Engineering & Sciences

| Computer Modeling in Engineering & Sciences |  |

DOI: 10.32604/cmes.2021.015685

ARTICLE

Robust Topology Optimization of Periodic Multi-Material Functionally Graded Structures under Loading Uncertainties

1College of Mechanical and Electrical Engineering, Qingdao University, Qingdao, 266071, China

2Power Integration and Energy Storage System Engineering Technology Center, Qingdao University, Qingdao, 266071, China

*Corresponding Author: Qinghai Zhao. Email: zqhbit@163.com

Received: 04 January 2021; Accepted: 24 February 2021

Abstract: This paper presents a robust topology optimization design approach for multi-material functional graded structures under periodic constraint with load uncertainties. To characterize the random-field uncertainties with a reduced set of random variables, the Karhunen-Loève (K-L) expansion is adopted. The sparse grid numerical integration method is employed to transform the robust topology optimization into a weighted summation of series of deterministic topology optimization. Under dividing the design domain, the volume fraction of each preset gradient layer is extracted. Based on the ordered solid isotropic microstructure with penalization (Ordered-SIMP), a functionally graded multi-material interpolation model is formulated by individually optimizing each preset gradient layer. The periodic constraint setting of the gradient layer is achieved by redistributing the average element compliance in sub-regions. Then, the method of moving asymptotes (MMA) is introduced to iteratively update the design variables. Several numerical examples are presented to verify the validity and applicability of the proposed method. The results demonstrate that the periodic functionally graded multi-material topology can be obtained under different numbers of sub-regions, and robust design structures are more stable than that indicated by the deterministic results.

Keywords: Multi-material; topology optimization; robust design; periodic functional gradient; sparse grid method

Functionally graded structure, known as non-uniform structure, has extensive application prospects in the fields of aerospace, aircraft design, communication and electronics, etc., due to excellent performances such as vibration absorption, heat insulation and noise reduction.

In recent years, there is a trend to optimize the design of functionally graded structures using topology optimization methods [1,2] to achieve specific performances. Paulino et al. [3] firstly discussed the effectiveness of the functionally graded structure topology optimization design using the criterion method. Since then, great achievements have been made in the study of topology optimization for functionally graded structures design. Xia et al. [4] achieved the parallel optimization design of material properties and material distribution of functionally graded structures. Huang et al. [5] employed the bi-directional evolutionary structural optimization (BESO) approach to obtain various anisotropic microstructures of porous materials and composite materials. Recently, a systematic multi-phase infill design method [6] is proposed to generate graded multi-material infill structures. According to the above introduction, existing topological optimization methods of functionally gradient structures generally ignore the influence of uncertain factors such as material uncertainty [7,8], load uncertainty [9,10], geometric size and boundary uncertainty [11,12], resulting in structural instability and unreliability after optimization. In this context, structural topology optimization considering uncertainties tends to make optimized topologies more stable and reliable [13,14].

Currently, topology optimization under loading uncertainties is generally classified into two categories, namely reliability-based topology optimization (RBTO) [15,16] and robust topology optimization (RTO) [17,18]. RBTO focuses on safety and aims to accurately provide structural safety measures, while RTO attaches importance to structural stability, which reduces the sensitivity of structural performance. Ben-Tal et al. [19] firstly employed the semidefinite programming to solve the RTO problem of truss structures. Compared with the discrete structure, the RTO problem of continuum structure is more practical and has become one of the research hotspots. Amir et al. [20] proposed a reanalysis method to solve RTO problem, aiming to improve the computational efficiency of RTO algorithm. Wu et al. [21] explored the RTO method for uncertainties of external load direction based on interval variables. Moreover, Zhang et al. [22] investigated a robust topology optimization method for designing the microstructures of PnCs by considering random field material properties. However, the above researches mainly focus on RTO of single material structures. The emergence of 3D additive printing technology makes the manufacturing and processing of multi-material structure possible. Recently, Kang et al. [23] proposed a robust shape and topology optimization method considering the uncertainties with the interface of multi-material structures. Chan et al. [24] presented a density-based RTO for meso- or macroscale multi-material lattice structures under any combination of material and load uncertainties. Zheng et al. [25] proposed an effective method for designing multi-material robust structures, aiming at minimizing the compliance of linear elastic structures. Romero et al. [26] performed the multi-material robust topology optimization problem by minimizing the topology derivative constructor of the functional to achieve the nucleation and evolution of the level set.

This paper optimizes the topology of the gradient layer with the mean and standard deviation weights of the structural compliance as the objective function and the volume fraction as the constraint to identify the optimal multi-material layout scheme. Meanwhile, considering the application in practical engineering, periodic constraints are applied in the macrostructure topology optimization model for easy manufacturing and assembly. A robust topology optimization design method for multi-material functionally graded structures with periodic constraints is proposed, which applies the Ordered-SIMP method to characterize the multi-material interpolation model. In terms of load random field distribution, the K-L expansion is employed to transform the random field into a finite number of unrelated load random variables, and the sparse grid numerical integration method is adopted to transform the RTO into a set of multi-weighted deterministic topology optimization (DTO).

The rest of the paper is organized as follows. Section 2 introduces the periodic multi-material functionally graded structure. Section 3 gives a brief introduction of multi-material structure interpolation model. The uncertainties in the characterization of the loading uncertainty with random fields are described in Section 4. Section 5 presents the establishment development and solution procedure of the proposed RTO formulation. Several numerical examples are given in Section 6 to verify the proposed method. Section 7 summarizes the remarkable conclusions.

2 Multi-Material Functionally Graded Structure

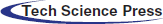

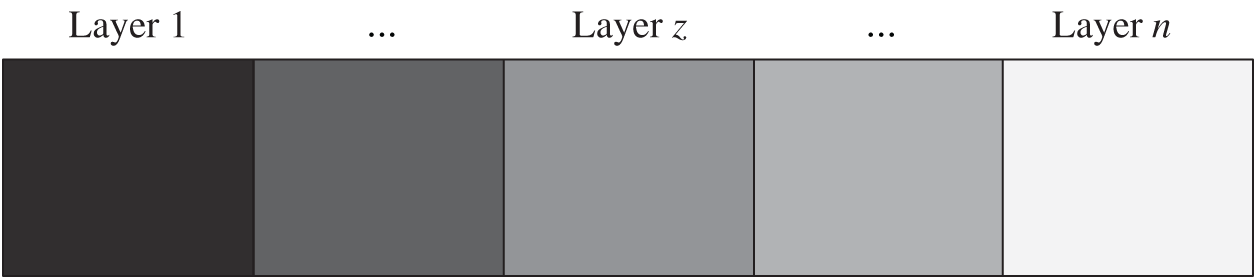

The macro design domain of a periodic multi-material functionally graded structure is divided into multiple gradient layers (

Figure 1: Periodic multi-material functionally graded structure

3 Multi-Material Interpolation Model Based on Ordered-SIMP

The SIMP method introduces cell design variables that vary continuously in the interval of 0–1 [27–29] to establish a nonlinear functional relationship between material properties and design variables.

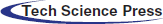

In terms of the design of multiple materials structure, the elastic modulus and density of each material are firstly normalized, and the material properties are transformed into dimensionless relative values

where

The multiple material interpolation model based on the ordered-SIMP method [30] can be expressed as

where xe denotes the relative density of element e, which is the design variable,

where

Figure 2: Three materials interpolation model based on Ordered-SIMP

4 Discretization of Random Field under Load Uncertainties

The load uncertainties can be characterized by random field or random variable. For distributed loads with spatial correlation, the commonly used discrete and simulation methods include the extended optimal linear estimation method [31] and the K-L expansion [32,33]. This paper uses the K-L expansion to transform the random field into the cumulative sum of a finite number of uncorrelated random variables under corresponding weights [34]. The K-L expansion of the random field can be described as

where

where

where

When the K-L expansion is applied to the discretization of random field

where e is the mean value of the random field at d observation points;

where the correlation matrix C is defined as

In practical problems, the main probability characteristics of a stochastic process are usually approximated by the random variables corresponding to the first few eigenvalues descending from the maximum eigenvalue. Taking the first M items and letting it as

when s is close enough to 1, the random field can be effectively characterized by dimensionality reduction K-L expansion [36,37].

5 Robust Topology Optimization Model of Multi-Material Functionally Graded Structure

5.1 Robust Topology Optimization Model

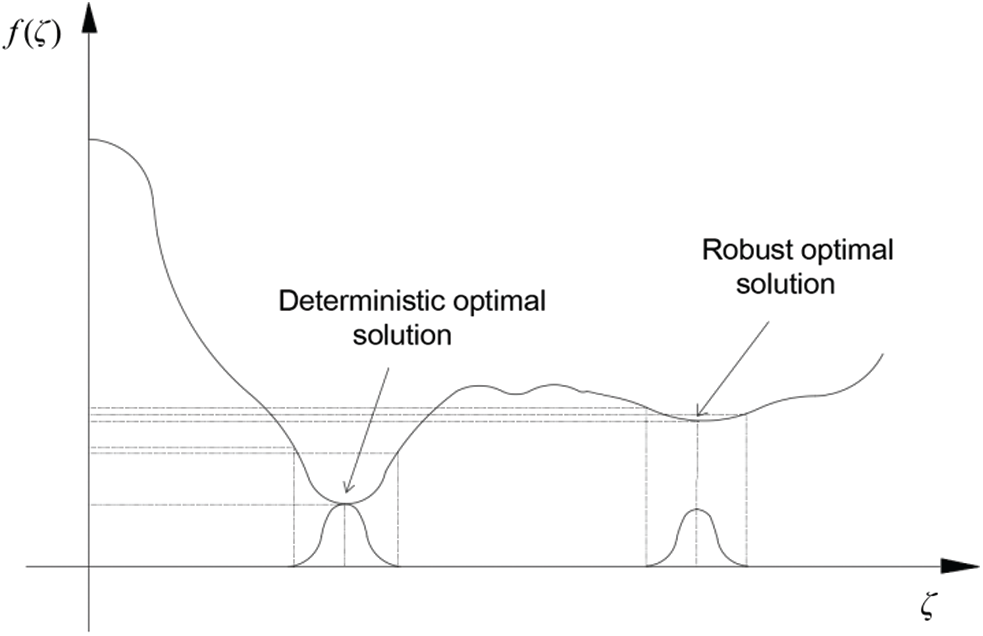

The purpose of robust topology optimization design is to reduce the sensitivity of performance function to uncertain random variables while optimizing the objective function, so as to minimize the variance of performance index fluctuation [38]. The difference between the deterministic optimal solution and the robust optimal solution is depicted in Fig. 3. It can be seen that the optimal performance of the robust design is worse than the former, but its performance index is less volatile and more superior to a certain extent. Therefore, robust topology optimization design, as a typical multi-objective optimization design problem, is usually achieved by weighting the expectation and standard deviation of the performance function into the objective function.

According to the mathematical description of uncertain variables, robust topology optimization design can be divided into non-probabilistic and probabilistic models [39]. Probabilistic models can be used to describe the characteristics of most uncertain factors. Based on probability theory and mathematical statistics, typical indicators for measuring the robustness of structural performance are termed as mean and standard deviation. The mathematical model for robust topology optimization of multi-material structures is established as follows:

where J is the objective function, w and

where

Figure 3: Deterministic optimal solution and robust optimal solution

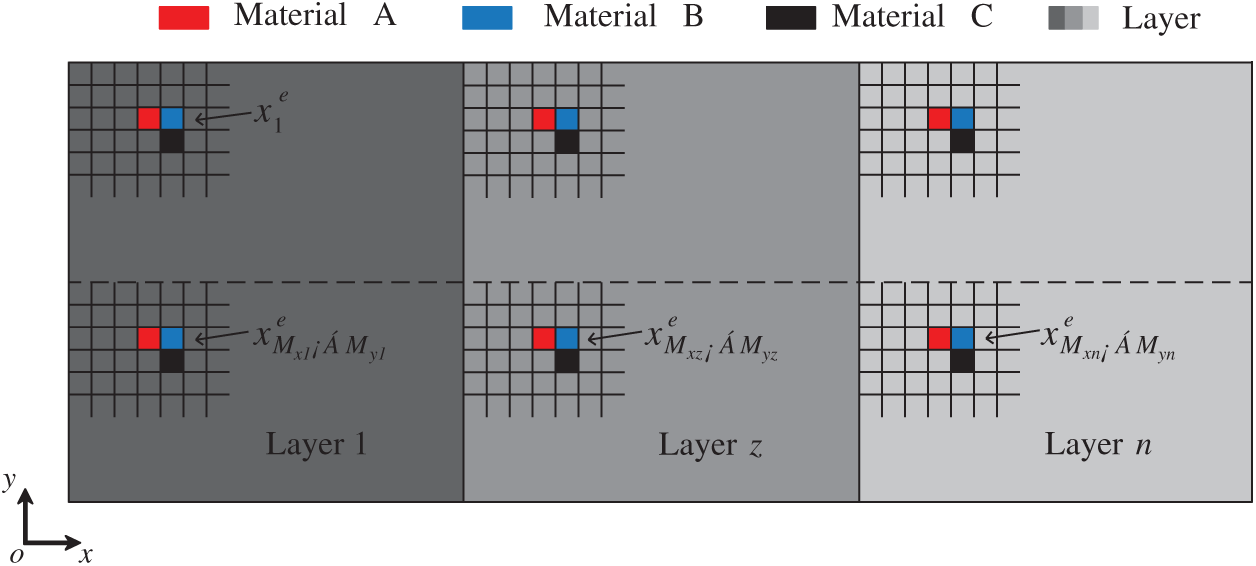

5.2 Robust Topology Optimization Model of Functionally Graded Structure

In order to calculate the overall layout of a functionally graded structure [41,42] under volume constraints. The volume fraction of each preset gradient layer in the optimal topological configuration is extracted from the multi-material structure topology optimization model. The two-dimensional rectangular design domain is divided into n gradient layers: Layer

Then, each gradient layer is individually designed for optimization. The topology optimization model of the functionally graded structure design can be defined as

where N represents the number of element in the gradient layer,

Figure 4: Layer-wise design

The optimization goal of this paper is the weighted sum of the mean and standard deviation of structural compliance. Among them, the sensitivity of the mean and standard deviation relative to the design variable

5.3 Sparse Grid Numerical Integration Method

In order to solve the objective function of the robust topology optimization design, a sparse grid method based on the Smolyak criterion [43] is employed. A basic idea is to construct a multidimensional product formulation using a special tensor product operation of one-dimensional configuration points as a linear combination. The advantage of this method is that the number of configuration points is limited, and the nodes that contribute less to the calculation accuracy are automatically deleted, so the sparse grid is applied to the robust design of statistical moment estimation. Based on the nested hierarchy principle, the one-dimensional interlayer difference is defined as

where k represents the dimension, when k = 0,

where

where

The corresponding weights are determined as

Thus, the configuration points are given as

By adjusting the level accuracy l value, the sparse grid integration accuracy is improved. Based on the Newton-Cotes integration rule, the Causs–Chebyshev [44] sparse grid

The sequence of figuration points is

Then, the corresponding weights are expressed as follows:

The sparse grid numerical integration method is employed to solve the mean and the standard deviation of the robust topology optimization design. The expression of mean and standard deviation can be modified as

According to Eqs. (17) and (18), the derivative of the optimization target J with respect to the density

The commonly used optimization solution algorithms include mathematical programming method and optimization criterion method. In the iterative process, MMA [45] has better applicability for problems with complex objectives and multi-constrained topology optimization. In this paper, MMA method is introduced to solve the topology optimization problem of multi-material functional graded structure. And the PDE filtering method based on Helmholts equation is adopted.

In order to obtain the periodic functionally graded structure, the elements of the different substructures of each gradient layer at the same position have the same material properties. The periodic layer-wise design is shown in Fig. 5. Each gradient layer is divided into

By reallocating the average element compliance in sub-regions, the periodic constraint setting of the gradient layer is achieved.

At this point, the sensitivity of elements at the same position is equal to that of different substructures to achieve periodic geometric constraints.

Figure 5: Periodic layer-wise design

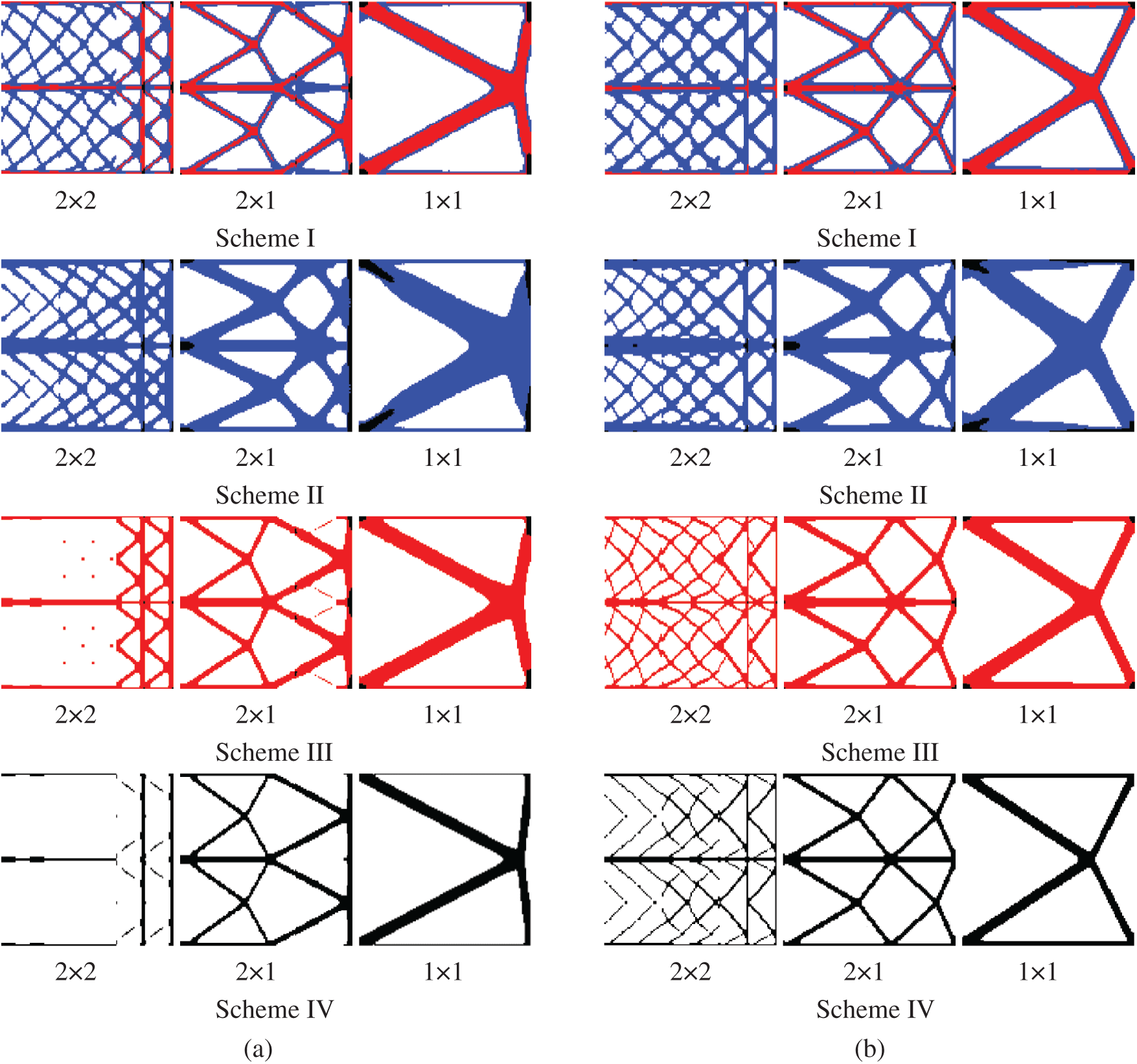

This paper proposes three numerical examples to illustrate the difference between the optimal topologies under loading uncertainties and deterministic loading conditions. For comparison, the settings in the DTO are the same as those in the RTO examples. In the calculation examples, the design domain is discretized by square elements, and the weight coefficients of mean value and standard deviation are set to 0.5, respectively. In order to prove the effectiveness of the proposed method, gradient layers of 2, 3, 4 and 6 are preset for different design domains in this paper, and for more intuitive comparison of DTO and RTO,

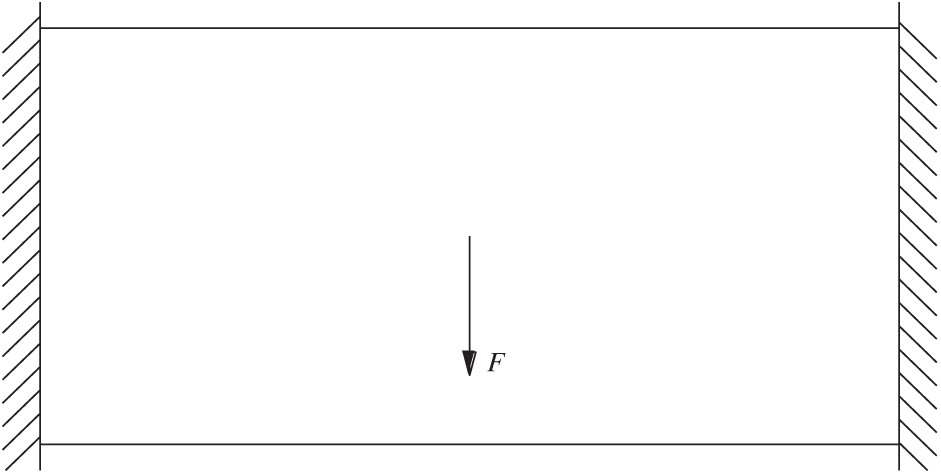

The double-sided fixed beam is shown in Fig. 6. The design domain is a

Figure 6: Design domain of double-sided fixed beam structure

Table 1: Implementation of three materials parameters

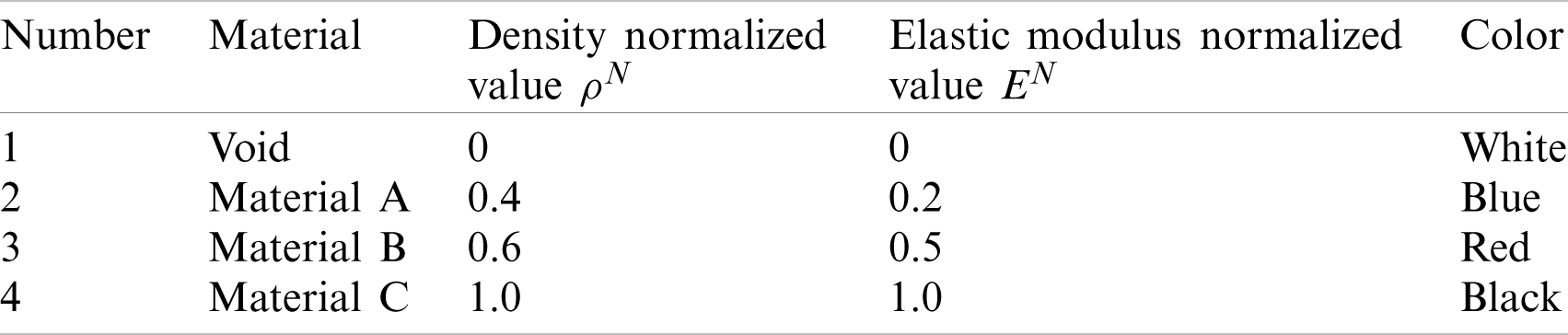

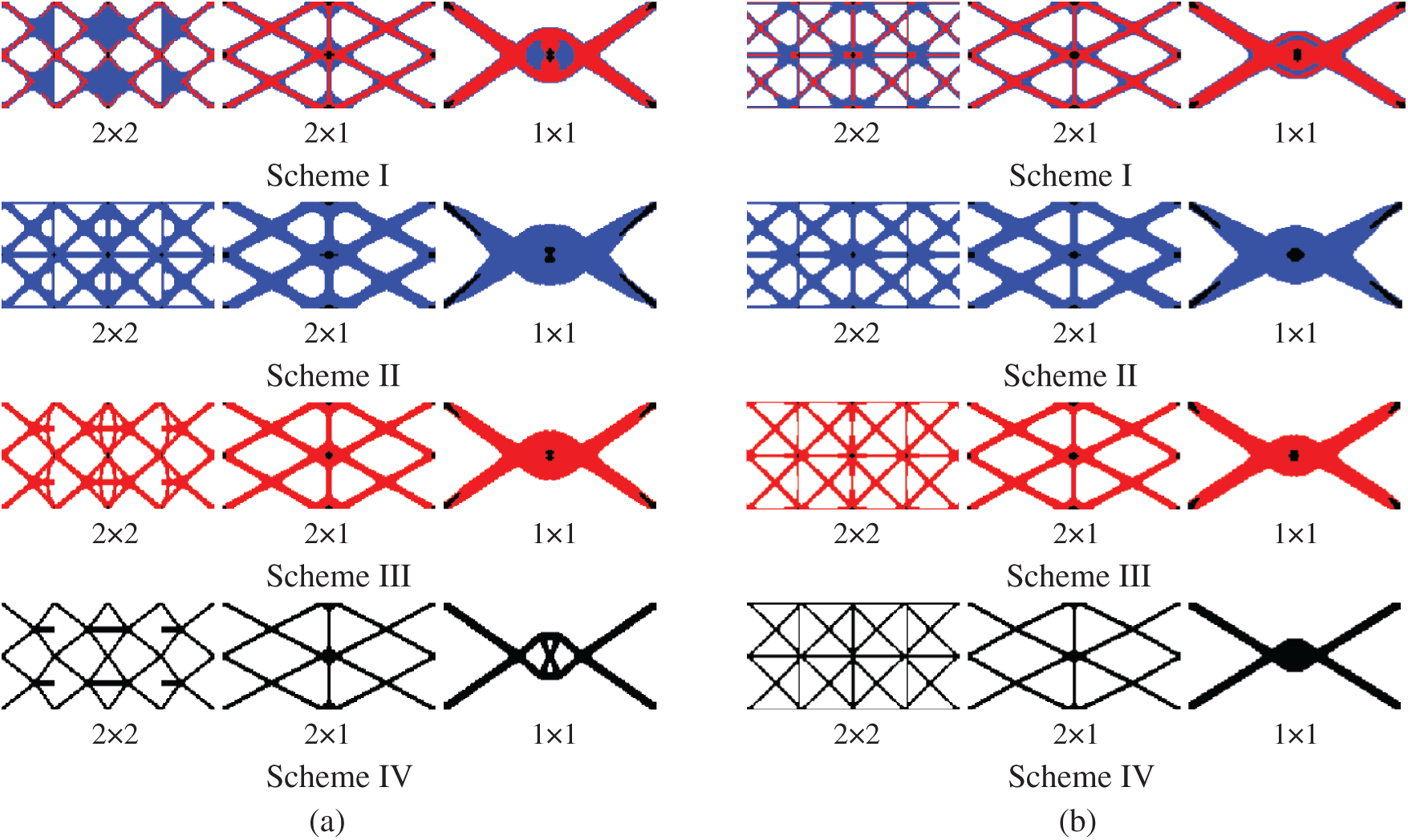

The design domain is discretized into 12800 (

Figure 7: Comparison of optimized topologies of multi-material DTO and RTO under two gradient layers. (a) Deterministic design (b) robust design

Figure 8: Comparison of optimized topologies of multi-material DTO and RTO under four gradient layers. (a) Deterministic design (b) robust design

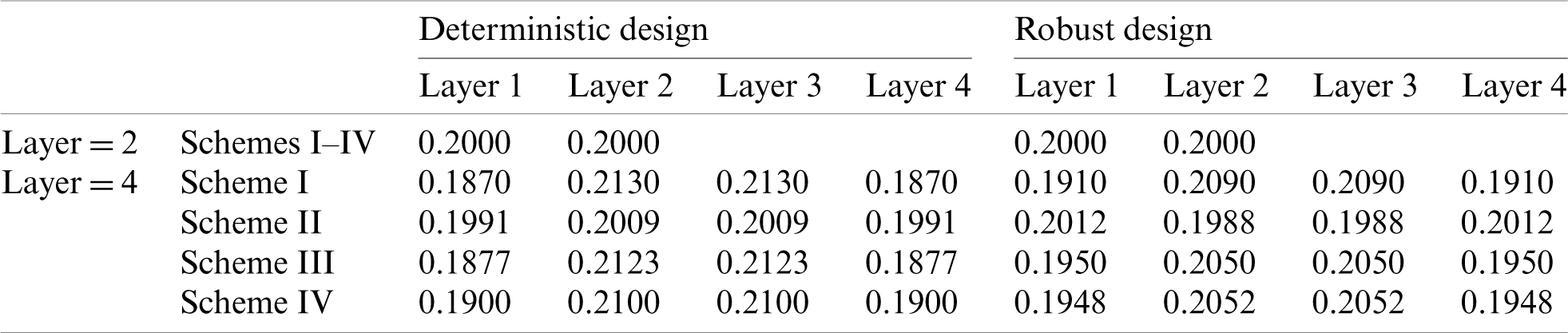

Table 2: Volume fraction of gradient layer

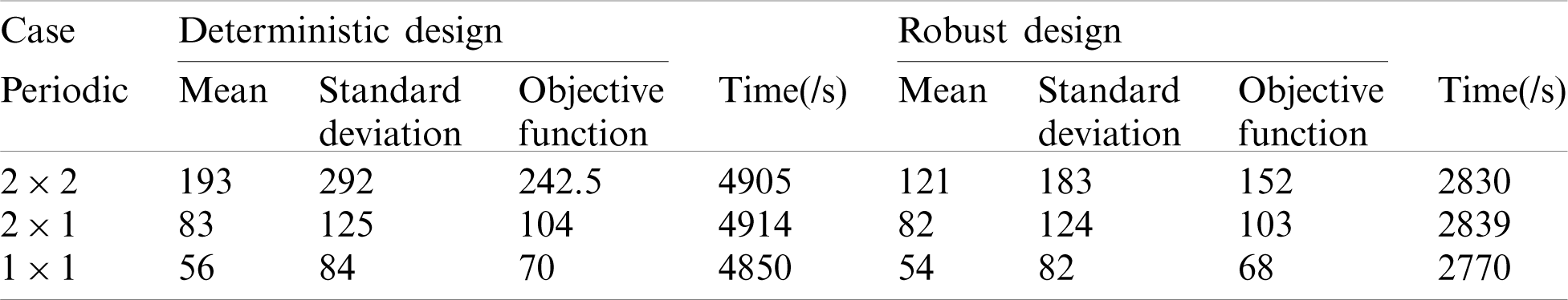

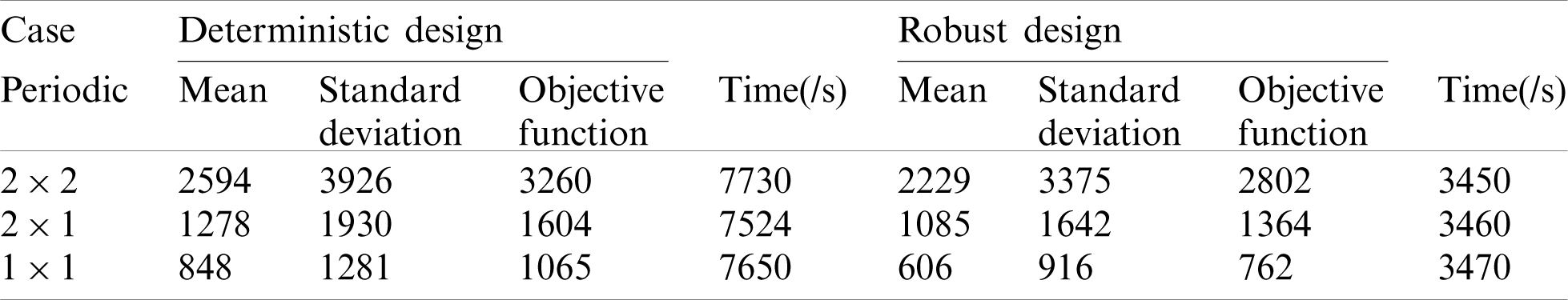

The optimization results show that the proposed method can effectively obtain the periodic functionally gradient structure under different gradient layers, periodic division and material combination schemes, and determine the reasonable material distribution, which shows the effectiveness of the proposed method. Compared with the DTO, the materials of the robust optimization structure are more concentrated on the horizontal force transmission route, thus improving the horizontal load capacity of the structure. It can be seen from Tab. 3 that the mean, standard deviation and objective function of the structural compliance obtained from the deterministic design are all higher than those obtained from the robust design. Therefore, the results of RTO have better stability under load uncertainty.

Table 3: The topology design result of double-sided fixed beam

For the periodic functionally graded structure under the layered setting, the optimal periodic structure of each gradient layer can be obtained. According to the

Table 4: Substructure of gradient layer

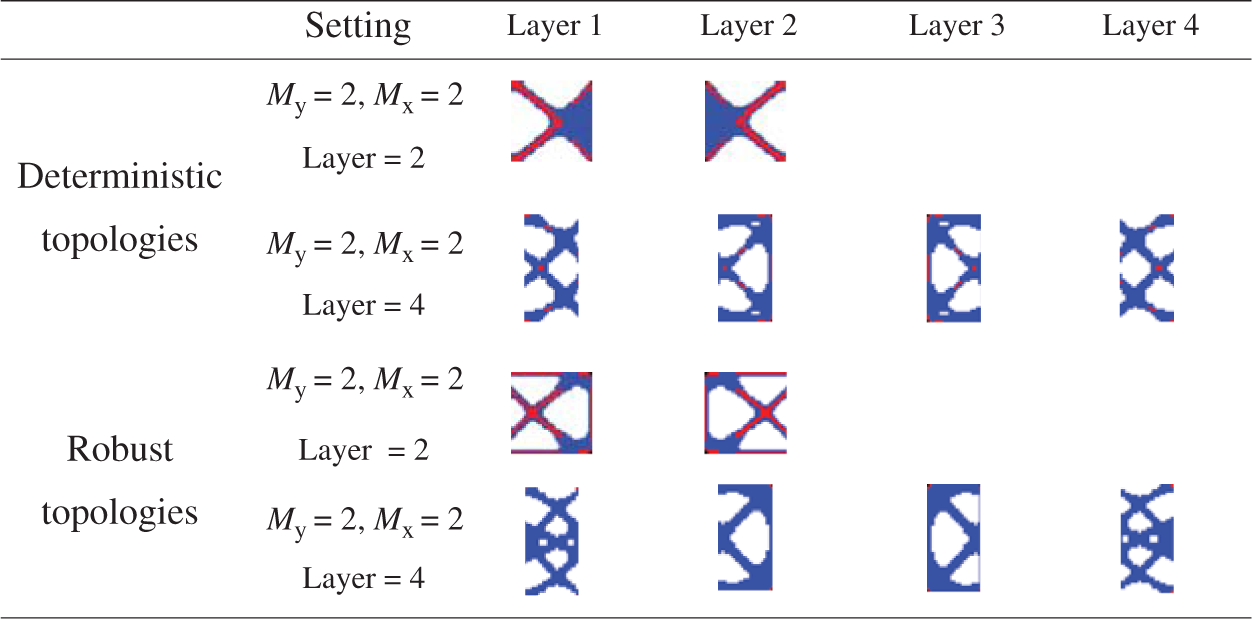

The design domain of cantilever beam is a

Figure 9: Design domain for a cantilever beam

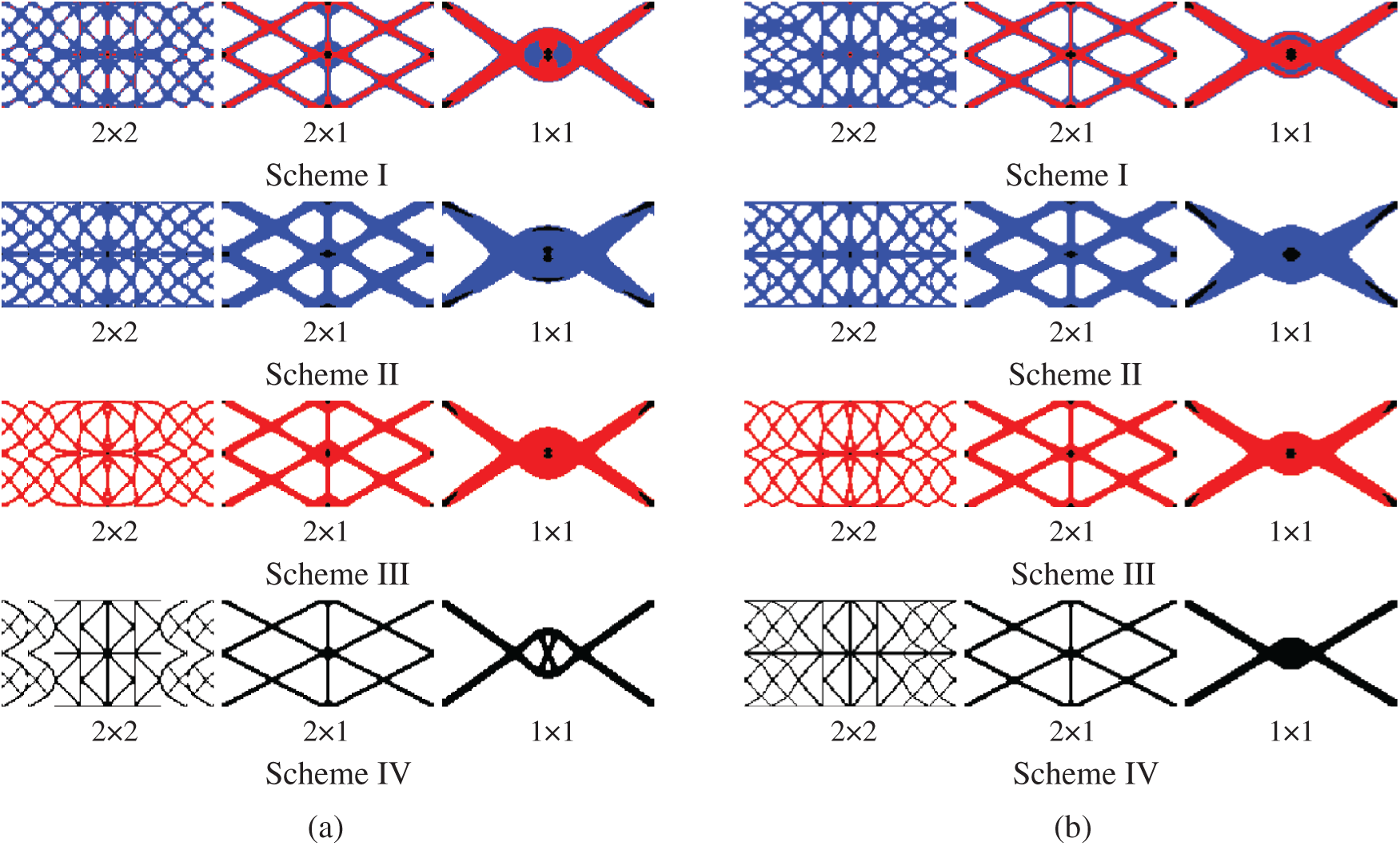

The design domain is discretized into 14400 (

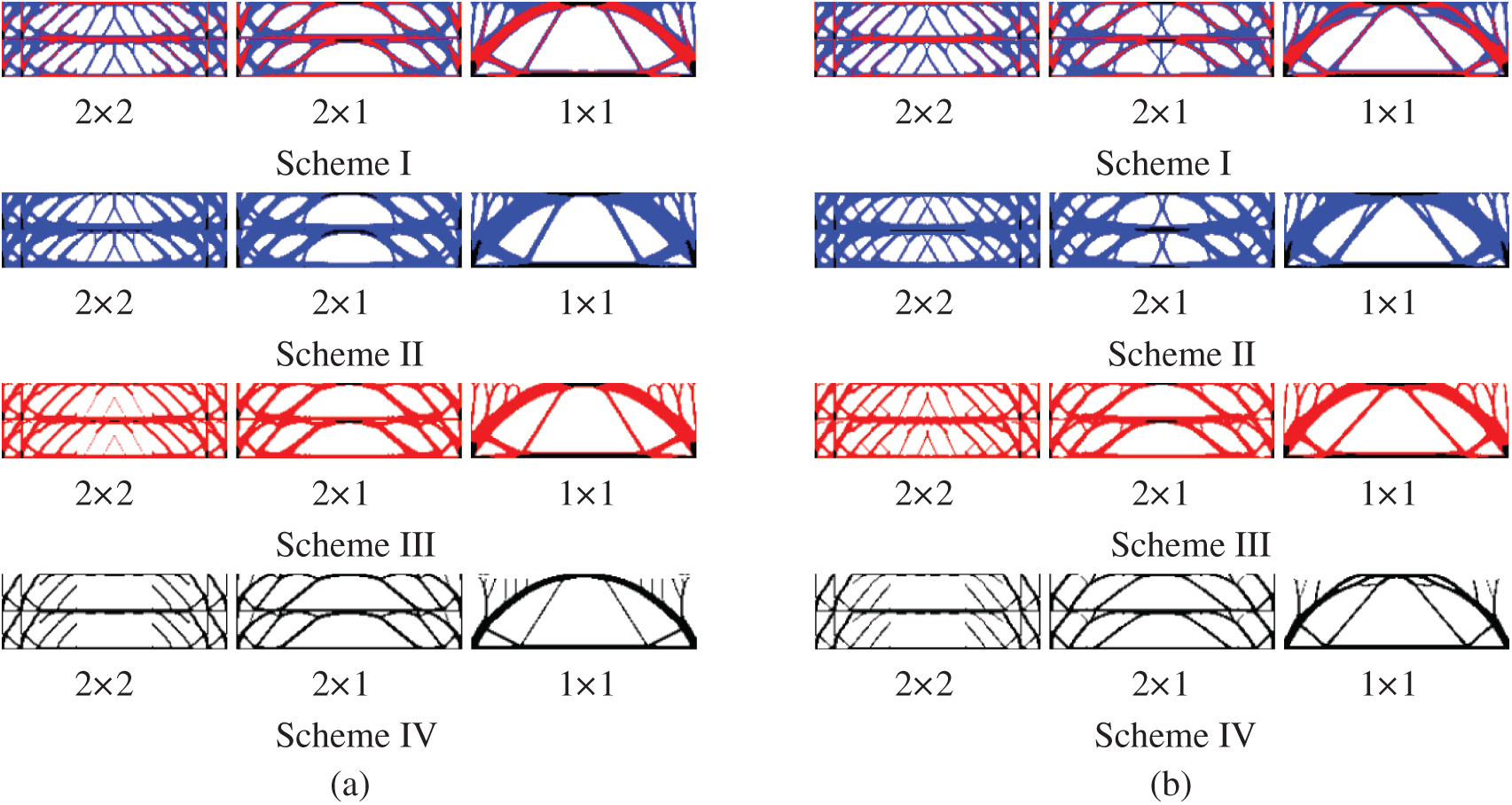

Figure 10: Comparison of optimized topologies of multi-material DTO and RTO under three gradient layers. (a) Deterministic design (b) robust design

The optimization results show that the optimized structures are symmetrical because the design domain, boundary conditions, and load effects of the two working conditions are all symmetrical. Compared with the deterministic design, the optimized results of the robust design have thicker upper and lower edges and better horizontal load bearing capacity due to the uncertain loads that generates horizontal partitioning. Although such a structure has a reduced vertical load bearing capacity, the horizontal load bearing capacity is enhanced and the overall structure becomes more stable.

Meanwhile, considering the influence of periodic functional gradient constraints, we observed that the material distribution of the fixed edge of the DTO was not obvious, and the load bearing capacity was weak. On the contrary, the overall material distribution of the RTO results is reasonable, which further proves that it exhibits better stability.

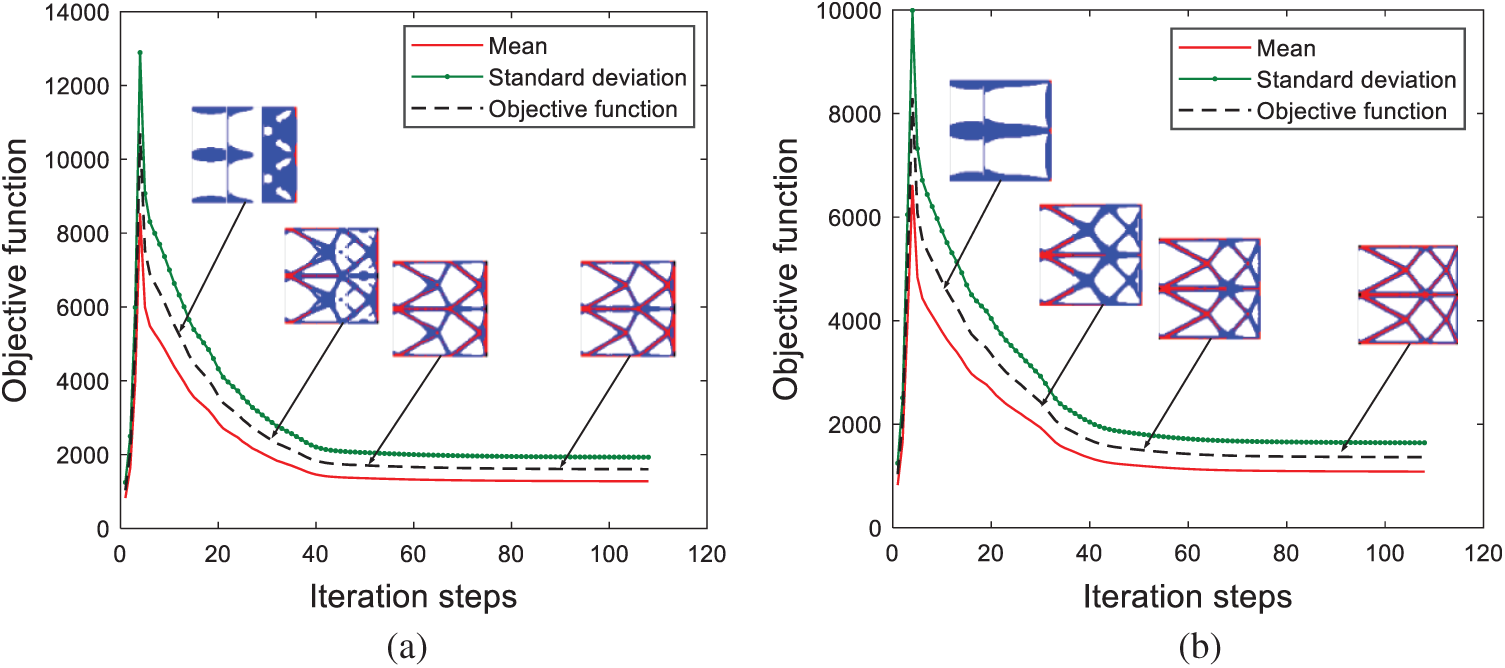

The convergence process is rapid and stable, indicating the stability of the algorithm. According to the

Figure 11: Variation curve of mean, standard deviation and objective function of compliance with the number of iterations. (a) Deterministic design (b) robust design

Table 5: The topology design result of cantilever beam

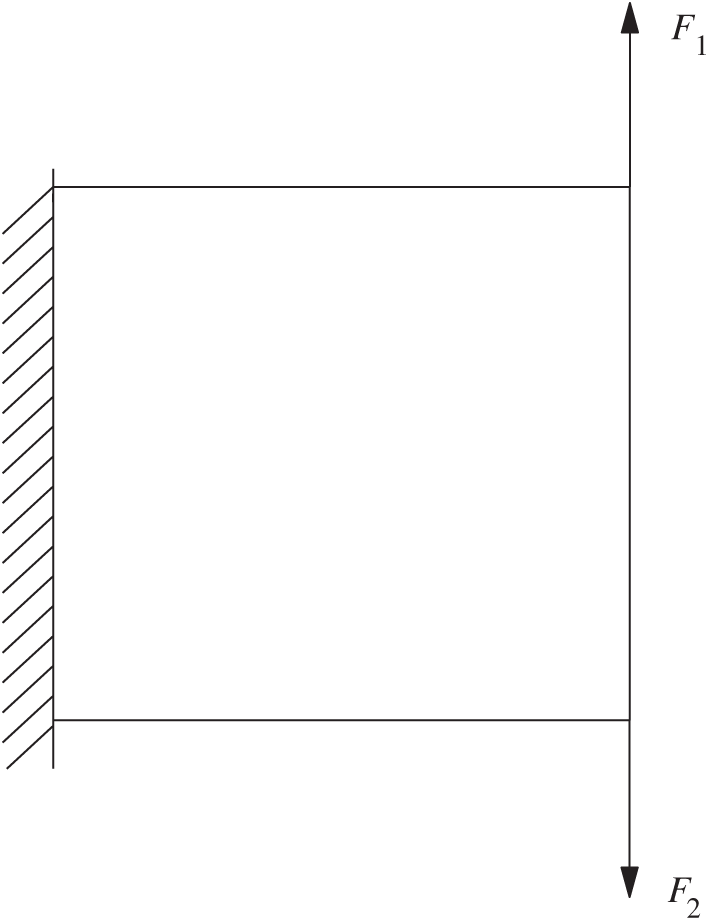

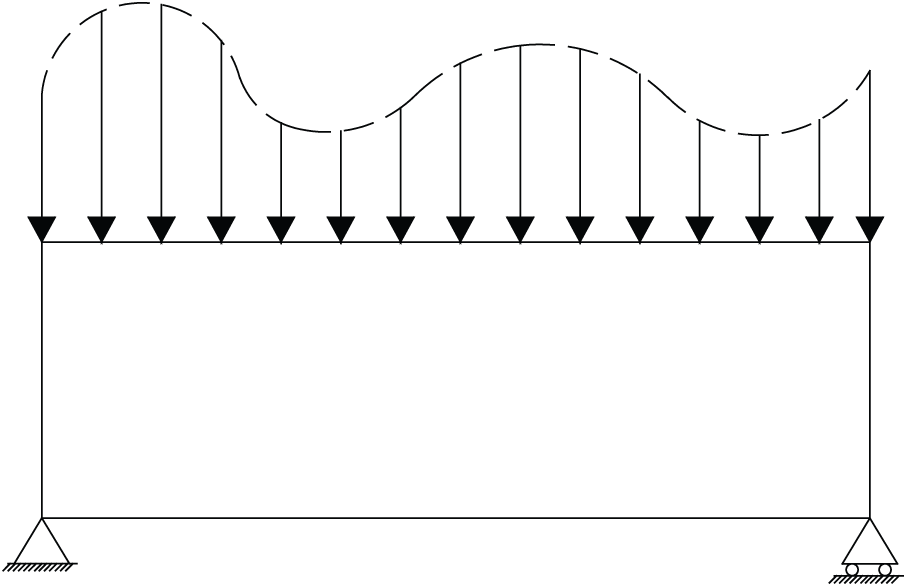

The simply supported beam structure is shown in Fig. 12. The design domain is a

where

Figure 12: Simple beam design space

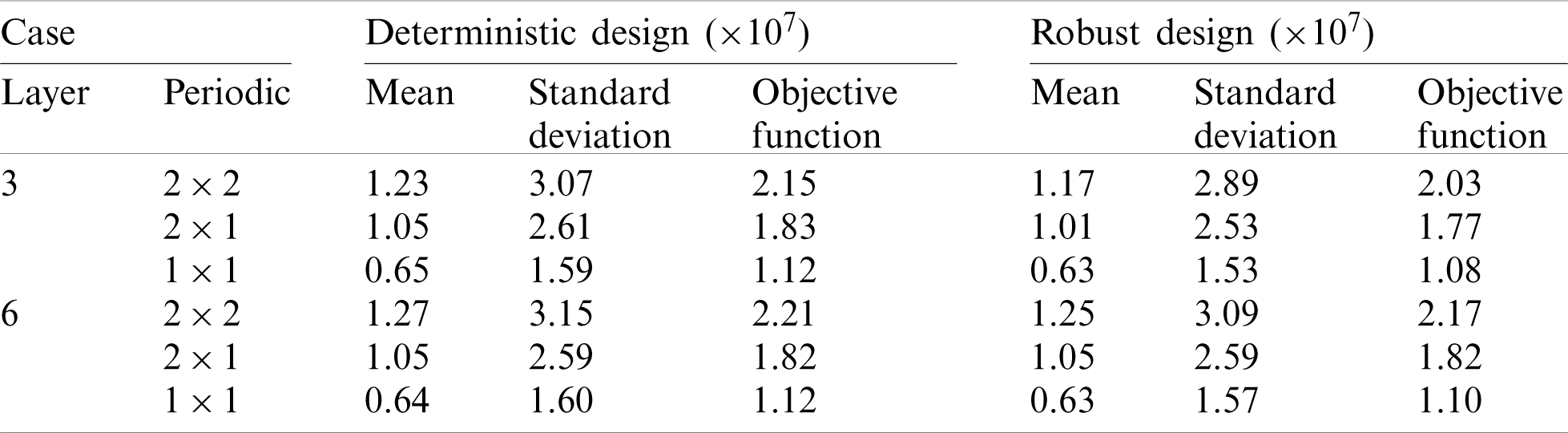

The design domain is discretized into 10800 (

where

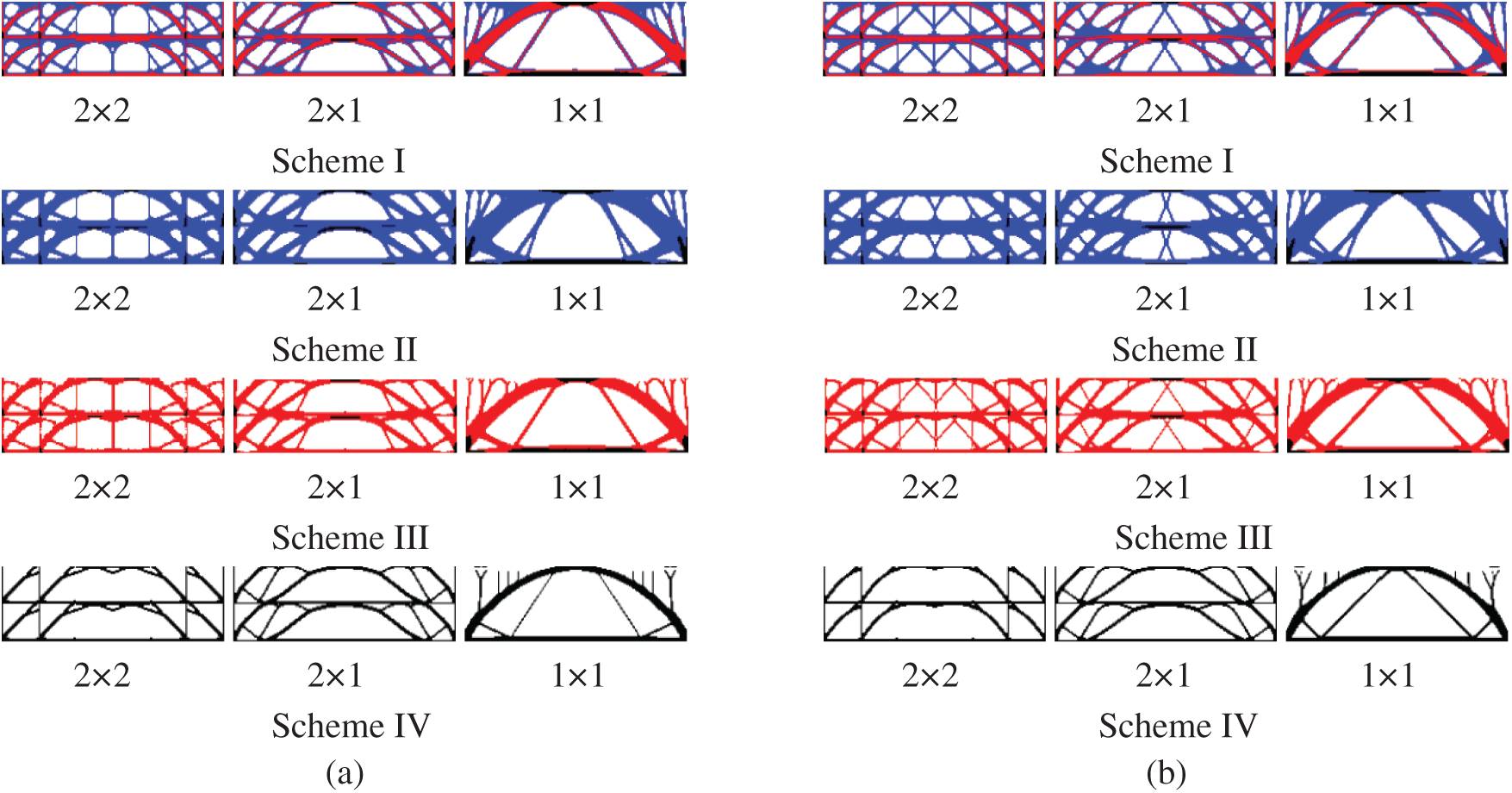

Figure 13: Comparison of optimized topologies of multi-material DTO and RTO under three gradient layers. (a) Deterministic design (b) robust design

Figure 14: Comparison of optimized topologies of multi-material DTO and RTO under six gradient layers. (a) Deterministic design (b) robust design

It can be seen from the Figs. 13 and 14 that the boundary of the optimization result is clear, and that the periodic setting in the gradient layer clearly demonstrates the effectiveness of this method. Due to the superposition of multiple loads under the influence of different amplitudes, the configuration change of RTO was significantly different from that of DTO, which was mainly reflected in the obvious supporting effect of filling the rod-shaped materials in the middle of the structure, thus improving the stability of the structure. Meanwhile, the model has excellent applicability to different material combination schemes.

According to the

Table 6: The topology design result of simply supported beam

Figure 15: Variation curve of objective function of compliance with the number of iterations. (a) Three layer gradient, (b) six layer gradient

This paper presents a robust topology optimization design method for multi-material functional gradients considering periodic constraints. In order to optimize the topology of the multi-material functionally graded structure and minimize the structural compliance under the volume constraint, an ordered-SIMP interpolation is proposed. Meanwhile, the structure is set periodically considering the practical engineering applications. Then, the sparse grid numerical integration method is introduced to calculate the objective function, the mean and standard deviation solutions for the robust topological optimization design. The design is explored in terms of both deterministic and robust design for different load conditions. By three arithmetic examples, the effectiveness of the design method is demonstrated. From the results, it can be seen that the robust design provides a more reliable and effective design solution compared with the corresponding deterministic topology optimization design. In addition, the proposed approach yields better design results for different functional gradient settings and material combination schemes, further demonstrating the practicality of the design solution.

Acknowledgement: The authors are thankful for Professor Krister Svanberg for MMA program made freely available for research purposes and the anonymous reviewers for their helpful and constructive comments.

Funding Statement: This work is supported by the Natural Science Foundation of China (Grant 51705268) and China Postdoctoral Science Foundation Funded Project (Grant 2017M612191).

Conflicts of Interest: The authors declare that we have no conflicts of interest to report regarding the present study.

1. Birman, V. (2007). Modeling and analysis of functionally graded materials and structures. Applied Mechanics Reviews, 60(5), 42. DOI 10.1115/1.2777164. [Google Scholar] [CrossRef]

2. Li, H., Luo, Z., Gao, L., Walker, P. (2017). Topology optimization for functionally graded cellular composites with metamaterials by level sets. Computer Methods in Applied Mechanics & Engineering, 328(1), 340–364. DOI 10.1016/j.cma.2017.09.008. [Google Scholar] [CrossRef]

3. Paulino, G. H., Silva, E. C. N. (2005). Design of functionally graded structures using topology optimization. Materials Science Forum, 492, 435–440. [Google Scholar]

4. Xia, Q., Wang, M. Y. (2008). Simultaneous optimization of the material properties and the topology of functionally graded structures. Computer Aided Design, 40(6), 660–675. DOI 10.1016/j.cad.2008.01.014. [Google Scholar] [CrossRef]

5. Huang, X. D., Zhou, S. W., Xie, Y. M., Li, Q. (2013). Topology optimization of microstructures of cellular materials and composites for macrostructures. Computational Materials Science, 67(2), 397–407. DOI 10.1016/j.commatsci.2012.09.018. [Google Scholar] [CrossRef]

6. Li, H., Gao, L., Li, H., Tong, H. (2020). Spatial-varying multi-phase infill design using density-based topology optimization. Computer Methods in Applied Mechanics and Engineering, 372, 113354. DOI 10.1016/j.cma.2020.113354. [Google Scholar] [CrossRef]

7. Guo, X., Bai, W., Zhang, W., Gao, X. X. (2009). Confidence structural robust design and optimization under stiffness and load uncertainties. Computer Methods in Applied Mechanics and Engineering, 198(41), 3378–3399. DOI 10.1016/j.cma.2009.06.018. [Google Scholar] [CrossRef]

8. Chen, S., Chen, W., Lee, S. (2010). Level set based robust shape and topology optimization under random field uncertainties. Structural Multidisciplinary Optimization, 41(4), 507–524. DOI 10.1007/s00158-009-0449-2. [Google Scholar] [CrossRef]

9. Dunning, P. D., Kim, H. A., Mullineux, G. (2011). Introducing loading uncertainty in topology optimization. AIAA Journal, 49(4), 760–768. DOI 10.2514/1.J050670. [Google Scholar] [CrossRef]

10. Carrasco, M., Ivorra, B., Ramos, A. M. (2012). A variance-expected compliance model for structural optimization. Journal of Optimization Theory and Applications, 152(1), 136–151. DOI 10.1007/s10957-011-9874-7. [Google Scholar] [CrossRef]

11. Lazarov, B. S., Schevenels, M., Sigmund, O. (2012). Topology optimization with geometric uncertainties by perturbation techniques. International Journal for Numerical Methods in Engineering, 90(11), 1321–1336. DOI 10.1002/nme.3361. [Google Scholar] [CrossRef]

12. Guo, X., Zhang, W., Zhang, L. (2013). Robust structural topology optimization considering boundary uncertainties. Computer Methods in Applied Mechanics and Engineering, 253, 356–368. DOI 10.1016/j.cma.2012.09.005. [Google Scholar] [CrossRef]

13. Guest, J. K., Igusa, T. (2008). Structural optimization under uncertain loads and nodal locations. Computer Methods in Applied Mechanics and Engineering, 198(1), 116–124. DOI 10.1016/j.cma.2008.04.009. [Google Scholar] [CrossRef]

14. Dunning, P. D., Kim, H. A., Mullineux, G. (2011). Introducing loading uncertainty in topology optimization. AIAA Journal, 49(4), 760–768. DOI 10.2514/1.J050670. [Google Scholar] [CrossRef]

15. Kharmanda, G., Olhoff, N., Mohamed, A., Lemaire, M. (2004). Reliability-based topology optimization. Structural & Multidisciplinary Optimization, 26(5), 295–307. DOI 10.1007/s00158-003-0322-7. [Google Scholar] [CrossRef]

16. Knoll, P., Reich, S. (2010). Level set based robust shape and topology optimization under random field uncertainties. Structural & Multidisciplinary Optimization, 41(4), 507–524. DOI 10.1007/s00158-009-0449-2. [Google Scholar] [CrossRef]

17. Zhao, Q. H., Chen, X. K., Ma, Z. D., Lin, Y. (2015). Robust topology optimization based on stochastic collocation methods under loading uncertainties. Mathematical Problems in Engineering, 580980(1), 1–14. DOI 10.1155/2015/580980. [Google Scholar] [CrossRef]

18. Long, K., Wang, X., Du, Y. X. (2018). Robust topology optimization formulation including local failure and load uncertainty using sequential quadratic programming. International Journal of Mechanics and Materials in Design, 15(2), 317–332. DOI 10.1007/s10999-018-9411-z. [Google Scholar] [CrossRef]

19. Ben-Tal, A., Nemirovski, A. (1997). Robust truss topology design via semidefinite programming. SIAM Journal on Optimization, 7(4), 991–1016. DOI 10.1137/S1052623495291951. [Google Scholar] [CrossRef]

20. Amir, O., Sigmund, O., Lazarov, B. S., Schevenels, M. (2012). Efficient reanalysis techniques for robust topology optimization. Computer Methods in Applied Mechanics and Engineering, 245(33–34), 217–231. DOI 10.1016/j.cma.2012.07.008. [Google Scholar] [CrossRef]

21. Wu, J., Gao, J., Luo, Z., Brown, T. (2016). Robust topology optimization for structures under interval uncertainty. Advances in Engineering Software, 99, 36–48. DOI 10.1016/j.advengsoft.2016.05.002. [Google Scholar] [CrossRef]

22. Zhang, X., He, J., Takezawa, A., Kang, Z. (2018). Robust topology optimization of phononic crystals with random field uncertainty. International Journal for Numerical Methods in Engineering, 115(9), 1154–1173. DOI 10.1002/nme.5839. [Google Scholar] [CrossRef]

23. Kang, Z., Wu, C., Luo, Y., Li, M. (2018). Robust topology optimization of multi-material structures considering uncertain graded interface. Composite Structures, 208, 305–406. [Google Scholar]

24. Chan, Y. C., Shintani, K., Chen, W. (2019). Robust topology optimization of multi-material lattice structures under material and load uncertainties. Frontiers of Mechanical Engineering, 14(2), 141–152. DOI 10.1007/s11465-019-0531-4. [Google Scholar] [CrossRef]

25. Zheng, Y., Da, D., Li, H., Xiao, M., Gao, L. (2020). Robust topology optimization for multi-material structures under interval uncertainty. Applied Mathematical Modelling, 78(5), 627–647. DOI 10.1016/j.apm.2019.10.019. [Google Scholar] [CrossRef]

26. Romero, A. A., Giusti, S. M. (2020). A robust topological derivative-based multi-material optimization approach: Optimality condition and computational algorithm. Computer Methods in Applied Mechanics and Engineering, 366(1), 113044. DOI 10.1016/j.cma.2020.113044. [Google Scholar] [CrossRef]

27. Chen, Z., Long, K., Wen, P., Nouman, S. (2020). Fatigue-resistance topology optimization of continuum structure by penalizing the cumulative fatigue damage. Advances in Engineering Software, 150(2), 102924. DOI 10.1016/j.advengsoft.2020.102924. [Google Scholar] [CrossRef]

28. Zheng, W., Wang, Y. J., Zheng, Y. F., Da, D. (2020). Efficient topology optimization based on DOF reduction and convergence acceleration methods. Advances in Engineering Software, 149, 102890. DOI 10.1016/j.advengsoft.2020.102890. [Google Scholar] [CrossRef]

29. Wang, Y. J., Liao, Z. Y., Ye, M., Zhang, Y., Li, W. H. et al. (2020). An efficient isogeometric topology optimization using multilevel mesh, MGCG and local-update strategy. Advances in Engineering Software, 139(8), 102733. DOI 10.1016/j.advengsoft.2019.102733. [Google Scholar] [CrossRef]

30. Zuo, W. J., Saitou, K. (2017). Multi-material topology optimization using ordered SIMP interpolation. Structural & Multidisciplinary Optimization, 55(2), 477–491. DOI 10.1007/s00158-016-1513-3. [Google Scholar] [CrossRef]

31. Li, C. C., Kiureghian, A. D. (1993). Optimal discretization of random fields. Journal of Engineering Mechanics, 119(6), 1136–1154. DOI 10.1061/(ASCE)0733-9399(1993)119:6(1136). [Google Scholar] [CrossRef]

32. Ghanem, R., Spanos, P. (2003). Stochastic finite elements—A spectral approach. New York: Dover. [Google Scholar]

33. Xiu, D. (2010). Numerical methods for stochastic computations: A spectral method approach (Ph.D. Thesis). Princeton University Press, Princeton. [Google Scholar]

34. Ghanem, R. G., Spanos, P. D. (1991). Stochastic finite elements: A spectral approach. New York: Springer. [Google Scholar]

35. Kang, Z., Liu, P. (2018). Reliability-based topology optimization against geometric imperfections with random threshold model. International Journal for Numerical Methods in Engineering, 115(1), 99–116. DOI 10.1002/nme.5797. [Google Scholar] [CrossRef]

36. Haldar, A., Mahadevan, S. (2000). Reliability assessment using stochastic finite element analysis. New York: Wiley. [Google Scholar]

37. Ghanem, R. G., Doostan, A. (2006). On the construction and analysis of stochastic models: Characterization and propagation of the errors associated with limited data. Journal of Computational Physics, 217(1), 63–81. DOI 10.1016/j.jcp.2006.01.037. [Google Scholar] [CrossRef]

38. Beyer, H., Sendhoff, B. (2007). Robust optimization: A comprehensive survey. Computer Methods in Applied Mechanics and Engineering, 196(33–34), 3190–3218. DOI 10.1016/j.cma.2007.03.003. [Google Scholar] [CrossRef]

39. Park, S. H. (1996). Robust design and analysis for quality engineering. London: Chapman and Hall. [Google Scholar]

40. Meng, Z., Wu, Y., Wang, X., Ren, S., Yu, B. (2020). Robust topology optimization methodology for continuum structures under probabilistic and fuzzy uncertainties. International Journal for Numerical Methods in Engineering, 1, 1–17. [Google Scholar]

41. Gao, J., Luo, Z., Li, H., Gao, L. (2019). Topology optimization for multiscale design of porous composites with multi-domain microstructures. Computer Methods in Applied Mechanics and Engineering, 334, 451–476. DOI 10.1016/j.cma.2018.10.017. [Google Scholar] [CrossRef]

42. Gao, J., Luo, Z., Li, H., Gao, L. (2019). Dynamic multiscale topology optimization for multi-regional micro-structured cellular composites. Composite Structures, 211, 401–417. DOI 10.1016/j.compstruct.2018.12.031. [Google Scholar] [CrossRef]

43. Eldred, M. S., Webster, C. G., Constantine, P. G. (2011). Design under uncertainty employing stochastic expansion methods. International Journal for Uncertainty Quantification, 1(2), 119–146. DOI 10.1615/Int.J.UncertaintyQuantification.v1.i2.20. [Google Scholar] [CrossRef]

44. Aicke, H., Erich, N., Mario, U. (2014). On weak tractability of the clenshaw–curtis smolyak algorithm. Journal of Approximation Theory, 183, 31–44. DOI 10.1016/j.jat.2014.03.012. [Google Scholar] [CrossRef]

45. Svanberg, K. (2010). The method of moving asymptotes—A new method for structural optimization. International Journal for Numerical Methods in Engineering, 24(2), 359–373. DOI 10.1002/nme.1620240207. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |