Open Access

Open Access

ARTICLE

Fault Identification for Shear-Type Structures Using Low-Frequency Vibration Modes

1 School of Civil Engineering, Shaoxing University, Shaoxing, 312000, China

2 School of Civil and Transportation Engineering, Ningbo University of Technology, Ningbo, 315211, China

3 Engineering Research Center of Industrial Construction in Civil Engineering of Zhejiang, Ningbo University of Technology, Ningbo, 315211, China

* Corresponding Author: Qiuwei Yang. Email:

(This article belongs to the Special Issue: Failure Detection Algorithms, Methods and Models for Industrial Environments)

Computer Modeling in Engineering & Sciences 2024, 138(3), 2769-2791. https://doi.org/10.32604/cmes.2023.030908

Received 02 May 2023; Accepted 31 July 2023; Issue published 15 December 2023

Abstract

Shear-type structures are common structural forms in industrial and civil buildings, such as concrete and steel frame structures. Fault diagnosis of shear-type structures is an important topic to ensure the normal use of structures. The main drawback of existing damage assessment methods is that they require accurate structural finite element models for damage assessment. However, for many shear-type structures, it is difficult to obtain accurate FEM. In order to avoid finite element modeling, a model-free method for diagnosing shear structure defects is developed in this paper. This method only needs to measure a few low-order vibration modes of the structure. The proposed defect diagnosis method is divided into two stages. In the first stage, the location of defects in the structure is determined based on the difference between the virtual displacements derived from the dynamic flexibility matrices before and after damage. In the second stage, damage severity is evaluated based on an improved frequency sensitivity equation. The main innovations of this method lie in two aspects. The first innovation is the development of a virtual displacement difference method for determining the location of damage in the shear structure. The second is to improve the existing frequency sensitivity equation to calculate the damage degree without constructing the finite element model. This method has been verified on a numerical example of a 22-story shear frame structure and an experimental example of a three-story steel shear structure. Based on numerical analysis and experimental data validation, it is shown that this method only needs to use the low-order modes of structural vibration to diagnose the defect location and damage degree, and does not require finite element modeling. The proposed method should be a very simple and practical defect diagnosis technique in engineering practice.Keywords

The shear-type structure is a common structural form in industrial and civil buildings, such as concrete and steel frame structures. For example, many high-rise residential buildings can be classified as the shear-type structures due to the particularly high stiffness of the floor compared to the columns. It is known that structural failures are inevitable due to the environmental corrosion, material fatigue, disaster loads, and other factors. In order to ensure residential safety, it is necessary to carry out structural health monitoring and defect diagnosis. Due to the large volume and numerous components of building structures, traditional non-destructive testing techniques such as ultrasound, radiographic testing, and penetration testing cannot complete defect diagnosis of large building structures. In the past few decades, methods for diagnosing structural damage using response parameters of structures under static or dynamic loads have been continuously studied in depth. The theoretical basis for this type of method is that faults in structures can cause changes in structural static and vibration response parameters [1–4]. In practice, the response data of structures can be measured through special testing equipment and then their changes can be used to diagnose structural fault conditions.

In recent years, many methods have been developed for structural fault diagnosis by using static or dynamic response parameters. Yang et al. proposed a fast static displacement analysis method for structural damage detection using flexible disassembly perturbation [5,6]. Peng et al. [7] developed a method for determining the damage location of beam structures by using redistribution of static shear energy. Li et al. [8] proposed a flexible method for damage identification of cantilever structures, such as high-rise buildings and chimneys, using a few dynamic modal data. Koo et al. [9] proposed a damage quantification method for shear buildings based on the modal data measured by ambient vibration. It is found from the experimental study that the damage quantity of the proposed method is very consistent with the actual damage quantity obtained from the static pushdown test. Zhu et al. [10] proposed an effective damage detection method for shear buildings by using the change of the first mode shape slope. An eight-layer numerical example and a three-layer experimental model verify the effectiveness of the method. Xing et al. [11] proposed a substructure method that allows local damage detection of shear structures. Their method only needs three sensors to identify the local damage of any floor of the shear structure building. The feasibility of the proposed method is tested by simulation and experiment on a five-storey building. Su et al. [12] developed a simple and effective method to locate the floors where the property (stiffness and mass) changes during the shear building life cycle. The floors that may be damaged are determined by comparing the natural frequencies of the substructure at different stages of the building life cycle. Sung et al. [13] conducted a comprehensive experimental verification of the damage induced deflection method for shear building damage detection. The results showed that the damaged floor was successfully located, and the damage rate estimated by the damage induced deflection method was consistent with the damage rate calculated by numerical simulation. Panigrahi et al. [14] developed a method based on residual force vector and genetic algorithm to identify damages of multi-layer shear structures from sparse modal information. Li et al. [15] proposed a data-driven method for seismic damage detection and location of multi-degree-of-freedom shear-type building structures under strong ground motions. The proposed method is based on the joint realization of time-frequency analysis and fractal dimension characteristics. An et al. [16] carried out the application research of damage location method based on impact energy in real-time damage detection of shear structures under random base excitation. The performance of their method in damage detection was experimentally verified using a laboratory scale 6-layer shear structure model. Wang et al. [17] proposed a damage identification method for the shear-type building based on proper orthogonal modes. The experimental results show that this method can effectively identify the location and severity of shear building structure damage. Mei et al. [18] proposed an improved substructure based damage detection method to locate and quantify damage in shear structures. Luo et al. [19] proposed a new method for extracting the spectral transfer function and detecting damage of shear frame structures under non-stationary random excitation. Shi et al. [20] studied the damage localization by using the curvature of the lateral displacement envelope in the shear building structure. The finite difference method and interpolation method are used to evaluate the modal curvature and frequency response function for damage localization. Mei et al. [21] presented a new substructure damage detection method based on the autoregressive moving average exogenous input (ARMAX) model and the optimal sub-mode assignment (OSPA) distance to locate and quantify the damage. Paral et al. [22] proposed a damage assessment method based on artificial neural network, which takes the change of the first mode slope damage index as the input layer of the artificial neural network. The effectiveness of their method is proved by the experimental tests of the three-story steel shear frame model. Liang et al. [23] carried out the damage detection of shear buildings by frequency-change-ratio and model updating algorithm. Ghannadi et al. [24] used a new bio-inspired optimization algorithm to identify the damage location and severity of the multi-layer shear frame. Do et al. [25] developed a new damage detection method based on output-only vibration information for shear-type structures. Zhao et al. [26] proposed a two-step modeling method based on wavelet frequency response function estimation and least squares iterative algorithm to identify structural vibration modal parameters. Liu et al. [27] studied schemes to repair earthquake damage from the aspects of load transfer path, enclosure structure, beam column nodes, and structural stiffness. It was found that the seismic performance of masonry walls can be greatly improved after being wrapped in reinforced concrete or seismic zones. Niu [28] proposed a damage detection method for shear frame structures based on frequency response function. The influence of noise on damage detection is greatly suppressed by simultaneously increasing the number of equations and reducing the unknown coefficients. Yang et al. [29,30] studied dynamic model reduction and used modal sensitivity for fault diagnosis based on the reduced model. Tan et al. [31] proposed a model- calibration-free method for damage identification of shear structures using modal data. The advantage of the proposed method is that the model-free calibration characteristics can avoid the need to calibrate the mass and stiffness parameters of the structure. Roy [32] proposed a new formula to establish the expression of damage severity in the form of mode shape slope. The derived closed-form solution directly relates the percentage of damage strength to the derivative of the vibration mode change in the shear building.

Although great progress has been made in damage diagnosis of shear structures, there are still many difficulties that need to be further studied to overcome. The main disadvantage of the existing methods described above is that accurate structural finite element model (FEM) is required in these methods to perform the damage assessment. However, it is difficult to obtain accurate FEMs for many shear-type structures. It is an urgent need in engineering practice to study defect diagnosis methods that do not require accurate finite element models. For this purpose, a FEM-free method for defect diagnosis of the shear structure is developed in this paper, which only needs to measure a few low-order vibration modes of the structure. The proposed defect diagnosis method is divided into two stages. In the first stage, the location of the defect is determined based on the virtual displacement difference derived from the dynamic flexibility matrix before and after damage. In the second stage, the damage severity is evaluated based on the improved frequency sensitivity equation. The main innovations of the proposed method lie in two aspects. The first is the development of a virtual displacement difference method for determining the location of damage in the shear structure. The second is to improve the existing frequency sensitivity equation to calculate the damage degree without constructing FEM. The proposed method has been validated on a numerical model of a 22-story shear-type frame structure and a three-story steel shear structure model. Based on numerical analysis and experimental data validation, it is shown that the proposed method can diagnose the defect location and damage degree only by using the lower order modes of structural vibration, and does not require finite element modeling. The proposed method should be a very simple and practical defect diagnosis technique in engineering practice.

2.1 Damage Localization by the Virtual Displacement Difference

In this section, the virtual displacement difference method is proposed for defect localization of shear-type structures. For an undamaged structure with

where

where

From Eq. (4), one has

Combining Eq. (3) with (7), one has

From Eq. (9), the inverse matrix of

Using Eqs. (7), (8), and (10) can be simplified as:

Using Eqs. (5), (6) and (11) can be rewritten as:

The eigenvalues of structural vibration are generally sorted from small to large, that is,

where

in which

From a static perspective, the displacement before and after structural damage under a certain static load can be obtained as follows:

where

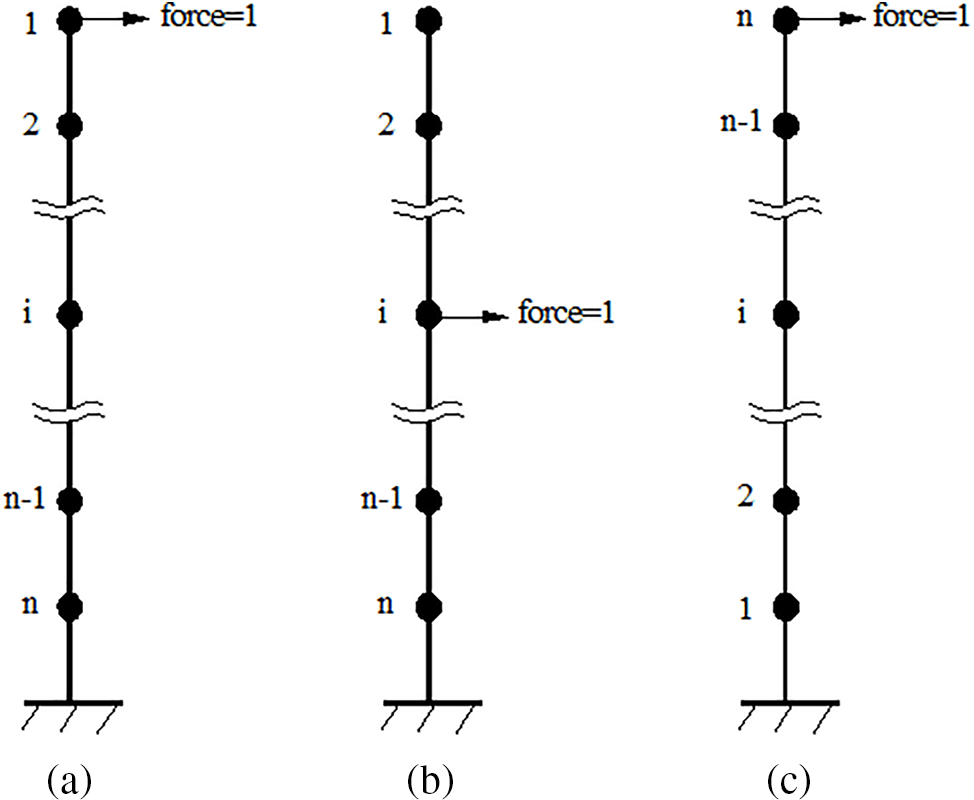

Figure 1: (a) A virtual load at the top floor (floors are numbered from top to bottom as 1, 2, … , n); (b) A virtual load at the middle layer; (c) A virtual load at the top floor (floors are numbered from bottom to top as 1, 2, … , n)

Therefore, the virtual displacement difference vector

According to the research results of the reference [33], it has been proven that the displacement difference vector for the linear structure before and after damage under the same static load will undergo a sudden change at the damage location. Thus the location of the fault in a shear structure can be determined by the location of the element value mutation in the vector

2.2 Damage Quantification by the Improved Frequency Sensitivity

An assessment of the defect severity is necessary to estimate the remaining life of the structure or to determine whether maintenance is required. To this end, an improved frequency sensitivity algorithm is developed for fault quantification of the shear structure. According to the FEM theory, the total stiffness matrix

where

where

in which

According to the FEM theory, the stiffness and mass matrices

Multiplying Eq. (24) by

Eq. (27) can be expanded as:

Substituting Eq. (2) into (28) yields

The eigenvalue (i.e., angular frequency) variation

Substituting Eq. (23) into (1) yields as:

Eq. (31) shows that

As stated before, the defect location has been determined based on the damage location vector

Substituting Eq. (29) into (33) yields

In the above derivation,

where

Note that

where

For multiple defect case, more vibration modes besides the first vibration mode are needed to solve the fault coefficients. The number of the used vibration modes should be greater than or equal to the number of damage locations determined by the above damage localization approach. Without losing generality, Eq. (32) can be expanded for multiple defects to

where the matrix

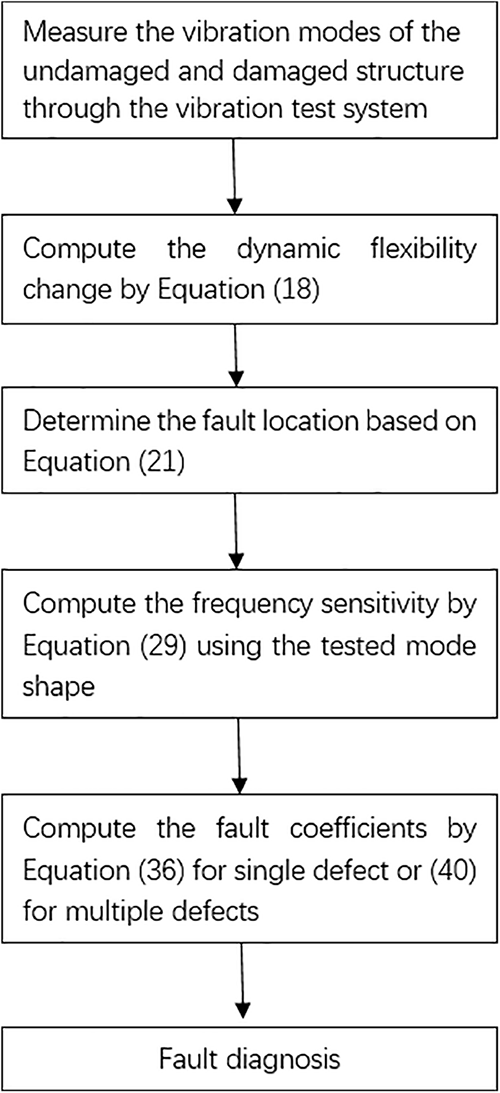

In Eq. (40), the superscript “+” denotes the matrix generalized inverse. Finally, the damage severity of shear structures can be evaluated based on the calculation results of Eq. (40). Fig. 2 shows the flow chart of the proposed algorithm to explain the process more clearly.

Figure 2: Flowchart of the proposed algorithm

3 Validation by the Numerical Model

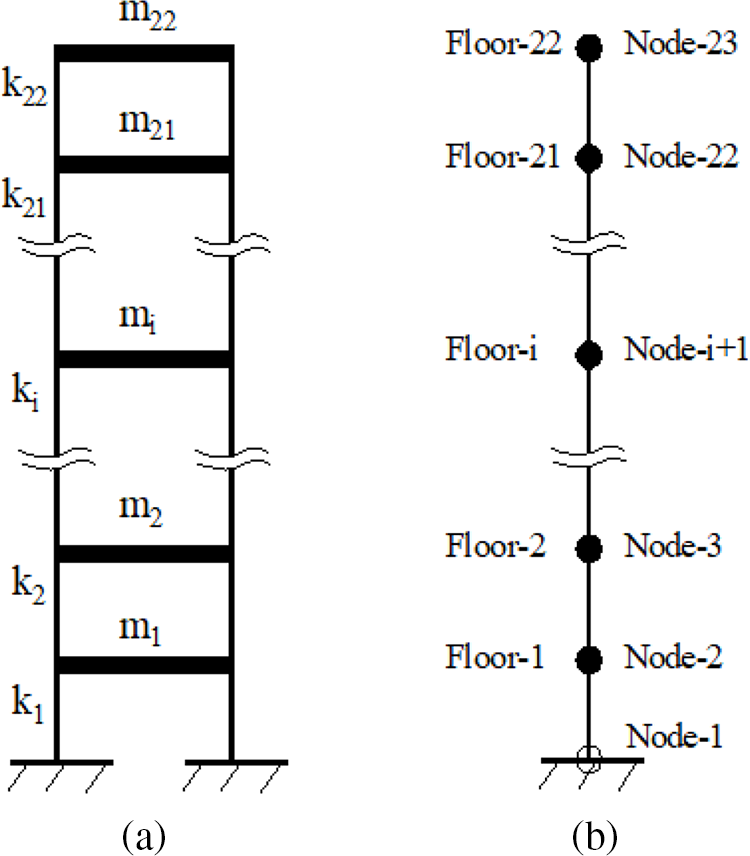

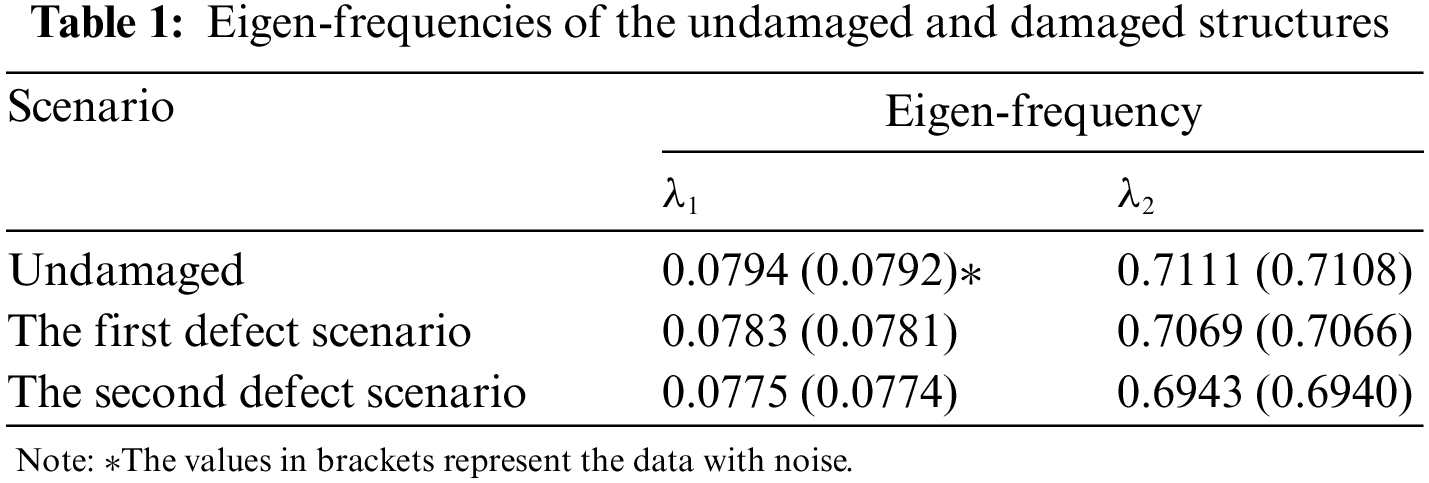

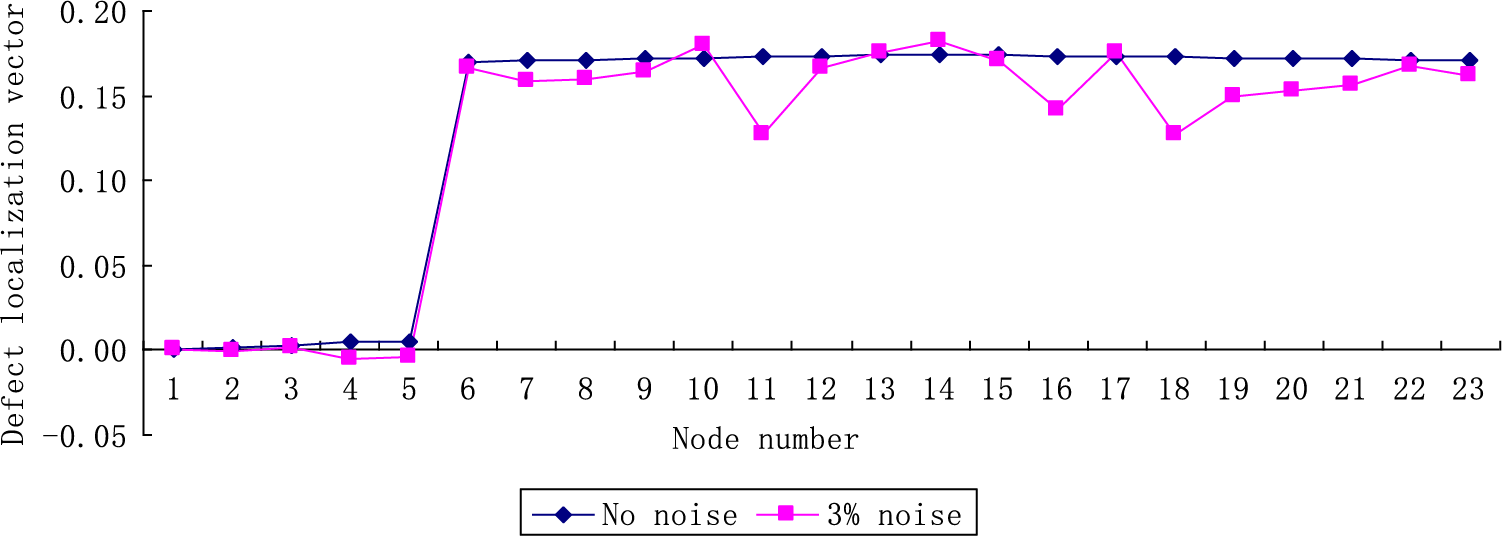

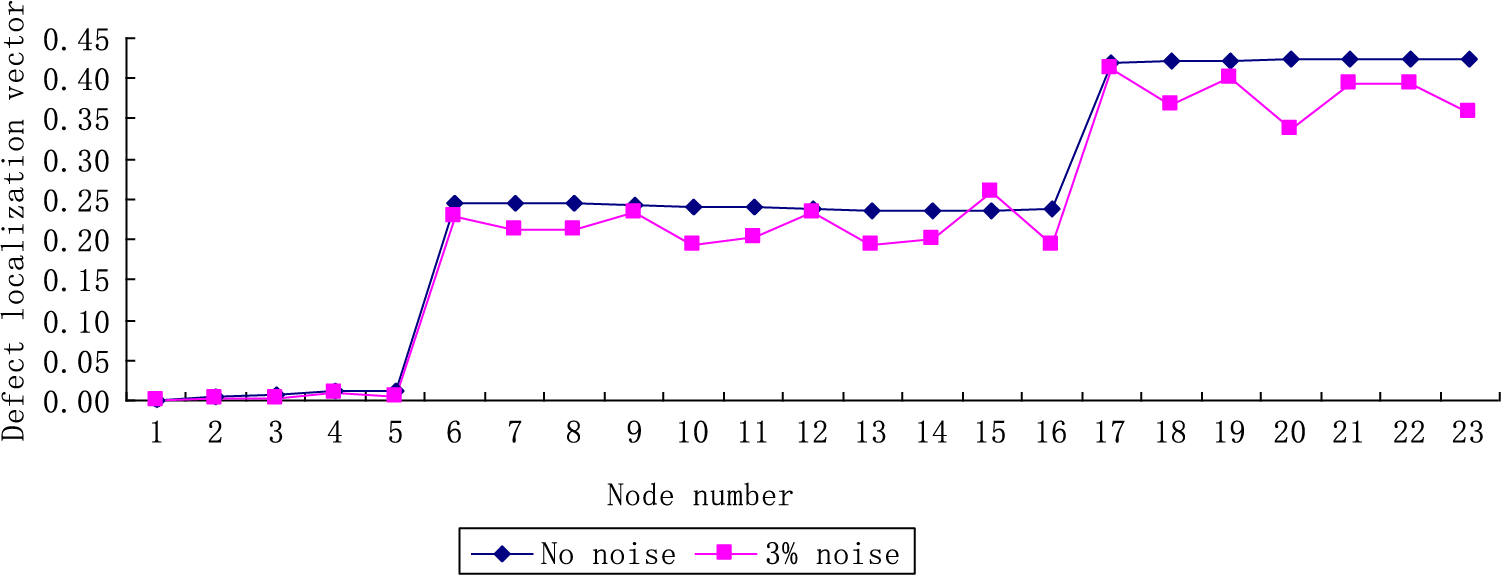

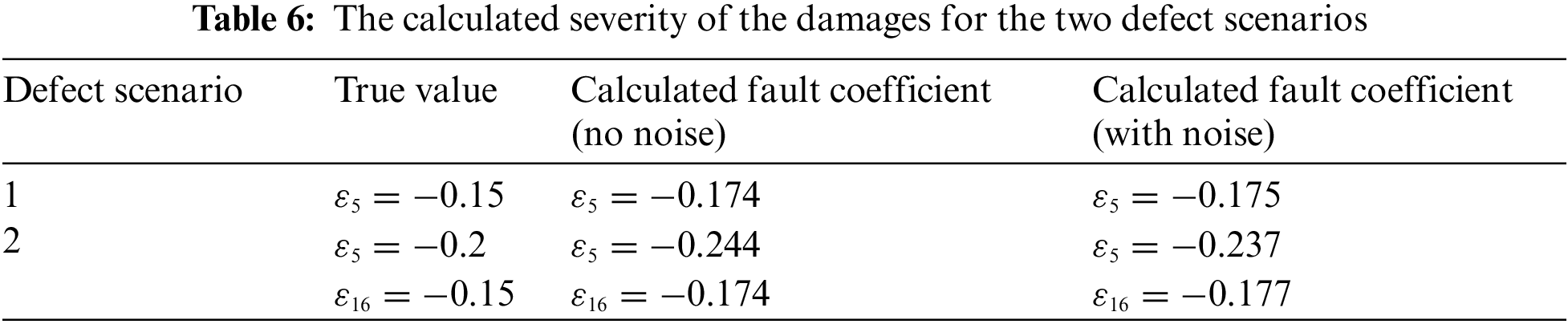

A 22-story shear frame structure shown in Fig. 3a is used to verify the feasibility of the presented approach. The stiffness and mass of each floor in Fig. 3a are

Figure 3: (a) A 22-story numerical shear frame structure; (b) Floor number and node number

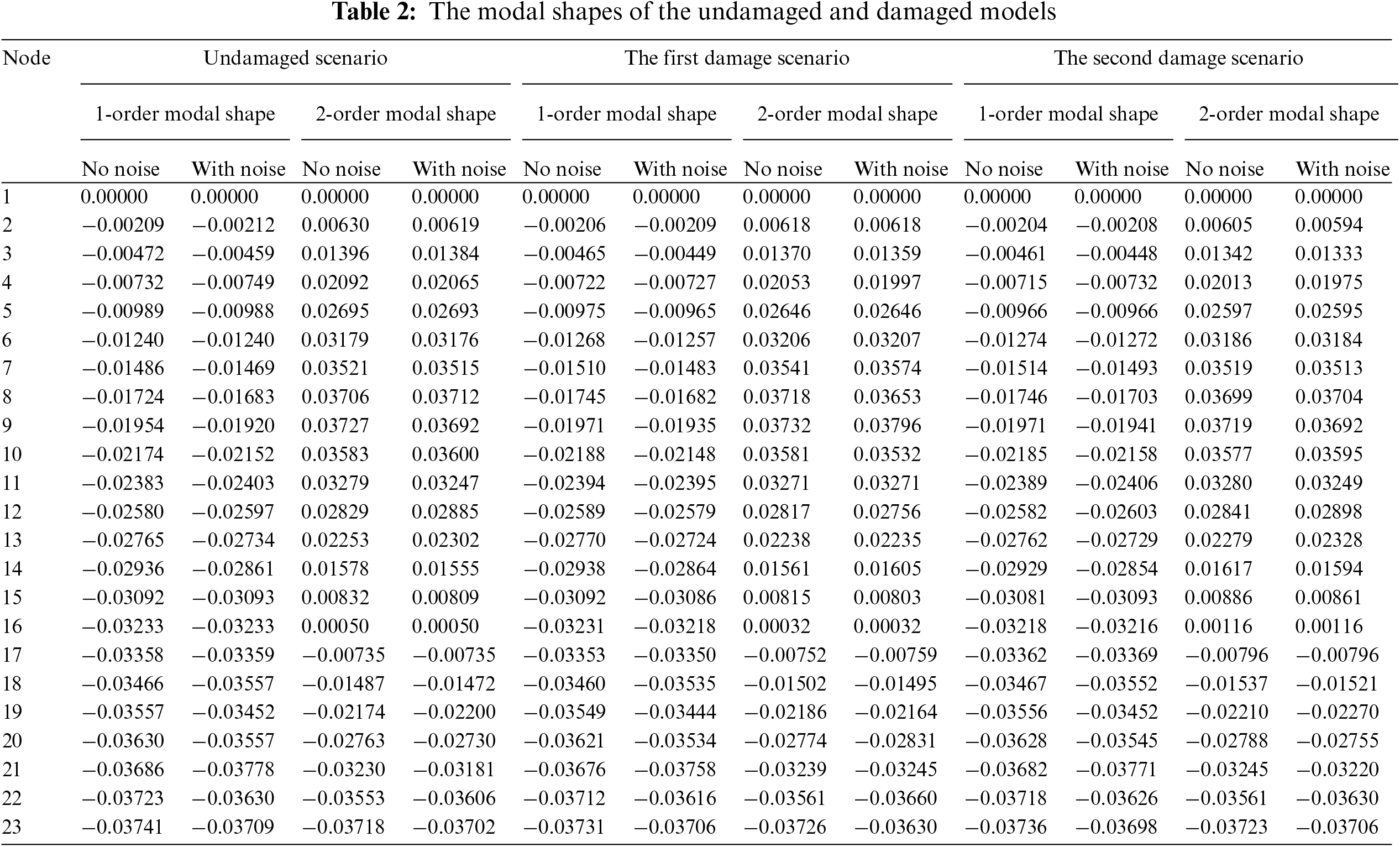

Taking the first defect scenario without data noise as an example, the specific process of calculating the damage localization vector

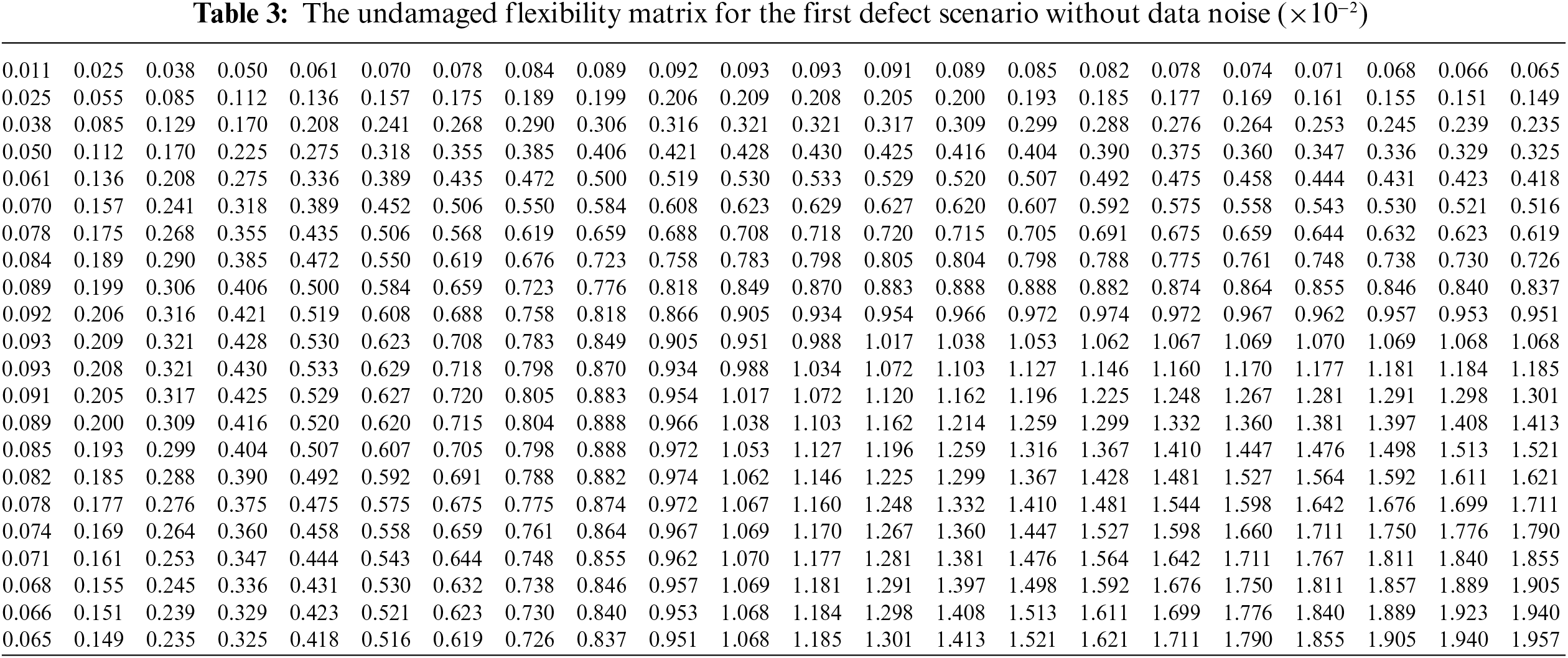

(1) Calculate the undamaged flexibility matrix

The result of

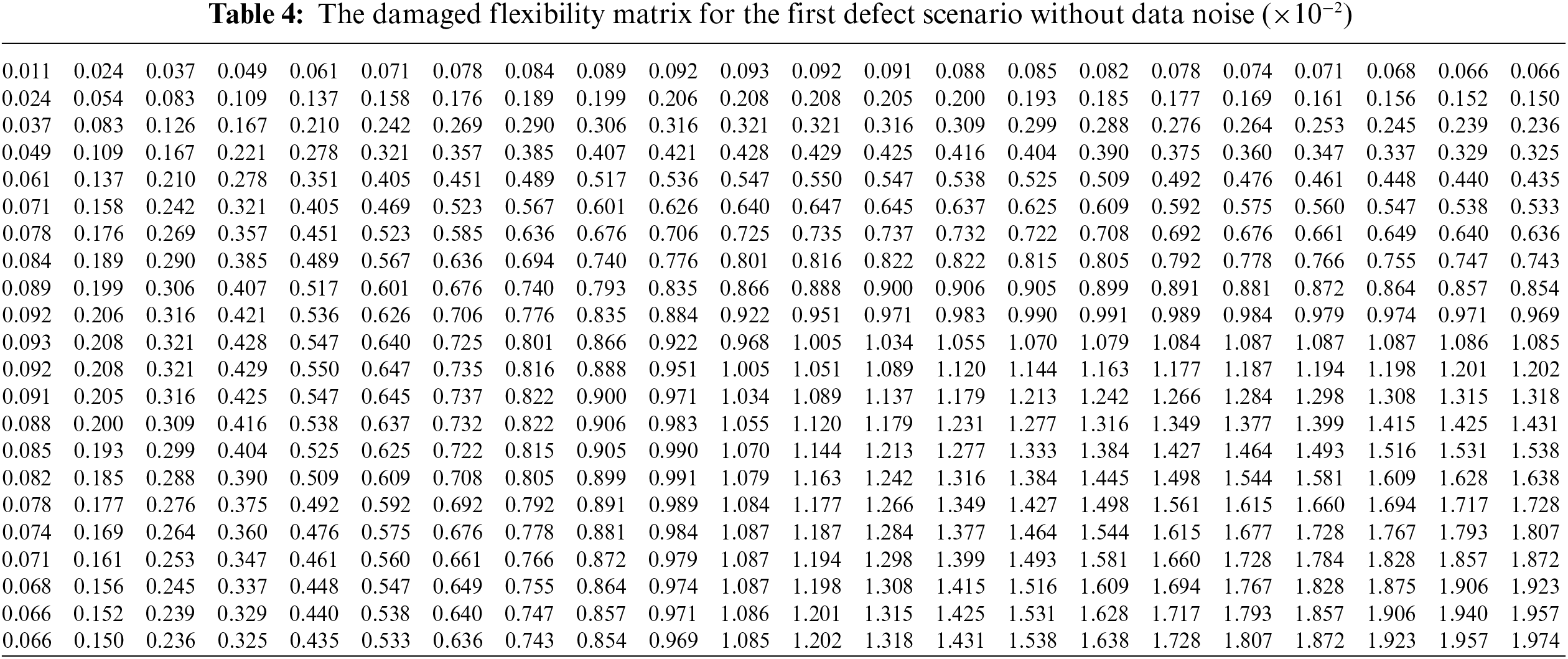

(2) Calculate the damaged flexibility matrix

The result of

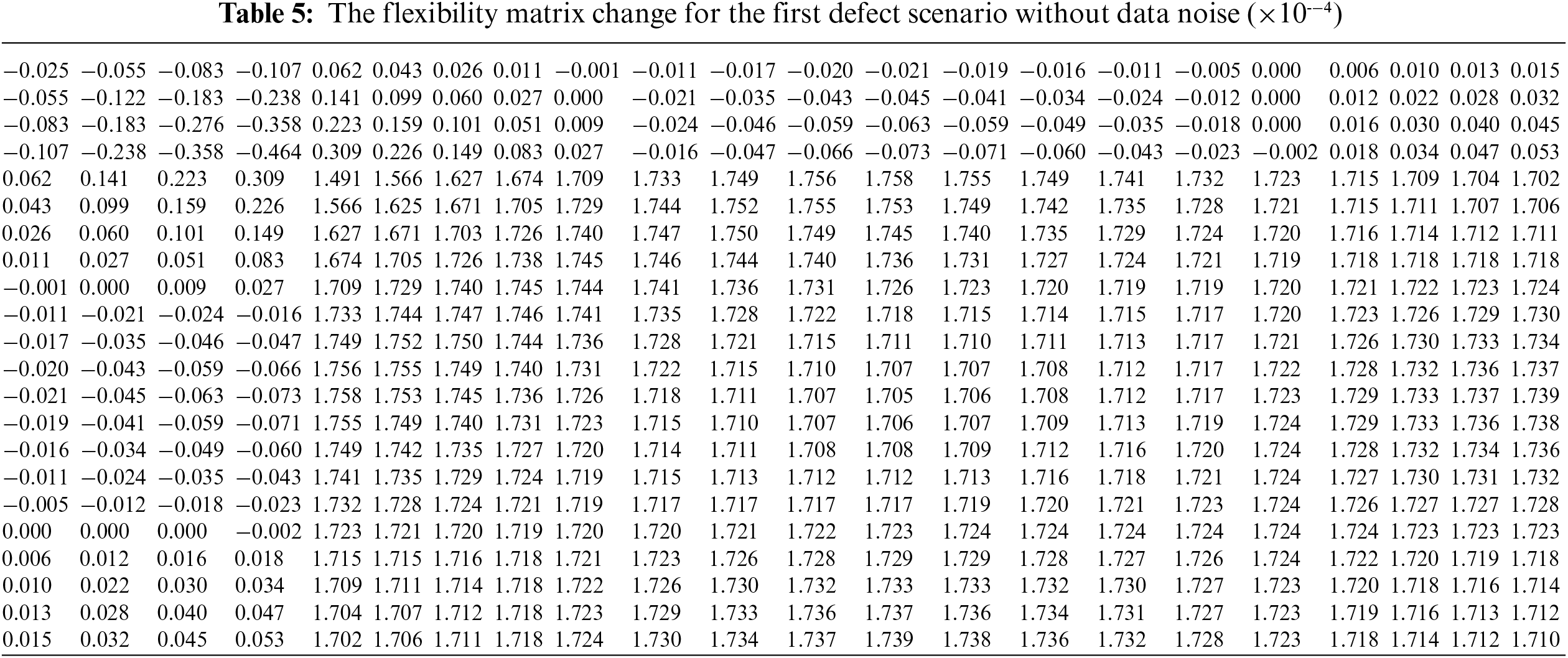

(3) Calculate the flexibility matrix change

The result of

(4) Calculate damage localization vector

Figure 4: The defect localization vector

Figure 5: The defect localization vector

4 Validation by Experimental Data

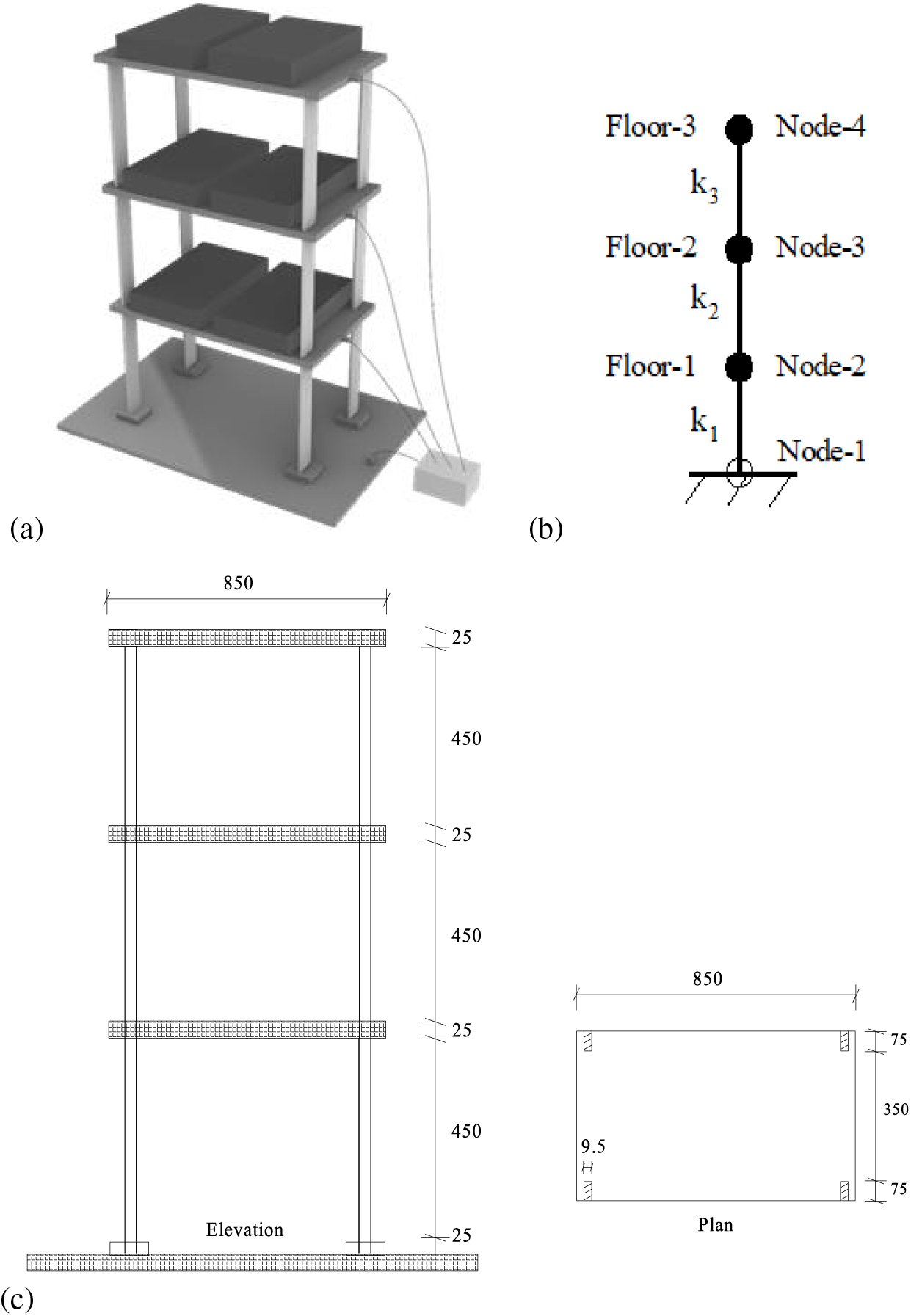

The proposed approach is validated again using the experiment data measured by Li from a three-story steel frame structure in reference [34]. The experimental structure, material parameters, and experimental process are described in detail in reference [34]. Fig. 6 provides the geometric model of this steel frame structure. From Fig. 6a, this structure is composed of three steel plates and four rectangular columns. These components are welded to simplify to a rigid shear system of Fig. 6b. The node numbers from bottom to top of this shear structure are 1, 2, 3, and 4. From vibration testing, the first natural frequency and modal shape of the undamaged structure are

Figure 6: (a) A three-story experimental shear structure; (b) Simplified shear system corresponding to the experimental structure; (c) Geometric size of the experimental structure

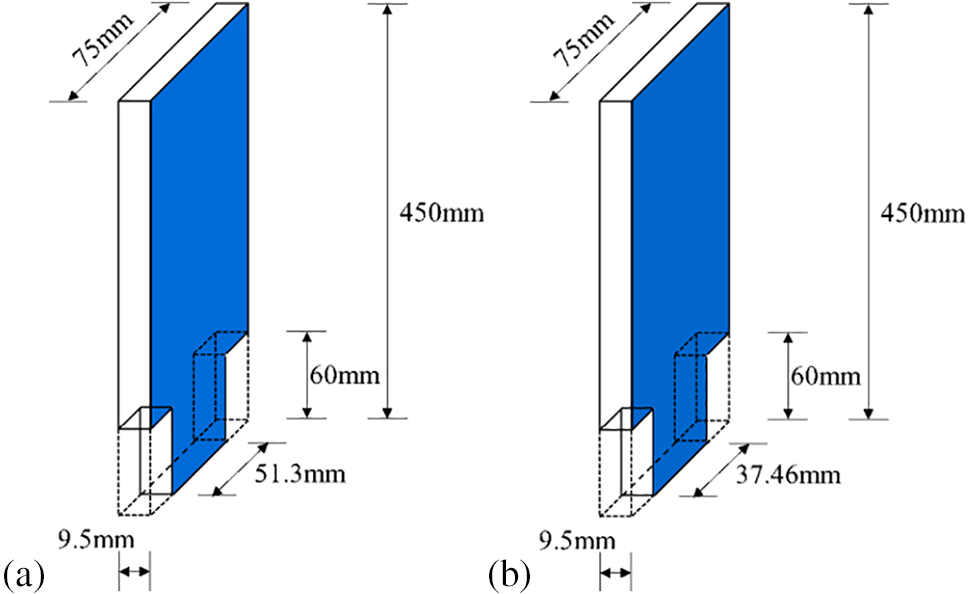

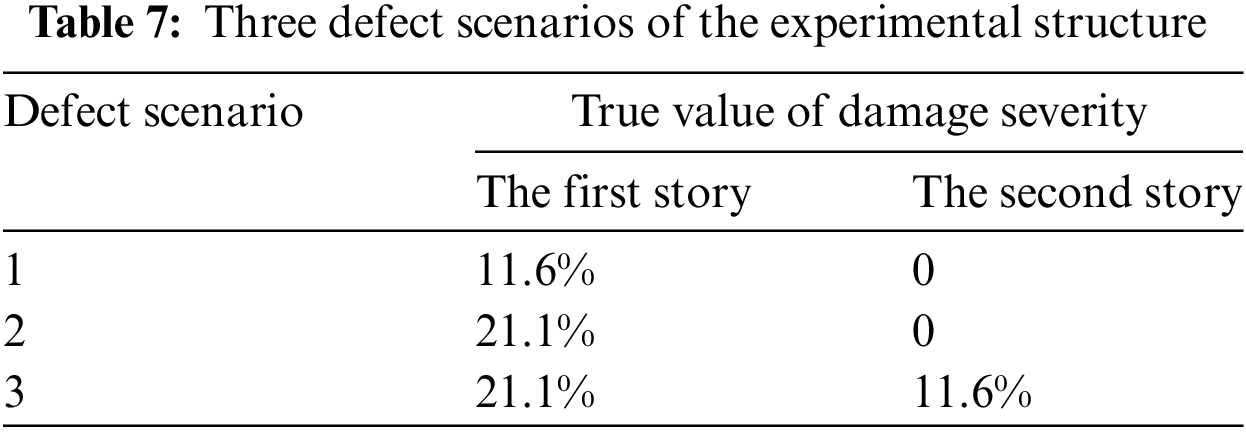

Some defect scenarios have been tested on this three-story steel frame structure in reference [34]. For the first defect scenario, the cross-sectional width of the lower ends of the four columns for the first floor has been reduced from 75 to 51.3 mm by cutting, as shown in Fig. 7a. The geometric dimensions before and after cutting are used to calculate the shear stiffness of the structure. The formula for calculating the shear stiffness was given in [34]. The ratio between the shear stiffness difference before and after cutting and the shear stiffness of the intact structure is used as the true value of the damage severity. For the first defect scenario, the true value of damage severity calculated based on the shear stiffness is 11.6%. For the second defect scenario, the cross-sectional width of the lower ends of the four columns for the first floor has been cut from 75 to 37.46 mm as shown in Fig. 7b. The corresponding true value of damage severity calculated based on the shear stiffness is 21.1%. The third damage scenario is to reduce the cross-sectional width of all column bottoms in the first floor from 75 to 37.46 mm, and to reduce the cross-sectional width of all column bottoms in the second floor from 75 to 51.3 mm, resulting in a damage degree of 21% and 11% for the first and second floors, respectively. These three defect scenarios are listed in Table 7.

Figure 7: (a) Cut the width of the column bottom from 75 to 51.3 mm; (b) Cut the width of the column bottom from 75 to 37.46 mm

For the first defect scenario, the measured first-order modal data are

(1) Calculate the undamaged flexibility matrix using Eq. (13) as:

(2) Calculate the damaged flexibility matrix using Eq. (17) as:

(3) Calculate the change of flexibility matrix as:

(4) Calculate damage localization vector

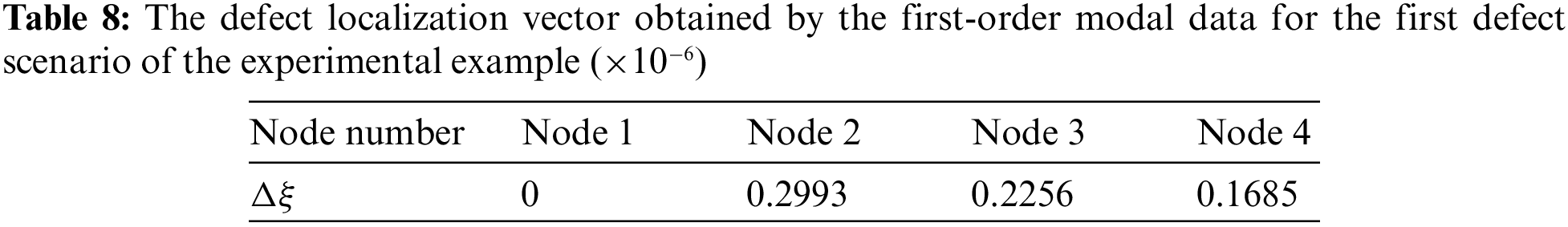

For convenience, Table 8 gives the calculation results of the defect localization vector

(1) Calculate the changes of the eigenvalues using Eq. (30) as:

(2) Calculate the eigenvalue sensitivity matrix

(3) Calculate the fault coefficients using Eq. (40) as:

From Eq. (51), the calculated values of the fault coefficients are

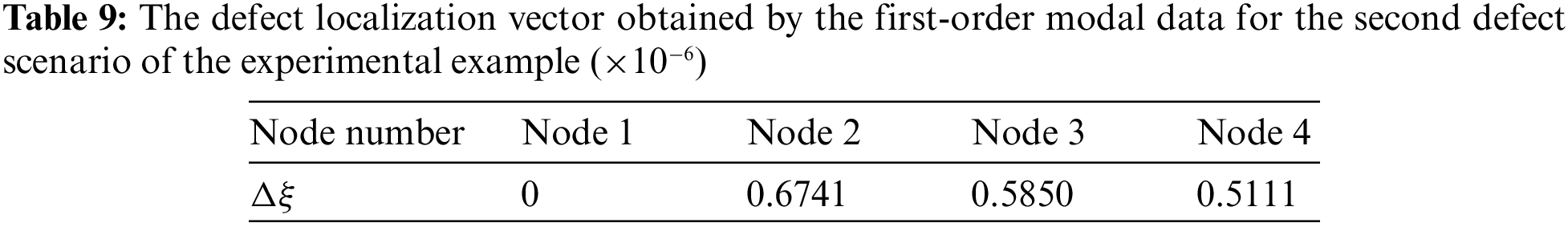

For the second defect scenario, the measured first-order modal data are

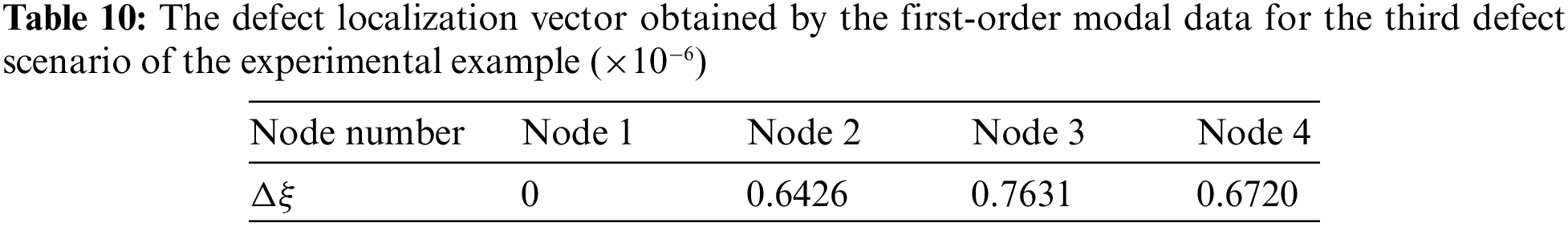

For the third defect scenario, the measured first-order modal data are

In this paper, a new method of defect localization and quantitative evaluation is developed for the diagnosis of shear-type structural defects. The greatest advantage of the proposed method is that only a few low-frequency vibration modes of the shear structure need to be measured for defect diagnosis, without requiring a FEM of the structure. The proposed method completes the task of damage diagnosis through the first stage of defect localization and the second stage of defect quantitative evaluation. The proposed method has been successfully verified on a numerical model and an experimental model. According to the computation results, some conclusions can be summarized as follows. (1) For the numerical example, the location and severity of defects in the shear structure can be correctly diagnosed using only the first two vibration modal data. The proposed method can successfully identify defects in the structure even under the interference of 3% level noise. (2) For the experimental example, the most obvious mutation location in the damage location vector also corresponds to the location of the defect in the shear structure. The improved frequency sensitivity method can further accurately diagnose the damage in the shear structure and obtain the severity of the damage. (3) The method proposed in this paper does not require an overall FEM of the structure and complex mathematical operations during implementation, so it is particularly suitable for engineering applications. It has been shown that the proposed method may be very effective for defect diagnosis of shear-type structures.

Acknowledgement: None.

Funding Statement: This work is supported by the Zhejiang Public Welfare Technology Application Research Project (LGF22E080021), Ningbo Natural Science Foundation Project (202003N4169), Natural Science Foundation of China (11202138, 52008215), the Natural Science Foundation of Zhejiang Province, China (LQ20E080013), and the Major Special Science and Technology Project (2019B10076) of “Ningbo Science and Technology Innovation 2025”.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: C.L., Q.Y.; data collection: Q.Y., X.P.; analysis and interpretation of results: C.L., Q.Y.; draft manuscript preparation: C.L., Q.Y., X.P. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data used to support the findings of this study are included within the article and also available from the corresponding author upon request.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Zhao, L., Shenton III, H. W. (2005). Structural damage detection using best approximated dead load redistribution. Structural Health Monitoring, 4(4), 319–339. [Google Scholar]

2. Abdo, M. A. B. (2012). Parametric study of using only static response in structural damage detection. Engineering Structures, 34, 124–131. [Google Scholar]

3. Avci, O., Abdeljaber, O., Kiranyaz, S., Hussein, M., Gabbouj, M. et al. (2021). A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mechanical Systems and Signal Processing, 147, 107077. [Google Scholar]

4. Ahmadi-Nedushan, B., Fathnejat, H. (2022). A modified teaching-learning optimization algorithm for structural damage detection using a novel damage index based on modal flexibility and strain energy under environmental variations. Engineering with Computers, 38(1), 847–874. [Google Scholar]

5. Yang, Q. W. (2019). Fast and exact algorithm for structural static reanalysis based on flexibility disassembly perturbation. AIAA Journal, 57(8), 3599–3607. [Google Scholar]

6. Yang, Q. W., Peng, X. (2023). A fast calculation method for sensitivity analysis using matrix decomposition technique. Axioms, 12(2), 179. [Google Scholar]

7. Peng, X., Yang, Q. W. (2022). Damage detection in beam-like structures using static shear energy redistribution. Frontiers of Structural and Civil Engineering, 16(12), 1552–1564. [Google Scholar]

8. Li, G. Q., Hao, K. C., Lu, Y., Chen, S. W. (1999). A flexibility approach for damage identification of cantilever-type structures with bending and shear deformation. Computers & Structures, 73(6), 565–572. [Google Scholar]

9. Koo, K. Y., Sung, S. H., Jung, H. J. (2011). Damage quantification of shear buildings using deflections obtained by modal flexibility. Smart Materials and Structures, 20(4), 045010. [Google Scholar]

10. Zhu, H., Li, L., He, X. Q. (2011). Damage detection method for shear buildings using the changes in the first mode shape slopes. Computers & Structures, 89(9–10), 733–743. [Google Scholar]

11. Xing, Z., Mita, A. (2012). A substructure approach to local damage detection of shear structure. Structural Control and Health Monitoring, 19(2), 309–318. [Google Scholar]

12. Su, W. C., Huang, C. S., Hung, S. L., Chen, L. J., Lin, W. J. (2012). Locating damaged storeys in a shear building based on its sub-structural natural frequencies. Engineering Structures, 39, 126–138. [Google Scholar]

13. Sung, S. H., Koo, K. Y., Jung, H. Y., Jung, H. J. (2012). Damage-induced deflection approach for damage localization and quantification of shear buildings: Validation on a full-scale shear building. Smart Materials and Structures, 21(11), 115013. [Google Scholar]

14. Panigrahi, S. K., Chakraverty, S., Mishra, B. K. (2013). Damage identification of multistory shear structure from sparse modal information. Journal of Computing in Civil Engineering, 27(1), 1–9. [Google Scholar]

15. Li, H., Tao, D., Huang, Y., Bao, Y. (2013). A data-driven approach for seismic damage detection of shear-type building structures using the fractal dimension of time-frequency features. Structural Control and Health Monitoring, 20(9), 1191–1210. [Google Scholar]

16. An, Y., Spencer Jr, B. F., Ou, J. (2015). Real-time fast damage detection of shear structures with random base excitation. Measurement, 74, 92–102. [Google Scholar]

17. Wang, D., Xiang, W., Zeng, P., Zhu, H. (2015). Damage identification in shear-type structures using a proper orthogonal decomposition approach. Journal of Sound and Vibration, 355, 135–149. [Google Scholar]

18. Mei, L., Mita, A., Zhou, J. (2016). An improved substructural damage detection approach of shear structure based on ARMAX model residual. Structural Control and Health Monitoring, 23(2), 218–236. [Google Scholar]

19. Luo, J., Liu, G., Huang, Z. (2017). Damage detection for shear structures based on wavelet spectral transmissibility matrices under nonstationary stochastic excitation. Structural Control and Health Monitoring, 24(1), e1862. [Google Scholar]

20. Shi, J. Y., Spencer Jr, B. F., Chen, S. S. (2018). Damage detection in shear buildings using different estimated curvature. Structural Control and Health Monitoring, 25(1), e2050. [Google Scholar]

21. Mei, L., Li, H., Zhou, Y., Wang, W., Xing, F. (2019). Substructural damage detection in shear structures via ARMAX model and optimal subpattern assignment distance. Engineering Structures, 191, 625–639. [Google Scholar]

22. Paral, A., Singha Roy, D. K., Samanta, A. K. (2019). Application of a mode shape derivative-based damage index in artificial neural network for structural damage identification in shear frame building. Journal of Civil Structural Health Monitoring, 9, 411–423. [Google Scholar]

23. Liang, Y., Feng, Q., Li, H., Jiang, J. (2019). Damage detection of shear buildings using frequency-change-ratio and model updating algorithm. Smart Structures and Systems, An International Journal, 23(2), 107–122. [Google Scholar]

24. Ghannadi, P., Kourehli, S. S. (2019). Model updating and damage detection in multi-story shear frames using Salp Swarm Algorithm. Earthquakes and Structures, 17(1), 63–73. [Google Scholar]

25. Do, N. T., Gül, M. (2020). A time series based damage detection method for obtaining separate mass and stiffness damage features of shear-type structures. Engineering Structures, 208, 109914. [Google Scholar]

26. Zhao, L., Jin, D., Wang, H., Liu, C. (2020). Modal parameter identification of time-varying systems via wavelet-based frequency response function. Archive of Applied Mechanics, 90(11), 2529–2542. [Google Scholar]

27. Liu, C., Fang, D., Zhao, L. (2021). Reflection on earthquake damage of buildings in 2015 Nepal earthquake and seismic measures for post-earthquake reconstruction. Structures, 30, 647–658. [Google Scholar]

28. Niu, Z. (2021). Two-step structural damage detection method for shear frame structures using FRF and Neumann series expansion. Mechanical Systems and Signal Processing, 149, 107185. [Google Scholar]

29. Yang, Q. W., Peng, X. (2023). A highly efficient method for structural model reduction. International Journal for Numerical Methods in Engineering, 124(2), 513–533. [Google Scholar]

30. Yang, Q. W., Peng, X. (2021). Sensitivity analysis using a reduced finite element model for structural damage identification. Materials, 14(19), 5514. [Google Scholar] [PubMed]

31. Tan, Y., Chen, Y., Lu, Z. R., Wang, L. (2022). Model-calibration-free damage identification of shear structures by measurement changes correction and sparse regularization. Structures, 37, 255–266. [Google Scholar]

32. Roy, K. (2023). Structural damage quantification in shear buildings using mode shape slope ratio. Structural Health Monitoring, 22(4), 2346–2359. [Google Scholar]

33. Yang, Q. W., Du, S. G., Liang, C. F., Yang, L. (2014). A universal model-independent algorithm for structural damage localization. Computer Modeling in Engineering & Sciences, 100, 223–248. https://doi.org/10.3970/cmes.2014.100.223 [Google Scholar] [CrossRef]

34. Li, L. (2005). Numerical and experimental studies of damage detection for shear buildings (Ph.D. Thesis). Huazhong University of Science and Technology, Wuhan, China. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools