| Computer Modeling in Engineering & Sciences |  |

DOI: 10.32604/cmes.2021.017211

ARTICLE

Multi-Material Topology Optimization of Structures Using an Ordered Ersatz Material Model

1Fujian Key Laboratory of Automotive Electronics and Electric Drive, Fujian University of Technology, Fuzhou, 350118, China

2Key Laboratory of Advanced Technology for Vehicle Body Design & Manufacture, Hunan University, Changsha, 410082, China

3Faculty of Science, Engineering and Technology, Swinburne University of Technology, Melbourne, VIC 3122, Australia

4Centre for Innovative Structures and Materials, School of Engineering, RMIT University, Melbourne, VIC 3001, Australia

*Corresponding Author: Xiaodong Huang. Email: xhuang@swin.edu.au

Received: 22 April 2021; Accepted: 27 May 2021

Abstract: This paper proposes a new element-based multi-material topology optimization algorithm using a single variable for minimizing compliance subject to a mass constraint. A single variable based on the normalized elemental density is used to overcome the occurrence of meaningless design variables and save computational cost. Different from the traditional material penalization scheme, the algorithm is established on the ordered ersatz material model, which linearly interpolates Young's modulus for relaxed design variables. To achieve a multi-material design, the multiple floating projection constraints are adopted to gradually push elemental design variables to multiple discrete values. For the convergent element-based solution, the multiple level-set functions are constructed to tentatively extract the smooth interface between two adjacent materials. Some 2D and 3D numerical examples are presented to demonstrate the effectiveness of the proposed algorithm and the possible advantage of the multi-material designs over the traditional solid-void designs.

Keywords: Multi-material topology optimization; ordered ersatz material model; mass constraint; single variable

Topology optimization aims at finding optimal material distribution within the prescribed design domain and achieving the best performance of the structure. Since the seminar paper of Bendsøe et al. [1] in 1988, several topology optimization methods have been developed, including the homogenization method [2,3], the solid isotropic material with penalization (SIMP) method [4,5], the level-set method (LSM) [6–8], the bi-directional evolutionary structural optimization (BESO) [9–12]. With the recent development of additive manufacturing, multi-material structures can be comfortably fabricated and play an important role in practical engineering applications. The multi-material topology optimization has attracted increasing attention for designing lightweight structures.

Multi-material topology optimization traditionally seeks the best distributions of materials under multiple volume constraints so that the objective performance of the resulting multi-material structure is optimal. Sigmund et al. [13] and Bendsoe et al. [5] proposed a mixture rule of the multi-material model to characterize the distributions of materials in the SIMP framework. For instance, the three-material model containing two solid and one void materials can be described as

In practical engineering applications, the total weight of a structure may be more concerned. This is a lightweight design, where the total mass should be reasonably adopted as a constraint or objective function for a multi-material design. However, when a single mass function is implemented with multiple design variables, some meaningless combinations of multiple design variables may occur and further bring some numerical difficulties for multi-material topology optimization. Yin et al. [34] introduced the peak function with SIMP method for the multi-material design using a single variable, but the horizontal zero slope of the peak function model has potential difficulties in numerical calculations. Gao et al. [35,36] developed a uniform multiphase materials interpolation (UMMI) scheme using multiple design variables. For example, a three-material UMMI model containing two solid and one void materials can be described by

The multi-material topology optimization using a single variable has an obvious advantage in saving computational cost [37]. However, the nonlinearity of the ordered-SIMP model could result in a local optimum as demonstrated in our late examples. Using the linear ordered-ersatz material model, this paper will develop a new multi-material topology optimization algorithm using a single variable based on the floating projection topology optimization (FPTO) method [39,40]. The FPTO method belongs to the element-based approach, but the structural topology is formed by the floating projection constraint, which simulates the 0/1 constraints of design variables. This provides the possibility for multi-material topology optimization using an ordered ersatz material model proposed in this paper. The remainder of this paper is organized as follows: Section 2 introduces the multi-material topology optimization problem and the ordered ersatz material model. In Section 3, the multi-material topology optimization algorithm is developed. Some 2D and 3D numerical examples are presented in Section 4 to verify the developed multi-material topology optimization algorithm, as well as its various applications. Finally, some conclusions are drawn in Section 5.

2 The Problem Statement and Material Model

2.1 Statement of the Topology Optimization Problem

Suppose that a multi-material structure is composed of M-phase materials within the design domain, where void is also as one material.

where

where

Figure 1: Schematic illustration of the three-material design with the smooth boundary under the fixed-mesh finite element analysis

When the design domain is made up of multiple materials, as shown in Fig. 1.

where

2.2 Ordered Ersatz Material Model

For an element with the normalized density

where

where

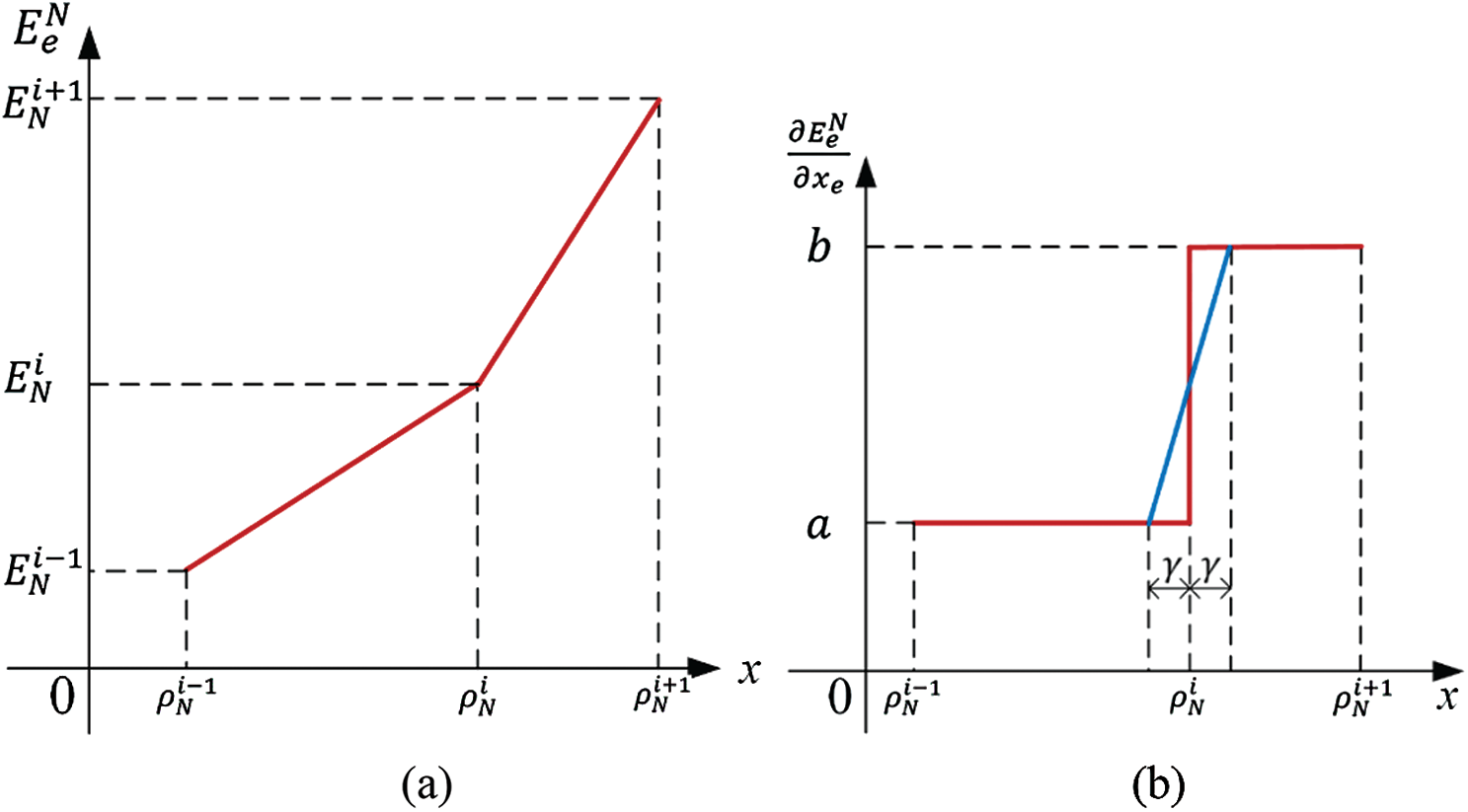

Figure 2: (a) Schematic diagram of the ordered ersatz material model containing three adjacent materials and (b) its linear transition scheme of the derivative near the point

However, such an ordered ersatz material model becomes non-differentiable at points,

where

3 Multi-Material Topology Optimization Algorithm

To consider the mass constraint defined in Eq. (3), the objective function can be modified by introducing a Lagrange multiplier as

where

where

where the sensitivity of the compliance can be easily derived by using the adjoint method.

According to Eq. (2), the sensitivity of the total mass fraction is straightforward

Meanwhile, the sensitivity of the compliance is averaged with its value in the previous iteration to damp the update of the design variables

where l is the current iteration number.

The optimality criterion in Eq. (9) can be further expressed by

Thus, the design variable of element e is updated by

where the negative sign before

where the

where the

In the traditional solid/void topology optimization, the implicit floating projection constraint simulates 0/1 constraints of design variables and further modifies the design variables after filtering. In the multi-material design, all design variables should be constrained to the discrete values,

where

With the increase of

where

3.2 Representation of a Solution with Smooth Interfaces between Two Adjacent Materials

Once the algorithm is convergent for a given

where

The threshold,

Obviously, the above level-set functions are purely based on imaging processing and the resulting multi-material design may be far different from the element-based design expressed by the design variables, x. To check the difference between the multi-material design and the element-based design, we project the resulting multi-material design back to the fixed mesh and re-calculate the density of each element. If an element is fully occupied by material i, the density of the element is assigned with

where C denotes the compliance of the element-based design. If

In this section, several 2D and 3D numerical examples are presented to demonstrate the effectiveness of the proposed multi-material topology optimization algorithm. It is assumed that Poisson's ratio of all candidate materials is

4.1 Multi-Material Cantilever Beam

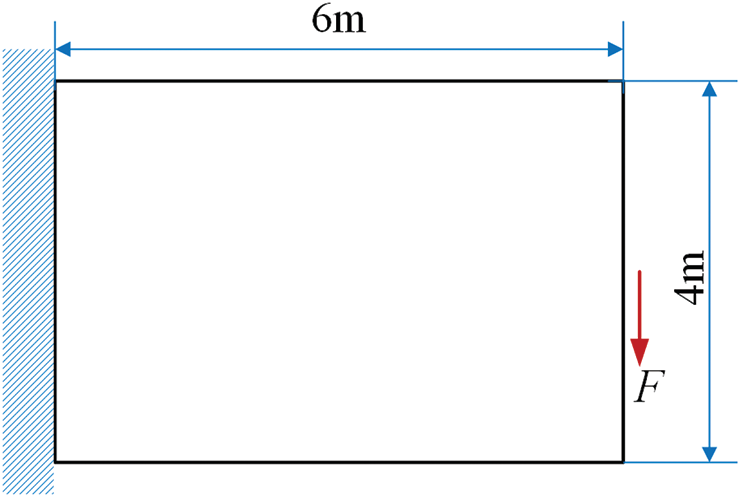

As shown in Fig. 3, a typical cantilever beam composes of two solid materials (m1, m2) and one void material. The design domain is discretized with 120 × 80 four-node plane-stress elements. A vertical concentrated force

Figure 3: Design domain, dimensions and boundary condition of a cantilever

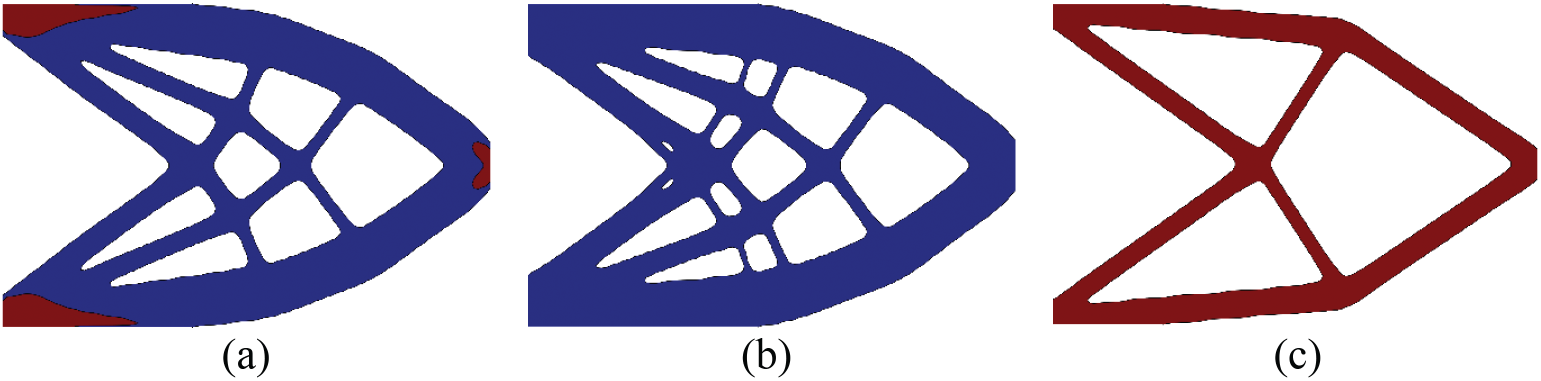

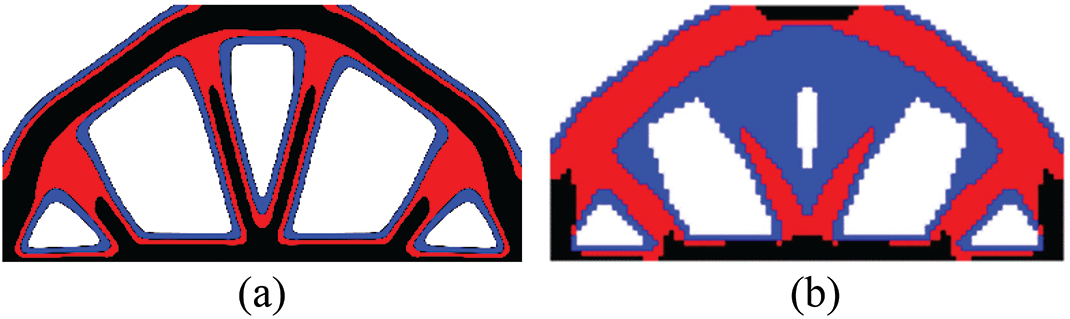

The optimized multi-material design is shown in Fig. 4a, whose compliance is

Figure 4: Comparison of the optimized designs where m1 and m2 are represented by blue and red colors, respectively. (a) the multi-material design and its compliance is

Fig. 5 shows the iteration histories of the compliance, topology and

Figure 5: Iteration histories of the compliance, topology and

4.2 Multi-Material Designs of a Simply Supported Beam

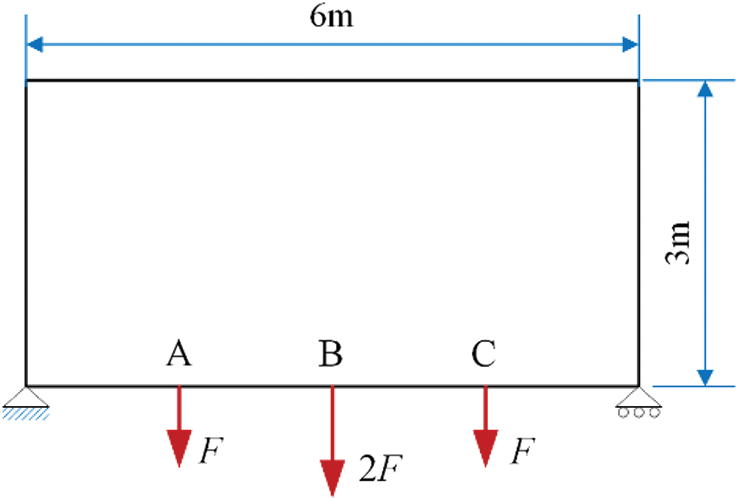

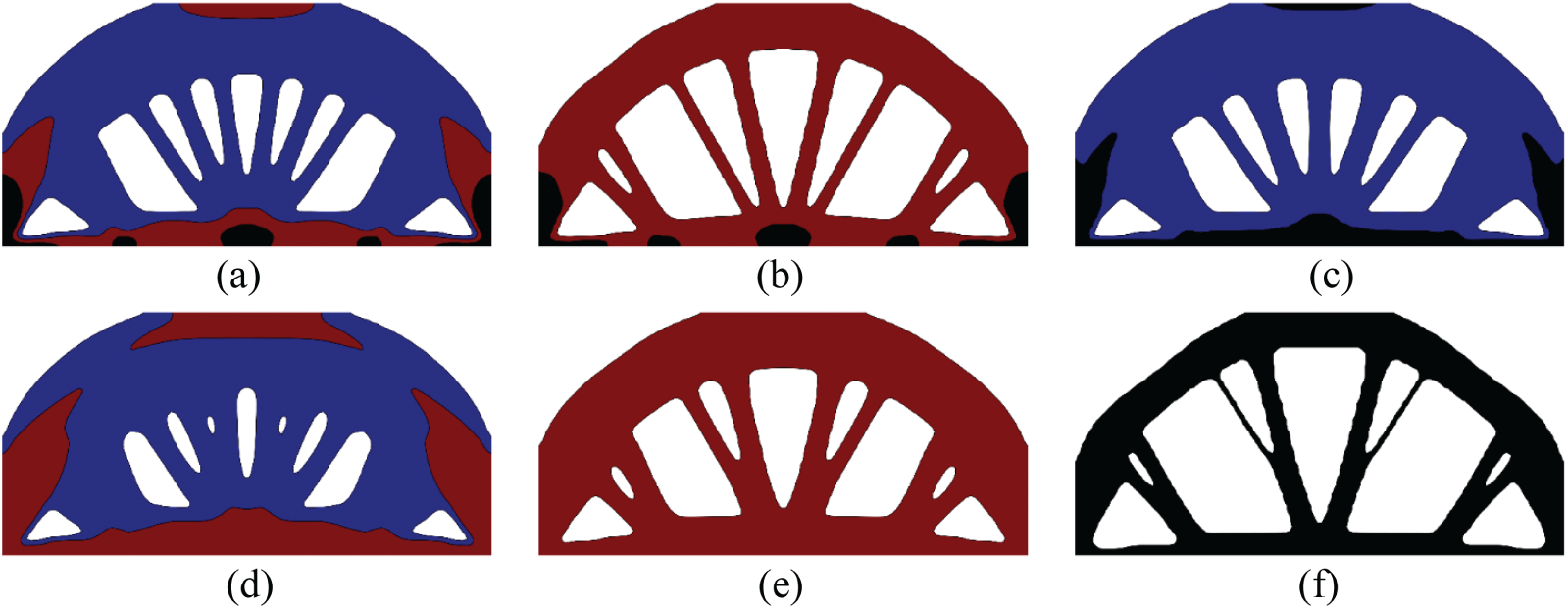

This example shows the multi-material design for a 2D beam as shown in Fig. 6 under the total mass constraint,

Figure 6: Design domain, dimensions and boundary condition of a simply supported beam

Under the given mass constraint, Fig. 7 shows the optimized results using the different combination of candidate materials: (a) void, m1, m2 and m3; (b) void, m2 and m3; (c) void, m1 and m3; (d) void, m1 and m2; (e) void and m1; (f) void and m2; (g) void and m3. In Fig. 7a, the compliance of the optimized design using all of the candidate materials is 193.32 Nm, which is the lowest one compared with other designs. The stiff material (m3) mainly distributes near the locations of concentrated forces and supports. The volume fraction of m1 is larger than that of m2 and m3 because its stiffness-density ratio is the highest. In these designs composed by two solid materials, as shown in Figs. 7b–7d, their corresponding compliances are 207.17 Nm, 195.49 Nm and 208.17 Nm, which are higher than that of the previous design. The compliances of the traditional solid/void designs shown in Figs. 7e–7g are 264.08 Nm, 221.63 Nm and 232.03 Nm, respectively. Therefore, the compliance of the multi-material design in Fig. 7a has the minimum compliance, which also indicates the advantage of optimally designing structures using multiple materials and the effectiveness of the proposed multi-material topology optimization algorithm.

Figure 7: Optimized designs under

Different from the ordered SIMP method, the structural topology is formed by the floating projection constraint in the proposed multi-material topology optimization algorithm. For the comparison, the above example is re-calculated using 100

Figure 8: Optimized designs resulting from different material models: (a) the multi-material optimized design from the proposed algorithm using the order-ersatz material model, and its compliance is 194.4; (b) the optimized multi-material design using the ordered SIMP model in the reference [37], and its compliance is 217.2

4.3 Lightweight Designs of a Simply Supported Beam Subject to Displacement Constraints

In practice, it preferably achieves a lightweight structure under single or multiple displacement constraints. The proposed multi-material topology optimization, similar to the FPTO method [39], can be easily extended to solve such a problem, which can be mathematically stated as

where

Taking the simply supported beam shown in Fig. 6 as an example, the vertical displacements at the point A, B and C are restricted as

Figure 9: Optimized designs for minimizing the mass subject to three displacement constraints,

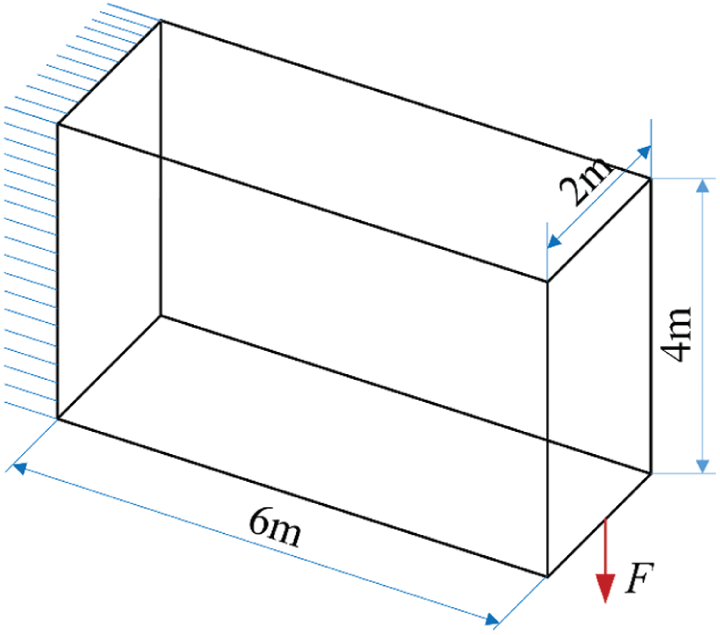

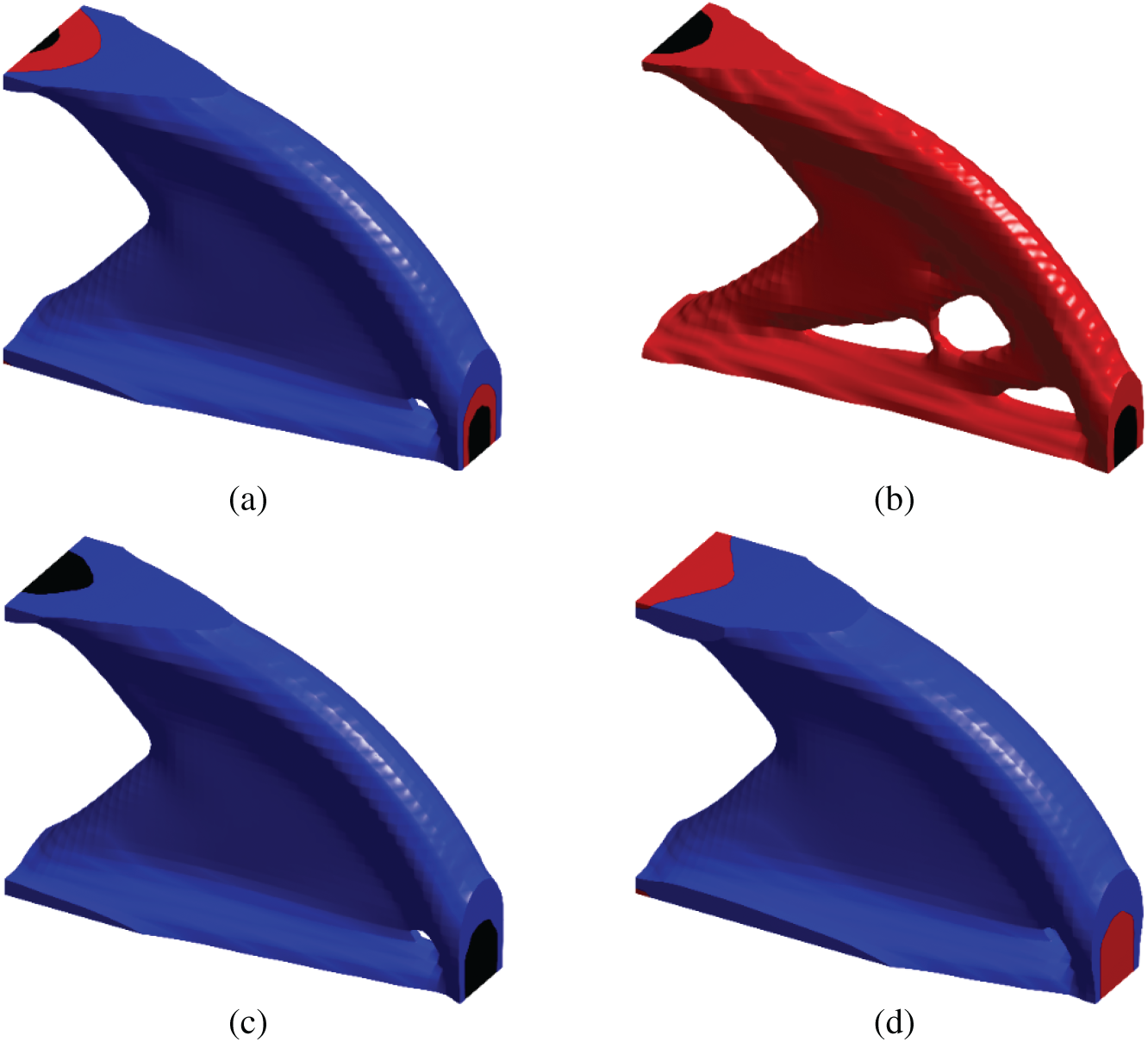

4.4 Multi-Material Designs of a 3D Cantilever

This example shows the multi-material designs for a 3D cantilever shown in Fig. 10, where a vertical load

Fig. 10: Design domain, dimensions and boundary condition of a 3D cantilever

When the compliance is minimized subject to the total mass constraint,

Next, the multi-material lightweight design is applied by specifying the displacement constraint at point A,

Figure 11: 3D Multi-material designs for minimizing compliance under a mass constraint,

Figure 12: 3D multi-material designs for minimizing mass under a displacement constraint,

This paper proposed a new and simple multi-material topology optimization algorithm for minimizing compliance subject to a single mass constraint based on the FPTO method. Under the framework of the finite element analysis, the elemental normalized density is used as a single variable for designing structures composed of multiple materials without the increase of the computational burden. The ordered ersatz material model is proposed to interpolate the material property for the relaxed design variables linearly. Some 2D and 3D examples are presented to demonstrate the effectiveness of the proposed multi-material topology optimization algorithm and optimized multi-material designs are represented by the smooth interfaces between any two adjacent materials. Besides, the proposed algorithm can be extended to minimizing the total mass subject to single or multiple displacement constraints for a lightweight design of structures. Numerical results show that the multi-material designs could outperform the traditional solid/void designs, and this performance improvement increases when more candidate materials are involved in optimization.

Funding Statement: This work was supported by Hunan Provincial Innovation Foundation for Postgraduate (CX20190278), FJUT Scientific Research Foundation (GY-Z17015), and Open Fund of Fujian Key Laboratory of Automotive Electronics and Electric Drive (KF-X19001).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Bendsøe, M. P., Kikuchi, N. (1988). Generating optimal topologies in structural design using a homogenization method. Computer Methods in Applied Mechanics and Engineering, 71(2), 197–224. DOI 10.1016/0045-7825(88)90086-2. [Google Scholar] [CrossRef]

2. Suzuki, K., Kikuchi, N. (1991). A homogenization method for shape and topology optimization. Computer Methods in Applied Mechanics and Engineering, 93(3), 291–318. DOI 10.1016/0045-7825(91)90245-2. [Google Scholar] [CrossRef]

3. Nishiwaki, S., Frecker, M. I., Min, S., Kikuchi, N. (1998). Topology optimization of compliant mechanisms using the homogenization method. International Journal for Numerical Methods in Engineering, 42(3), 535–559. DOI 10.1002/(ISSN)1097-0207. [Google Scholar] [CrossRef]

4. Bendsøe, M. P. (1989). Optimal shape design as a material distribution problem. Structural Optimization, 1, 193–202. DOI 10.1007/BF01650949. [Google Scholar] [CrossRef]

5. Bendsøe, M. P., Sigmund, O. (2003). Topology optimization: Theory, methods and applications. Verlag, Berlin: Springer. [Google Scholar]

6. Sethian, J. A., Wiegmann, A. (2000). Structural boundary design via level set and immersed interface methods. Journal of Computational Physics, 163(2), 489–528. DOI 10.1006/jcph.2000.6581. [Google Scholar] [CrossRef]

7. Wang, M. Y., Wang, X., Guo, D. (2003). A level set method for structural topology optimization. Computer Methods in Applied Mechanics and Engineering, 192(1/2), 227–246. DOI 10.1016/S0045-7825(02)00559-5. [Google Scholar] [CrossRef]

8. Allaire, G., Jouve, F., Toader, A. M. (2004). Structural optimization using sensitivity analysis and a level-set method. Journal of Computational Physics, 194(1), 363–393. DOI 10.1016/j.jcp.2003.09.032. [Google Scholar] [CrossRef]

9. Querin, O. M., Steven, G. P., Xie, Y. M. (1998). Evolutionary structural optimization (ESO) using a bi-directional algorithm. Engineering Computations, 15, 1031–1048. DOI 10.1108/02644409810244129. [Google Scholar] [CrossRef]

10. Huang, X., Xie, Y. M. (2007). Convergent and mesh-independent solutions for the bi-directional evolutionary structural optimization method. Finite Elements in Analysis and Design, 43(14), 1039–1049. DOI 10.1016/j.finel.2007.06.006. [Google Scholar] [CrossRef]

11. Huang, X., Xie, Y. M. (2010). Evolutionary topology optimization of continuum structures: Methods and applications. John Wiley & Sons, Chichester. [Google Scholar]

12. Huang, X., Zuo, Y. H., Xie, Y. M. (2010). Evolutionary topological optimization of vibrating continuum structures for natural frequencies. Computers and Structures, 88, 357–364. DOI 10.1016/j.compstruc.2009.11.011. [Google Scholar] [CrossRef]

13. Sigmund, O., Torquato, S. (1997). Design of materials with extreme thermal expansion using a three-phase topology optimization method. Journal of the Mechanics & Physics of Solids, 45(6), 1037–1067. DOI 10.1016/S0022-5096(96)00114-7. [Google Scholar] [CrossRef]

14. Sigmund, O. (2001). Design of multiphysics actuators using topology optimization—Part II: Two-material structures. Computer Methods in Applied Mechanics and Engineering, 190, 6605–6627. DOI 10.1016/S0045-7825(01)00252-3. [Google Scholar] [CrossRef]

15. Gibiansky, L. V., Sigmund, O. (2000). Multiphase composites with extremal bulk modulus. Journal of the Mechanics & Physics of Solids, 48(3), 461–498. DOI 10.1016/S0022-5096(99)00043-5. [Google Scholar] [CrossRef]

16. Chu, S., Xiao, M., Gao, L., Li, H., Zhang, J. et al. (2019). Topology optimization of multi-material structures with graded interfaces. Computer Methods in Applied Mechanics and Engineering, 346, 1096–1117. DOI 10.1016/j.cma.2018.09.040. [Google Scholar] [CrossRef]

17. Jeong, S. H., Choi, D. H., Yoon, G. H. (2014). Separable stress interpolation scheme for stress-based topology optimization with multiple homogenous materials. Finite Elements in Analysis and Design, 82, 16–31. DOI 10.1016/j.finel.2013.12.003. [Google Scholar] [CrossRef]

18. Wang, M. Y., Wang, X. (2004). “Color” level sets: A multi-phase method for structural topology optimization with multiple materials. Computer Methods in Applied Mechanics and Engineering, 193, 469–496. DOI 10.1016/j.cma.2003.10.008. [Google Scholar] [CrossRef]

19. Guo, X., Zhang, W. S., Zhong, W. (2014). Stress-related topology optimization of continuum structures involving multi-phase materials. Computer Methods in Applied Mechanics and Engineering, 268, 632–655. DOI 10.1016/j.cma.2013.10.003. [Google Scholar] [CrossRef]

20. Huang, X., Xie, Y. M. (2009). Bi-directional evolutionary topology optimization of continuum structures with one or multiple materials. Computational Mechanics, 43(3), 393–401. DOI 10.1007/s00466-008-0312-0. [Google Scholar] [CrossRef]

21. Xu, B., Jiang, J. S., Xie, Y. M. (2015). Concurrent design of composite macrostructure and multi-phase material microstructure for minimum dynamic compliance. Composite Structures, 128, 221–233. DOI 10.1016/j.compstruct.2015.03.057. [Google Scholar] [CrossRef]

22. Da, D., Cui, X. Y., Long, K., Li, G. Y. (2017). Concurrent topological design of composite structures and the underlying multi-phase materials. Computers and Structures, 179, 1–14. DOI 10.1016/j.compstruc.2016.10.006. [Google Scholar] [CrossRef]

23. Xu, B., Huang, X., Zhou, S. W., Xie, Y. M. (2016). Concurrent topological design of composite thermoelastic macrostructure and microstructure with multi-phase material for maximum stiffness. Composite Structures, 150, 84–102. DOI 10.1016/j.compstruct.2016.04.038. [Google Scholar] [CrossRef]

24. Radman, A., Huang, X., Xie, Y. M. (2014). Topological design of microstructures of multi-phase materials for maximum stiffness or thermal conductivity. Computational Materials Science, 91, 266–273. DOI 10.1016/j.commatsci.2014.04.064. [Google Scholar] [CrossRef]

25. Da, D., Cui, X., Long, K., Cai, Y., Li, G. (2019). Multiscale concurrent topology optimization of structures and microscopic multi-phase materials for thermal conductivity. Engineering Computations, 36(1), 126–146. DOI 10.1108/EC-01-2018-0007. [Google Scholar] [CrossRef]

26. Zhang, W. S., Song, J., Zhou, J., Du, Z., Zhu, Y. et al. (2018). Topology optimization with multiple materials via moving morphable component (MMC) method. International Journal for Numerical Methods in Engineering, 113, 1653–1675. DOI 10.1002/nme.5714. [Google Scholar] [CrossRef]

27. Wang, M., Zhou, S. (2004). Phase field: A variational method for structural topology optimization. Computer Modeling in Engineering and Science, 6(6), 547–566 DOI 10.1115/DETC2004-57637. [Google Scholar] [CrossRef]

28. Tavakoli, R., Mohseni, S. (2013). Alternating active-phase algorithm for multimaterial topology optimization problems: A 115-line MATLAB implementation. Structural and Multidisciplinary Optimization, 49(4), 621–642. DOI 10.1007/s00158-013-0999-1. [Google Scholar] [CrossRef]

29. Park, J., Sutradhar, A. (2015). A multi-resolution method for 3D multi-material topology optimization. Computer Methods in Applied Mechanics and Engineering, 285, 571–586. DOI 10.1016/j.cma.2014.10.011. [Google Scholar] [CrossRef]

30. Wang, N. F., Hu, K., Zhang, X. M. (2017). Hierarchical optimization for topology design of multi-material compliant mechanisms. Engineering Optimization, 49(12), 2013–2035. DOI 10.1080/0305215X.2016.1277062. [Google Scholar] [CrossRef]

31. Wei, P., Wang, M. Y. (2009). Piecewise constant level set method for structural topology optimization. International Journal for Numerical Methods in Engineering, 78, 379–402. DOI 10.1002/nme.2478. [Google Scholar] [CrossRef]

32. Luo, Z., Tong, L., Luo, J., Wei, P., Wang, M. Y. (2009). Design of piezoelectric actuators using a multiphase level set method of piecewise constants. Journal of Computational Physics, 228, 2643–2659. DOI 10.1016/j.jcp.2008.12.019. [Google Scholar] [CrossRef]

33. Wang, Y., Luo, Z., Kang, Z., Zhang, N. (2015). A multi-material level set-based topology and shape optimization method. Computer Methods in Applied Mechanics and Engineering, 283, 1570–1586. DOI 10.1016/j.cma.2014.11.002. [Google Scholar] [CrossRef]

34. Yin, L., Ananthasuresh, G. K. (2001). Topology optimization of compliant mechanisms with multiple materials using a peak function material interpolation scheme. Structural and Multidisciplinary Optimization, 23, 49–62. DOI 10.1007/s00158-001-0165-z. [Google Scholar] [CrossRef]

35. Gao, T., Zhang, W. (2011). A mass constraint formulation for structural topology optimization with multiphase materials. International Journal for Numerical Methods in Engineering, 88, 774–796. DOI 10.1002/nme.3197. [Google Scholar] [CrossRef]

36. Gao, T., Xu, P., Zhang, W. (2016). Topology optimization of thermos-elastic structures with multiple materials under mass constraint. Computers and Structures, 173, 150–160. DOI 10.1016/j.compstruc.2016.06.002. [Google Scholar] [CrossRef]

37. Zuo, W., Saitou, K. (2017). Multi-material topology optimization using ordered SIMP interpolation. Structural and Multidisciplinary Optimization, 55, 477–491. DOI 10.1007/s00158-016-1513-3. [Google Scholar] [CrossRef]

38. Yang, X. T., Li, M. (2018). Discrete multi-material topology optimization under total mass constraint. Computer-Aided Design, 102, 182–192. DOI 10.1016/j.cad.2018.04.023. [Google Scholar] [CrossRef]

39. Huang, X. (2020). Smooth topological design of structures using the floating projection. Engineering Structures, 208, 110330. DOI 10.1016/j.engstruct.2020.110330. [Google Scholar] [CrossRef]

40. Huang, X. (2021). On smooth or 0/1 designs of the fixed-mesh element-based topology optimization. Advances in Engineering Software, 151, 102942. DOI 10.1016/j.advengsoft.2020.102942. [Google Scholar] [CrossRef]

41. Sigmund, O., Petersson, J. (1998). Numerical instabilities in topology optimization: A survey on procedures dealing with checkerboards, mesh-dependencies and local minima. Structural Optimization, 16(1), 68–75. DOI 10.1007/BF01214002. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |