Open Access

Open Access

REVIEW

A Review of Electromagnetic Energy Regenerative Suspension System & Key Technologies

School of Transmission and Vehicle Engineer, Shandong University of Technology, Zibo, 255000, China

* Corresponding Author: Jiayu Lu. Email:

Computer Modeling in Engineering & Sciences 2023, 135(3), 1779-1824. https://doi.org/10.32604/cmes.2022.023092

Received 09 April 2022; Accepted 07 July 2022; Issue published 23 November 2022

Abstract

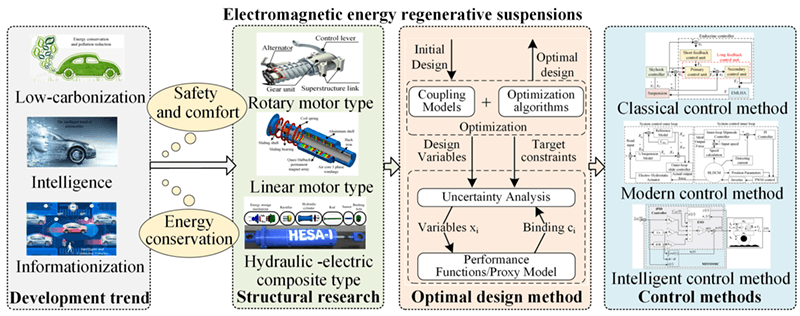

The active suspension has undoubtedly improved the performance of the vehicle, however, the trend of “lowcarbonization, intelligence, and informationization” in the automotive industry has put forward higher and more urgent requirements for the suspension system. The automotive industry and researchers favor active energy regeneration suspension technology with safety, comfort, and high energy regenerative efficiency. In this paper, we review the research progress of the structure form, optimization method, and control strategy of electromagnetic energy regenerative suspension. Specifically, comparing the pros and cons of the existing technology in solving the contradiction between dynamic performance and energy regeneration. In addition, the development trend of electromagnetic energy regenerative suspension in the field of structure form, optimization method, and control technology prospects.Graphic Abstract

Keywords

According to 2020 statistics from the International Energy Agency (IEA), the transport sector accounts for 26% of global carbon emissions [1]. Among them, automobiles are an important emission source in the field of transportation. Therefore, energy regenerative and low-carbon technology is in line with the development theme of green transformation of the world automotive industry and is also a strategic need to implement China’s “double carbon” goal [2].

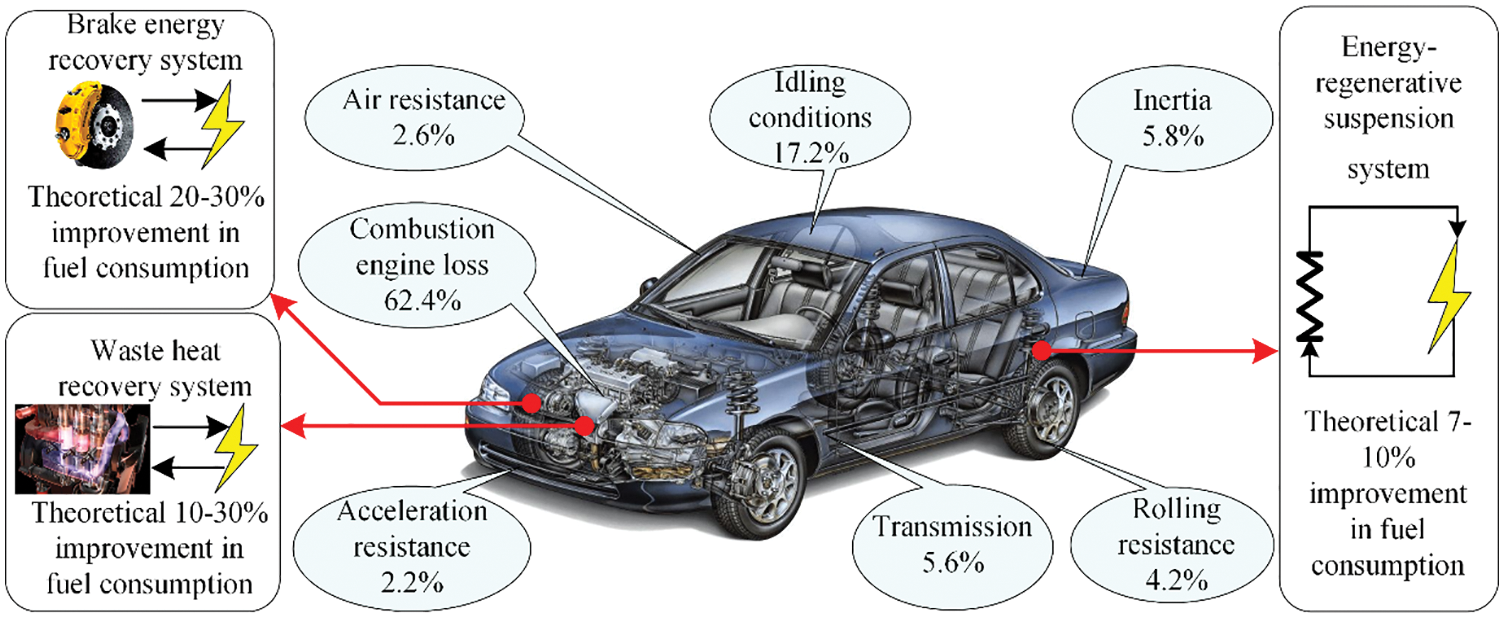

As the automotive industry develops in the direction of “low-carbonization, intelligence, and informationization” [3]. The traditional chassis can no longer meet the future development needs of intelligent electric vehicles, and the suspension system is undergoing technological innovation as a key part of the automotive chassis. The active suspension system can realize dynamic adaptive adjustment according to driving conditions and road excitation so that the suspension system is always in the best damping working condition to ensure the driving stability and comfort of the driver and passengers. At present, electromagnetic, air, and hydraulic active suspension technology has become mature, and its improvement in vehicle performance is undoubted [4]. But the performance improvement requires additional energy consumption, which is not conducive to the improvement of the overall energy efficiency of the vehicle. However, in the study of vehicle energy distribution, researchers found that, as shown in Fig. 1, the vibration energy recovery technology can reduce the energy consumption of the vehicle by 7%–10%, make up for the energy consumption of the active suspension, and improve the utilization efficiency of the vehicle power source to achieve the purpose of energy-saving and emission reduction [5,6].

Figure 1: Energy consumption and energy-harvesting potential

The energy regenerative process of the existing air-type and hydraulic-type active suspensions is relatively complicated: the vibration energy needs to be converted into internal energy, and then converted into electrical energy using a motor [7,8]. Both of them need to add subsidiary institutions, which increases the difficulty of control and lowers the energy conversion efficiency [9]. The electromagnetic suspension uses current as the working medium to facilitate linear control. At the same time, according to the characteristics of the motor itself, the vibration energy can be directly converted into electrical energy, which has the characteristics of compact structure, and high energy regenerative efficiency [10]. Therefore, the electromagnetic energy regenerative suspension system, which considers the characteristics of active dynamic performance and energy regeneration, meets the development needs of future chassis and gradually becomes a hot spot for scholars from various countries to study.

This paper reviews the latest advances in dynamic performance and energy harvesting of electromagnetic energy regenerative suspensions. The main purpose of the research is to explore the structural form of the electromagnetic energy regenerative suspension according to the recovery effect of the suspension system on the vibration energy and the dynamic performance. On this basis, the multidisciplinary optimization design method of electromagnetic energy regenerative suspension system is further analyzed. In addition, the coordination of various control methods in the performance of electromagnetic energy regenerative suspension systems is discussed. And the existing problems and future development trends of the current electromagnetic energy regenerative suspension system and its key technologies are discussed, which will help to expand the development of the electromagnetic energy regenerative suspension optimization design method and control theory.

2 Structural Research of Electromagnetic Energy Regenerative Suspensions

In the late 1980s, Karnopp verified the feasibility of combining permanent magnet motors with automotive suspension systems through theoretical analysis [11]. With the development of permanent magnet materials and electronic control technology, electromagnetic energy regenerative suspension has gradually attracted the research interest of scholars from all over the world. At present, there are various forms of mainstream electromagnetic energy regenerative suspensions. The different structural solutions of electromagnetic energy regenerative suspensions can be divided into three categories: rotary motor energy regenerative suspensions, linear motor energy regenerative suspensions, and hydraulic-electric composite energy regenerative suspensions.

2.1 Rotary Motor Electromagnetic Energy Regenerative Suspensions

The rotating electromagnetic energy regenerative suspension generally consists of a set of motion conversion mechanisms and a rotating motor [12]. The development of the rotating motor is relatively mature, and has the remarkable characteristics of small quality and high reliability; the motion conversion mechanism converts the reciprocating motion of the suspension into the rotating motion of the motor, and the vibration energy can be converted into electrical energy by using the characteristics of the rotating motor yitself. According to the different forms of motion conversion mechanisms, rotary energy regenerative suspensions are divided into three categories: ball-screw type, rack-pinion type, and rocker-arm type.

2.1.1 Ball-Screw Type Electromagnetic Energy Regenerative Suspensions

The ball-screw mechanism has the advantages of high efficiency, smooth motion, and accurate positioning, and can realize the mutual transformation of linear motion and rotary motion, which is now applied to the rotary electromagnetic energy regenerative suspension system.

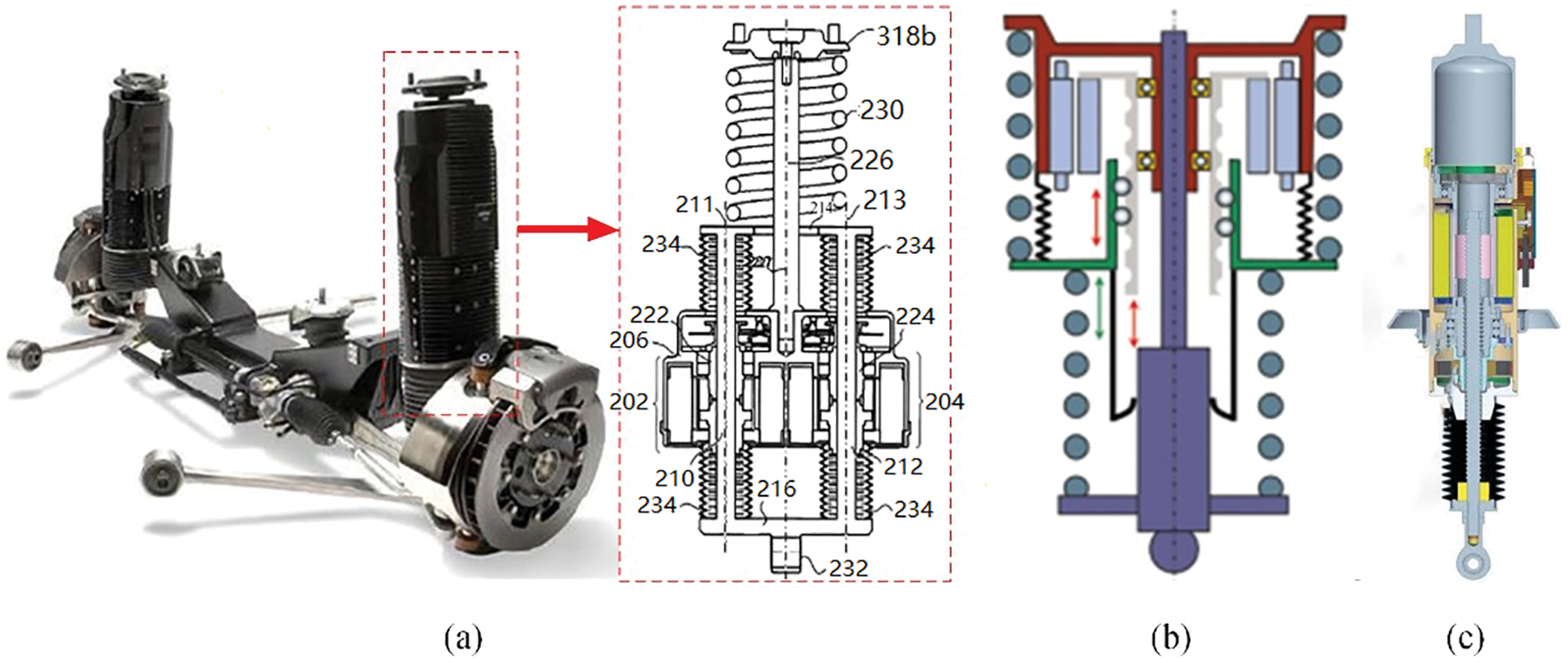

The rotary electromagnetic energy regenerative suspension is easy to cause problems such as large fluctuation of electromagnetic output force and overload operation of the motor due to the addition of a motion conversion mechanism. Therefore, stability and safety are the first key issues to be considered in the design process of electromagnetic energy regenerative suspensions. Bose Corporation uses dual motors combined with ball-screws in a symmetrical arrangement, as shown in Fig. 2a. To ensure that the output forces are equal in size and opposite in direction, reducing the impact of electromagnetic force fluctuations on the rotating electromagnetic energy regenerative suspension [13]. The electromagnetic energy regenerative suspension system designed by Xie et al. [14] is shown in Fig. 3. The stator of the generator has 12 independently controlled slot windings, which can generate different electromagnetic damping by controlling the number of generator switches and adjusting the external resistance to ensure the stable output of electromagnetic force in real-time. ZF and Volkswagen Group jointly developed the upper and lower spring arrangement of the electromagnetic energy regenerative suspension, as shown in Fig. 2b, to avoid excessive inertial shocks damaging the suspension system [15]. The Schaeffler Group has designed an electromagnetic energy regenerative suspension using a combination of brushless DC motor and ball-screw solution, as shown in Fig. 2c. The centrifugal brake inside the electromagnetic actuator can effectively reduce the motor speed and avoid the overload operation of the motor [16].

Figure 2: (a) Bose suspension system; (b) Bose suspension system; (c) Schaeffler “electromagnetic energy regenerative suspension mechanism”

Figure 3: Prototype of the energy regenerative suspension mechanism

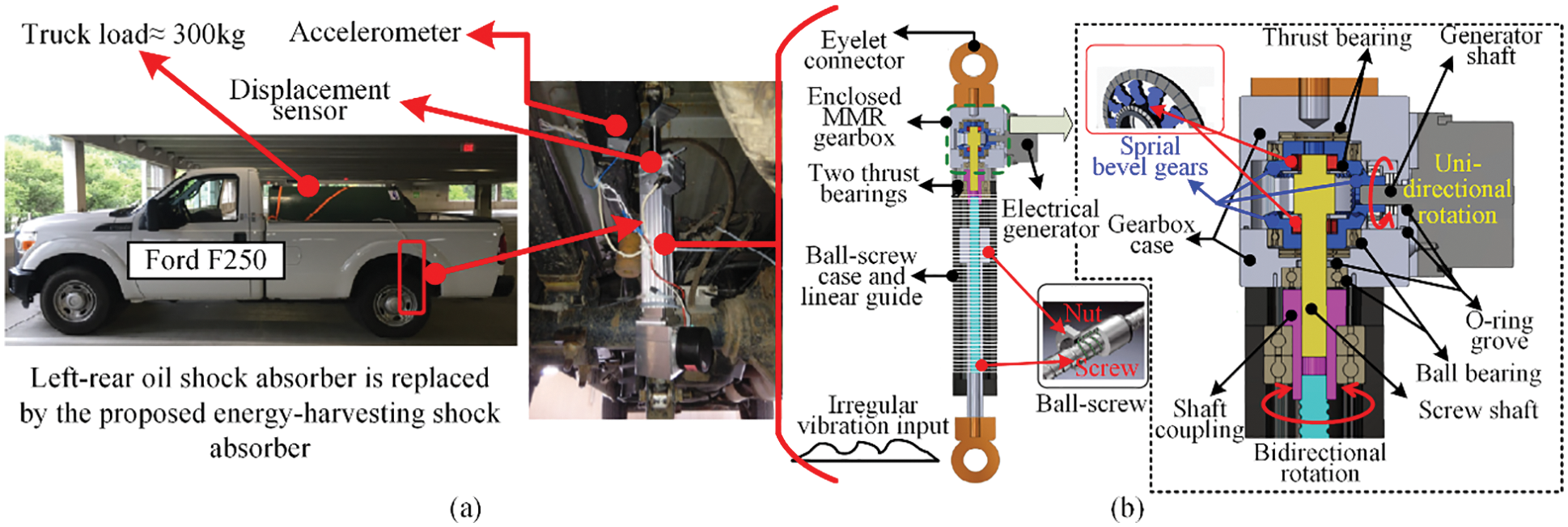

The working efficiency of the rotary electromagnetic energy regenerative suspension cannot be ignored. Zhao et al. [17] proposed the method of changing the charging voltage in segments to convert the vibration energy into electrical energy through the motor and input it directly into the battery pack; by reducing the charging voltage of the battery pack, the problem that the excitation speed is small and the recycling voltage is too small to be charged is solved. Zuo et al. [18] designed a new integrated mechanical motion rectifier in the electromagnetic energy regenerative suspension with the structure shown in Fig. 4b, which always ensures the conversion of reciprocating suspension vibration into unidirectional rotational motion of the motor, reduces the gear shock caused by external oscillation, ensures that the generator rotates at a relatively stable speed during irregular vibration, and significantly improves the energy regenerative characteristics of the electromagnetic energy regenerative suspension. In the performance test on Ford F250, as shown in Fig. 4a, when the vehicle is driving on the road at a speed of 40 miles per hour, the energy regenerative suspension can reduce the RMS value of the ground acceleration by 11.12% in a period of 8 s, the average power harvested by the quarter electromagnetic energy regenerative suspension system is 13.3 W [19].

Figure 4: A mechanical-motion-rectifier-based energy regenerative; (a) Setup of field tests; (b) Prototype and working principle

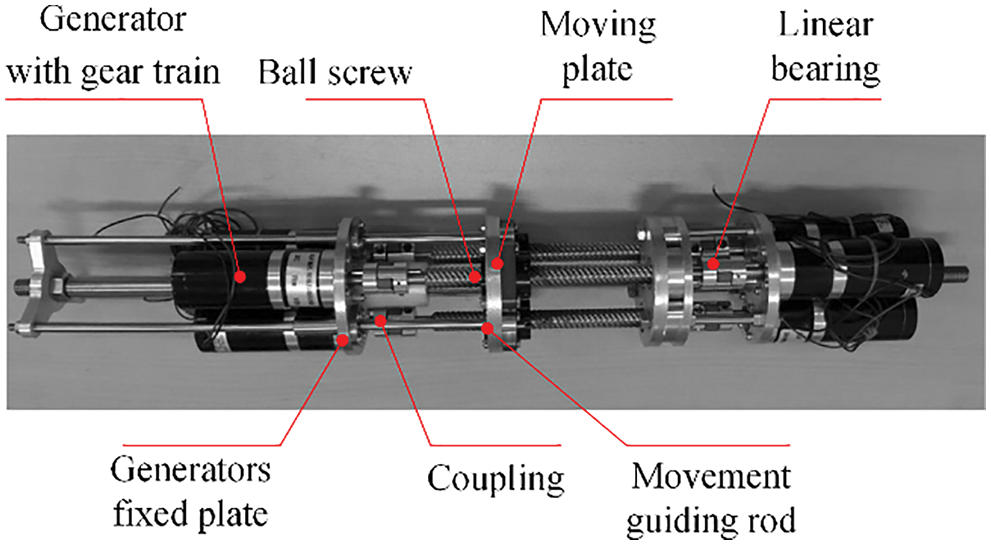

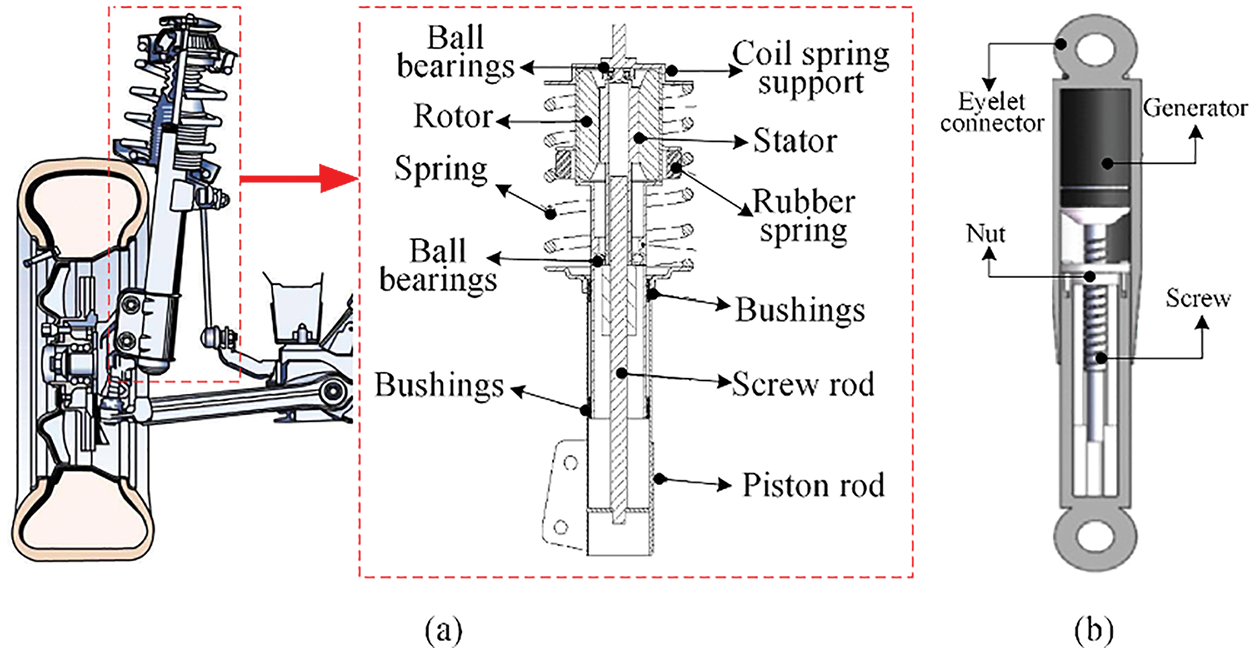

Due to the limited installation space of the rotary electromagnetic energy regenerative suspension system, there is a conflicting relationship between its structural size and its working performance. Galluzzi et al. [20] proposed an integrated design method of electromechanical parameters, which integrates the rotating motor and the suspension design. As shown in Fig. 5a, the overall quality of the parallel design of the electrical terminals of the motor and the resistive load is reduced by 12% compared with previous similar studies. However, when the voltage regulator is not connected in parallel with the electromagnetic load, the energy regenerative suspension has a damped failure zone proportional to the battery voltage, and the constant output voltage regulator has fluctuations in the damping coefficient. Li et al. [21,22] designed a new type of undamped failure energy regenerative suspension, as shown in Fig. 5b, to eliminate damping fluctuations and damping failure zones. Zhang et al. [23] adopted a single ball-screw mechanism and carried out a modular design of the energy regenerative suspension from the perspective of the operation stability, flexibility, and energy application of the electromagnetic energy regenerative suspension, which is divided into vibration input module, transmission module, and generator module as shown in Fig. 6a. The working principle is as follows: the suspension vibration caused by road excitation is transmitted to the vibration input module; the reciprocating vibration is converted into the rotary motion required for the motor work by the transmission module, and the ball-screw mechanism, as the core component of the transmission module, can generate the corresponding damping by different pitches to improve the comfort of the vehicle; the electrical energy can be generated by the generator module. Based on this, Zhang et al. [24] tried to replace the single ball-screw in the original transmission module with a pair of ball-screw, as shown in Fig. 6b. An electrical energy storage module was added, and the electrical energy generated by the generator was stored in a supercapacitor, thus extending the driving range of the electric vehicle, which can extend the driving range by approximately 1 mile per 100 miles when the electric vehicle is driven at 60 km/h on Class B roads.

Figure 5: (a) Electromagnetic energy regenerative suspension mechanism integrated into a McPherson suspension and cross-section of the mechanism; (b) Energy regenerative suspension mechanism

Figure 6: (a) Details of the energy regenerative suspension mechanism section A-A; (b) Structure of the energy regenerative suspension mechanism

According to the in-depth research of ball-screw type energy regenerative suspension by the above scholars, the ball-screw type energy regenerative suspension system has the advantages of good reliability, high transmission efficiency and compact structure, but the internal clearance between the mechanical mechanism is easy to cause its damping performance to be attenuated under the condition of the high road excitation frequency.

2.1.2 Rack-Pinion Type Electromagnetic Energy Regenerative Suspensions

The rack-pinion mechanism has many advantages such as simple structure, high transmission efficiency, and conversion between circular motion and unidirectional motion, etc. It is now widely used in rotary electromagnetic energy regenerative suspension systems.

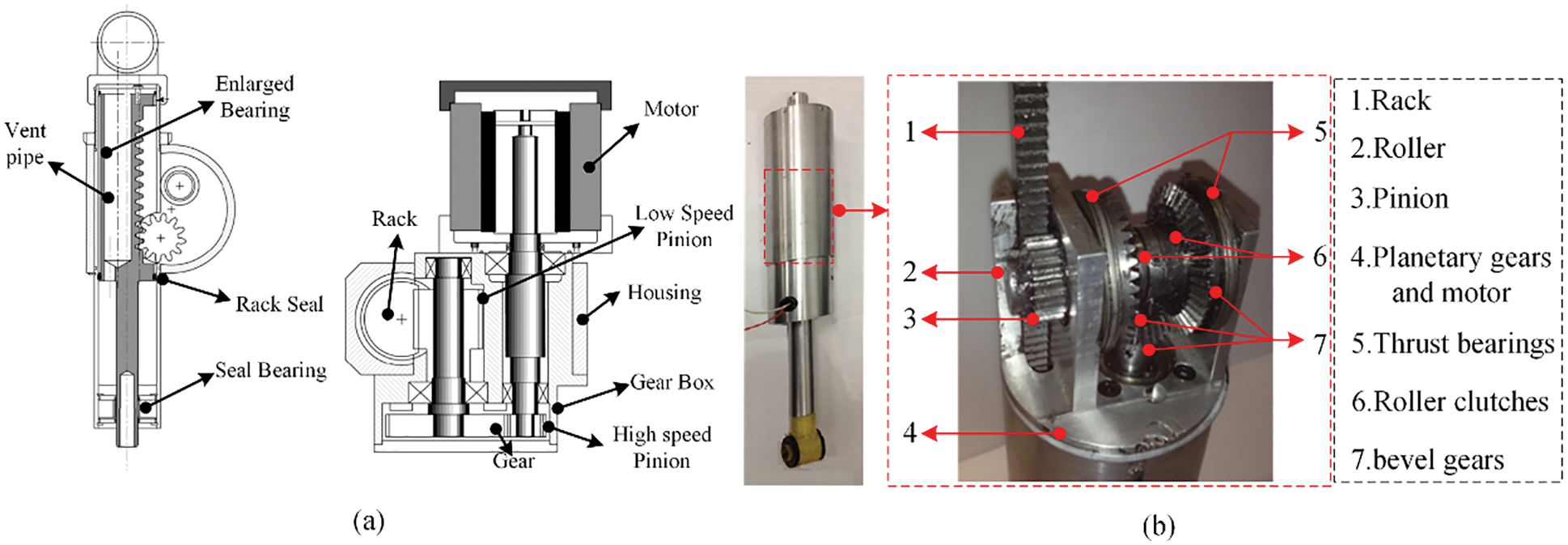

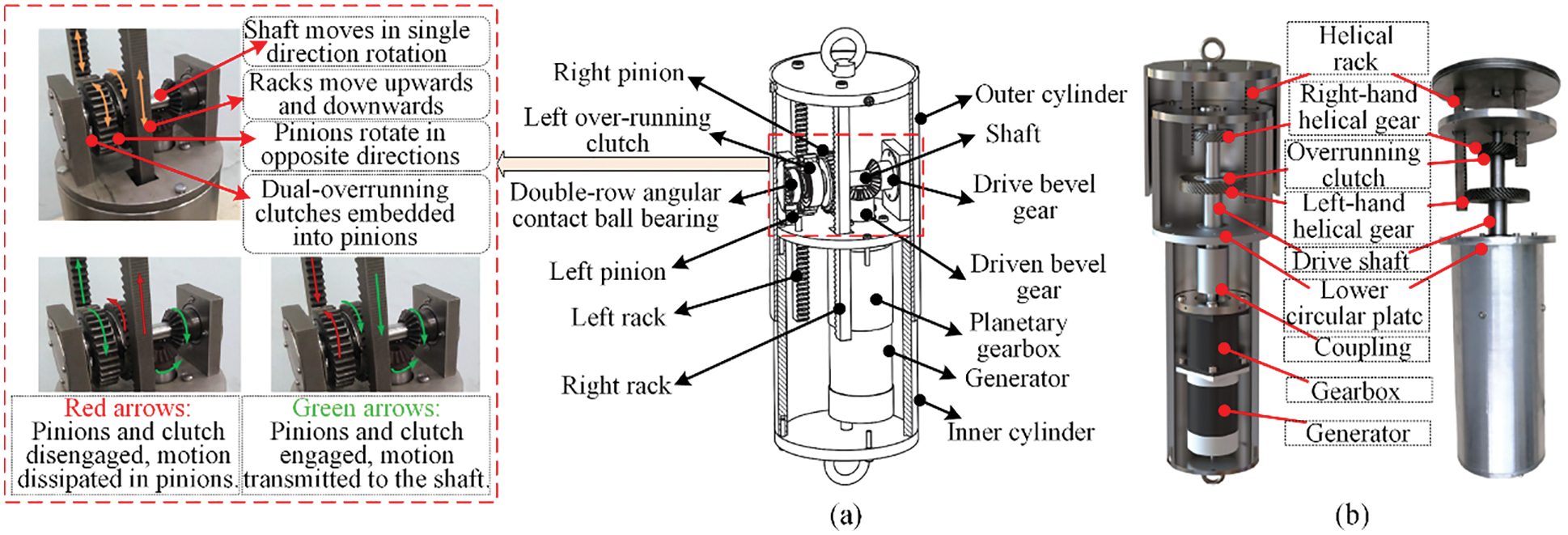

Since the 1990s, foreign scholars have begun to research the energy regenerative suspension based on the rack-pinion mechanism. Suda et al. [25] pioneered the design of an electromagnetic energy regenerative suspension based on a rack and pinion mechanism that achieves good dynamic performance and ensures low energy consumption. Beno et al. [26] and the U.S. Department of Defense jointly developed a rack-pinion electromagnetic energy regenerative suspension named UT-CEMAS for military vehicles. The schematic diagram is shown in Fig. 7a. Road tests have shown that the electromagnetic energy regenerative suspension has improved off-road performance, but there is still room for improvement in regenerative [27]. After verifying the feasibility of the rack-pinion energy regenerative suspension, researchers conducted in-depth research on the coordination between its reliability, energy regenerative performance, and functions.

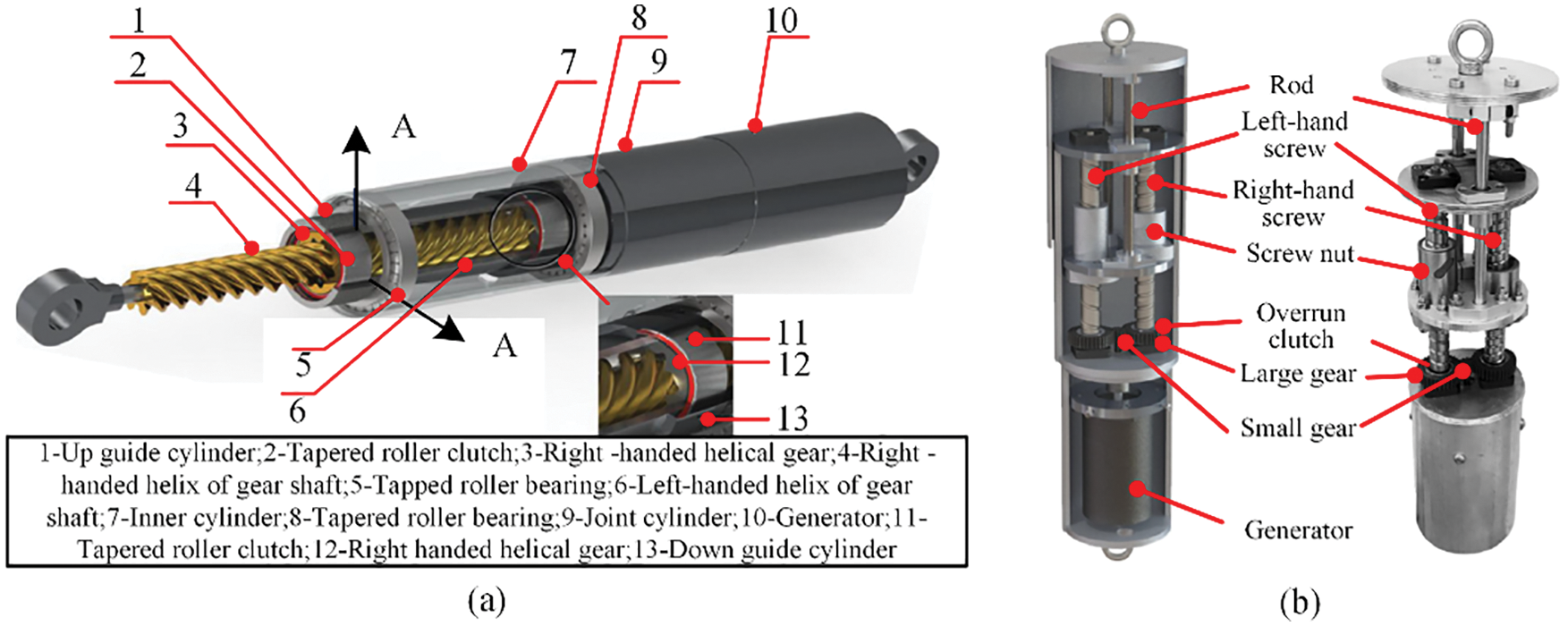

Figure 7: (a) Rack and pinion type electromagnetic energy regenerative suspension mechanism; (b) Actual prototype and inner structure

The rack and pinion mechanism are the core component of the electromagnetic energy regenerative suspension, and its reliability will directly affect the driving safety of the vehicle. Papageorgiou [28] was the first to test the mechanical properties of the developed rack-pinion suspension, and its theoretical damping matched the actual damping when the effect of nonlinear factors was eliminated. Zuo et al. [29–31] achieved variable damping coefficients and asymmetry of vibration and rebound motion by controlling the electrical loading of the electromagnetic energy regenerative suspension, as shown in Fig. 7b; using rollers to guide the preload on the gear carrier and gear transmission to reduce tooth clearance and friction and improve the reliability of the system. Zhang et al. [32,33] developed a modular design for the energy regenerative suspension, as shown in Fig. 8a, which is divided into a vibration energy harvesting module, a motion conversion module, a power generation module, and an electrical energy storage module. The motion conversion module can steadily output the asymmetric compression/extension damping force required by the suspension system. Based on this, Zhang et al. [34] used a tree mechanism architecture for the design of the energy regenerative suspension, as shown in Fig. 8b. The motion conversion mechanism consists of two helical racks with opposite threads, which further improves the reliability of the system. Guo [35] designed an electromagnetic energy regenerative suspension based on a rack-and-pinion mechanism for a heavy-duty vehicle. The system only uses a single pinion shaft drive and is equipped with a mechanical rectifier bridge, which improves the durability of the drive system, reduces energy loss, and improves energy regenerative efficiency. To further improve its energy regenerative efficiency as well as the reliability of the system operation, the electromagnetic energy regenerative suspension designed by Wang et al. [36] effectively alleviated the outstanding contradiction between vibration control and energy recovery.

Figure 8: (a) Detailed marks of all of the parts; (b) Structure of the energy regenerative suspension mechanism

The rack-pinion energy regenerative suspension has high transmission precision and good stability, but when the road impact is too large, the rack-pinion mechanism is easy to break, which affects the driving safety of the vehicle.

2.1.3 Rocker-Arm Type Electromagnetic Energy Regenerative Suspensions

Compared with the ball-screw type and the rack-pinion type, the rotary motor combined with the rocker type electromagnetic energy regenerative suspension system has smaller inertia and faster response speed, but it is more difficult to install and more difficult to control.

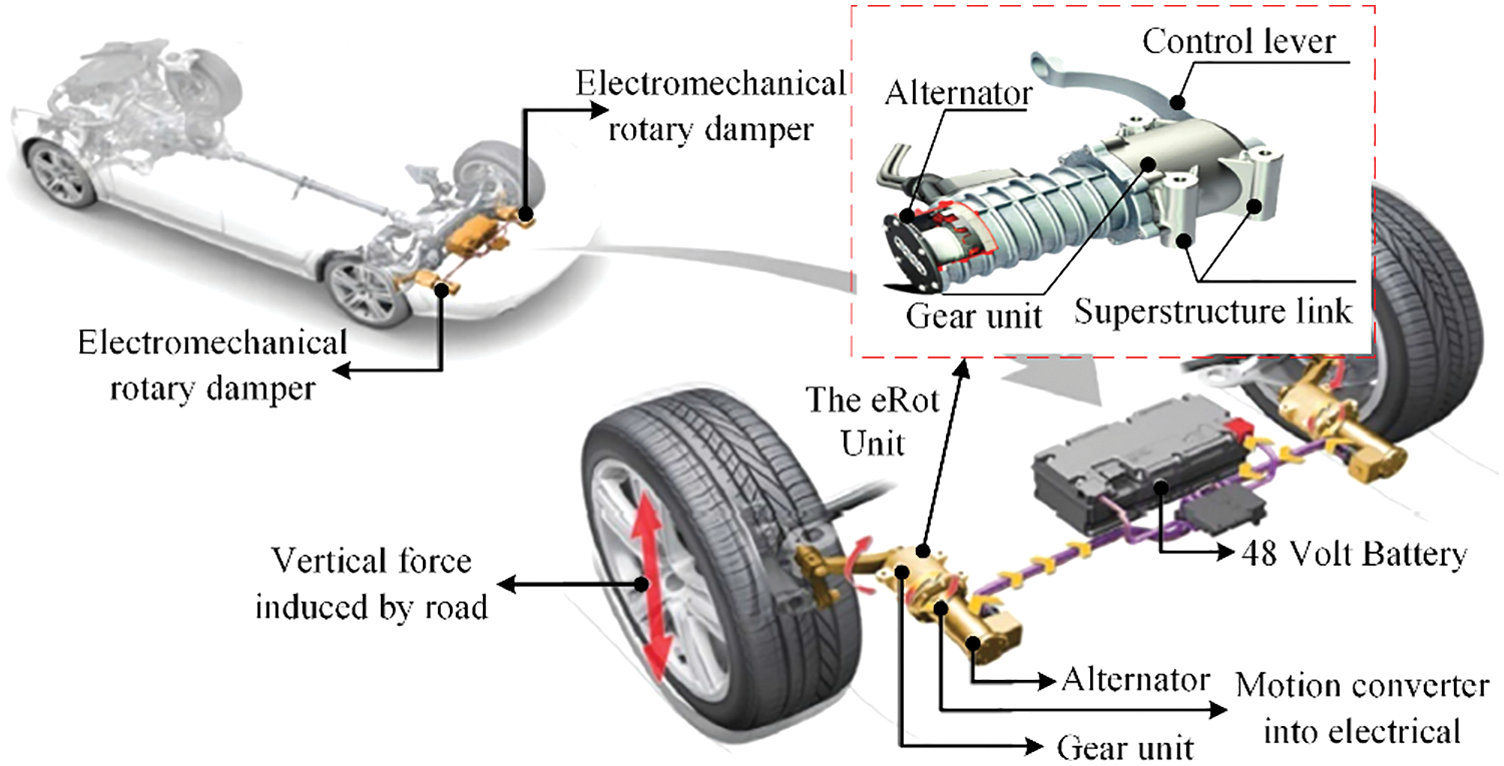

The rocker-arm type electromagnetic energy regenerative suspension designed by Chen et al. [37,38] can satisfy the ride comfort and safety of the vehicle. Jonasson et al. [39] at the Royal Institute of Technology in Sweden, in conjunction with Volvo, have studied an electromagnetic energy regenerative suspension based on a rocker mechanism with a dual-motor design that broadens the operating bandwidth of the electromagnetic energy regenerative suspension. Audi et al. [40–42] announced a new electromagnetic energy regenerative suspension technology in 2016, which is named “eROT”. As shown in Fig. 9, the electromagnetic energy regenerative suspension consists of an alternator, a gear unit, a fixed connection, and a rocker-arm. The gear unit and the rocker-arm mechanism cooperate to be responsible for deceleration and torque increase or speed increase and torque decrease to meet the dynamic performance and energy regenerative performance of the suspension. When the vehicle is excited by the uneven road, the average energy regenerative of each suspension motor is 100–150 W. And the system can reduce CO2 emissions by up to 3 grams per kilometer in daily driving conditions. Considering the limitation of installation space, scholars from all over the world have little research on rocker-arm electromagnetic energy regenerative suspension. With the continuous development of the automobile industry, the changes in the layout of the automobile chassis will promote the further development of the rocker-arm type electromagnetic energy regenerative suspension.

Figure 9: The innovative “eROT” based on a horizontally arranged electromechanical rotary suspension mechanism

The rotating motor type energy regenerative suspension has been widely studied because of the reliability of the motion conversion mechanism and the high efficiency of the rotating motor. The simulation and test results in Table 1 show that its damping effect and energy regenerative effect is significant. However, the energy regenerative suspension structure is mainly completed by a mechanical mechanism, and problems such as component wear and structure noise cannot be ignored. It requires regular maintenance and increases additional costs.

2.2 Linear Motor Electromagnetic Energy Regenerative Suspensions

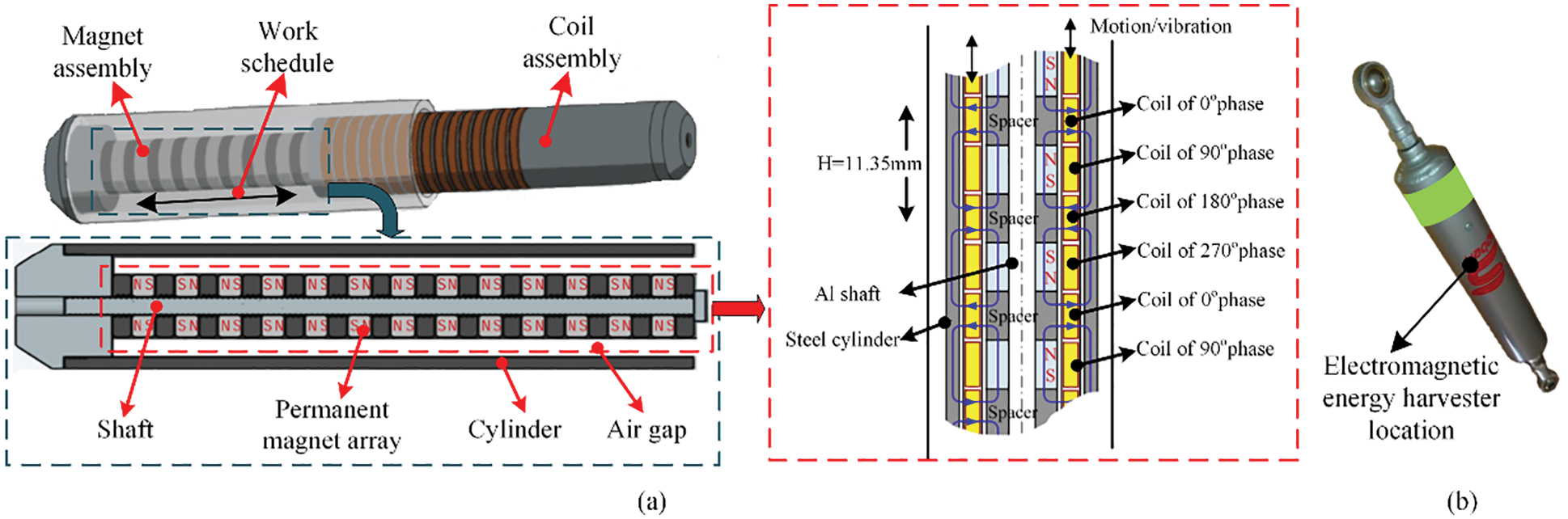

The linear motor is the core component of the electromagnetic energy regenerative suspension, and its performance directly affects the dynamic performance and energy regenerative performance of the electromagnetic energy regenerative suspension [43]. Compared with the rotary motor, its structure is more versatile, with the advantages of fast response, high efficiency, high power density, etc. The linear-motors are now widely used in the field of industrial automation and drive systems, such as Siemens, Bosch’s precision machines, Inductrack suspension systems, etc. [44,45]. The cylindrical linear motor has the same reciprocating linear motion as the motion stroke of the suspension, and it is used as the actuator of the active suspension to output the main power to suppress the vibration of the body. Under random pavement excitation, the relative motion of the coil and the permanent magnet causes a change in the magnetic flux in the induction coil, and according to Faraday’s law of electromagnetic induction, the vibration energy can be converted into electrical energy.

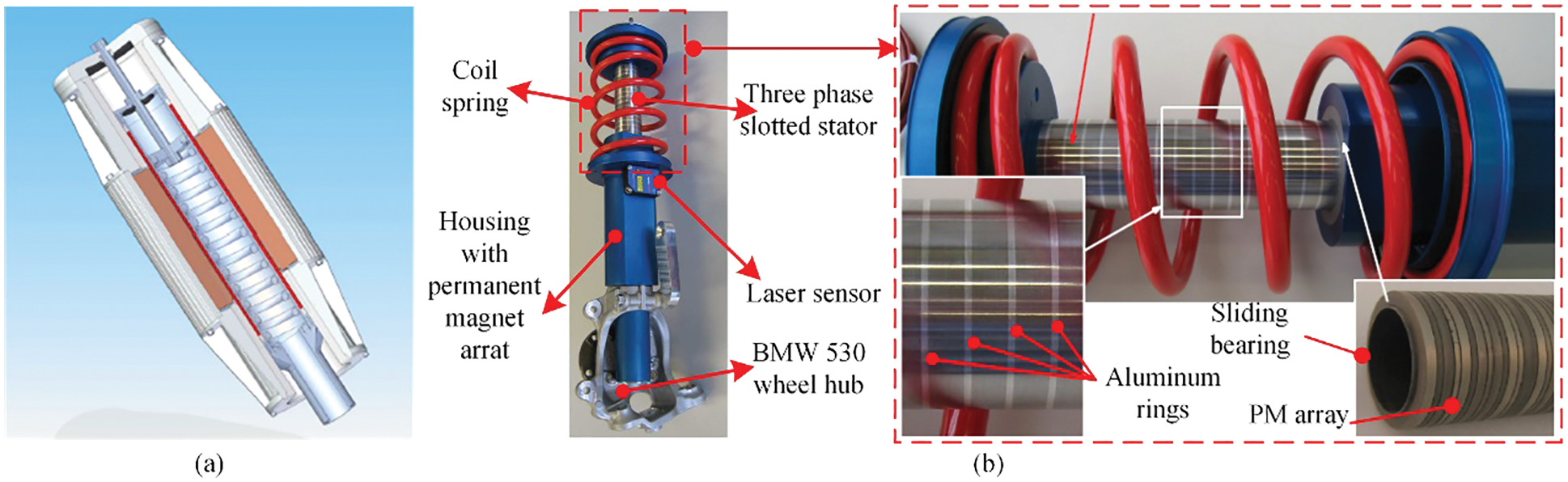

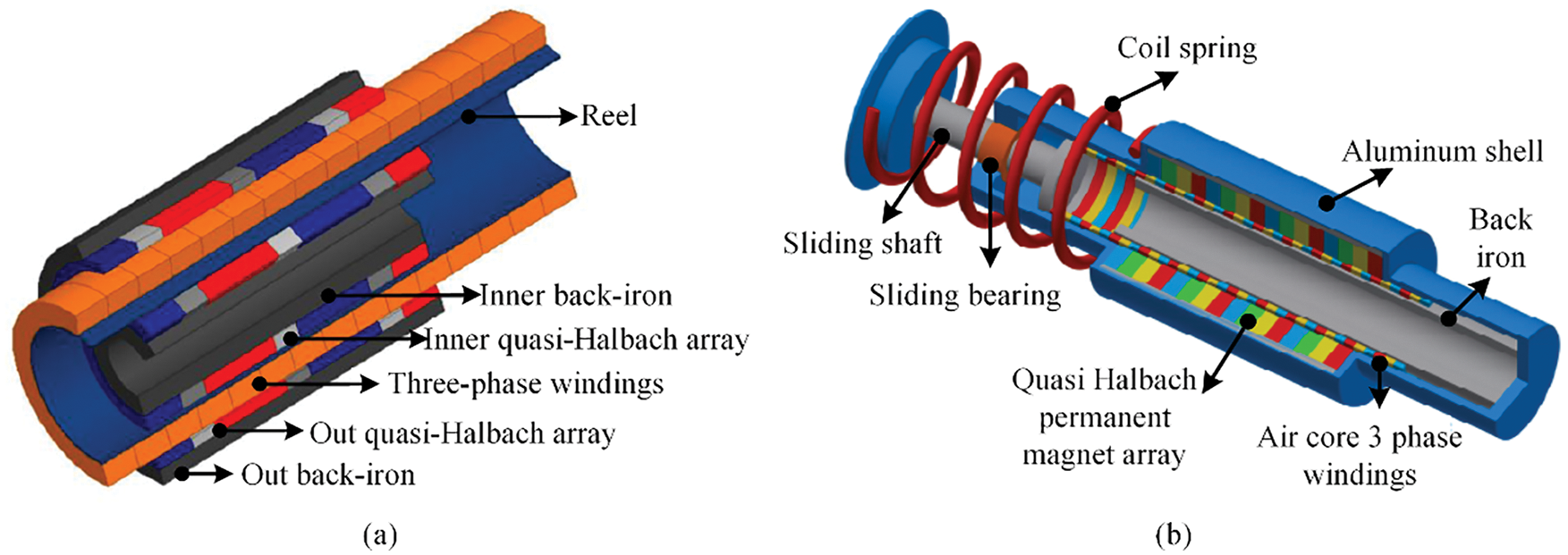

Okada et al. [46] designed an electromagnetic energy regenerative suspension based on a permanent magnet synchronous motor, which can realize the energy regenerative function at high-speed motion and generate adapted electromagnetic damping to ensure the damping performance at low-speed motion. Wang et al. [47] investigated the topology of different tubular linear motors and found that the regenerative suspension designed based on quasi-Halbach array kinematic linear motors has superior controllability bandwidth, as shown in Fig. 10a. The vehicle has improved smoothness, comfort, safety, and maneuverability. Gysen et al. [48,49] proposed a general harmonic modeling method to calculate the three-dimensional magnetic field distribution of the Halbach array based on electromagnetic energy regenerative suspension and conducted in-depth research on the topology and performance of electromagnetic energy regenerative suspension. They analyzed the efficiency of the electromagnetic energy regenerative suspension and determined the synergistic relationship between the losses, output power, and input current of the electromagnetic energy regenerative suspension under comfort and safety [50]. Based on this research, Gysen et al. [51] jointly developed a prototype electromagnetic energy regenerative suspension system with SKF and BMW of Sweden. As shown in Fig. 10b. To further improve the magnetic flux density inside the linear motor to improve the overall performance of the electromagnetic energy regenerative suspension system. Eckert et al. [52,53] designed a two-layer Halbach array of tubular linear motors integrated with the suspension system, as shown in Fig. 11a. To avoid the continuous power supply of the electromagnetic suspension system, Ye et al. [54] adopted a direct-drive electromagnetic active suspension system designed in parallel with a tubular linear motor with a double-layer Halbach array and a coil spring. The spring can support the sprung mass, as shown in Fig. 11b. The hollow topology has a good dynamic response, servo characteristics, and a small force fluctuation rate.

Figure 10: (a) Linear electromagnetic actuator based active vehicle suspension unit; (b) Prototype of the electromagnetic active suspension system for a BMW 530i together with the wheel hub

Figure 11: (a) Linear tubular moving-coil actuator with a four-pole dual quasi-Halbach array; (b) The structure of a direct-drive electromagnetic active suspension system

The current research shows that Halbach arrays can generate ideal sinusoidal distributed magnetic fields inside electromagnetic linear actuators, and double-layer Halbach arrays can increase the internal magnetic flux density to ensure smooth electromagnetic force output and vibration energy conversion. However, the electromagnetic energy regenerative suspension has problems such as excessive mass, long displacement, and working dead zone in actual operation, and scholars from various countries have conducted corresponding research. To reduce the mass of the electromagnetic energy regenerative suspension system, the performance deterioration of the suspension system caused by excessive unsprung mass is avoided. Zuo et al. [55,56] designed a compact energy regenerative suspension based on a four-phase electromagnetic actuator. The working principle is shown in Fig. 12a. By using the alternating operation of the electromagnetic actuator in four operating quadrants, vibration energy recovery is achieved without loss of ride comfort. Lafarge et al. [57,58] designed and fabricated an embedded linear electromagnetic energy regenerative suspension structure, as shown in Fig. 12b, which avoided the problems caused by the volume and complexity of the electromagnetic energy regenerative suspension during the installation process. And to achieve the damping and energy regenerative functions without changing the initial structure of the suspension. Stribrsky et al. [59,60] used Copley Controls’ tubular permanent magnet linear motor TBX3810 to design an electromagnetic energy regenerative suspension and develop a test signal for simulating a real road to verify the feasibility that the electromagnetic energy regenerative suspension can be used to determine regenerative requirements based on road conditions and the vehicle’s energy storage state. Wang et al. [61] introduced a rectifier module and voltage regulator module in the energy regenerative circuit of electromagnetic energy regenerative suspension, and the transient one-way current generated by electromagnetic energy regenerative suspension was changed into a low-pulse DC power supply to charge the battery through the rectifier module and voltage regulator module. To avoid the “dead zone” of the electromagnetic energy regenerative suspension, Lai et al. [62] made the “dead zone” generating unit required by the driving circuit in the driving circuit of the linear motor, which improved the movement range of the electromagnetic energy regenerative suspension work efficiency.

Figure 12: (a) Diagram of the four-phase generator configuration: the coils move in the magnetic field during the vibration of the vehicle suspension mechanism; (b) The prototype embedded in the suspension mechanism

At present, scholars from various countries have carried out extensive and in-depth research on linear electromagnetic energy regenerative suspension. The simulation and test data are shown in Table 2. According to the data, it can be concluded that the linear electromagnetic energy regenerative suspension has no motion conversion structure, and the work efficiency is significantly improved; the motion trajectory matches the suspension stroke, which significantly improves the dynamic performance of the vehicle; the mechanical friction loss is small, and the system reliability is good.

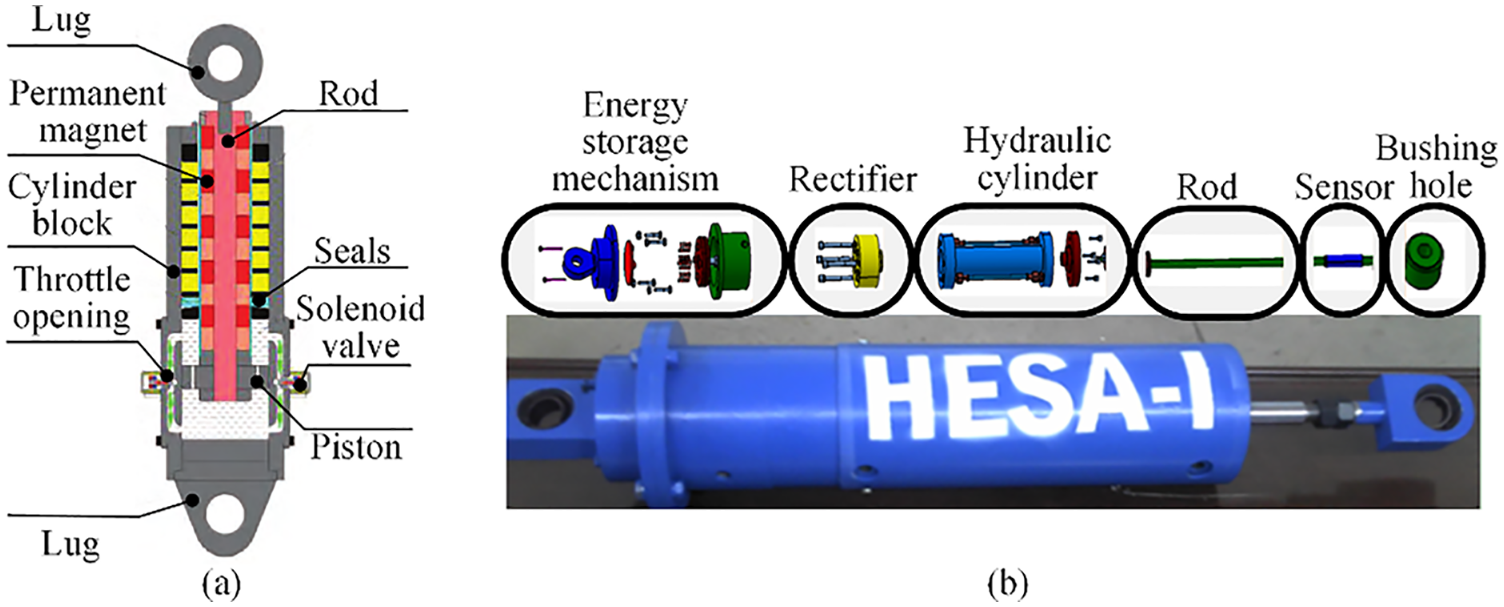

2.3 Hydraulic-Electric Composite Electromagnetic Energy Regenerative Suspensions

In view of the fact that the rotary electromagnetic energy regenerative suspension adopts a mechanical mechanism for power transmission, the clearance of mechanical transmission is unavoidable, and the backlash seriously affects the reliability and durability of the energy recovery system. when received severe road impact will lead to gear cracking or even broken teeth. The hydraulic-electric composite design can effectively avoid such problems [63,64]. The hydraulic-electric energy regenerative suspension system, which integrates the hydraulic-electric mechanism and the suspension system, takes into account the flexibility of the hydraulic system layout and the effectiveness of the electromagnetic energy regenerative.

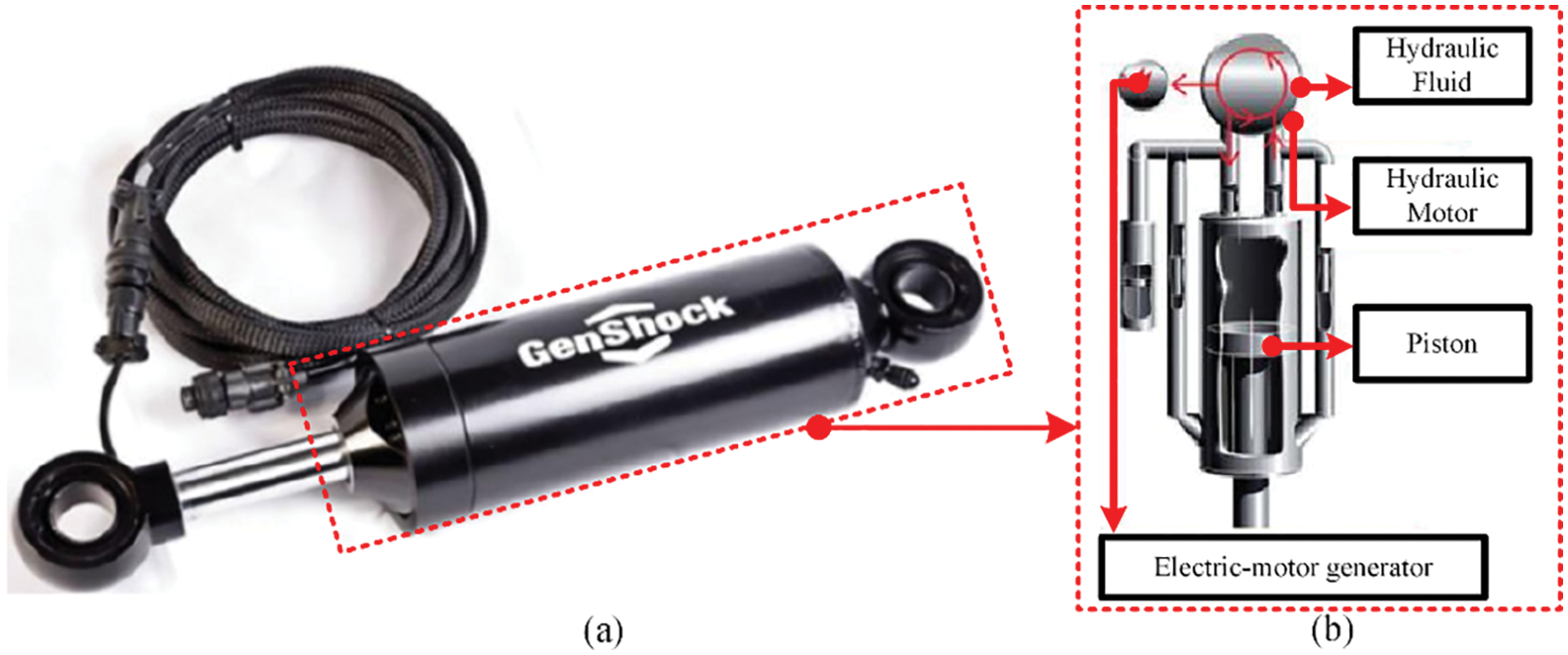

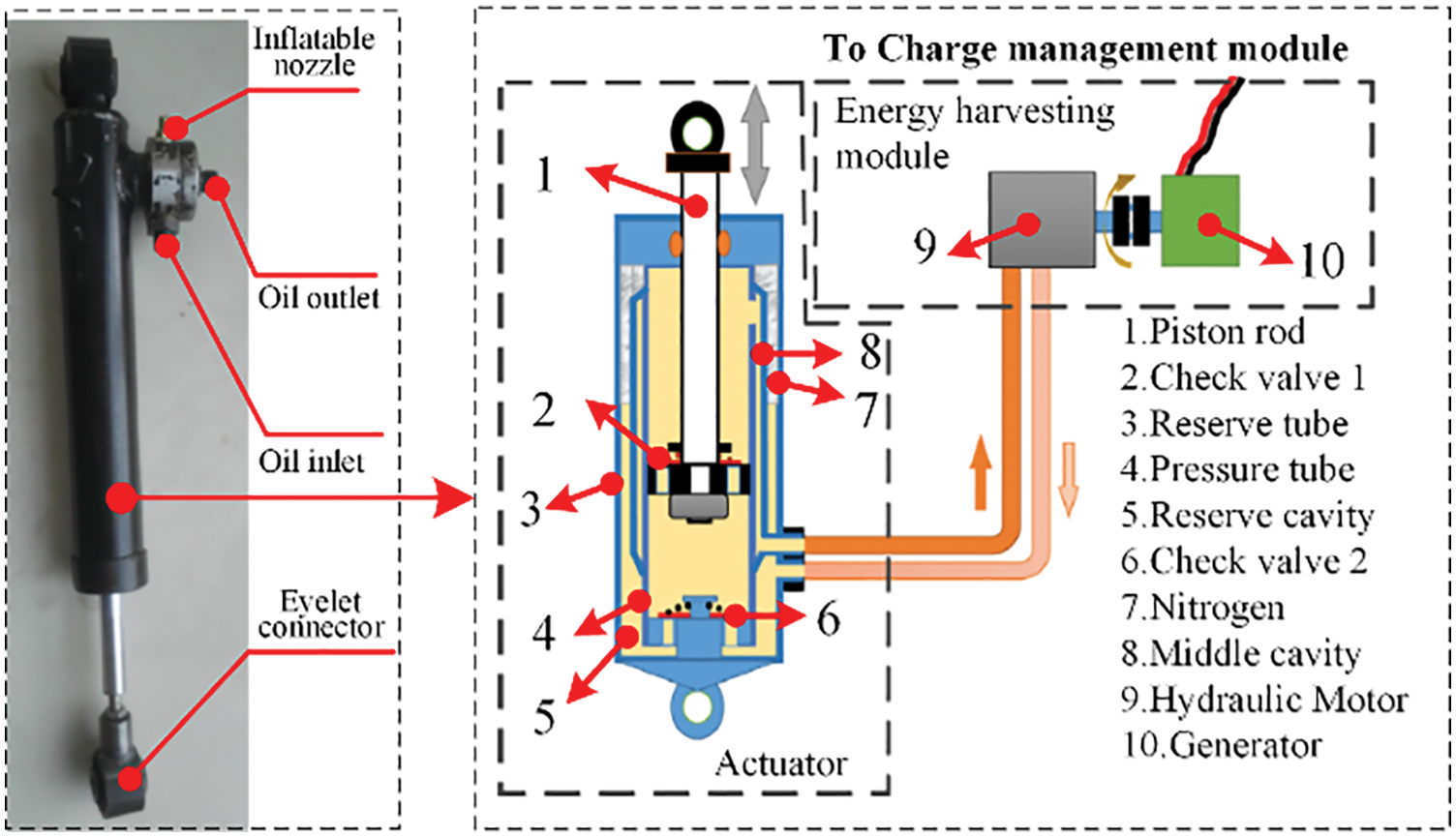

At the end of the 20th century, as PBW (Power-by-Wire) drive system came into people’s view [65]. The hydraulic-electric actuation technology attracted scholars to carry out research based on the hydraulic-electric composite suspension system, because of its high-power output and high reliability [66]. NISSAN has developed a hydraulic interconnection-based body attitude control system that can be used to adjust the body attitude [67]. Satoh et al. [68] proposed an initial design idea for a hydraulic energy regenerative suspension mechanism. Wendel et al. [69] added energy harvesting functions to the hydraulic active suspension system. In 2009, a research group at MIT developed a hydraulic-electric composite energy regenerative suspension structure, and later they founded the company Levant Power and developed an energy regenerative suspension mechanism called Gen-shock. The structure is shown in Fig. 13. The core of the electromagnetic energy regenerative shock absorber is a hydraulic system composed of a hydraulic cylinder, pipeline, one-way valve, accumulator, and hydraulic motor. They conducted road tests on vehicles such as military Humvees and heavy trucks, the result showed that they were able to save about 6% of the fuel and were 71% more durable than conventional passive suspensions [70,71].

Figure 13: Gen-shock energy regenerative suspension mechanism and its working principle diagram

To further promote the development of hydraulic-electric hybrid actuator technology, reducing losses is of great significance for saving suspension energy, improving system reliability, and improving power conversion efficiency [72]. Chen et al. [73] designed a dual-chamber hydraulic energy regenerative suspension and analyzed its dynamics, but lacked a method to calculate the energy regenerative efficiency. Kou et al. [74] designed a new type of hydraulic-electric composite electromagnetic energy regenerative suspension, as shown in Fig. 14a. They carried out research on its dynamic performance and energy regenerative performance. Ding et al. [75] connected a mechanical speed change mechanism composed of a gear system and a one-way cutter in series between the hydraulic motor and the generator, which solved the problem of frequent commutation of the motor, but increased the weight and volume of the suspension system, and affect the energy regenerative efficiency. Xu et al. [76,77] designed a hydraulic rectifier bridge according to the working principle of the Wheatstone bridge, and realized a highly integrated design of the hydraulic-electric composite energy regenerative suspension system, as shown in Fig. 14b, which reduces the complexity of the energy harvesting module. Fang et al. [78,79] improved the hydraulic-electric composite energy regenerative suspension, using a low-pressure accumulator to replace the hydraulic oil tank, and the energy collection efficiency of the energy regenerative suspension was about 16.3%. Guo et al. [80,81] analyzed the relationship between hydraulic-electric composite energy regenerative suspension and vehicle fuel consumption. The hydraulic-electric composite energy regenerative suspension significantly improves the fuel economy of off-road vehicles and heavy trucks and provides the higher damping force required for vehicle off-road performance. Considering the energy regenerative potential of off-road vehicles, Jin et al. [82] designed a hydraulic-electric composite energy regenerative suspension for an off-road vehicle, which can increase the speed of the hydraulic motor as the road surface level decreases, and maintain the energy regenerative efficiency between 25% and 45%.

Figure 14: (a) Structure principle of electromagnetic compound energy regenerative suspension mechanism; (b) Hydraulic regenerative suspension mechanism with HMR

When the speed of the hydraulic motor-driven generator is lower than the minimum working speed of the generator, the hydraulic-electric composite energy regenerative suspension system will produce the phenomenon of a “power dead zone”. Zhou et al. [83,84] increased the speed of the hydraulic motor by reducing the displacement of the hydraulic motor, and adjusted the minimum working speed of the generator to avoid the phenomenon of a “power dead zone”, to improve the reliability of the hydraulic-electric composite energy regenerative suspension system. However, the recovery of vibration energy inevitably leads to the degradation of the dynamic performance of the hydraulic-electric composite energy regenerative suspension. Galluzzi et al. [85] added a rectification to the hydroelectric energy regenerative suspension. The rectification could transfer mechanical power between the linear and rotary domains. In addition, rectification could introduce the potential benefits of reduced wear in the rotating parts and increased volumetric efficiency of the pump. Miragli et al. [86] discussed the main relations ruling the dynamics of a regenerative suspension. They presented a method to build the RV by properly select off-the shelf components, in order to comply with dimensional, performance and safety requirement. The compact design of the RSA, with a mass of only 5.8 kg, allows its installation into the suspension of a B-class SUV.

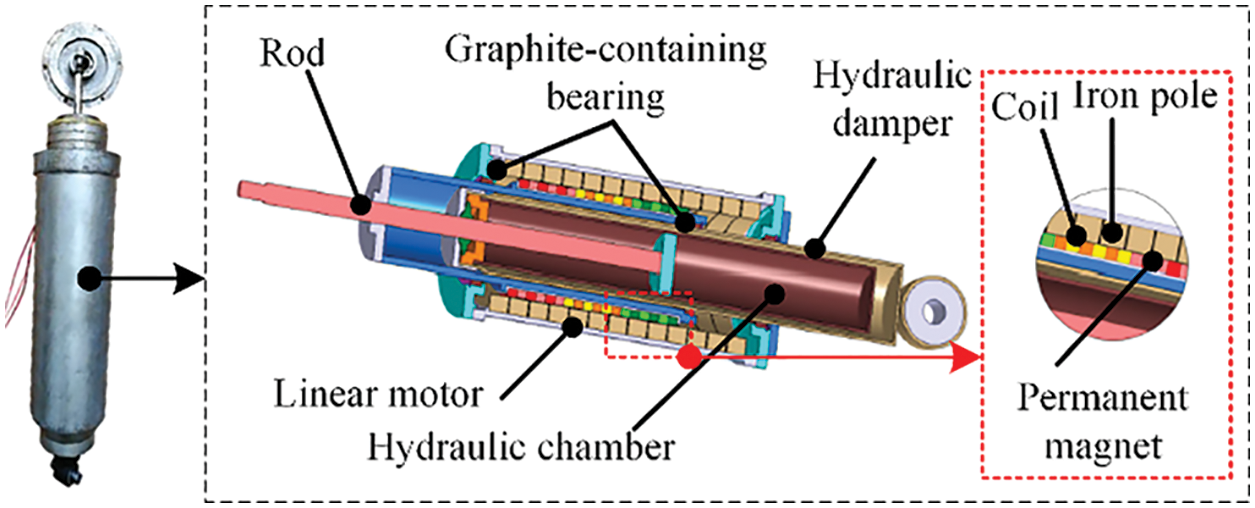

To improve the ride comfort of the vehicle and realize the decoupling of various motion modes of the vehicle, the conflict between the dynamic reduction performance and energy recovery of the energy regenerative suspension system is avoided. Wang et al. developed a hydraulic-electric composite energy regenerative suspension system by designing a linear motor in parallel with a hydraulic system, as shown in Fig. 15. According to the working range of the motor and the characteristics of the hydraulic system, they divided the working modes of the energy regenerative suspension system: comfort mode, safety mode, and energy regenerative mode to coordinate the contradiction between damping output and energy harvesting. Hydraulic-electric composite energy regenerative suspension system allows for near-asymmetric rebound/compression damping forces through specific piping connections [87–90]. Zhang et al. [91–93] designed and studied the double-pipe hydraulic-electric composite energy regenerative suspension, as shown in Fig. 16. During the upward and downward movement of the piston, the flow direction of the hydraulic oil and the rotation direction of the motor is not changed, and the unidirectional rotation of the generator is realized to ensure the energy collection capacity. In addition, a check valve is set in the pipeline to achieve a large controllable range of the damping force to ensure the smoothness of the vehicle. Qin [94] proposed a new hydraulic-electric composite energy regenerative suspension system with reliable load-bearing performance and adjustable damping characteristics. It combines the characteristics of the interconnected suspension cross-connection to significantly improve the road adaptability, body stability, and energy regenerative efficiency of the vehicle.

Figure 15: Schematic of new HEMA

Figure 16: (a) Actuator prototype of the pumping regenerative suspension mechanism; (b) Twin-tube pumping regenerative suspension mechanism

According to the characteristics of the hydraulic-electric composite energy regenerative suspension structure itself, researchers from various countries have carried out simulation and experimental verification on the comfort performance, safety performance, and energy-saving performance, as shown in Table 3. Under certain conditions, the maximum output force of the hydraulic-electric composite energy regenerative suspension is higher than that of the linear motor type and the rotary motor type, but it has the characteristics of easy leakage, low power density, and complex structure, which lead to its use restricted.

This chapter mainly summarizes the structure of the electromagnetic energy regenerative suspension, as shown in Table 4. More efficient and energy regenerative structural solutions are the basis of electromagnetic energy regenerative suspension research, while a more practical optimization design is an effective way to improve the reliability performance of electromagnetic energy regenerative suspension. The research of both provides a strong basis for improving the performance of electromagnetic energy regenerative suspension, which is the key issue of electromagnetic energy regenerative suspension research and development.

3 Optimal Design Method for Electromagnetic Energy Regenerative Suspensions

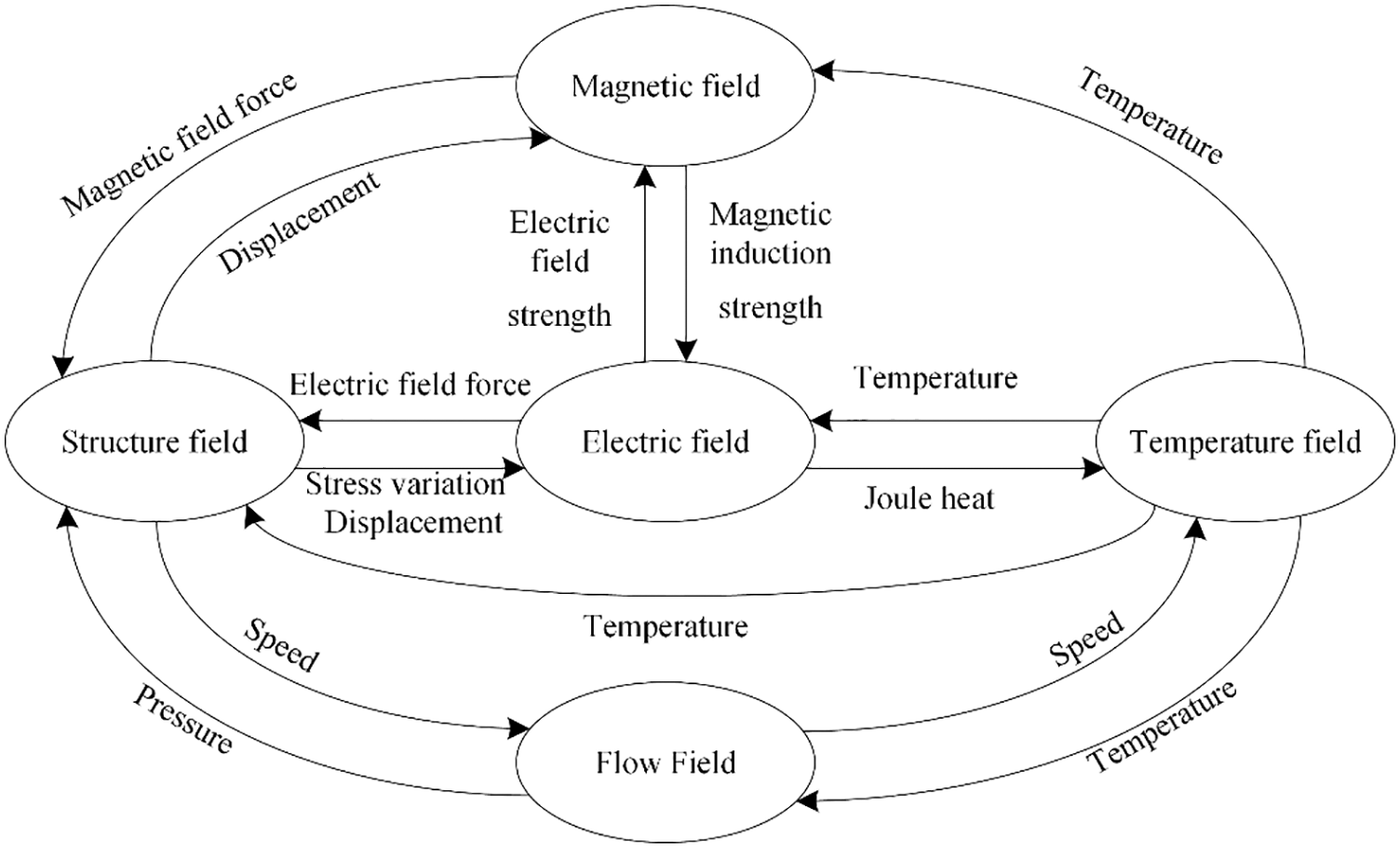

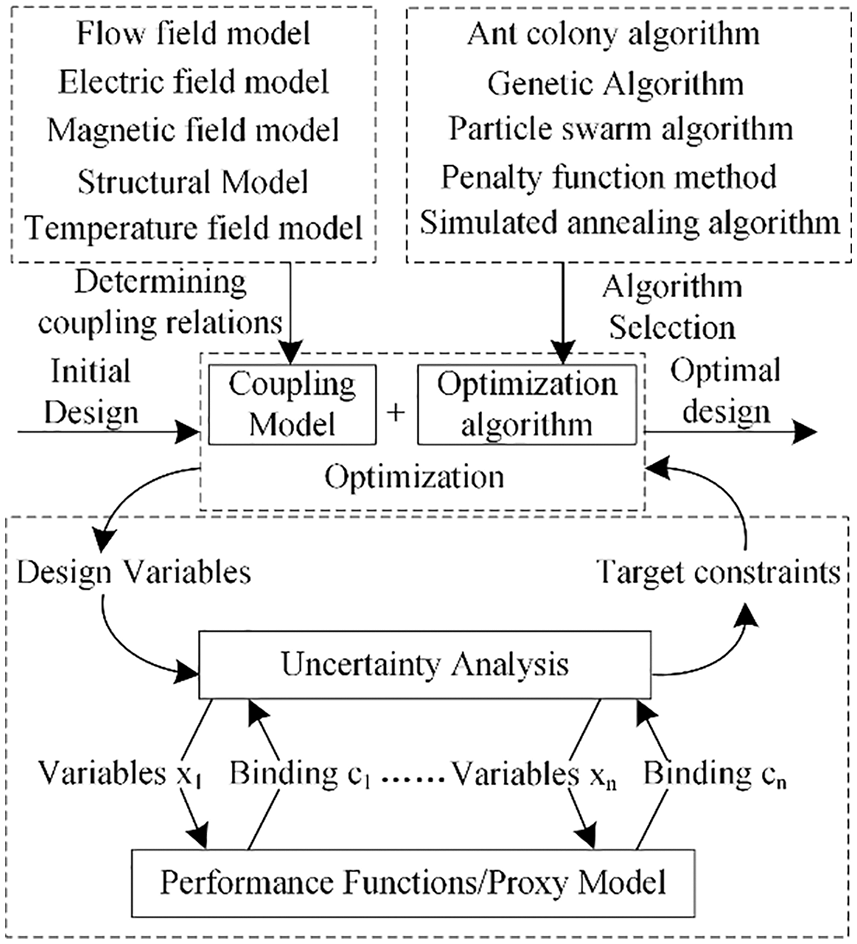

In the field of electromagnetic energy regenerative suspension research [95], multi-objective optimization [96,97] can simultaneously consider the damping performance and energy regenerative efficiency of the system to accomplish a balance between the objectives. Multidisciplinary optimization is a further development of multi-objective optimization, which considers the reliability of the structure, noise, and other factors caused by parameter uncertainty while focusing on performance [98]. Given the characteristics of multi-disciplinary coupling and uncertainty of the electromagnetic energy regenerative suspension system, as shown in Fig. 17, its design difficulty is increased [99]. At present, under the premise of clarifying the working principle in the electromagnetic energy regenerative suspension systems, researchers from various countries have established hybrid models including mechanical field, magnetic field, temperature field, fluid field, etc. To ensure the accuracy of the model analysis, the researchers adopted the reliability analysis methods to reduce the influence of uncertain factors, and finally combined the optimization algorithms to improve the optimization design efficiency of the electromagnetic energy regenerative suspension.

Figure 17: Multi-field coupling relation diagram of fundamental field

3.1 Research of Optimization Models

The disciplines are coupled with each other in the design process of electromagnetic energy regenerative suspension optimization [100]. Establish a multidisciplinary nonlinear coupled model with the support of single discipline theory, and determine the design parameters according to each model output variable. Through the coupling analysis of parameters, the optimization variables of the system are determined, to improve the credibility of the performance analysis results of the electromagnetics, dynamics, and fluid dynamics of the system.

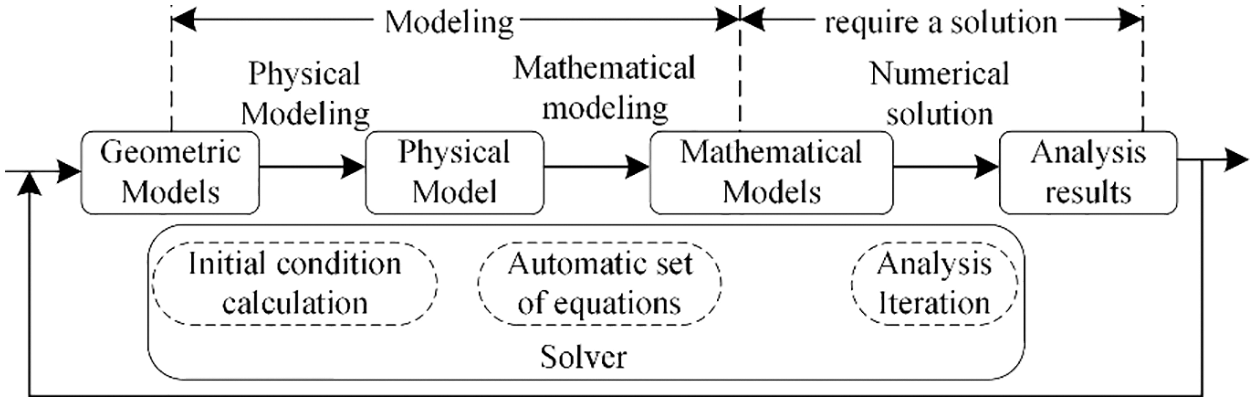

The dynamic analysis of the suspension mainly studies the transmission characteristics of the suspension elastic elements and damping elements to the body of the road vibration excitation [101]. Therefore, most of the current research on dynamic analysis of suspension systems focuses on K&C performance. Zhang [102] proposed a general process for computational suspension system multi-body dynamics modeling and solution. As shown in Fig. 18, it provides a theoretical basis for the multidisciplinary design of electromagnetic energy regenerative suspension. The K&C performance directly affects the damping performance of the electromagnetic energy regenerative suspension system. Wang et al. [103] analyzed the damping performance of the electromagnetic energy regenerative suspension under different road classes based on a hybrid suspension dynamics model, and the body acceleration increased by 2.73%, and the dynamic tire load amplitude decreased by 38.1%. Considering the contradictory relationship between damping performance and energy regenerative performance of the electromagnetic energy regenerative suspension. Kou et al. [104] established a nonlinear model of the energy regenerative suspension and used the least-squares recursive algorithm to identify the parameters of the system model. Coordinate the relationship between dynamic performance and energy regenerative performance. Wang et al. [105,106] added an equivalent circuit model to the electromagnetic suspension model. The relationship between the energy regenerative characteristics and its dynamic performance is clarified, which is only related to tire stiffness, suspension controllable damping, vehicle speed, and road surface.

Figure 18: Multi-body dynamics calculation process

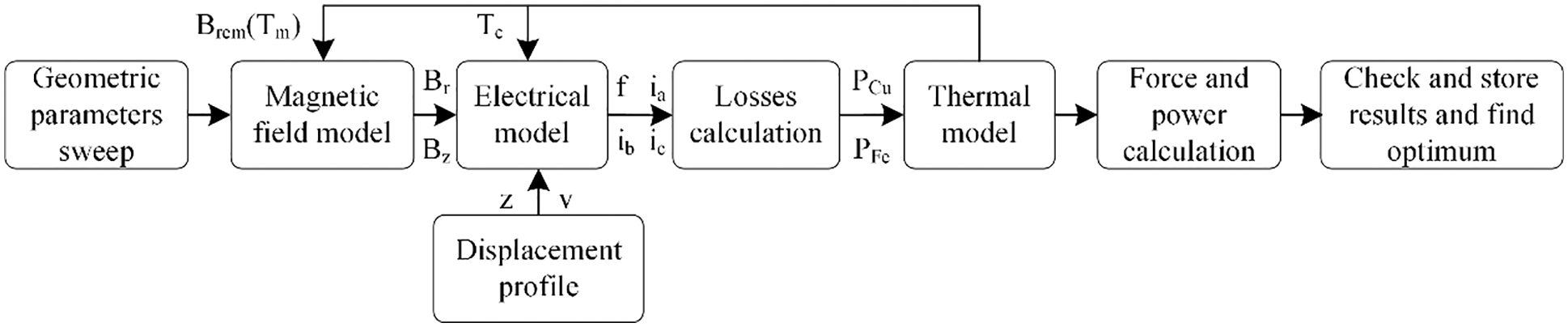

The coupling relationship between the electric and magnetic fields of the electromagnetic energy regenerative suspension is prone to its electromagnetic force fluctuations, and the effective output of electromagnetic damping directly affects the dynamic performance of the system. Yang et al. [107] established an actuator output model with electromagnetic force fluctuations and a quarter vehicle dynamics model, and carried out the dynamic analysis and induced electromotive force harmonic analysis. Peng et al. [108] established a theoretical and simulation analysis model of electromagnetic suspension actuator based on the electromagnetic theory of permanent magnet linear motor, to meet the demand of full linear control four-wheel independent drive electromagnetic active suspension. According to the radial air gap magnetic field distribution, induced electromotive force and other parameters Validate the analytical model. Ataei et al. [109] analyzed the geometry of the electromagnetic suspension actuator using the magnetic circuit method, determined the relationship between design parameters and damping characteristics, and optimized the non-dimensional geometric parameters of the tubular slotless permanent magnet motor, which can obtain a high electromagnetic damping coefficient. Friedrich et al. [110] proposed a semi-analytic model based on the harmonic Fourier model to calculate the magnetic field generated by permanent magnets. The electrical and thermal iterative models are coupled with the magnetic field model into a fast and accurate multidisciplinary design tool, as shown in Fig. 19. The bond graph language can be well adapted to the energy conversion of multi-physics, and it is helpful to analyze the energy flow of the system, so as to clarify the energy harvesting efficiency of the system [111–114]. Lafarge et al. [115] proposed a bond graph model for predicting piezoelectric cantilever beam energy harvesting in automotive suspensions to derive power exchanges between subsystems.

Figure 19: Modeling and analysis process

CFD and finite element methods developed in recent years occupy an important position in multi-body dynamics, electromagnetism, and fluid dynamics. They integrate multidisciplinary theories and high-precision algorithms to accurately calculate and analyze system performance and improve the efficiency of optimal design. CFD and finite element methods are based on geometric models, which need to be parameterized. During the optimization process, the geometric model can be automatically updated according to the optimization variables, thus finding the optimal design solution among the executable design solutions. Zhou et al. [116] built a 1/4 vehicle dynamics model on the AMEsim simulation platform for the new hydraulic-electric energy regenerative suspension system and optimized the hydraulic-electric energy regenerative suspension system with ride comfort as a constraint. Average power increased by 12.7%. Wang et al. [117] used the finite element analysis software Ansoft to determine the magnetization method of the permanent magnets inside the motor of the hydraulic-electric energy regenerative suspension. Zhang et al. [118] used the electromagnetic field simulation software JMAG to build a finite element model of a permanent magnet synchronous motor, combined with Simulink to build a JMAG-RT model, and combined with a DSP controller to build a hardware-in-the-loop system of a permanent magnet synchronous motor.

At present, researchers have carried out a variety of modeling methods to further deepen the dynamic, electromagnetic, and fluid mechanics analysis of the electromagnetic energy regenerative suspension system. The multidisciplinary coupled model is established under the support of single discipline theory and combined with finite element analysis software, the analysis efficiency of system performance is improved.

3.2 Uncertainty Analysis Methods

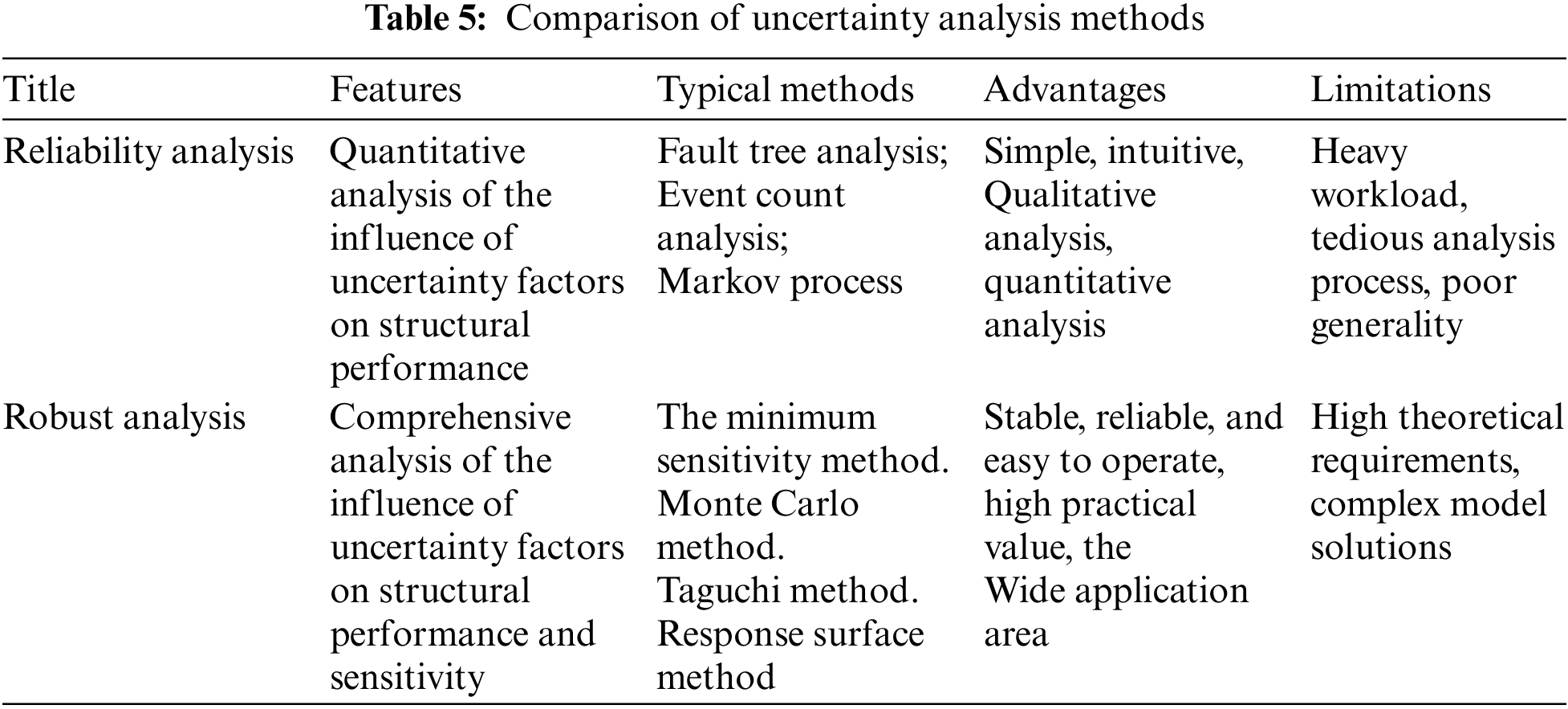

The electromagnetic energy regenerative suspension system is a multi-disciplinary strong coupling nonlinear uncertainty system, and its uncertainty is divided into parameter uncertainty and model structure uncertainty [119]. The operating state of the electromagnetic energy regenerative suspension system varies with the road surface and climate, leading to uncertainties in its estimated parameter characteristics. Uncertainty in the model structure due to different assumptions in the modeling process of electromagnetic energy regenerative suspensions [120]. The uncertainty will directly affect the performance of the electromagnetic energy regenerative suspension system. Therefore, the uncertainty analysis of electromagnetic energy regenerative suspension structures by researchers from various countries mainly focuses on the influence of uncertainty input on the structural response. According to the application in practice, the commonly used uncertainty analysis methods are mainly divided into reliability analysis and robustness analysis, and the comparative analysis is shown in Table 5.

Reliability analysis can obtain the failure probability of the system. In the research of electromagnetic energy regenerative suspension systems, reliability analysis ensures the driving safety of the vehicle; robustness analysis estimates the sensitivity of uncertainties to the system response and achieves controllable product quality characteristics [121]. According to the requirements of the comfort, safety, and energy-harvesting performance of the energy regenerative suspension system [122]. Scholars currently use robustness analysis methods to conduct in-depth research on the suspension system, such as the Taguchi method, Monte Carlo method, etc. To reduce the influence of uncertainty factors on the comprehensive performance of electromagnetic energy regenerative suspension systems.

The Taguchi method was first proposed by Taguchi Genichi, and the basic idea is to determine the output response by adjusting the control factor and considering the effect of uncertainty factors while the input response is constant [123,124]. To reduce the variation of vehicle ride comfort with sprung mass, Mitra et al. [125] used the Taguchi method to analyze the ride performance of vehicle suspension, looking for the relationship between tire pressure, spring stiffness, and damping coefficient to determine the constant target comfort value. Reddy et al. [126] used an optimization method combining the response surface method and the Taguchi method to analyze the suspension system of the vehicle suspension. The response surface method can derive the main factors affecting the suspension performance parameters and the Taguchi method can predict the parameters of the suspension system to verify the accuracy of the response surface method. Liu et al. [127] used the Taguchi method to find the optimal combination of suspension parameters based on the Kriging surrogate model. The method adopted improved the lateral and longitudinal stability of the vehicle by 10.08% and 9.18%. Zhang et al. [128] used the Taguchi method to analyze the energy regenerative efficiency of the energy regenerative suspension system under the grades A, C, and E of IS08606.

The Monte Carlo method can determine the correlation between random variables in the suspension system to ensure high confidence in the system analysis results. Hamid et al. established a dynamic model of the commercial vehicle suspension system and used Monte Carlo analysis to obtain the correlation between the energy regenerative power and driving conditions under different suspension and road conditions [129]. Zhang et al. [130] used the Monte Carlo method to analyze the parameter sensitivity of the indirect-driven and direct-driven energy regenerative suspension systems and compared the performance of the two systems in improving the peak power output and broadening the energy harvesting frequency band. Abdelkareem et al. [131] used the Monte Carlo method for frequency-based parametric sensitivity analysis of vehicle suspension dynamics and energy harvesting potential to reveal the relationship between suspension parameters and energy regenerative, which helps to conceptualize the design of electromagnetic energy regenerative suspension systems to improve their energy regenerative efficiency under different road conditions.

The uncertainty analysis method can further clarify the correlation of the performance parameters of the electromagnetic energy regenerative suspension system, which helps to make trade-offs among the performance parameters and then coordinate the performance requirements of the electromagnetic energy regenerative suspension system to meet the researchers’ requirements on the damping performance, energy regenerative performance and safety performance of the electromagnetic energy regenerative suspension system.

3.3 Research of Optimization Algorithms

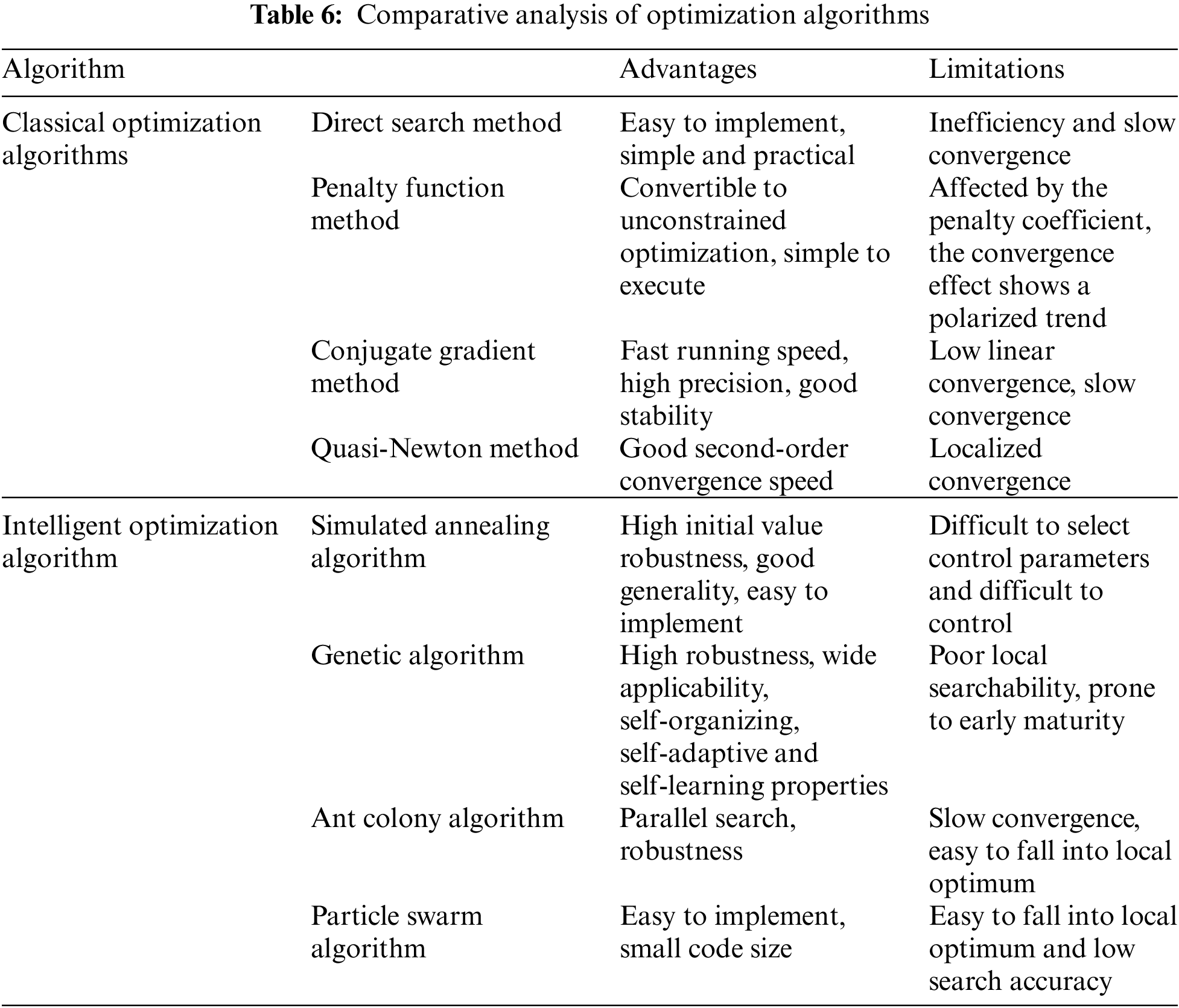

In the optimization process, advanced optimization algorithms are the key to improving the efficiency of optimal design and promoting multidisciplinary and multi-objective optimization to practical applications. The objects of multidisciplinary optimization are generally nonlinear systems. Therefore, the optimization algorithms are mainly nonlinear programming methods. The commonly used optimization algorithms are shown in Table 6, which are roughly divided into two categories: classical optimization algorithms and intelligent optimization algorithms. Classical optimization algorithms include the direct search method [132], penalty function method [133], conjugate gradient method [134], and quasi-Newton method [135], whose theories are very mature. The intelligent optimization algorithm has the self-adaptive characteristics of organisms in the face of environmental changes in nature, cooperates, and shares information in the process of finding the optimal solution, which ensures the robustness and stability of the algorithm. Intelligent algorithms include simulated annealing algorithm [136], genetic algorithm [137], ant colony algorithm [138], particle swarm algorithm [139], etc. At present, genetic algorithm and particle swarm optimization algorithm has been well applied in the optimal design of electromagnetic energy regenerative suspension.

In the optimization design process of the electromagnetic energy regenerative suspension, the parameters involved in the genetic algorithm are random. This stochastic search characteristic makes the genetic algorithm has strong robustness in the operation process, and the search mode is not limited to a certain point, expanding the search range and easy to obtain the global optimal solution. Li et al. [140] proposed a multi-objective optimization function based on weight coefficients and applied multiple genetic algorithms with strong search capability and fast convergence to optimize the mechanism size of the motor. Compared with the standard genetic algorithm, the multiple genetic algorithms used can effectively suppress the premature convergence problem of the SGA algorithm. Based on a comprehensive genetic algorithm, Shao et al. designed an adaptive function to optimize the parameters of the electromagnetic energy regenerative suspension and the active controller. The optimized electromagnetic energy regenerative suspension improved the ride comfort of the vehicle [141]. Li et al. [142] evaluated the performance of electromagnetic energy regenerative suspension system based non-dimensional mixed index of safety probability and used a genetic algorithm to optimize the smoothness and maneuvering stability indexes of the system. The optimization alleviated the contradictory problem between the two and ensured the maneuvering stability based on improving the smoothness of the suspension. Kou et al. [143] used a genetic algorithm to coordinate the damping performance and energy regenerative performance of the electromagnetic energy regenerative suspension system, and the optimized spring-loaded mass acceleration was reduced by 22.23% and the energy regenerative power was increased by 40.51%. The regenerative performance of the electromagnetic energy regenerative suspension is improved while ensuring a certain level of vehicle comfort and driving safety.

Compared with the genetic algorithm, the particle swarm algorithm contains fewer parameters, runs faster, and is easy to implement, but like a genetic algorithm, it is easy to fall into local optimum. Yu et al. [144] introduced a multi-objective particle swarm optimization algorithm to obtain the Pareto front in the optimal design of electromagnetic energy regenerative suspension, applied hierarchical analysis to find the optimal design of the Pareto front, and verified the feasibility of multi-objective optimization and multi-objective decision-making methods. Zhou et al. [145] added a learning framework to the optimization process and developed a recent particle swarm global optimization algorithm that combines human knowledge for local optimization. The new algorithm reduces the computational load by reducing the learning space, and the optimized electromagnetic energy regenerative suspension achieves maximum energy efficiency with the best-optimized design parameters. Peng et al. [146] optimized the actuator structure parameters of electromagnetic active suspension based on a multi-objective particle swarm optimization algorithm with adaptive penalty function, and the optimized actuator structure is compact and loss reduction. Based on this, Yang et al. [147] used linearly adjusted inertia weight coefficients combined with a particle swarm optimization algorithm to optimize and improve the system, which eliminated the influence of the electromechanical coupling problem on the dynamic performance of the electromagnetic energy regenerative suspension system. Li et al. [148] used a multi-objective particle swarm optimization algorithm to optimize the road adaptability of the electromagnetic energy regenerative suspension system. The optimized electromagnetic energy regenerative suspension system can realize the comprehensive optimization of the safety, comfort, and energy harvesting of the suspension system under different road grades.

By using the optimization algorithm, the loop nesting problem existing in the system optimization design process is solved, and the sensitivity to uncertain factors and the optimization efficiency is improved. The current optimization algorithm still has the problems of premature convergence and insufficient diversity when solving the multidisciplinary optimization design problem of the electromagnetic energy regenerative suspension system.

At present, researchers at home and abroad have achieved certain results in the optimization design of electromagnetic energy regenerative suspension. The optimization process is shown in Fig. 20, which verifies the feasibility of the multidisciplinary and multi-objective optimization design method applied to the optimization design of electromagnetic energy regenerative suspension. However, due to the imperfection of multidisciplinary and multi-objective optimization design itself, as well as the complexity of the electromagnetic energy regenerative suspension system, the current optimization design method still has many shortcomings, such as large calculation volume and convergence difficulties. Therefore, we need to improve and refine the optimization method itself, and then better integrate the multidisciplinary and multi-objective optimization design method according to the performance characteristics of the electromagnetic regenerative suspension to improve the comprehensive performance of the electromagnetic regenerative suspension system.

Figure 20: An optimization framework

4 Electromagnetic Energy Regenerative Suspension Control Methods

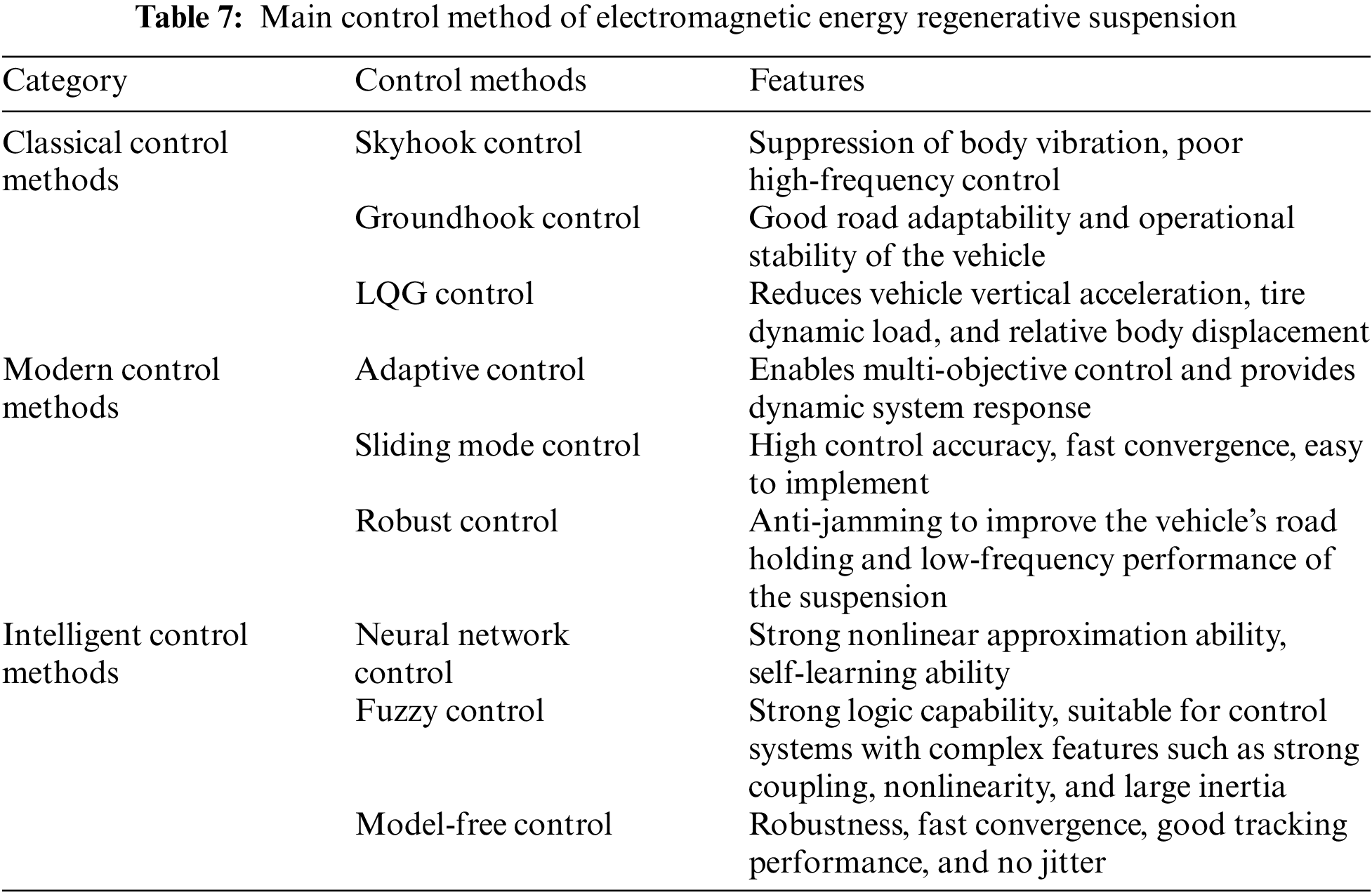

In the design and research process of the electromagnetic energy regenerative suspension at this stage, the electromagnetic energy regenerative suspension structure and the system controller are the key contents of the research. A good structure can ensure the dynamic performance of the electromagnetic energy regenerative suspension, and the system controller is responsible for calculating the control rate to optimize the vehicle’s motion posture [149,150]. The coordinated control of the dynamic performance and the energy regenerative performance of the electromagnetic energy regenerative suspension is a key problem that needs to be broken through. In past research, researchers have analyzed the feasibility of the electromagnetic energy regenerative suspension system from a single perspective [151]. As the performance requirements of electromagnetic energy regenerative suspensions continue to improve, the control methods of electromagnetic energy regenerative suspensions are constantly being improved, allowing them to change their vibration and energy regenerative characteristics according to specific requirements to improve the overall performance of electromagnetic energy regenerative suspensions. At present, the control methods of electromagnetic energy regenerative suspension are mainly divided into three categories: classical control methods, modern control methods, and intelligent control methods.

Classical control theory is a theory based on the frequency response method and the root trajectory method, using the Laplace transform as a mathematical tool, and has significant results for linear time-invariant systems with a single input and a single output [152,153]. With the application of the state space method and the development of the control theory, the current control method can solve the multi-dimensional space system with multiple inputs and multiple outputs. At present, the classical control theories applied to the energy regenerative suspension include skyhook control, groundhook control, LQG control, etc.

4.1.1 Skyhook Control & Groundhook Control

The skyhook control algorithm was first proposed by Karnopp in the United States and was originally used for the control of semi-active suspension [154]. With the development of the suspension system and the deepening of control research, it has been developed into ideal skyhook control [155], skyhook active control [156], and skyhook on-off control [157].

To improve the practicality and effectiveness of semi-active control of energy regenerative suspensions, Chen et al. [158] proposed the skyhook on-off control algorithm. Compared with the skyhook active control, the skyhook on-off control can well suppress the vertical body vibration acceleration in the low-frequency resonance region, mid-frequency region, and high-frequency region, and improve the smoothness of vehicle driving. Moallem et al. [159] used a regenerative skyhook control strategy, which can achieve continuous variable damping force output of the electromagnetic suspension, significantly improve the damping performance of the suspension and enhance the energy harvesting efficiency of the system. To coordinate the relationship between the dynamic performance and energy consumption of the hybrid electromagnetic suspension, Wang et al. [160–162] determined the conditions for multi-mode switching of the system. They adopted a mode switching control method based on skyhook control to realize the fast and slow switching control of the electromagnetic suspension system in all road conditions, ensuring the stability of mode switching.

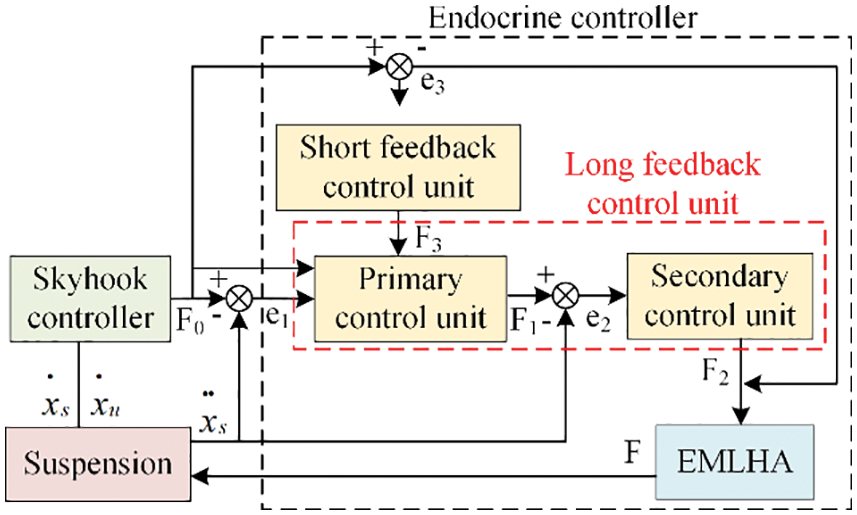

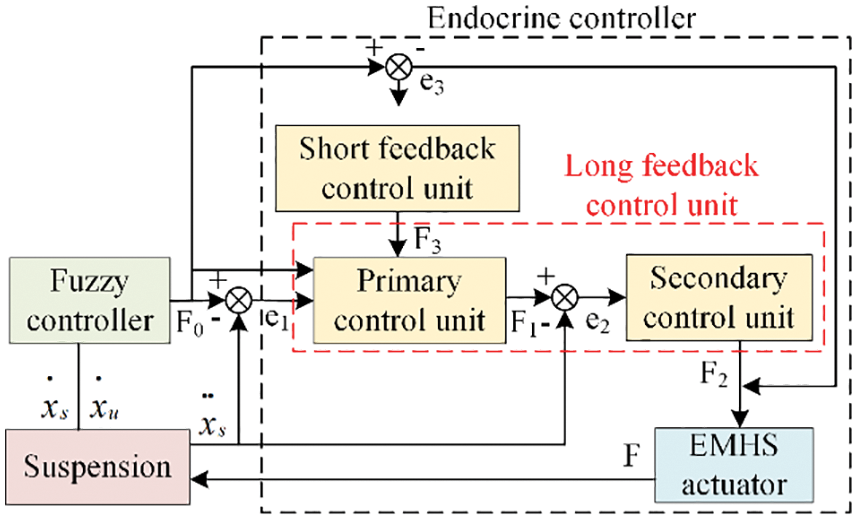

The control principle of groundhook control is the same as that of skyhook control [163]. Kopylov et al. [164] proposed an acceleration-based groundhook control method for electromagnetic energy regenerative suspensions to improve the energy regenerative capability under random road surfaces. Kou et al. [165] divided the suspension movement into four modes: economy, safety, comfort, and comprehensive according to the driving conditions of the vehicles, and adopts endocrine composite skyhook-groundhook control, as shown in Fig. 21. Compared with the skyhook-groundhook control, the endocrine composite skyhook-groundhook shed control has a better damping effect and better adaptability to the simulation of changing parameters.

Figure 21: Block diagram of the control structure of the endocrine compound world shed

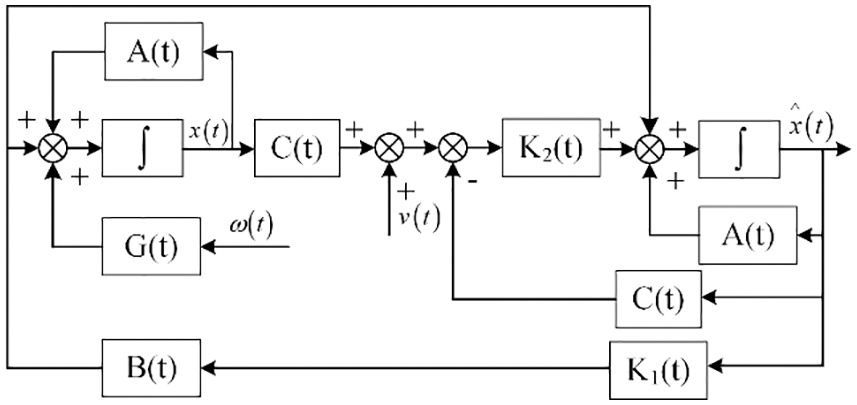

LQG (Linear Quadratic Guass) optimal control is a classic optimal control algorithm [166,167], and its working principle is shown in Fig. 22. Compared with skyhook control and groundhook control, LQG control has great advantages in the robustness of the control system. The design of the weighting matrices Q and G is the core of the LQG active control algorithm. The traditional method to determine the values of the weighting matrices is less efficient and difficult to obtain the optimal solution. The global search ability of intelligent algorithms such as genetic algorithms and fruit fly algorithms can improve the optimization efficiency of LQG.

Figure 22: LQG control system block diagram

There are three main performance evaluation indexes for energy regenerative suspensions, which are body acceleration representing ride comfort, suspension dynamic deflection representing safety, and average energy regenerative efficiency representing energy regenerative characteristics [168]. Hansen uses the LQG optimal control method to coordinate the relationship between the performance indicators of the electromagnetic energy regenerative suspension and the output force [169]. Wang et al. [170,171] used the LQG control method to determine the damping value in different working modes and achieved the mode switching control of the electromagnetic energy regenerative suspension. Dai et al. [172] used optimal control theory to design the active suspension LQG controller, and used hierarchical analysis (AHP) and particle swarm optimization (PSO) methods to optimize the controller design parameters. An optimized controller improves vehicle dynamics and energy regenerative efficiency. Kou et al. [173,174] used an improved fruit fly algorithm to optimize the weighting coefficients of LQG under different fitness functions, which improved the adaptive performance of the control system under mixed grade pavement.

Traditional control methods are simple, reliable, and easy to implement. However, traditional control methods require high precision system models. They are difficult to meet the high-performance requirements of the electromagnetic energy regenerative suspension system, when solving the performance coordination problem of the electromagnetic energy regenerative suspension system. With the continuous development of theories in various disciplines, the combination of advanced algorithms can improve the adaptability of traditional control methods to complex coupled systems.

Modern control methods do not require parameter identification, but need to define the variation law of adaptive parameters to reduce system errors and ensure system stability. They are suitable for complex systems such as multi-input multi-output systems and nonlinear systems. They are the characteristics of clear theory and convenient operation. Modern control methods mainly include: adaptive control, sliding mode control, robust control, etc.

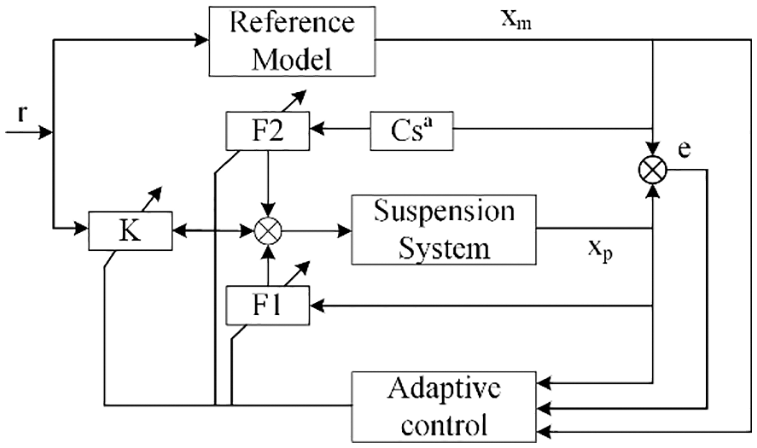

In the 1960s, the concept of adaptive control was proposed by Aseltine, and it was first used for control problems in the aerospace field [175]. Adaptive control has fast adaptability to the system with parameter changes and model uncertainty. As shown in Fig. 23, it can automatically adjust the system according to the output state of the controlled object, so that the system is always in the best condition [176,177]. In the control process of the electromagnetic energy regenerative suspension system, there are a large number of nonlinear uncertain factors that interfere with the control performance of the system [178,179], so as to affect the dynamic performance of the electromagnetic energy regenerative suspension system. Therefore, adaptive control is suitable for electromagnetic energy regenerative suspension systems.

Figure 23: The structure block diagram of adaptive control

In recent years, researchers have adopted adaptive control for the electromagnetic energy regenerative suspension system, which improves the dynamic performance and energy regenerative performance of the electromagnetic energy regenerative suspension system and ensures its safety performance. Li et al. [180] adopted the adaptive filter compensation method to reduce the influence of nonlinear factors on the electromagnetic energy regenerative suspension system. By controlling the first-order resonance of the suspension system, the effective output force of the electromagnetic suspension is amplified, which ensures the dynamic performance of the electromagnetic energy regenerative suspension system. Min et al. [181] used an adaptive fuzzy output feedback inverse optimization strategy to achieve the inverse optimization related to the energy consumption function, which ensured the stability of the vehicle attitude. Sun et al. [182] adopted the fuzzy adaptive backstepping control method to precisely and precisely control the active suspension system, which not only improved the comfort but also ensured safety. For uncertain nonlinear systems with dead-zone actuators and random failures, Hua et al. [183] used an adaptive control strategy to compensate for the unknown dead-zone input nonlinearity of the automotive suspension system and improve the dynamic response performance of the system. Liu et al. [184] used the adaptive back-thrusting method to ensure the boundedness of the failure probability of the electromagnetic suspension system. Pan et al. [185] proposed an adaptive fault-tolerant method to comprehensively compensate for the controller performance. The proposed control method can achieve arbitrarily small tracking errors in the presence of random failures in nonlinear systems.

Sliding mode control, also known as variable structure control, is essentially discontinuous nonlinear control and was first proposed by Utkin [186]. Sliding mode control is characterized by high control accuracy, fast convergence, robustness, and easy implementation of controller design. Sliding mode control can quickly switch the control state of the system on the pre-designed sliding mode surface with high frequency switching characteristics, which is suitable for mode switching control of electromagnetic energy regenerative suspension systems.

Due to the different working characteristics of the electromagnetic energy regenerative suspension modes, the mode switching is prone to generate thrust fluctuations, and it is difficult to achieve smooth dynamic control of the switching process. Shi et al. [187] combined fuzzy control based on sliding mode control, which eliminated the discontinuous chattering of sliding mode control, maintained the stability of the system, improved the control effect of the suspension system, and improved the performance and energy recovery utilization of electromagnetic energy regenerative suspension system. However, the adaptive performance of the electromagnetic energy regenerative suspension under different road grades needs to be improved. Li et al. [148] designed an adaptive sliding mode controller. They comprehensively considered issues such as the uncertainty of sprung mass caused by fuel consumption, the number of passengers, and cargo load during vehicle driving, and realized the comprehensive optimization of the safety, comfort, and energy efficiency of the suspension system under different road classes. The phenomenon of system instability exists when the electromagnetic energy regenerative suspension fails. Xu et al. [188,189] established a dual sliding mode switching control system for its active mode and failure mode, as shown in Fig. 24. They use the Kalman filter estimation algorithm to continuously detect the dynamic characteristics of the vehicle suspension system. When the electromagnetic energy regenerative suspension system fails, the dual sliding mode switching control strategy controls it to switch to the failure mode to ensure the driving safety of the vehicle.

Figure 24: A double sliding mode control strategy of the active suspension mechanism

In 1978, Davison of the University of Toronto first proposed robust control [190], and subsequently developed various control methods such as H∞ robust control [191] and structural singular value theory [192]. Among them, the application of H∞ control in the energy regenerative suspension system is relatively mature. The basic idea is to use the H∞ parametric optimal regulation of the controlled system to ensure the robustness of the system. Effectively solve the influence of disturbance information such as noise and uncertainty on system stability. At present, it has applications in many fields such as electromagnetic energy regenerative suspension systems.

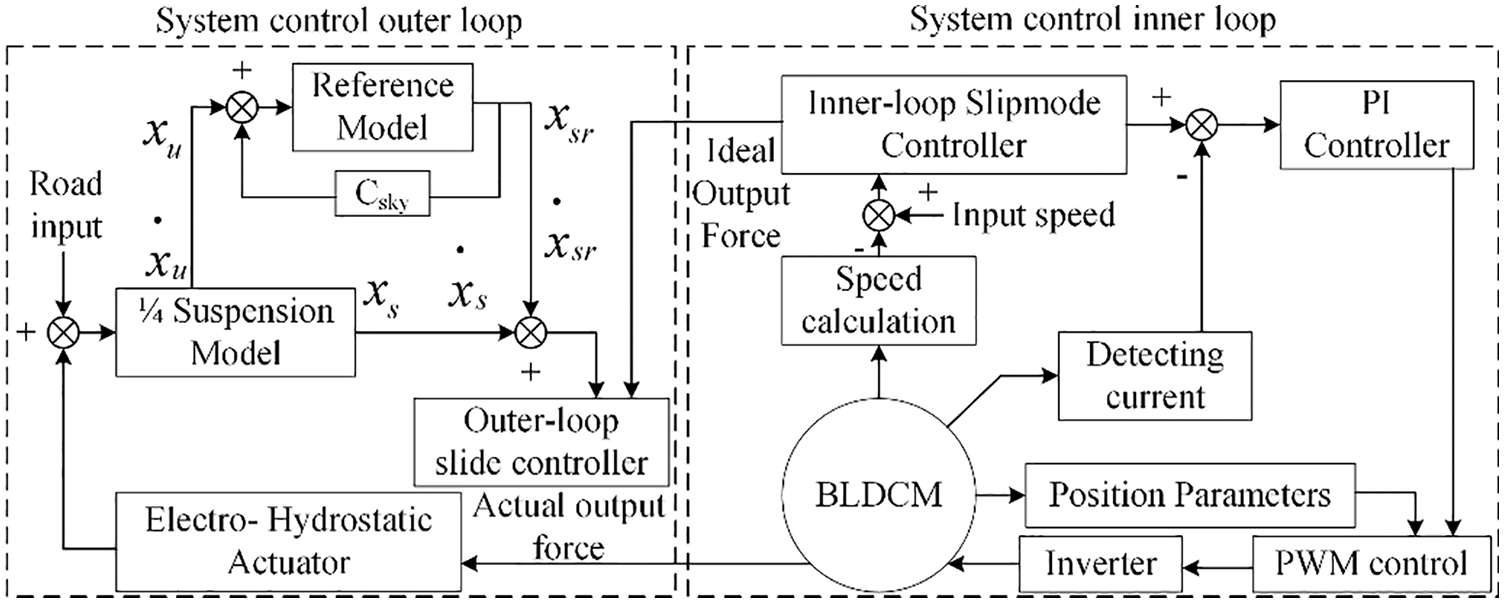

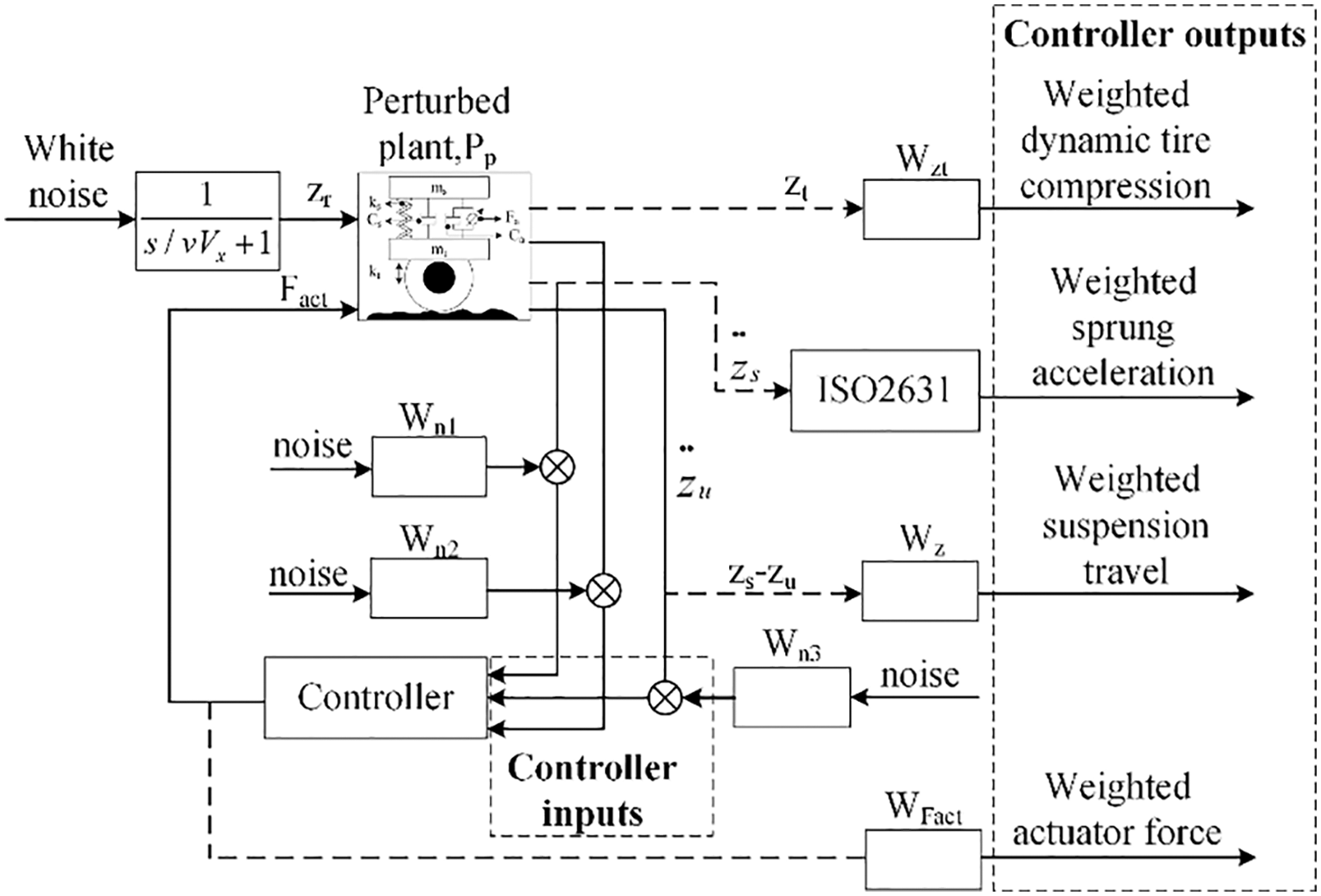

Electromagnetic energy regenerative suspension systems are nonlinear systems with bounded uncertain parameters, which can be transformed into robust problems with linear intervals. Thereby, the control performance of the electromagnetic energy regenerative suspension system is improved. Joo et al. [193] verified that the nonlinear feedback controller of the electromagnetic suspension system is robust to mass parameter perturbation and force perturbation. According to the working area of the actuator in the electromagnetic energy regenerative suspension, Zhang et al. [194] used robust control to design the controller of the vehicle suspension, and realized that the constraining strategy of the controller and the motor working area was consistent. Gysen et al. [195] considered the control of a novel high bandwidth electromagnetic active suspension system for a quarter car model in both simulations and experiments. They took white noise as the random road signal input to the system, and adopted an improved robust controller. The control principle was shown in Fig. 25. The improved robust controller achieved a comprehensive improvement in comfort performance and handling stability performance of the electromagnetic energy regenerative suspension system, with a 41.2% improvement in comfort and a 31.4% improvement in handling performance. Jibril et al. [196] combined H∞ and μ-synthesis to improve the acceleration and motion travel of the suspension and improve the road holding of the vehicle. Roinila et al. [197] designed and tested H∞(H) control structures suitable for cascade and direct control methods. On the premise of ensuring low energy consumption of the suspension system, the method broadens the control bandwidth of the system and improves the low-frequency performance of the suspension system. According to the performance requirements of the suspension system under fault conditions, Jeyasenthil et al. [198] had designed the robust controller on quantitative feedback theory. This controller had achieved similar performance to passive fault-tolerant control. The problem of dynamic performance in the state of electromagnetic energy regenerative suspension failure was solved, and the driving safety of the vehicle was ensured.

Figure 25: Schematics used for the design of robust control

Modern control methods have better suppression of nonlinear effects, uncertainty factors and environmental disturbances in electromagnetic energy regenerative suspension systems. They can realize the closed-loop stable control of the system, which makes up for the shortcomings of traditional control. And they have obvious advantages in improving the dynamic performance, energy regenerative performance and safety performance of the electromagnetic energy regenerative suspension system.

4.3 Intelligent Control Methods

The intelligent control method is a control method spanning multiple disciplines that have been continuously developed based on “classical control” and “modern control”, combined with advanced technologies in different fields [199]. The multidisciplinary coupling of the electromagnetic energy regenerative suspension system leads to the complexity of the modeling process, the increase of nonlinearity and uncertainty factors of the model, and the inability to obtain an accurate mathematical model. This makes it difficult to achieve optimal control of the electromagnetic energy regenerative suspension using previous control methods. Therefore, intelligent control methods such as fuzzy logic control, neural network control and model-free control have become the research hotspots in the field of electromagnetic energy regenerative suspension control. The use of intelligent control to handle the unknown dynamics of the electromagnetic energy regenerative suspension system is estimated to ensure the stability of the control system and to help improve the overall performance of the electromagnetic energy regenerative suspension system.

Neural network control has strong nonlinear approximation capability, self-learning capability, and the ability to obtain the corresponding neural network model according to the input and output characteristics of the controlled system. In the process of engineering application, there are uncertain factors in the complex model of the electromagnetic energy regenerative suspension system. Neural network control has strong fitting ability to uncertainty functions, especially for uncertain nonlinear systems, which ensures that the system has strong adaptability.

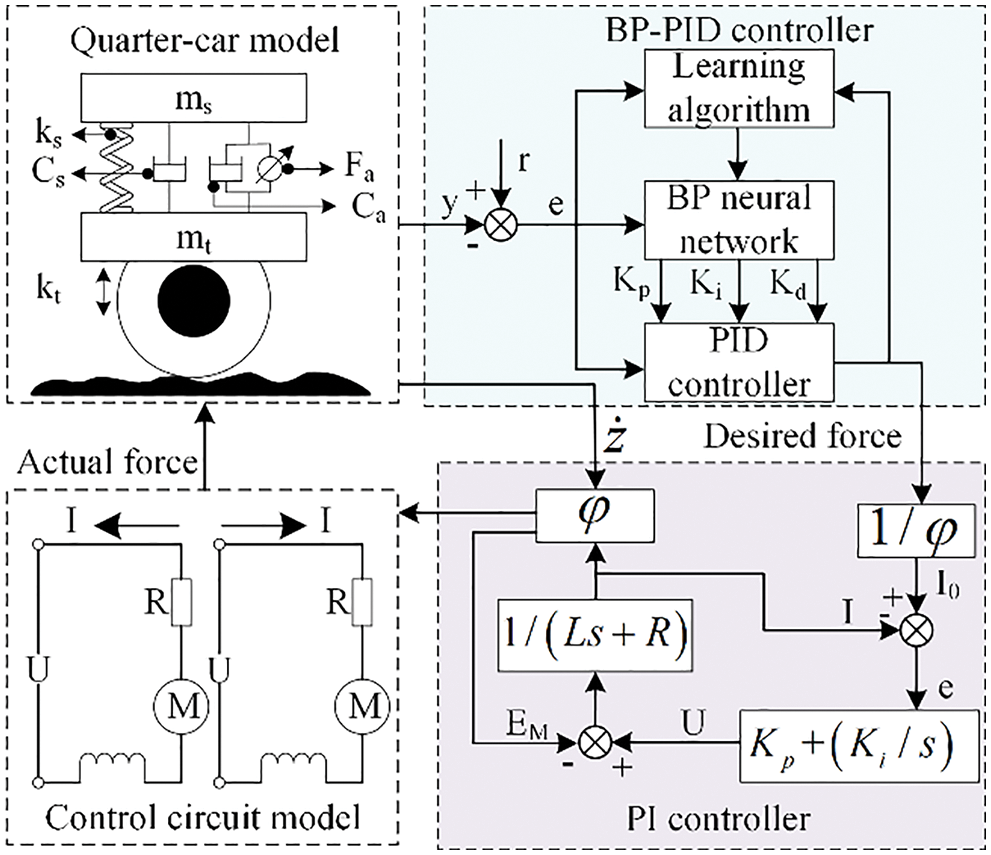

Liu et al. [200] used a convolutional neural network to identify the road type, which can adjust the controller parameters according to the output response of the suspension system under different road excitation, thus ensuring that the suspension maintains optimal performance under different road surfaces. Chen et al. [201] introduced a Boost/Buck type DC-DC converter in the circuit of the energy regenerative suspension system and designed an adaptive offline neural network inverse controller. The adaptive offline neural network inverse controller enables the electromagnetic damping force to better track the ideal force and improves the comfort and smoothness of the vehicle, but the regenerative efficiency is not significant. Liu et al. [202] designed a PID controller based on the BP neural network algorithm, as shown in Fig. 26, to perform PI control on the energy regenerative circuit. The energy regenerative suspension can effectively improve the vehicle performance under different input conditions; and the system can recover part of the suspension vibration energy, in which the energy regenerative efficiency is stable at about 55% and the energy regenerative efficiency is stable at about 16%.

Figure 26: Energy regenerative active suspension based on BP neural network PID control

Fuzzy control is an intelligent control algorithm developed based on Zade’s fuzzy set theory [203], which does not require a precise mathematical model and achieves good control effects by establishing expert experience in formulating fuzzy control rules.

Su et al. [204] applied the T-S fuzzy model to a nonlinear electromagnetic suspension system for the first time, and used a fuzzy state feedback controller to ensure that the required hybrid e2-e∞ performance of the electromagnetic suspension system was achieved. Choi et al. [205] used a T-S fuzzy control system to describe an extended system containing electromagnetic energy regenerative suspension and road disturbance information, and the resulting closed-loop electromagnetic energy regenerative suspension control system is asymptotically stable and has good robustness. Sivakumar et al. [206]. used a fuzzy controller to control the seven-degree-of-freedom suspension system, which reduced the body displacement and acceleration magnitude, eliminated the body-induced resonance peaks, and ensured the smoothness of the body. To make the vehicle achieve more stringent comfort, Mahmoodabadi et al. [207,208] proposed an optimal adaptive fuzzy controller based on a gravity search algorithm. The gravitational search algorithm optimizes the control parameters to reduce the acceleration of the body, the relative displacement between the tires and the sprung mass. To improve the control effect of the electromagnetic energy regenerative suspension based on the fuzzy control strategy, Kou et al. [209] designed a novel endocrine compound fuzzy control strategy, as shown in Fig. 27. The control effect of endocrine compound fuzzy control is better than fuzzy control, which improves the dynamic performance of the system and achieves vibration energy regeneration.

Figure 27: Control structure block diagram of endocrine composite fuzzy

Model-free control is not limited by the specific mathematical model of the system, and only uses the input and output data of the nonlinear system to be controlled to complete the real-time control of the system, improving the robustness of the controller in the energy regenerative suspension system [210].

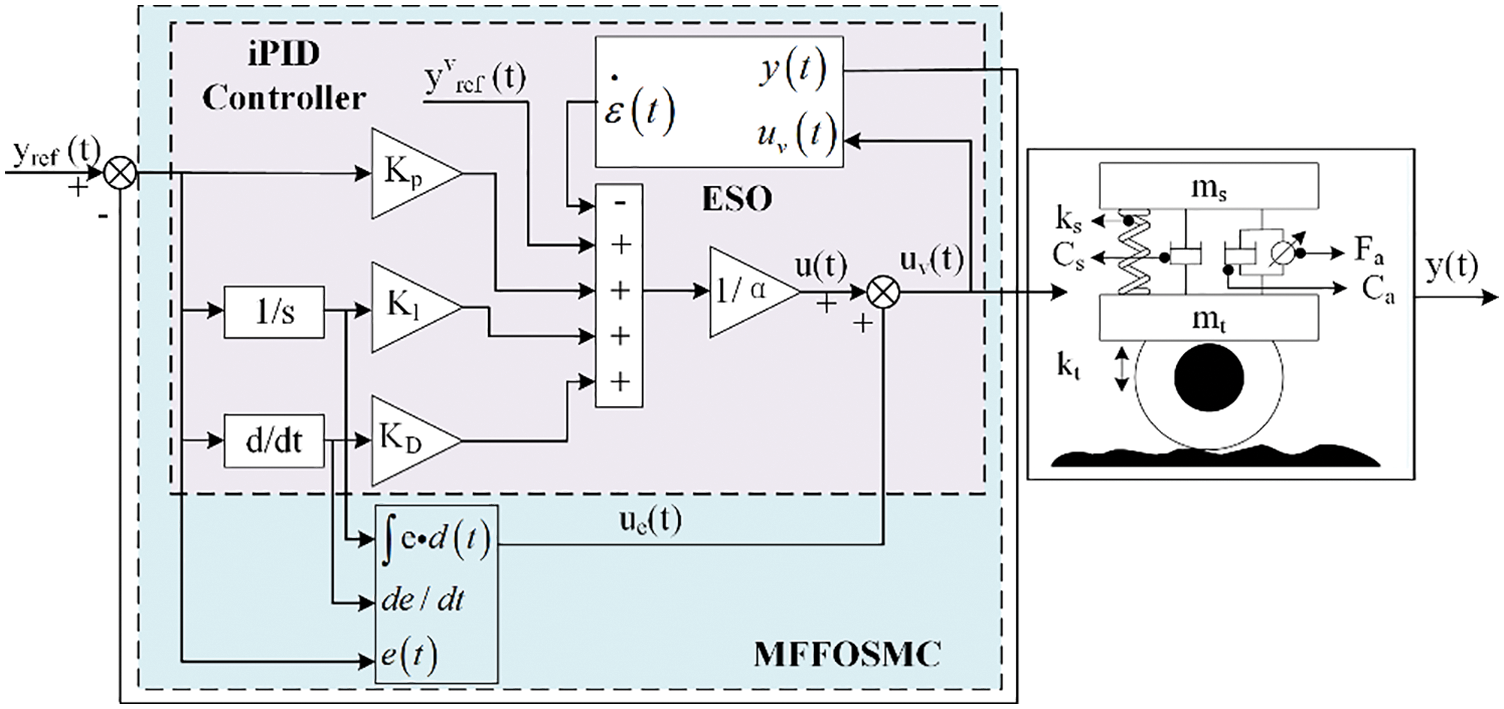

Yonezawa et al. [211–213] can achieve a model-free design that does not require an actual object model by designing a controller for a 2-DOF system consisting of actuators and virtual objects. The hybrid Eta(2)/Eta(∞) control theory is used to achieve high vibration control performance and robust stability against actuator uncertainty. Combined with sliding mode control theory, a controller that compensates for the uncertainty of actuator parameters is designed to improve the robustness of the system to the parameters of the actuator, thereby ensuring the vibration suppression performance of the system. Wang et al. [214] proposed a novel scheme of model-free finite-time tracking control methods to achieve the motion control of the active suspension system. They estimated the vertical dynamics of the suspension including external disturbances through the time-lapse estimation method. The error generated in the estimation process was compensated by the integral sliding mode control. In the process of model running, the combination of delay estimation method and integral sliding mode control method can effectively prevent the occurrence of jitter. x. Based on the contradictory relationship between the three performance indicators of the suspension (ride smoothness, suspension dynamic deflection and road holding), Ghazally Ibrahim Yousif Mustsfa used a model-free fractional order sliding mode control method, as shown in Fig. 28. This approach resolves the conflict between ride comfort and driving safety [215].

Figure 28: MFFOSMC control structure

Researchers using intelligent control technology can abstract the control problem of the electromagnetic energy regenerative suspension system, combined with artificial intelligence technology, coordinate the relationship between its system performance, and improve the comprehensive performance of the electromagnetic energy regenerative suspension system.