| Computer Modeling in Engineering & Sciences |  |

DOI: 10.32604/cmes.2021.017268

ARTICLE

Modelling of Contact Damage in Brittle Materials Based on Peridynamics

1Nanjing Institute of Railway Technology, Nanjing, 210031, China

2Tongji University, Shanghai, 200092, China

3Department of Engineering Mechanics, Hohai University, Nanjing, 211100, China

4Nanjing High Speed Gear Manufacturing Co., Ltd., Nanjing, 211100, China

*Corresponding Author: Jingjing Zhao. Email: zhaojingjing198678@126.com

Received: 27 April 2021; Accepted: 11 August 2021

Abstract: As a typical brittle material, glass is widely used in construction, transportation, shipbuilding, aviation, aerospace and other industries. The unsafe factors of glass mainly come from its rupture. Thus, establishing a set of prediction models for the cracks growth of glass under dynamic load is necessary. This paper presents a contact damage model for glass based on the ordinary state-based peridynamic theory by introducing a contact force function. The Hertz contact (nonembedded contact) problem is simulated, and the elastic contact force is determined by adjusting the penalty factor. The proposed model verifies the feasibility of penalty-based method to simulate the contact problem of glass. The failure process of glass specimen under impact is simulated, where two loading methods, the drop ball test and the split Hopkinson pressure bar are considered. Numerical results agree well with the experimental observations, thereby verifying the effectiveness of the proposed model.

Keywords: The ordinary state-based peridynamic; glass; numerical simulation; contact damage; impact failure

Glass is a highly homogeneous brittle material and it can be made into any shape and mass produced due to its homogeneity. Hence, glass materials are widely used in construction, transportation, shipping, aviation, aerospace and other industries. However, the glass is extremely easy to break when its surface is subjected to impact load. Effectively revealing the mesoscopic failure mechanism of glass under low-velocity impact loads is of great importance to improve its resistance and safety.

In the early days, many scholars investigated the damage of glass under impact, mainly focusing on the crack initiation, propagation, and crack development patterns of glass through a series of experimental studies [1–6]. In 1931, Andrews [1] pointed out that a force threshold is found for the crack formation of glass under impact load. Roesler [2] considered the conical indentation of a glass specimen and measured its fracture energy to verify Griffith [3] energy balance condition for brittle material cracking. Knight et al. [4], Chaudhri et al. [5] studied the crack development patterns of glass under medium and high-speed loading by changing the impact velocity of iron ball. The results show that the crack appears in the non-loading section, and the Hertzian cone angle of the crack zone varies with the loading speed. Ball et al. [6] observed that glass specimens exhibit a star-shaped fragmentation failure mode under low-speed conditions. In recent years, Bouzid et al. [7], Nyongue et al. [8], and Daryadel et al. [9] conducted relevant quantitative experimental analysis on the dynamic response and fracture criterion for glass under impact loading. The failure mechanism for different types of glass is realized in the work of Kumar et al. [10]. These test results reveal the response law and failure mechanism of glass as a typical brittle material under impact load from different aspects.

With the development of computers, numerical simulation methods have been widely used to reproduce and explain the phenomena observed in experiments. Numerical models based on traditional continuum mechanics, such as finite element method [11] and boundary element method [12], are gradually used in many experimental studies. However, for discontinuities, such as crack bifurcation in solid materials and structures, traditional numerical methods are faced with the problems of singularity and low computational efficiency. The use of grid reconstruction [13] or the method of adding a cohesive element [14] in the finite element would cause to grid-dependent results. The partition algorithm [15] and fictitious crack model [16] adopted by the boundary element method (BEM) have similar limitations to the finite element method in the analysis of crack propagation problems. Therefore, researchers have proposed the extended finite element method [17]. Compared with the traditional finite element method, it reduces the strict requirements on the mesh discontinuity. However, in the construction of enrichment function, the extended finite element method needs to know the characteristics of the problem to be solved in advance. This condition is relatively demanding for complex problems, such as crack branching and multi-crack intersection. In recent years, many researchers have studied the contact damage of brittle materials under impact load. Oliveira et al. [18] proposed an alternative BEM formulation to model the cohesive stresses through the domain term of the direct integral. Wang et al. [19] proposed a field-enriched finite element method to simulate the failure process of rocks. Kouet et al. [20] presented a bonded-particle methodology to investigate the crack growth and crack branching. Bo et al. [21,22] developed some explicit Galerkin formulations which can capture ductile fractures during high-speed impacts and simulate fracture of a plate under impact loads.

To solve contradiction between the continuity assumption and the discontinuity phenomenon of the failure problem, Silling [23] proposed a nonlocal method called peridynamics (PD) [24] to described the motion process of the material points through an integral equation. In the development of the peridynamics, researchers have conducted numerous quantitative analyses on the brittle fracture of polycrystalline materials [25], impact failure of shale materials [26], and the thermal brittleness and failure of glass plate under impact [27–29], and the problem of interaction between ice and seawater [30]. Those results show that peridynamics does not have the singularity problem when analyzing the failure problem and can simulate the whole process of the material, including macroscopic crack initiation, propagation, and final failure. The above simulation of failure is based on the bond-based peridynamics theory (BBPD). However, bond-based peridynamics theory has some problems, such as the limitation of Poisson’s ratio and the lack of connection with traditional continuum theory. Silling et al. [31–32] proposed an ordinary state-based peridynamic theory (OSBPD) and a non-ordinary state-based peridynamics(NOSB PD). Both of them inherit the advantages of BBPD for solving discontinuous problems, and have a similar definition of state quantities to traditional physical quantities. To address the limitations of material calculation scale. Breitenfeld et al. [33], O’Grady et al. [34], and Chowdhury et al. [35] supplemented and developed the OSBPD theory. Song et al. [36] proposed a state-based peridynamic model by using adaptive particle refinement to simulate the formation of water ice crater under impact loads. Zhou et al. [37] developed a 2D elastoplastic model of the ordinary state-based peridynamic theory to analyze the plastic zone of the crack tip of rock material. Wu et al. [38] proposed a concrete impact failure model based on NOSBPD theory. In recent years, many scholars began to study the contact model based on PD method. Xin et al. [39] developed a NOSBPD model for brittle fracture to simulate the edge-on impact and drop ball test and discussed the contact algorithm between the projectile and target. Littlewood et al. [40] summarized the simulation results of finite element method and peridynamics. A combined approach of finite element method and peridynamics is utilized via a contact algorithm. Ye et al. [41] proposed a continuous contact detection algorithm to simulate the brittle failure behavior of ice during the contact between propeller and ice. This algorithm can well capture the ice damage characteristics. Kamensky et al. [42] summarized several existing peridynamic contact friction models and introduced a state-based nonlocal friction formulation to demonstrate the properties of various peridynamic contact models through some impact and penetration problems. Silling et al. [43] proposed a new PD model to simulate the elastoplastic response, creep, and fracture. In the case of small deformation, this model is consistent with classical Hertz contact analysis. Wang et al. [44] proposed a 3D conjugated bond-pair-based peridynamic model to simulate the failure characteristics of rock materials with different forms of central fissure.

This paper presents a new contact damage model based on the OSBPD theory for glass by introducing a contact force function. The arrangement of the rest sections is as follows. In Section 2, the governing equations based on OSBPD theory are described in brief, followed by the contact model and algorithm. In Section 3, the Hertz contact (nonembedded contact) problem is simulated, and the elastic contact force is determined by adjusting the penalty factor. The proposed model verifies the feasibility of penalty-based method to simulate the contact problem of glass. In Section 4, the failure process of glass specimen under impact is simulated, and two loading methods, drop ball test (DBT) and split Hopkinson pressure bar (SHPB), are considered. The numerical results agree well with the experimental results, which verifies the effectiveness of the proposed model.

2.1 Fundamentals of Peridynamics Theory

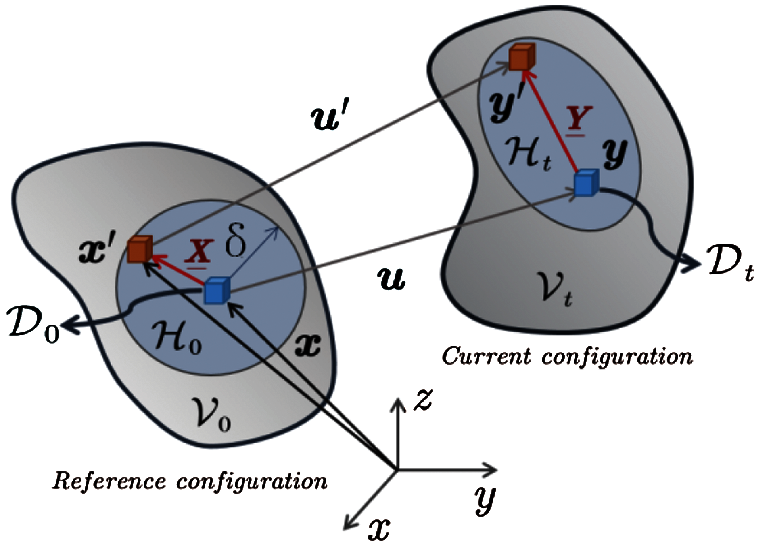

In PD theory, an object occupies a region

where

where

Figure 1: Reference configuration of particle movement

Therefore, a momentum balance equation at particle

The above formula is the governing equation of peridynamics [31–32], and its above derivation shows that the peridynamics theory still belongs to the Lagrangian system. The difference from the traditional continuum mechanics is that it considers the nonlocal interaction between the particles.

where

2.2 Force State of State-Based Peridynamics Theory

Let

where

The volume dilatation

In accordance with elastic mechanics, the extension scalar state

and deviatoric part

Therefore, the elastic energy density contains two parts

Correspondingly, the scalar force

In accordance with the energy equivalence between the deformation energy density (11) and the strain energy density of classical elasticity,

The above formula is the force state of state-based peridynamics theory, which includes traditional material parameters, such as bulk modulus

where

where

where

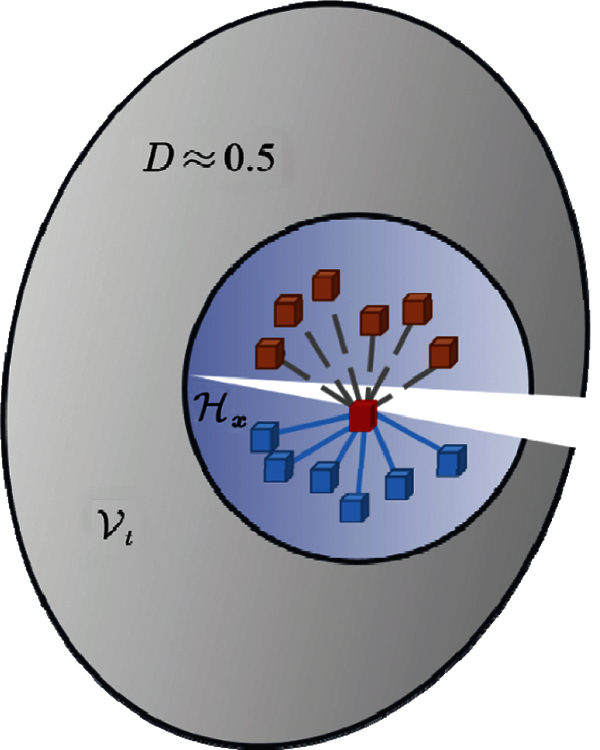

Figure 2: Damage between material point pairs when

2.3 Contact Model of Peridynamics

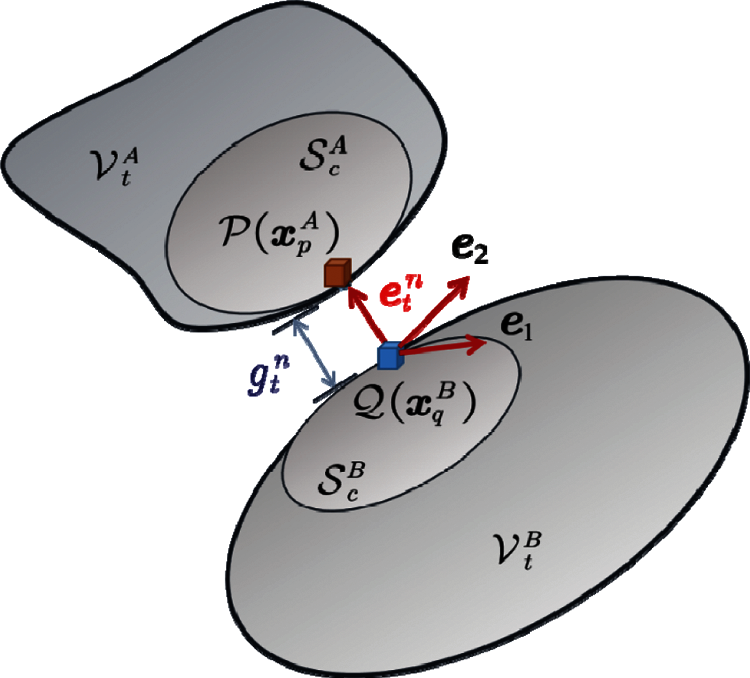

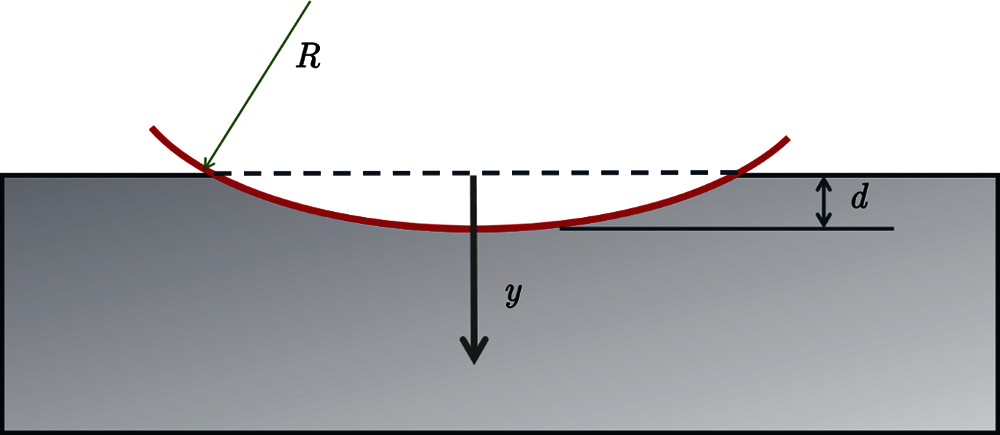

The contact problem of two objects shown in Fig. 3 is considered. Let

where the unit normal

Considering the impenetrability of contact, any material point on

Note

where

Figure 3: Contact point pair and the distance between them

The energy function, which includes

where

where

where

For a certain contact deformation body, if its contact surface is

where

The contact force is related to the selection of the penalty factor. In theory, the larger the penalty factor

2.4 Numerical Discretization and Solution

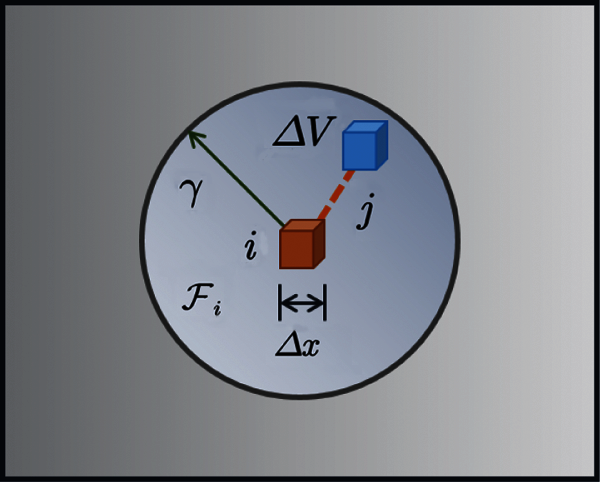

Regarding the spatial discretization, peridynamics divides the material uniformly into a cubic lattice of side length

Correspondingly, the discretization of the motion equation considering the contact force in the space domain is

Similar discrete operations are applied to the weighted volume

Figure 4: Discretization of spatial domain

Let

Substituting the above formula into the Eq. (29). Thus, we have

where

The time step should satisfy [33]

The virtual rigid “spring” is added, that is, the rigidity of contact area

The value of penalty factors

3 Verification of the Elastic Contact Problem

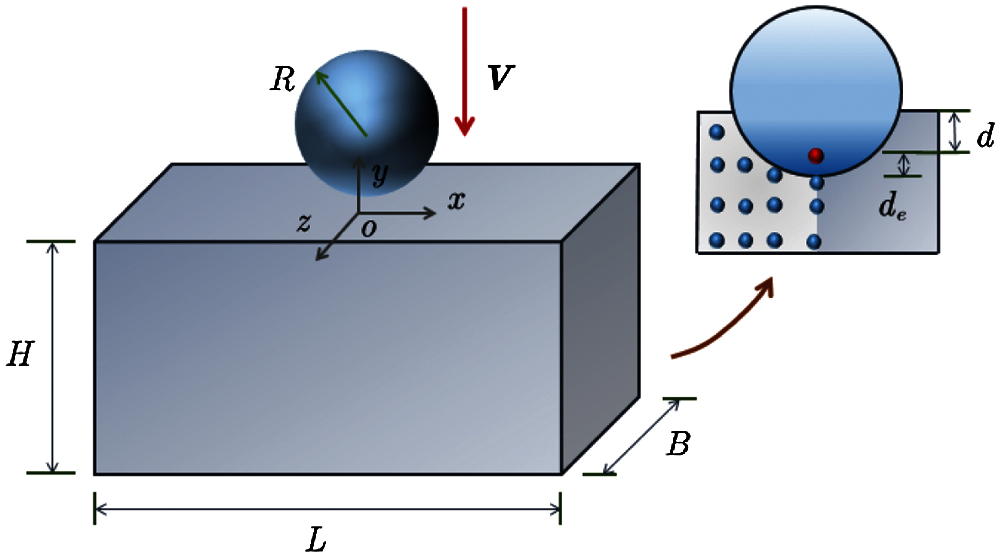

The Hertzian contact (no embedded contact) is considered, as shown in Fig. 5. The size parameters of the deformation body are

Figure 5: Hertzian contact problem

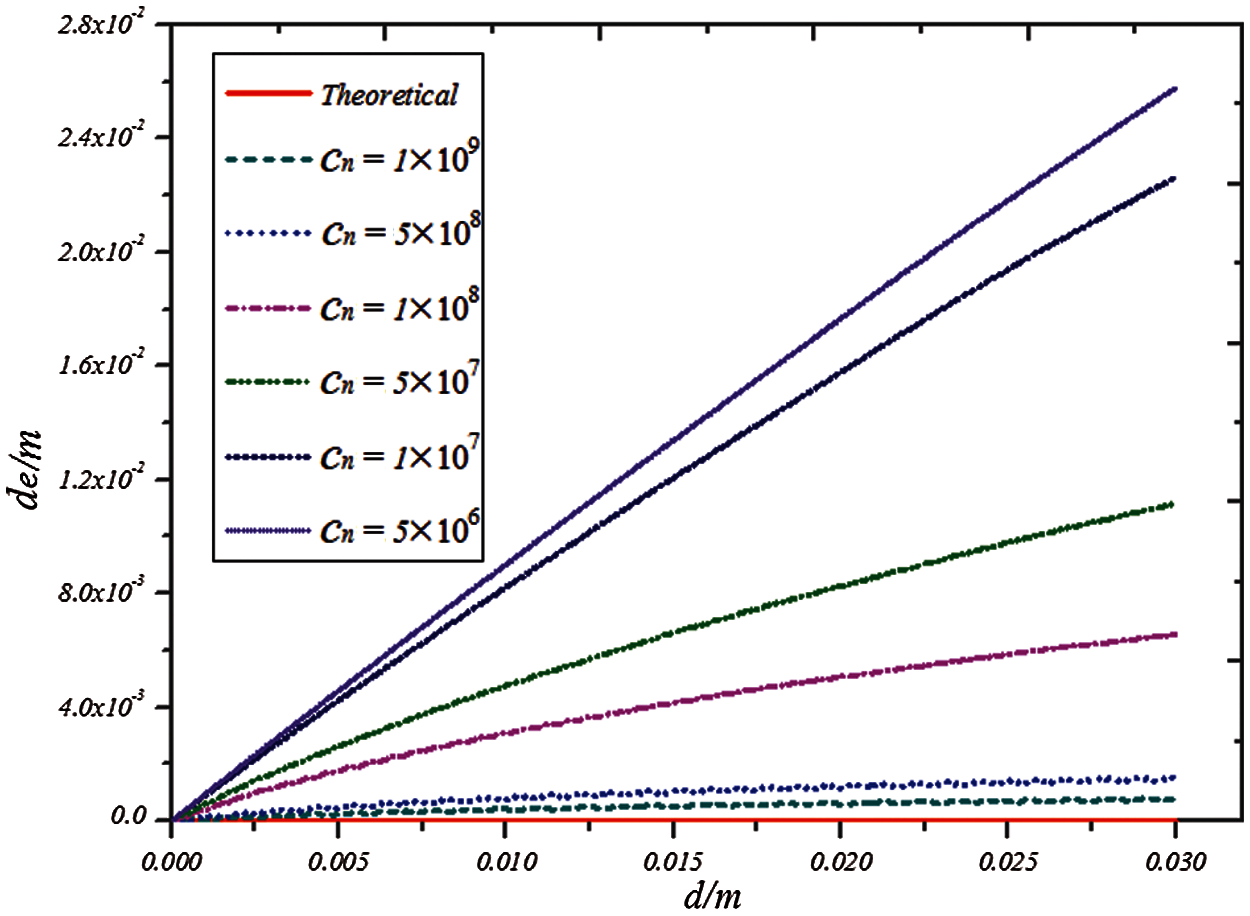

When the rigid sphere is in contact with the deformable body at a constant speed

Figure 6: Graph of embedded distance

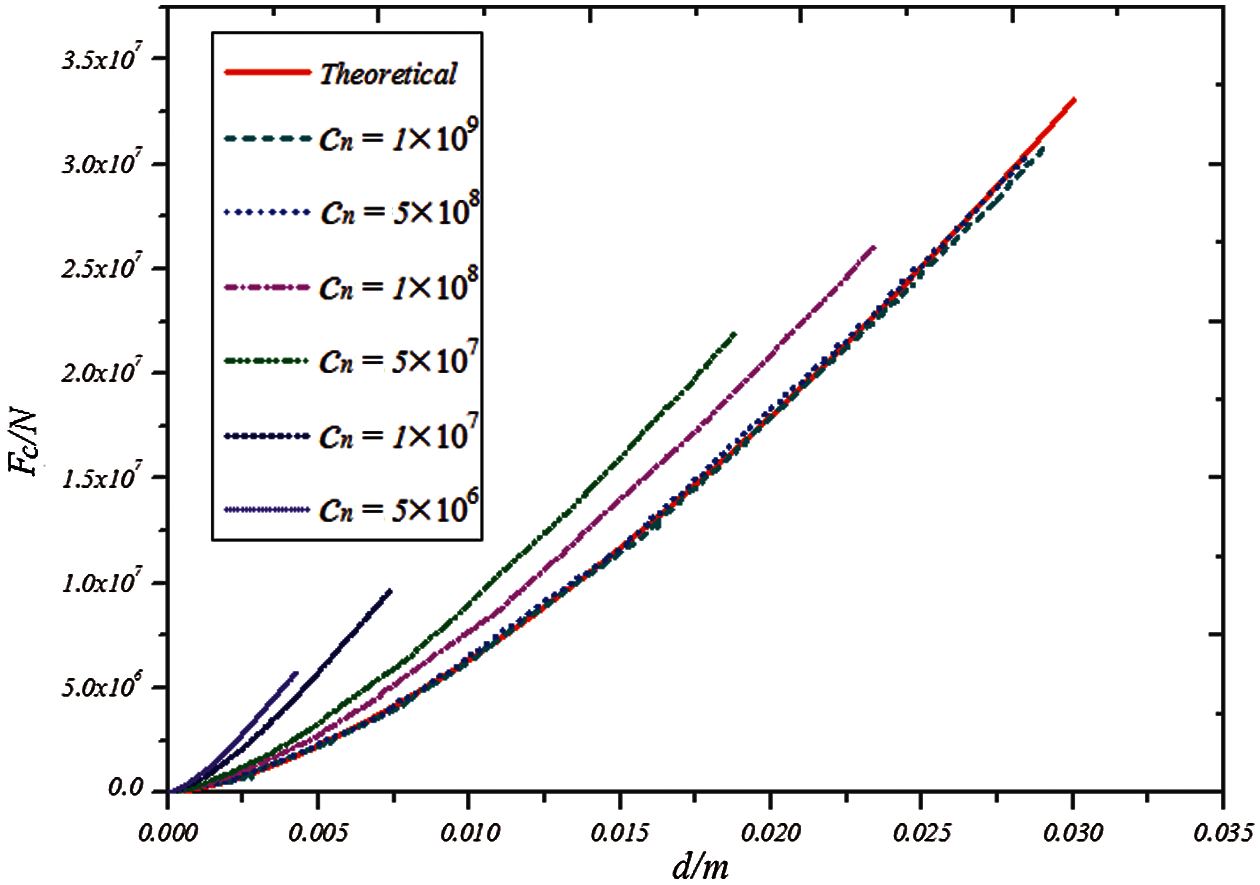

For the case of

The discrete distance is still set as

Figure 7: Relationship between contact force

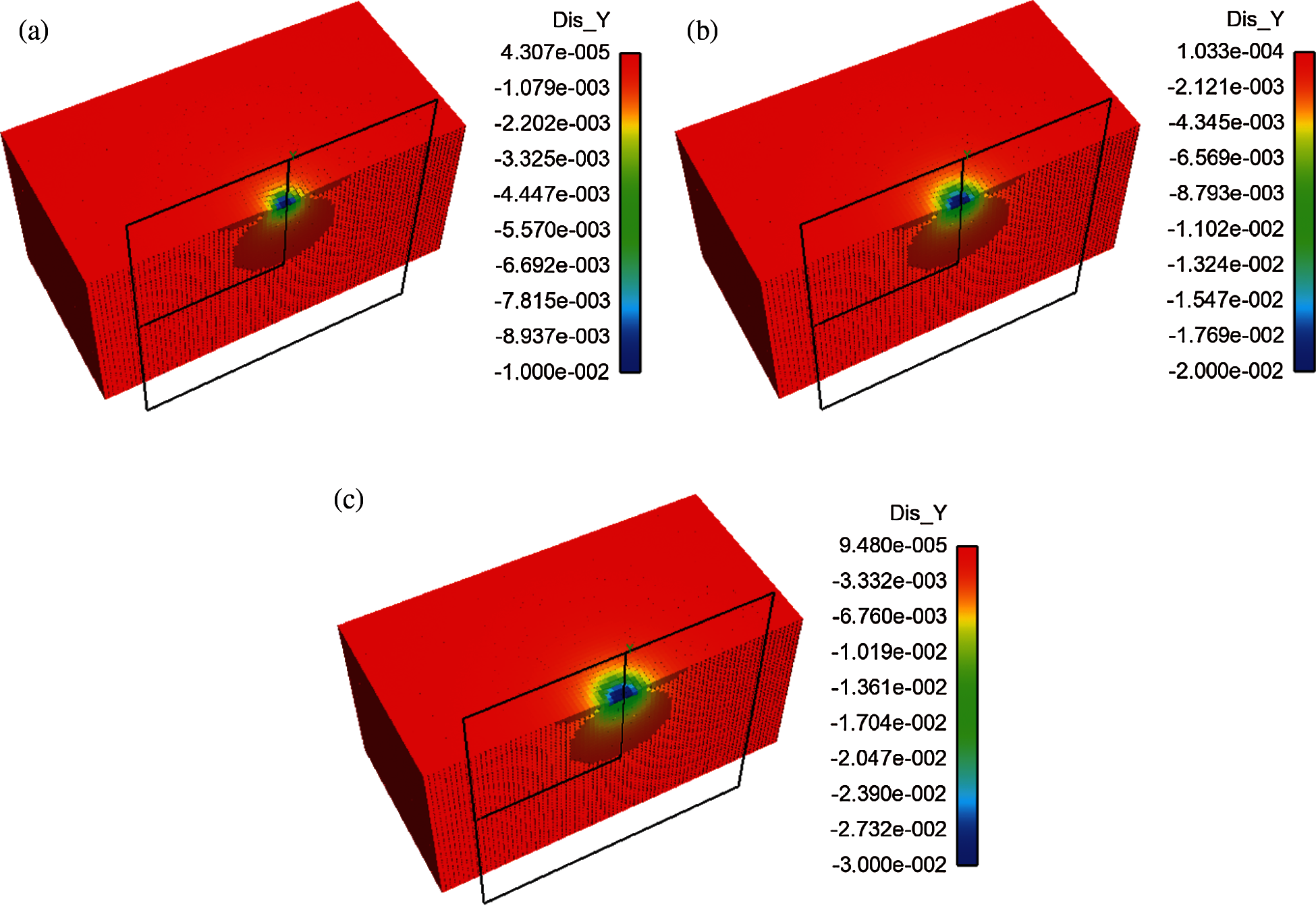

Figure 8: Displacement profile of the deformable body (a)

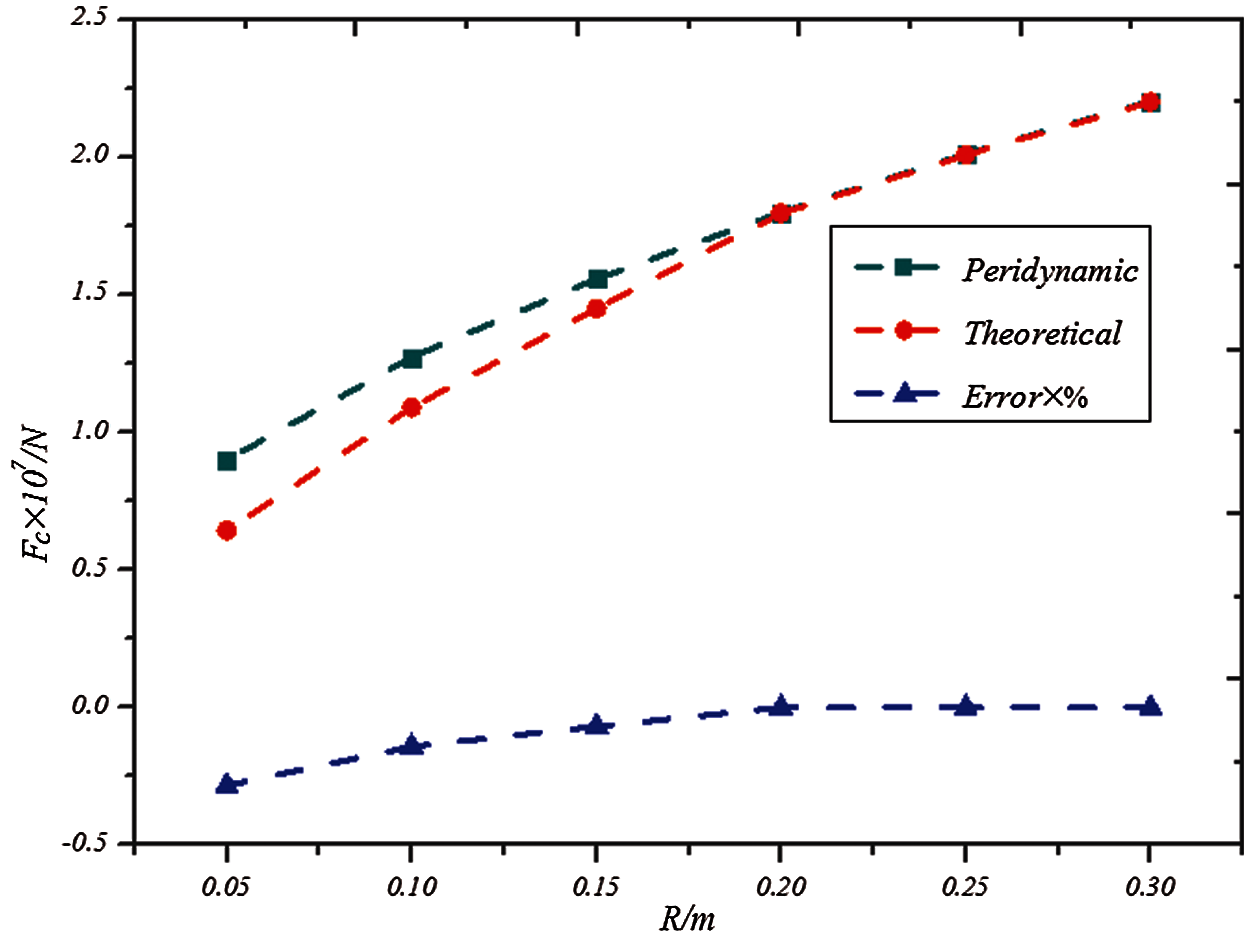

Figure 9: Plots of the contact force vs. the radius of rigid sphere

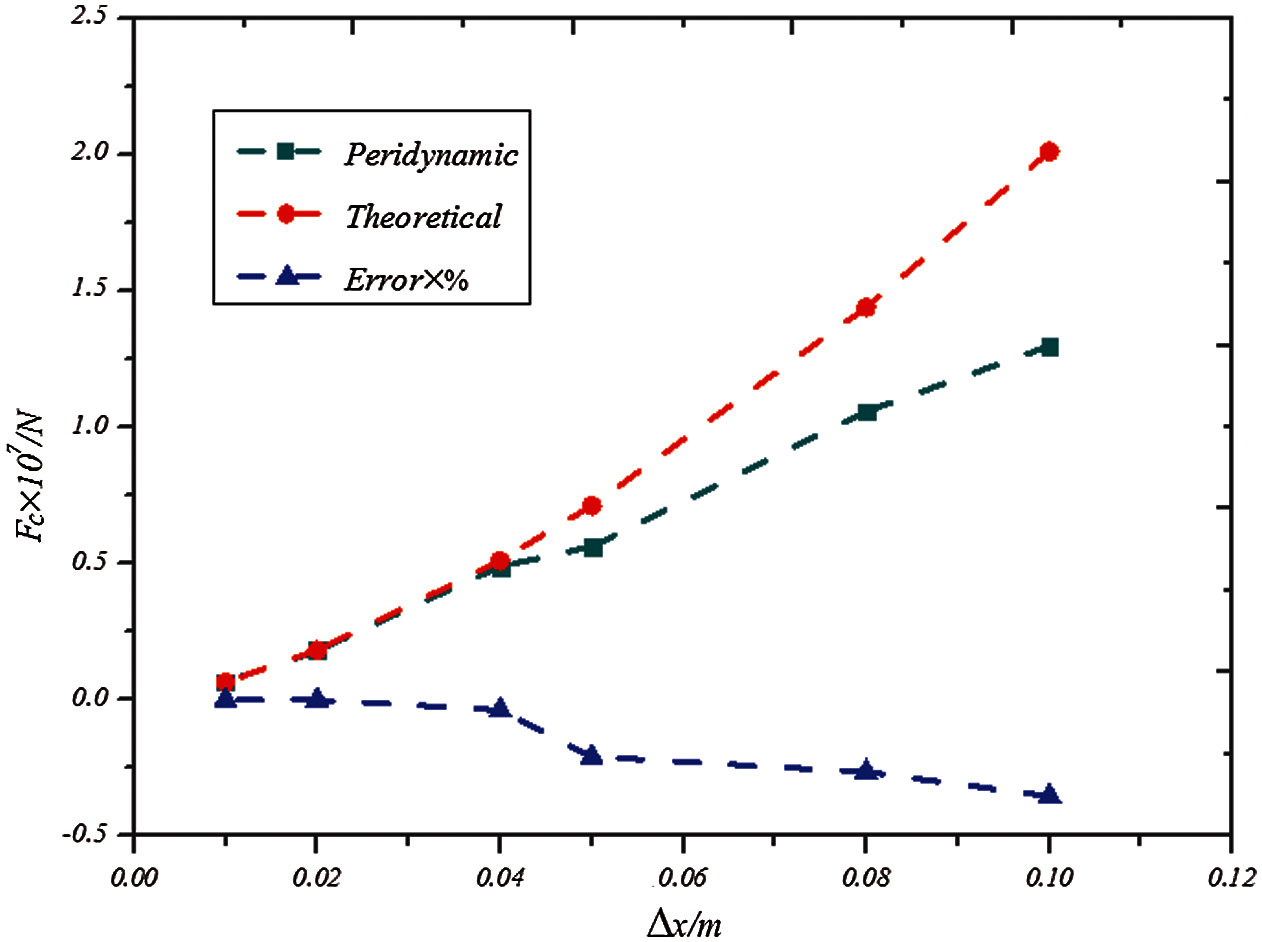

Figure 10: Plots of the contact force vs. the discrete distance

In summary, the influencing factors in the contact model of peridynamics are discussed and compared with the theoretical solution. The penalty-based method can be used to simulate the contact problem well by selecting the appropriate relative discrete size and the contact modulus. This process meets the requirements of computer truncation error and stable calculation. Therefore, on the basis of experience and the calculation results of this case, the calculation formula of contact modulus can be given as follows:

The range of adjustment coefficient

4 Contact Failure of Glass Specimen under Impact

Float glass material [7] is selected for analysis. The elastic modulus is

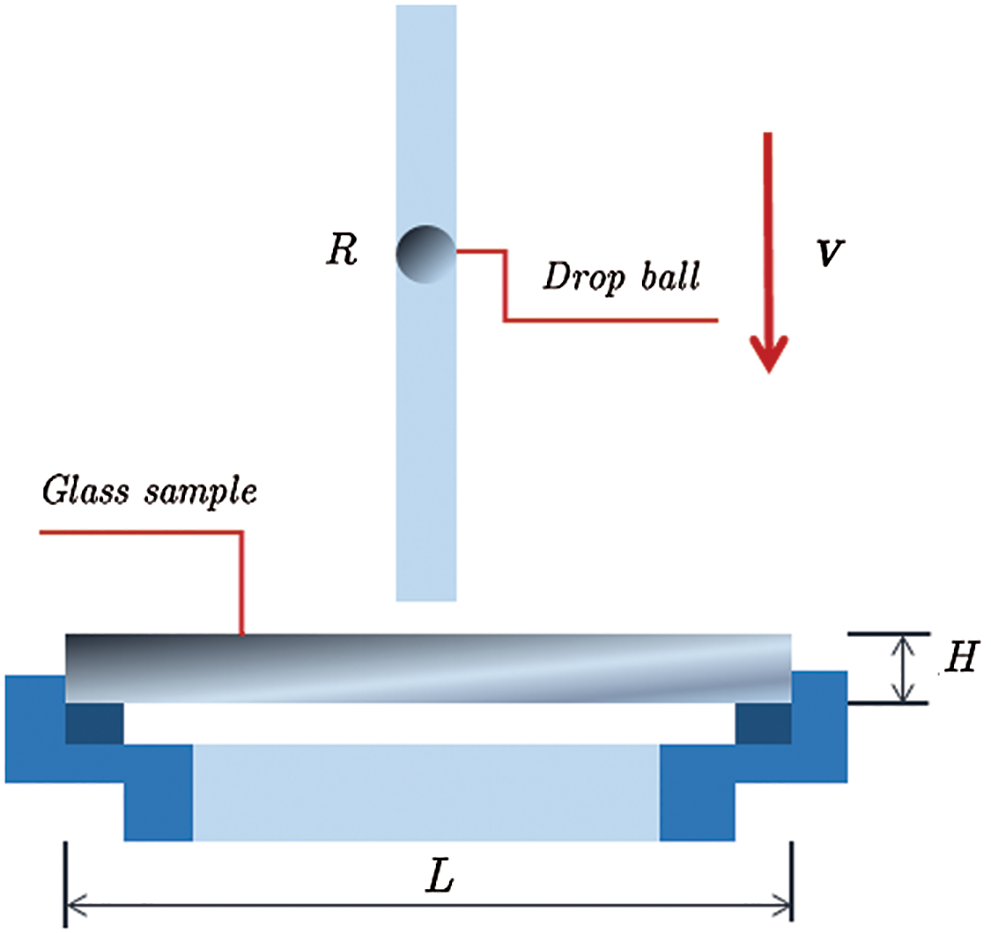

Figure 11: Geometric model of DBT [7]

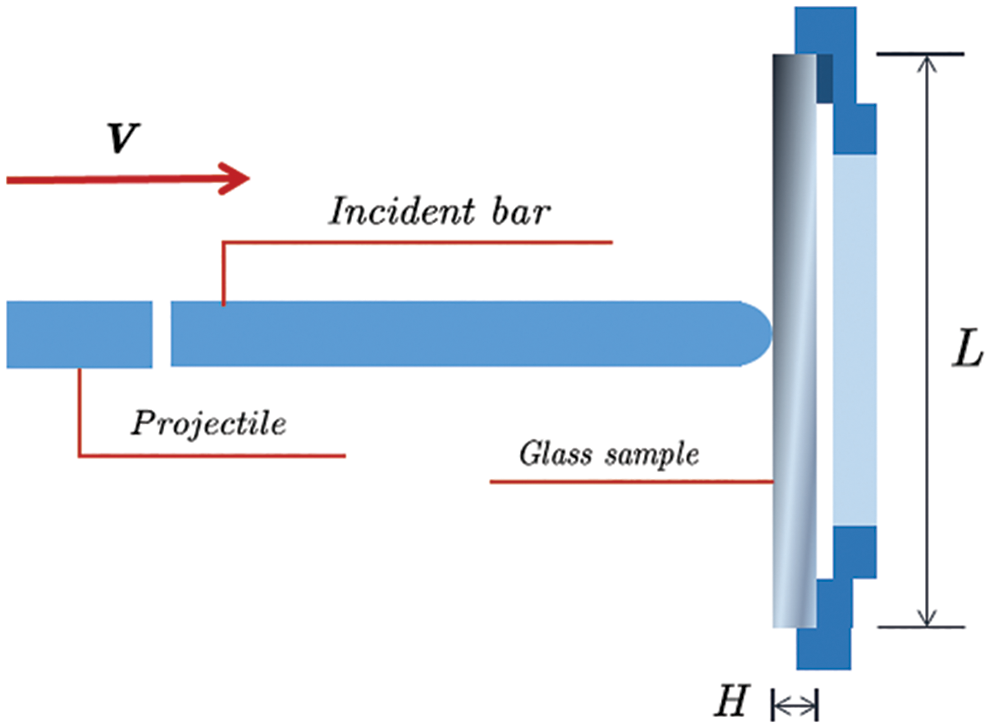

Figure 12: Geometric model of SHPB [7]

In the analysis of peridynamics, the contact modulus is taken as

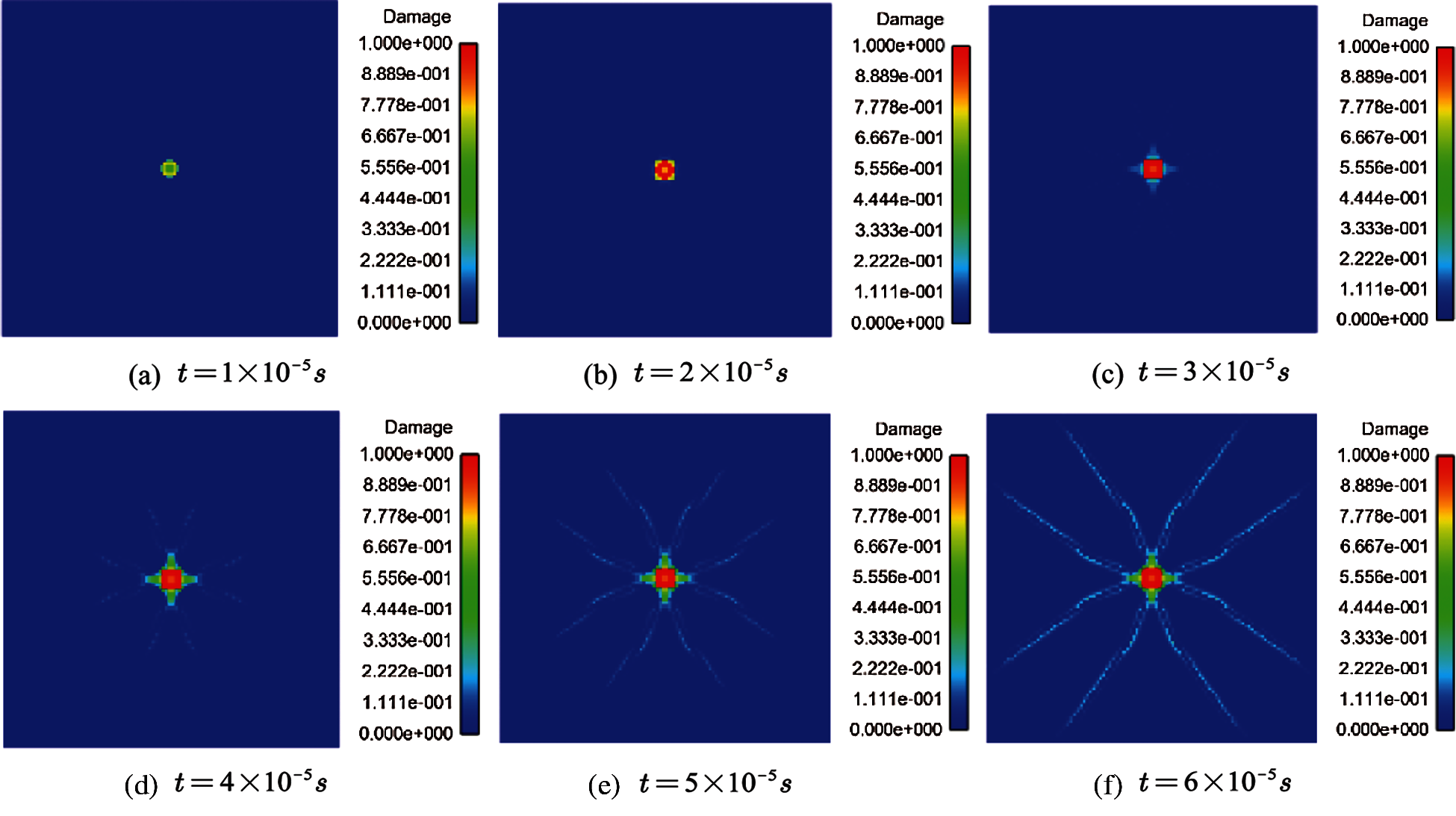

Figure 13: Damage of DBT model at different times (

Considering the low loading rate (

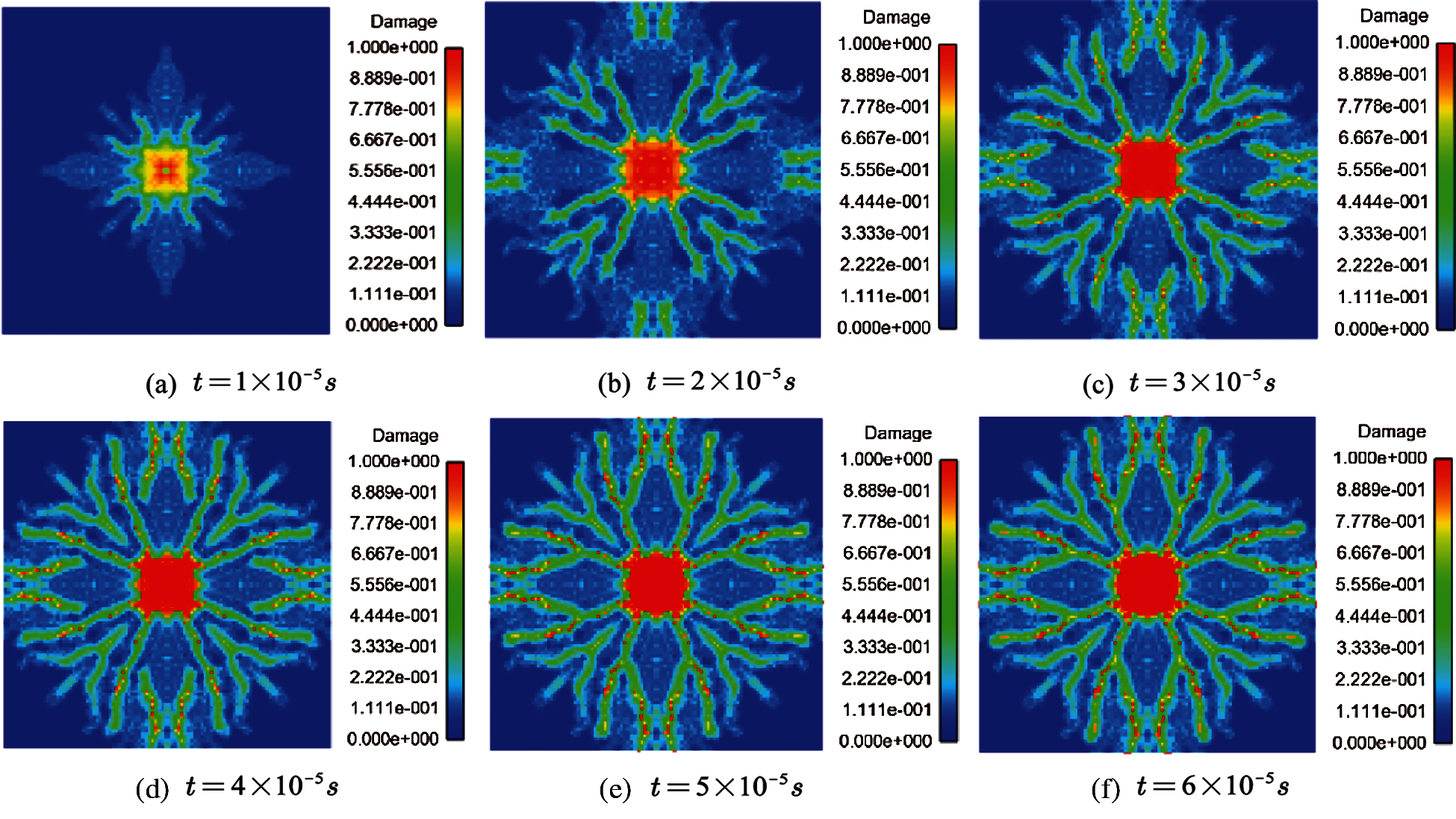

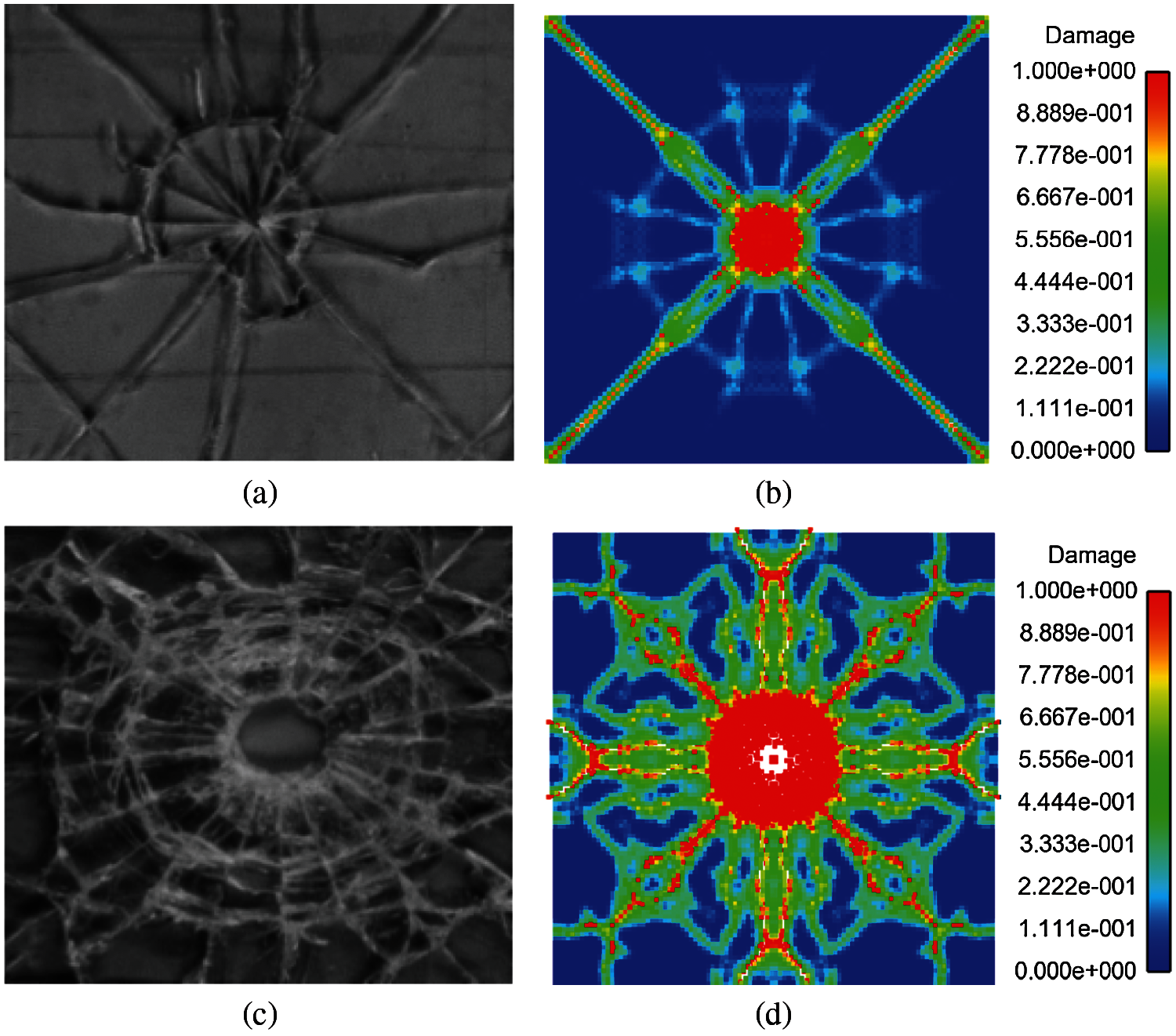

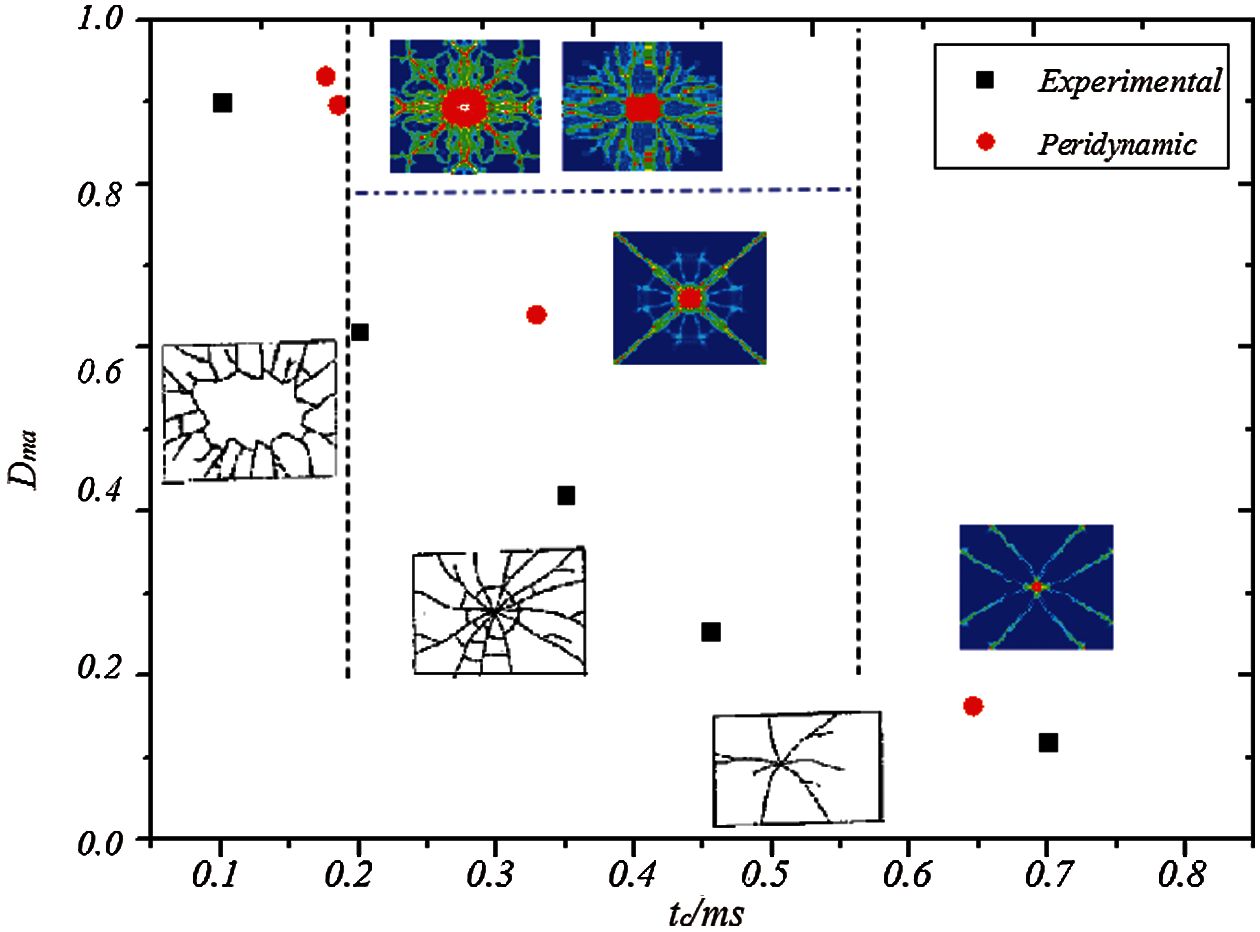

The damage of glass specimens in different times is shown in Fig. 18. With the increase in loading speed, the damage time becomes shorter, and the damage degree becomes more serious. The simulation results are consistent with the experimental results. Therefore, the contact model of peridynamics can well simulate the failure of brittle materials under impact conditions.

Figure 14: Damage of SHPB model at different times (

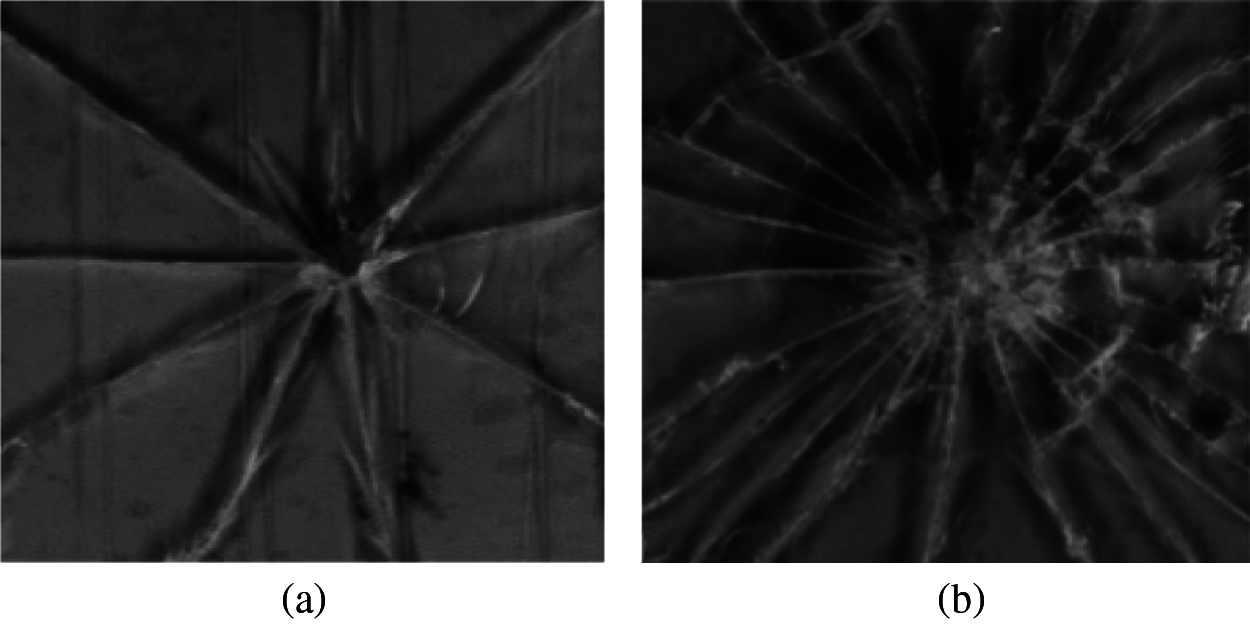

Figure 15: Experimental results [7] (a) Low loading rate of DBT (b) High loading rate of SHPB

Figure 16: Comparison of experimental results and simulation results (a) Experimental results of DBT [7] (b) Peridynamics results of DBT (

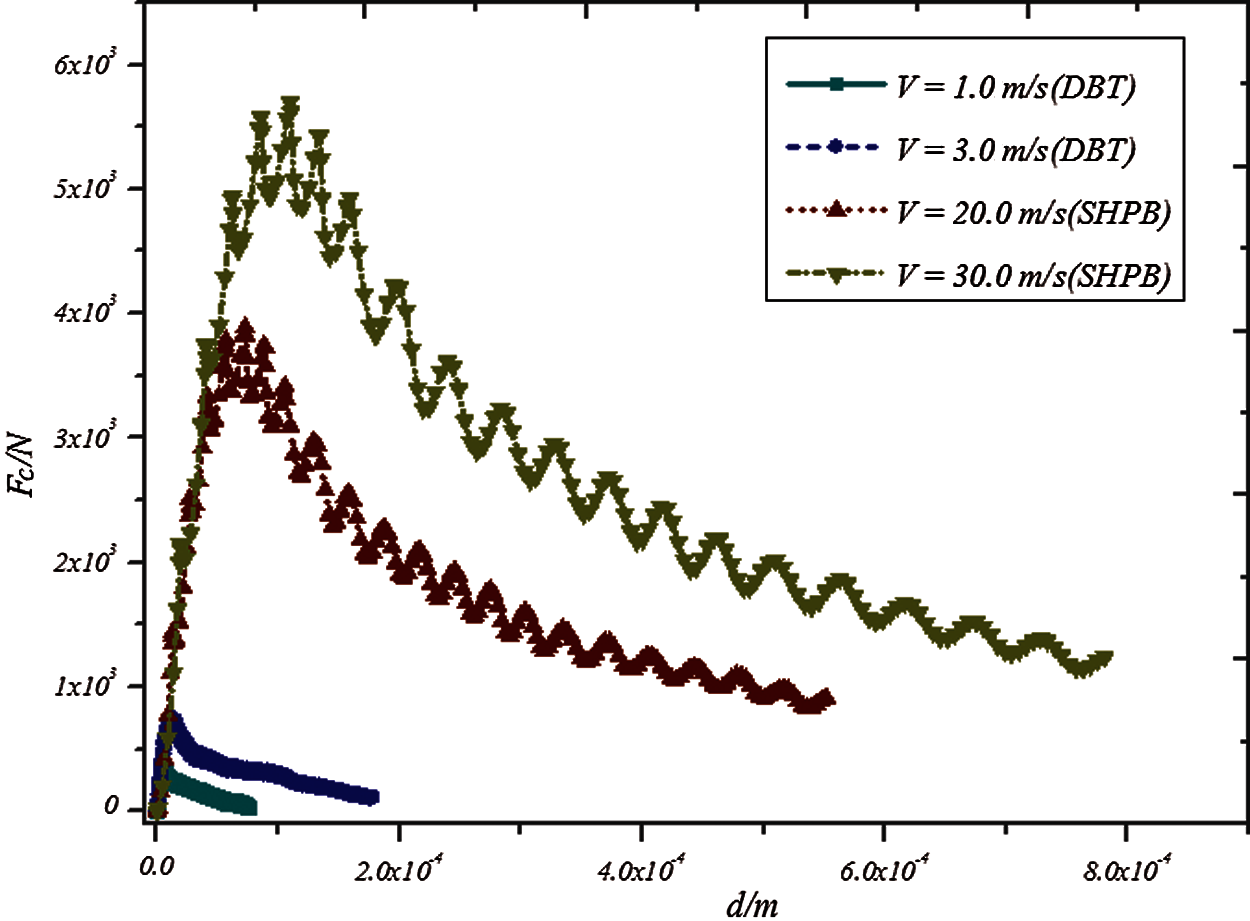

Figure 17: Curve of contact force vs. indentation depth at different impact speeds

Figure 18: Damage of glass specimens at different times

This paper proposes a new contact damage model of brittle materials based on ordinary state-based peridynamic theory by introducing the contact force function. The simulation results of the Hertzian contact (nonembedded contact) problem show that the embedded distance

The proposed damage contact model of peridynamics has a good application prospect and can be extended to the simulation of other similar materials, such as the impact fracture process of ice. The calculation model can be enriched and developed. The contact force only considers the vertical force. If the horizontal friction force is considered simultaneously, the response and failure mechanism of typical brittle materials under impact load can be better analyzed.

Acknowledgement: This research is financially by the National Natural Science Foundation of China (Nos. 11932006, U1934206, 12002118). And The Natural Science Foundation of the Jiangsu Higher Education Institutions of China (No. 20KJB580015). The snapshots were performed using the visualisation tool Ensight.

Funding Statement: This study was funded by National Natural Science Foundation of China (Nos. 11932006, U1934206), Recipient: Qing Zhang. And National Natural Science Foundation of China (No. 12002118), Recipient: Xin Gu. And Natural Science Foundation of the Jiangsu Higher Education Institutions of China (No. 20KJB580015). Recipient: Runpu Li.

Conflicts of Interest: The authors claim that none of the material in the paper has been published or is under consideration for publication elsewhere. The publication has been approved by all co-authors. We have no conflict of interest to declare, All data generated or analysed during this study are included in this published article.

1. Andrews, J. P. (1931). Observations on percussion figures. Proceedings of the Physical Society, 43(1), 18–25. DOI 10.1088/0959-5309/43/1/304. [Google Scholar] [CrossRef]

2. Roesler, F. C. (1956). Brittle fractures near equilibrium. Proceedings of the Physical Society. Section B, 69(10), 981–992. DOI 10.1088/0370-1301/69/10/303. [Google Scholar] [CrossRef]

3. Griffith, A. A. (1921). The phenomena of rupture and flow in solids. Philosophical Transactions of the Royal Society of London. Series A, Containing Papers of a Mathematical or Physical Character, 221, 163–198. DOI 10.1098/rsta.1921.0006. [Google Scholar] [CrossRef]

4. Knight, C. G., Swain, M. V., Chaudhri, M. M. (1977). Impact of small steel spheres on glass surfaces. Journal of Materials Science, 12(8), 1573–1586. DOI 10.1007/BF00542808. [Google Scholar] [CrossRef]

5. Chaudhri, M. M., Walley, S. M. (1978). Damage to glass surfaces by the impact of small glass and steel spheres. Philosophical Magazine A, 37(2), 153–165. DOI 10.1080/01418617808235430. [Google Scholar] [CrossRef]

6. Ball, A., Mckenzie, H. W. (1994). On the low velocity impact behaviour of glass plates. Journal de Physique IV, 7(C8), 783–788. [Google Scholar]

7. Bouzid, S., Nyoungue, A., Azari, Z. (2001). Fracture criterion for glass under impact loading. International Journal of Impact Engineering, 25(9), 831–845. DOI 10.1016/S0734-743X(01)00023-9. [Google Scholar] [CrossRef]

8. Nyoungue, A., Azari, Z., Abbadi, M., Dominiak, S., Hanim, S. (2005). Glass damage by impact spallation. Materials Science and Engineering: A, 407(1), 256–264. DOI 10.1016/j.msea.2005.07.031. [Google Scholar] [CrossRef]

9. Daryadel, S. S., Mantena, R. P., Kim, K., Stoddard, D., Rajendran, M. A. (2016). Dynamic response of glass under low-velocity impact and high strain-rate SHPB compression loading. Journal of Non-Crystalline Solids, 432(2), 432–439. DOI 10.1016/j.jnoncrysol.2015.10.043. [Google Scholar] [CrossRef]

10. Kumar, P., Shukla, A. (2011). Dynamic response of glass panels subjected to shock loading. Journal of Non-Crystalline Solids, 357(24), 3917–3923. DOI 10.1016/j.jnoncrysol.2011.08.009. [Google Scholar] [CrossRef]

11. Clough, R. W. (1960). The finite element method in plane stress analysis. Proceedings of the 2nd Conference on Electronic Computation of American Society of Civil Engineers, pp. 345–378. Pittsburgh, USA. [Google Scholar]

12. Rizzo, F. J. (1967). An integral equation approach to boundary value problems of classical elastostatics. Quarterly of Applied Mathematics, 25(1), 83–95. DOI 10.1090/qam/99907. [Google Scholar] [CrossRef]

13. Schöllmann, M., Fulland, M., Richard, H. A. (2003). Development of a new software for adaptive crack growth simulations in 3d structures. Engineering Fracture Mechanics, 70(2), 249–268. DOI 10.1016/S0013-7944(02)00028-0. [Google Scholar] [CrossRef]

14. Wells, G. N., Sluys, L. J. (2001). A new method for modelling cohesive cracks using finite elements. International Journal for Numerical Methods in Engineering, 50(12), 2667–2682. DOI 10.1002/(ISSN)1097-0207. [Google Scholar] [CrossRef]

15. Cen, Z., Maier, G. (1992). Bifurcations and instabilities in fracture of cohesive-softening structures: A boundary element analysis. Fatigue & Fracture of Engineering Materials & Structures, 15(9), 911–928. DOI 10.1111/j.1460-2695.1992.tb00066.x. [Google Scholar] [CrossRef]

16. Saleh, A. L., Aliabadi, M. H. (1995). Crack growth analysis in concrete using boundary element method. Engineering Fracture Mechanics, 51(4), 533–545. DOI 10.1016/0013-7944(94)00301-W. [Google Scholar] [CrossRef]

17. Belytschko, T., Black, T. (1999). Elastic crack growth in finite elements with minimal remeshing. International Journal for Numerical Methods in Engineering, 45(5), 601–620. DOI 10.1002/(ISSN)1097-0207. [Google Scholar] [CrossRef]

18. Oliveira, H. L., Leonel, E. D. (2013). Cohesive crack growth modelling based on an alternative nonlinear BEM formulation. Engineering Fracture Mechanics, 111(12), 86–97. DOI 10.1016/j.engfracmech.2013.09.003. [Google Scholar] [CrossRef]

19. Wang, L. F., Zhou, X. P. (2021). A field-enriched finite element method for simulating the failure process of rocks with different defects. Computers & Structures, 250(23–24), 106539. DOI 10.1016/j.compstruc.2021.106539. [Google Scholar] [CrossRef]

20. Kou, M. M., Lian, Y. J., Wang, Y. T. (2019). Numerical investigations on crack propagation and crack branching in brittle solids under dynamic loading using bond-particle model. Engineering Fracture Mechanics, 212(1), 41–56. DOI 10.1016/j.engfracmech.2019.03.012. [Google Scholar] [CrossRef]

21. Bo, R., Li, S. (2010). Meshfree simulations of plugging failures in high-speed impacts. Computers & Structures, 88(15–16), 909–923. DOI 10.1016/j.compstruc.2010.05.003. [Google Scholar] [CrossRef]

22. Bo, R., Li, S., Qian, J., Zeng, X. (2011). Meshfree simulations of spall fracture. Computer Methods in Applied Mechanics and Engineering, 200(5–8), 797–811. DOI 10.1016/j.cma.2010.10.003. [Google Scholar] [CrossRef]

23. Silling, S. A. (2000). Reformulation of elasticity theory for discontinuities and long-range forces. Journal of the Mechanics and Physics of Solids, 48(1), 175–209. DOI 10.1016/S0022-5096(99)00029-0. [Google Scholar] [CrossRef]

24. Huang, D., Zhang, Q., Qiao, P., Shen, F. (2010). Peridynamics method and its application. Advances in Mechanics, 40(4), 448–459. [Google Scholar]

25. Askari, E., Bobaru, F., Lehoucq, R. B., Parks, M. L., Silling, S. A. et al. (2008). Peridynamics for multiscale materials modeling. Journal of Physics Conference, 125, 012078. DOI 10.1088/1742-6596/125/1/012078. [Google Scholar] [CrossRef]

26. Cheng, Z., Wang, Z., Luo, Z. (2019). Dynamic fracture analysis for shale material by peridynamic modelling. Computer Modeling in Engineering and Sciences, 118(3), 509–527. DOI 10.31614/cmes.2019.04339. [Google Scholar] [CrossRef]

27. Kilic, B., Madenci, E. (2009). Prediction of crack paths in a quenched glass plate by using peridynamic theory. International Journal of Fracture, 156(2), 165–177. DOI 10.1007/s10704-009-9355-2. [Google Scholar] [CrossRef]

28. Ha, Y. D., Bobaru, F. (2011). Characteristics of dynamic brittle fracture captured with peridynamics. Engineering Fracture Mechanics, 78(6), 1156–1168. DOI 10.1016/j.engfracmech.2010.11.020. [Google Scholar] [CrossRef]

29. Hu, W., Wang, Y., Yu, J., Yen, C. F., Bobaru, F. (2013). Impact damage on a thin glass plate with a thin polycarbonate backing. International Journal of Impact Engineering, 62, 152–165. DOI 10.1016/j.ijimpeng.2013.07.001. [Google Scholar] [CrossRef]

30. Liu, R., Yan, J., Li, S. (2019). Modeling and simulation of ice-water interactions by coupling peridynamics with updated lagrangian particle hydrodynamics. Computational Particle Mechanics, 7(11–12), 241–255. DOI 10.1007/S40571-019-00268-7. [Google Scholar] [CrossRef]

31. Silling, S. A., Epton, M., Weckner, O., Xu, J., Askari, E. (2007). Peridynamic states and constitutive modeling. Journal of Elasticity, 88(2), 151–184. DOI 10.1007/s10659-007-9125-1. [Google Scholar] [CrossRef]

32. Silling, S. A., Lehoucq, R. B. (2010). Peridynamic theory of solid mechanics. Advances in Applied Mechanics, 44, 73–168. DOI 10.1016/S0065-2156(10)44002-8. [Google Scholar] [CrossRef]

33. Breitenfeld, M. S., Geubelle, P. H., Weckner, O., Silling, S. A. (2014). Non-ordinary state-based peridynamic analysis of stationary crack problems. Computer Methods in Applied Mechanics & Engineering, 272, 233–250. DOI 10.1016/j.cma.2014.01.002. [Google Scholar] [CrossRef]

34. O’Grady, J., Foster, J. (2014). Peridynamic beams: A non-ordinary, state-based model. International Journal of Solids & Structures, 51(18), 3177–3183. DOI 10.1016/j.ijsolstr.2014.05.014. [Google Scholar] [CrossRef]

35. Chowdhury, S. R., Rahaman, M. M., Roy, D., Sundaram, N. (2015). A micropolar peridynamic theory in linear elasticity. International Journal of Solids and Structures, 59(5), 171–182. DOI 10.1016/j.ijsolstr.2015.01.018. [Google Scholar] [CrossRef]

36. Song, Y., Yan, J. L., Li, S. F., Kang, Z. (2019). Peridynamic modeling and simulation of ice craters by impact. Computer Modeling in Engineering & Sciences, 121(2), 465–492. DOI 10.32604/cmes.2019.07190. [Google Scholar] [CrossRef]

37. Zhou, X. P., Shou, Y. D., Berto, F. (2018). Analysis of the plastic zone near the crack tips under the uniaxial tension using ordinary state-based peridynamics. Fatigue & Fracture of Engineering Materials & Structures, 41(5), 1159–1170. DOI 10.1111/ffe.12760. [Google Scholar] [CrossRef]

38. Wu, L., Huang, D., Xu, Y., Wang, L. (2019). A non-ordinary state-based peridynamic formulation for failure of concrete subjected to impacting loads. Computer Modeling in Engineering & Sciences, 118(3), 561–581. DOI 10.31614/cmes.2019.04347. [Google Scholar] [CrossRef]

39. Xin, L., Liu, L., Li, S., Zeleke, M. A., Zhen, W. (2018). A non-ordinary state-based peridynamics modeling of fractures in quasi-brittle materials. International Journal of Impact Engineering, 111, 130–146. DOI 10.1016/j.ijimpeng.2017.08.008. [Google Scholar] [CrossRef]

40. Littlewood, D. J. (2010). Simulation of dynamic fracture using peridynamics, finite element modeling, and contact. ASME International Mechanical Engineering Congress & Exposition, Vancouver, British Columbia, Canada. [Google Scholar]

41. Ye, L. Y., Wang, C., Chang, X., Zhang, H. Y. (2017). Propeller-ice contact modeling with peridynamics. Ocean Engineering, 139(4), 54–64. DOI 10.1016/j.oceaneng.2017.04.037. [Google Scholar] [CrossRef]

42. Kamensky, D., Behzadinasab, M., Foster, J. T., Bazilevs, Y. (2019). Peridynamic modeling of frictional contact. Journal of Peridynamics and Nonlocal Modeling, 1(2), 107–121. DOI 10.1007/s42102-019-00012-y. [Google Scholar] [CrossRef]

43. Silling, S. A., Barr, C., Cooper, M., Lechman, J., Bufford, D. C. (2021). Inelastic peridynamic model for molecular crystal particles. In: Computational particle mechanics, pp. 1–13. Berlin: Springer. [Google Scholar]

44. Wang, Y. T., Zhou, X. P., Kou, M. M. (2019). Three-dimensional numerical study on the failure characteristics of intermittent fissures under compressive-shear loads. Acta Geotechnica, 14(4), 1161–1193. DOI 10.1007/s11440-018-0709-7. [Google Scholar] [CrossRef]

45. Silling, S. A., Askari, E. (2005). A meshfree method based on the peridynamic model of solid mechanics. Computers & Structures, 17(18), 1526–1535. DOI 10.1016/j.compstruc.2004.11.026. [Google Scholar] [CrossRef]

46. Landau, L. D., Lifshitz, E. M. (1959). Theory of easticity. Oxford: Pergamon Press. [Google Scholar]

The Herzian contact of the rigid body is considered in Fig. A-1, and the contact stress of the sphere can be expressed as

where

Figure A-1: Herzian contact problem of Rigid body

For a semi-infinite elastic body, the elastic mechanics solution of the concentrated force

When the contact surface

Then, when the distributed force is considered

where

And

where

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |