Open Access

Open Access

ARTICLE

Optimization of Charging/Battery-Swap Station Location of Electric Vehicles with an Improved Genetic Algorithm-Based Model

1 Beijing University of Posts and Telecommunications, Beijing, 100876, China

2 PLA Army Academy of Artillery and Air Defense, Zhengzhou, 450000, China

3 Beijing Information Science and Technology University, Beijing, 100192, China

* Corresponding Author: Bida Zhang. Email:

(This article belongs to the Special Issue: Artificial Intelligence in Renewable Energy and Storage Systems)

Computer Modeling in Engineering & Sciences 2023, 134(2), 1177-1194. https://doi.org/10.32604/cmes.2022.022089

Received 20 February 2022; Accepted 08 April 2022; Issue published 31 August 2022

Abstract

The joint location planning of charging/battery-swap facilities for electric vehicles is a complex problem. Considering the differences between these two modes of power replenishment, we constructed a joint location-planning model to minimize construction and operation costs, user costs, and user satisfaction-related penalty costs. We designed an improved genetic algorithm that changes the crossover rate using the fitness value, memorizes, and transfers excellent genes. In addition, the present model addresses the problem of “premature convergence” in conventional genetic algorithms. A simulated example revealed that our proposed model could provide a basis for optimized location planning of charging/battery-swapping facilities at different levels under different charging modes with an improved computing efficiency. The example also proved that meeting more demand for power supply of electric vehicles does not necessarily mean increasing the sites of charging/battery-swap stations. Instead, optimizing the level and location planning of charging/battery-swap stations can maximize the investment profit. The proposed model can provide a reference for the government and enterprises to better plan the location of charging/battery-swap facilities. Hence, it is of both theoretical and practical value.Keywords

With the ever-growing energy consumption and increase in the environmental effects of fossil-fuel based energy sources, the use of collection technology of clean energies has undergone a remarkable growth in the Chinese market [1]. In 2020, the ownership of electric vehicles (EVs) in China reached approximately 4.5 million, which is expected to exceed 21 million by 2025, and 65 million by 2030. The number of battery-swap EVs has also exhibited an evident growth tendency. In fact, the number of EVs in 2021 was 155,900, an increase of more than 30% compared to that of 2019, including approximately 79,000 private passenger vehicles, accounting for nearly 50%. With the advancement of wind energy, solar energy, and other new energy industries, the demand for energy storage systems is worth increasing [2]. Moreover, as reported by the Chinese Electric Vehicle Charging Infrastructure Promotion Alliance, the number of charging facilities (public and private) reached 1.87 million nationwide in May 2021, marking a 43.9% annual growth. Nevertheless, half of the owners of EVs have no household charging piles and must rely on public charging facilities. As the central government proposed the need to “increase the number of charging piles and battery-swap stations” in China’s Government Work Report, for the first time in March 2021, battery-swap stations have gained popularity and been promoted along with fast-charging facilities. The two modes of power replenishment (i.e., charging and battery swap) are expected to develop together in the future.

However, power replenishment systems for EVs still face several challenges. First, the total number of available facilities is still lower than the demand, despite the fact of increasing initiatives to build more charging/battery-swap facilities. In addition, existing facilities often suffer from low utilization rates and poor customer perception because of spatial and temporal randomness and uncertainty in the need for power replenishment [3]. The conflicts between the increasing need for EVs, power replenishment, and the limited investments in charging/battery-swapping facilities have curbed the development of EVs. Therefore, an efficient method to optimize the location planning of charging/battery-swap facilities, improve their utilization, and enhance customers’ perception is required.

Research on methods for optimized location planning of charging/battery-swap stations has advanced. Cheng et al. [4] proposed a cost minimization model that considered the investments of charging networks, depreciation costs for EVs, and investments in power distribution networks. Yang et al. [5] established a new multi-target model that aimed at minimizing the construction cost of charging piles and maximizing the average capacity of charging stations. Song et al. [6] proposed a location selection method for fast-charging stations that considered the operators, drivers, vehicles, traffic flows, and power grids. Existing works on the location planning of charging/battery-swap stations mainly focused on one or multiple of the following aspects: the income of the power grid operator [7,8], investment in charging facilities [9,10], user costs [11,12], and new types of energy storage devices [13,14]. Most reported studies have created a location optimization problem with the following objectives: minimum cost, maximum fulfillment of needs, and maximum efficiency. Many achievements have been reported from various investigations regarding location planning methods of charging and battery-swap stations. However, no reports have explored the simultaneous location planning of fast-charging and battery-swap stations to achieve effective coordination between these two types of charging facilities. In the present work, we considered the location selection problem of these two types of facilities and established a joint location planning model of charging/battery-swap facilities to minimize the sum of construction, operation, charging, traveling, and penalty costs.

Location selection modeling is a complicated optimization problem that makes it almost impractical to use the traditional linear algorithm [15]. The global optimal solution is difficult to be obtained by predominantly adopting heuristic algorithms such as the particle swarm optimization (PSO) [16], genetic (GA) [17], firefly [18], simulated annealing [19], artificial neural network [20], and improved algorithms [21]. Standard heuristic algorithms cannot provide an accurate and efficient solution to the joint location-selection modeling problem of charging/battery-swap facilities. For example, in the GA, the population diversity decreases after selection, and the population presents phenotype consistency during convergence, resulting in premature convergence. Two optimization solutions have been reported to address this problem. First, before the first round of inheritance, the operators are modified or upgraded under the premise that the individual with the largest fitness value has a high probability of being selected [22–24]. The second solution is to introduce a new notion after the first round of inheritance or use the population maturity degree as an indicator to evaluate whether the algorithm prematurely converges and hence improve the inheritance strategy [25,26]. However, the improved GAs proposed in previous studies are not suitable for the combined optimization problem of complicated systems that consider the location selection of both charging and battery-swap facilities. Although many studies have focused on the location planning of charging and battery-swap stations, very few have combined these two in location selection. To fill this research gap, in this work, we constructed a model for location planning including both charging and battery-swap facilities to optimize the level and location planning of charging/battery-swap stations and to maximize the investment profit.

2 Model Description and Construction

In addition to differences in the investment and operation costs, charging and battery-swap facilities also differ in their selection of locations. As the investors vary, we considered only fast-charging/battery-swap facilities. When planning the locations of the charging/battery-swap facilities, the demand for power replenishment of EVs drivers must be met. Simultaneously, the social costs should be minimized, including the station construction, operation, and driver’s energy replenishment costs. Thus, the following three objectives should be considered in the construction of the location planning model:

(1) Minimizing the gross cost of construction and operation of charging/battery-swap facilities;

(2) Minimizing the driver’s traveling costs, including the time and fees spent on driving, charging, and waiting;

(3) Minimizing the penalty cost (i.e., minimizing the EV driver’s dissatisfaction), which involves two scenarios. First, when all charging piles are occupied, some drivers would leave. This results in a reduced customer perception. Second, the proportion of the overall battery-swap facilities is low (for both types of charging facilities). Because of the large traveling distances between battery-swap stations, drivers may opt for the fast-charging piles for power replenishment, which also results in a lower customer perception.

(1) In the network, there are two types of fast-charging facilities: fast-charging stations (40–60 min for a full charge) and battery-swap stations (3–5 min for a full charge);

(2) There are two types of EVs in the road network: the charging and battery-swap types. The charging type can only be recharged by fast-charging piles, whereas battery-swap EVs can be recharged by either fast-charging piles or battery-swap stations;

(3) Regardless of the traffic conditions and driver habits, power consumption has a simple linear correlation with the driving distance;

(4) Given the limited capacity of a charging station, when the number of vehicles exceeds the number of charging piles in the station, there are considerable waiting times. However, the swap process is quick and no waiting time is incurred.

2.2.1 Construction and Operation Cost

(1) Level of charging/battery-swap stations

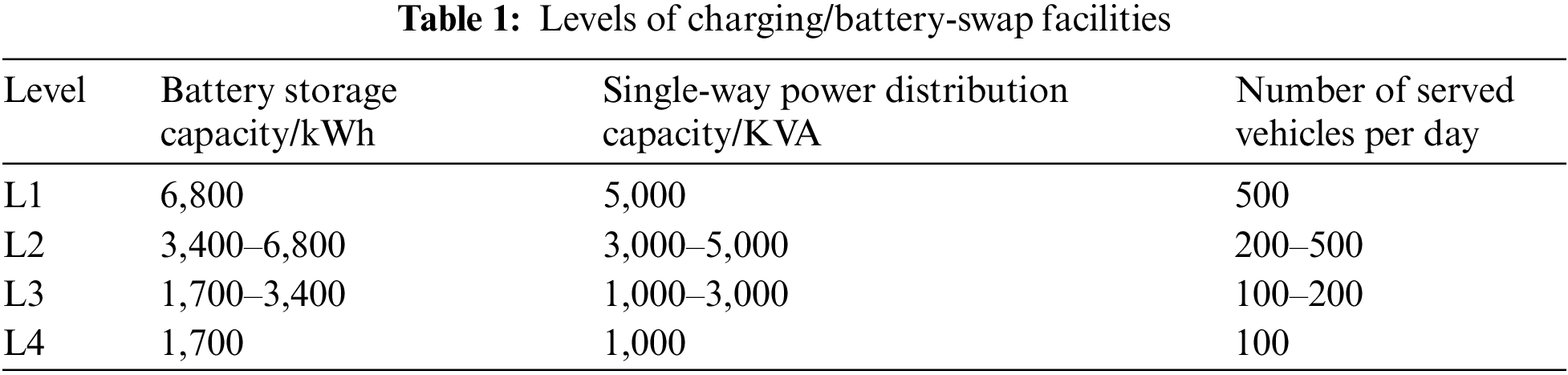

According to the “Technical Specifications of Electricity Supply and Assurance for Electric Vehicle: Electric Vehicle Charging Station” [27] released by the government of Beijing, charging stations for EVs can be classified into four levels with different battery storage, single-way power distribution, and daily service capacities. Table 1 shows the division of these levels.

(2) Construction cost

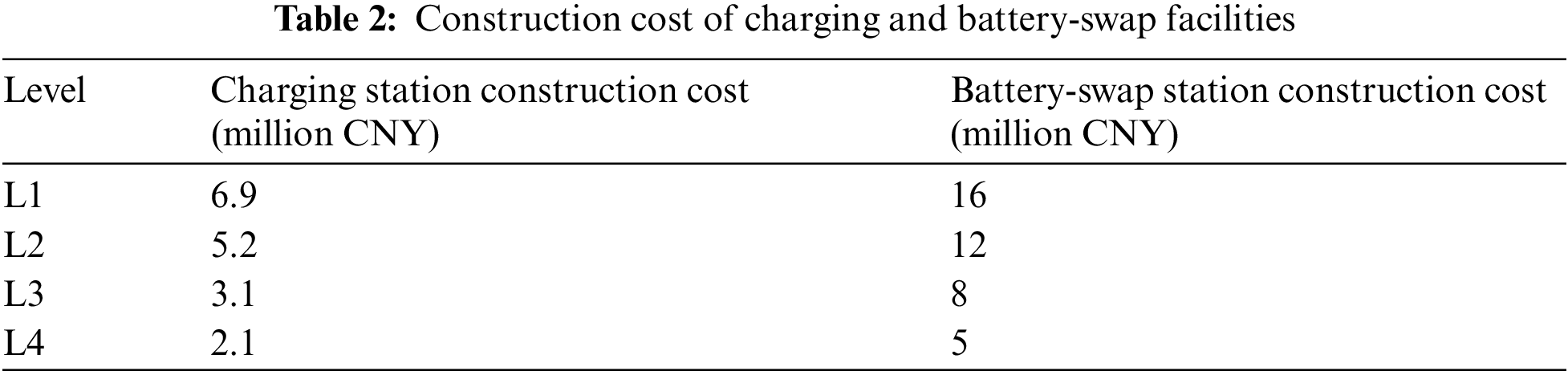

In the construction of charging/battery-swap stations, costs include land and facility costs, where the facility cost involves spending on the power distribution system and the charging/battery-swap system. For battery-swap stations, additional large-scale batteries must be installed. Based on the notions of discount rate and depreciable life, the costs for the construction of fast-charging and battery-swap stations are expressed as

where

(3) Operation cost

The operation cost consists of the labor, material, and maintenance costs, which are calculated based on the construction costs. We assume that the conversion coefficient between the operation cost and the construction cost is

The time cost of users for charging-type EVs consists of three parts: the driving, charging, and waiting times. In battery-swap vehicles, the time cost of users mainly refers to the driving time, whereas the time for battery swapping and waiting is largely negligible, and the time required for battery swapping is irrelevant to the remaining power of the EV.

(1) Vehicle types

Based on the service purposes, the EVs are divided into two categories: passengers’ EVs (private cars and operating vehicles) and commercial EVs (logistics vehicles and buses). They differ in terms of the frequency and method of power replenishment.

A. Private cars distributed in residential and office areas mainly rely on public power replenishment stations to recharge slowly. Charging-type vehicles rely on fast-charging piles to recharge, and the charging time varies with the remaining electricity, power rate of the charging piles, and user’s expectation of fully charging the vehicle or not. Battery-swap vehicles mainly rely on battery-swap facilities. However, if the time required by the battery-swap vehicle at site i to reach the nearest swap station exceeds the time it takes to reach the closest charging station plus the waiting time, there is a probability (

where

where the average waiting time at charging station j is

B. Operating vehicles, including taxis and online-hailing cars, rely primarily on public charging stations. In scheduled rotations, the operating vehicles often do not have considerable time to stay at the station for charging; thus, when they are short of electricity, they will need quick charging, depending on fast charging or battery swaps for power replenishment.

C. Commercial vehicles generally rely on charging stations specifically built by the vehicle operators; hence, this type of vehicle is not considered in the present work.

(2) Waiting cost

In the fast-charging service, the EVs conform to the hybrid multi-server queuing model (M/M/s/K), that is, the arrival time of the drivers conforms to the negative exponential distribution of the parameter

where

Owing to limited system space, the effective arrival rate of customers (

Then, using the formula for Little’s law, we obtain the expected queuing and waiting times. The average waiting time of a vehicle at charging station j is

(3) Traveling cost power replenishment costs

A. The traveling costs of EVs requiring fast charging and battery swaps are denoted as

where

B. The electricity cost for traveling and power replenishment was also considered in the overall cost. In the case of EVs that rely on fast charging, the electricity cost for traveling is

A. In the case of vehicles that rely on fast charging, we must consider the customer’s loss caused by the limited system capacity and the corresponding penalty cost. The penalty cost is calculated based on the traveling time and power replenishment costs:

B. As the vehicles that rely on battery swaps account for a small proportion of the total number of EVs, a scenario in which a penalty cost is incurred when the driver opts for the fast-charging station instead of the battery-swap station, when the latter is farther away, should be considered. This penalty cost is calculated based on the waiting and charging times:

The objective function for location planning of charging/battery-swap stations is established considering the construction and operation costs, waiting and traveling cost of the user, and penalty cost.

A total cost model was built based on the objective function of location planning of charging/ battery-swap stations.

The constraints are as follows:

where the objective function in Eq. (19) represents the minimum sum of costs of charging and battery swap stations, including the construction, operation, driver access, and penalty costs. Constraint (20) means that only one candidate site can be used to construct one type of facility, either a charging station or a battery-swap station. Constraints (21) and (22) indicate that only when there are charging facilities (charging piles or battery-swap stations), vehicles will come to this site for charging. Constraint (23) considers the limits of governmental and corporate investments, and the maximum investment budget is set as

Charging/battery-swap facility location selection modeling is a complex optimization problem. GA, which searches from the solution set and minimizes the probability of the local optimum, is an efficient, parallel, and global search method. However, it suffers from intrinsic shortcomings. First, it is likely to converge before the optimal or satisfying solution is reached, that is, the premature convergence problem. Second, during gene transmission, the excellent individual gene is susceptible to damage, which results in the loss of useful information.

The crossover operator, which is a key factor in the GA, can be optimized for specific tasks to improve its performance. This can be achieved in two manners: the first one is to improve the crossover operator. A dynamic adjustment factor of the crossover probability can be designed to dynamically adjust the operator in the evolution process, according to the fitness function. The second method is to search and memorize an excellent gene cluster to increase its likelihood of being passed on to the offspring.

3.1 Coding and Initial Population

(1) Decision variable of initial allocation

Population coding converts feasible solutions to problems into the search space of the GA. Thus, in the present work, a given number of candidate sites (the location of the candidate site overlaps with the location of the demand site) are selected according to the location planning principle of the charging piles and battery-swap stations. The traffic conditions and the candidate sites are encoded based on whether a charging facility will be built there or not. Specifically, the candidate site is expressed as j and is encoded as 1, 2, …, j. The binary-encoded chromosomes are

(2) Identifying the level of the charging station and the battery-swap station (

Step 1: The service capacity of an

Step 2: When

The two steps above describe the process of identifying the level of a candidate site for a charging station. The process in the battery-swap station is the same. Here, the distances from the demand site to the charging station and battery-swap station are considered together, and the demand for charging stations that are excessively far is assigned to a closer battery-swap station.

The fitness function is the basis for evaluating the quality of the set of solutions and the standard for genetic selection, which is converted from an objective function. The objective of the location planning of charging and battery-swap stations in the present study is to minimize the annual operation cost while meeting the needs of drivers. Thus, the reciprocal of the objective function is considered as the fitness function.

The common fitness-proportionate selection technique, which is the roulette-wheel selection strategy, was employed in the present work. We assume that the population scale is

The crossover and mutation operators are self-adaptively improved and the crossover operator dynamically changes according to the different stages of the population evolution. In the initial stage of population evolution, a strong crossover is adopted. When the population evolution decelerates and reduces to a local optimum, a weak crossover is adopted, and the mutation rate changes dynamically. We define the crossover probability as a sigmoid function, and map the fitness value to a range between 0 and 1:

where

3.3.3 Transfer of Excellent Genes

Individuals with high fitness values often share the same or a similar range of gene combinations, which can generate an excellent gene cluster. To reduce the search time and avoid damage to the excellent gene cluster when searching for a solution, we can extract candidate sites and demand sites with wide coverage to generate a set as a gene cluster to enhance the convergence speed.

(1) Division of the optimal solution search space. The set of fast-charging and battery-swap stations and the demand sites they cover are identified, and there are n sets that form a gene cluster. For all individuals, the optimal solution search space is divided using the same method. All m individuals are sequenced in descending order of fitness value:

(2) Optimal gene cluster selection. For the first nm individuals in the sequence, n is the preset proportion of selection, and a weight b is assigned to all nm individuals (top ranked individuals are assigned a larger weight). The same gene clusters among the individuals were marked. For similar gene clusters among the individuals, the product of the fitness value and weight of the gene cluster was obtained, and the cluster with a larger product was retained.

(3) Crossover of parent genes and generation of child gene clusters. Each gene cluster is regarded as a gene, and in crossover, two individuals exchange part of their gene clusters and genes outside the gene cluster crossover on a free basis. When child individuals are generated, the algorithm searches for a new gene cluster.

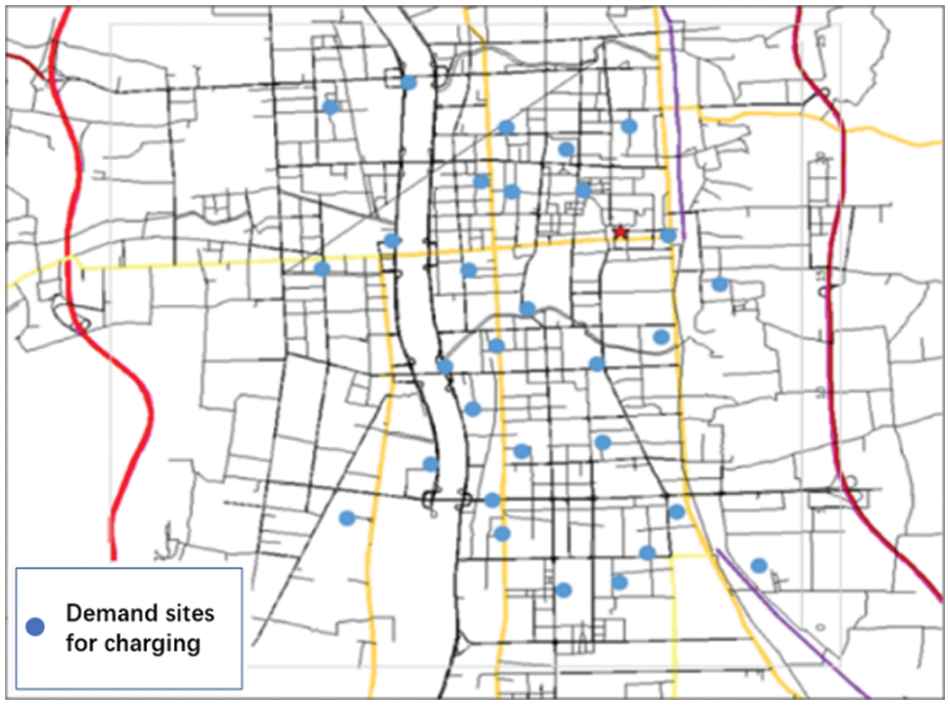

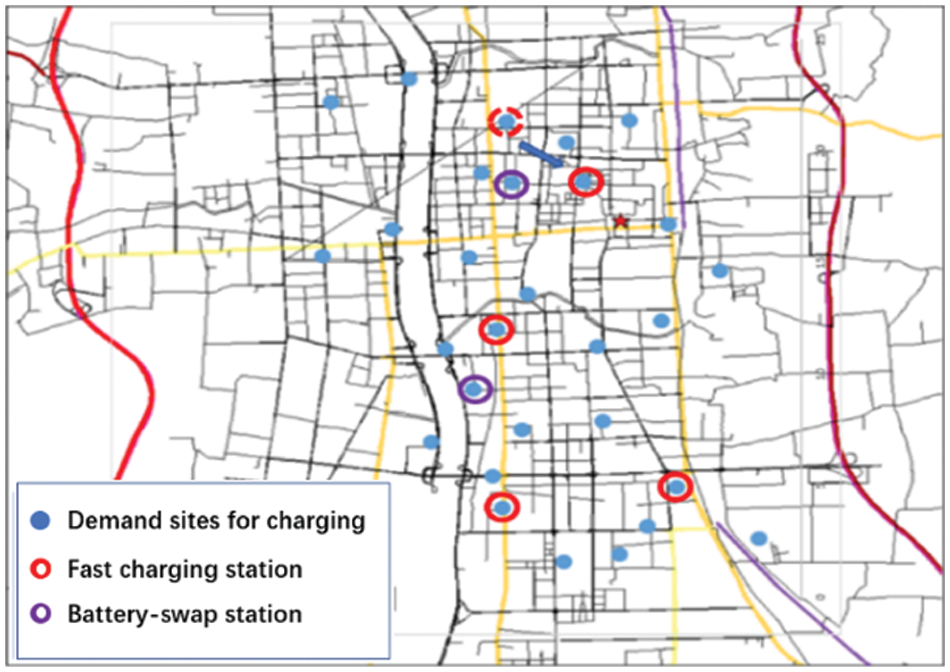

A simulated case was used to confirm the effectiveness of the proposed model. As shown in Fig. 1, the simulation example is based on the main urban area of a city in Central China, with a total area of approximately 139.2 km². Combined with statistical practice, 30 sub-areas of energy supply demand in this area were studied and appropriate locations for the construction of charging stations were selected.

Figure 1: Area of simulation

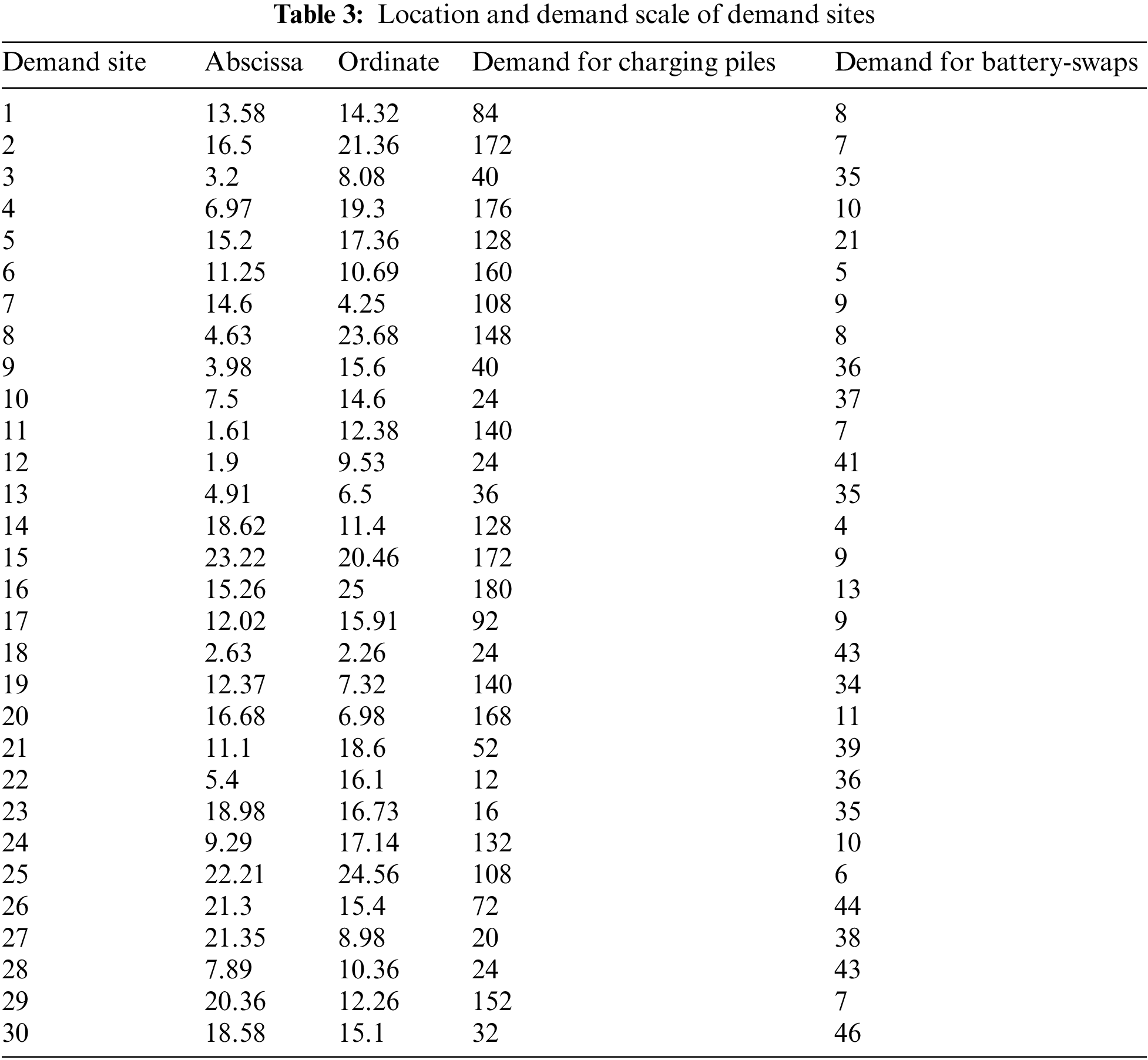

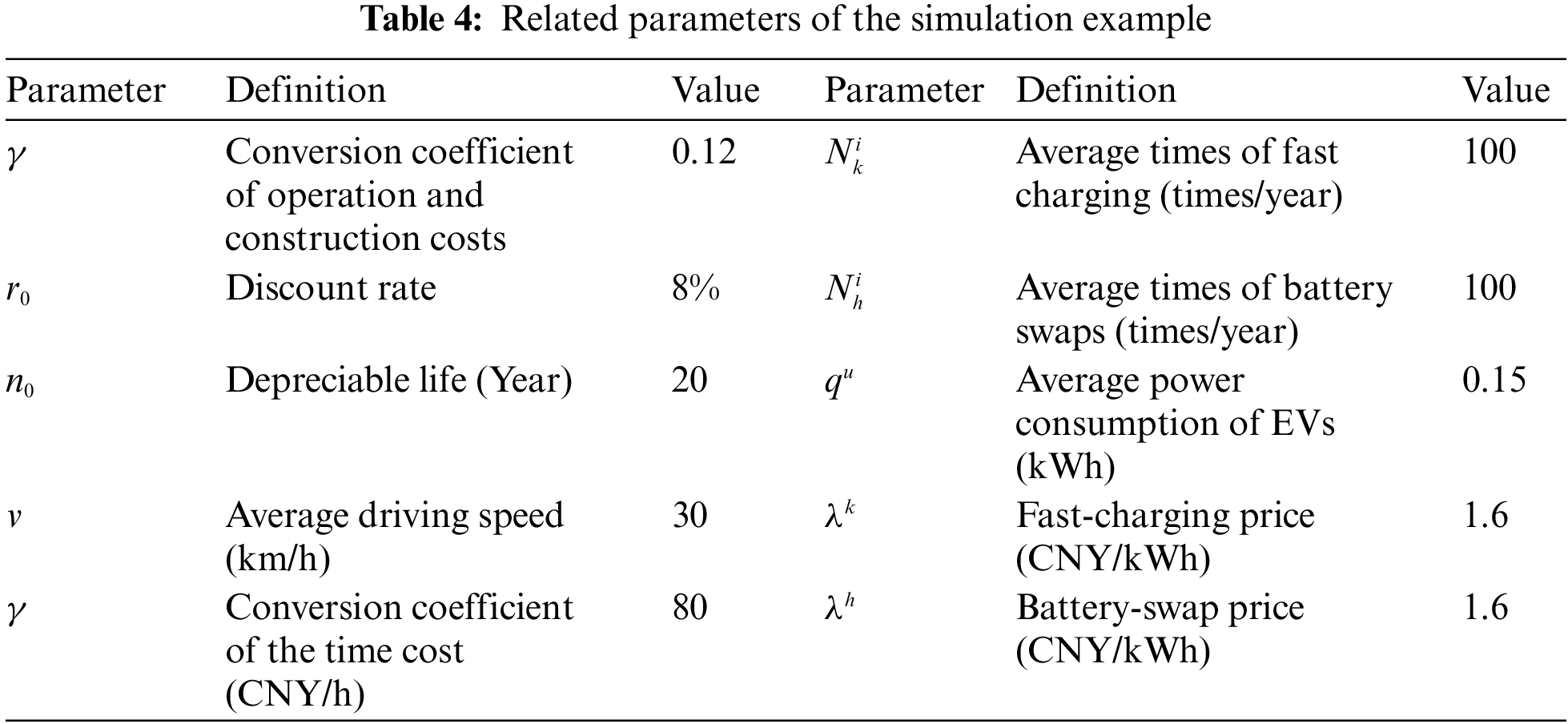

There are 3,490 EVs in this region, of which 2,804 are charging vehicles and 686 are battery swap ones. The ratio of private cars to operating vehicles was 9.8:0.2. Private cars and operating vehicles need to charge 0.2 and 2 times per day at public charging facilities, respectively. Table 3 lists the locations and corresponding demand scales of the 30 demand sites, and Table 4 lists the specific parameters.

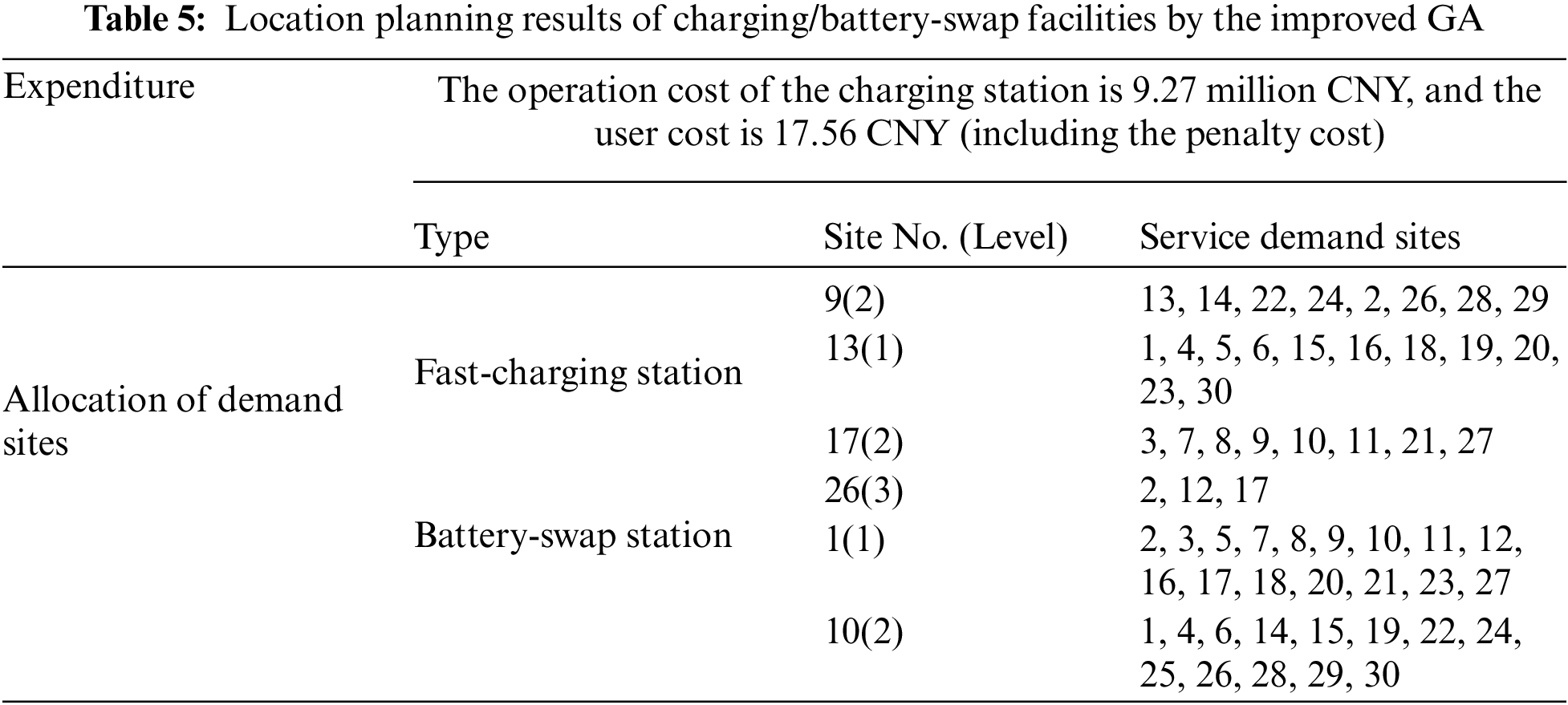

The improved GA and MATLAB were used to find the solutions. The algorithm was set as follows: the population was 50, the iteration was 200 times, and in the termination rules, the maximum iteration was 50 times for the current optimal solution to remain unchanged. The simulation was run 20 times, and the results are listed in Table 5.

For convenient calculation, we assumed that the land prices of all sites remained the same. Table 5 shows the location planning results of the fast-charging stations and battery-swap stations. Sites 9, 13, 17, and 26 are planned for charging piles, whereas sites 1 and 10 are arranged for battery-swap stations.

Fig. 2 shows the construction locations and allocation of demand points. For different locations of the charging facilities, different demand sites are assigned, and the level of the sites of charging facilities vary. In practice, it is unnecessary to build all facilities into high-level facilities; building charging/battery-swap facilities of different levels helps avoid waste of investment, improve efficiency, and maximize customer perception.

Figure 2: Construction locations and allocation of demand points (basic model)

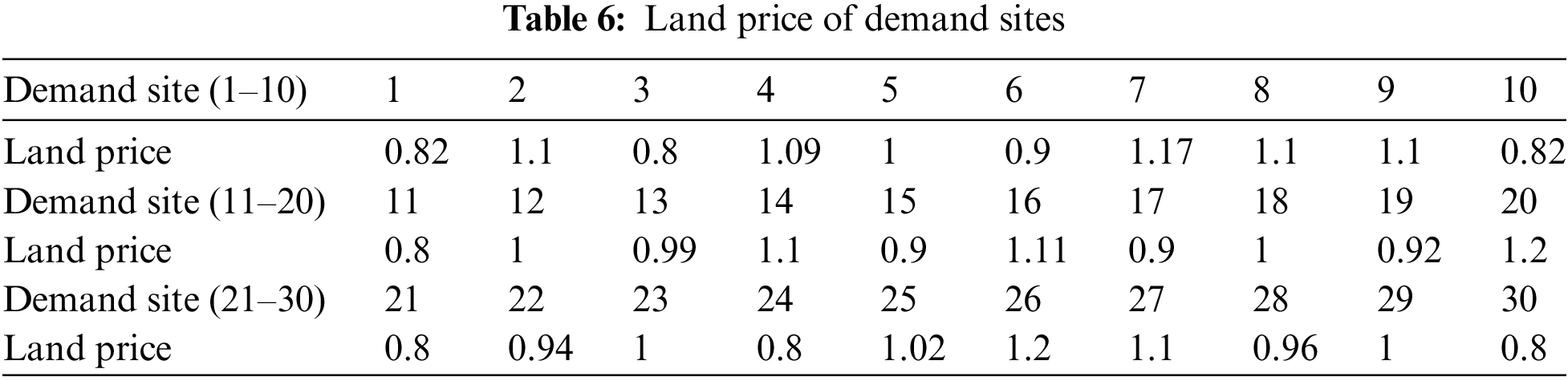

4.2.2 Planning Results under Varied Construction Costs

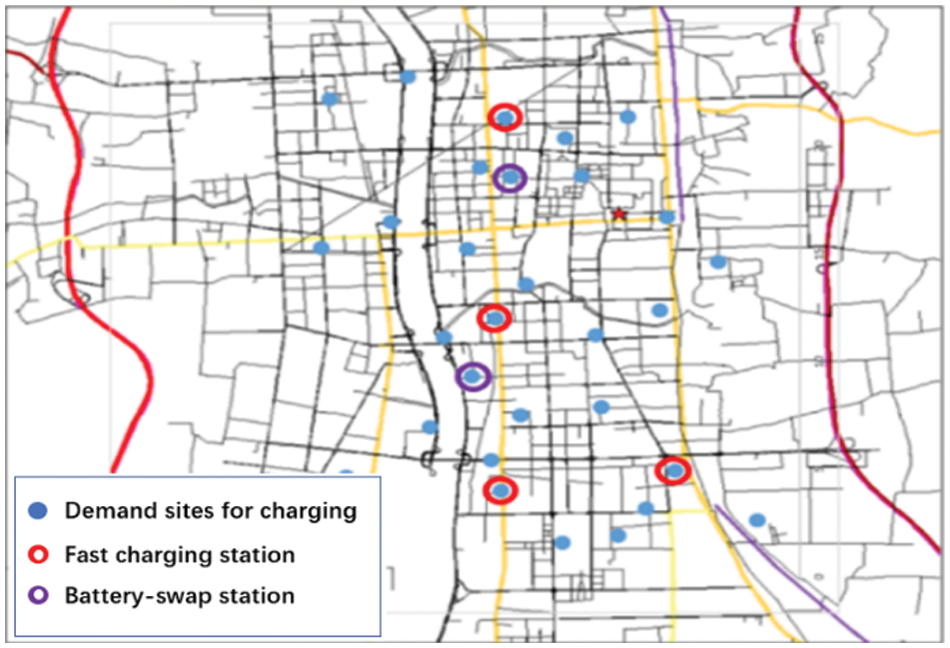

For convenient calculation, we assumed that the land prices for all facilities remained the same, but this is not true in reality. With other conditions held the same as in Section 4.2.1, we discuss the location selection of charging/battery-swap facilities under varied land prices, as shown in Table 6.

As shown in Fig. 3, the result differs from that in Section 4.2.1. Sites 9, 13, and 17 are still planned for charging piles; however, site 26 is no longer reserved for a charging station, and site 12 is arranged for a new charging station. Charging stations were planned for regions with lower construction costs to reduce the overall value of the objective function.

Figure 3: Construction locations and allocation of demand points (under varied construction costs)

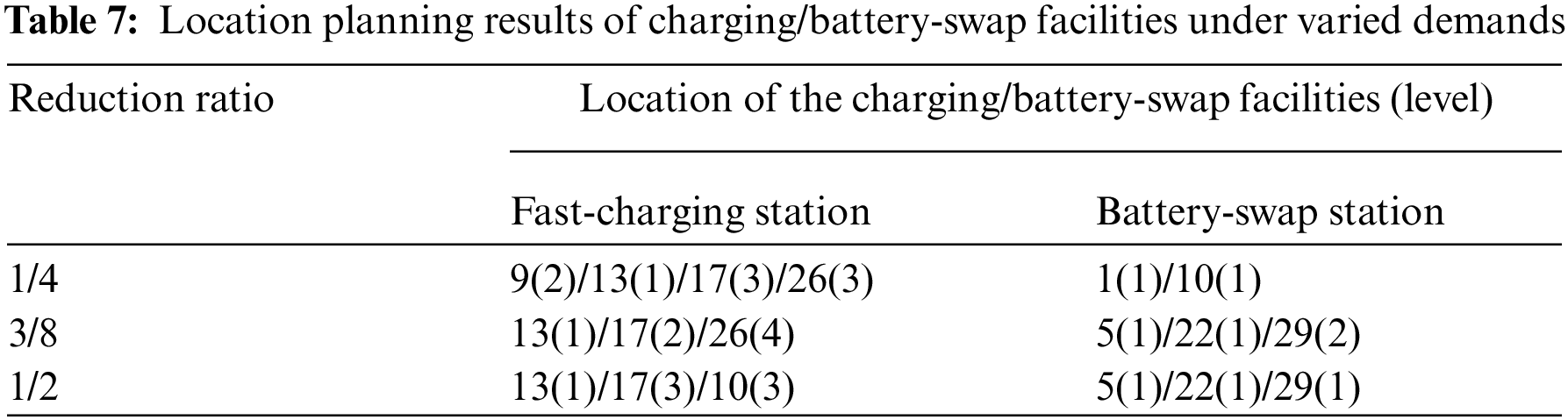

4.2.3 Planning Results under Varied Demand Structures

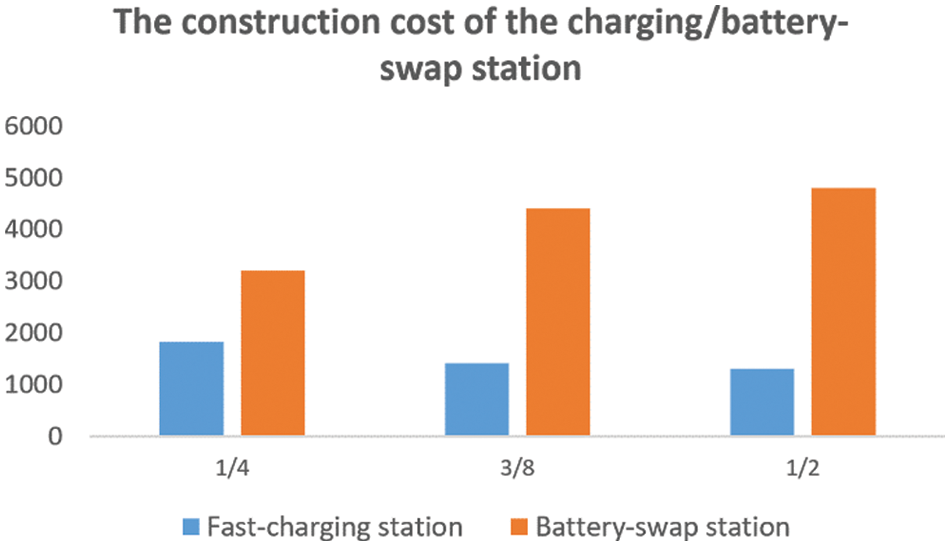

Vehicles that rely on battery swaps for charging comprise a small proportion of all vehicles in the road network. As shown in Table 7, the ratio of fast-charging vehicles to battery-swap vehicles was 4:1. To simulate the increased proportion of battery-swap vehicles, we reduced the number of fast-charging vehicles by 1/4, 3/8, and 1/2 for each demand site, and the reduced demand for fast-charging vehicles was due to the increased number of battery-swap vehicles. As the ratio of fast-charging vehicles to battery-swap vehicles varies, the location and level of fast-charging stations and battery-swap stations also differ. When the scale of the fast-charging stations was reduced by 1/4, the location of the fast-charging stations remained constant, but the level of the stations decreased, thus reducing demand. As the demand continued to decrease, the location and scale of fast-charging stations varied. In this case, the level of the fast-charging station and the location of the stations changed to minimize the overall cost. Moreover, the location and scale of the battery-swap stations varied to meet changing demands.

Because the average construction cost of the battery-swap station is higher than that of the fast-charging station, with an increasing proportion of EVs, the overall construction cost of energy supply stations increases linearly. As shown in Fig. 4, when the proportion of battery-swap vehicles is changed to 1/4, 3/8, and 1/2, the construction costs of battery-swap stations are 32 million CNY, 44 million CNY, and 48 million CNY, and the overall construction costs are 50.3 million CNY, 58.2 million CNY, and 61.1 million CNY, respectively. This represents an increase of 18.6%, 15.7% and 4.98%, respectively, compared to the original cost.

Figure 4: Construction cost of the charging/battery-swap station under different reduction ratios

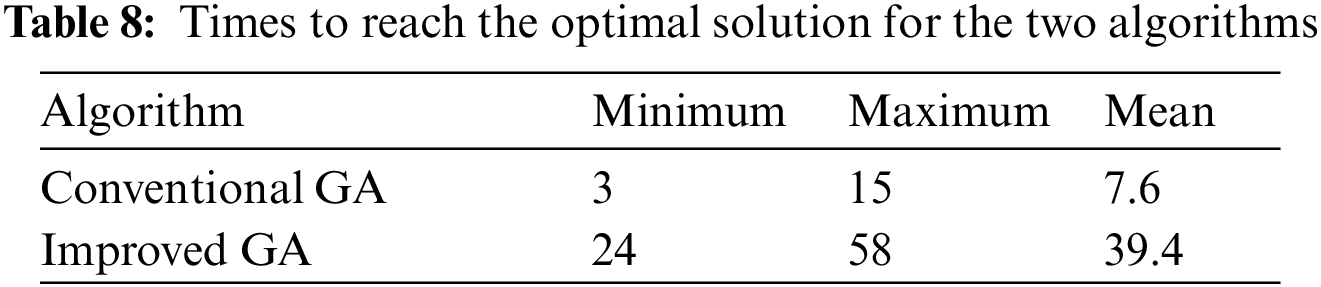

4.2.4 Comparison between Two Algorithms

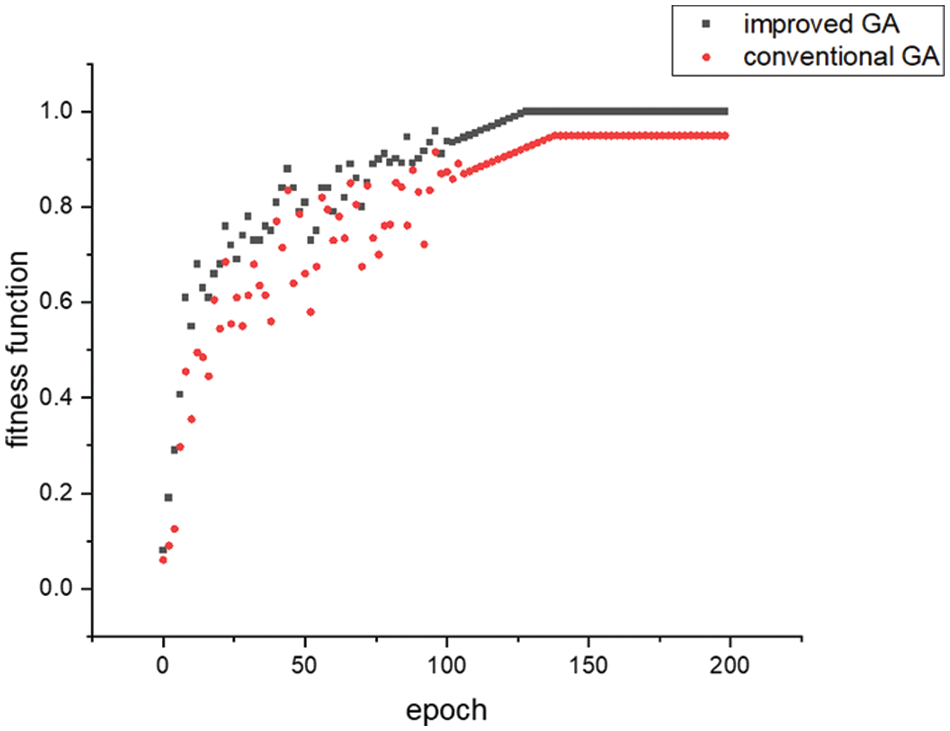

In the present work, the conventional GA and improved GA were employed to solve the model, and their performances were compared. The algorithms were run 200 times for 50 iterations, and the changes in the fitness curve were used as the evaluation standard. Both algorithms can achieve the optimal solution, but the effect varies (Table 8). Specifically, the improved GA had a stronger search capacity and a higher search speed than the standard algorithm. The reason for this difference is that after genetic operation, the population diversity in the conventional GA decreased sharply, and under a small mutation probability, the algorithm has a high probability of reaching premature convergence towards the local optimum. However, the improved algorithm is “directional” (evolves towards child generations with a higher fitness value), but retains the selection operation. Consequently, the improved GA outperformed its conventional counterpart.

As shown in Fig. 5, when the initial parameters were held constant, the fitness function curve of the improved algorithm increased rapidly, with a higher fitness value and a higher rising speed than those of the conventional GA. Moreover, as the number of epochs increased, the fitness values of both algorithms increased until convergence. The improved algorithm converged at the 130th epoch. However, the conventional algorithm did not exhibit a steadily reduced fitness value as the number of epochs increased. Within 200 epochs, the conventional GA converged at the 152nd epoch, but did not converge to the global optimum. The improved GA has better stability and poorer convergence than its conventional counterpart.

Figure 5: Fitness function curves of the improved GA and conventional GA

Meeting the demand for power supply of EVs does not necessarily mean increasing the number of charging/battery-swap stations. Instead, optimizing the level and location planning of these stations can maximize the investment profit. A case simulation revealed that our proposed model for the location selection of multilevel charging/battery-swap stations could provide a basis for decision-making. In the location selection of charging/battery-swap facilities, the construction, operation, charging, traveling, and waiting costs, as well as customer satisfaction with the service of the facilities, should be considered. Location selection is a multi-target and nonlinear combination optimization problem subject to different influencing factors. Therefore, the difference between the fast-charging and battery-swap stations was considered. We built a location selection optimization model for charging/battery-swap facilities. To solve this model, we designed an improved GA that can dynamically change the crossover and mutation rates according to the fitness values, memorize, and transfer excellent genes with a large probability. This improved algorithm avoids the problem of premature convergence of conventional GAs, provides a new solution to complex optimization problems, and increases the computing efficiency; hence, it has theoretical significance. A simulated case study confirmed the effectiveness and utilization efficiency of the proposed model and algorithm. The proposed problem and solution can provide a reference for the government and enterprises to better plan the location of charging/battery-swap facilities, having both theoretical and practical value.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Zhao, J., Li, F., Wang, Z., Dong, P., Wang, K. (2021). Flexible PVDF nanogenerator-driven motion sensors for human body motion energy tracking and monitoring. Journal of Materials Science: Materials in Electronics, 32(11), 14715–14727. DOI 10.1007/s10854-021-06027-w. [Google Scholar] [CrossRef]

2. Li, D., Li, S., Zhang, S., Sun, J., Wang, L. et al. (2022). Aging state prediction for supercapacitors based on heuristic kalman filter optimization extreme learning machine. Energy, 250, 123773. DOI 10.1016/j.energy.2022.123773. [Google Scholar] [CrossRef]

3. Rahman, I., Vasant, P. M., Singh, B. S. M., Abdullah-Al-Wadud, M., Adnan, N. (2016). Review of recent trends in optimization techniques for plug-in hybrid, and electric vehicle charging infrastructures. Renewable and Sustainable Energy Reviews, 58, 1039–1047. DOI 10.1016/j.rser.2015.12.353. [Google Scholar] [CrossRef]

4. Cheng, Y., Tao, J. (2018). Optimal planning model of electric bus charging network under fast charging mode. Diangong Jishu Xuebao/Transactions of China Electrotechnical Society, 33, 586–595. DOI 10.19595/j.cnki.1000-6753.tces.L80558. [Google Scholar] [CrossRef]

5. Yang, J., Jiang, X., Zhao, K. (2020). Multi-objective optimization method of location and capacity determination problems of highway charging stations. Journal of Chongqing Normal University: Natural Science Edition, 38, 1–10. DOI 10.11721/cqnuj20200611. [Google Scholar] [CrossRef]

6. Song, Y. (2016). Optimization of electric vehicles’ charging station location (Ph.D. Thesis). Southwest Jiaotong University. China. [Google Scholar]

7. Ren, Y., Shi, L., Zhang, Q., Han, W., Huang, S. (2011). Optimal distribution and scale of charging stations for electric vehicles. Automation of Electric Power Systems, 35(14), 53–57. DOI 10.1080/17415993.2010.547197. [Google Scholar] [CrossRef]

8. Kang, Q., Wang, J. B., Zhou, M. C., Ammari, A. C. (2015). Centralized charging strategy and scheduling algorithm for electric vehicles under a battery swapping scenario. IEEE Transactions on Intelligent Transportation Systems, 17(3), 659–669. DOI 10.1109/TITS.2015.2487323. [Google Scholar] [CrossRef]

9. Ju, R. (2011). Electric vehicle charging station constraint conditions and comprehensive benefit analysis. East China Electric Power, 39(4), 547–550. [Google Scholar]

10. Wei, T., Qlab, D., Zf, D., Slse, D., Bzab, C. et al. (2016). Optimizing the locations of electric taxi charging stations: A spatial–temporal demand coverage approach. Transportation Research Part C: Emerging Technologies, 65, 172–189. DOI 10.1016/j.trc.2015.10.004. [Google Scholar] [CrossRef]

11. Cai, H., Jia, X., Chiu, A. S., Hu, X., Xu, M. (2014). Siting public electric vehicle charging stations in Beijing using big-data informed travel patterns of the taxi fleet. Transportation Research Part D: Transport and Environment, 33, 39–46. DOI 10.1016/j.trd.2014.09.003. [Google Scholar] [CrossRef]

12. Kong, W., Luo, Y., Feng, G., Li, K., Peng, H. (2019). Optimal location planning method of fast charging station for electric vehicles considering operators, drivers, vehicles, traffic flow and power grid. Energy, 186, 115826. DOI 10.1016/j.energy.2019.07.156. [Google Scholar] [CrossRef]

13. Wang, K., Wang, W., Wang, L., Li, L. (2020). An improved SOC control strategy for electric vehicle hybrid energy storage systems. Energies, 13(20), 5297. DOI 10.3390/en13205297. [Google Scholar] [CrossRef]

14. Liu, C., Zhang, Y., Sun, J., Cui, Z., Wang, K. (2022). Stacked bidirectional LSTM RNN to evaluate the remaining useful life of supercapacitor. International Journal of Energy Research, 46(3), 3034–3043. DOI 10.1002/er.7360. [Google Scholar] [CrossRef]

15. Hua, Y., Wang, N., Zhao, K. (2021). Simultaneous unknown input and state estimation for the linear system with a rank-deficient distribution matrix. Mathematical Problems in Engineering, 2021. DOI 10.1155/2021/6693690. [Google Scholar] [CrossRef]

16. Hou, W., Luo, Q., Wu, X., Zhou, Y., Si, G. (2021). Multiobjective optimization of large-scale EVs charging path planning and charging pricing strategy for charging station. Complexity, 2021. DOI 10.1155/2021/8868617. [Google Scholar] [CrossRef]

17. Ding, D. J., Dai, K., Zhang, X. S., Gu, J. P., Zhou, H. et al. (2018). Network planning for electric vehicle charging based on fuzzy multi-objective optimization. Power System Protection and Control, 46(3), 43–50. DOI 10.7667/PSPC170006. [Google Scholar] [CrossRef]

18. Qiu, J. P., Niu, D. X., Zhu, G. D. (2016). Optimized layout of charging station for electric vehicle based on firefly algorithm. Journal of North China Electric Power University (Natural Science Edition), 43(5), 105–110. DOI 10.3969/j.ISSN.1007-2691.2016.05.16. [Google Scholar] [CrossRef]

19. Jia, H. P., Liu, S. G., Xie, S. L., Huang, S. L., Pei, S. T. (2013). The location model of the electric vehicle charging station based on simulated annealing algorithm. Advanced Materials Research, 805, 1895–1899. DOI 10.4028/www.scientific.net/AMR.805-806.1895. [Google Scholar] [CrossRef]

20. Liu, C., Li, Q., Wang, K. (2021). State-of-charge estimation and remaining useful life prediction of supercapacitors. Renewable and Sustainable Energy Reviews, 150, 111408. DOI 10.1016/j.rser.2021.111408. [Google Scholar] [CrossRef]

21. Li, Q., Li, D., Zhao, K., Wang, L., Wang, K. (2022). State of health estimation of lithium-ion battery based on improved ant lion optimization and support vector regression. Journal of Energy Storage, 50, 104215. DOI 10.1016/j.est.2022.104215. [Google Scholar] [CrossRef]

22. Li, S., Wei, T., Muke, B., Lu, Z. (2014). Locating and sizing of centralized charging stations in distribution network considering load shifting. Proceedings of the CSEE, 34(7), 1052–1060. DOI 10.13334/j.0258-8013.pcsee.2014.07.00. [Google Scholar] [CrossRef]

23. Awasthi, A., Venkitusamy, K., Padmanaban, S., Selvamuthukumaran, R., Blaabjerg, F. et al. (2017). Optimal planning of electric vehicle charging station at the distribution system using hybrid optimization algorithm. Energy, 133, 70–78. DOI 10.1016/j.energy.2017.05.094. [Google Scholar] [CrossRef]

24. Xu, Y., Zhi, J. (2015). Optimal PMU configuration based on improved adaptive genetic algorithm. Power System Protection and Control, 43(2), 55–62. [Google Scholar]

25. Hu, F. H., Ma, B. L., Yang, L., Li, W. (2014). Research on vehicle scheduling optimization in emergency material distribution based on improved genetic algorithm. Application Research of Computers, 31(10), 2928–2932. DOI 10.3969/j.issn.1001-3695.2014.10.010. [Google Scholar] [CrossRef]

26. Liu, L., Jing, P. (2015). A mutation strategy to suppress premature of genetic algorithm. The Application of Computer Technology, 2015(23), 179. [Google Scholar]

27. Beijing Bureau of Quality and Technical Supervision. DB11/Z 728-2010 Technical Specification for Electric Energy Supply and Guarantee of Electric Vehicles: Charging Station. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools