Open Access

Open Access

ARTICLE

An Isogeometric Cloth Simulation Based on Fast Projection Method

1 Department of Mechanical Engineering, Suzhou University of Science and Technology, Suzhou, 215009, China

2 Simshow High Technology Co., Ltd., Chengdu, 610042, China

3 Department of Mechanical and Industrial Engineering, The University of Iowa, Iowa City, IA 52242-1527, USA

* Corresponding Authors: Xuan Peng. Email: ; Chao Zheng. Email:

(This article belongs to the Special Issue: Recent Advance of the Isogeometric Boundary Element Method and its Applications)

Computer Modeling in Engineering & Sciences 2023, 134(3), 1837-1853. https://doi.org/10.32604/cmes.2022.022367

Received 07 March 2022; Accepted 21 April 2022; Issue published 20 September 2022

Abstract

A novel continuum-based fast projection scheme is proposed for cloth simulation. Cloth geometry is described by NURBS, and the dynamic response is modeled by a displacement-only Kirchhoff-Love shell element formulated directly on NURBS geometry. The fast projection method, which solves strain limiting as a constrained Lagrange problem, is extended to the continuum version. Numerical examples are studied to demonstrate the performance of the current scheme. The proposed approach can be applied to grids of arbitrary topology and can eliminate unrealistic over-stretching efficiently if compared to spring-based methodologies.Keywords

Cloth simulation has many practical applications, such as computer-aided garment design, character animation, and electronic e-commerce. Terzopoulos et al. [1] were among the first to develop a physical model for use in the simulation of cloth. Breen et al. [2–4] developed a spring-based model, and their initial motivation was to accurately represent complex fabric behaviors using nonlinear springs. Provot [5] modeled cloth by employing linear springs characterized by low stiffness and he achieved acceptable results with high efficiency. Eischen et al. [6] modeled cloth using finite-element shell theory. Baraff et al. [7] proposed to employ implicit time integration to increase the time step, while the Newton iteration was suggested to be halted at the first step to achieve high efficiency. Choi et al. [8] proposed an immediate buckling model to ensure that the Jacobi matrix in the implicit method was definite. Bridson et al. employed a velocity Verlet algorithm [9] to increase the time increment. In addition to the cloth model, the collision response was also largely improved. Baraff et al. [7] simulated collision as a velocity constraint and Bridson et al. [10] proposed a decoupled bullet-proof collision scheme.

The garment industry is now beginning to use virtual simulation for prototyping [11,12]. However, as reported in [13], there are still many challenges in the application of virtual simulation. One of the challenges is to develop a high-efficiency continuum approach. The continuum approach has many advantages over the spring-based approach. For example, the material properties of the continuum approach are independent of the topology of the grid. Another attraction of the continuum approach is that many studies of material and geometric nonlinearity have been conducted in this field. However, conventional finite-element shell theory has low efficiency due to two reasons: (1) it needs more degrees of freedom for the same grid, and (2) the collision response is more complex.

Another challenge of cloth simulation is how to efficiently enforce realistic strain on cloth. One of the characteristics of fabric is that the bending stiffness is far lower than the in-plane stiffness. A consequence of this property is that in-plane deformation of practical cloth in most cases is negligible if compared to the out-of-plane deformation. However, using high physical in-plane stiffness introduces significant difficulty in simulation. For explicit methods, higher in-plane stiffness requires smaller time increments. In Barraf et al. [7] semi-implicit method, the frictional damping is proportional to the in-plane stiffness. Thus, to reduce the computational burden, in many practical cloth simulations, the value of the in-plane stiffness is artificially reduced to enable the simulation of more complex problems in reasonable time. However, this approach can introduce unrealistic overstretching of the cloth.

To overcome this undesired side effect, Provot [5] proposed an explicit method of strain limiting that restores the over-stretched springs by adjusting the particle position directly. Because adjusting the position of one spring may result in over-stretching of another spring, an iteration is required. Both Jacobi and Gauss-Seidel iterations [10] are utilized, but neither one can guarantee convergence. Implicit methods of strain limiting have also been proposed [4,14]. These approaches are mainly based on the constrained Lagrange method and consider in-plane strain as a constraint condition. Goldenthal et al. [15] proposed a fast projection method that can solve the constrained Lagrange problem much more efficiently. The implicit method requires solving a linear system for each iteration, but it can converge very quickly. The fast projection method in [15] constrains the spring length of a weft and warp aligned quadrilateral grid, but this kind of grid is difficult to obtain for practical garments. To obtain a grid-independent strain-limiting scheme, one must resort to a continuum model. Studies of continuum-based strain limiting are limited at present. Thomaszewski et al. [16] proposed explicit strain limiting for triangular elements.

Isogeometric analysis has been proposed to bridge computer-aided design (CAD) and analysis seamlessly [17]. The IGA owns the salient features such as higher-order continuity and exact geometry preservation etc., which provides an effective solution for problems that conventional finite element methods are not proper qualified to solve [18–20], thus it has received much attention in many fields. For cloth simulation, a systematic method is proposed by the authors [21]. This method uses the rotational-free Kirchhoff-Love shell model [22,23], wherein CAD geometry is directly utilized in analysis. Recent developments in cloth-like simulation involve large deformation shells or membrane modeling [24–26]. The present work proposes a continuum version of a strain-limiting scheme by applying the fast projection method, such that the shell model for cloth simulation can be solved quickly with an acceptable resultant shape. Another advantage of this model is that it performs the simulation directly on the NURBS surface, which is widely implemented in CAD software. This property ensures the high fidelity of the simulated cloth and provides convenience of interactive design in three-dimensional (3D) space.

The rest of this paper is organized as follows. Section 2 briefly reviews the rotation-free Kirchhoff-Love Shell on a NURBS basis. Section 3 outlines the continuum-based fast projection method for (trimmed) NURBS geometry. Finally, four example problems are solved to validate the proposed approach and their results are presented in Section 4. Conclusions are presented in Section 5.

Kirchhoff-Love shell theory assumes the following:

• The normal to the undeformed middle surface remains straight and perpendicular to the deformed middle surface.

• The transverse normal stress is small compared with other normal stress components and may be neglected.

• The thickness of the shell is small compared to the other dimensions.

• The displacements of any given point on the shell are small in comparison to the thickness.

These assumptions are a good approximation for fabrics in which the energetic contribution from transverse shear is negligibly small compared to the bending and in-plane energy. Hence, the kinetics are completely characterized by the surface strain and curvature, which are determined by the surface geometry. For numerical computation, the theory can lead to a displacement-only formulation, which does not involve rotational degrees of freedom, thus increasing the efficiency of the method. A Kirchhoff-Love shell element is not commonly used in traditional finite-element analysis because constructing a

In the present NURBS Kirchkoff-Love shell element, the primary unknowns are the displacements of the control points. No rotational degree-of-freedoms are introduced.

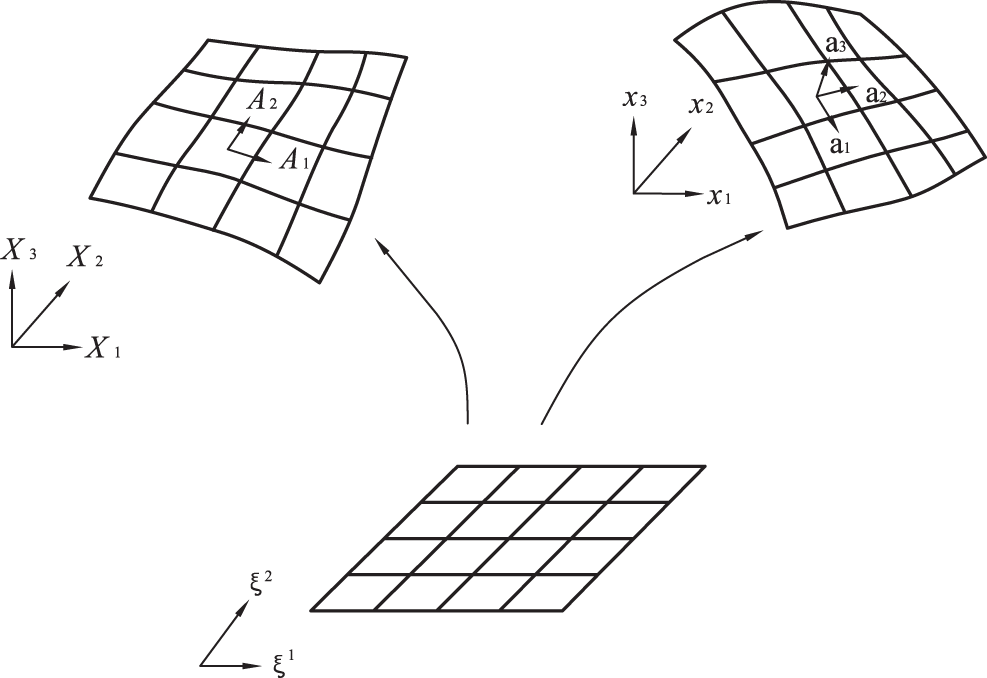

The NURBS formulation below follows that of Kiendl et al. [22]. We use the same set of NURBS basis functions to parameterize the reference and current configurations of the cloth surface:

Here, the

Figure 1: Illustration of shell kinematics

The unit normal

With respect to the convected basis vectors, the surface deformation tensor

respectively. The surface curvature tensor

It is convenient to use a local ortho-normal basis to perform the element computations presented later. To this end, we introduce a pair of orthonormal bases

Derivatives of a basis function N in local physical coordinates follow the chain rule:

In the current configuration, the bases (

With respect to the physical basis, the Green-Lagrangian strain assumes the form

The local bases

Cloth response is typically inelastic, exhibiting anisotropic properties and a small to moderate amount of hysteresis [27–29]. Since the focus of the present work is on geometry, we simplify the constitutive description by using an isotropic elastic model. The in-plane strain of fabrics is usually small (<2%); however, since large rotation is involved, the use of finite strain is necessary. Because of the small strain range, any mechanically sound finite-strain constitutive model should reasonably describe the in-plane response. Here, we use a linear anisotropic relation [7] between the (in-plane) Piola-Kirchhoff stress

in which I can be replaced by “weft,” “warp,” or “shear,” and

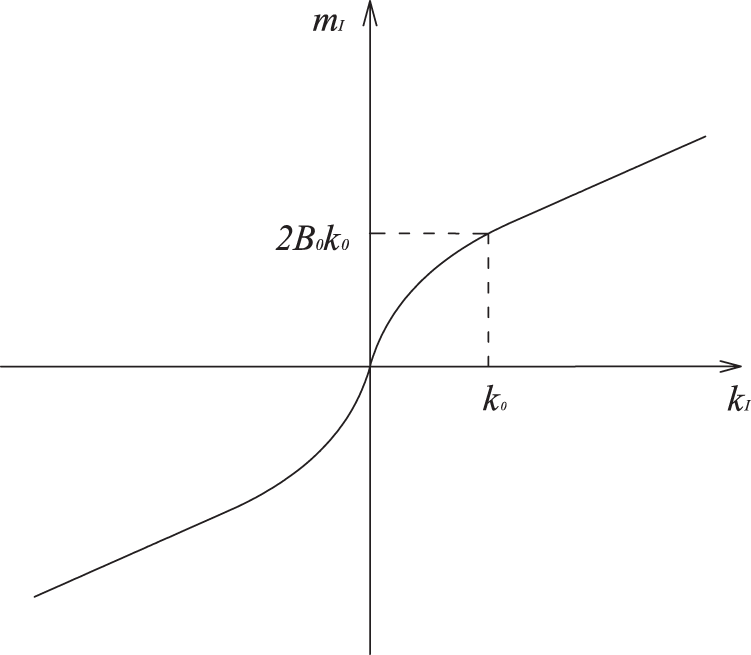

For the bending model, we employ a nonlinear bending function [29] for curvatures in weft and warp directions,

where I can be replaced by “weft” or “warp,” and

Figure 2: Moment-curvature curve in principal space

External forces acting on a piece of cloth normally include a body force

In the NURBS representation,

where

where

Similarly, from the definition of curvature, we can derive

where

In the above,

Substituting Eqs. (11), (12), and (14) into Eq. (10) yields the discrete dynamic equation

where

For low-speed air drag, we assume that

Our strain-limiting scheme is independent of time integration. Here, we use the velocity Verlet scheme that was first applied to cloth simulation by [9]. The flow process for time integration is as follows:

1. Predict average velocity and candidate configuration at

2. Compute

3 Continuum-Based Fast Projection Method

3.1 Constrained Lagrange Method

The fast projection method begins with the constrained Lagrange problem. For the general coordinates

in which

The Euler-Lagrange equation is:

Thus, we have,

Supposing that we check the constraint condition at the end of a time step,

Now, we use the splitter:

1. Predict candidate configuration

This sub-step can be replaced by any time-integration scheme.

2. Correct the candidate configuration by

Eqs. (25a) and (25b) are equivalent to

The second term of W projects

Linearizing Eqs. (25a) and (25b) by the Newton method, we have the following flow process:

1. Solve

2. Correct

The iteration exits when the

We note that Eq. (25a) keeps the property of “closest” and Eq. (25b) keeps the constraint conditions. In the actual problem, we have a high requirement on constraint conditions but a low requirement on the property of “closest.” Goldenthal et al. [15] suggested solving Eq. (25a) using the Euler method while solving Eq. (25b) using the Newton method. We expand

Substituting Eq. (29) into Eq. (25a) yields

Eq. (25b) is still linearized by the Newton method

Substituting Eq. (30) into Eq. (31) yields the basic equation of the fast projection method

The iterative fast projection process flow is as follows:

1. Solve

2. Correct

The iteration exits when the

3.3 Spring-Based Fast Projection

For the spring-mass method, the length of each spring is a constraint,

in which

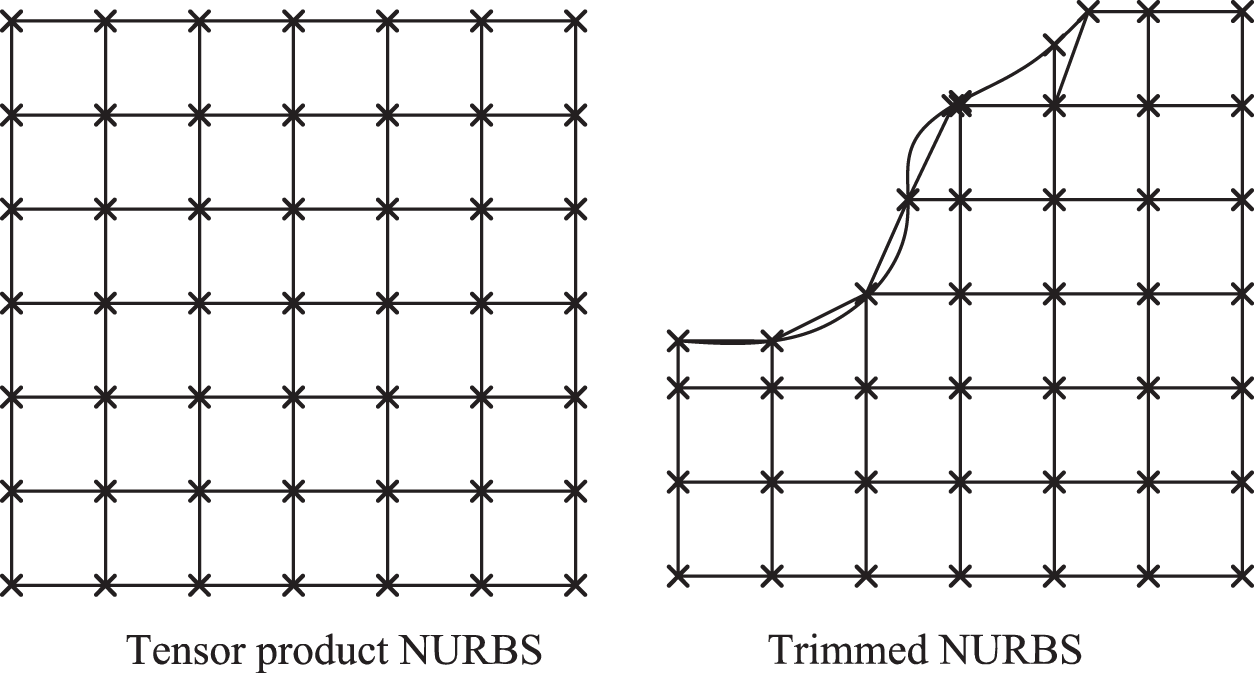

3.4 Continuum-Based Fast Projection

For the continuum-based approach, the first task is to select sampling points. We tried to select the Gaussian points as sampling points, but that does not work well. Because the number of cells are close to the number of control points, and if there are three or more constraint conditions on each cell, the model will be locked. Thus,

Figure 3: Constraint points

The constraint condition

in which

The constraint energy term

where

However, we found a checkerboard pattern in the values of

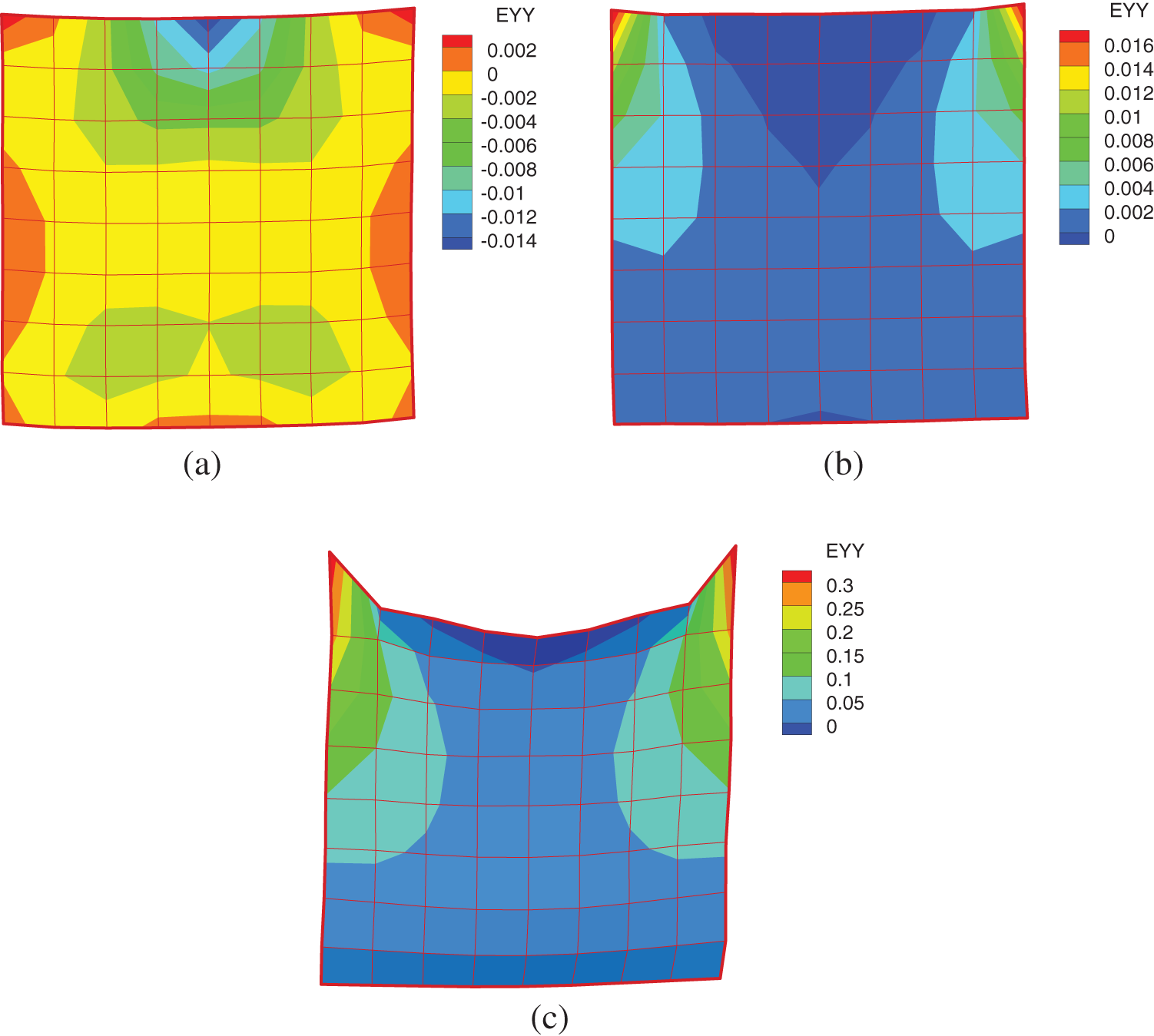

A piece of cloth in the x-y plane is subject to constraints at two corners and will swing under gravity in the z direction. The cloth is represented by a second-order NURBS patch with 100 control points. The bending parameters are

The simulation results of different Young’s moduli at

Figure 4: Corner kidnapped cloth at t = 0.6 for cases (a)–(c)

The draping of a soft armor was simulated in this example. The armor is represented by a second-order NURBS patch with 1,616 control points. The initial configuration is obtained by virtual try-on simulation and is shown in Fig. 5. The bending parameters are

Figure 5: Initial configuration of soft armor

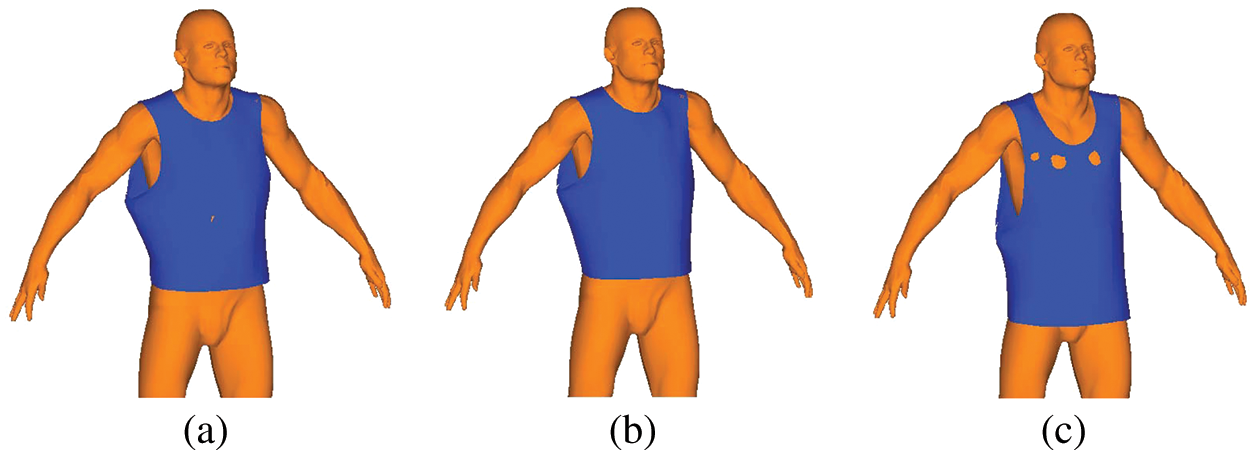

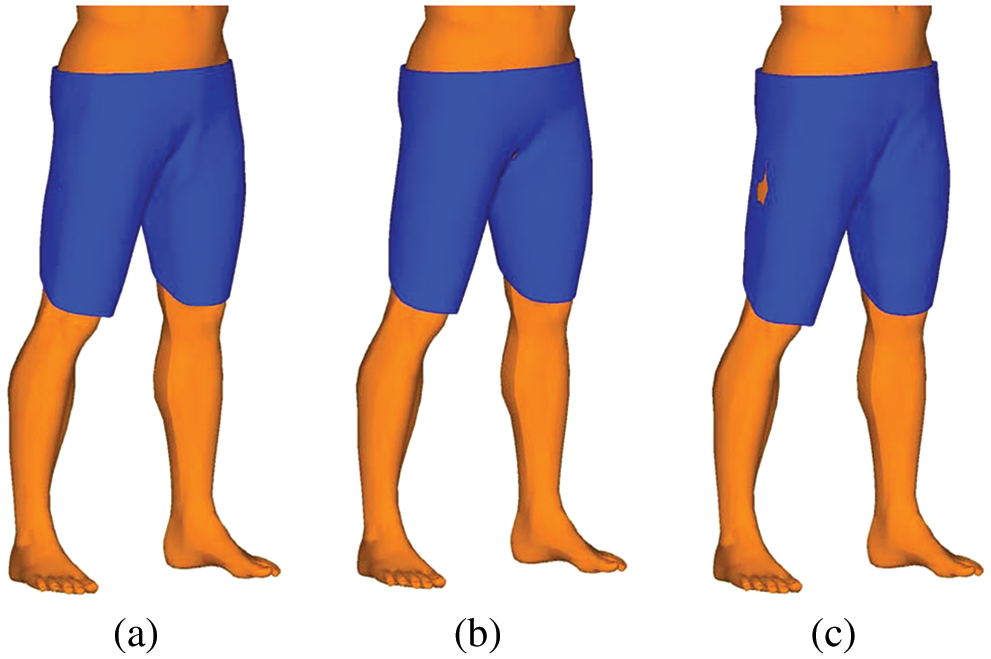

To more clearly show the results, the simulation results of upper- and lower-body armor at

Figure 6: Upper-body armor after draping simulation for cases (a)–(c)

Figure 7: Lower-body armor after draping simulation for cases (a)–(c)

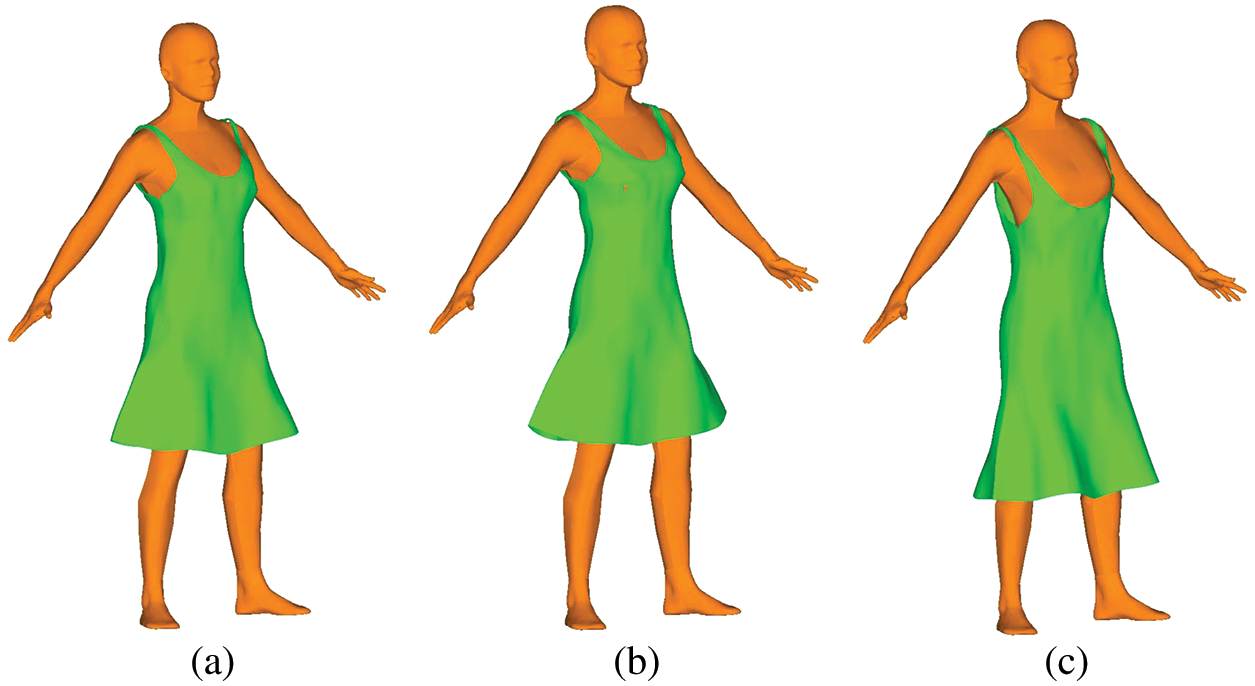

This example simulates the draping process of a skirt. The initial configuration of the skirt is obtained by a try-on simulation and is shown in Fig. 8. The entire model contains 960 control points. The woman’s body is represented by a discrete mesh of 17,068 cells. The bending parameters are

Figure 8: Initial configuration of skirt

The garment shape at

Figure 9: Skirt after draping simulation for cases (a)–(c)

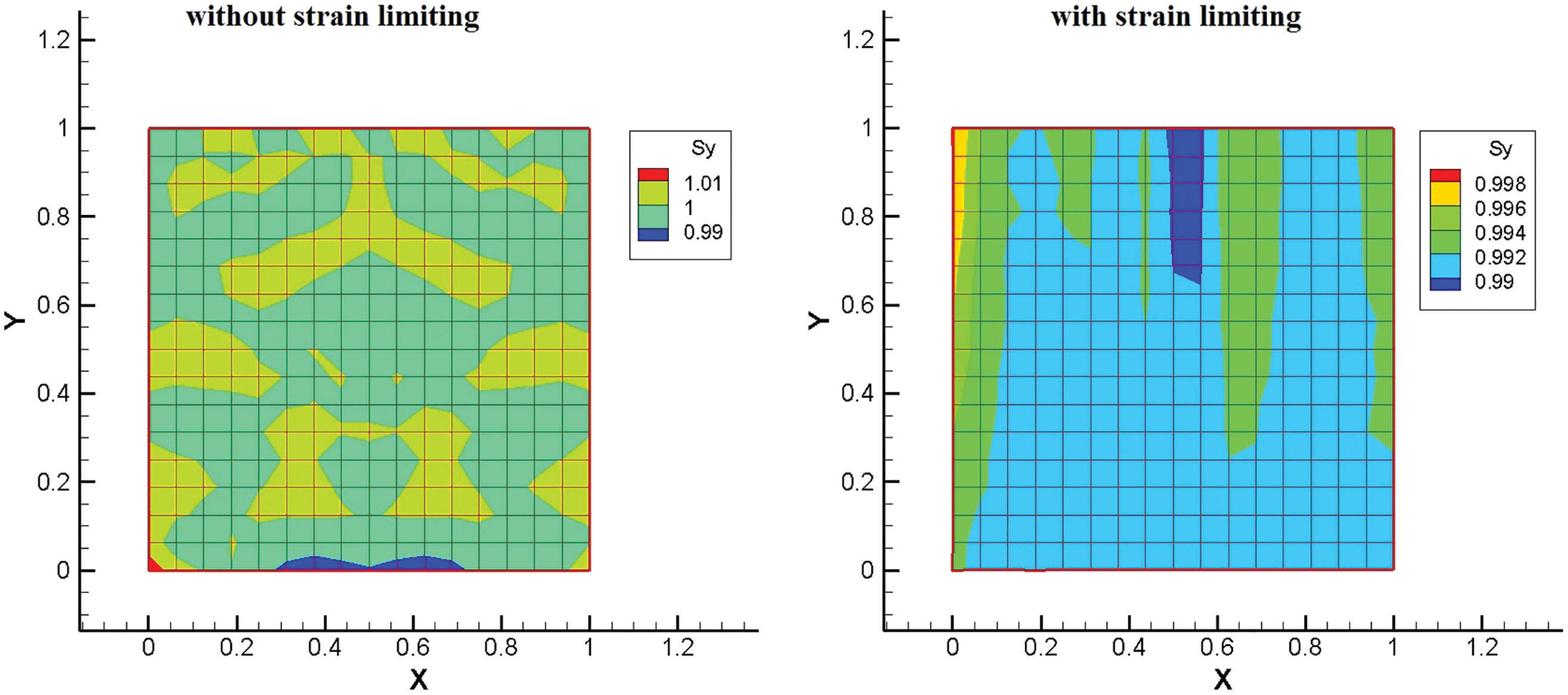

Finally, we conducted a standard patch test to check the stress obtained from the fast projection method. A 1 m-by−1 m square was fixed on the top edge and we applied 1 N/m of uniform force on the bottom edge. As the problem itself is based on dynamic analysis, we modeled the static patch test by applying a large damping factor and waiting until the vibration was damped out. Fig. 10 shows the static stress obtained from analysis with or without the fast projection method. It is observed that for both cases the stresses are close to 1 Pa, which means that the fast projection method cannot only eliminate unrealistic strain, but can also provide a reliable stress field.

Figure 10: Patch test stress

In this work, a rotational-free Kirchhoff-Love shell-based isogeometric analysis was outlined for cloth simulation. To overcome the numerical burden caused by high in-plane stiffness, a continuum version of the fast projection method was applied. The highlights of this work are the following:

• Compared with spring-based models, the constraint directions of strain limiting are independent of grid lines. This implies that the fast projection method can be applied to a grid with arbitrary topology.

• Examples show that the present scheme can eliminate unrealistic over-stretching efficiently, while the stress field remains reliable.

• The trimmed NURBS patches are used directly for geometry, indicating seamless application of CAD and analysis.

Future work will focus on developments of efficient numerical methods to handle localized features, e.g., wrinkles, to facilitate a “real-time” simulation of cloth.

Funding Statement: Chao Zheng thanks the support from Sichuan Science and Technology Program [Grant No. 2021JDRC0007].

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Terzopoulos, D., Platt, J., Barr, A., Fleischer, K. (1987). Elastically deformable models. Proceedings of the 14th Annual Conference on Computer Graphics and Interactive Techniques, pp. 205–214. New York, USA. [Google Scholar]

2. Breen, D., House, D., Getto, P. (1992). A physically based particle model of woven cloth. The Visual Computer, 8, 264–277. DOI 10.1007/BF01897114. [Google Scholar] [CrossRef]

3. Breen, D., House, D., Wozny, M. (1994). Predicting the drape of woven cloth using interacitng particles. Proceeding of the 21th Annual Conference on Computer Graphics and Interactive Techniques, pp. 365–372, New York, USA. [Google Scholar]

4. House, D., Devaul, R. W., Breen, D. E. (1996). Towards simulating cloth dynamics using interacting particles. International Journal of Clothing Science and Technology, 8, 75–94. DOI 10.1108/09556229610147959. [Google Scholar] [CrossRef]

5. Provot, X. (1995). Deformation constrains in a mass-spring model to describe rigid cloth behavior, pp. 147–154. New York, USA: Canadian Human-Computer Communication Society. [Google Scholar]

6. Eischen, J., Deng, S., Clapp, T. (1996). Finite-element modeling and control of flexible fabric parts. IEEE Computer Graphics and Applications, 16(5), 71–80. DOI 10.1109/38.536277. [Google Scholar] [CrossRef]

7. Baraff, D., Witkin, A. (1998). Large steps in cloth simulation. Proceeding of the 25th Annual Conference on Computer Graphics and Interactive Techniques, pp. 43–54. New York, USA. [Google Scholar]

8. Choi, K. J., Ko, H. S. (2002). Stable but responsive cloth. Proceedings of the 29th Annual Conference on Computer Graphics and Interactive Techniques, pp. 604–611. New York, USA. [Google Scholar]

9. Bridson, R., Marino, S., Fedkiw, R. (2003). Simulation of clothing with folds and wrinkles. Proceedings of the 2003 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, pp. 28–36. Goslar, DEU. [Google Scholar]

10. Bridson, R., Fedkiw, R., Anderson, J. (2002). Robust treatment of collisions, contact and friction for cloth animation. ACM Transactions on Graphics, 21, 594–603. DOI 10.1145/566654.566623. [Google Scholar] [CrossRef]

11. Keckeisen, M., Stoev, S. L., Feurer, M., Strasser, W. (2003). Interactive cloth simulation in virtual environments. Proceedings of the IEEE Virtual Reality, vol. 2003, pp. 71–78. USA. [Google Scholar]

12. Volino, P., Cordier, F., Magnenat-Thalmann, N. (2005). From early virtual garment simulation to interactive fashion design. Computer-Aided Design, 37(6), 593–608. DOI 10.1016/j.cad.2004.09.003. [Google Scholar] [CrossRef]

13. Jin Choi, K., Seok Ko, H. (2005). Research problems in clothing simulation. Computer-Aided Design, 37, 585–592. [Google Scholar]

14. Hong, M., Choi, M. H., Jung, S., Welch, S., Trapp, J. (2005). Effective constrained dynamic simulation using implicit constraint enforcement. Proceedings of the 2005 IEEE International Conference on Robotics and Automation, pp. 4520–4525. Barcelona, Spain. [Google Scholar]

15. Goldenthal, R., Harmon, D., Fattal, R., Bercovier, M., Grinspun, E. (2007). Efficient simulation of inextensible cloth. ACM Transactions on Graphics, 26(3), 49–57. [Google Scholar]

16. Thomaszewski, B., Pabst, S., Strasser, W. (2009). Continuum-based strain limiting. Computer Graphics Forum, 28(2), 569–576. DOI 10.1111/j.1467-8659.2009.01397.x. [Google Scholar] [CrossRef]

17. Hughes, T. J. R., Cottrell, J. A., Bazilevs, Y. (2005). Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Computer Methods in Applied Mechanics and Engineering, 194, 4135–4195. DOI 10.1016/j.cma.2004.10.008. [Google Scholar] [CrossRef]

18. Wu, S. C., Peng, X., Zhang, W. H., Bordas, S. P. A. (2013). The virtual node polygonal element method for nonlinear thermal analysis with application to hybrid laser welding. International Journal of Heat and Mass Transfer, 67, 1247–1254. DOI 10.1016/j.ijheatmasstransfer.2013.08.062. [Google Scholar] [CrossRef]

19. Peng, X., Lian, H., Ma, Z., Zheng, C. (2022). Intrinsic extended isogeometric analysis with emphasis on capturing high gradients or singularities. Engineering Analysis with Boundary Elements, 134, 231–240. DOI 10.1016/j.enganabound.2021.09.022. [Google Scholar] [CrossRef]

20. Nguyen, V. P., Anitescu, C., Bordas, S. P. A., Rabczuk, T. (2015). Isogeometric analysis: An overview and computer implementation aspects. Mathematics and Computers in Simulation, 117, 89–116. DOI 10.1016/j.matcom.2015.05.008. [Google Scholar] [CrossRef]

21. Lu, J., Zheng, C. (2014). Dynamic cloth simulation by isogeometric analysis. Computer Methods in Applied Mechanics and Engineering, 268, 475–493. DOI 10.1016/j.cma.2013.09.016. [Google Scholar] [CrossRef]

22. Kiendl, J., Bletzinger, K. U., Linhard, J., Wüchner, R. (2009). Isogeometric shell analysis with kirchhoff-love elements. Computer Methods in Applied Mechanics and Engineering, 198, 3902–3914. DOI 10.1016/j.cma.2009.08.013. [Google Scholar] [CrossRef]

23. Benson, D., Bazilevs, Y., Hsu, M., Hughes, J. (2010). Isogeometric shell analysis: The reissner-mindlin shell. Computer Methods in Applied Mechanics and Engineering, 199, 276–289. DOI 10.1016/j.cma.2009.05.011. [Google Scholar] [CrossRef]

24. Chen, L., Nguyen-Thanh, N., Nguyen-Xuan, H., Rabczuk, T., Bordas, S. P. A. et al. (2014). Explicit finite deformation analysis of isogeometric membranes. Computer Methods in Applied Mechanics and Engineering, 277, 104–130. DOI 10.1016/j.cma.2014.04.015. [Google Scholar] [CrossRef]

25. Shin, S. G., Lee, C. O. (2020). Splitting basis techniques in cloth simulation by isogeometric analysis. Computer Methods in Applied Mechanics and Engineering, 362, 112871. DOI 10.1016/j.cma.2020.112871. [Google Scholar] [CrossRef]

26. Nakashino, K., Nordmark, A., Eriksson, A. (2020). Geometrically nonlinear isogeometric analysis of a partly wrinkled membrane structure. Computers & Structures, 239, 106302. DOI 10.1016/j.compstruc.2020.106302. [Google Scholar] [CrossRef]

27. Peng, X., Cao, J. (2005). A continuum mechanics-based non-orthogonal constitutive model for woven composite fabrics. Composites: Part A, 36, 859–874. DOI 10.1016/j.compositesa.2004.08.008. [Google Scholar] [CrossRef]

28. Lahey, T. J., Heppler, G. R. (2004). Mechanical modeling of fabrics in bending. Transactions of the ASME, 71, 32–40. DOI 10.1115/1.1629757. [Google Scholar] [CrossRef]

29. Abbott, G., Grosberg, P., Leaf, G. (1971). The mechanical properties of woven fabrics, Part VII: The hysteresis during bending of woven fabrics. Textile Research Journal, 41, 345–358. DOI 10.1177/004051757104100411. [Google Scholar] [CrossRef]

30. Kawabata, S. (1980). The standardization and analysis of hand evaluation. Osaka: The Textile Machinery Society of Japan. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools