Open Access

Open Access

ARTICLE

Determination of Monitoring Control Value for Concrete Gravity Dam Spatial Deformation Based on POT Model

Department of Engineering Mechanics, Hohai University, Nanjing, 211100, China

* Corresponding Author: Tiantang Yu. Email:

(This article belongs to the Special Issue: New Trends in Statistical Computing and Data Science)

Computer Modeling in Engineering & Sciences 2023, 135(3), 2119-2135. https://doi.org/10.32604/cmes.2023.025070

Received 20 June 2022; Accepted 16 August 2022; Issue published 23 November 2022

Abstract

Deformation can directly reflect the working behavior of the dam, so determining the deformation monitoring control value can effectively monitor the safety of dam operation. The traditional dam deformation monitoring control value only considers the single measuring point. In order to overcome the limitation, this paper presents a new method to determine the monitoring control value for concrete gravity dam based on the deformations of multi-measuring points. A dam’s comprehensive deformation displacement is determined by the measured values at different measuring points on the positive inverted vertical line and the corresponding weight of each measuring point. The projection pursuit method (PPM) combined with the grey wolf optimization (GWO) algorithm is used to determine the weight of each measuring point according to the spatial correlation distribution characteristics of dam deformation. The peaks over threshold (POT) model based on the extreme value theory is adopted to determine the monitoring control value with the obtained dam comprehensive deformation displacement. In addition, the POT model is improved with the automatic threshold determination method based on the criterion in probability theory and the GWO algorithm, which can avoid subjectivity and randomness in determining the threshold. The results of the engineering application show the feasibility and applicability of the proposed method.Keywords

To ensure the safety operation of dams, it is necessary to understand the service behavior of dams by analyzing monitoring data in real time [1–5]. Dam deformation is one of the main means to monitor and judge the operation behavior of the dam. The deformation monitoring control value is a crucial index to evaluate and monitor dam safety. If the control value is too large, the danger cannot be found in time. If the control value is too small, it tends to be conservative. Therefore, the determination of appropriate monitoring control value is pivotal for evaluating the service safety of the dam.

The commonly used methods to estimate the control value of monitoring effect quantity are mathematical statistics and structural analysis. For the long-term monitoring data series, mathematical statistics is usually used to formulate the control value of dam deformation monitoring effect quantity. Yang et al. [6] proposed an expression of temperature entropy in concrete dams based on the synergetics and entropy, and determined the sequential value and the early-warning index value of temperature entropy with this expression via the small probability method. Lei et al. [7] established an entropy formula to measure the deformation of high concrete dam, and suggested a method of calculating early warning index of spatial deformation by low probability principle based on series of calculated deformation entropy values. Qin et al. [8] presented a multi-block combined diagnosis indexes based on dam block comprehensive displacement of concrete dams, which is made up of single-point displacements with different weights determined with improved projection pursuit method (PPM). Su et al. [9] extracted inherent characteristics of deformation and seepage accurately using the kernel principal component analysis (KPCA) method and determined the spatial multi-point security warning domain of deformation and seepage in typical dam sections. Li et al. [10] proposed an online robust recognition and early warning model based on an M-estimator and a confidence interval, and a threshold

Many monitoring points are often arranged for dam monitoring, but the traditional dam monitoring control values are mostly based on a single monitoring point on deformation, seepage or stress, ignoring the spatial correlation between the monitoring points. Fully considering the correlation characteristics of time and space distribution of monitoring information at multiple measuring points, comprehensively reflecting the integrity of dam deformation can more effectively reflect the overall working behavior of the dam. In this study, the plane deformation field of the positive inverted vertical line measuring points in the concrete gravity dam is constructed. The projection pursuit method (PPM) [17] combined with the grey wolf optimization (GWO) algorithm [18] is used to project the deformation field data to the low dimensional space, and the peaks over threshold (POT) model [19] is used to comprehensively determine the threshold value. The POT model is improved with the automatic threshold determination method based on the

The rest of the manuscript is structured as follows. The methodology is described in Section 2. Case studies and discussion are given in Section 3. Some conclusions are presented in Section 4.

The traditional dam monitoring control values are determined based on the measured values of single measuring point, ignoring the spatial correlation among measuring points. In this work, the deformation field is constructed according to the characteristics of the measuring points of the positive inverted vertical lines. The PPM combined with the GWO algorithm is used to project the deformation field data into the low dimensional space, and the comprehensive displacement of the dam deformation is determined according to the weight of each measuring point. The POT model is improved by using automatic threshold determination method, which evaluates the threshold based on the

2.1 Dam Comprehensive Deformation Displacement

A large number of monitoring instruments are arranged at different parts of the dam to jointly monitor the working behavior of the dam. In fact, the deformation of each measuring point is not independent. The correlation of the spatial structure exists. Therefore, it is necessary to comprehensively consider the correlation among spatial monitoring effects, and mine the spatial characteristics and development laws of dam deformation from the data.

With the development of spatial metrology, data representation methods have been expanded from one dimension to a high dimension, from time or cross-section to spatial panel data, and combination of cross-section, time and spatial data. For the dam, the deformation data of each measuring point is not independent of each other, but there is spatial structure correlation under the action of external load. Therefore, it is necessary to comprehensively consider the correlation between different spatial monitoring effects, and mine the spatial characteristics and development laws of dam deformation from the data.

The horizontal displacement vector field

where i and j are the unit vectors along the river and across the river, respectively.

The monitoring values of all measuring points at the same time of the dam can generally reflect the spatial deformation behavior of the structural system. For the vertical measuring points of the typical dam section of a concrete gravity dam, by continuously monitoring the downstream or transverse deformation of all measuring points on a vertical line, the downstream or transverse deformation values of different elevations at different times can be obtained as follows:

where n denotes the number of elevations, and T is the number of times.

where

2.2 Determination of Weight Values of Measuring Points Based on PPM-GWO

The information contained in the spatial deformation section data of the dam is mined with the PPM, then the weight distribution of each measuring point at different elevations of a certain section of the dam can be determined. The PPM searches the projection direction that can comprehensively reflect the characteristics or structure of the original high-dimensional data by polarizing a projection index, projects the high-dimensional data to the low-dimensional subspace, and analyzes the high-dimensional data by studying the data structure and projection characteristics of the low-dimensional space.

The samples of all displacement measuring points can be expressed as

where

Normalized measured value sequence

where

After the normalized sample set is determined, the value of the projection index function Z(l) will be determined by the projection direction l and will change accordingly. According to the relationship between l and Z(l), the maximum value of Z(l) corresponds to the best projection direction

with

where

The GWO algorithm is a global random search algorithm established by simulating the hunting and search behavior of grey wolves in the process of hunting. The GWO algorithm is similar to the particle swarm optimization (PSO). It is a random search algorithm that converges to the global optimal solution with a large probability. Compared with the PSO, grid search optimization algorithm, the GWO has fewer parameters, simple structure and strong convergence. In this study, the GWO algorithm is used to solve the objective function of the PPM to determine the weight of spatial measurement points.

The best, second and third best solutions are respectively considered as

with

where t denotes the number of iterations,

To simulate the hunting behavior of grey wolves,

with

where

The main procedures of the GWO algorithm are as follows: (1) Utilize initial parameters (number of grey wolves, number of iterations, etc.); (2) Create initial population of grey wolves with different social hierarchy (

Mark the obtained best projection direction as

where

2.3 Determination of Monitoring Control Values Based on POT Model

The POT model in extreme value theory focuses on the sequence distribution beyond the threshold, which can better consider the occurrence of large measured values, and the calculated results are more close to the actual situation of dam operation and service.

For the comprehensive displacement

According to the extreme value theorem, when the threshold is large enough, it converges to the generalized Pareto distribution.

where

As long as the threshold value is determined, the transfinite sequence can be obtained. The shape parameter and scale parameter can be solved by using the maximum likelihood function, which is expressed as

After

where

Thus, the estimated value of

In the process of using the POT model to draw up dam displacement monitoring control values, if the threshold value is too large, the variance of estimated values of shape and scale parameters will be too large due to too few samples exceeding the limit value; If the threshold value is too small, the distribution of the over limit value may not converge, resulting in great errors for determining monitoring control values. The methods to determine the threshold value mainly include over limit expectation graph method and Hill graph method. Both of these two methods are graphical methods, which are more intuitive, but require manual judgment, which is easy to cause subjective errors. In this paper,

According to the

The steps of threshold selection based on the GWO algorithm are as follows: (1) Determine the upper and lower limits of the threshold. The threshold sequence meets the convergence of the conditional distribution function

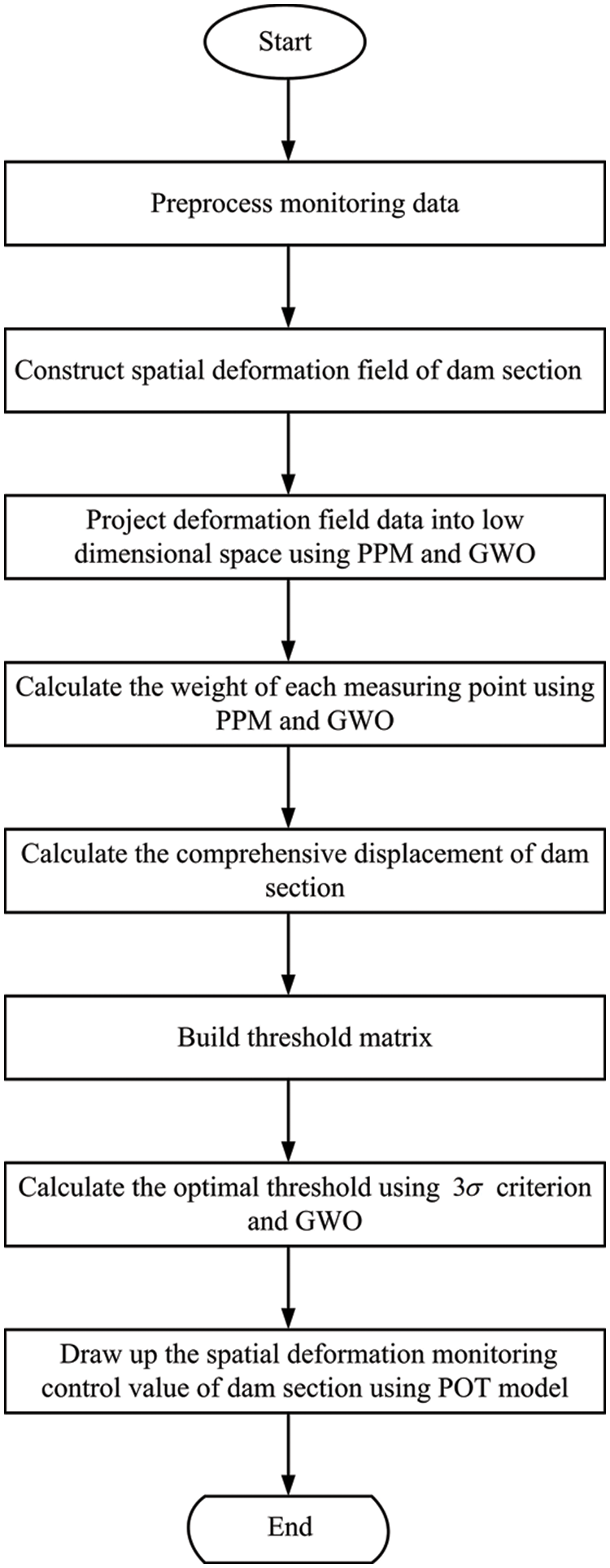

Fig. 1 shows the workflow of determining the monitoring control value for concrete gravity dam spatial deformation based on POT model.

Figure 1: Workflow of determining the monitoring control value for concrete gravity dam spatial deformation based on POT model

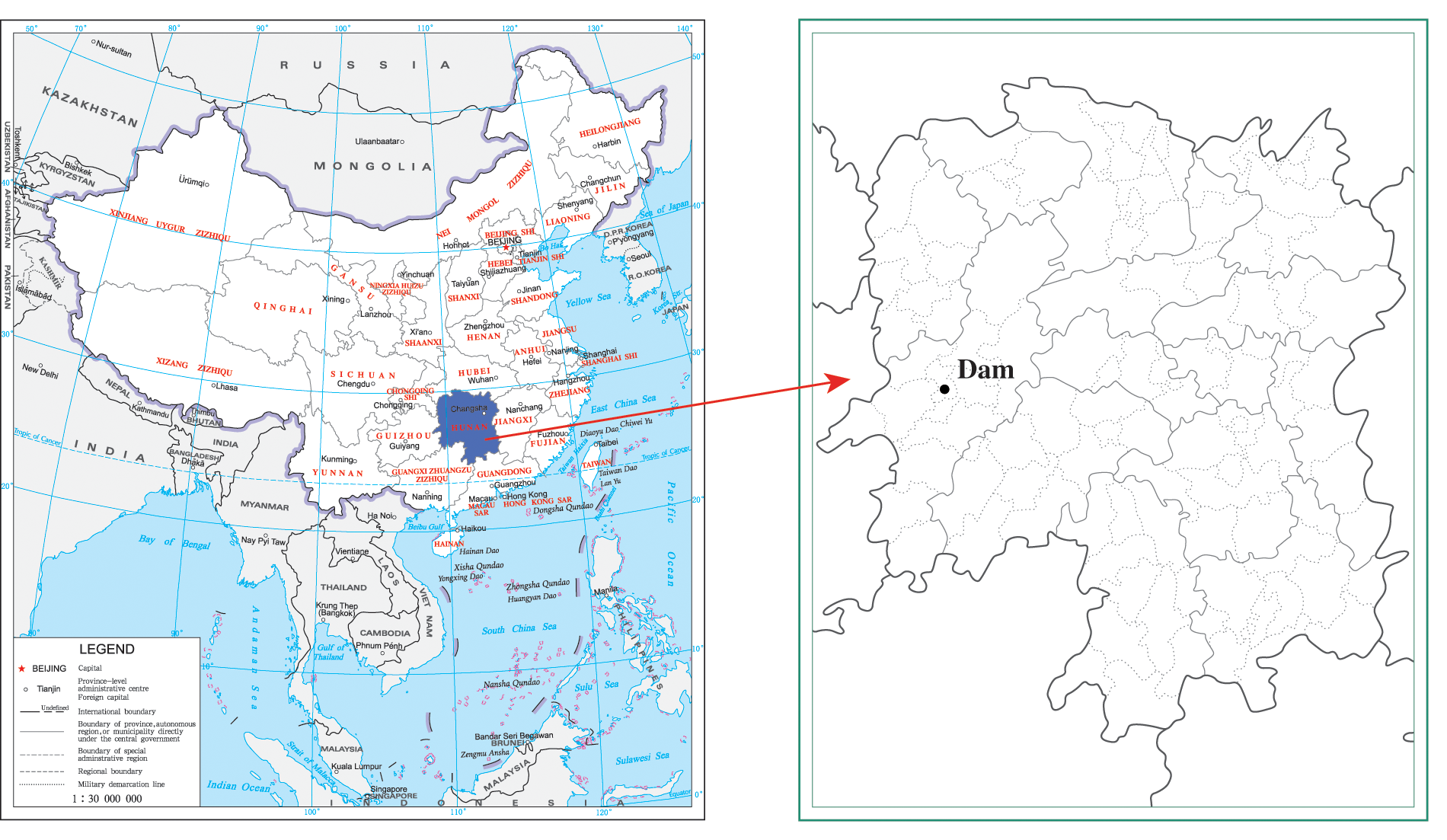

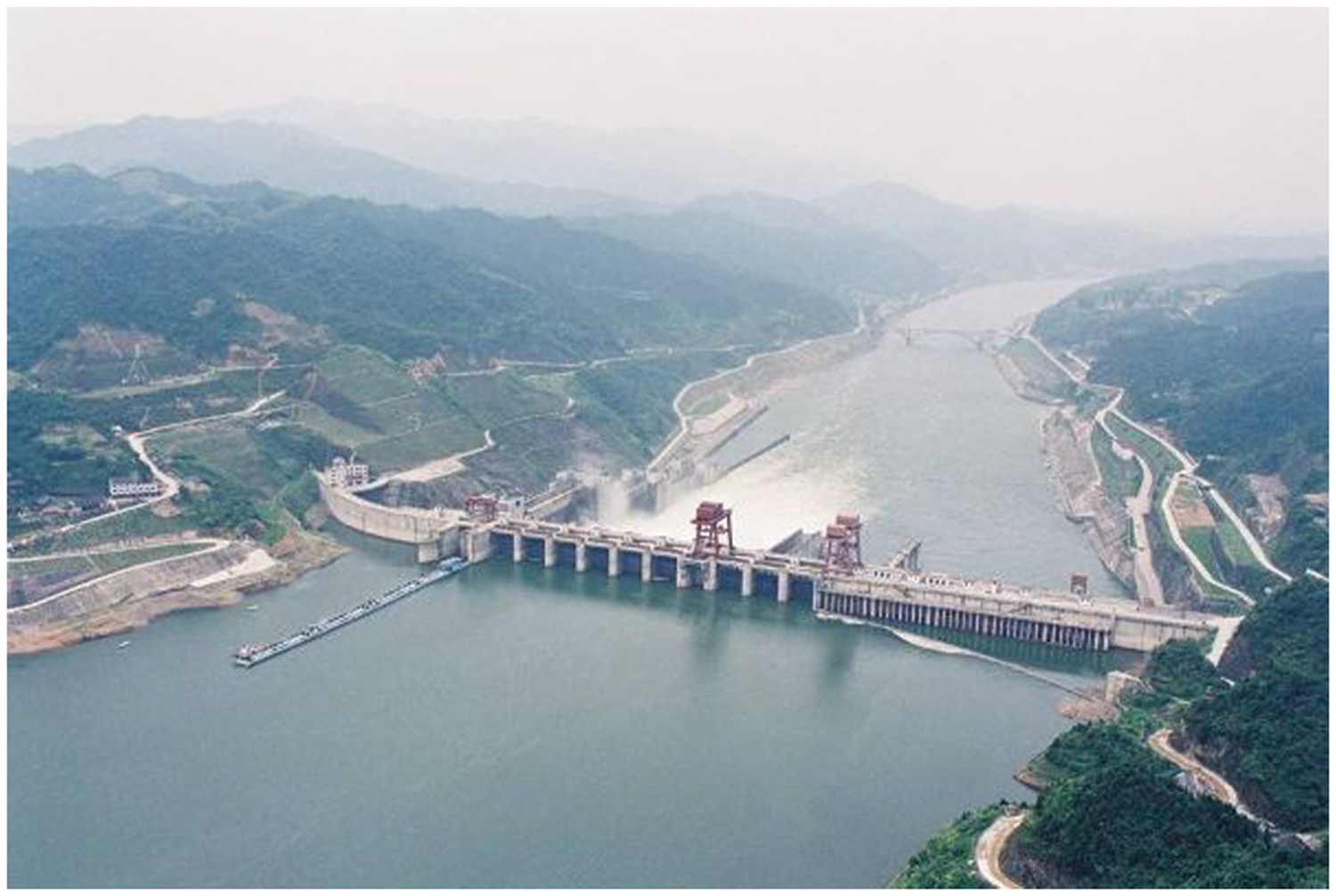

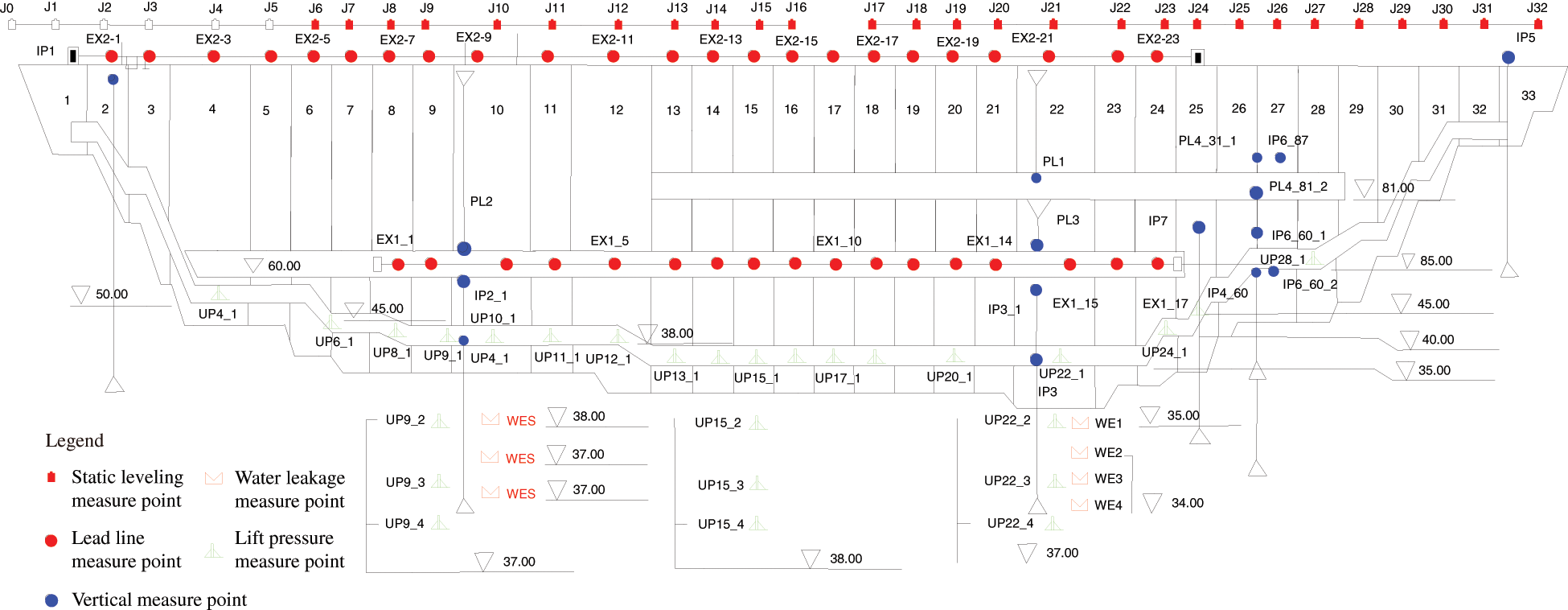

Fig. 2 presents the location of Wuqiangxi hydropower station, which consists of the river blocking dam, the powerhouse behind the dam and the three-stage ship lock. The schematic diagram of layout of Wuqiangxi hydropower station is shown in Fig. 3. The dam is a concrete gravity dam. The crest elevation is 117.5 m, the highest dam height is 85.83 m, and the total crest length is 719.7 m. The main dam is divided into 33 dam sections, and the layout of dam deformation measuring points is shown in Fig.4.

Figure 2: Location of Wuqiangxi hydropower station (the longitude and latitude of the dam are 110.6294 and 28.5783, respectively)

Figure 3: Wuqiangxi hydropower station

Figure 4: Layout of deformation measuring points

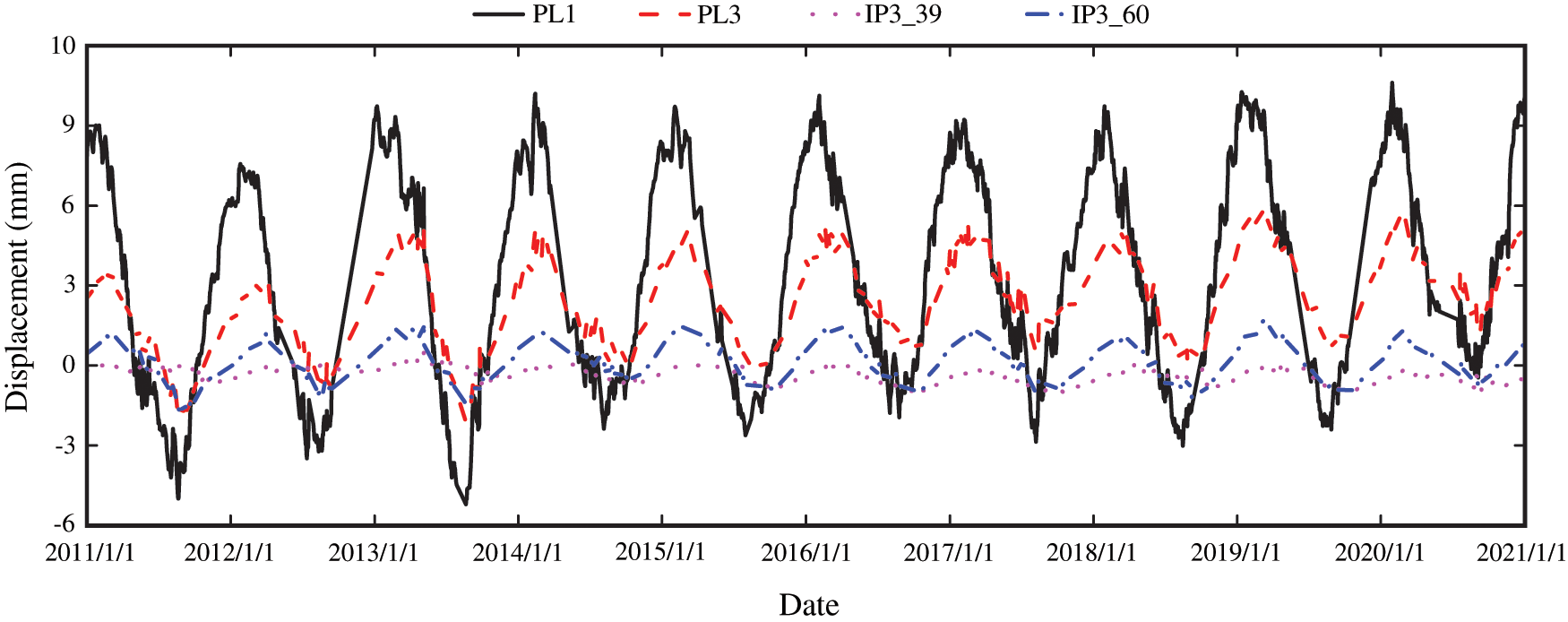

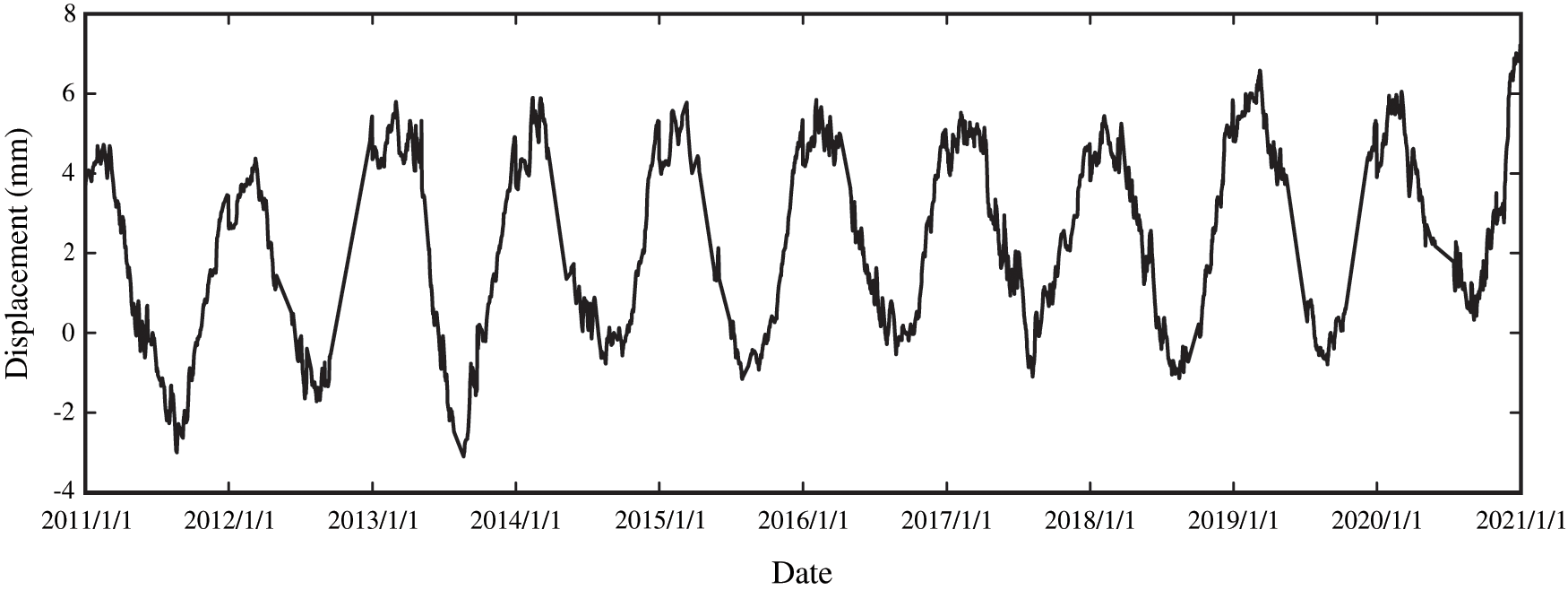

The displacements along the river from January 2011 to December 2020 of the positive inverted vertical lines PL1, PL3, IP3

Figure 5: The process lines of measured displacements along the river of all measuring points on dam section 22

3.2 Comparison of Optimization Algorithm Selection

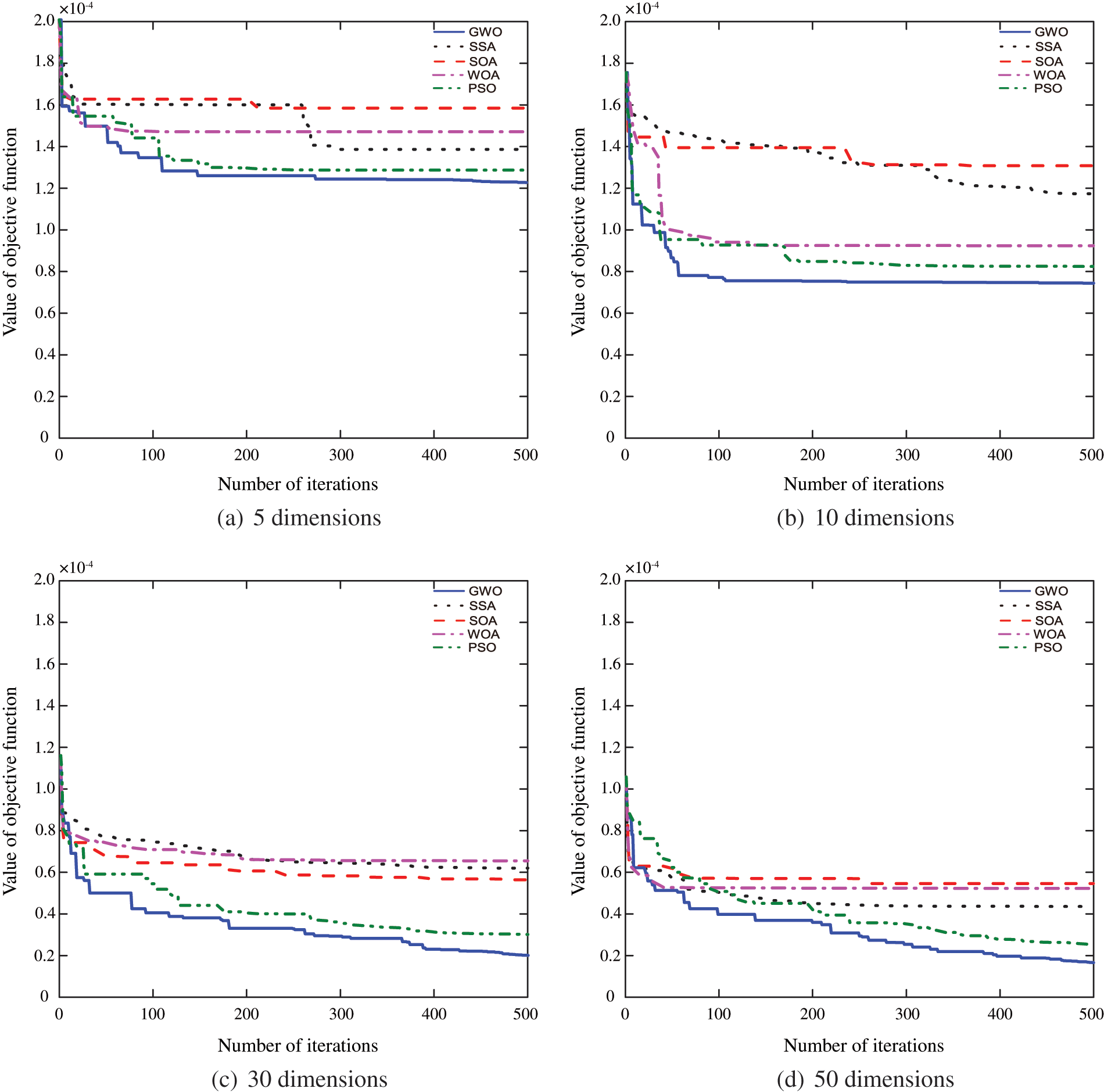

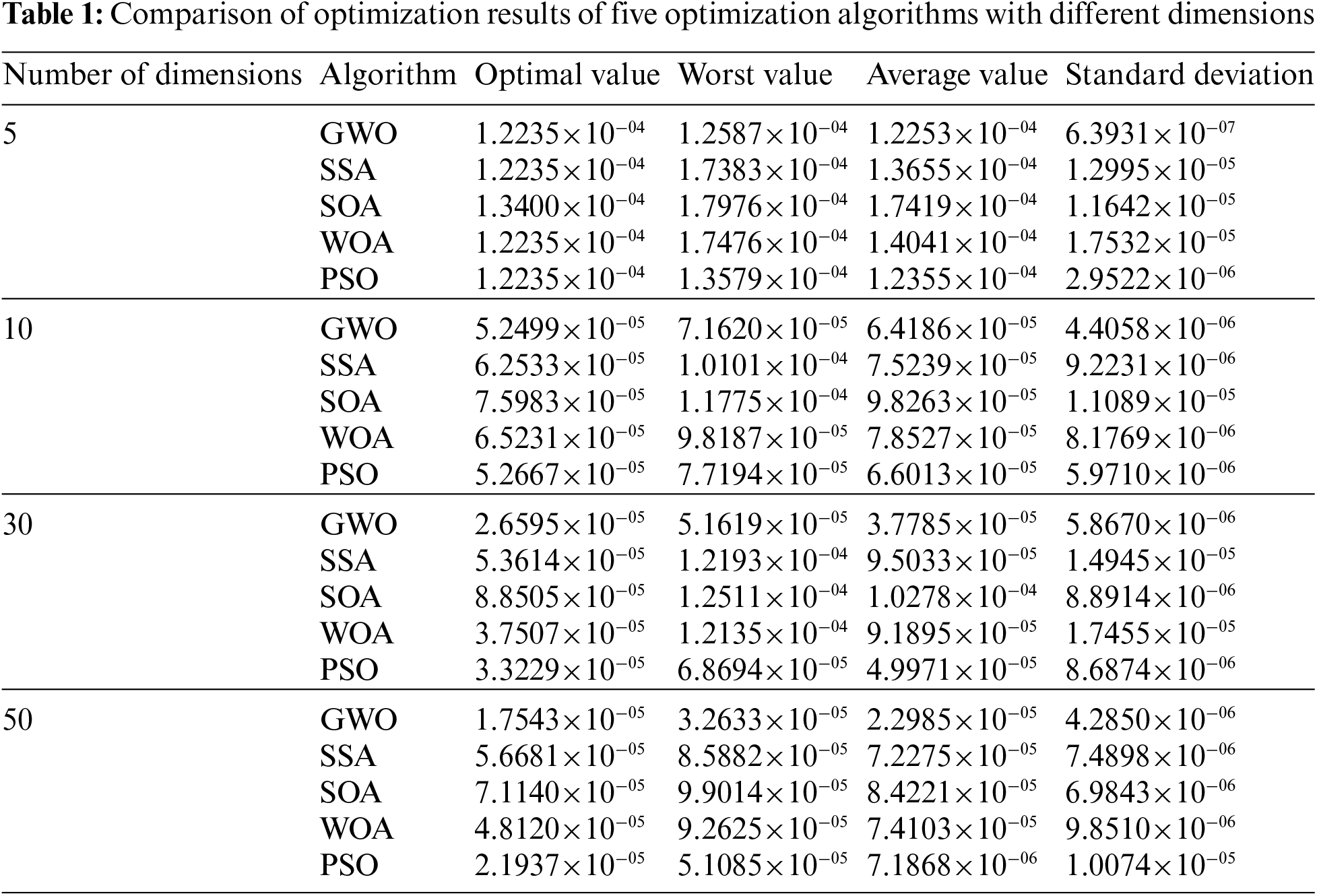

For the PPM to determine the weight of spatial measurement points, we select the sparrow search algorithm (SSA) [20], seagull optimization algorithm (SOA) [21], whale optimization algorithm (WOA) [22] and particle swarm optimization (PSO) algorithm [23] to compare with the GWO algorithm. The function of adjusting the PPM to find the best projection direction changes from finding the maximum value to finding the minimum value. If the upper and lower limits of the test data set are set to [−50, 50], the solution domain is [0.01, 1], the population number is 30, and the maximum number of iterations is 500. For data of different dimensions, each algorithm is solved 30 times independently, and four statistical indicators such as the optimal value, the worst value, the average value and the standard deviation of the fitness are selected to comprehensively evaluate the algorithm.

The variations of fitness values for different algorithms are shown in Fig. 6.

Figure 6: The iteration process of different algorithms

FromTable 1, when the data dimension is low, there is little difference in the optimal values of the fitness of five algorithms, but the worst value and mean value of the GWO’s fitness are the smallest, and the standard deviation of the GWO’s fitness is much smaller than that of the other four algorithms, indicating that the GWO is more stable. With the increase of data dimension, the GWO’s advantages in dealing with the problem of determining the weight of spatial measurement points by PPM are reflected. The optimal value, the worst value, the average value and the standard deviation of the GWO’s fitness are the smallest of the five algorithms, and the higher the dimension, the more obvious the advantages of the GWO. From the iteration curves, it can be found that the GWO algorithm has the best effect. Whether it is high-dimensional or low-dimensional, the GWO has the fastest convergence speed and the highest convergence accuracy at the same iteration times. In conclusion, the GWO has the best effect in dealing with the problem of determining the weight of spatial measurement points by PPM.

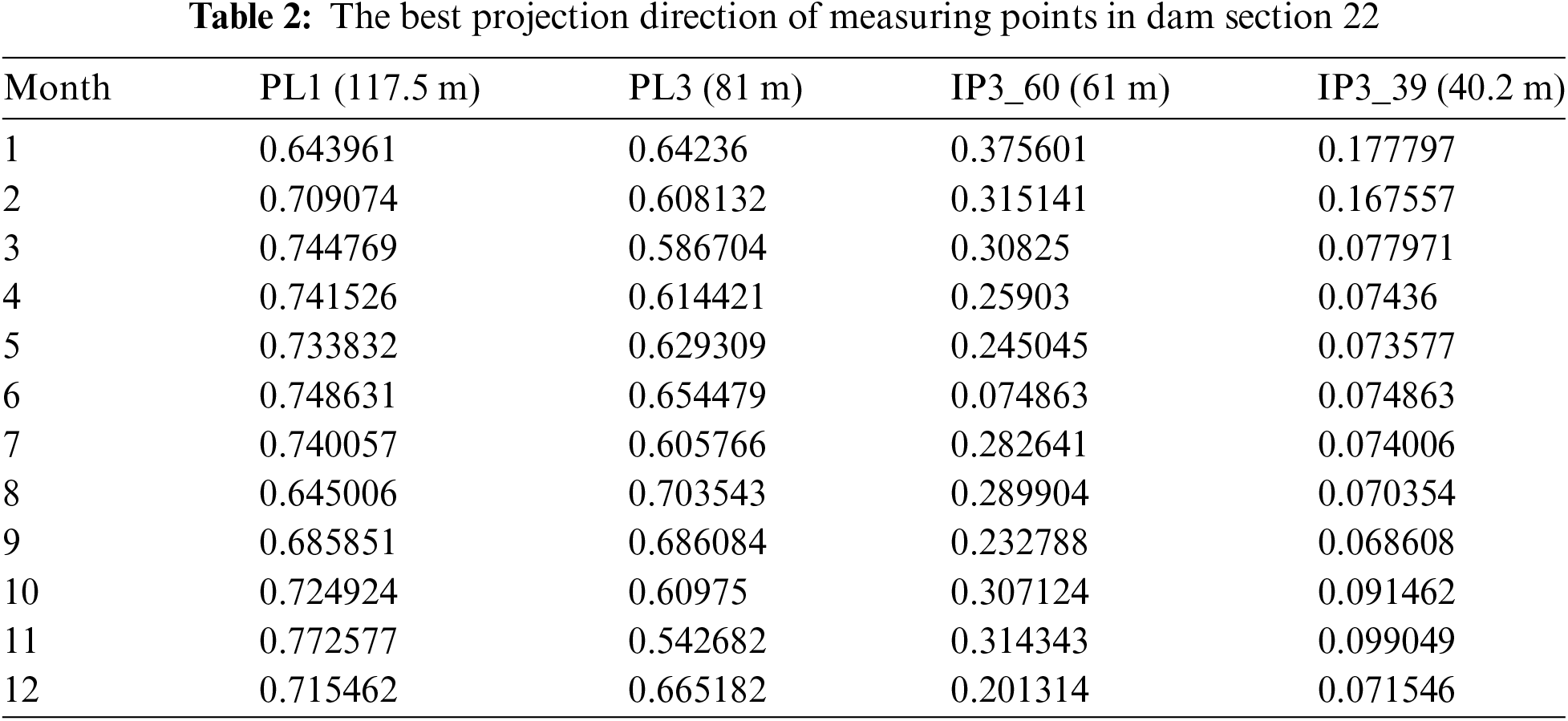

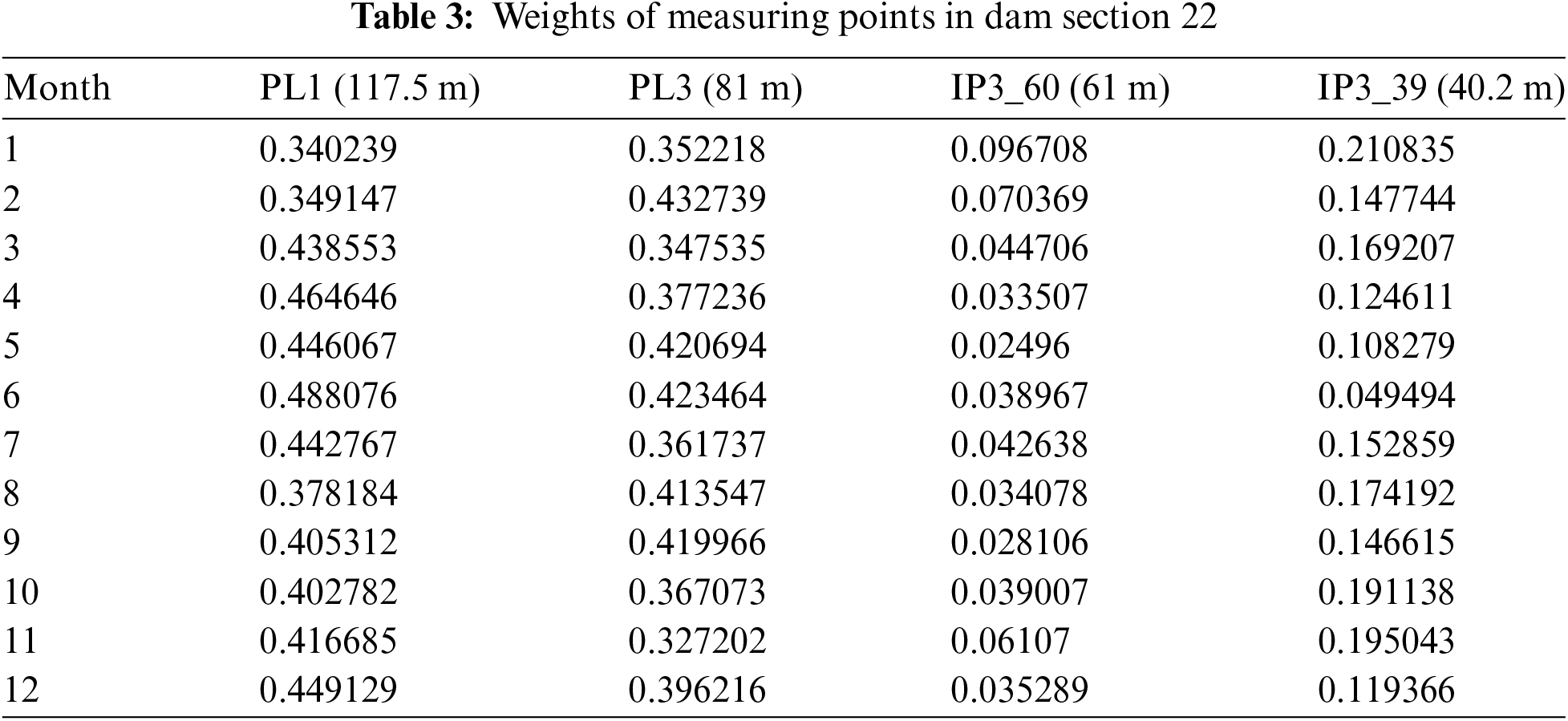

3.3 Determination of Measuring Point Weight

The environmental variables have a non-linear relationship with the measuring points at different elevations on the vertical line. In the weighted displacement calculation, the weight should change with the change of environmental quantities, not a fixed value. The environmental quantities in the same month have little difference. Therefore, the data in different months are projected separately. The PPM is used to reduce the dimension of the data of the dam deformation field, and the best projection direction is shown inTable 2. The weight of measuring points in different months is shown in Table 3. According to the weights and data of each measuring point, the comprehensive displacement of the dam section can be obtained, and the process line is shown in Fig.7.

Figure 7: The process line of comprehensive displacement of dam section 22

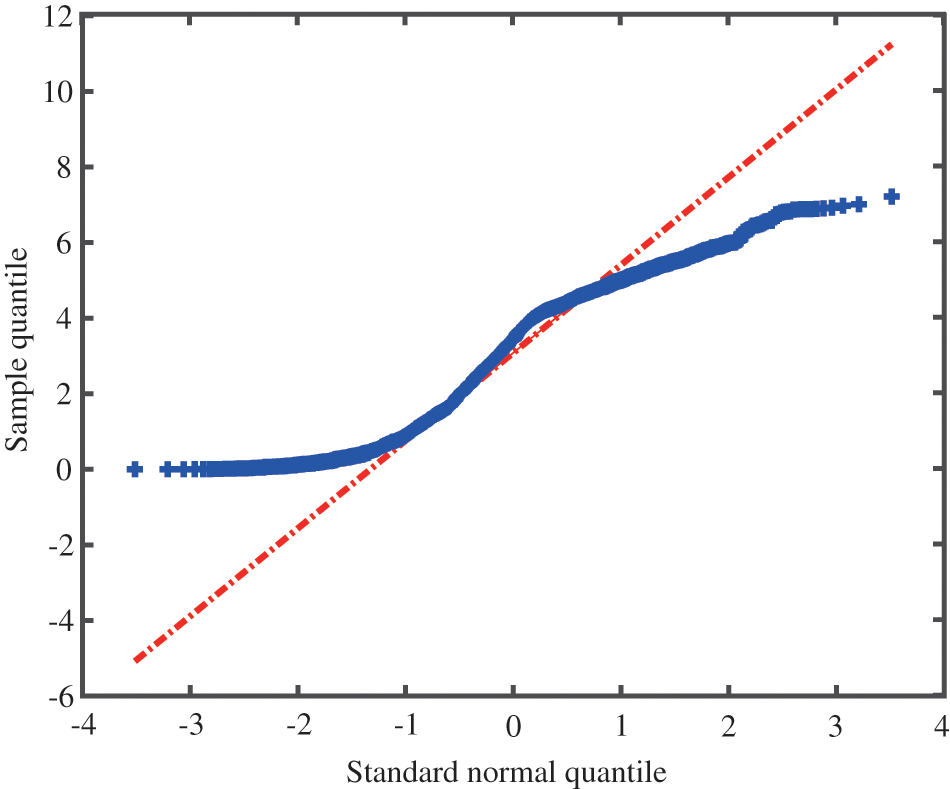

The obtained comprehensive displacement value integrates the monitoring data of the positive inverted vertical lines of the dam section, and well reflects the variation law of the displacement along the river of the whole dam section. The Q-Q diagram method is used to carry out the heavy-tail test of the downstream displacement data. The results are shown in Fig. 8. It can be seen that the lower end is upward and the upper end is downward on both sides of the diagonal of the comprehensive displacement data, and the middle is approximately in a straight line, which conforms to the characteristics of the heavy-tail distribution of the data and meets the preconditions of the POT model.

Figure 8: Q-Q diagram of dam section 22

3.4 Determination of Threshold

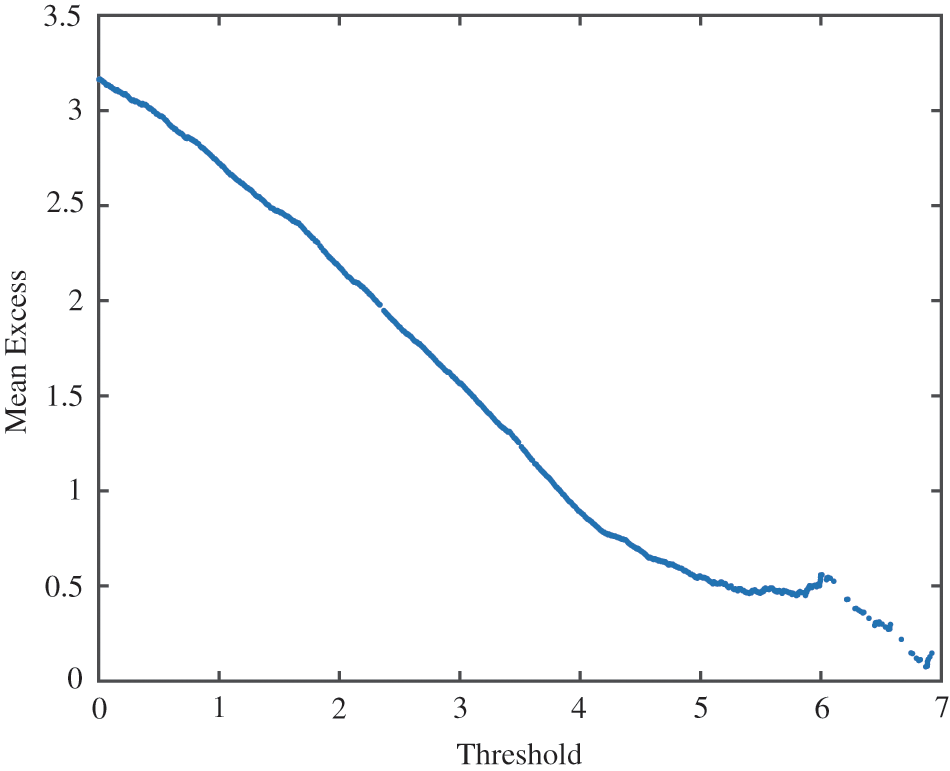

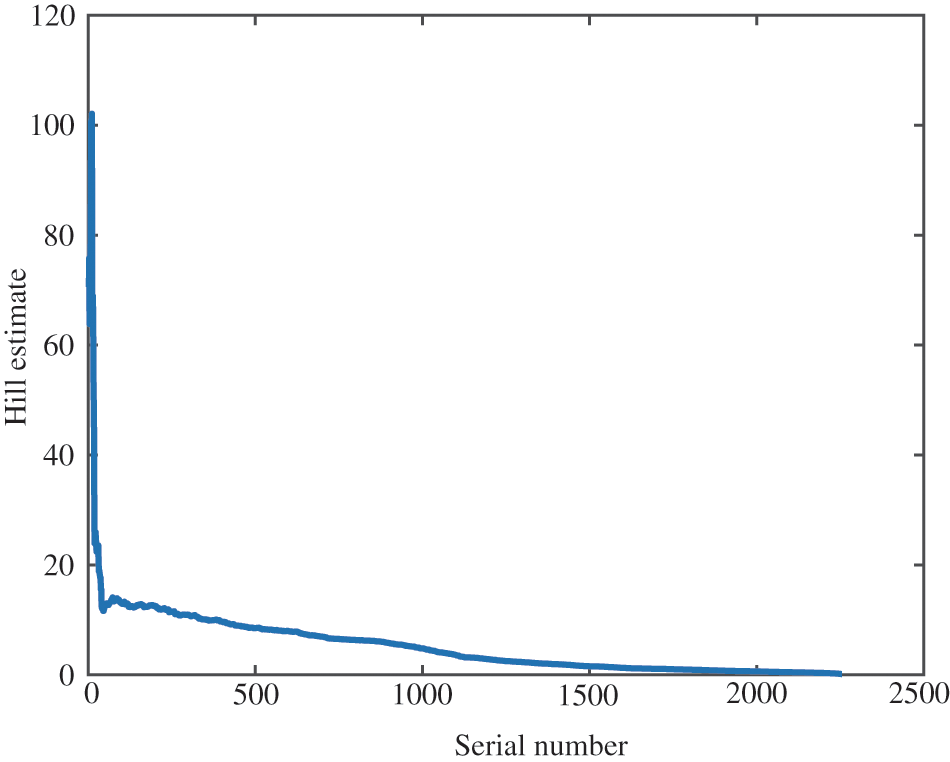

When determining the threshold, too many or too few tail samples will lead to failure to grasp the characteristics of the tail distribution of the sequence. Generally, it is considered that when the number of tail samples is 10%∼30% of the total samples, the conditional distribution function corresponding to the over threshold sequence converges to the generalized Pareto distribution. Therefore, this paper selects the threshold optimization solution domain as the value corresponding to 30% of the sample data and the value corresponding to the upper limit of 5%, sets the dimension number as 4, and uses the GWO to find the optimal threshold. The transfinite threshold diagram and Hill diagram are drawn according to the downstream displacement data, as shown in Figs. 9 and 10.

Figure 9: The transfinite threshold diagram of dam section 22

Figure 10: The Hill diagram of dam section 22

The threshold is 5.2886 for the GWO, 5.3 for the transfinite expectation graph, and 5.242 for the Hill diagram. It can be found that the threshold value determined by the threshold value selection method based on the GWO is basically close to the threshold values determined by the transfinite threshold diagram and Hill diagram, which shows that the threshold value selection method based on the GWO is reasonable. After the threshold range is determined, the method automatically finds the optimal threshold value by the GWO. The selected threshold value is more objective and more accurate.

3.5 Determination of Deformation Monitoring Control Value

Taking the probability of 4.55% and 0.27% as the probability of early warning value and danger value, the monitoring index of downstream displacement, the parameters and calculation results of the POT model based on the GWO to determine the threshold are as follows: the number of samples is 2285, the number of over threshold is 2254, the shape parameter is −0.12361, the scale parameter is 0.54055, the early warning value is 7.7416 mm, and the danger value is 9.5338 mm.

In this paper, the cloud model (CM) [24] is used to test the calculation results. The CM model is a model based on the principle of normal distribution. The reverse cloud generator is used to calculate the expectation

The method used in this paper is close to the calculation results of the cloud model, and both of them are greater than the extreme value of the weighted displacement, indicating that there is no alarm at dam section 22. Through the dam safety monitoring system, there is no alarm information at the vertical measuring points of dam section 22 from 2011 to 2020, which proves the effectiveness of the model.

This paper presented a new method to determine the monitoring control value for concrete gravity dam based on the deformations of multi-measuring points, which overcomes the limitation of single measuring point information. Based on the spatial correlation distribution characteristics of dam deformation, the weight of each measuring point is determined by the PPM combined with the GWO algorithm. The comprehensive displacement of the dam deformation is determined with the measured values at different measuring points and the corresponding weight of each measuring point. The improved POT model is adopted to determine the monitoring control value with the obtained dam comprehensive deformation displacement, which can avoid subjectivity and randomness in determining the threshold.

With the proposed method, the early warning value and the danger value of dam section 22 in Wuqiangxi hydropower station are 7.7416and 9.5338 mm, respectively, and the results match well with those of the cloud model (the early warning value is 7.4014 mm, and the danger value is 9.9230 mm). The results of the engineering application show the performance of the proposed method.

Acknowledgement: The authors wish to express their appreciation to the reviewers for their helpful suggestions which greatly improved the presentation of this paper.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Sortis, A. D.,Paoliani, P. (2007). Statistical analysis and structural identification in concrete dam monitoring. Engineering Structures,29(1), 110–120. [Google Scholar]

2. Yang, S. L.,Han, X. J.,Kuang, C. F.,Fang, W. H.,Zhang, J. F. et al. (2022). Comparative study on deformation prediction models of Wuqiangxi concrete gravity dam based on monitoring data. Computer Modeling in Engineering & Sciences,131(1), 49–72. DOI 10.32604/cmes.2022.018325. [Google Scholar] [CrossRef]

3. Hu, J.,Ma, F. H. (2020). Statistical modelling for high arch dam deformation during the initial impoundment period. Structural Control and Health Monitoring,27(12), e2638. [Google Scholar]

4. Yuan, D. Y.,Wei, B. W.,Xie, B.,Zhong, Z. M. (2020). Modified dam deformation monitoring model considering periodic component contained in residual sequence. Structural Control and Health Monitoring,27(12), e2633. [Google Scholar]

5. Beaupré, L.,St-Hilaire, A.,Daigle, A.,Bergeron, N. (2020). Comparison of a deterministic and statistical approach for the prediction of thermal indices in regulated and unregulated river reaches: Case study of the Fourchue River (Quebec, Canada). Water Quality Research Journal of Canada,55(4), 394–408. [Google Scholar]

6. Yang, G.,Gu, C. S.,Bao, T. F.,Cui, Z. M.,Kan, K. (2016). Research on early-warning index of the spatial temperature field in concrete dams. SpringerPlus,5, 1968. [Google Scholar]

7. Lei, P.,Chang, X. L.,Xiao, F.,Zhang, G. J.,Su, H. Z. (2011). Study on early warning index of spatial deformation for high concrete dam. Science China-Technological Sciences,54(6), 1607–1614. [Google Scholar]

8. Qin, X. N.,Gu, C. S.,Chen, B.,Liu, C. G.,Dai, B. et al. (2017). Multi-block combined diagnosis indexes based on dam block comprehensive displacement of concrete dams. Optik,129, 172–182. [Google Scholar]

9. Su, H. Z.,Wen, Z. P.,Ren, J. (2020). A kernel principal component analysis-based approach for determining the spatial warning domain of dam safety. Soft Computing,24, 14921–14931. [Google Scholar]

10. Li, X.,Li, Y. L.,Lu, X.,Wang, Y. F.,Zhang, H. et al. (2019). An online anomaly recognition and early warning model for dam safety monitoring data. Structural Health Monitoring,19(3), 796–809. [Google Scholar]

11. Chen, B.,Huang, Z. S.,Bao, T.,Zhu, Z. (2021). Deformation early-warning index for heightened gravity dam during impoundment period. Water Science and Engineering,14(1), 54–64. [Google Scholar]

12. Chen, W. L.,Wang, X. L.,Tong, D. W.,Cai, Z. J.,Zhu, Y. S. et al. (2021). Dynamic early-warning model of dam deformation based on deep learning and fusion of spatiotemporal features. Knowledge-Based Systems,233, 107537. [Google Scholar]

13. Su, H. Z.,Yan, X. Q.,Liu, H. P.,Wen, Z. P. (2017). Integrated multi-level control value and variation trend early-warning approach for deformation safety of arch dam.Water Resources Management,31(6), 2025–2045. [Google Scholar]

14. Yang, G.,Yang, M. (2016). Multistage warning indicators of concrete dam under influences of random factors. Mathematical Problems in Engineering,2016, 6581204. [Google Scholar]

15. Wang, S. W.,Gu, C. S.,Bao, T. F. (2013). Safety monitoring index of high concrete gravity dam based on failure mechanism of instability. Mathematical Problems in Engineering,2013, 732325. [Google Scholar]

16. Li, W.,Ye, Y. C.,Hu, N. Y.,Wang, X. H.,Wang, Q. H. (2019). Real-time warning and risk assessment of tailings dam disaster status based on dynamic hierarchy-grey relation analysis. Complexity,2019, 5873420. [Google Scholar]

17. Friedman, J. H.,Tukey, J. W. (1974). A projection pursuit for exploratory data analysis. IEEE Transactions on Computers,C-23(9), 881–890. [Google Scholar]

18. Mirjalili, S.,Mirjalili, S. M.,Lewis, A. (2014). Grey wolf optimizer. Advances in Engineering Software,69, 46–61. [Google Scholar]

19. Pickands, J. (1975). Statistical inference using extreme order statistics. The Annals of Statistics,3, 119–131. [Google Scholar]

20. Xue, J.,Shen, B. (2020). A novel swarm intelligence optimization approach: Sparrow search algorithm. Systems Science and Control Engineering,8(1), 22–34. [Google Scholar]

21. Dhiman, G.,Kumar, V. (2019). Seagull optimization algorithm: Theory and its applications for large-scale industrial engineering problems. Knowledge-Based Systems,165, 169–196. [Google Scholar]

22. Mirjalili, S.,Lewis, A. (2016). The whale optimization algorithm. Advances in Engineering Software,95, 51–67. [Google Scholar]

23. Sun, S. H.,Yu, T. T.,Nguyen, T. T.,Atroshchenko, E.,Bui, T. Q. (2018). Structural shape optimization by IGABEM and particle swarm optimization algorithm. Engineering Analysis with Boundary Elements,88, 26–40. [Google Scholar]

24. Tassa, A.,Michele, S. D.,Mugnai, A.,Marzano, F. S.,Baptista, J. P. V. P. (2003). Cloud model-based Bayesian technique for precipitation profile retrieval from the Tropical Rainfall Measuring Mission Microwave Imager. Radio Science,38(4). DOI 10.1029/2002RS002674. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools