a potential problem. Control charts are used to control quality in production to ensure consistency and help identify areas for improvement. The concept of statistical process control (SPC) was introduced by Walter A. Shewhart during the 1920s. One of his key contributions to SPC was the development of the control chart, which is a tool used to monitor and control a process over time. Shewhart’s control chart revolutionized the field of quality control by providing a way to monitor processes in real-time and make data-driven decisions to improve quality according to Montgomery [1]. Presently, control charts have many applications in manufacturing and are also used in healthcare, finance, and other fields. They aim to monitor and control processes and ensure consistent quality over time. The two control chart types are variable and attribute control charts. The most important difference between the two control charts is the type of data used to monitor them. A variable control chart serves to monitor continuous or quantitative data that are measurable using a numerical scale, such as weight, length, temperature, or time. On the other hand, the number of defects or the proportion or percentage of defects in a sample of a process can be monitored using an attribute control chart.

The np control chart finds widespread use in industry because it offers a simple and effective way to monitor the stability of a process by tracking the number of non-conforming items in a sample. However, it is known that the standard np charts are not effective at detecting process shifts when the proportion of nonconforming items (p) is moderate or small. Therefore, some researchers have focused on improving the efficiency of the np chart to detect process shifts through various methods such as that of Gan [2], who proposed an optimized design for CUSUM np charts. Gan [3] developed the concept of the modified exponentially weighted moving average (EWMA) chart together with the np chart. Epprecht et al. [4] studied the properties of the np chart in cases where sample sizes varied between small and large. Luo et al. [5] designed optimal variable sample sizes and variable sampling intervals np charts in a steady-state mode. Double sampling (DS) was first presented by Croasdale [6], who adopted the idea from the acceptance sampling plan and used it to apply the technique to the

There are also different techniques in sampling plans proposed by many researchers to improve processes to be more efficient. One popular acceptance sampling technique is MDS sampling proposed by Wortham et al. [15]. Since the acceptance or rejection of current lots depends on previous and current lots, the MDS sampling plan is intended for a continuous production process whereby lots are sent for serial inspection, which reduces the sample size. Several researchers have adopted MDS sampling plans to develop a more efficient acceptance sampling plan [16–19]. Many researchers created designs to apply MDS sampling in the area of control charts, such as Aslam et al. [20] who provided the

During this study, the modified attributed np chart will be designed through a combination of GMDS sampling with the DS np chart approach, based upon the time truncated life test where the product lifespan adheres to a Weibull distribution. Genetic algorithm optimization during the in-control process serves to establish the optimal parameters for the developed control chart. The performance of the chart was assessed using the average run length, while sensitivity analysis was investigated using an orthogonal experimental design with multiple linear regression. One objective was to determine the influence of the model parameters on the solution delivered by the developed control chart. Comparisons between the developed control chart and the existing control charts could be drawn using the out-of-control average run length. Simulated data drawn from the parameters of the real set of data are used to present an example of the developed control chart.

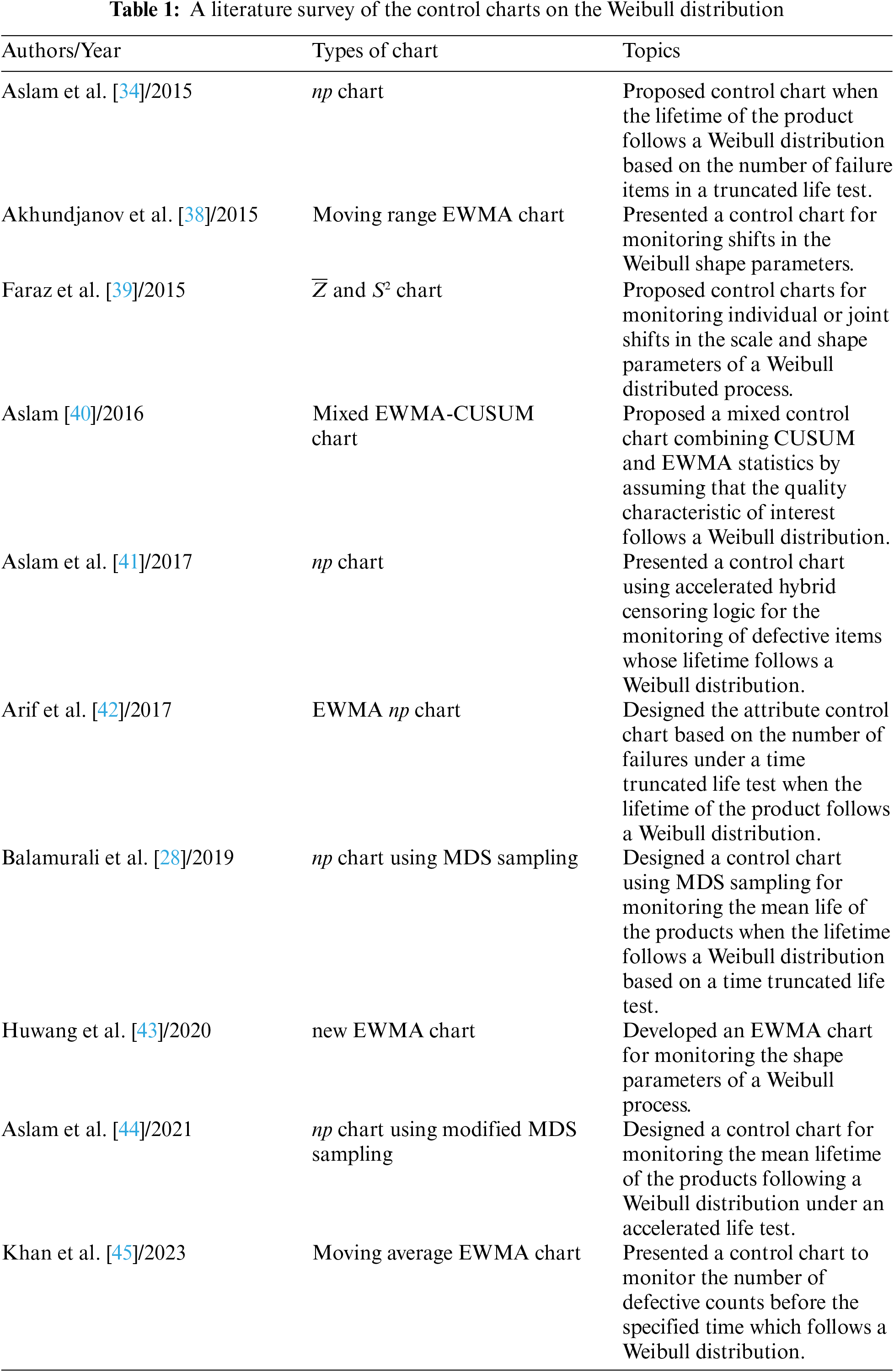

The Weibull distribution is often employed in statistical quality control studies [16–19,28]. Because of its flexibility and closed shape, the Weibull distribution serves as the most popular choice to model the data lifespan.

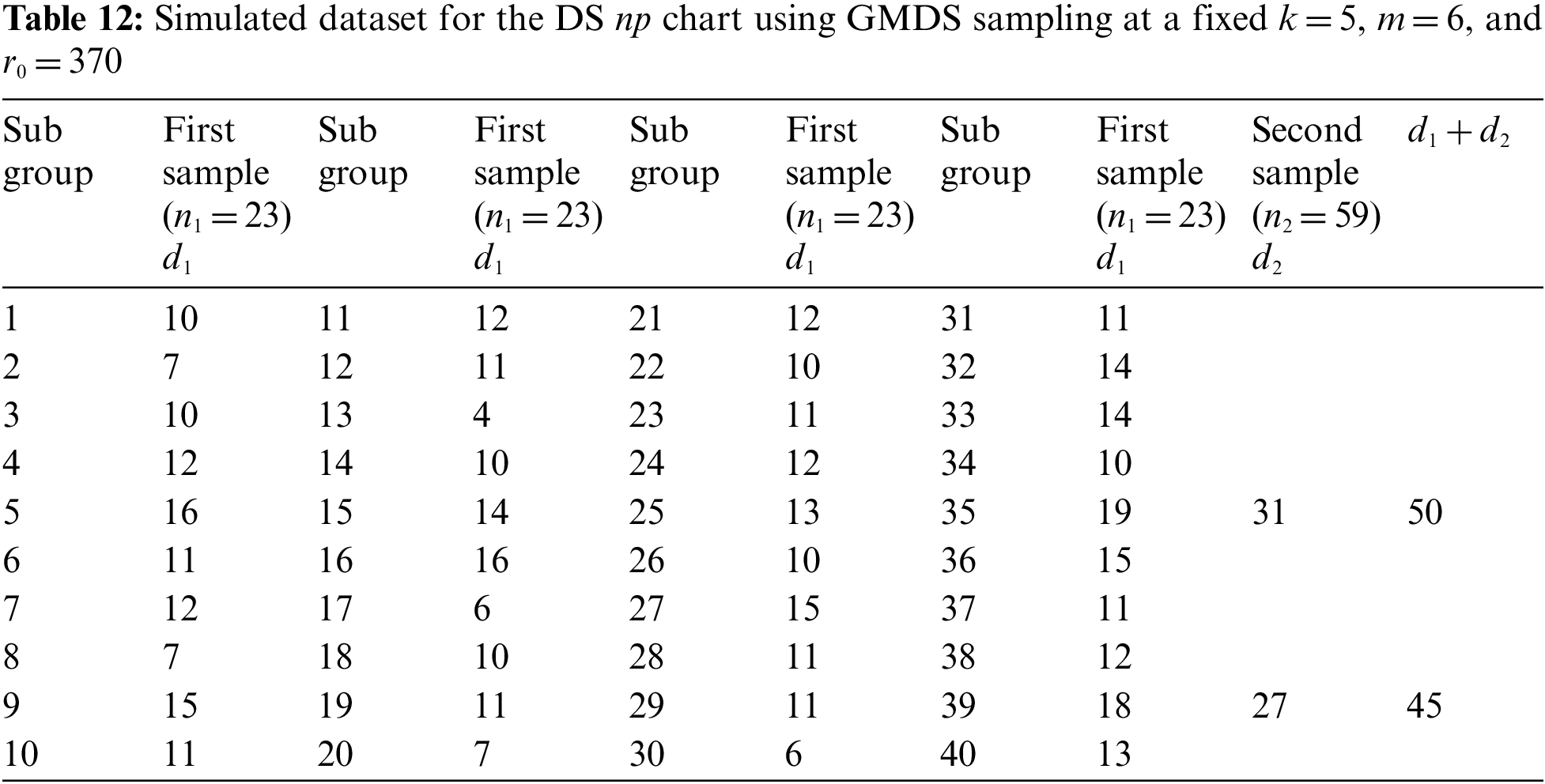

Table 1 shows that researchers applied the Weibull distribution to the attributed control chart to monitor the number of failures or mean life of products under a time truncated life test when the lifetime of the product follows a Weibull distribution. For the variable control chart, the Weibull distribution is often used to monitor variation in the manufacturing process because of the flexible selection of shape and scale parameters. Therefore, this research designs the modified DS np chart using GMDS sampling to monitor the mean life of the product based on the time truncated life test under the Weibull distribution. Let t represent the product lifespan under the Weibull distribution, so the cumulative distribution function can be expressed as follows:

where

Let

The value of

If the process mean is the same as the target mean, or

where

From Eq. (6), we obtain the probability of a given item failing when there is a shift in process in terms of the specified values of

2.2 Design of the Modified DS np Chart Using GMDS Sampling

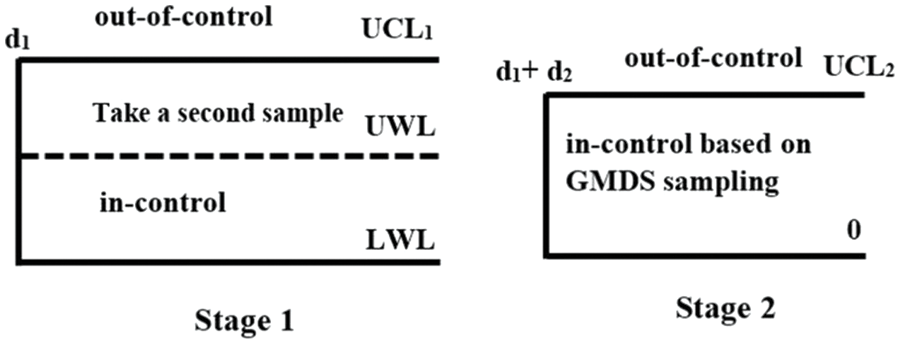

The following section presents the modified DS np control chart using GMDS sampling to monitor the mean life of the product created on the basis of time truncated life tests under the Weibull distribution. The developed control chart includes a pair of inspection stages. In Stage 1, two warning control limits are indicated by

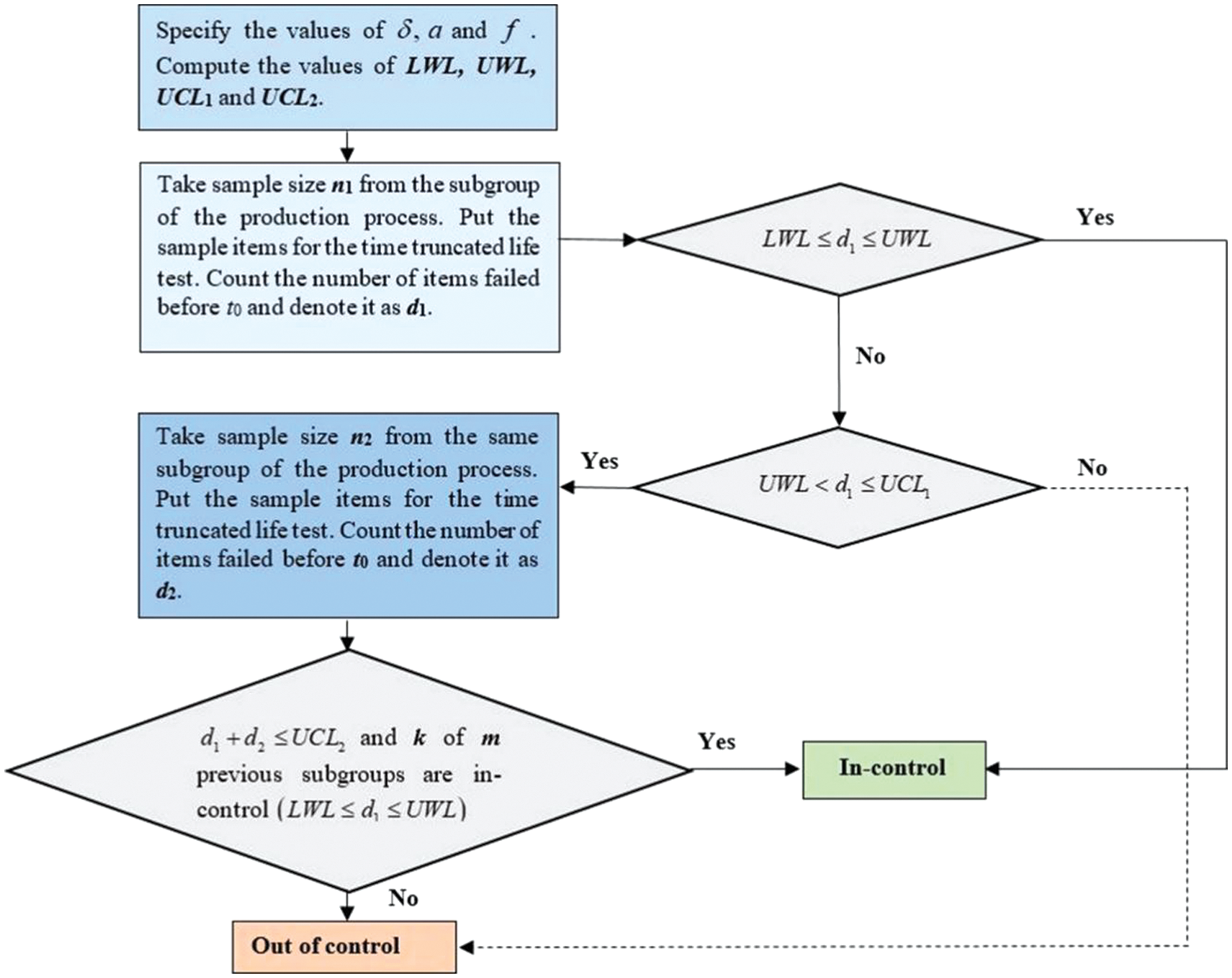

1. Specify the limits indicated as

2. The initial sample, of size

3. In Stage 1 (see Fig. 1)

3.1If

If

If

In Stage 2 (see Fig. 1), if

Figure 1: The modified DS np chart based on GMDS sampling procedure

Let

1. The developed control chart monitors the mean life of products under a time-truncated life test when the lifetime of the product follows a Weibull distribution.

2. The developed control chart is constructed based on a double sampling np chart together with GMDS sampling where

3. At the start of the process, the process is assumed to fit the in-control region, that is

Figure 2: Flowchart of the inspection procedure for the modified DS np chart based on GMDS sampling

The process mean may be shifted to the out-of-control region, that is

4. In this study, the genetic algorithm (GA) with the R program is used to find the optimal parameters.

Therefore, the control limits for Stages 1 and 2 are shown as follows:

Stage 1

Stage 2

where

Based on the developed control chart, the probability that the process will be considered in-control at Stage 1 is indicated by

where

The probability declares that the process is in-control at Stage 2 when given that k of m from the previous subgroup must be in-control at Stage 1, denoted by

According to the modified DS np chart using GMDS sampling, the probability that the process was considered to be in-control is indicated as:

The probability of declaring that a process is in-control when it is actually in-control

Moreover, the probability of declaring that a process is in-control when it is actually out-of-control

The

The

Additionally, the average sample size

where

2.3 Optimal Design of the Modified DS np Chart Using GMDS Sampling Based on the Weibull Distribution

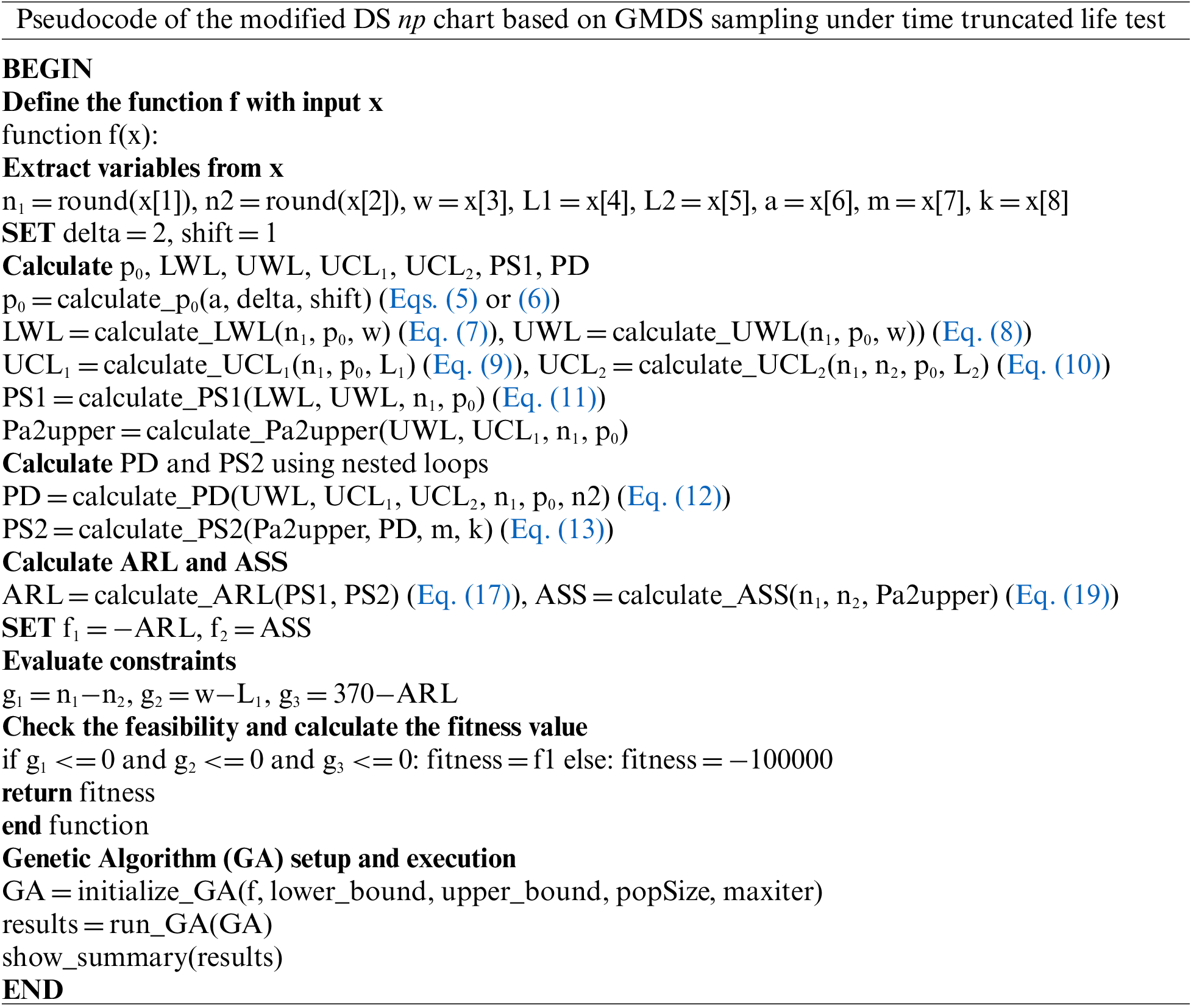

In this section, we used the following optimization problem to obtain the optimal parameters for constructing the modified DS np chart using GMDS sampling as follows:

where

1. Assign the values of

2. Find out the values of the optimal parameters

3. Calculate the ARL1 in Eq. (18) using the optimal parameters

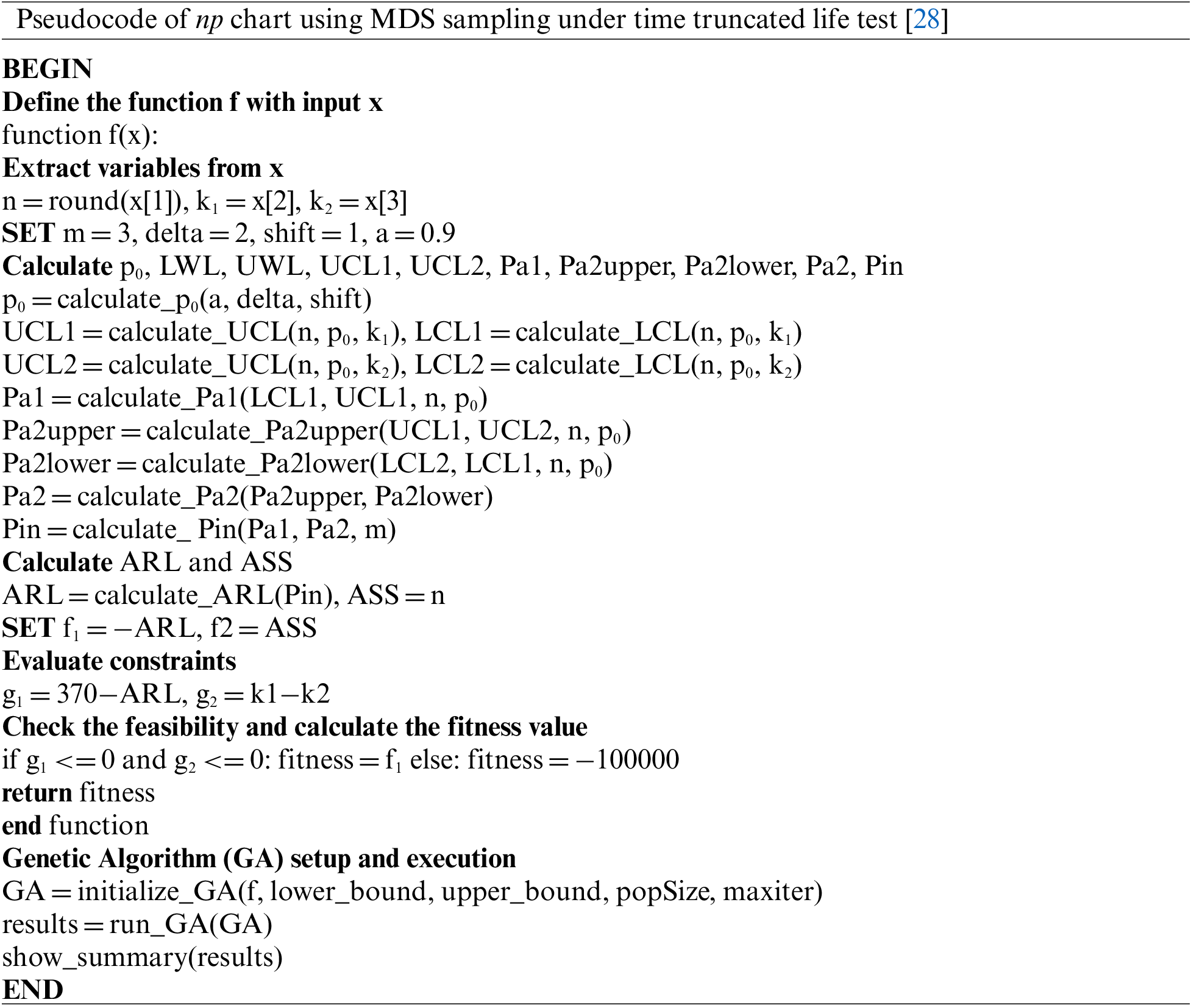

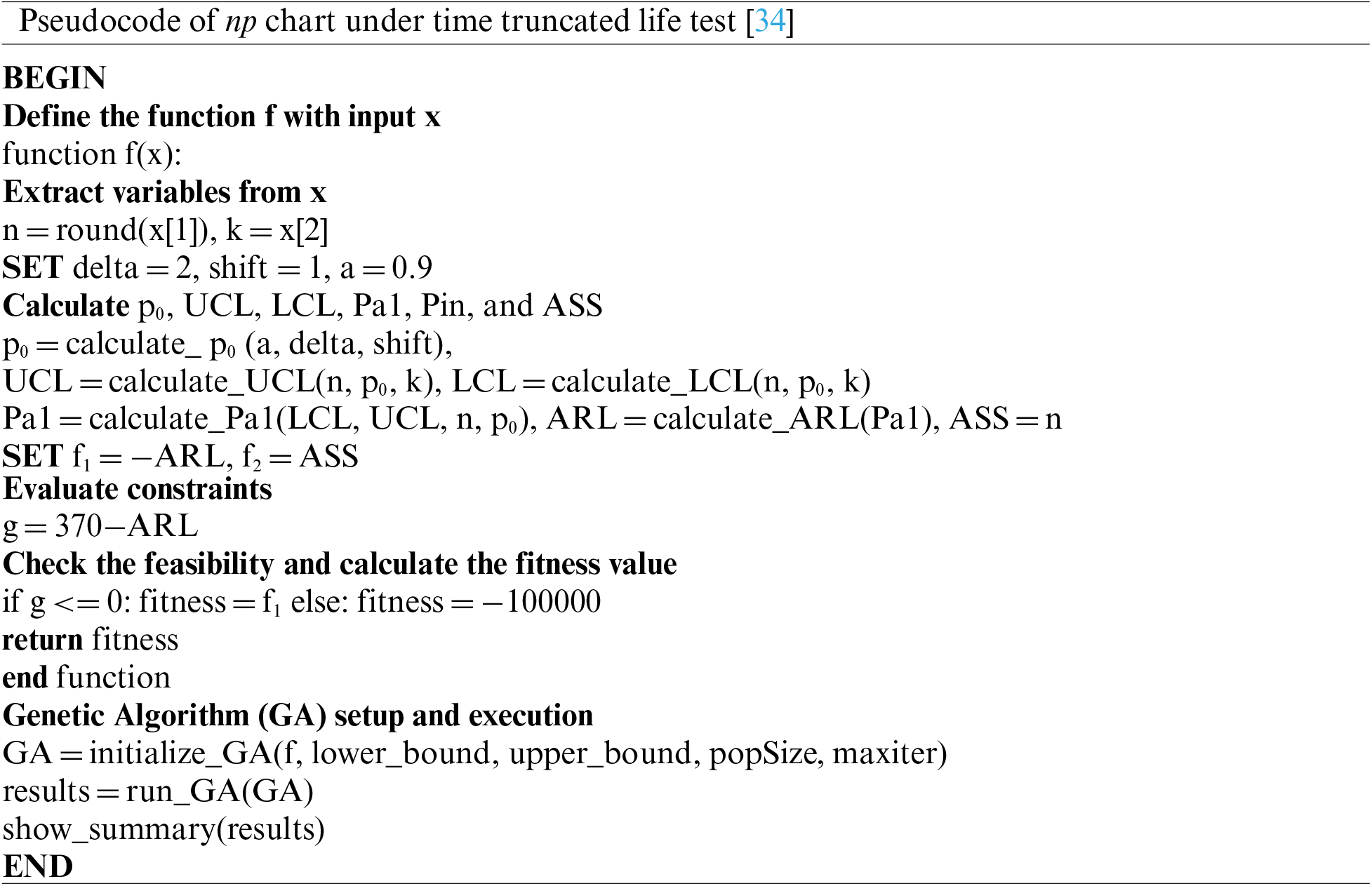

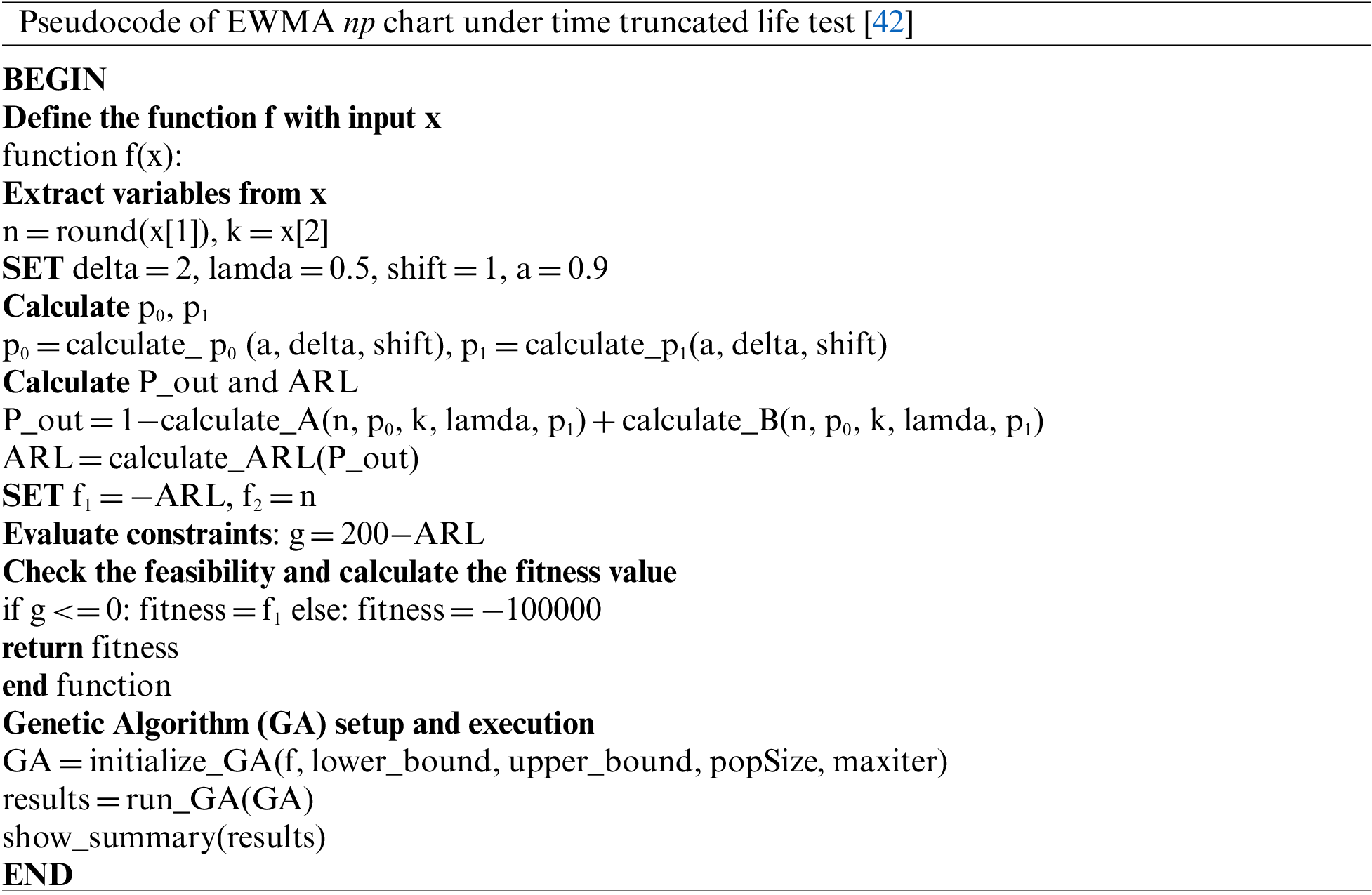

The pseudocode of the modified DS np chart based on GMDS sampling is shown as follows:

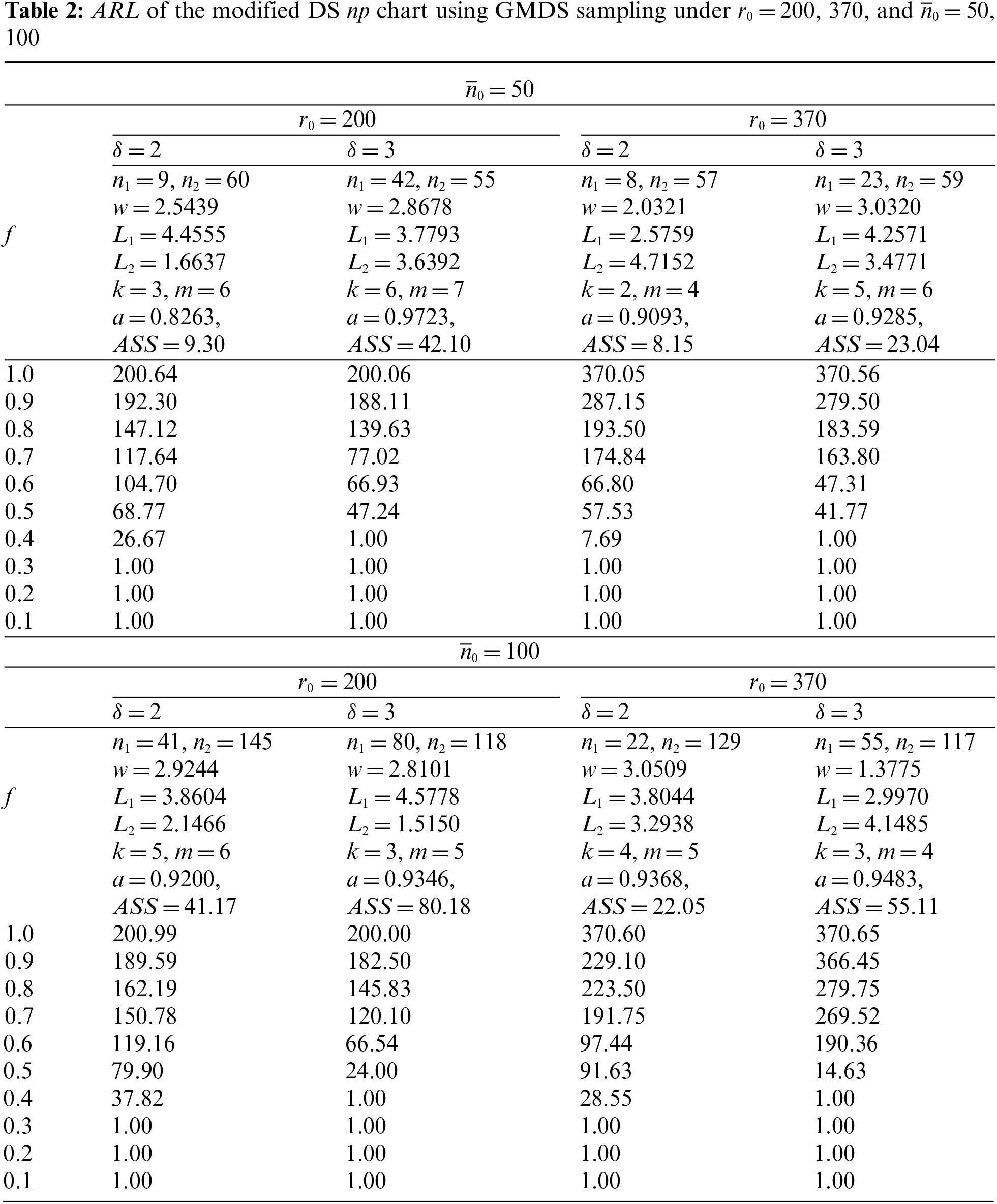

The following section presents the assessment of the performance achieved by the modified DS np chart with GMDS sampling through the use of ARL and ASS. The optimal parameters for the developed control chart

1. When

2. When

3. It was found that if

4. As ASS increases, the developed control chart shows greater efficiency in the detection of process shifts. It is also apparent that

5. The findings also indicate a decrease in the values of

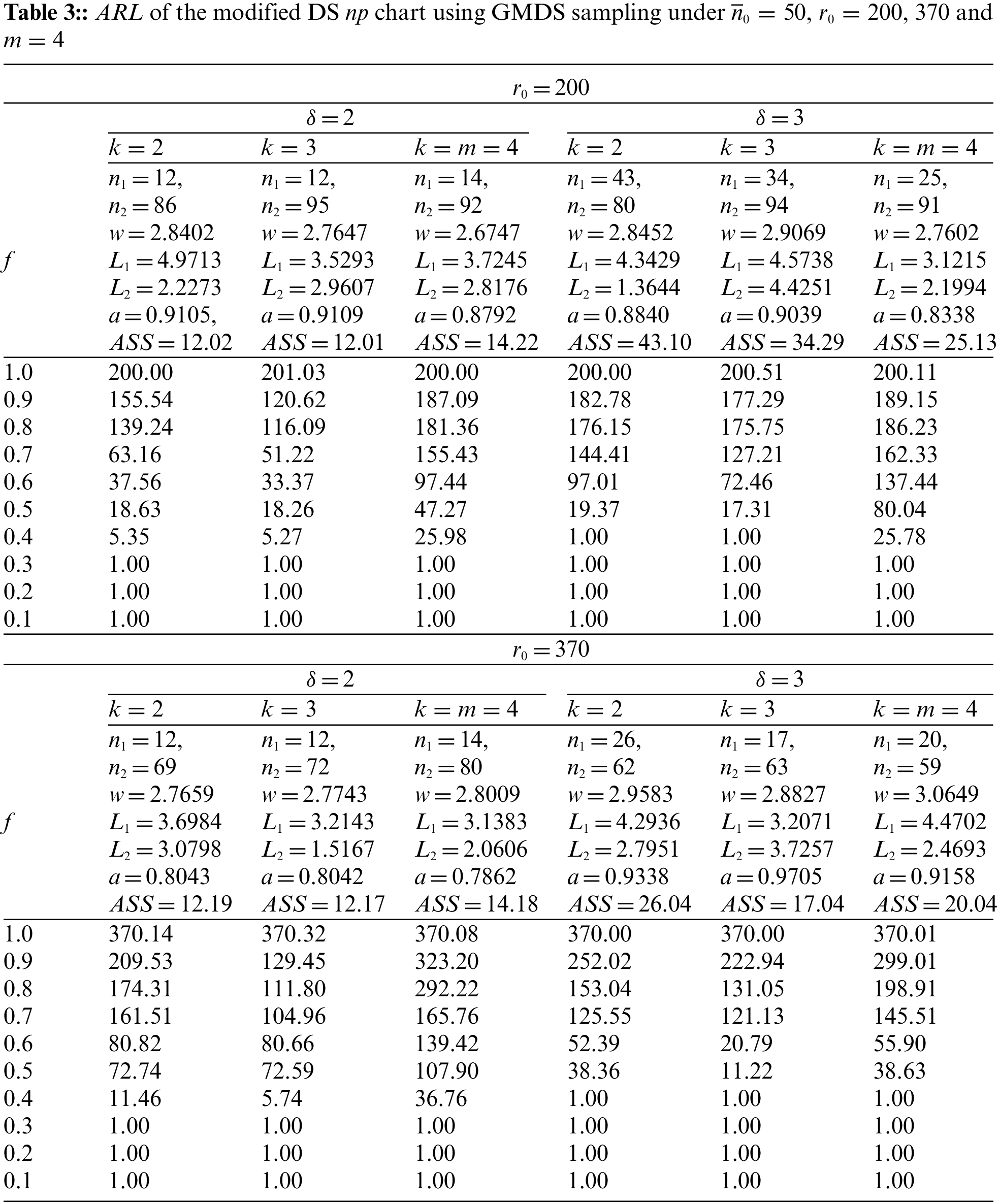

In Table 3, the

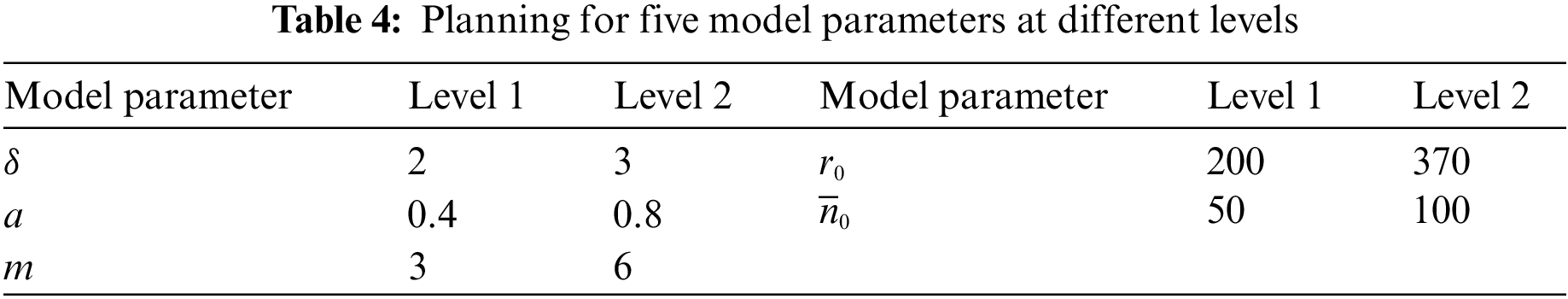

In some cases, the parameters presented in Tables 2 and 3 showed no clear trends or strong correlations. The use of sensitivity analysis can, therefore, help to determine the extent of the influence of these parameters upon the solution from the developed control chart. An orthogonal-array experimental design is used along with multiple linear regression to conduct the sensitivity analysis. For independent variables, the model parameters (

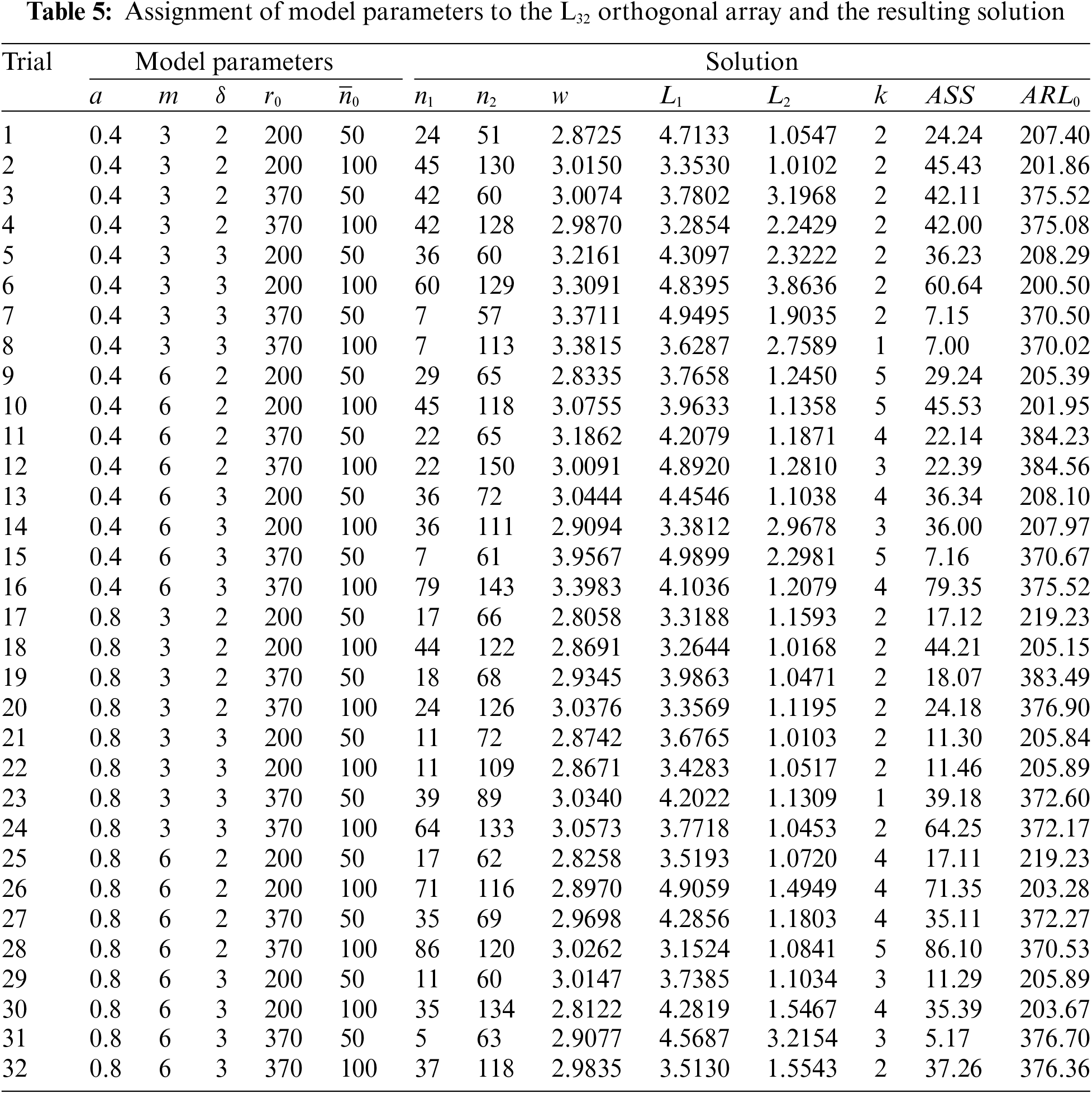

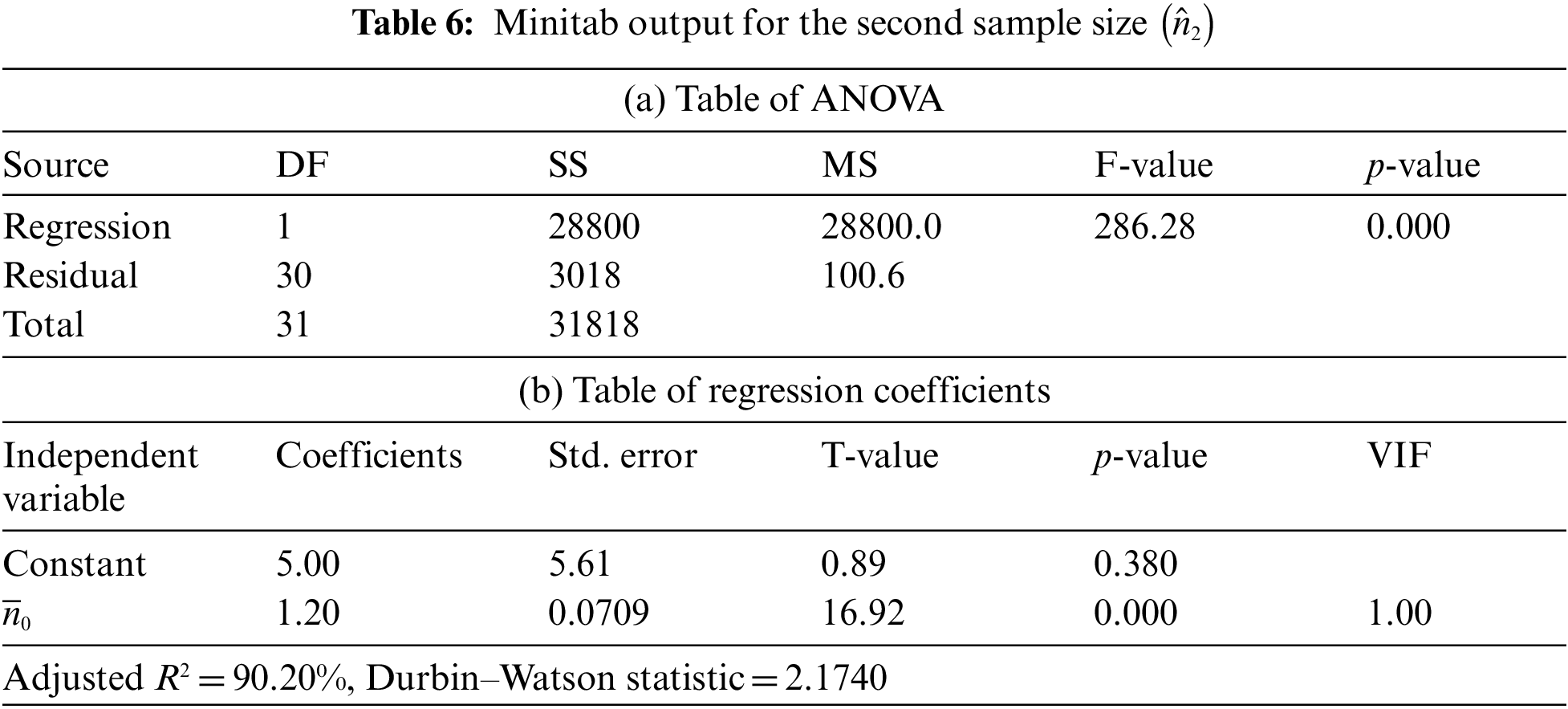

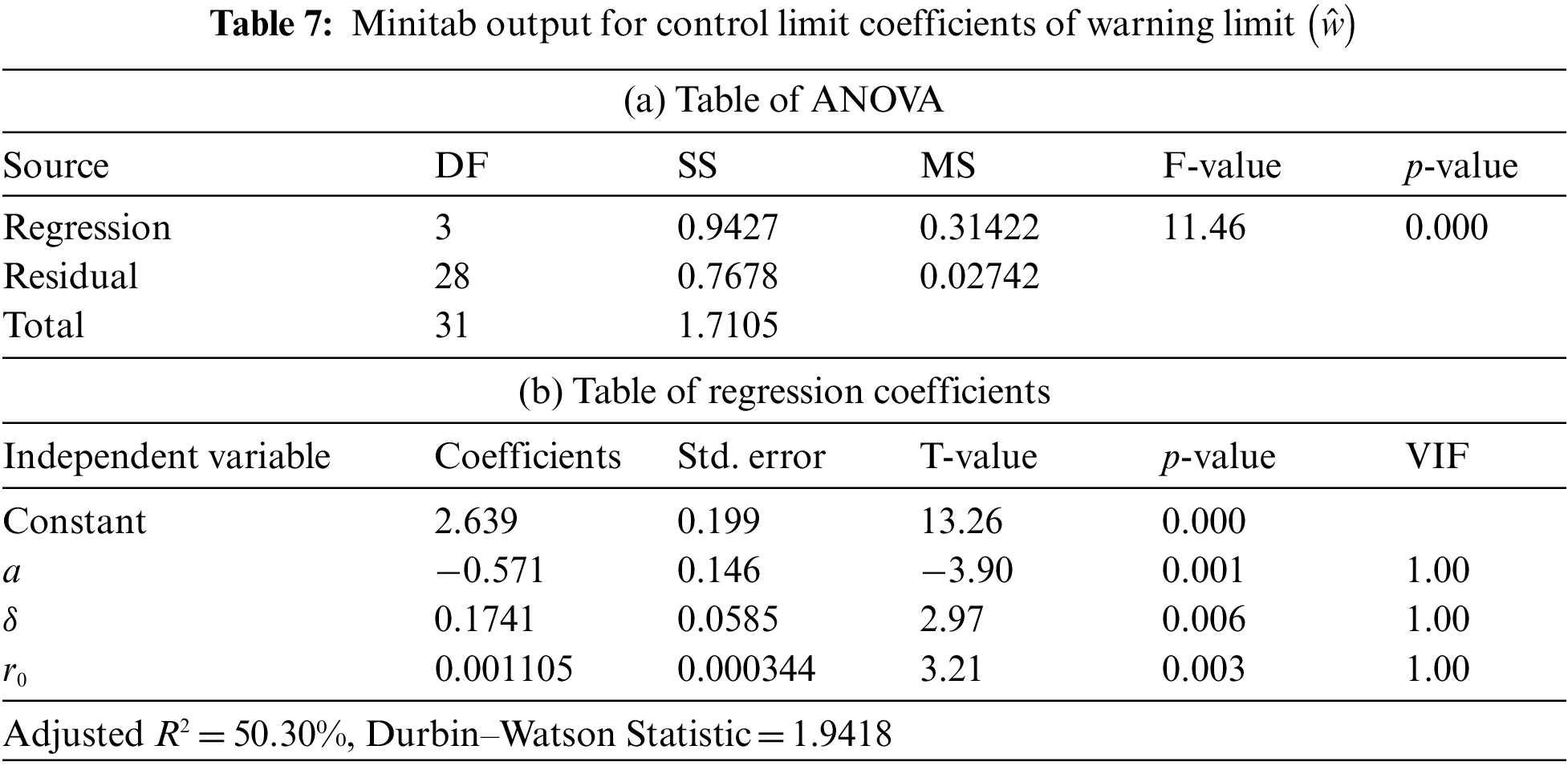

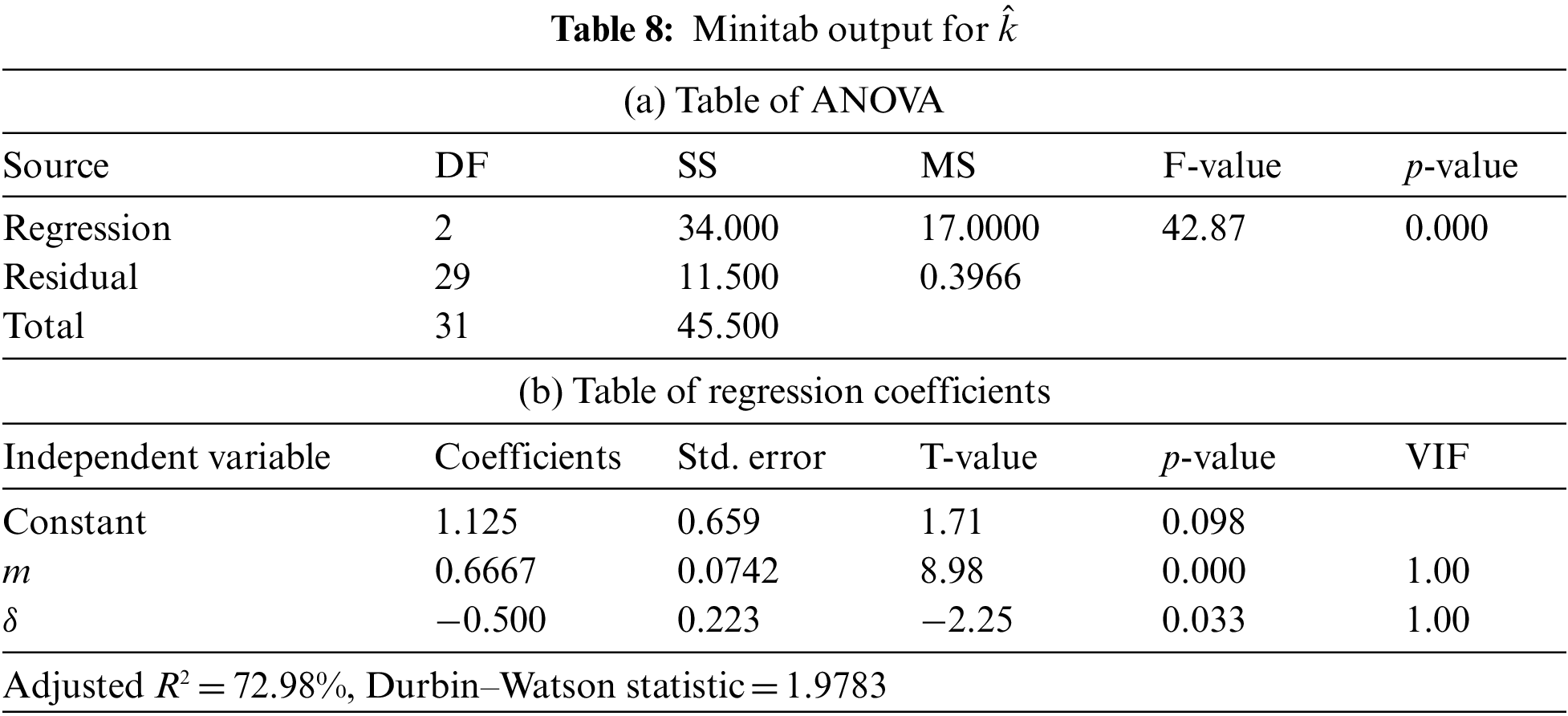

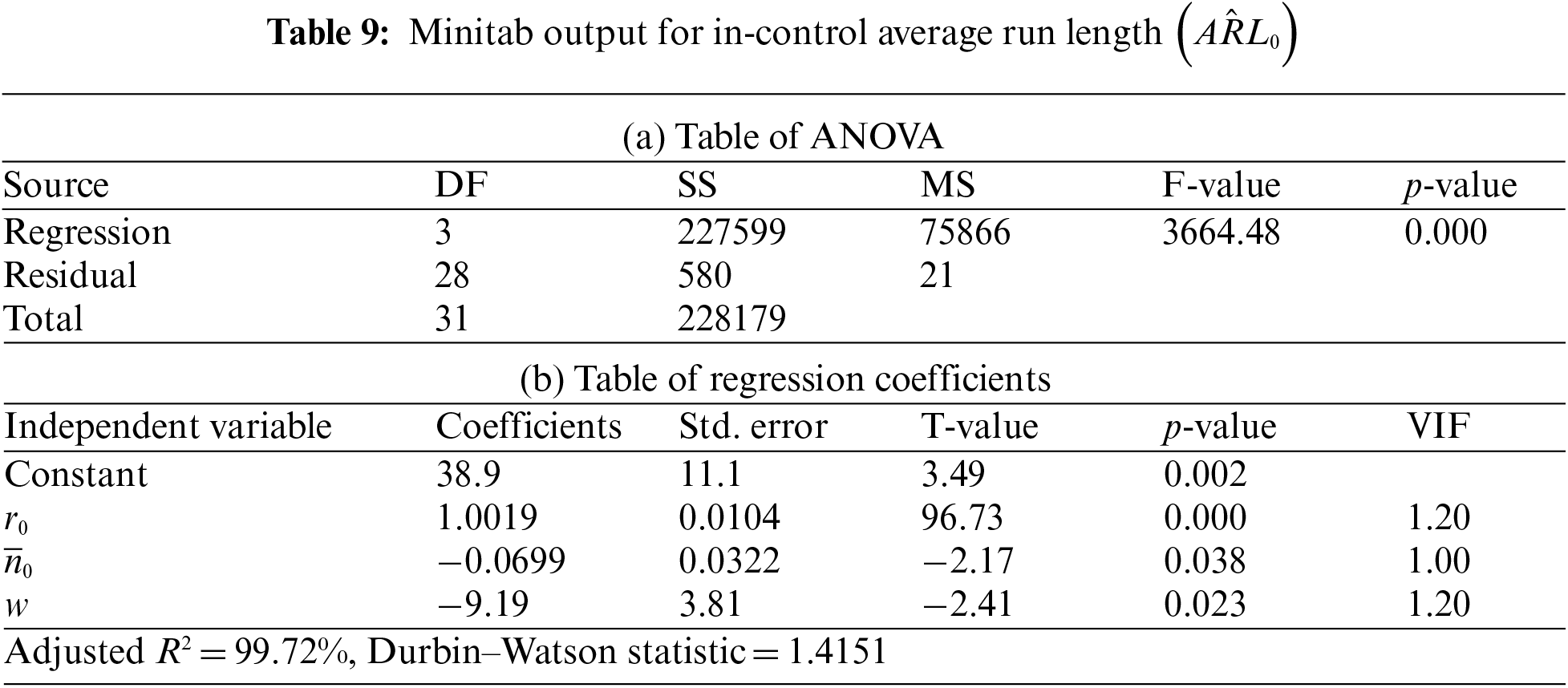

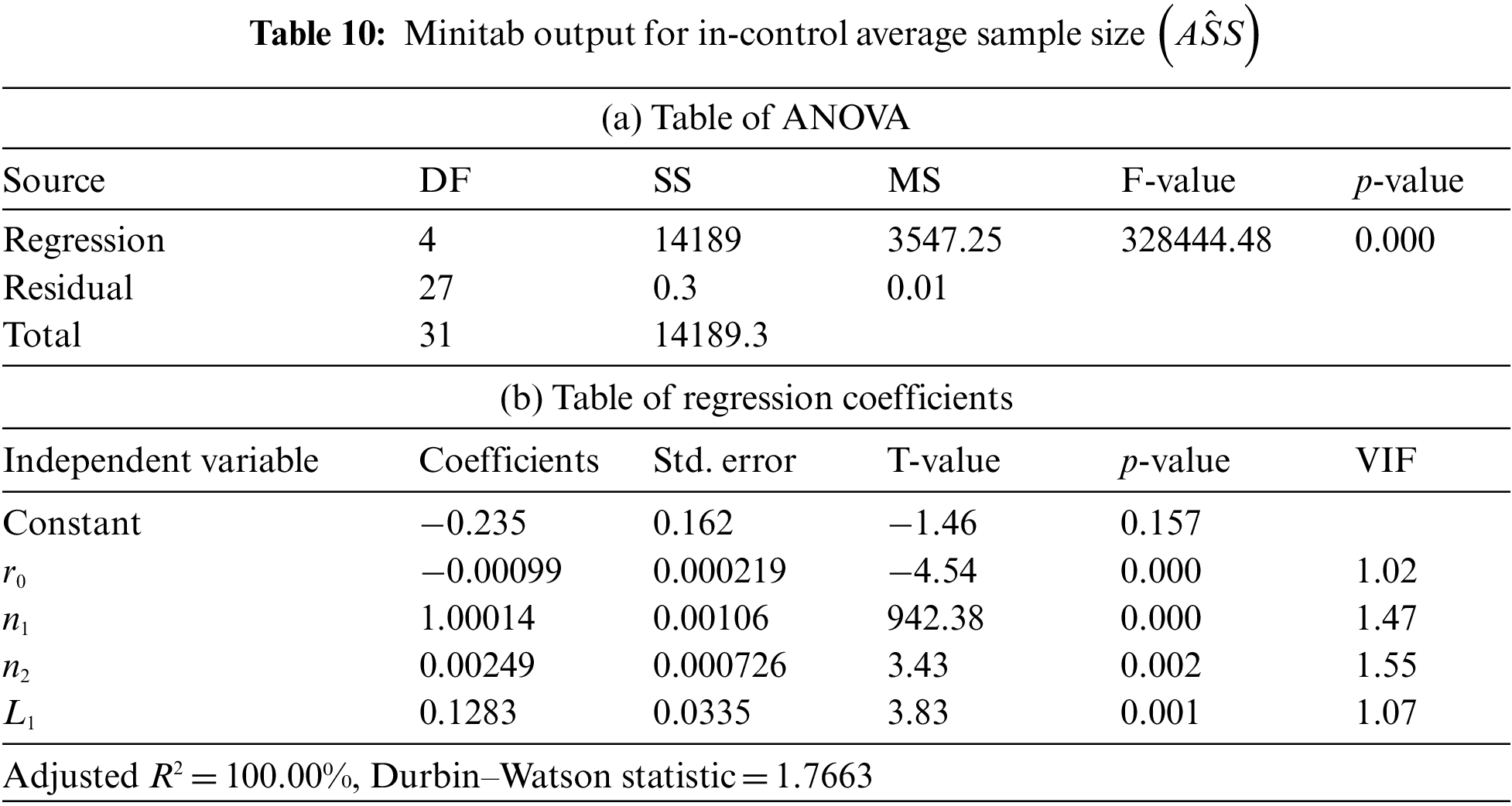

The data shown in Table 5 represents the results from the use of an L32 orthogonal array in the experiment, whereby the five model parameters of the L32 array columns are defined. Accordingly, 32 experiments are required in the L32 orthogonal array experiment design. For the developed control chart, the best solution was produced in each of the trials via GA optimization, which can be seen in Table 5. Multiple linear regression analysis using Minitab 19.0 software was then performed to assess the impact of the various independent parameters on the control chart. ANOVA analysis and multiple linear regression findings for each of the dependent variables are presented in Tables 6–10, and these data can be employed to test statistical hypotheses. Stepwise regression is used to examine the relationships between all values at a significance level of 0.05. The results in Tables 6a–10a indicate that the values of

In Table 7b, it can be observed that

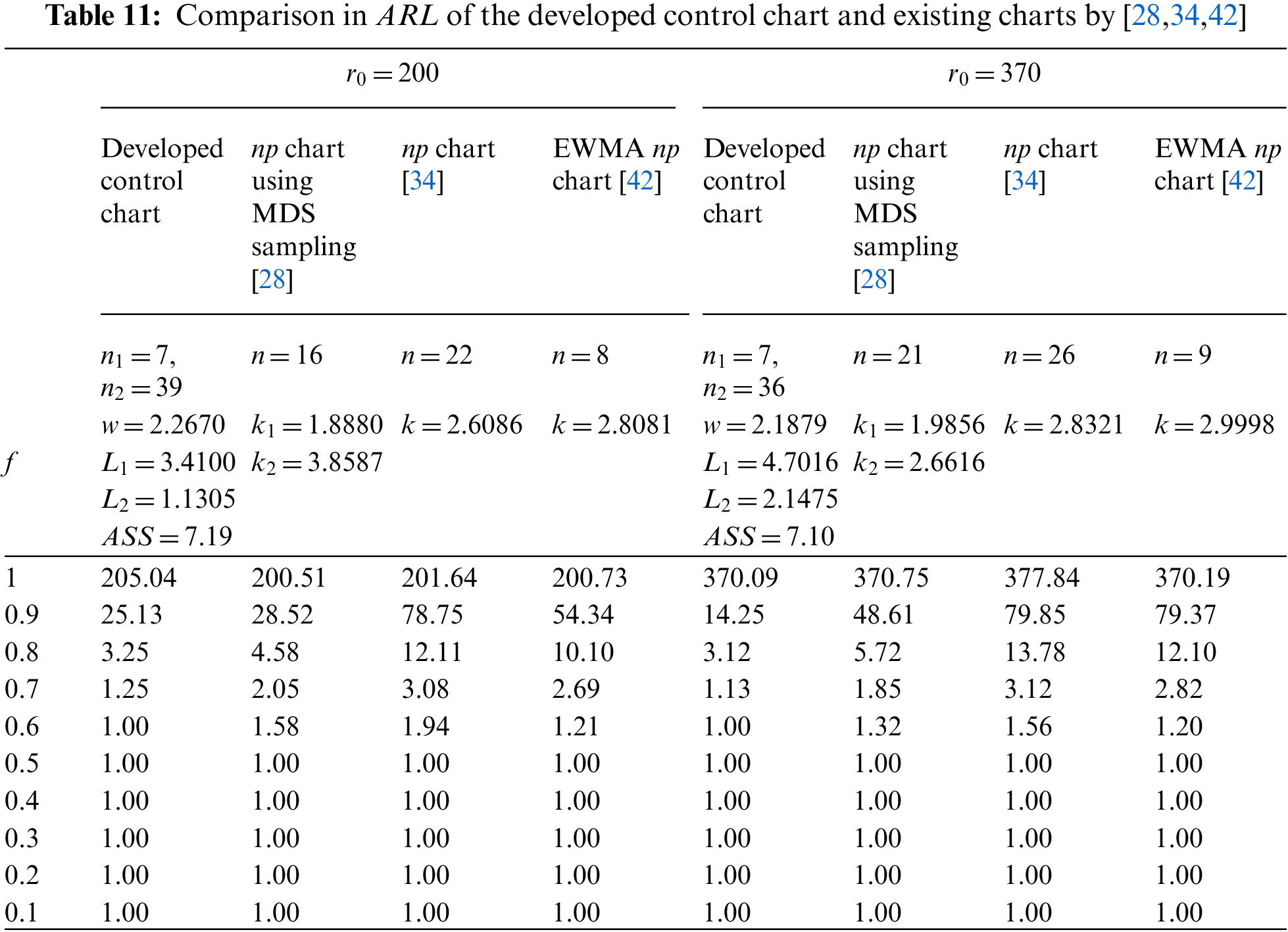

Comparisons are drawn in this section between the performance of the modified DS np chart with GMDS sampling and the control charts of Balamurali et al. [28], Aslam et al. [34] and Arif et al. [42]. The work of Balamurali et al. [28] described an attribute np chart that uses MDS sampling, while the work of Aslam et al. [34] covered an attribute np chart based on single sampling. In addition, the work of Arif et al. [42] presented the design of an attribute EWMA np chart. In all cases, the product lifespan followed a Weibull distribution based on the time-truncated life test. Accordingly, comparisons of the control charts’ performance can be shown using

Table 11 presents the optimal parameters at

4 The Application of the Developed Control Chart Using Real Data

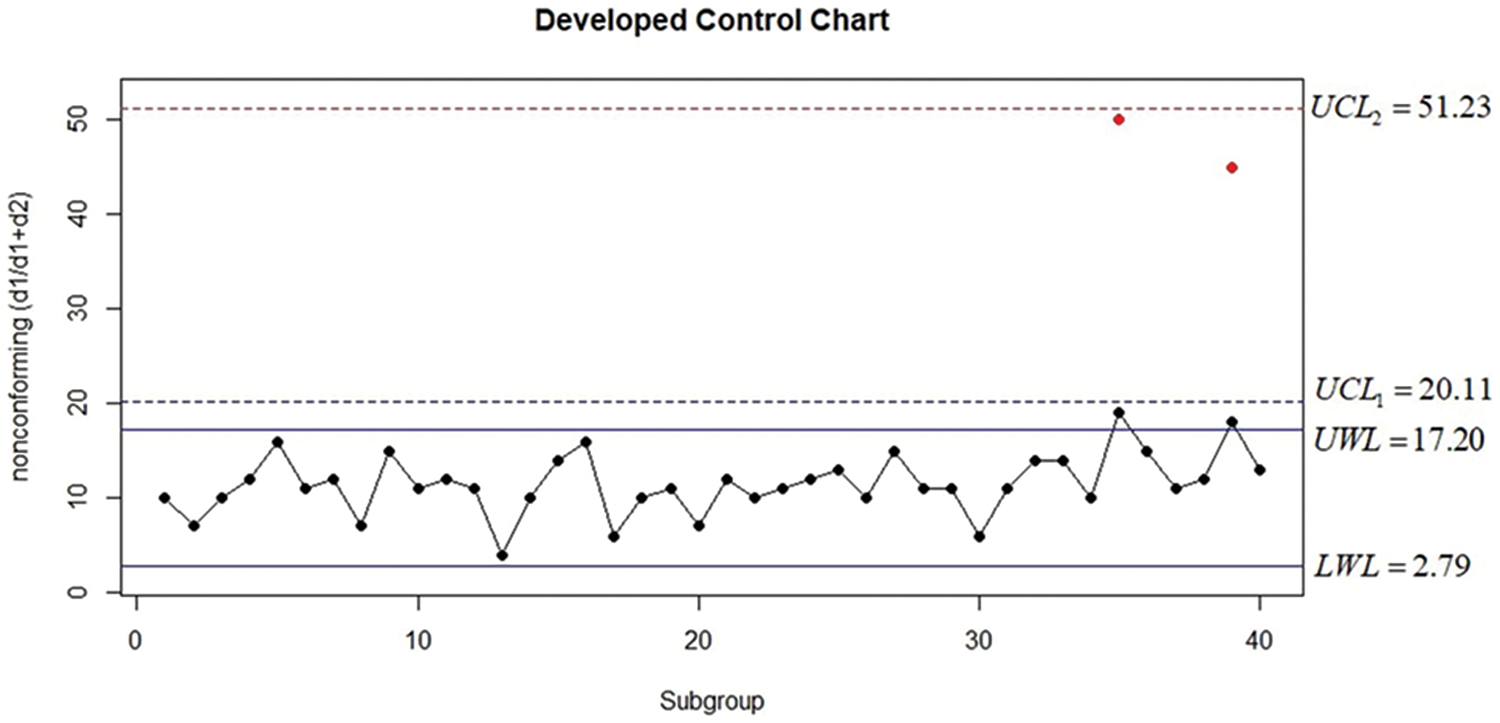

The following section presents the implementation of a modified DS np chart using GMDS sampling in the context of real data concerning the times to failure for 20 aluminum reduction cells where the units are thousands of days [47].

First of all, the dataset must be examined to determine whether a Weibull distribution is applicable. To check the goodness of fit, the Kolmogorov–Smirnov (K-S) test was used, while the unknown parameters were estimated using the maximum likelihood method. The result for the K-S test is 0.11212, giving a p-value of 0.9391. It can thus be concluded that the data follow the Weibull distribution. Meanwhile, the shape parameter

Figure 3: The modified DS np chart using GMDS sampling for simulated data

The design of a novel attributed control chart is achieved through the application of the DS np chart combined with GMDS sampling based on a time-truncated life test under the Weibull distribution. The optimal parameters

Acknowledgement: The authors are highly grateful to the reviewers and editors for taking the time to make their comments and suggestions very helpful to the paper.

Funding Statement: This research was supported by the Science, Research and Innovation Promotion Funding (TSRI) (Grant No. FRB660012/0168). This research block grants was managed under Rajamangala University of Technology Thanyaburi (FRB66E0646O.4).

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: W. Bamrungsetthapong, P. Charongrattanasakul; data collection: P. Charongrattanasakul; analysis and interpretation of results: W. Bamrungsetthapong, P. Charongrattanasakul; draft manuscript preparation: W. Bamrungsetthapong. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data used in this article are freely available in the cited references.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Montgomery, D. C. (2009). Introduction to statistical quality control, 9th edition. New York: John Wiley and Sons. [Google Scholar]

2. Gan, F. F. (1993). An optimal design of cusum control charts for binomial counts. Journal of Applied Statistics, 20(4), 445–460. https://doi.org/10.1080/02664769300000045 [Google Scholar] [CrossRef]

3. Gan, F. F. (1990). Monitoring observations generated from a binomial distribution using modified exponentially weighted moving average control chart. Journal of Statistical Computation and Simulation, 37, 45–60. https://doi.org/10.1080/00949659008811293 [Google Scholar] [CrossRef]

4. Epprecht, E. K., Costa, A. F. B. (2001). Adaptive sample size control charts for attributes. Quality Engineering, 13(3), 465–473. https://doi.org/10.1080/08982110108918675 [Google Scholar] [CrossRef]

5. Luo, H., Wu, Z. (2002). Optimal np control charts with variable sample sizes or variable sampling intervals. Economic Quality Control, 17(1), 39–61. https://doi.org/10.1515/EQC.2002.39 [Google Scholar] [CrossRef]

6. Croasdale, R. (1974). Control charts for a double-sampling scheme based on average production run lengths. International Journal of Production Research, 12(5), 585–592. https://doi.org/10.1080/00207547408919577 [Google Scholar] [CrossRef]

7. He, D., Grigoryan, A. (2003). An improved double sampling s chart. Economic Quality Control, 41(12), 2663–2679. https://doi.org/10.1080/0020754031000093187 [Google Scholar] [CrossRef]

8. Costa, A. F. B., Claro, F. A. E. (2008). Double sampling

9. Torng, C. C., Lee, P. H. (2009). The performance of double sampling control charts under non-normality. Communication in Statistics—Simulation and Computation, 38(3), 541–557. https://doi.org/10.1080/036109108025711 [Google Scholar] [CrossRef]

10. Khoo, M. B. C., Lee, H. C., Wu, Z., Chen, C. H., Castagliola, P. (2010). A synthetic double sampling control chart for the process mean. IIE Transactions, 43(1), 23–38. https://doi.org/10.1080/0740817X.2010.491503 [Google Scholar] [CrossRef]

11. De Araújo Rodrigues, A. A., Epprecht, E. K., de Magalhaes, M. S. (2011). Double sampling control charts for attributes. Journal of Applied Statistics, 38(1), 87–112. https://doi.org/10.1080/02664760903266007 [Google Scholar] [CrossRef]

12. Chong, Z. L., Khoo, M. B. C., Castagliola, P. (2014). Synthetic double sampling np control chart for attributes. Computers & Industrial Engineering, 75, 157–169. https://doi.org/10.1016/j.cie.2014.06.016 [Google Scholar] [CrossRef]

13. Zhou, W., Wan, Q., Zheng, Y., Zhou, Y. (2017). A joint-adaptive np control chart with multiple dependent state sampling scheme. Communications in Statistics—Theory and Methods, 46(14), 6967–6979. https://doi.org/10.1080/03610926.2015.1132323 [Google Scholar] [CrossRef]

14. Lee, M. H., Khoo, M. B. C. (2021). Double sampling np chart with estimated process parameter. Communications in Statistics—Simulation and Computation, 50(8), 2232–2250. https://doi.org/10.1080/03610918.2019.1599017 [Google Scholar] [CrossRef]

15. Wortham, A. W., Baker, R. C. (1976). Multiple deferred state sampling inspection. International Journal of Production Research, 14(6), 719–731. https://doi.org/10.1080/00207547608956391 [Google Scholar] [CrossRef]

16. Nadi, A. A., Gildeh, B. S. (2019). A group multiple dependent state sampling plan using truncated life test for the Weibull distribution. Quality Engineering, 31(2), 1–11. https://doi.org/10.1080/08982112.2018.1558250 [Google Scholar] [CrossRef]

17. Aslam, M., Jeyadurga, P., Balamurali, S., Azam, M., Al-Marshadi, A. (2021). Economic determination of modified multiple dependent state sampling plan under some lifetime distributions. Journal of Mathematics, 2021, 1–13. https://doi.org/10.1155/2021/7470196 [Google Scholar] [CrossRef]

18. Charongrattanasakul, P., Bamrungsetthapong, W., Kumam, P. (2022). A novel multiple dependent state sampling plan based on time truncated life tests using mean lifetime. Computers, Materials & Continua, 73(3), 4611–4626. https://doi.org/10.32604/cmc.2022.030856 [Google Scholar] [CrossRef]

19. Charongrattanasakul, P., Bamrungsetthapong, W., Kumam, P. (2023). Designing adaptive multiple dependent state sampling plan for accelerated life tests. Computer Systems Science and Engineering, 46(2), 1631–1651. https://doi.org/10.32604/csse.2023.036179 [Google Scholar] [CrossRef]

20. Aslam, M., Khan, N., Chi-Hyuck, J. (2014). A multiple dependent state control chart based on double control limits. Research Journal of Applied Sciences, Engineering and Technology, 7(21), 4490–4493. https://doi.org/10.19026/rjaset.7.825 [Google Scholar] [CrossRef]

21. Aslam, M., Azam, M., Khan, N., Chi-Hyuck, J. (2015). A control chart for an exponential distribution using multiple dependent state sampling. Quality & Quantity, 49, 455–462. https://doi.org/10.1007/s11135-014-0002-2 [Google Scholar] [CrossRef]

22. Aslam, M., Nazir, A., Chi-Hyuck, J. (2015). A new attribute control chart using multiple dependent state sampling. Transactions of the Institute of Measurement and Control, 37, 569–576. https://doi.org/10.1177/0142331214549094 [Google Scholar] [CrossRef]

23. Aslam, M., Arif, O. H., Jun, C. H. (2017). A control chart for gamma distribution using multiple dependent state sampling. Industrial Engineering & Management Systems, 16(1), 109–117. https://doi.org/10.7232/iems.2017.16.1.109 [Google Scholar] [CrossRef]

24. Khan, N., Aslam, M. (2019). Design of an EWMA adaptive control chart using MDS sampling. Journal of Statistics and Management Systems, 22(3), 535–555. https://doi.org/10.1080/09720510.2018.1564206 [Google Scholar] [CrossRef]

25. Aslam, M., Raza, M. A., Ahmad, L., Jun, C. H. (2019). Design of a t-chart using generalized multiple dependent state sampling. Quality and Reliability Engineering, 35(6), 1789–1802. https://doi.org/10.1002/qre.2475 [Google Scholar] [CrossRef]

26. Raza, M. A., Aslam, M. (2019). Design of control charts for multivariate poisson distribution using generalized multiple dependent state sampling. Quality Technology and Quantitative Management, 16(6), 629–650. https://doi.org/10.1080/16843703.2018.1497935 [Google Scholar] [CrossRef]

27. Balamurali, S., Jeyadurga, P. (2019). An attribute np control chart for monitoring mean life using multiple deferred state sampling based on truncated life tests. International Journal of Reliability, Quality and Safety Engineering, 26(1), 1–18. https://doi.org/10.1142/S0218539319500049 [Google Scholar] [CrossRef]

28. Balamurali, S., Jeyadurga, P. (2019). Economic design of an attribute control chart for monitoring mean life based on multiple deferred state sampling. Applied Stochastic Models in Business and Industry, 35(3), 893–907. https://doi.org/10.1002/asmb.2419 [Google Scholar] [CrossRef]

29. Aslam, M., Khan, N., Albassam, M. (2019). Shewhart attribute and variable control charts using modified multiple dependent state sampling. Symmetry, 11(1), 1–14. https://doi.org/10.3390/sym11010053 [Google Scholar] [CrossRef]

30. Aslam, M., Balamurali, S., Periyasamypandian, J., Khan, N. (2021). Designing of an attribute control chart based on modified multiple dependent state sampling using accelerated life test under Weibull distribution. Communication in Statistics—Simulation and Computation, 50(3), 902–916. https://doi.org/10.1080/03610918.2019.1571606 [Google Scholar] [CrossRef]

31. Woodall, W. H., Saleh, N. A., Mahmoud, M. A. (2023). Equivalences between multiple dependent state sampling, chain sampling, and control chart runs rules. Quality Engineering, 35(1), 142–151. [Google Scholar]

32. Aslam, M., Bantan, R. A., Khan, N. (2019). Design of X-bar control chart using multiple dependent state sampling under indeterminacy environment. IEEE Access, 7(1), 152233–152242. https://doi.org/10.1109/ACCESS.2019.2947598 [Google Scholar] [CrossRef]

33. Khan, N., Ahmad, L., Aslam, M. (2022). Monitoring using X-bar control chart using neutrosophic-based generalized multiple dependent state sampling with application. International Journal of Computational Intelligence Systems, 15, 73. https://doi.org/10.1007/s44196-022-00131-3 [Google Scholar] [CrossRef]

34. Aslam, M., Jun, C. H. (2015). Attribute control charts for the Weibull distribution under truncated life tests. Quality Engineering, 27(3), 283–288. https://doi.org/10.1080/08982112.2015.1017649 [Google Scholar] [CrossRef]

35. Khan, N., Aslam, M., Khan, M. Z., Jun, C. H. (2018). A variable control chart under the truncated life test for a Weibull distribution. Technologies, 6(2), 1–10. https://doi.org/10.3390/technologies6020055 [Google Scholar] [CrossRef]

36. Aslam, M. (2019). Time truncated attribute control chart for the Weibull distribution using multiple dependent state sampling. Communication in Statistics—Simulation and Computation, 48(4), 1219–1228. https://doi.org/10.1080/03610918.2017.1408823 [Google Scholar] [CrossRef]

37. Adeoti, O. A., Gadde, S. R. (2021). Moving average control charts for the Rayleigh and inverse Rayleigh distributions under time truncated life test. Quality and Reliability Engineering, 37(8), 3552–3567. https://doi.org/10.1002/qre.2933 [Google Scholar] [CrossRef]

38. Akhundjanov, S. B., Pascual, F. (2015). Moving range EWMA control charts for monitoring the weibull shape parameter. Journal of Statistical Computation and Simulation, 85(9), 1864–1882. https://doi.org/10.1080/00949655.2014.907574 [Google Scholar] [CrossRef]

39. Faraz, A., Saniga, E. M., Heuchenne, C. (2015). Shewhart control charts for monitoring reliability with Weibull lifetimes. Quality and Reliability Engineering International, 31(8), 1565–1574. https://doi.org/10.1002/qre.1692 [Google Scholar] [CrossRef]

40. Aslam, M. (2016). A mixed EWMA–CUSUM control chart for Weibull-distributed quality characteristics. Quality and Reliability Engineering International, 32(8), 2987–2994. https://doi.org/10.1002/qre.1982 [Google Scholar] [CrossRef]

41. Aslam, M., Arif, O. H., Jun, C. H. (2017). An attribute control chart for a Weibull distribution under accelerated hybrid censoring. PLoS One, 12(3), 1–11. https://doi.org/10.1371/journal.pone.0173406 [Google Scholar] [PubMed] [CrossRef]

42. Arif, O. H., Aslam, M., Jun, C. H. (2017). EWMA np control chart for the Weibull distribution. Journal of Testing and Evaluation, 45(3), 1022–1028. https://doi.org/10.1520/JTE20150429 [Google Scholar] [CrossRef]

43. Huwang, L., Lin, L. W. (2020). New EWMA control charts for monitoring the Weibull shape parameter. Quality and Reliability Engineering International, 36(6), 1872–1894. https://doi.org/10.1002/qre.2663 [Google Scholar] [CrossRef]

44. Aslam, M., Balamurali, S., Jeyadurga, P., Khan, N. (2021). Designing of an attribute control chart based on modified multiple dependent state sampling using accelerated life test under Weibull distribution. Communications in Statistics—Simulation and Computation, 50(3), 902–916. https://doi.org/10.1080/03610918.2019.1571606 [Google Scholar] [CrossRef]

45. Khan, N., Nawaz, M. S., Sherwani, R. A. K., Aslam, M. (2023). Moving average EWMA chart for the weibull distribution. Communications in Statistics—Simulation and Computation, 52(5), 2231–2240. https://doi.org/10.1080/03610918.2021.1901119 [Google Scholar] [CrossRef]

46. Adeoti, O. A., Gadde, S. R. (2022). Attribute control chart for Rayleigh distribution using repetitive sampling under truncated life test. Journal of Probability and Statistics, 2022, 1–11. https://doi.org/10.1155/2022/8763091 [Google Scholar] [CrossRef]

47. Whitmore, G. A. (1983). A regression model for censored inverse Gaussian data. Canadian Journal of Statistics, 11(4), 305–315. https://doi.org/10.2307/3314888 [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools